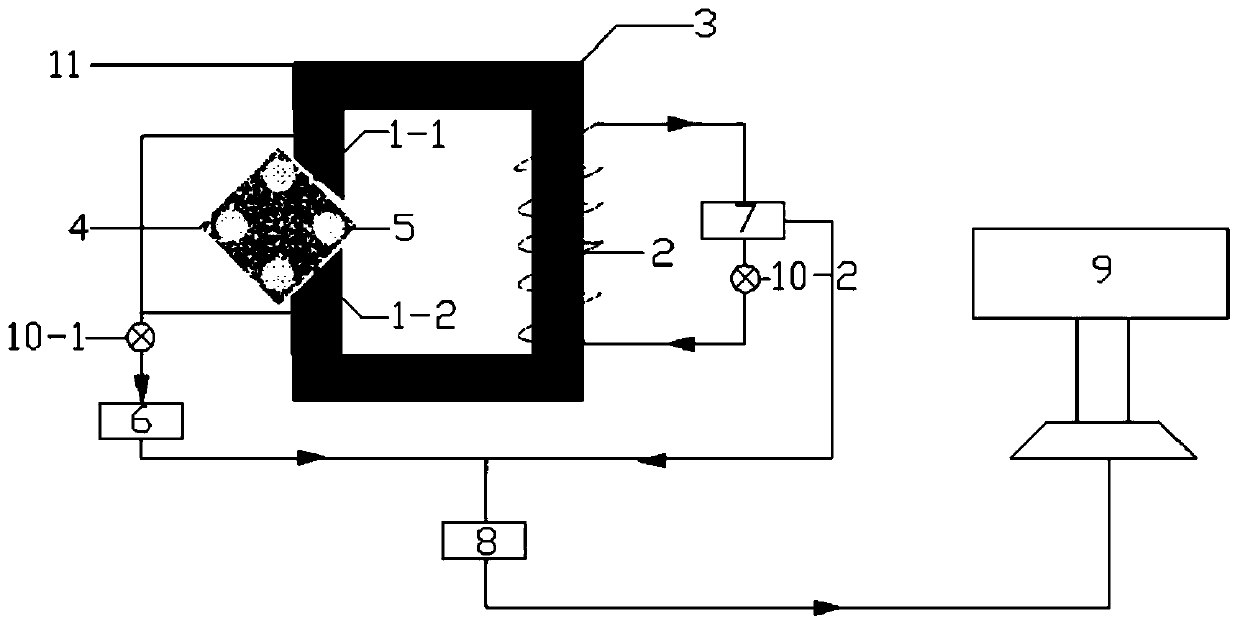

Electromagnetic field principle-based external nondestructive steel bar corrosion monitoring sensor and testing method

A technology for monitoring sensor and steel corrosion, applied in the direction of material magnetic variables, etc., can solve the problems of no external dynamic monitoring sensor and test method for accurately measuring the corrosion rate of steel bars, inability to quantitatively measure the corrosion rate of steel bars, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

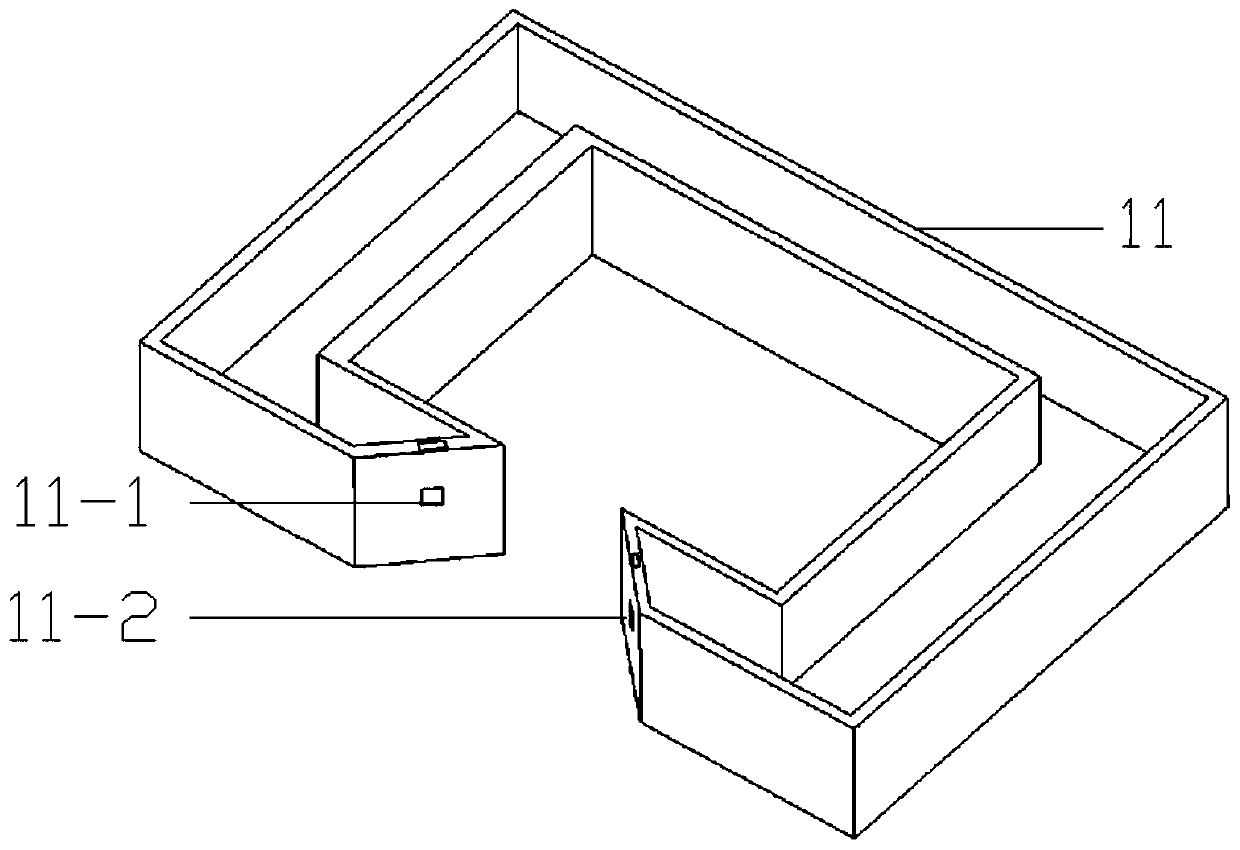

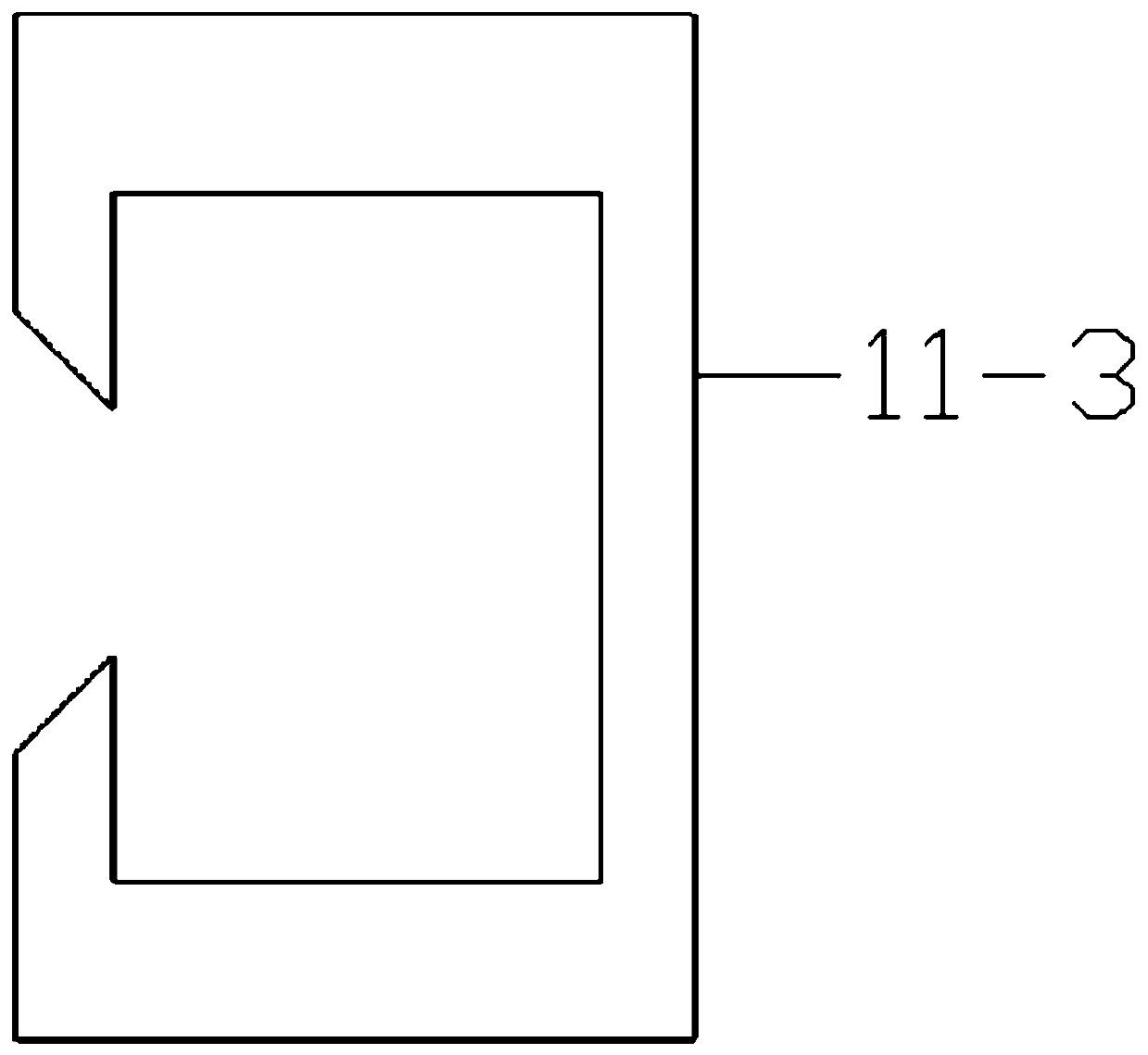

Examples

Embodiment 2

[0120] Embodiment 2, the steel bar diameter is 16mm and the length is 20cm HPB300 light round steel bar, the raw material of concrete is: cement is P.I 525 grade Portland cement, sand adopts the river sand of fineness modulus 2.6, coarse aggregate adopts continuous gradation The crushed stone (maximum particle size is 25mm), the water is tap water, and the effective cross-sectional size of the test piece is poured in the standard mold. After forming, it is cured in the curing room for 28 days. Take the poured reinforced concrete specimen as an example to explain the influence of the position change of the steel bar on the magnetic induction intensity:

[0121] Establish the x-axis in the front-back direction, the y-axis in the left-right direction, and the z-axis in the up-down direction. Move the reinforced concrete specimen to the center of the sensor magnetic core bayonet, and define the three-dimensional relative coordinate value (x, y, z) of the magnetic core bayonet cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com