Patents

Literature

256 results about "Time pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

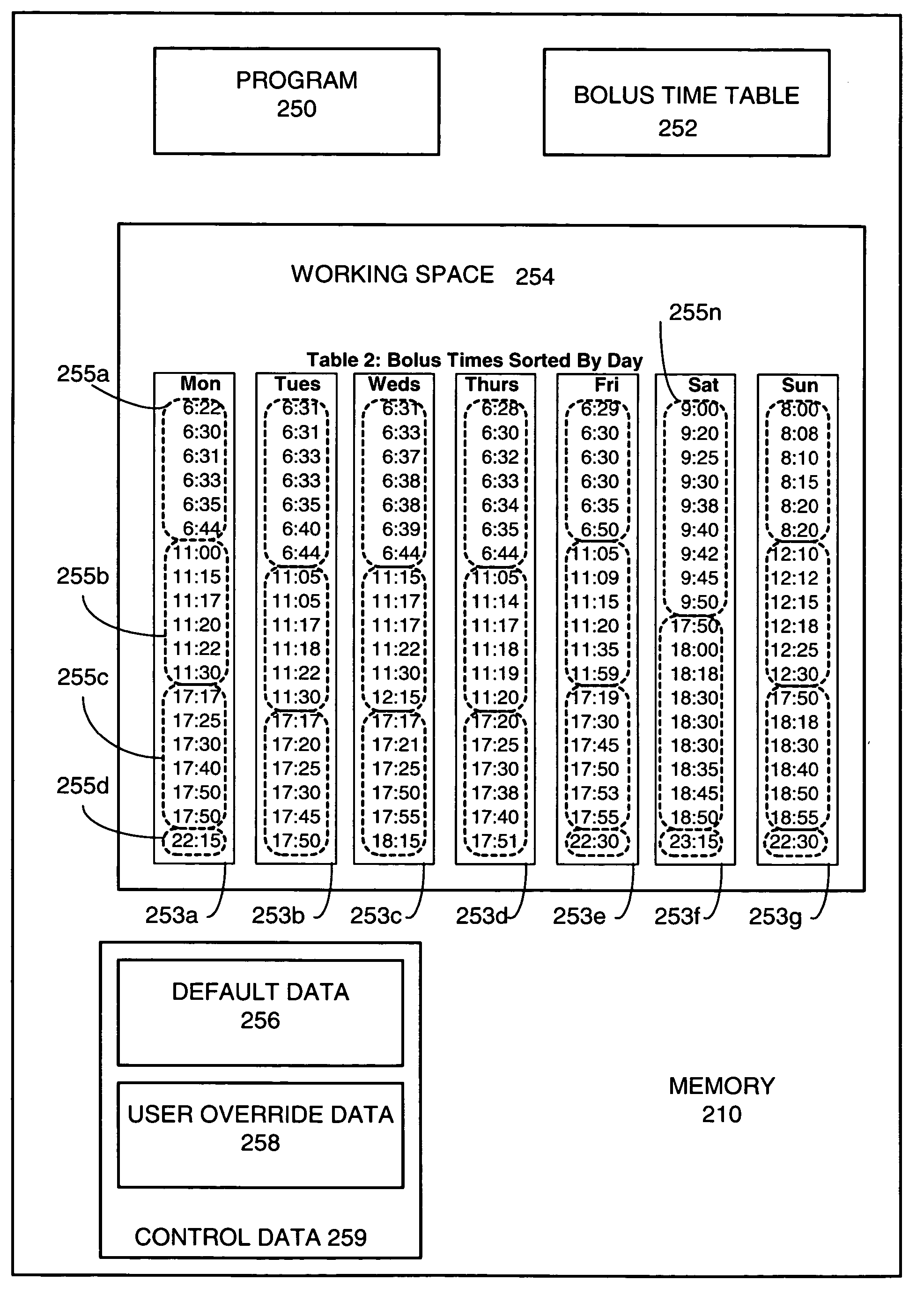

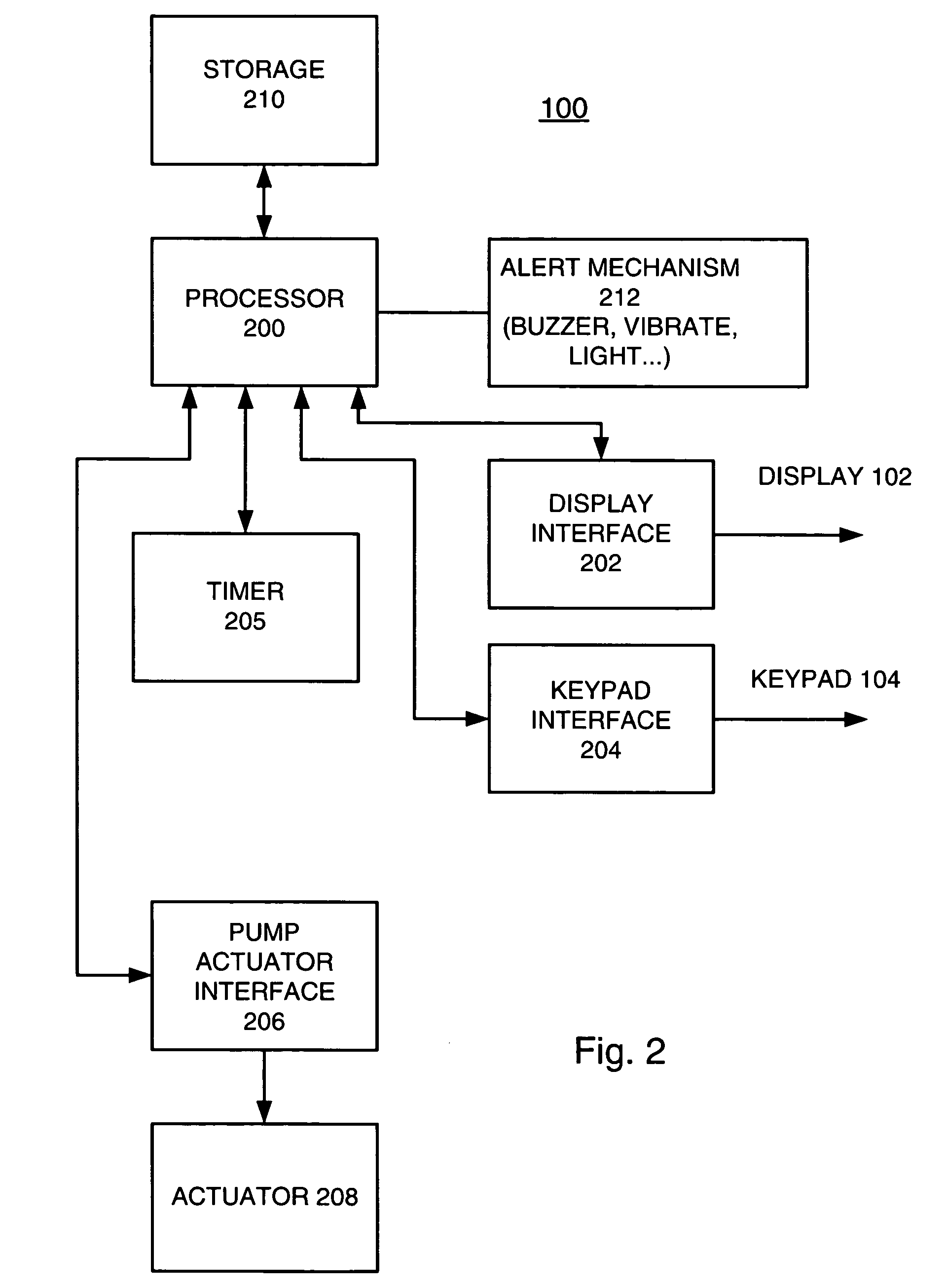

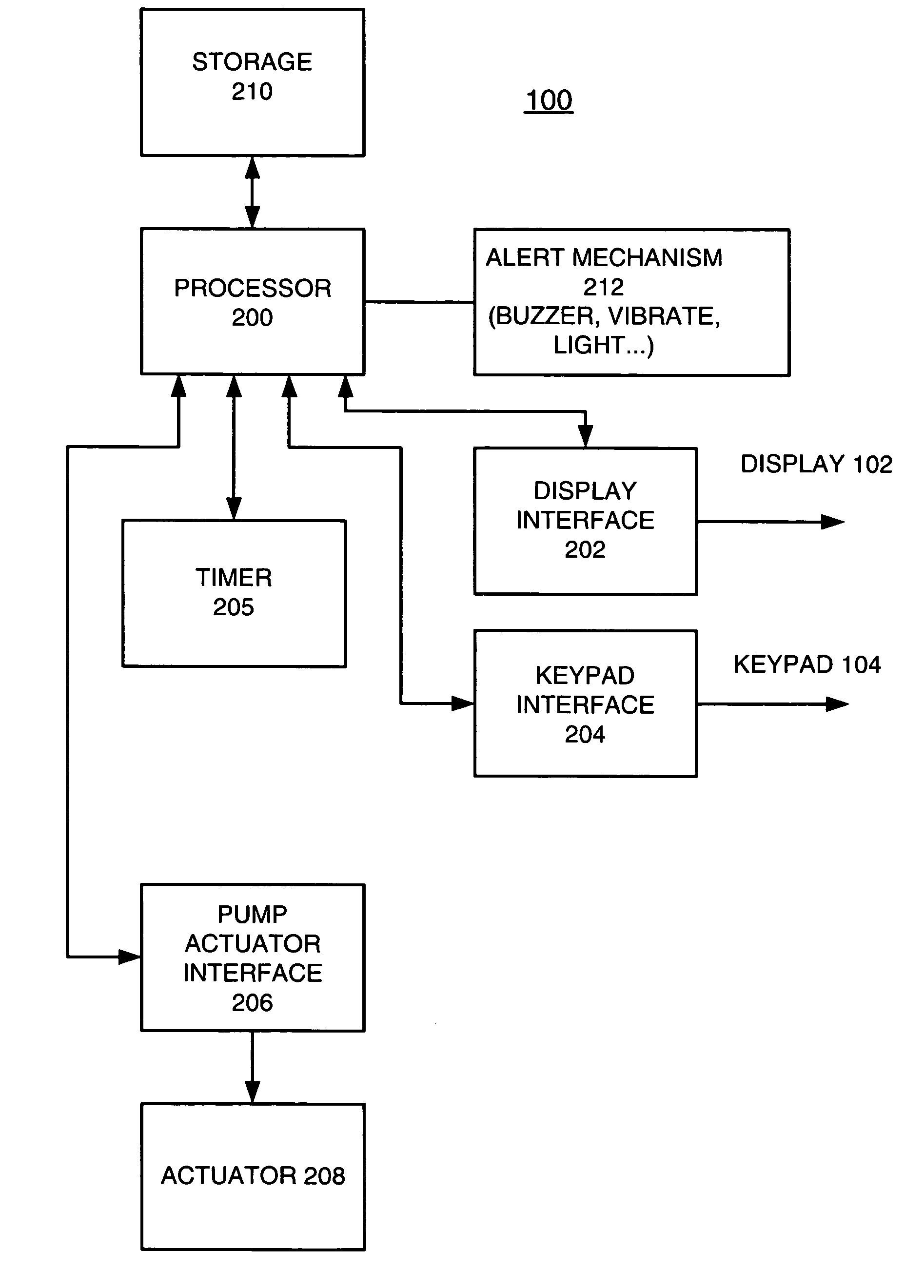

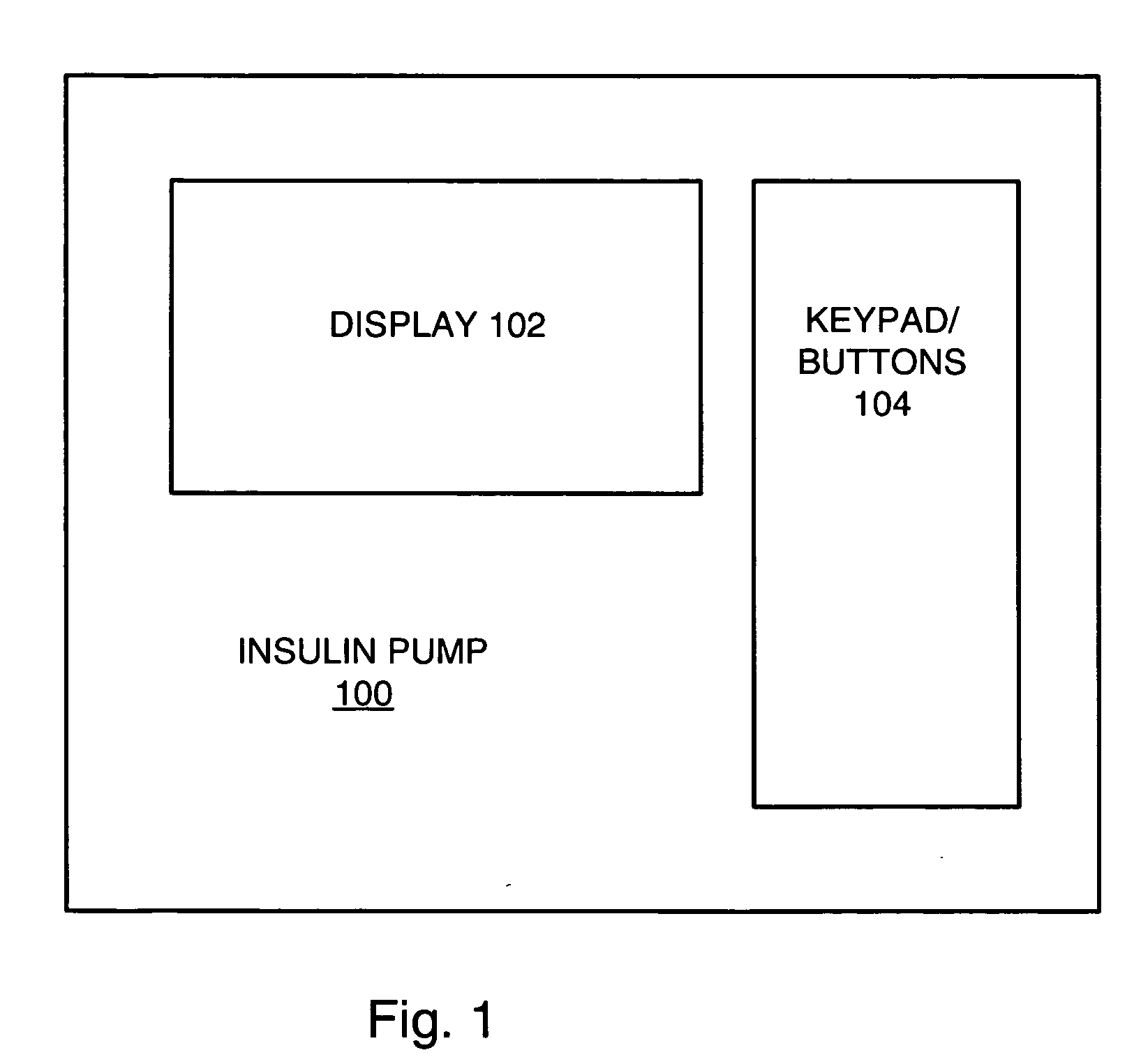

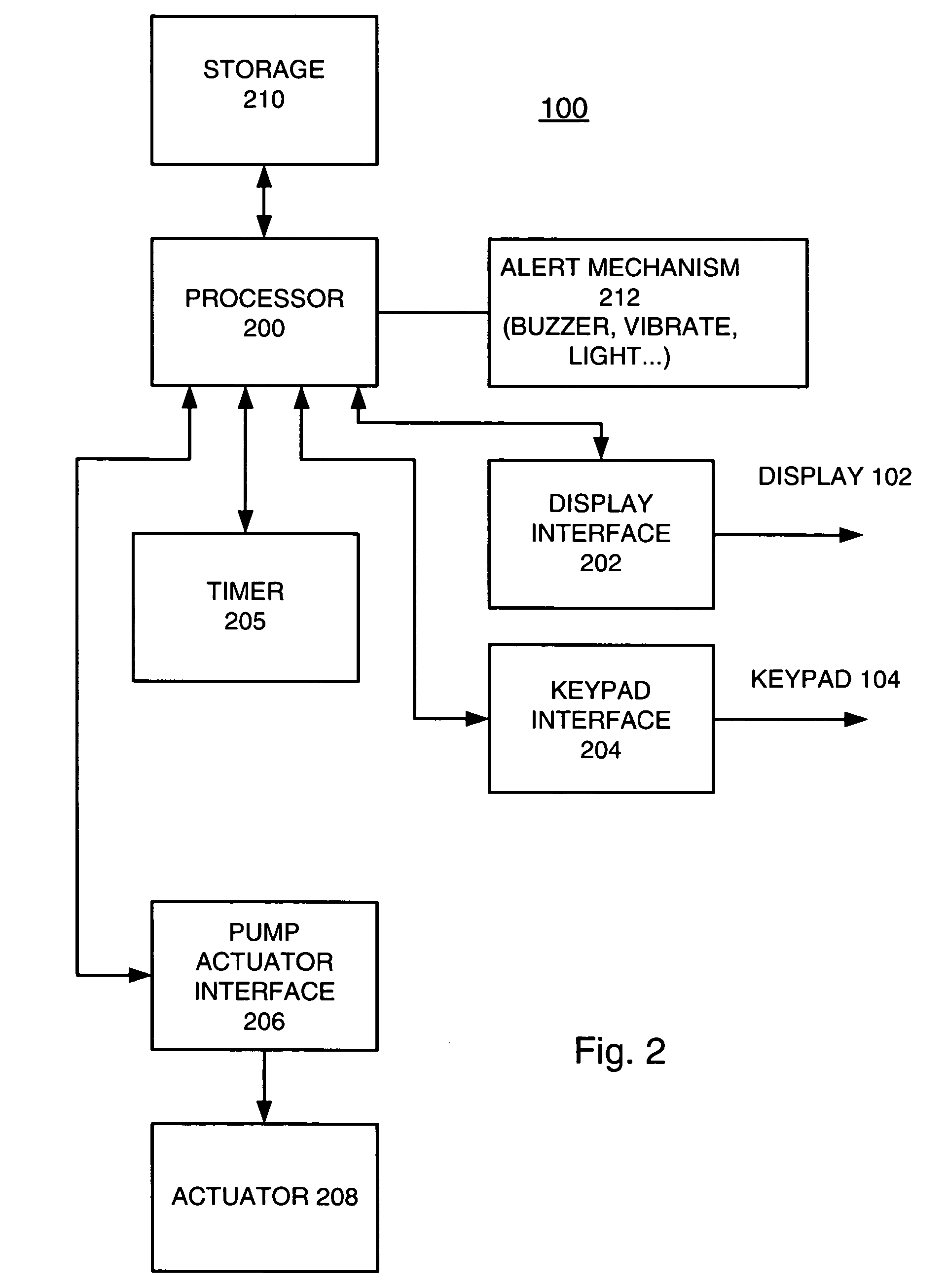

Medical infusion pump capable of learning bolus time patterns and providing bolus alerts

ActiveUS6999854B2Drug and medicationsPharmaceutical delivery mechanismInsulin pumpEmergency medicine

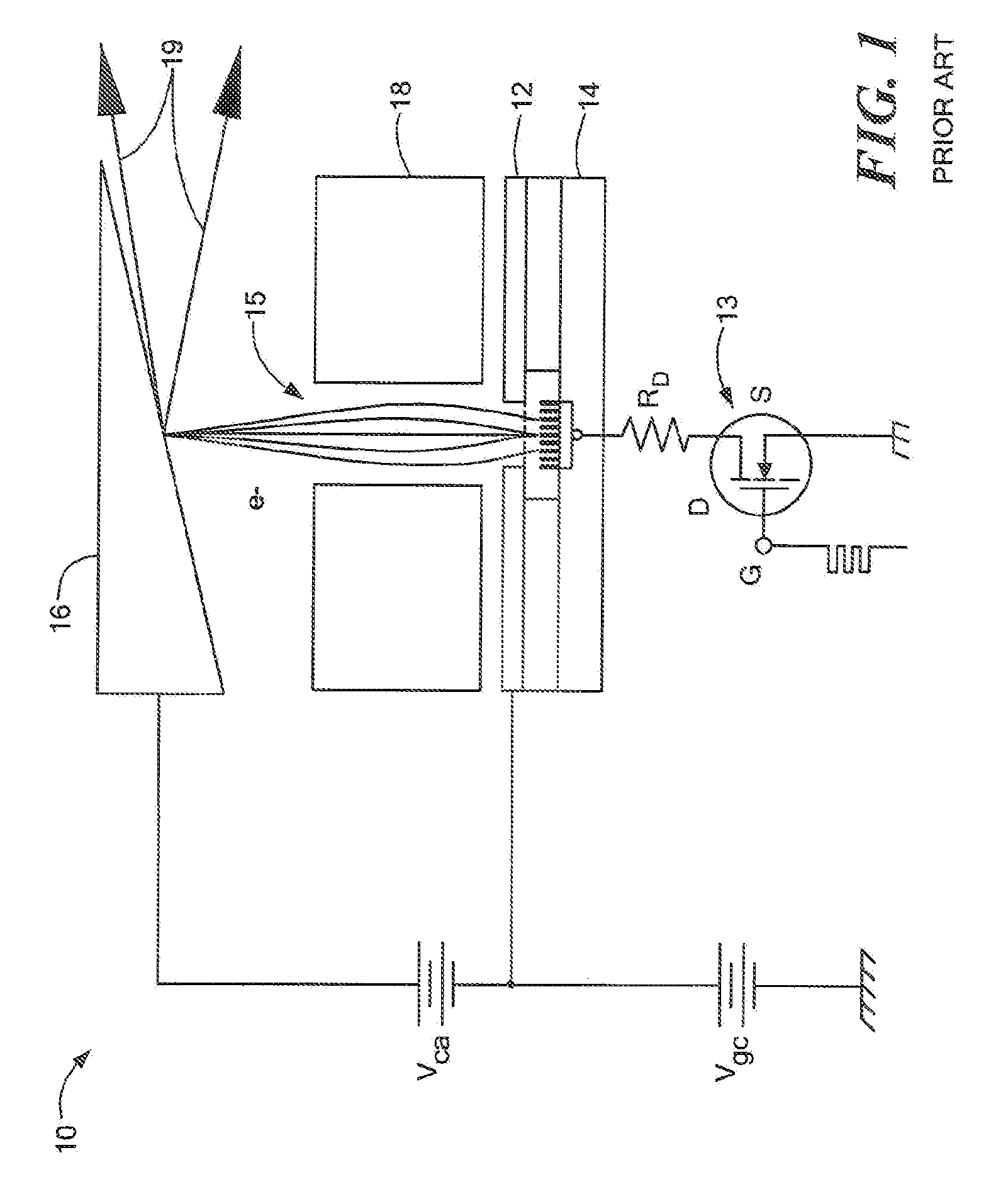

An apparatus and method are disclosed for improving a medical infusion pump. Users of medical infusion pumps, such as insulin pumps, require a bolus of a medication at predicable times of the day, such as at or near mealtimes for insulin pumps. The disclosed medical infusion pump determines bolus time intervals during which boluses are usually taken, and, alerts the user at one or more calculated alert times during an active bolus time interval when a bolus has not yet been delivered during the active bolus time interval. Advantageously, a different set of bolus time intervals are determined by day of week, to accommodate, for example, different bolus patterns during weekends versus weekdays.

Owner:TANDEM DIABETES CARE INC

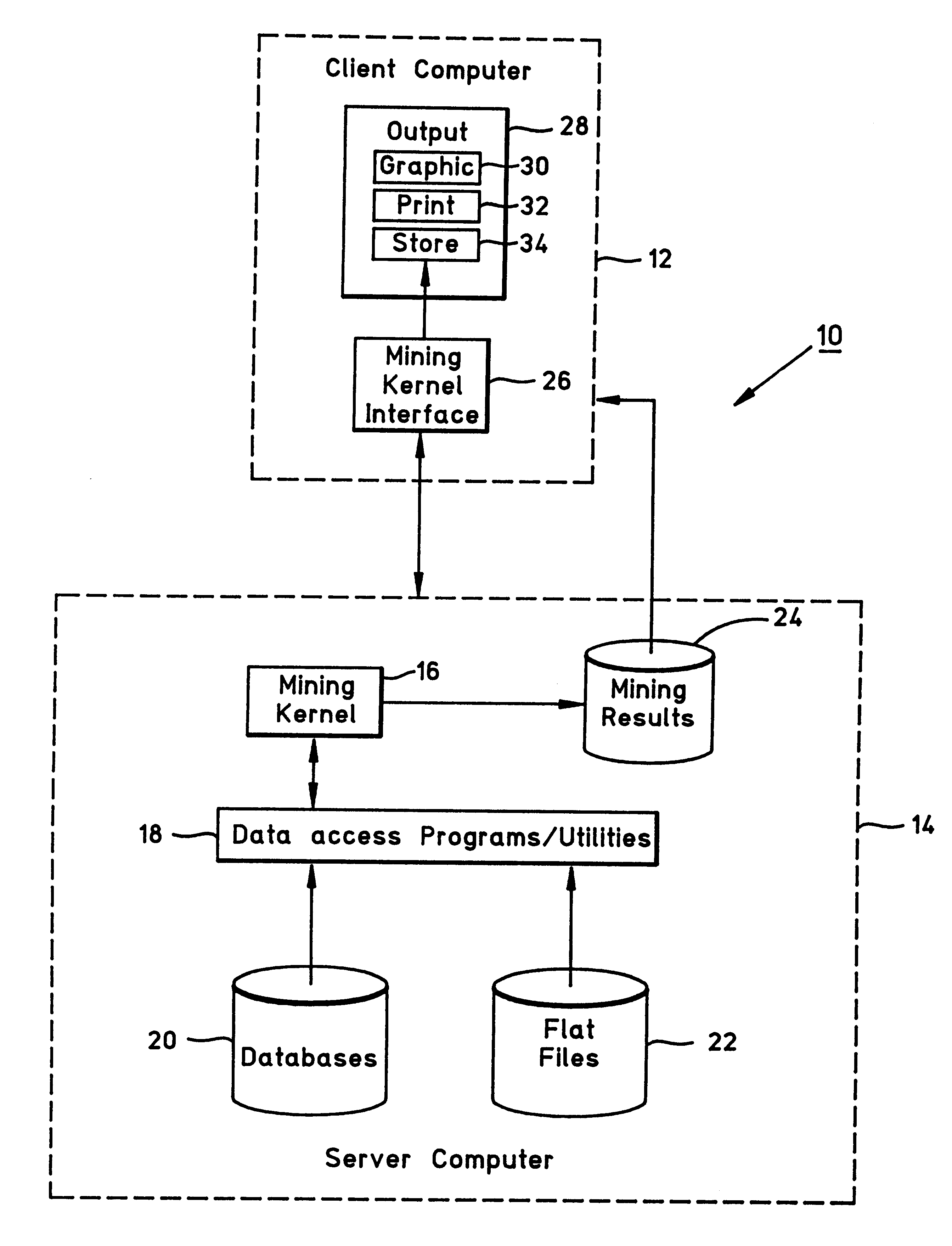

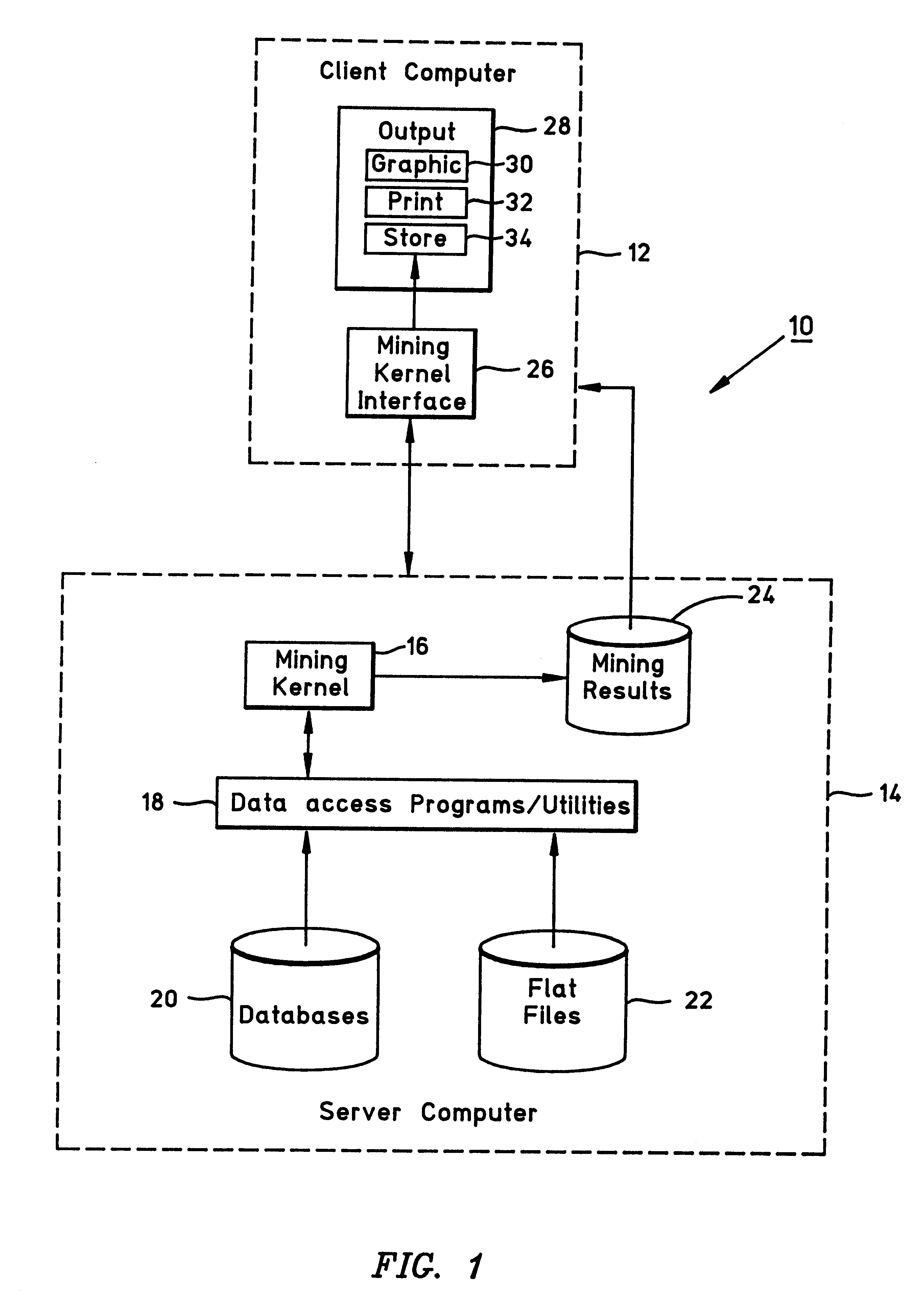

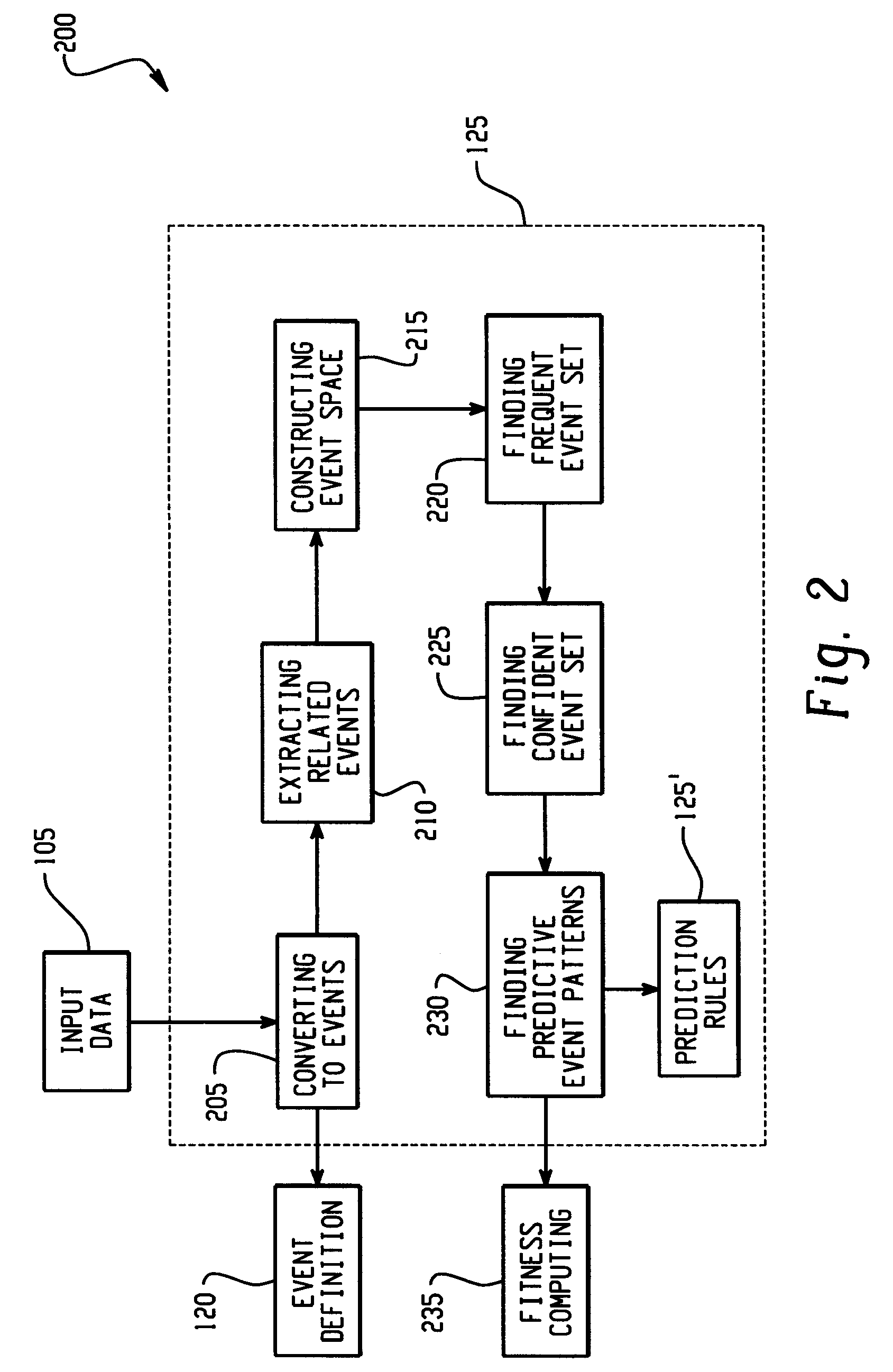

System and method for mining surprising temporal patterns

InactiveUS6189005B1Improve system accuracyAccurate representationData processing applicationsDigital data information retrievalMinimum description lengthMachine learning

A system and method for data mining is provided in which temporal patterns of itemsets in transactions having unexpected support values are identified. A surprising temporal pattern is an itemset whose support changes over time. The method may use a minimum description length formulation to discover these surprising temporal patterns.

Owner:IBM CORP

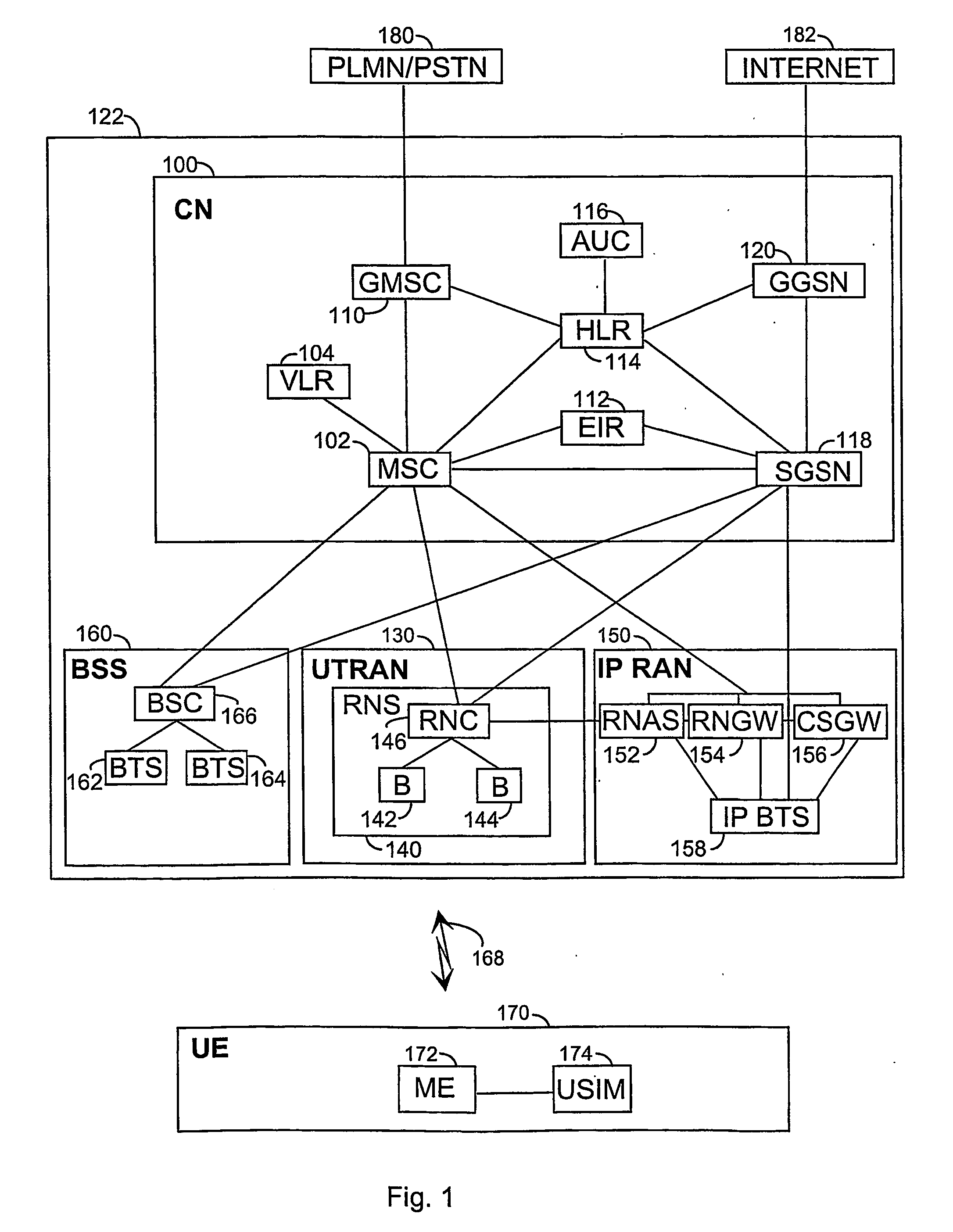

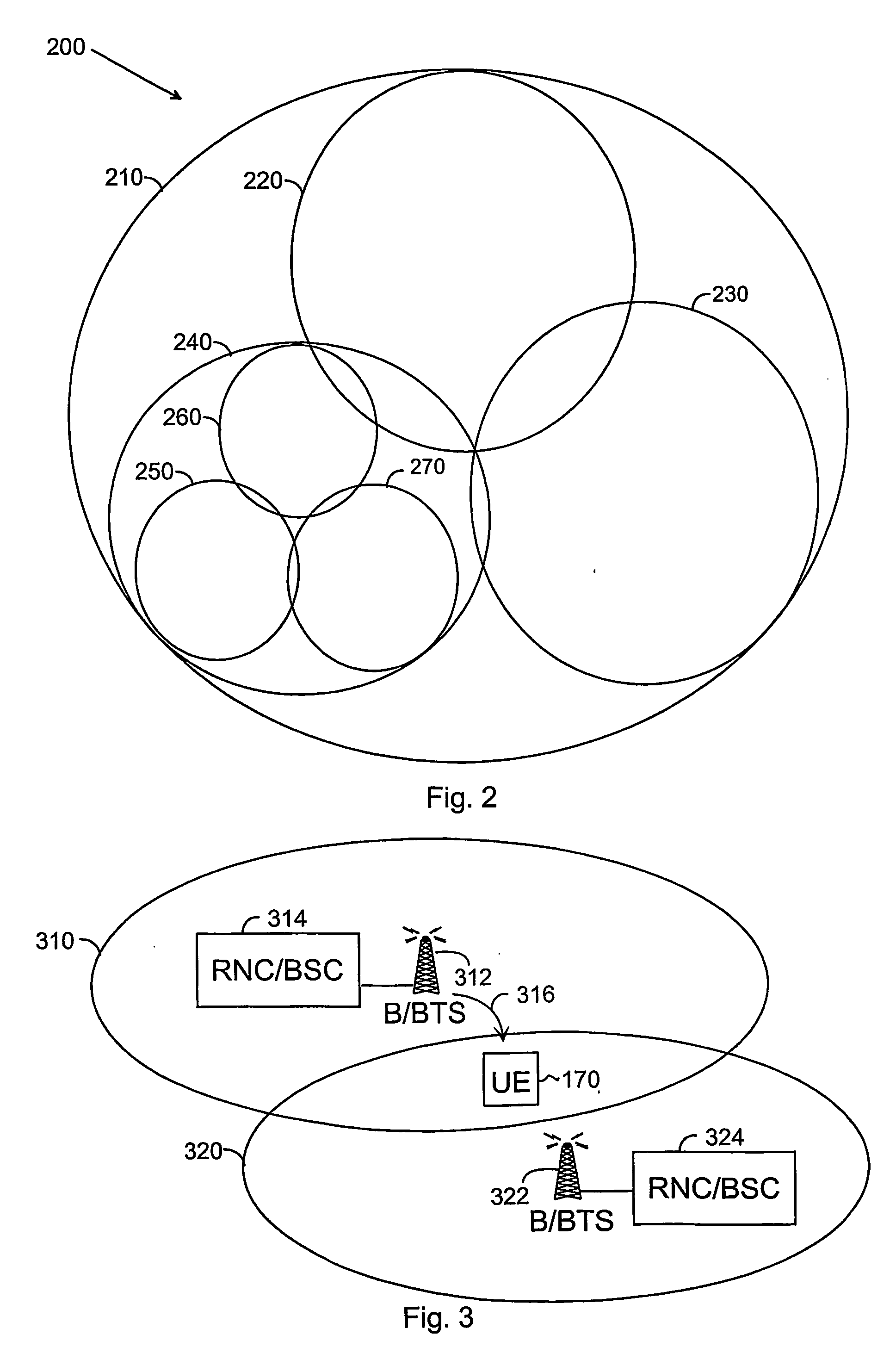

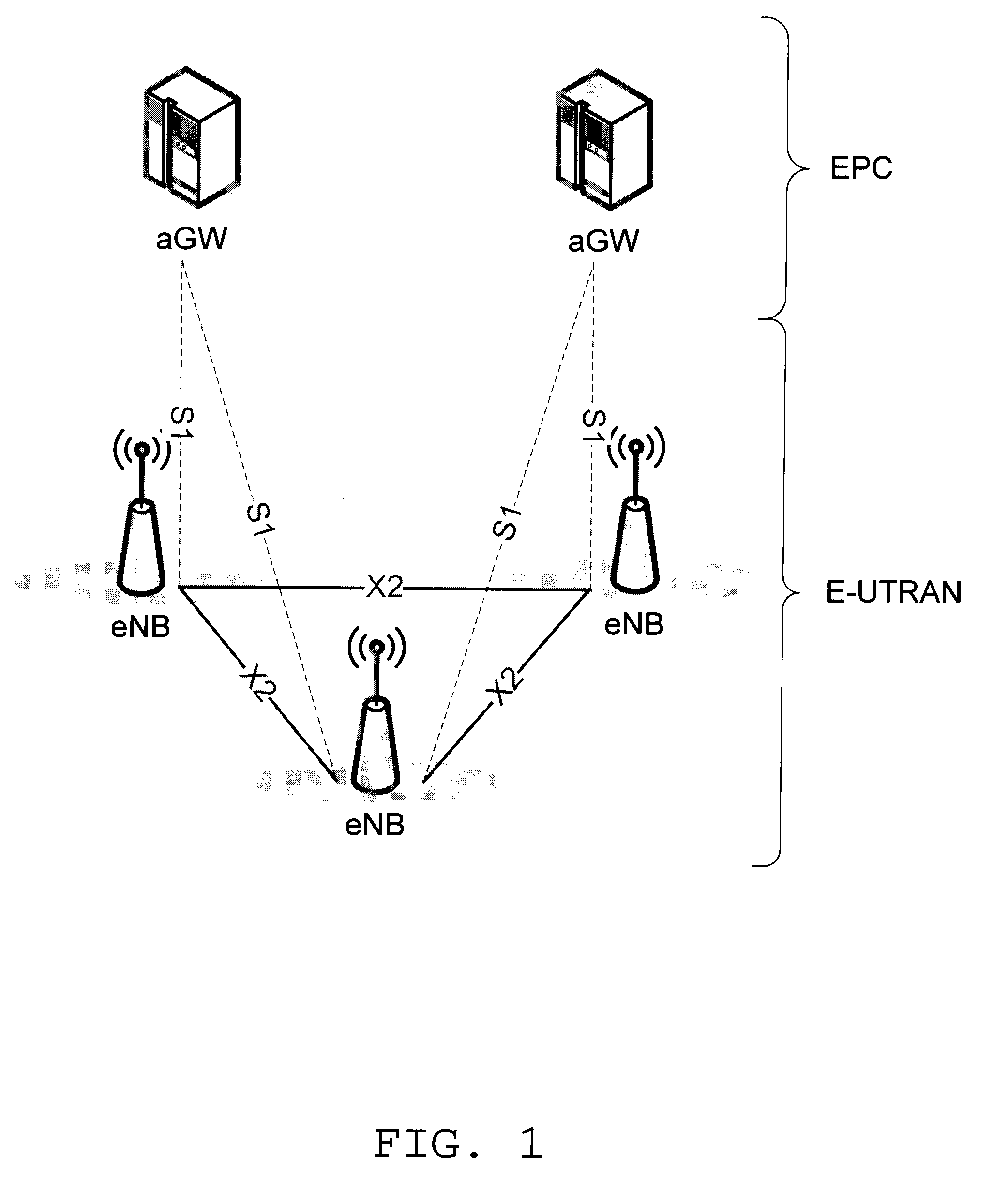

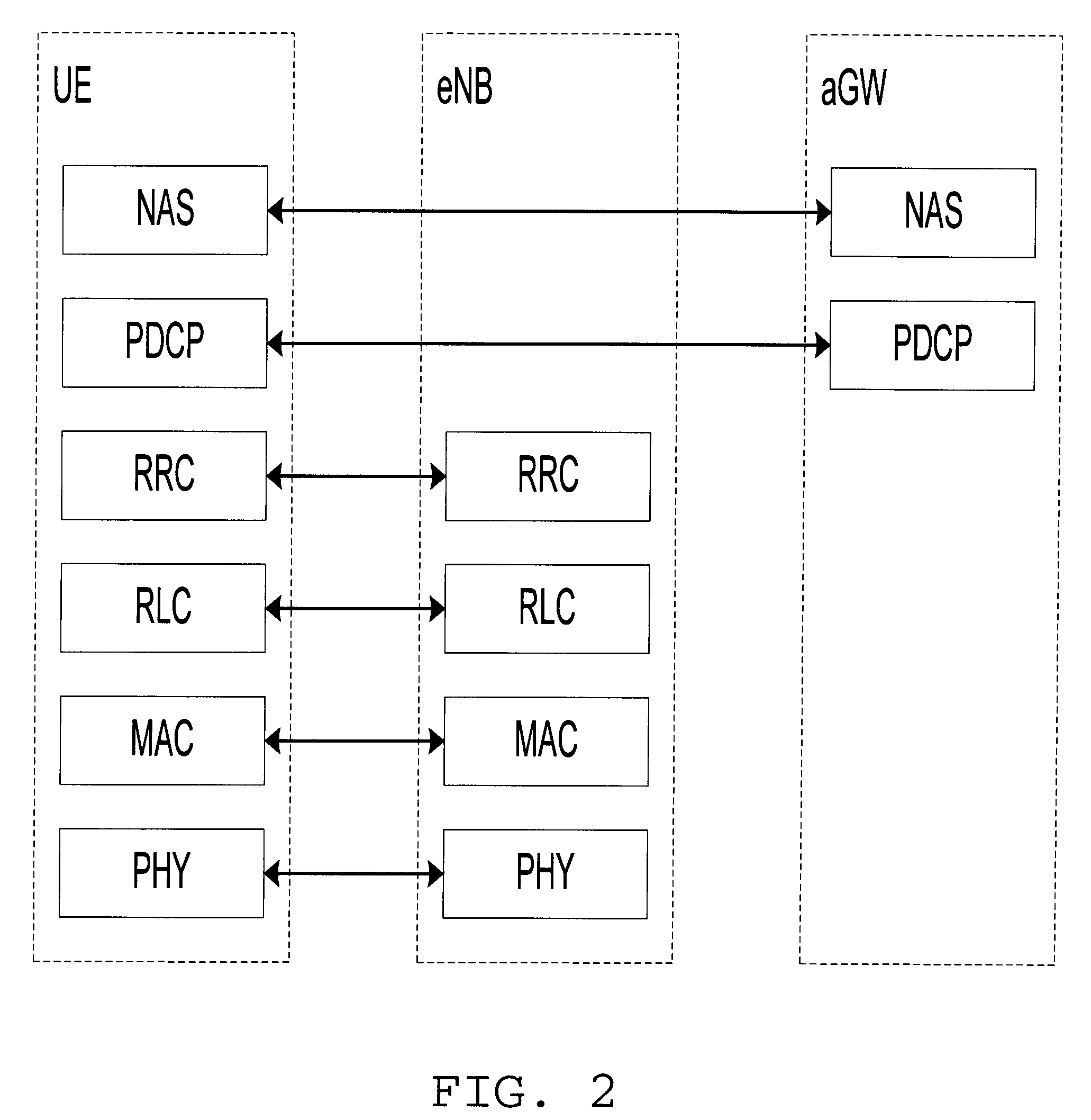

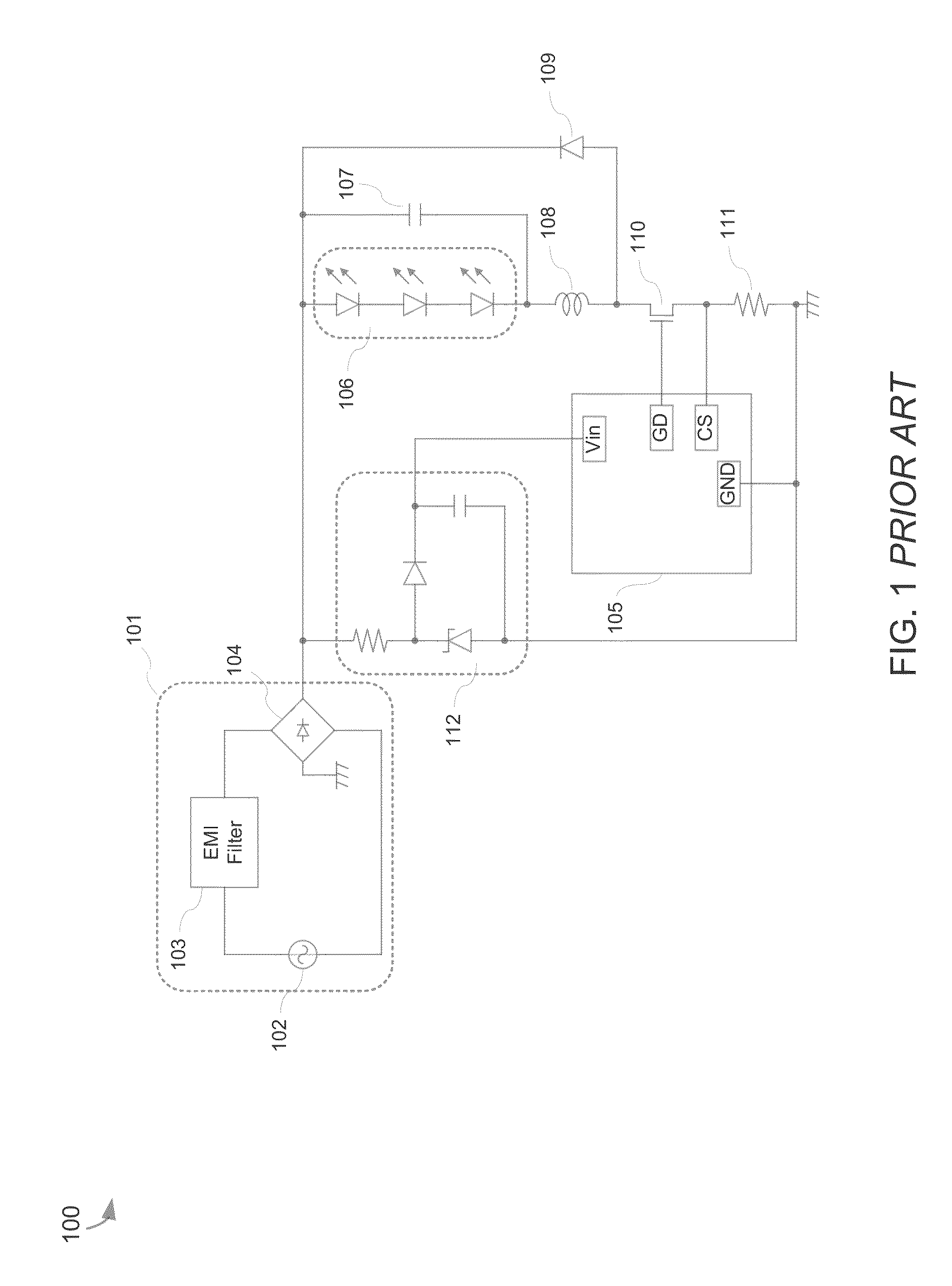

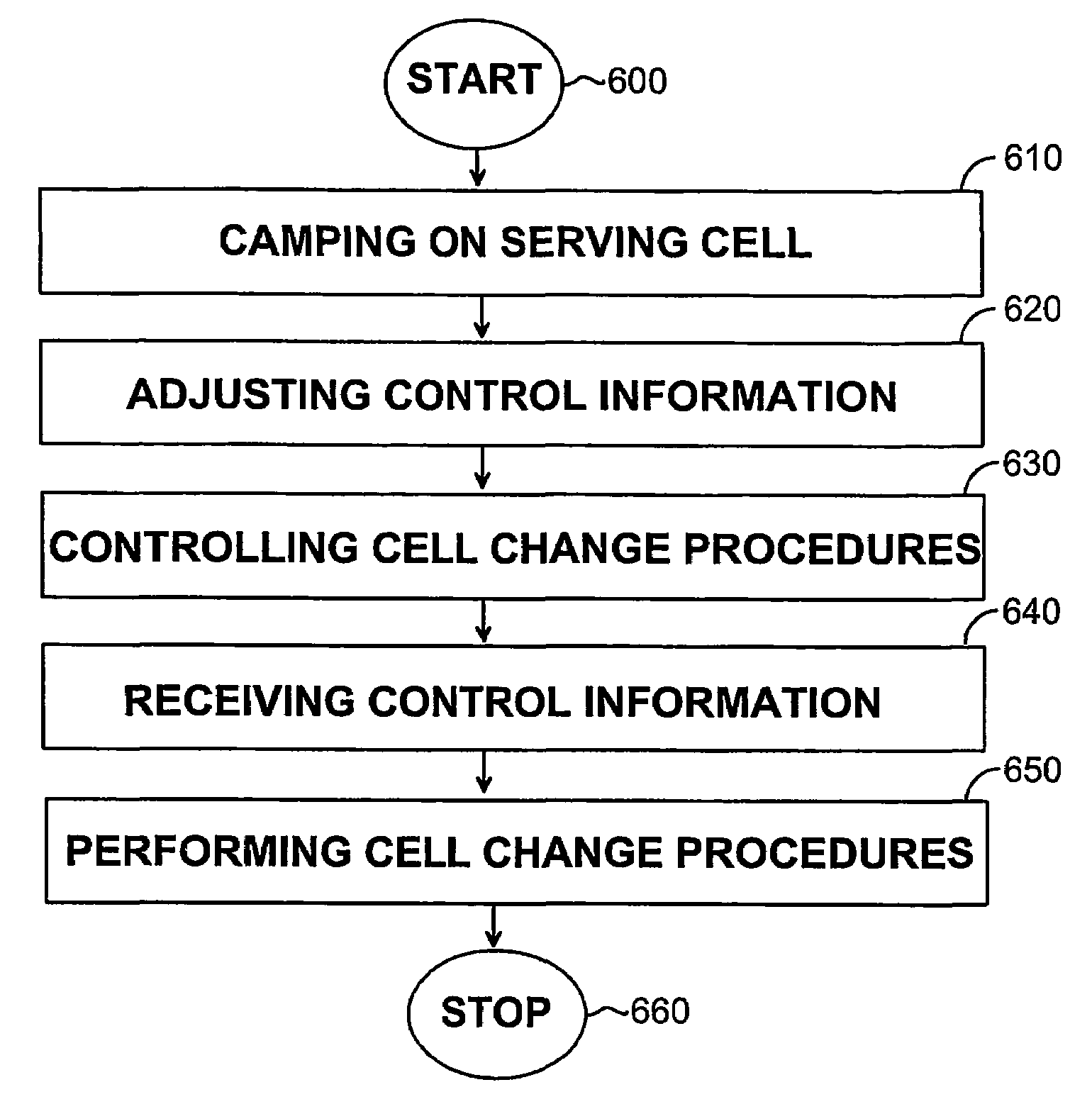

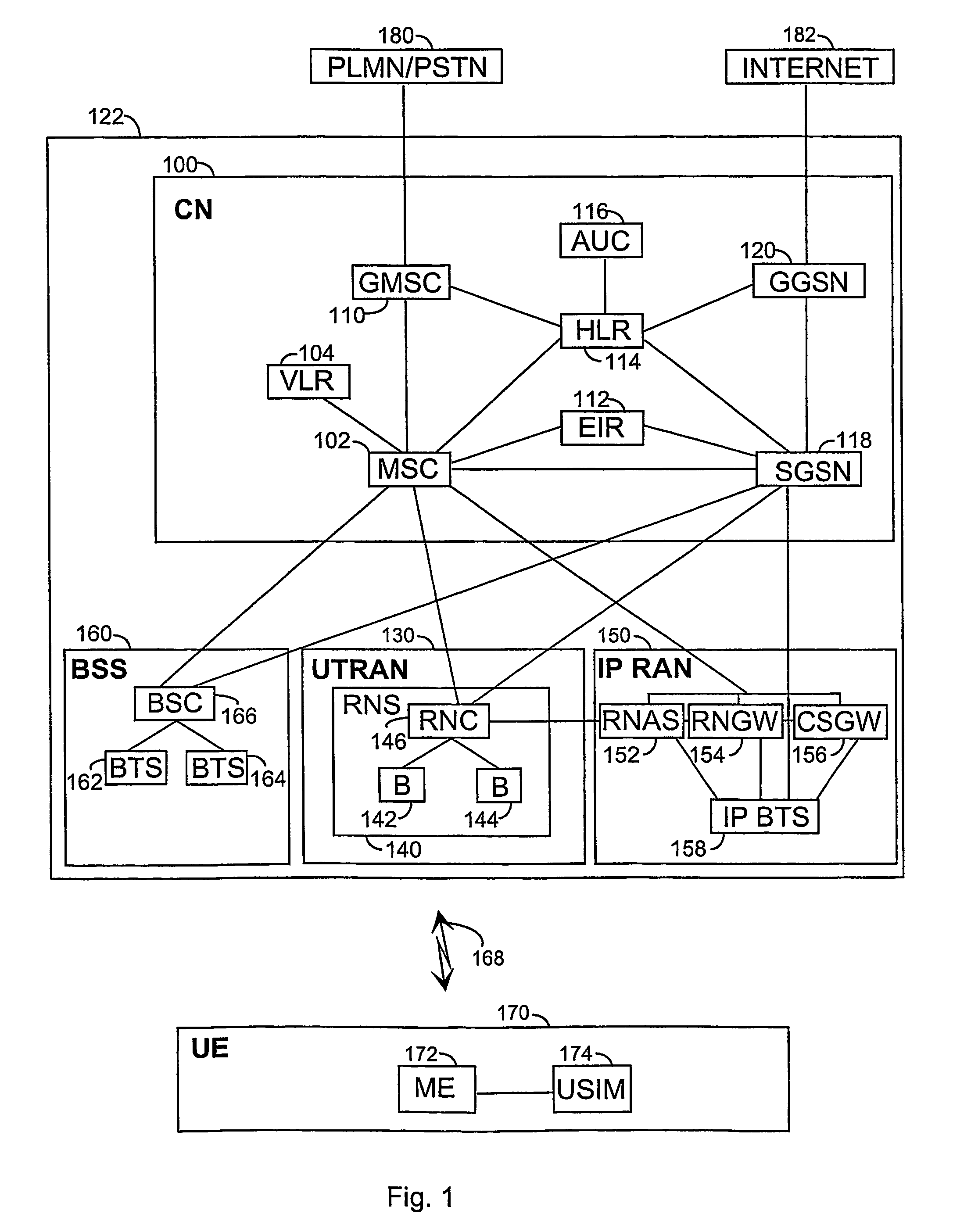

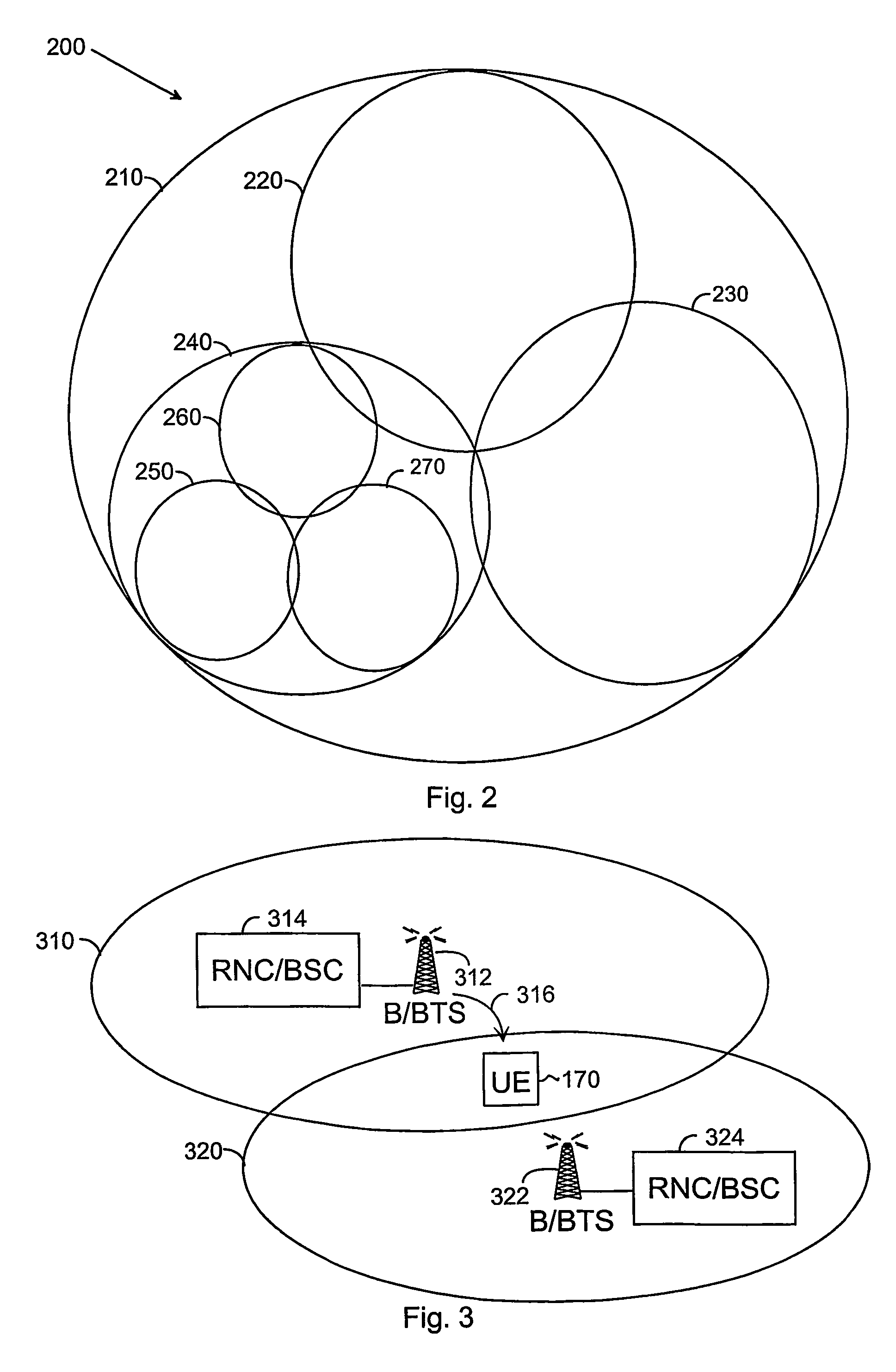

Radio resource control method in mobile communication system, and mobile communication system

InactiveUS20060111110A1Reducing mobile measurementReduce signalingAssess restrictionRadio/inductive link selection arrangementsCommunications systemMobile communication systems

The invention relates to a radio resource control method, a mobile communications system and a network element implementing the method. According to the invention, the cell change procedures performed by the user equipment in an idle state are controlled dynamically with control information that is adjusted according to a predetermined time pattern. The invention enables for instance an advanced cell change in an idle state, thus reducing the probability of a handover while the user equipment is in a dedicated connection to the network.

Owner:NOKIA TECHNOLOGLES OY

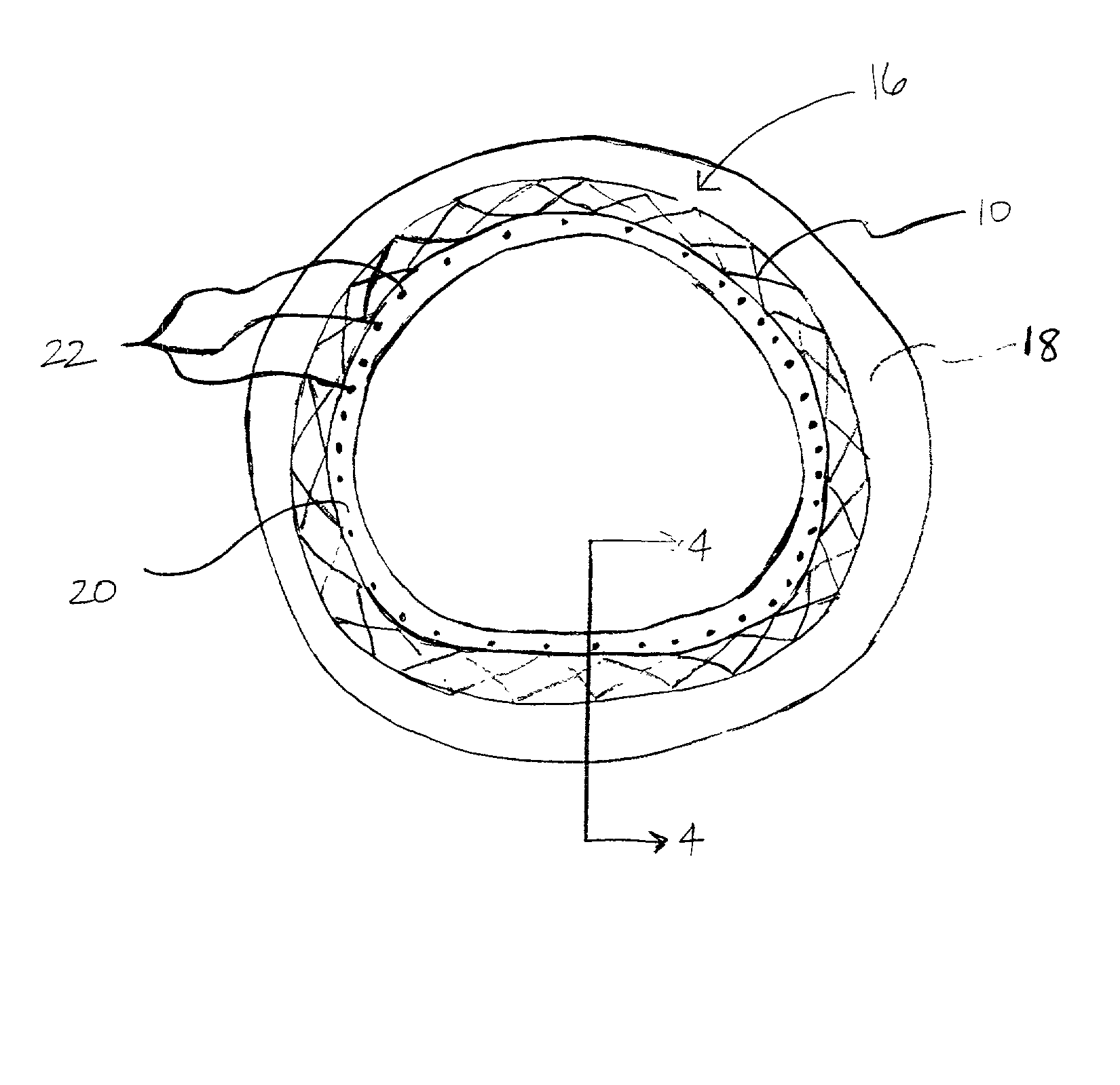

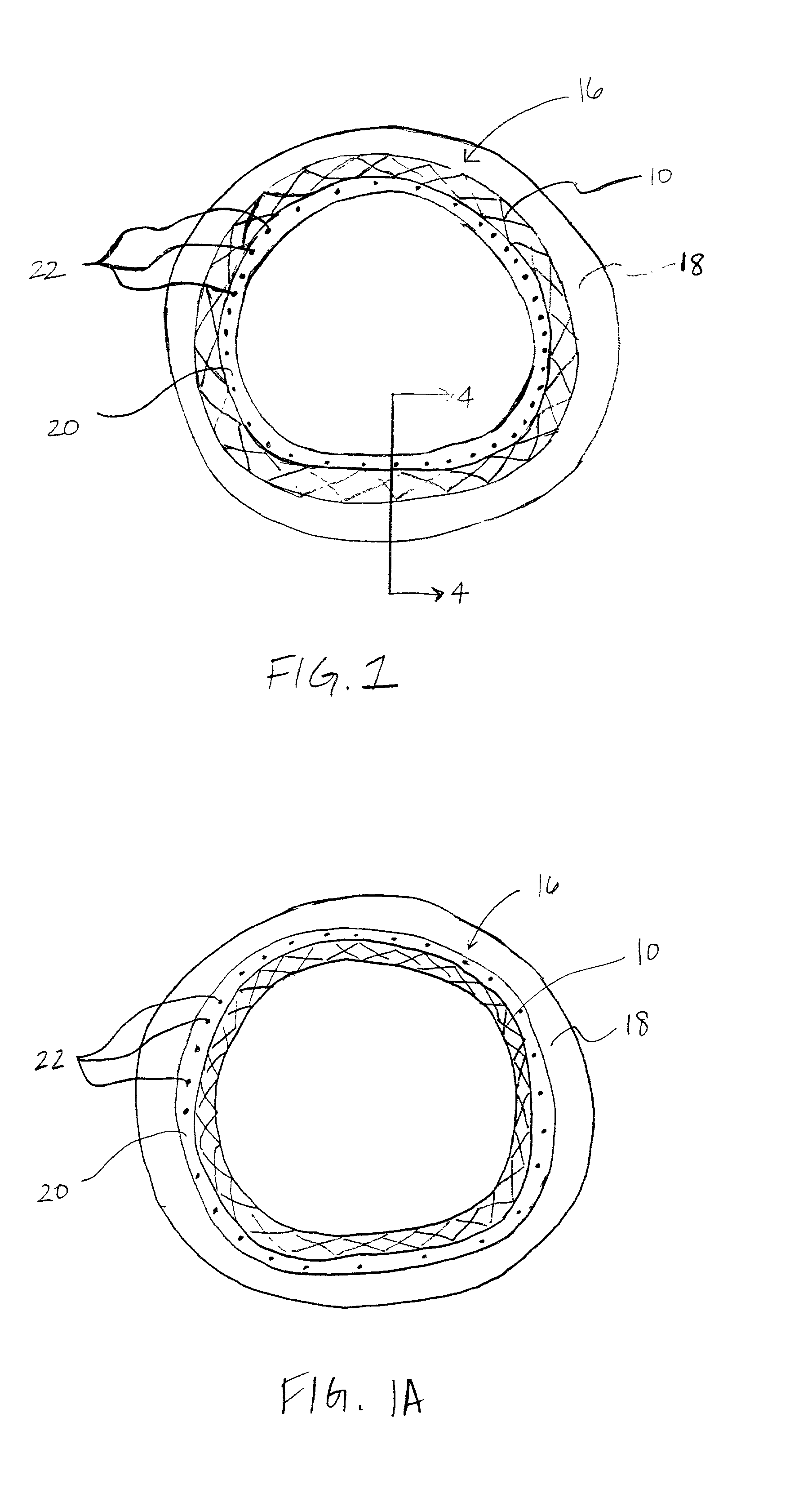

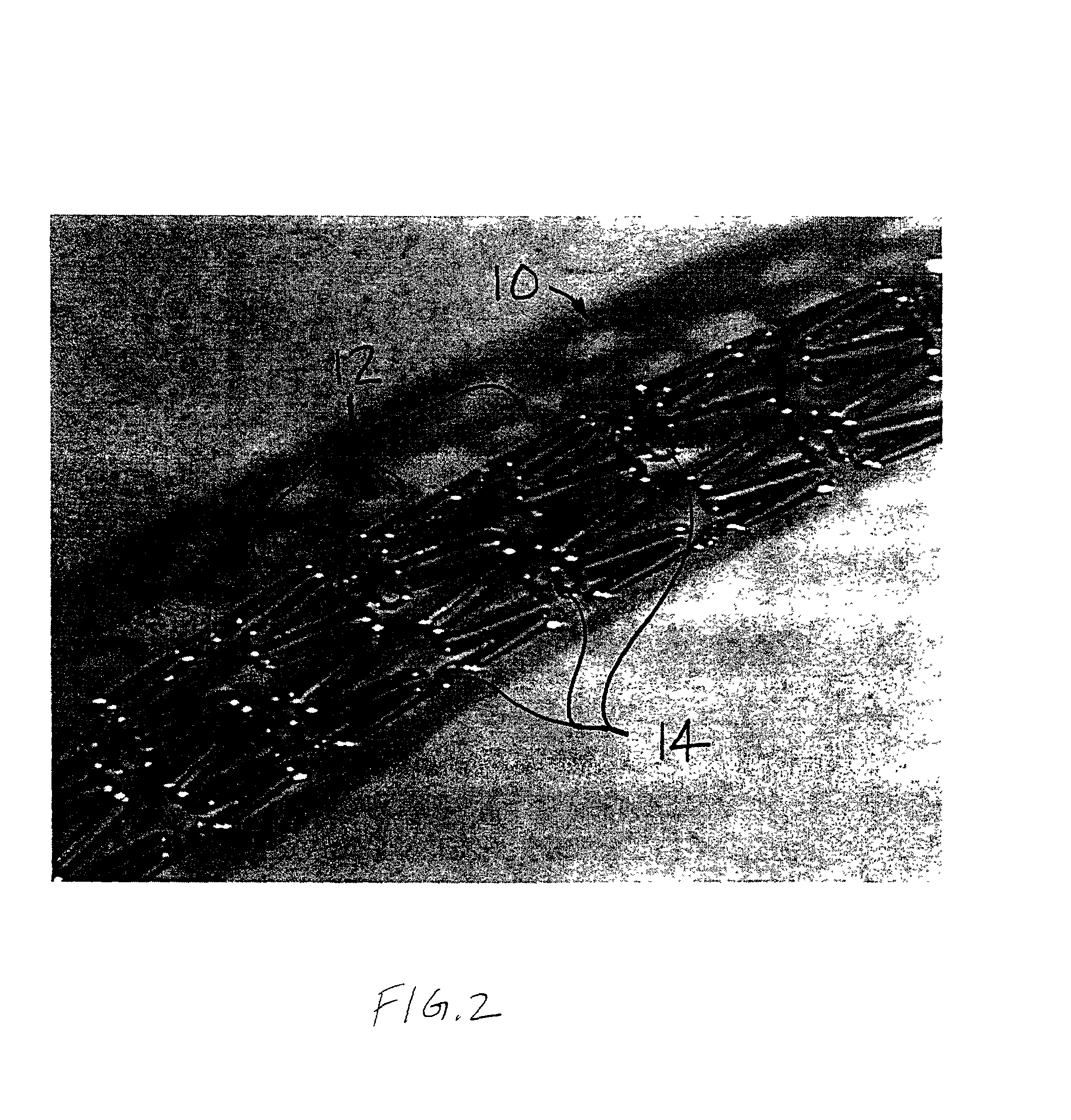

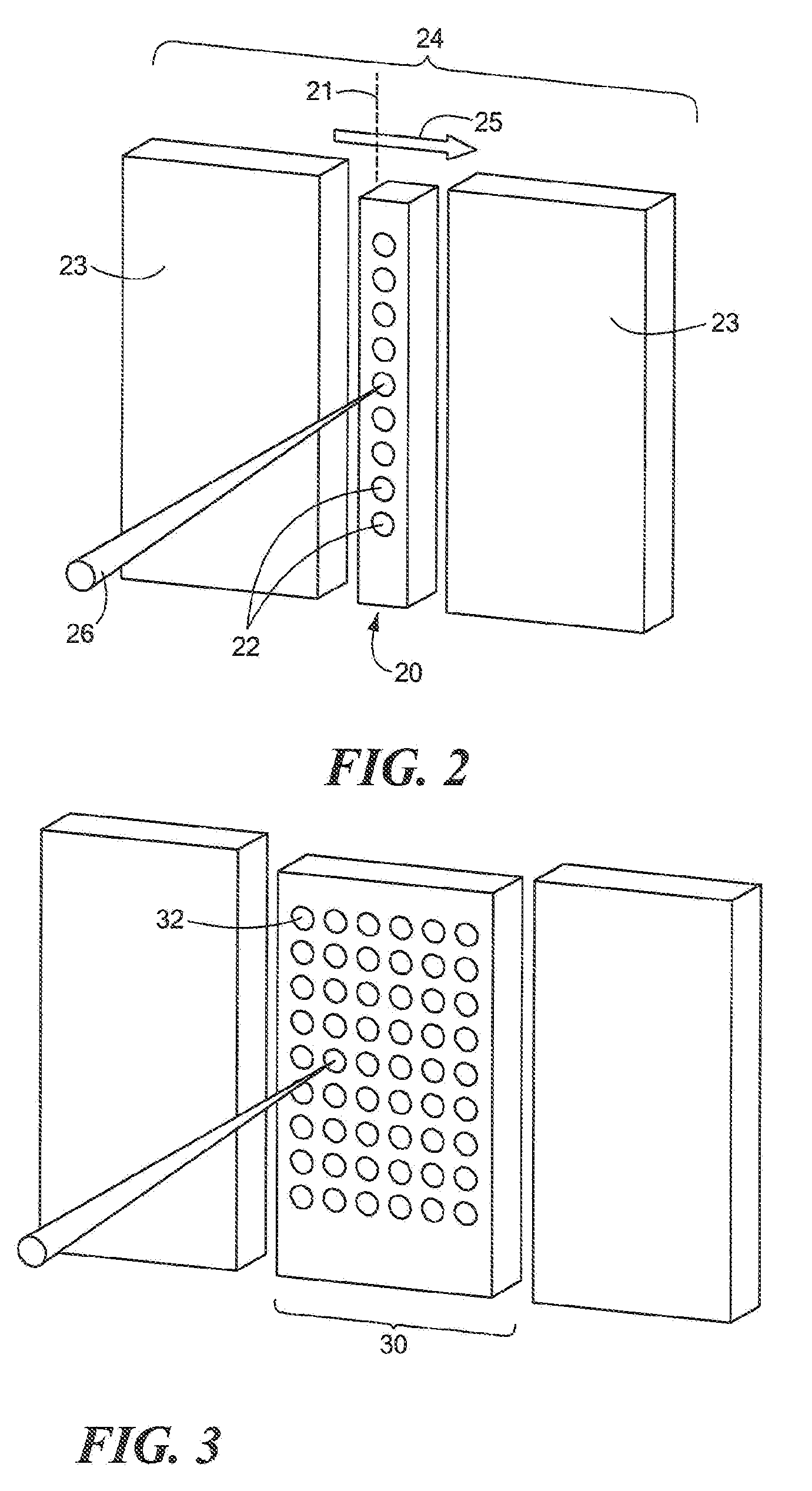

Apparatus and methods for controlled substance delivery from implanted prostheses

InactiveUS20020082685A1Improve drug delivery efficiencyReduce lossesStentsSurgeryPercent Diameter StenosisControl substances

The present invention provides improved devices and methods for inhibiting restenosis and hyperplasia after intravascular intervention. In particular, the present invention provides luminal prostheses which allow for programmed and controlled substance delivery with increased efficacy to selected locations within a patient's vasculature to inhibit restenosis. The luminal delivery prosthesis comprises a scaffold which is implantable within a body lumen and means on the scaffold for releasing a substance from the scaffold. The substance is released over a predetermined time pattern comprising an initial phase wherein the substance delivery rate is below a threshold level and a subsequent phase wherein the substance delivery rate is above a threshold level.

Owner:ALTAI MEDICAL TECH

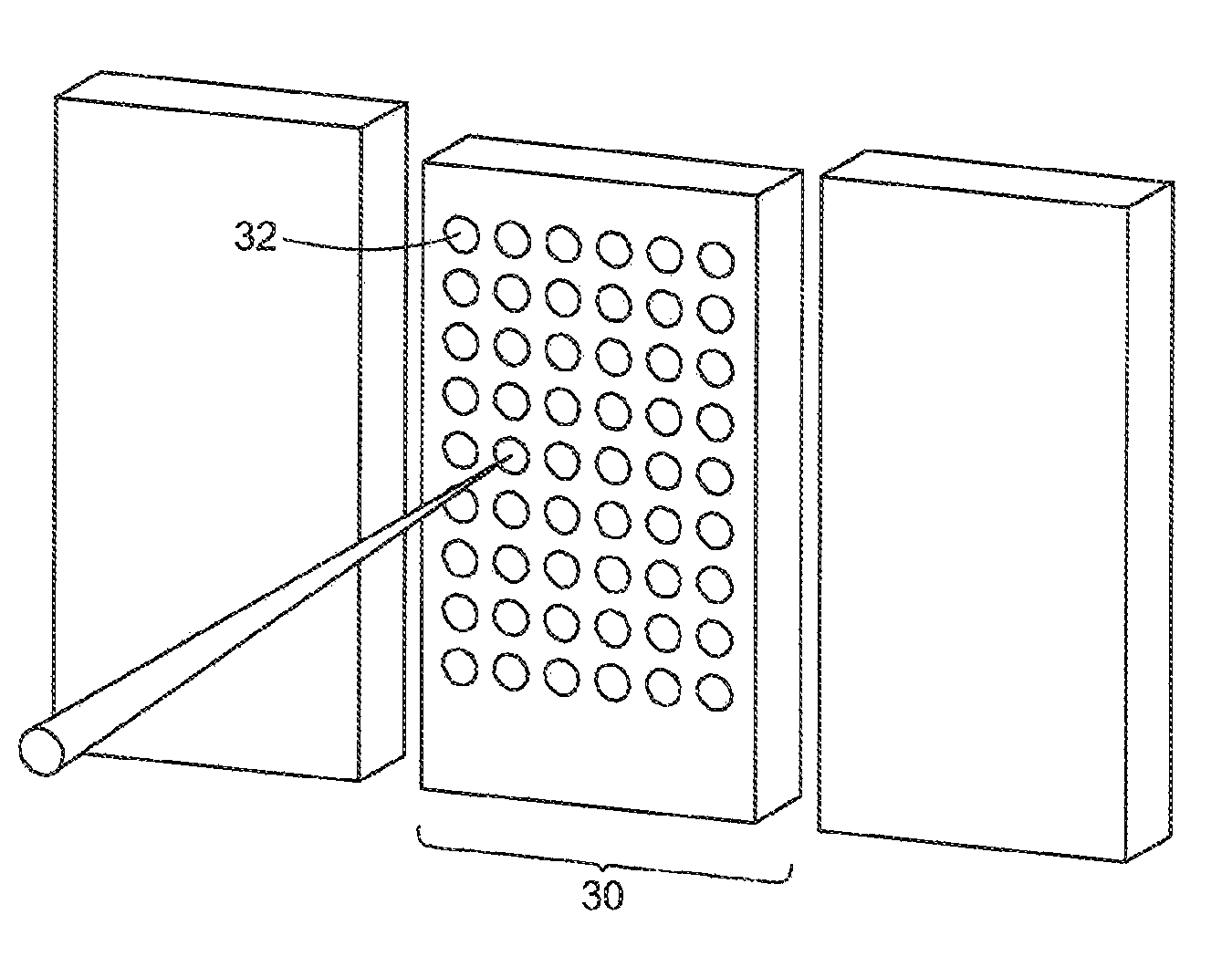

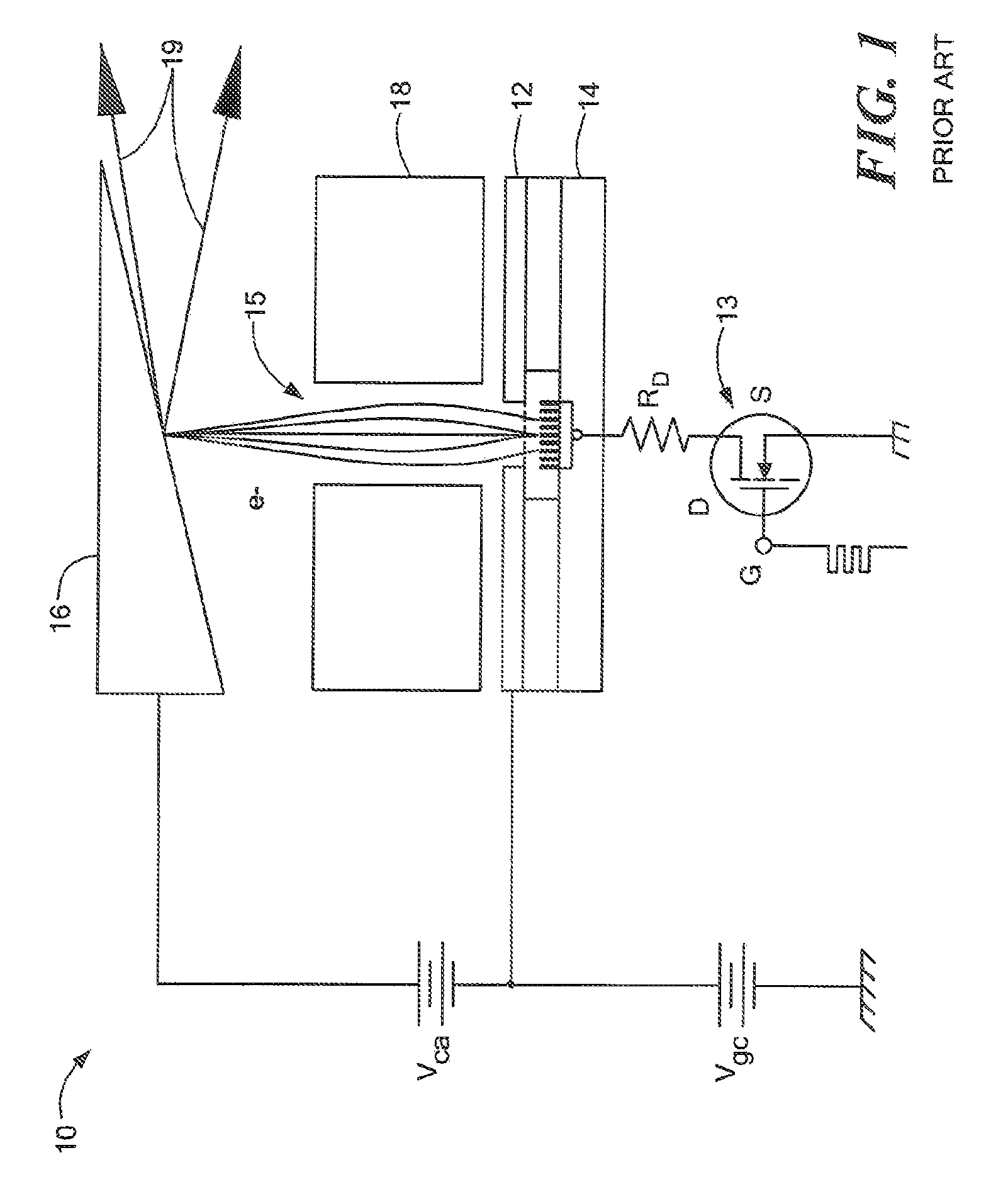

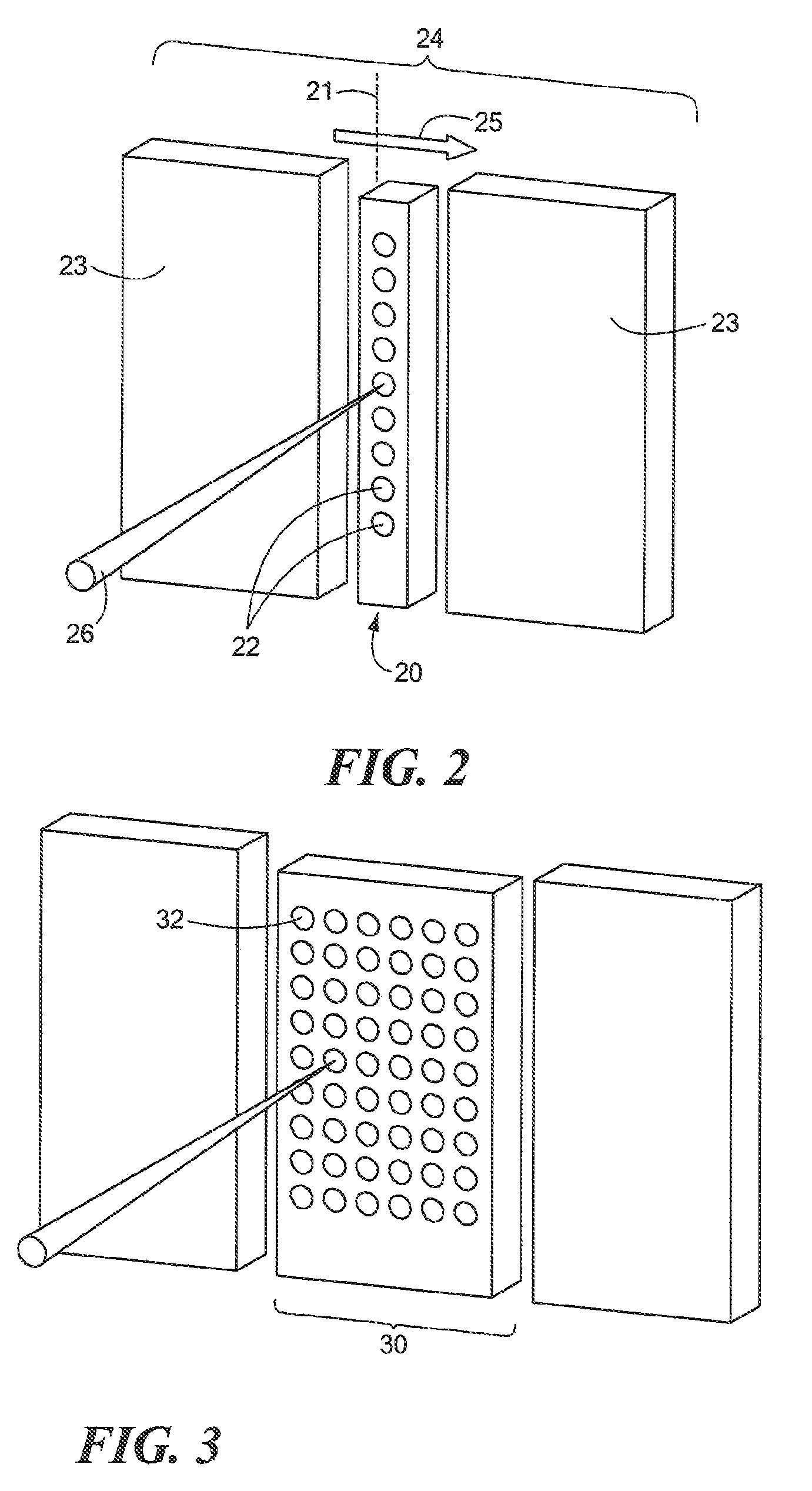

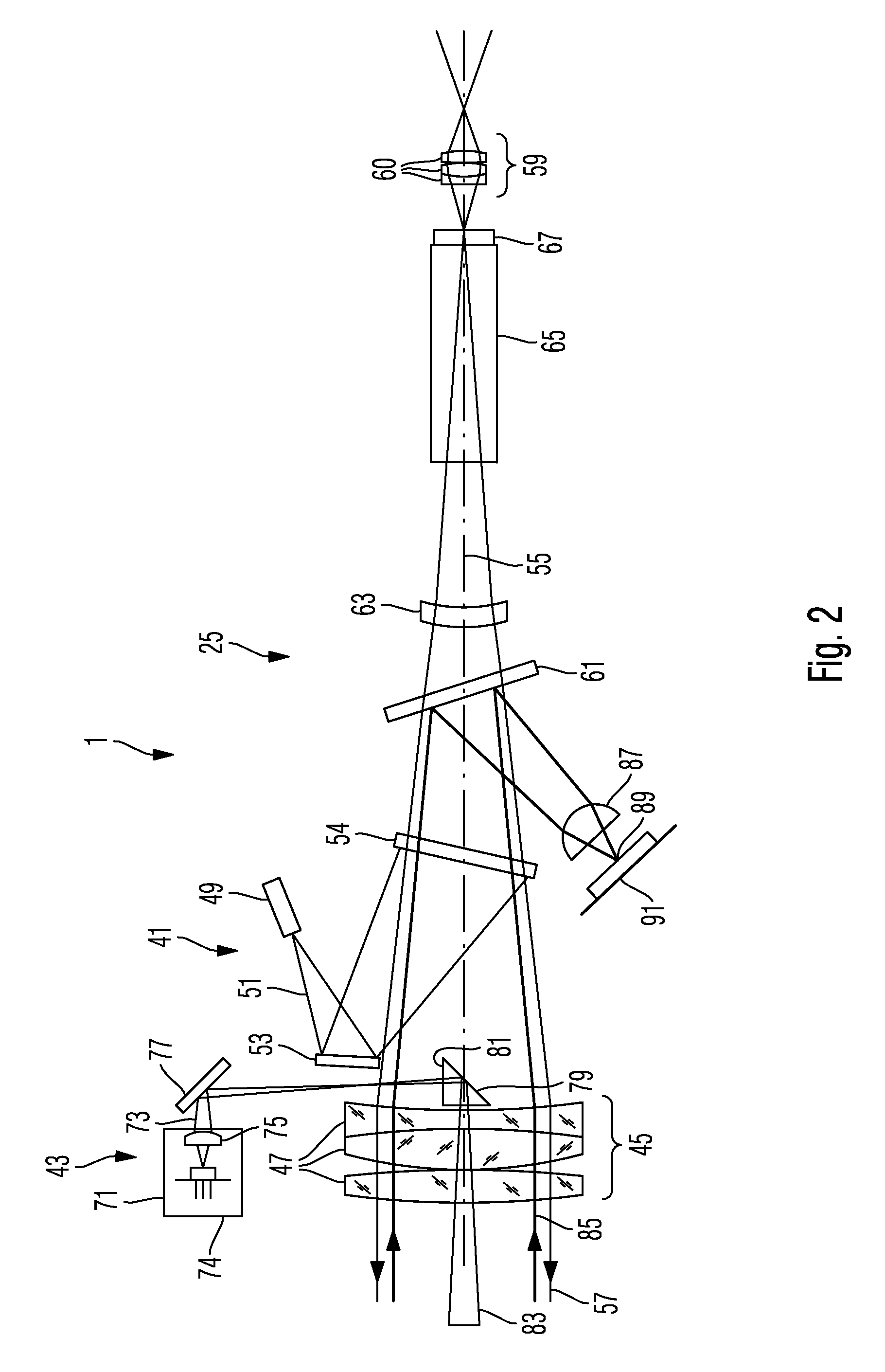

X-ray imaging of baggage and personnel using arrays of discrete sources and multiple collimated beams

ActiveUS7505562B2Material analysis by transmitting radiationNuclear radiation detectionSpatial OrientationsCarbon nanotube

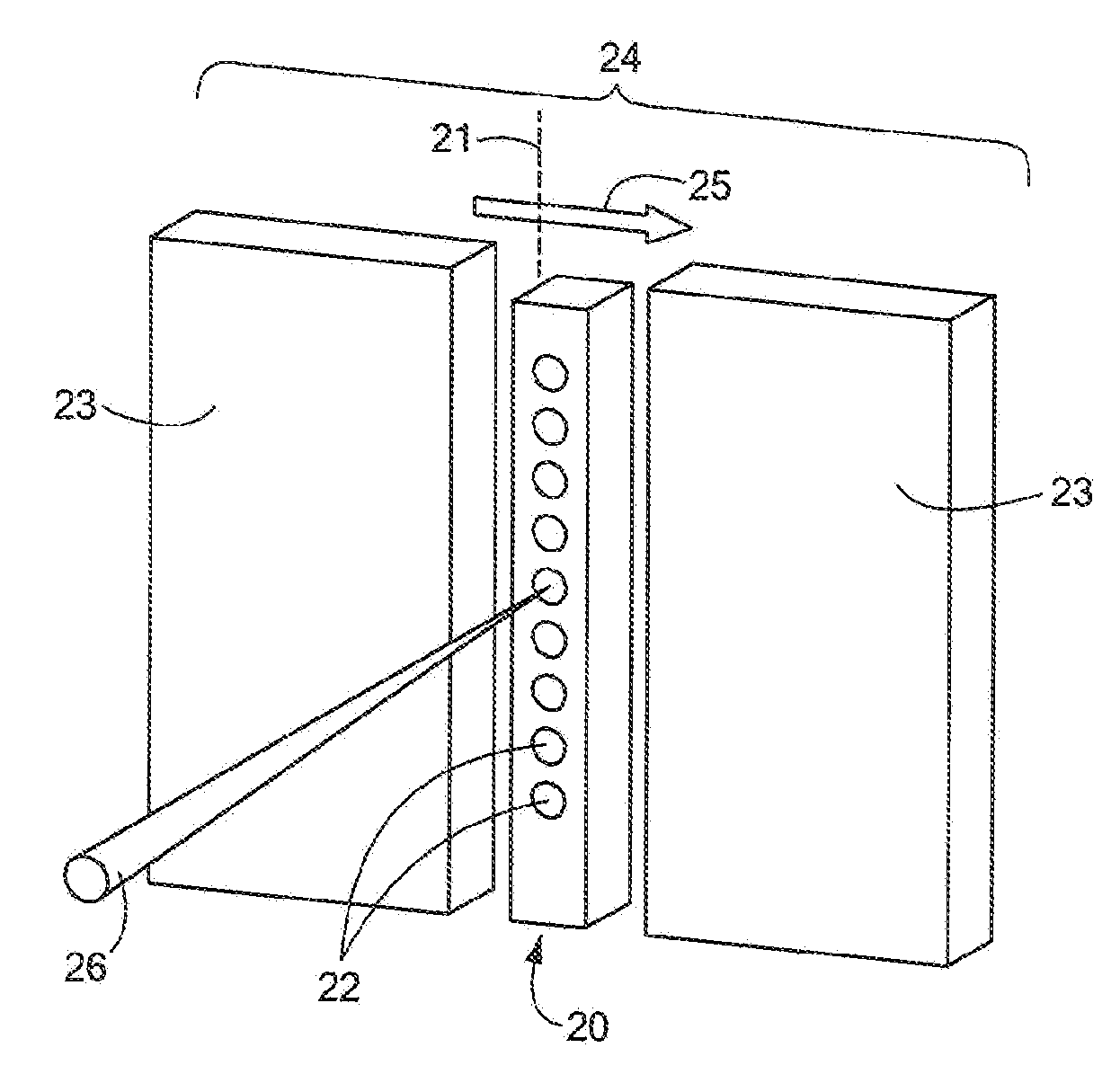

A system and methods are provided for imaging an object, based on activating an array of discrete X-ray sources in a prescribed temporal pattern so as to illuminate the object with a beam varying in spatial orientation, and detecting X-rays of the beam after interaction with the object and generating a detector signal. An image of the object may then be constructed on the basis of the time variation of the detector signal. The discrete X-ray sources may be moved during the course of inspection, moreover, the prescribed temporal pattern may constitute a Hadamard code. The discrete sources may be carbon nanotube x-ray sources.

Owner:AMERICAN SCI & ENG INC

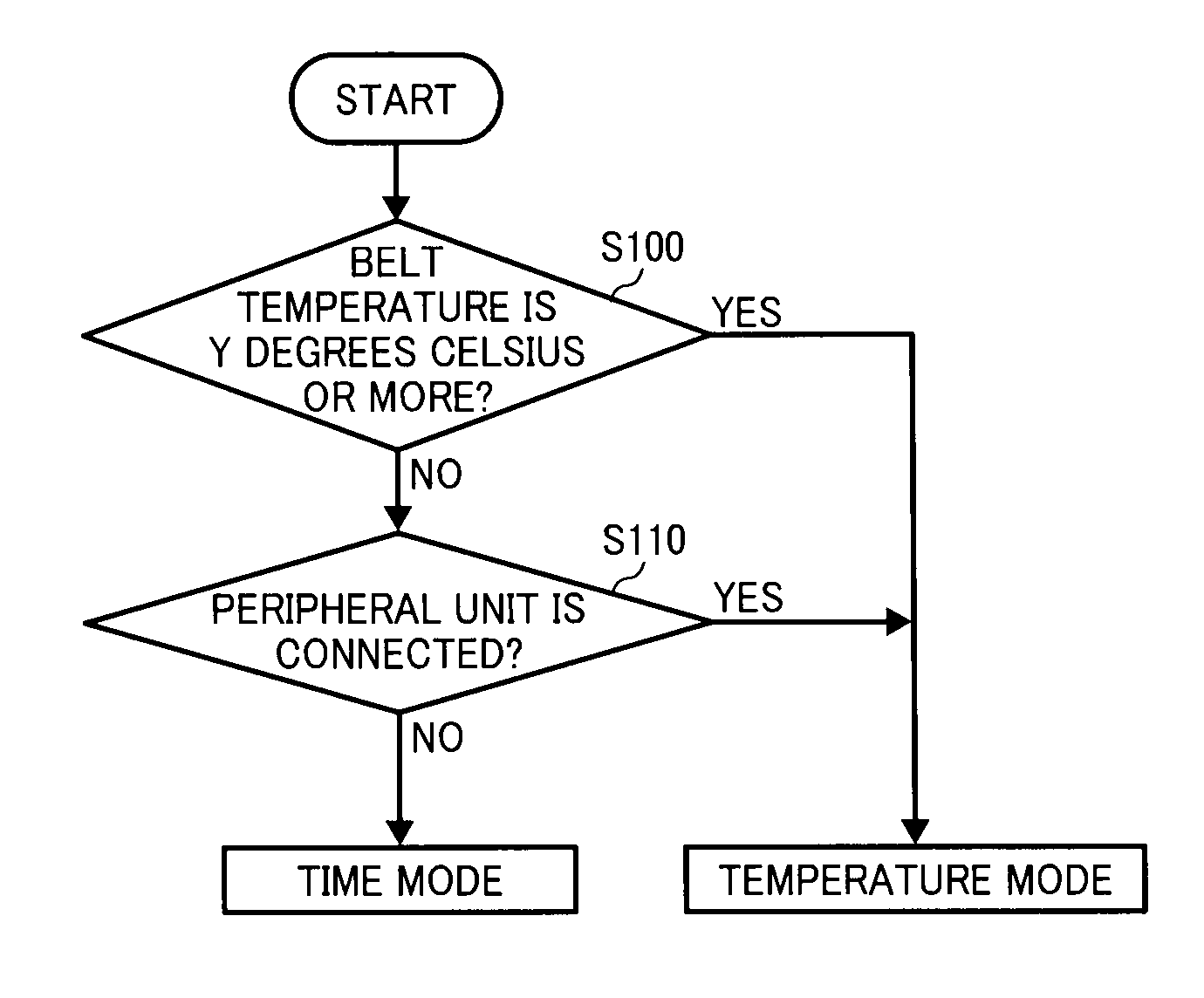

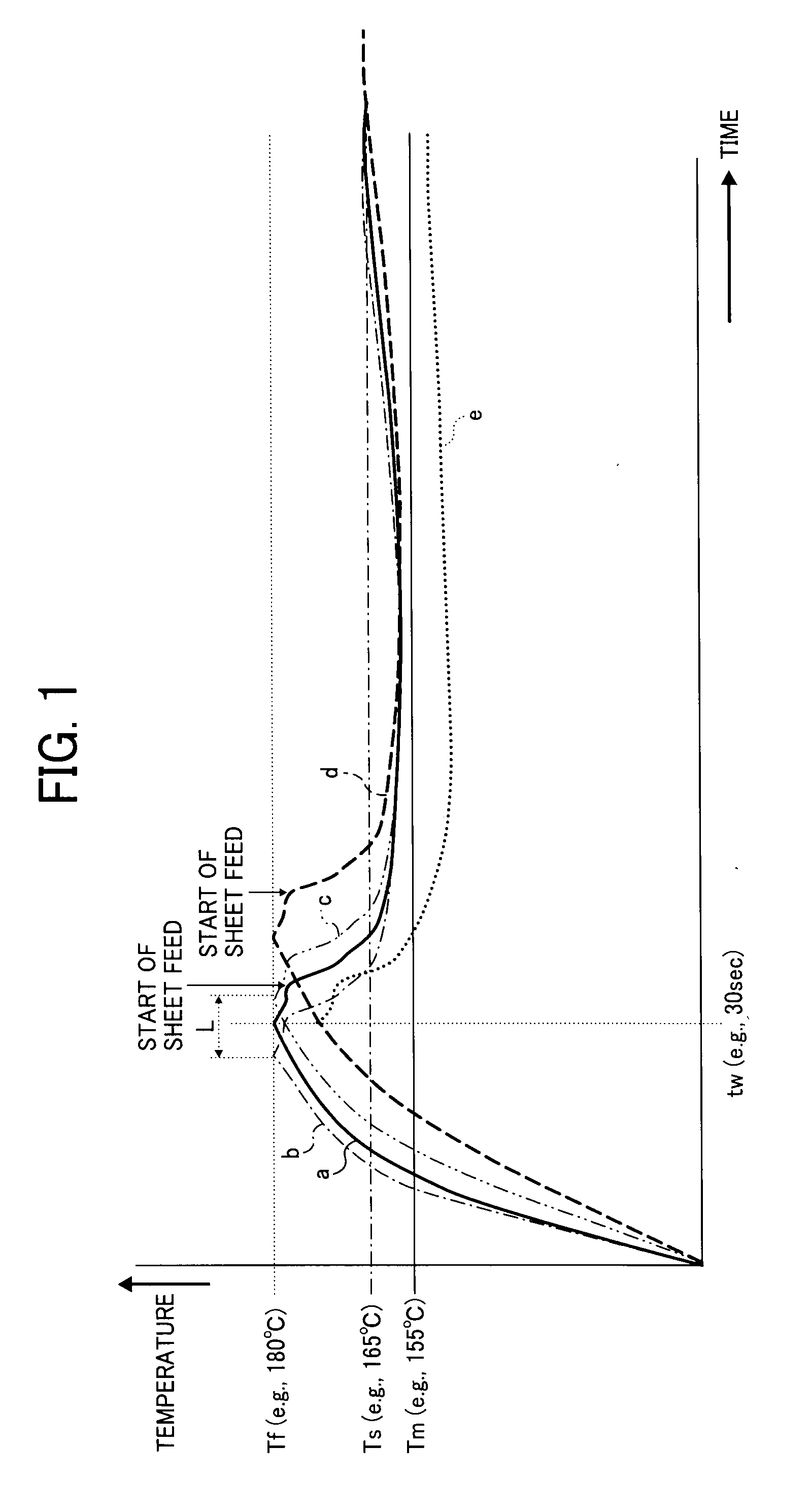

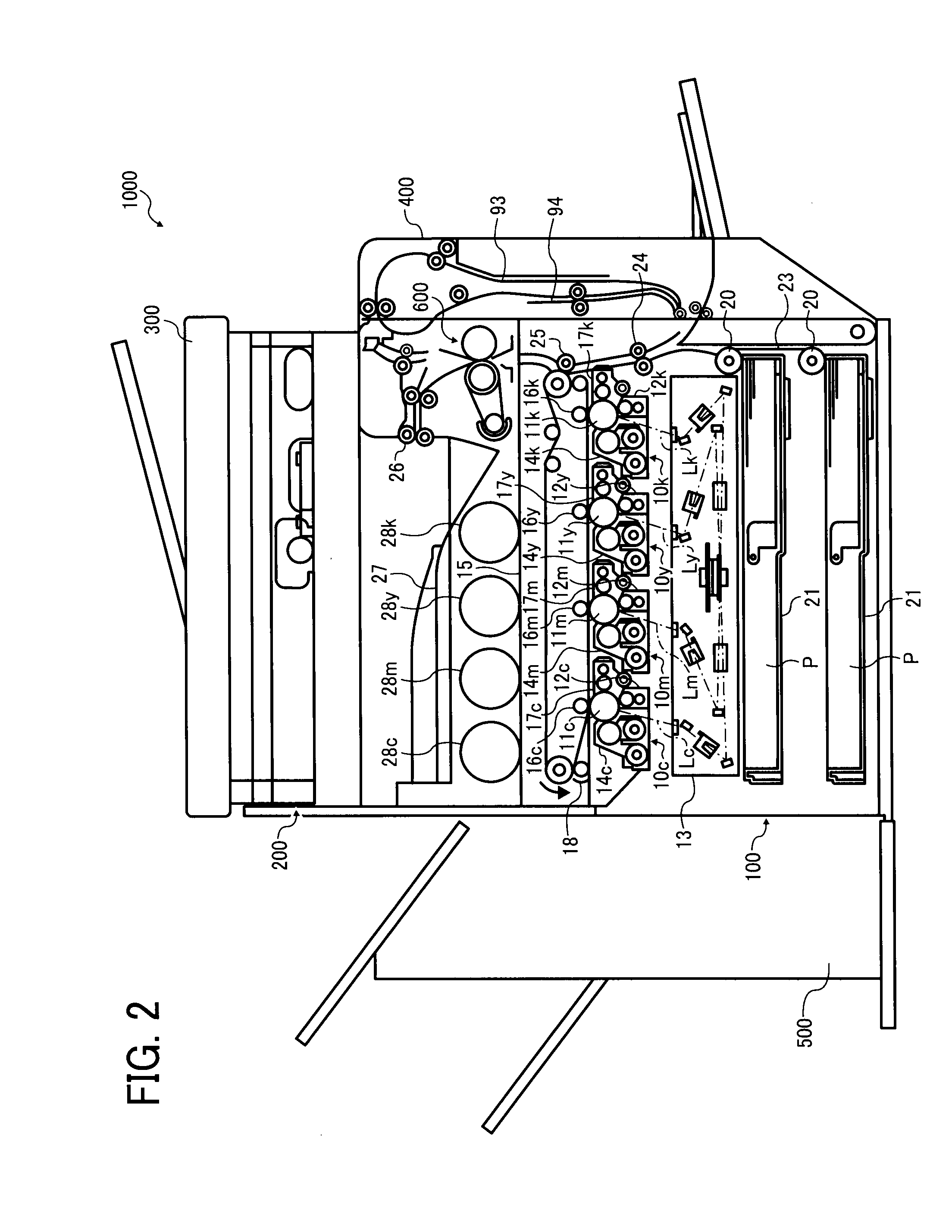

Image forming apparatus, and method of controlling warming-up time of image forming apparatus

An image forming apparatus includes a fixing unit and a fixing process managing system. The fixing process managing system, including a mode switchover unit, controls a time mode and a temperature mode for heating a fixing member. In the time mode, the fixing unit is determined to be ready for a fixing process when a given time elapses after activation of the image forming apparatus. In the temperature mode, the fixing unit is determined to be ready for a fixing process when a temperature of the fixing member attains a given reference temperature after activation of the image forming apparatus. The mode switchover unit selects between the temperature mode and the time mode. The fixing process managing system selects the temperature mode instead of the time mode when a supply amount of electrical power to the fixing unit is determined to be below a required electrical power supply level.

Owner:RICOH KK

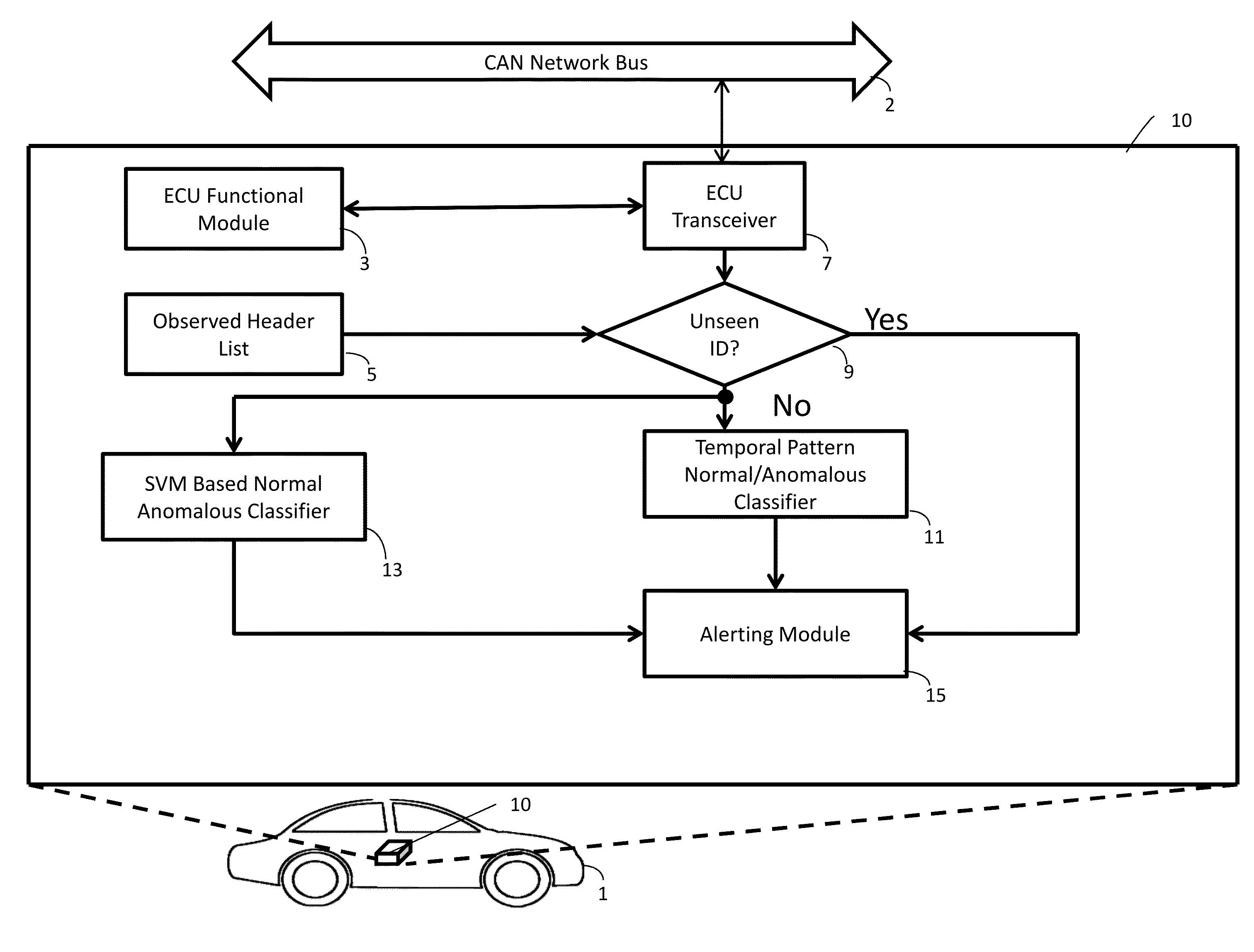

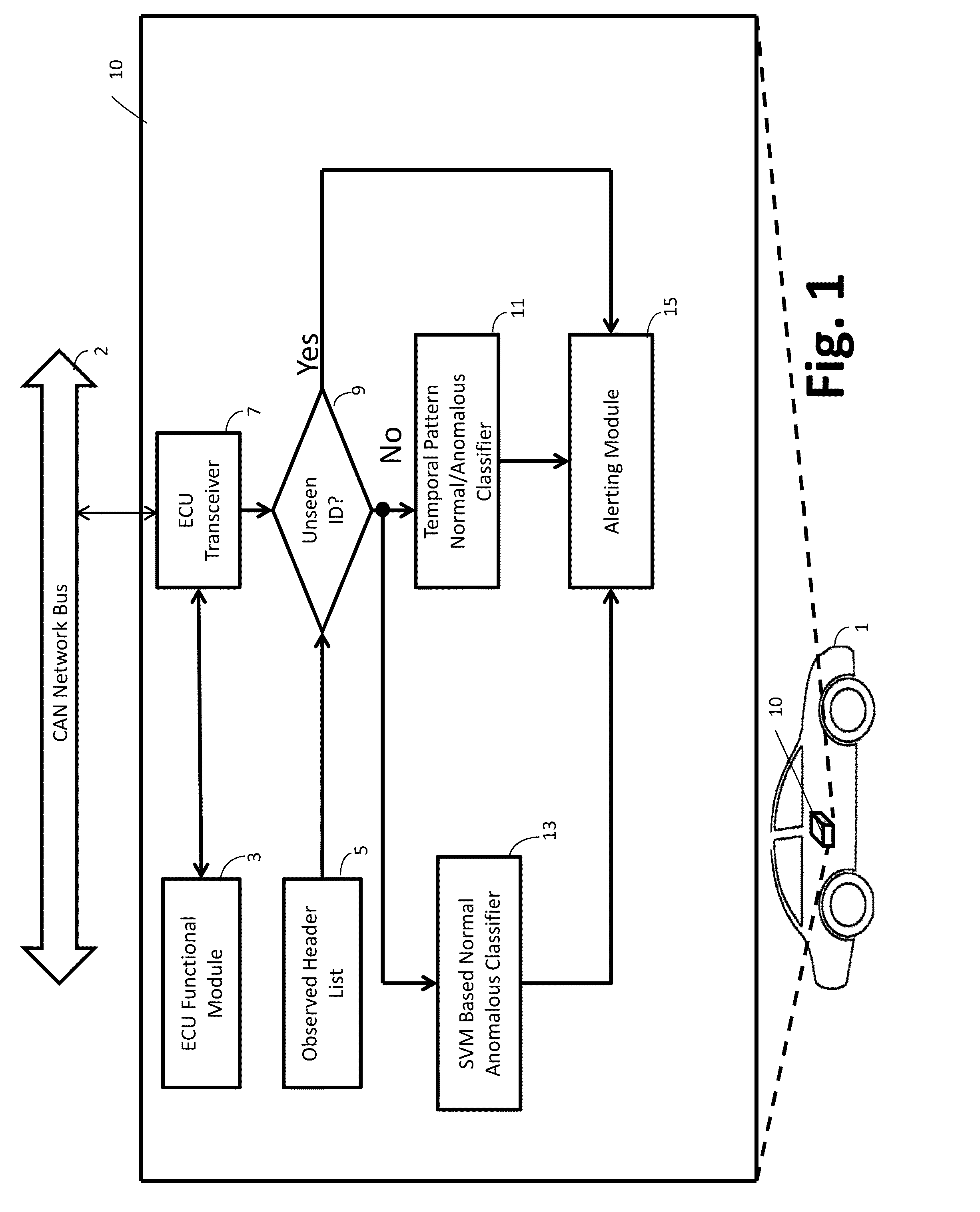

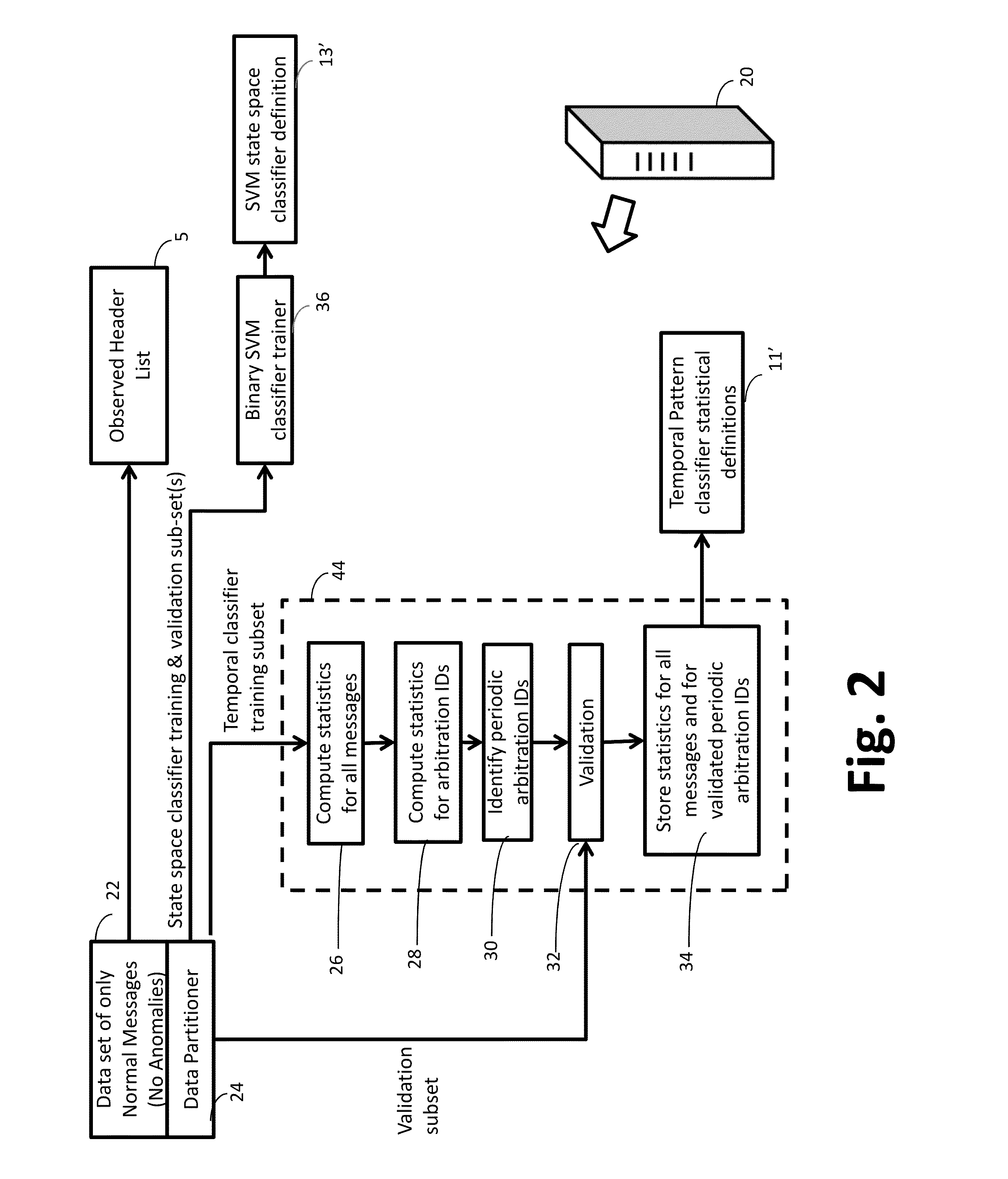

Temporal anomaly detection on automotive networks

An anomaly detector for a Controller Area Network (CAN) bus performs state space classification on a per-message basis of messages on the CAN bus to label messages as normal or anomalous, and performs temporal pattern analysis as a function of time to label unexpected temporal patterns as anomalous. The anomaly detector issues an alert if an alert criterion is met that is based on the outputs of the state space classification and the temporal pattern analysis. The temporal pattern analysis may compare statistics of messages having analyzed arbitration IDs with statistics for messages having those analyzed arbitration IDs in a training dataset of CAN bus messages, and a temporal pattern is anomalous if there is a statistically significant deviation from the training dataset. The anomaly detector may be implemented on a vehicle Electronic Control Unit (ECU) communicating via a vehicle CAN bus. The anomaly detector does not rely on an database of messages and their periodicity from manufacturers (dbc files) and in that sense is truly a zero knowledge detector.

Owner:BATTELLE MEMORIAL INST

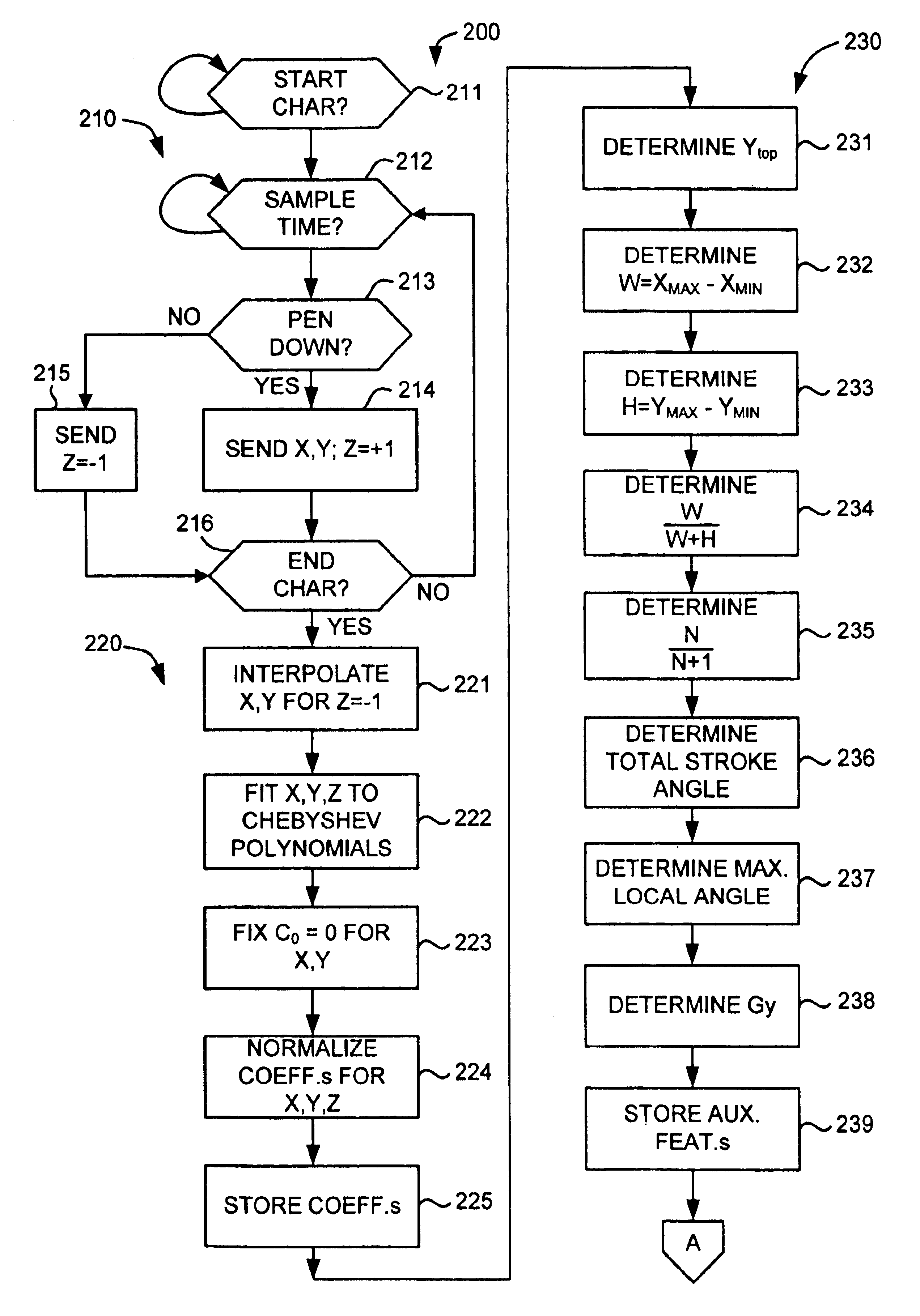

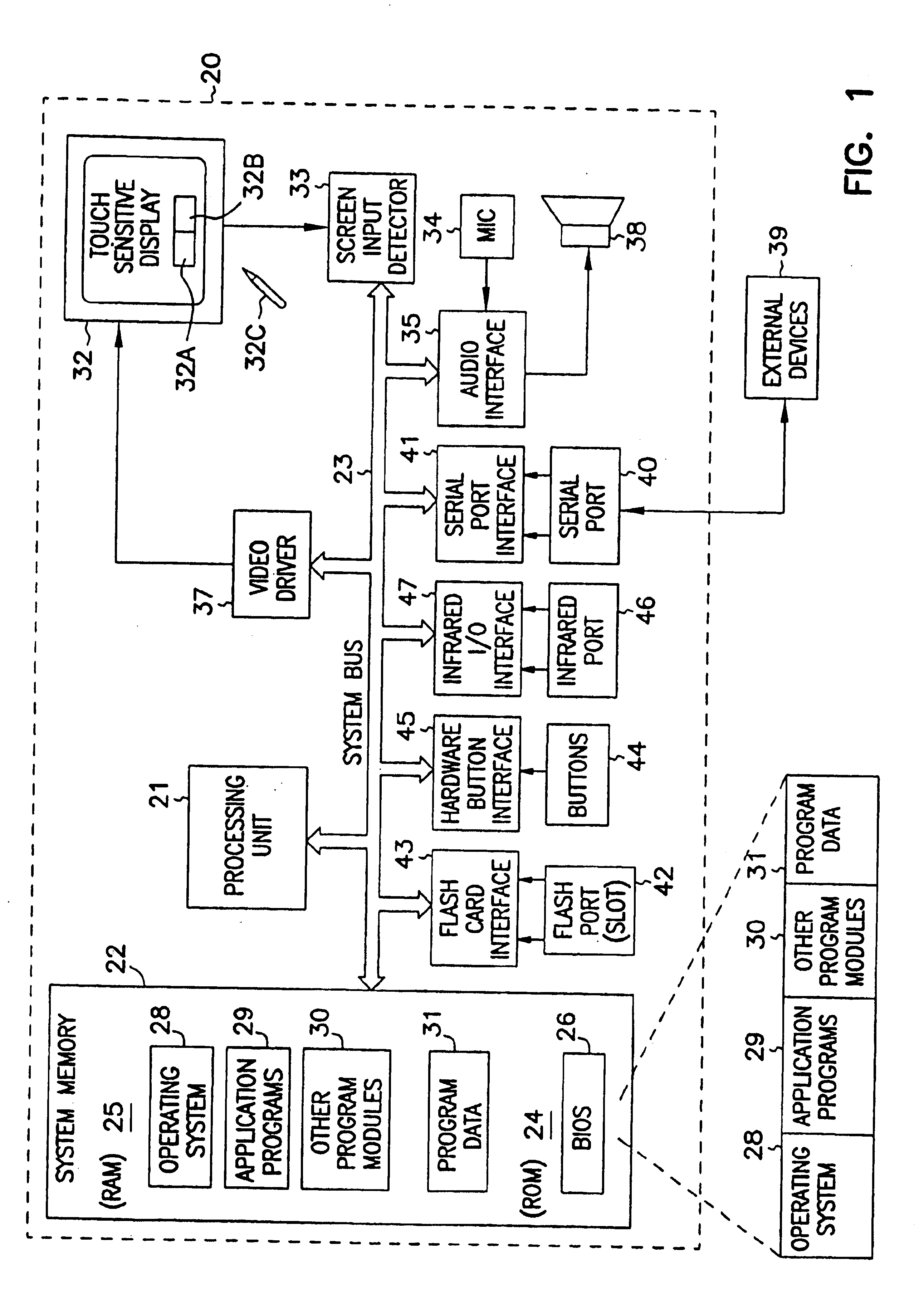

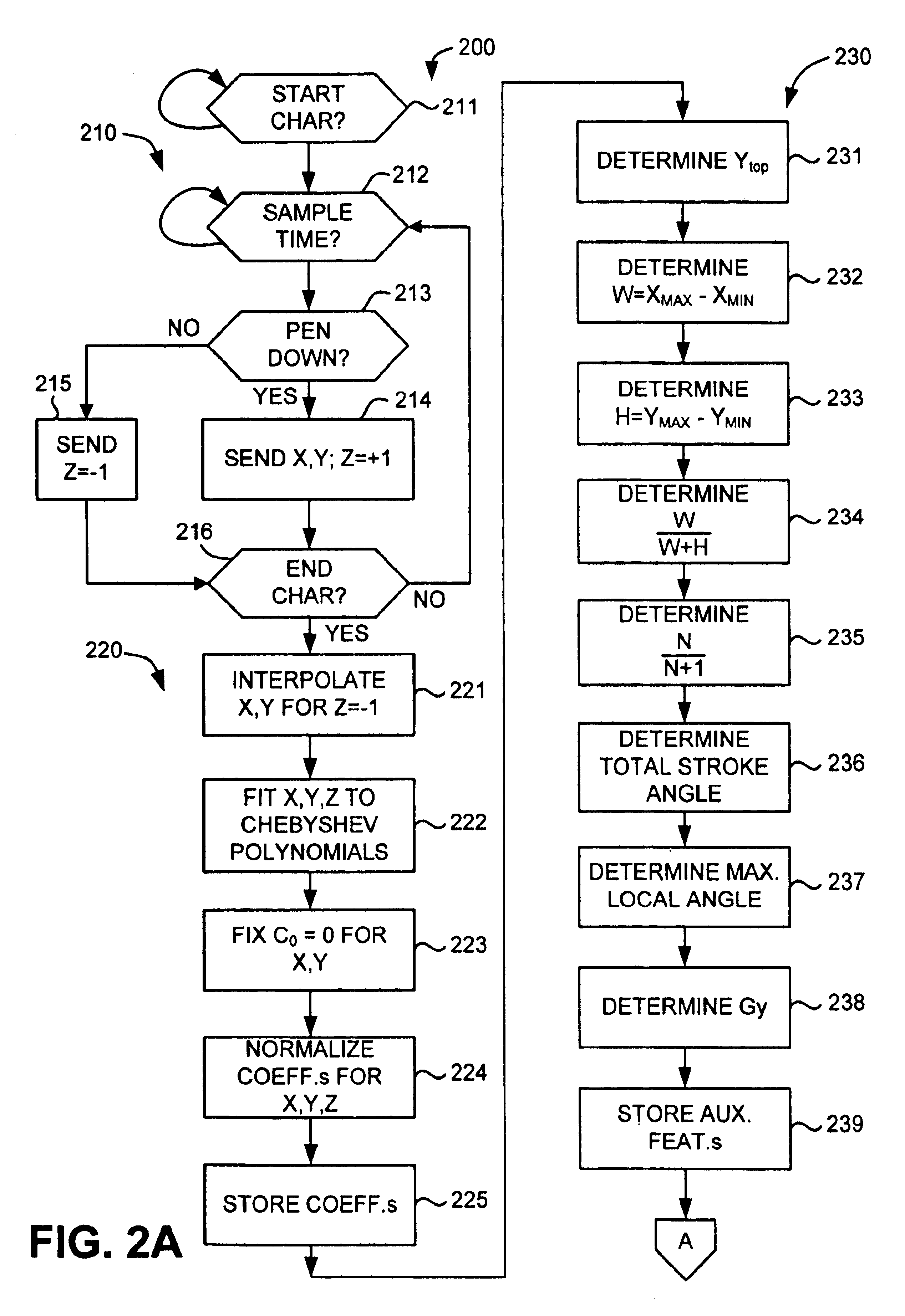

Feature extraction for real-time pattern recognition using single curve per pattern analysis

InactiveUS6898315B2Easy to operateSmall sizeCharacter and pattern recognitionFeature extractionZ-Coordinate

A feature extractor samples points on an input pattern drawn in real time. In addition to X and Y coordinates, each sample has an up / down or Z coordinate value representing whether or not the sample point is a perceptible part of the pattern. The groups of coordinate values are transformed into respective sets of coefficients of Chebyshev polynomials by least-squares fit. A recognition unit can use the coefficients as features to identify the character. Additional features, such as aspect ratio and center of gravity, are also derived to aid in recognizing the pattern or reconstructing its image.

Owner:MICROSOFT TECH LICENSING LLC

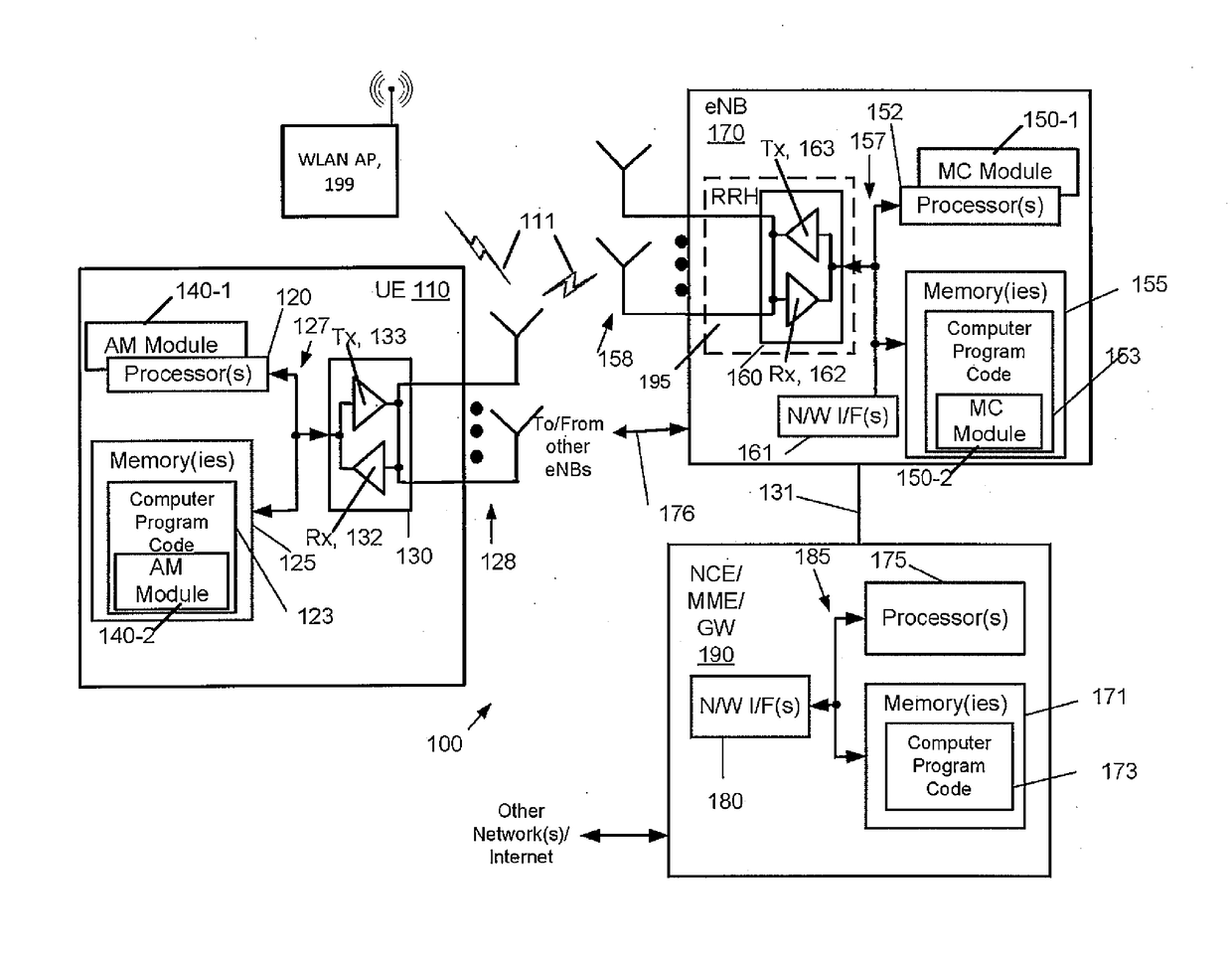

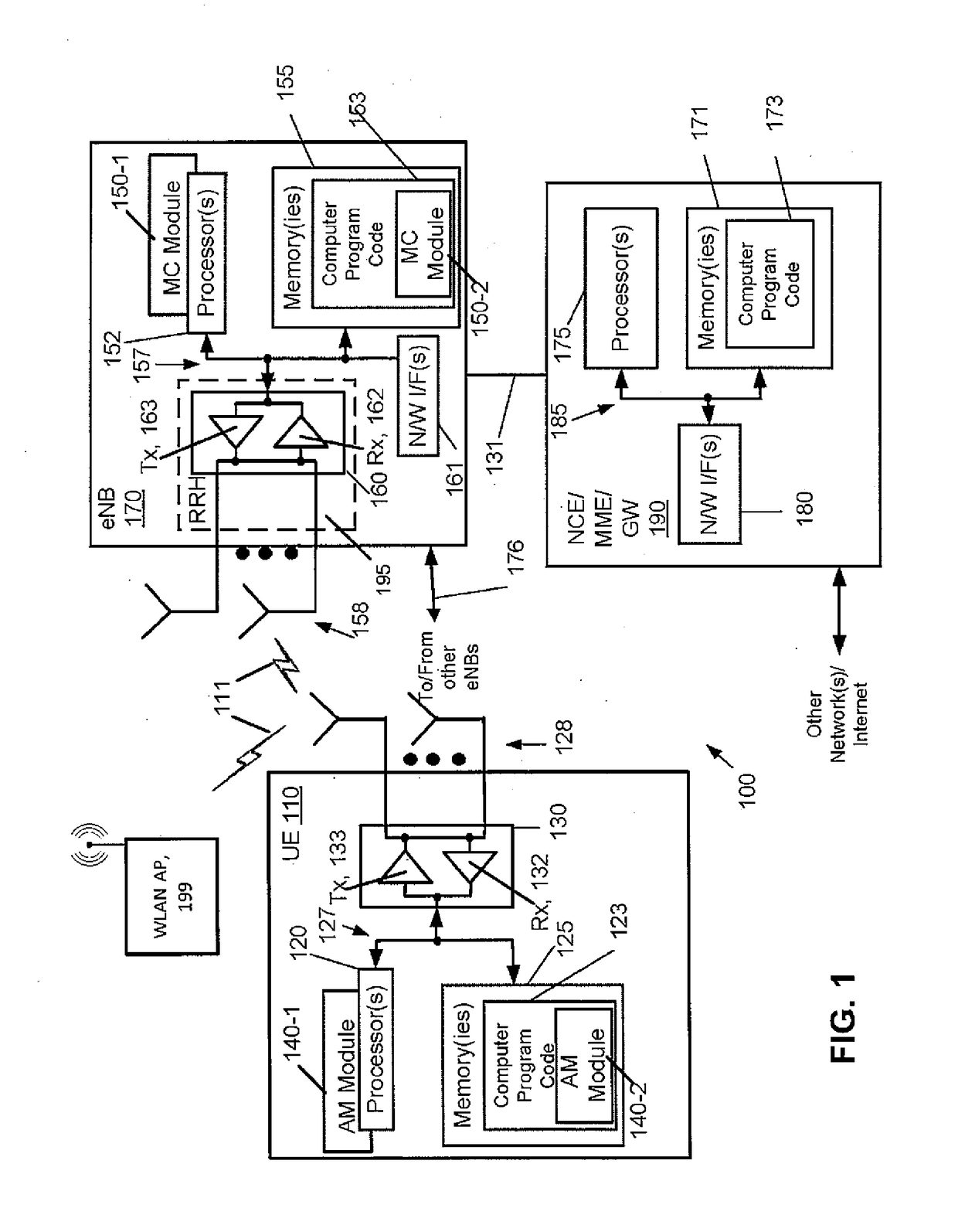

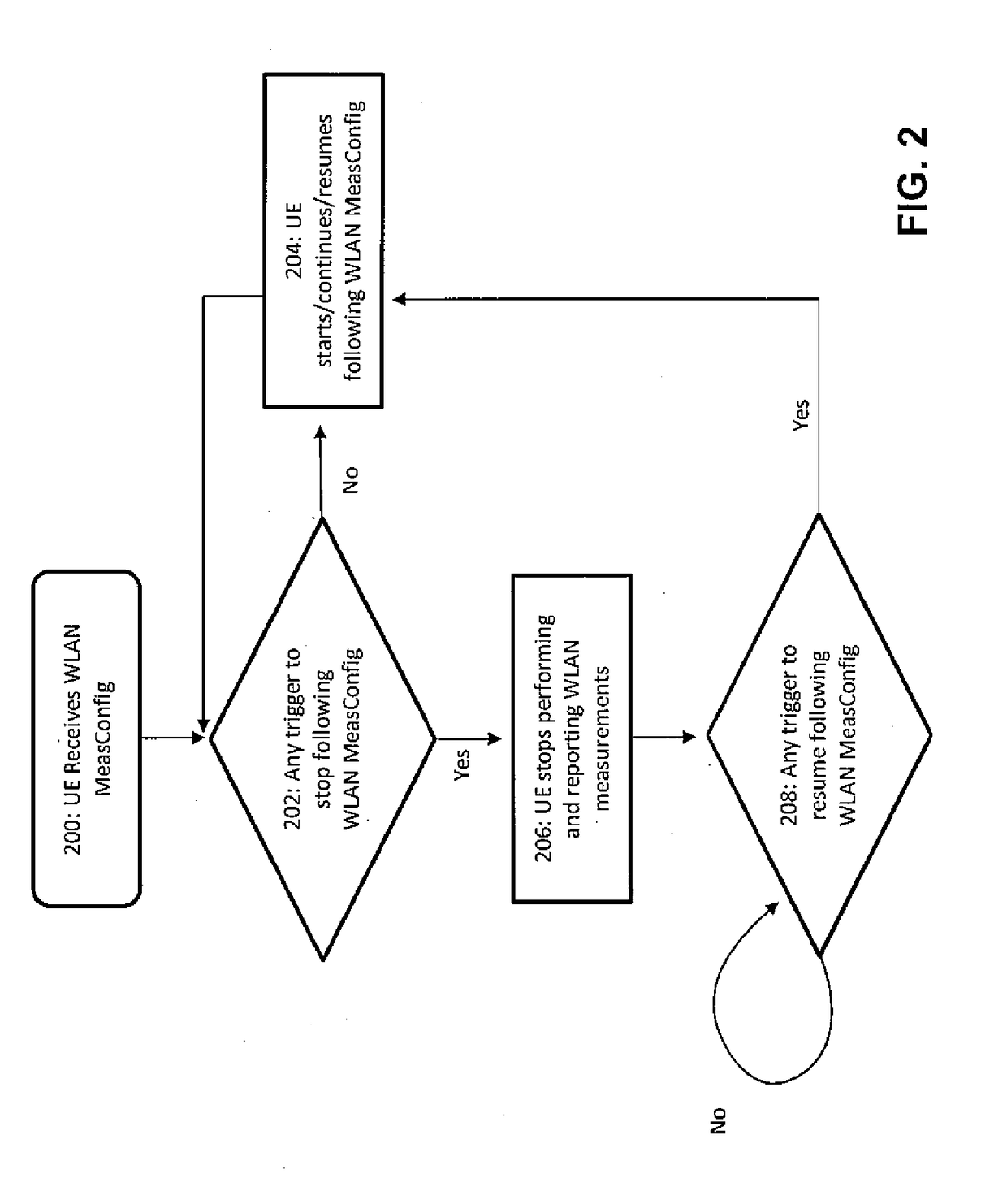

Method of UE Autonomous Measurement Related Actions Upon Implicit Triggers

Embodiment of the invention include a process of receiving an indication from a first wireless network to configure a user equipment to enter a first operating mode, wherein the first operating mode comprises performing measurements according to a first time pattern for at least one second wireless network signal to detect at least one second wireless network; determining whether the user equipment is stationary; and identifying, at the user equipment, a first condition from at least the measurements performed according to the first time pattern which triggers the user equipment to autonomously enter a second operating mode while the user equipment is determined to be stationary.

Owner:NOKIA TECHNOLOGLES OY

Method and an apparatus for distance measurement

InactiveUS20050248749A1Cancel noiseClosely placedBeacon systemsDevices using optical meansAnalog signalElectromagnetic radiation

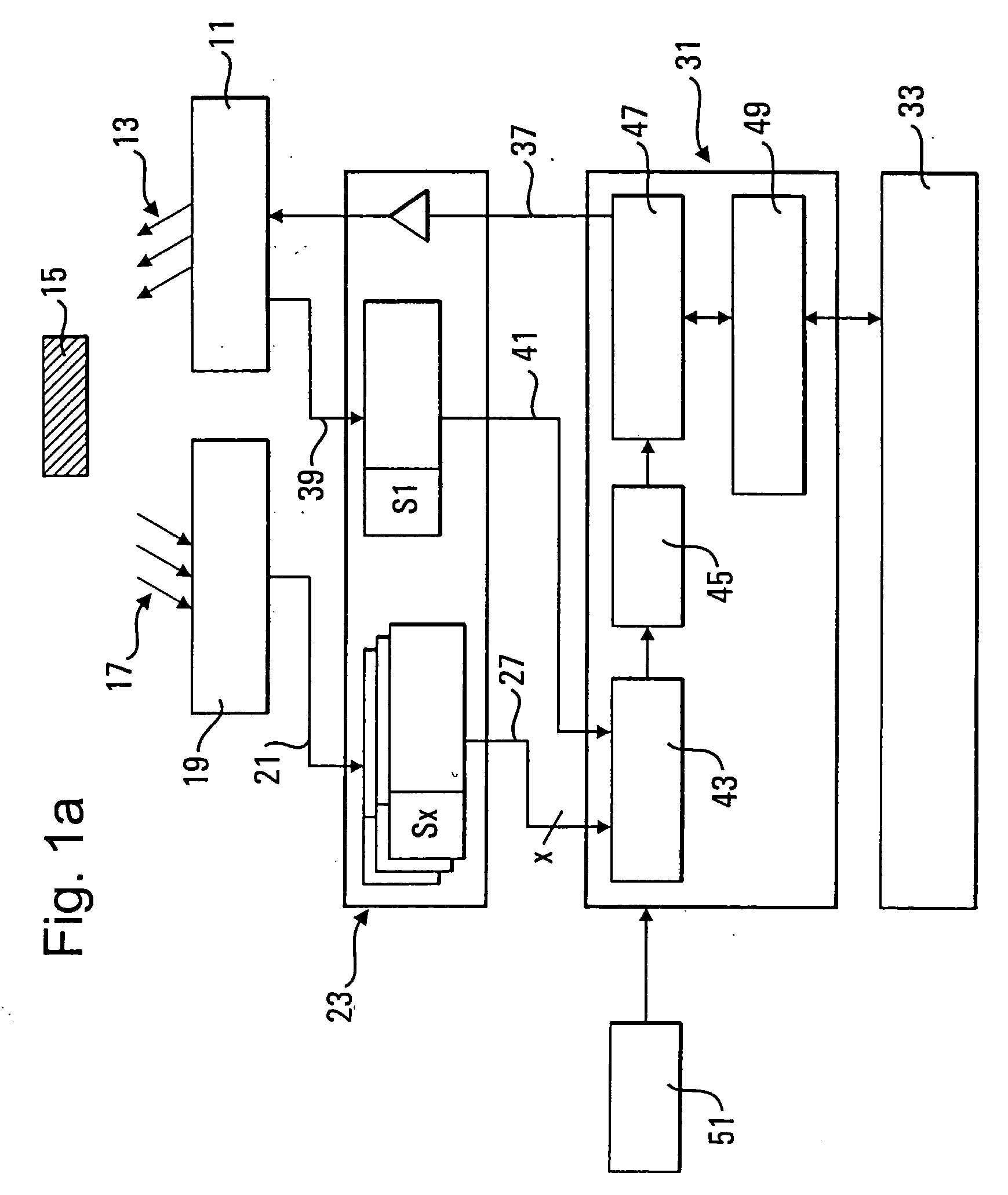

The invention relates to a method for distance measurement by determining the pulse transit time, in which pulsed electromagnetic radiation is transmitted using at least one transmitter and signal pulses reflected at objects are detected using at least one receiver, wherein at least one received logic signal containing logic signals is generated from the received analog signal containing the signal pulses, in particular by means of a threshold circuit, and is evaluated with respect to the transit times of the logic signals, and wherein the received logic signal is read into a programmable logic circuit by means of a clocked data reading device and is mapped onto a time pattern in the logic circuit, in that instantaneous values of the received logic signal are stored in logic units of the logic circuit associated with the time windows for time windows of the time pattern corresponding to at least one clock pulse of the data reading device. The invention moreover relates to an apparatus for distance measurement.

Owner:IBEO AUTOMOBILE SENSOR

X-ray Imaging of Baggage and Personnel Using Arrays of Discrete Sources and Multiple Collimated Beams

ActiveUS20070258562A1Material analysis by transmitting radiationNuclear radiation detectionSpatial OrientationsX-ray

A system and methods are provided for imaging an object, based on activating an array of discrete X-ray sources in a prescribed temporal pattern so as to illuminate the object with a beam varying in spatial orientation, and detecting X-rays of the beam after interaction with the object and generating a detector signal. An image of the object may then be constructed on the basis of the time variation of the detector signal. The discrete X-ray sources may be moved during the course of inspection, moreover, the prescribed temporal pattern may constitute a Hadamard code. The discrete sources may be carbon nanotube x-ray sources.

Owner:AMERICAN SCI & ENG INC

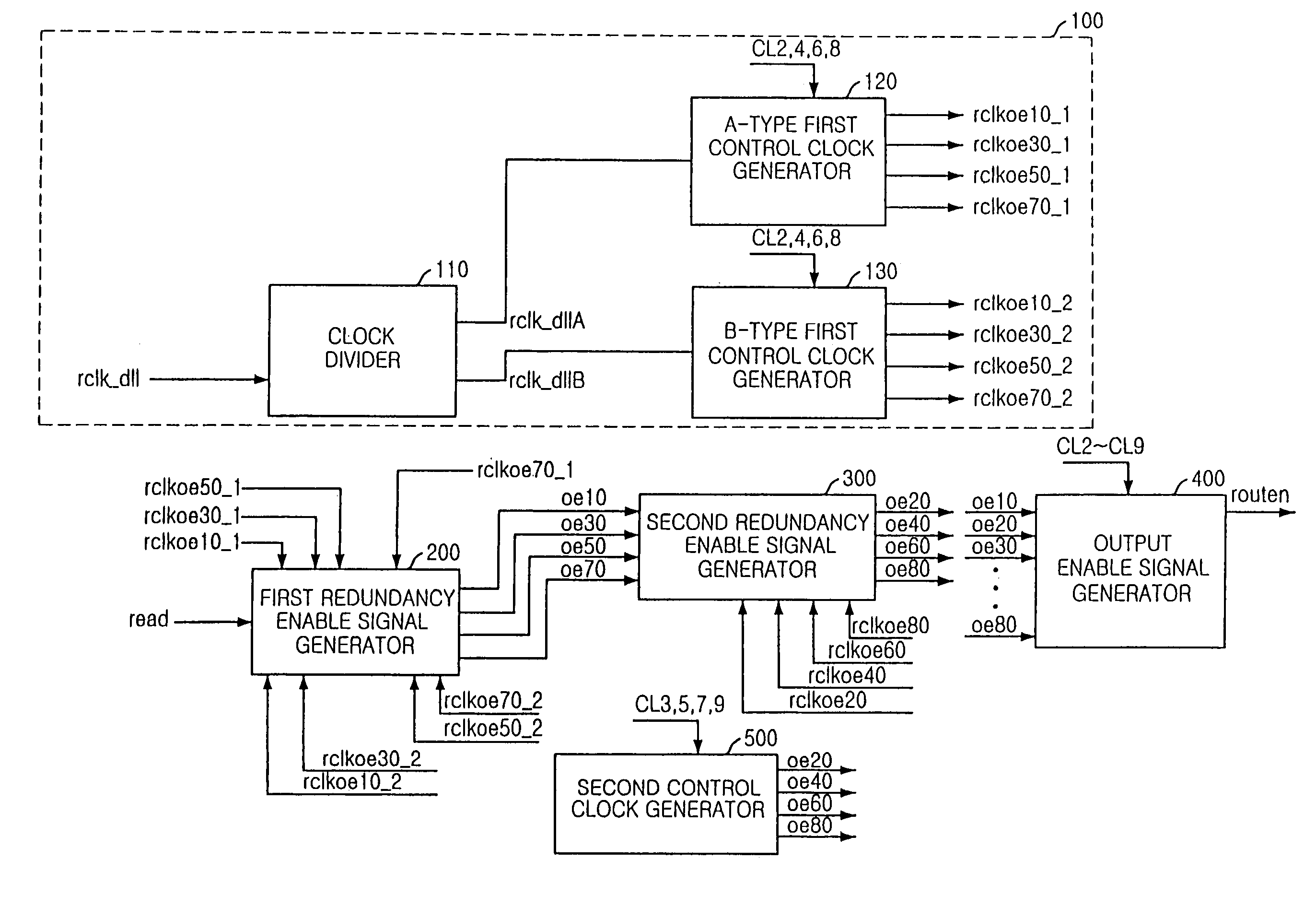

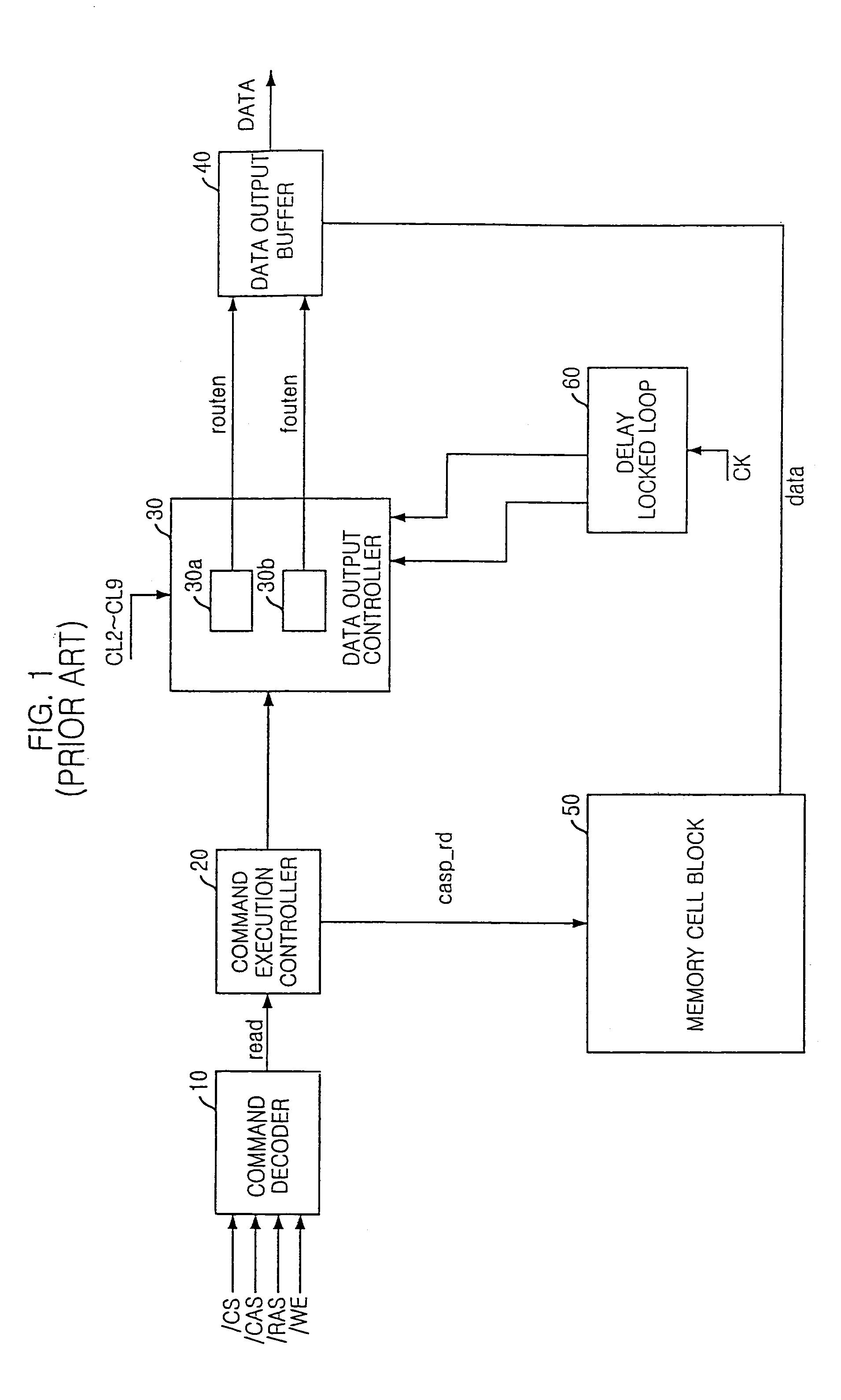

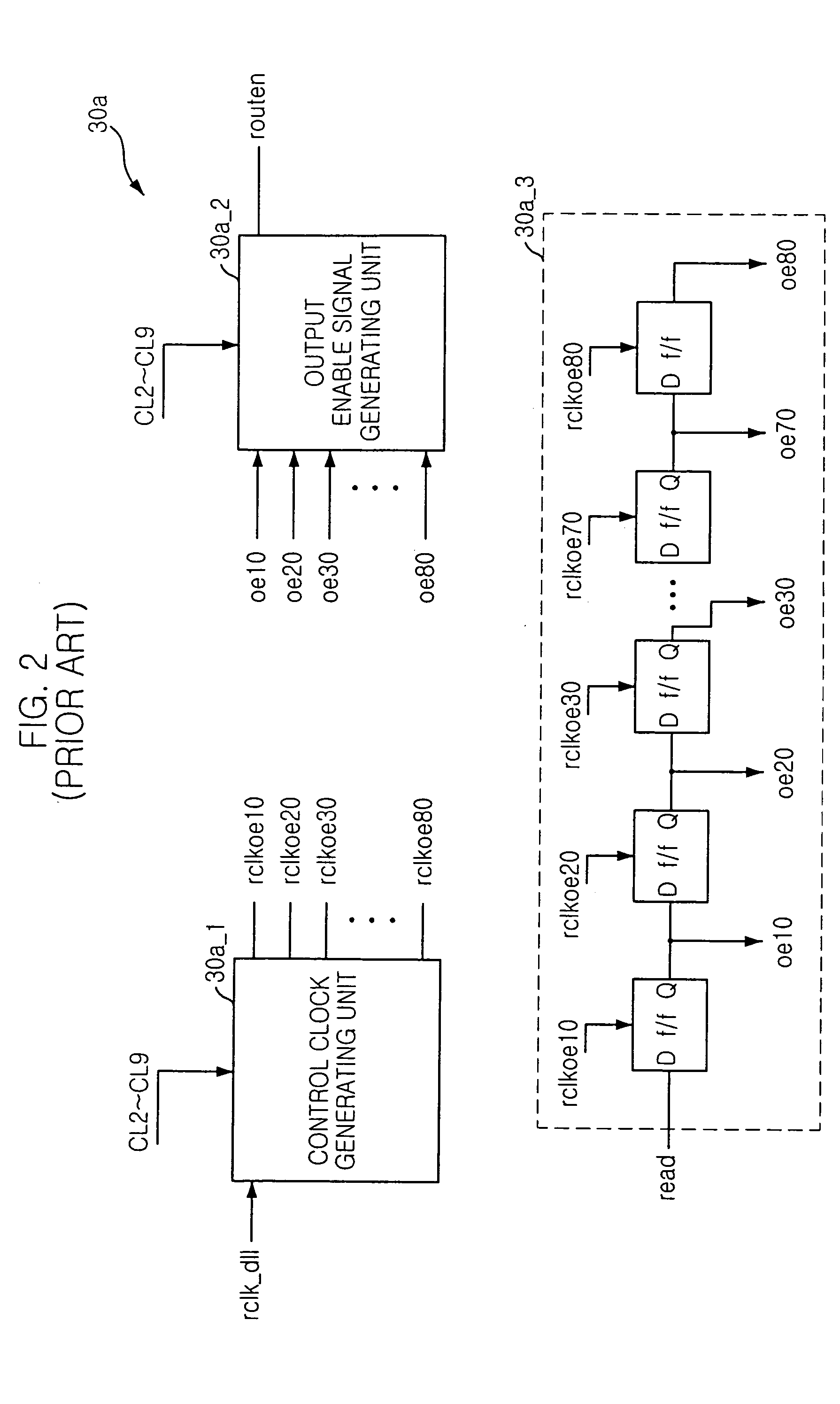

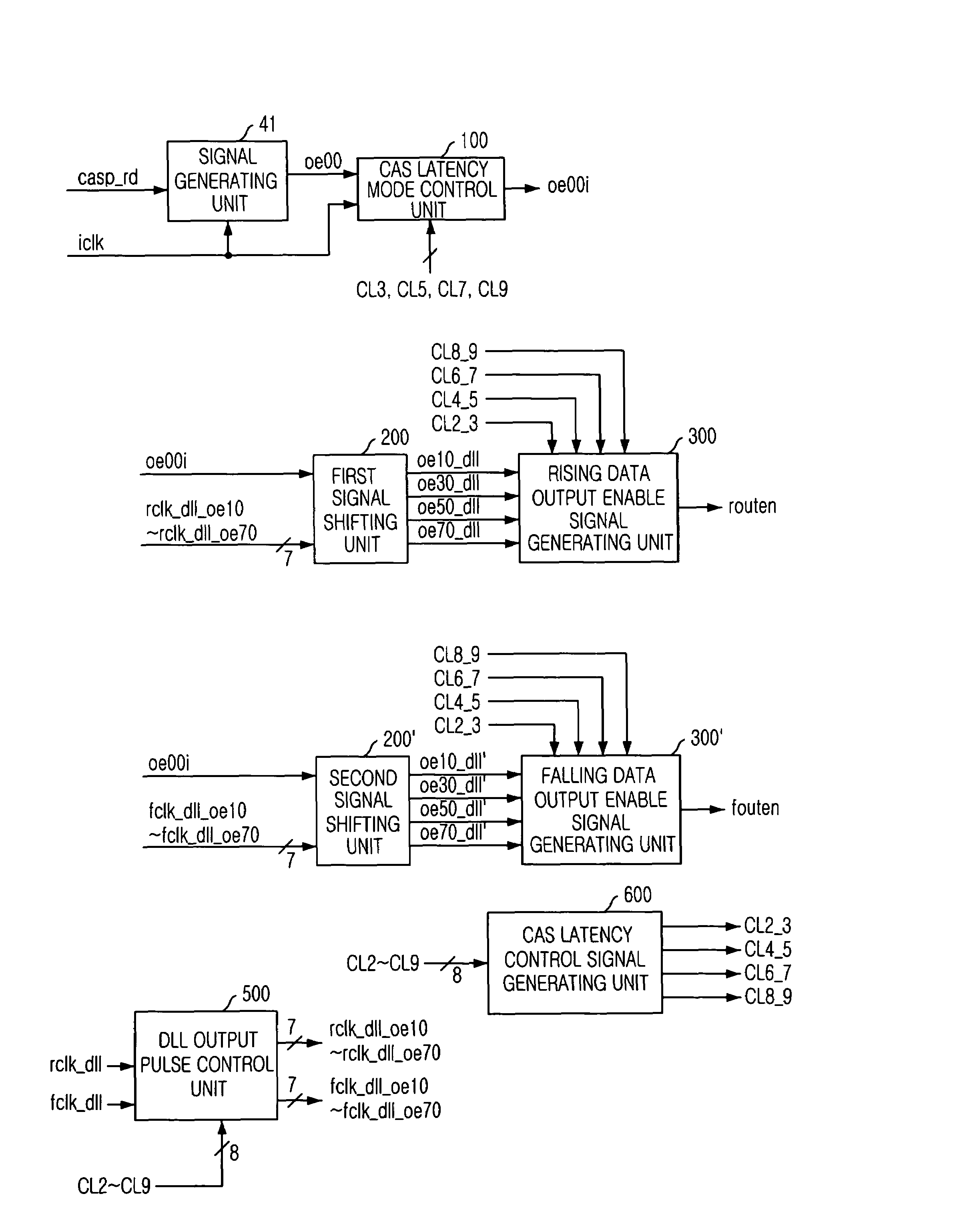

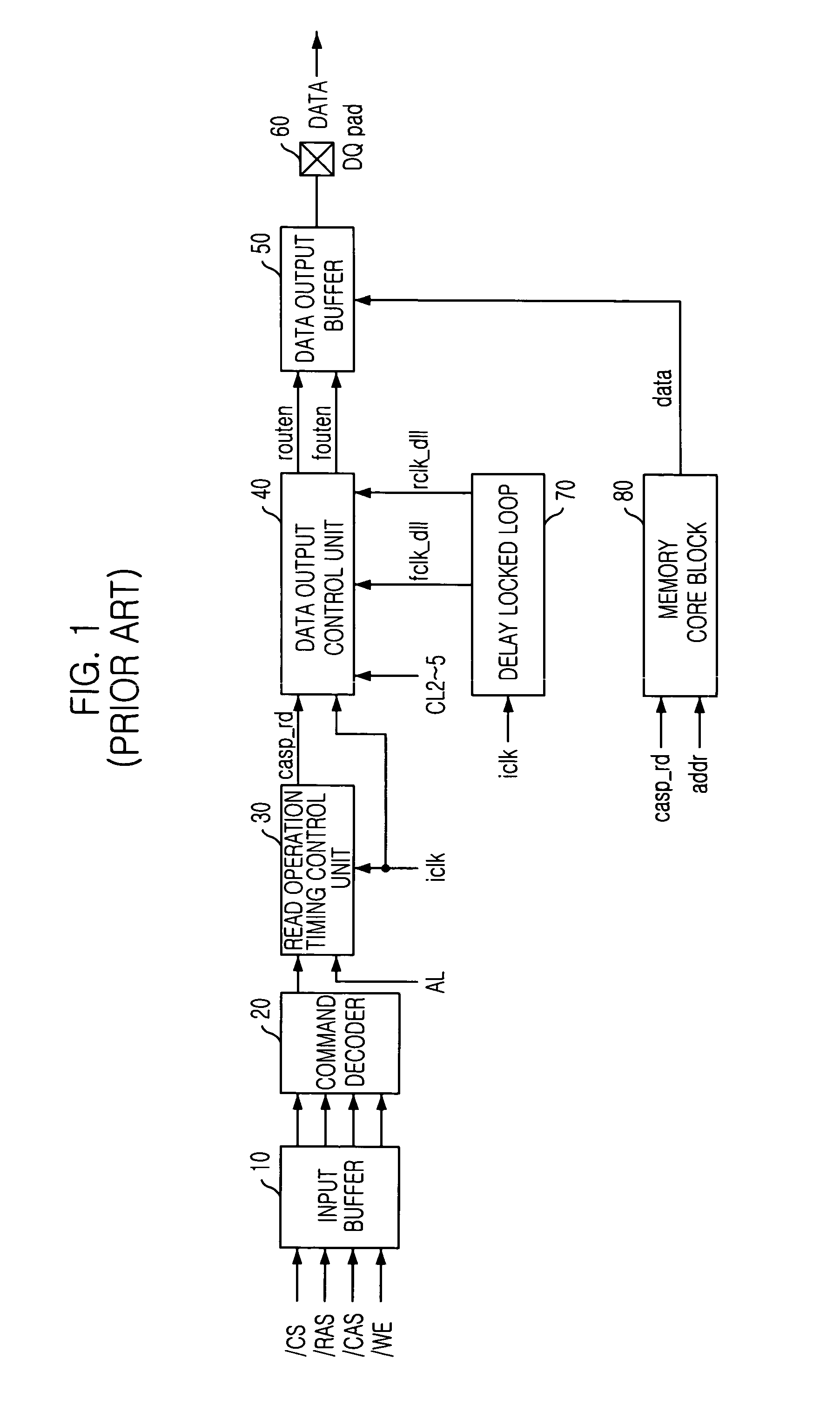

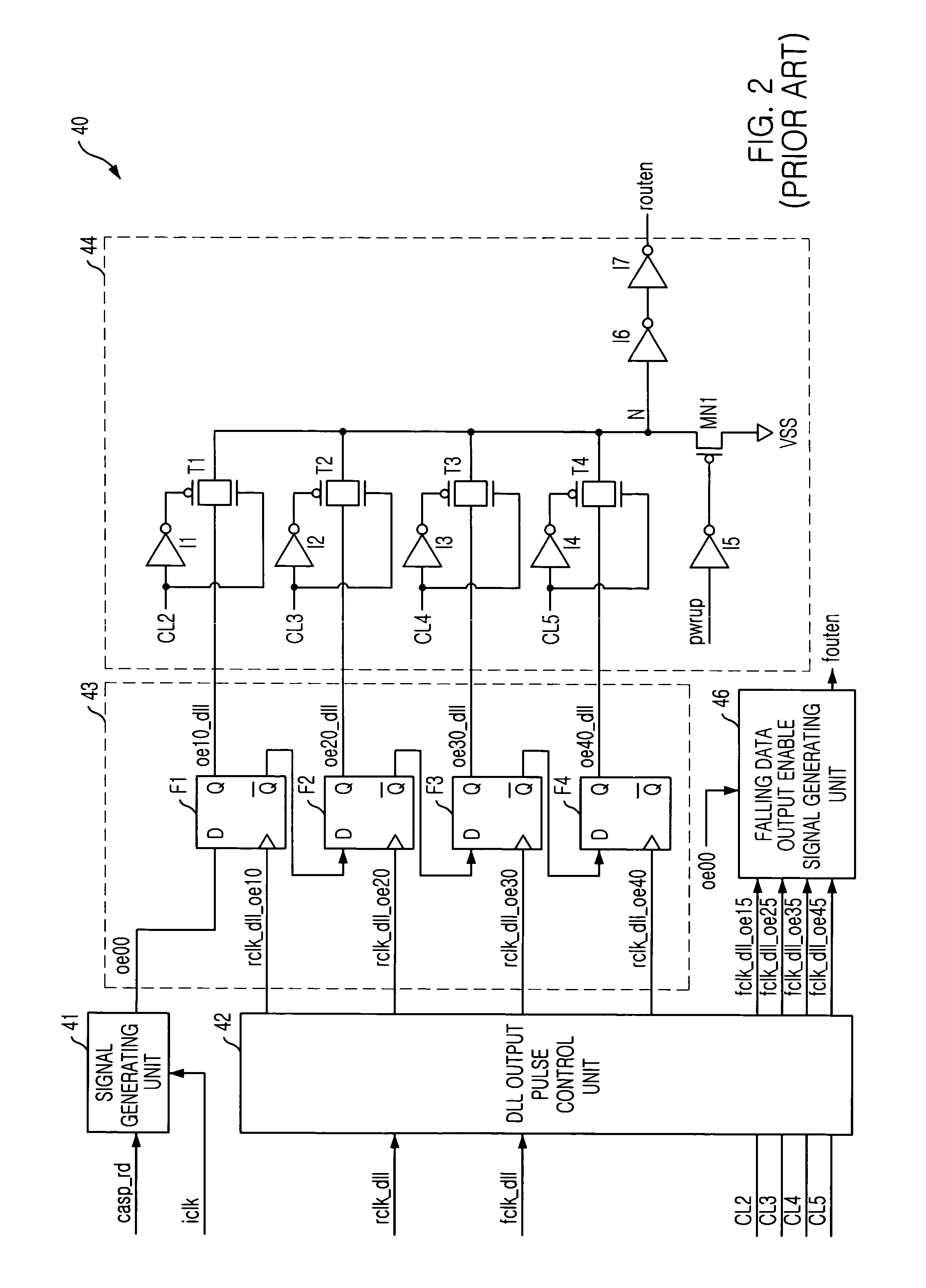

Memory device with improved output operation margin

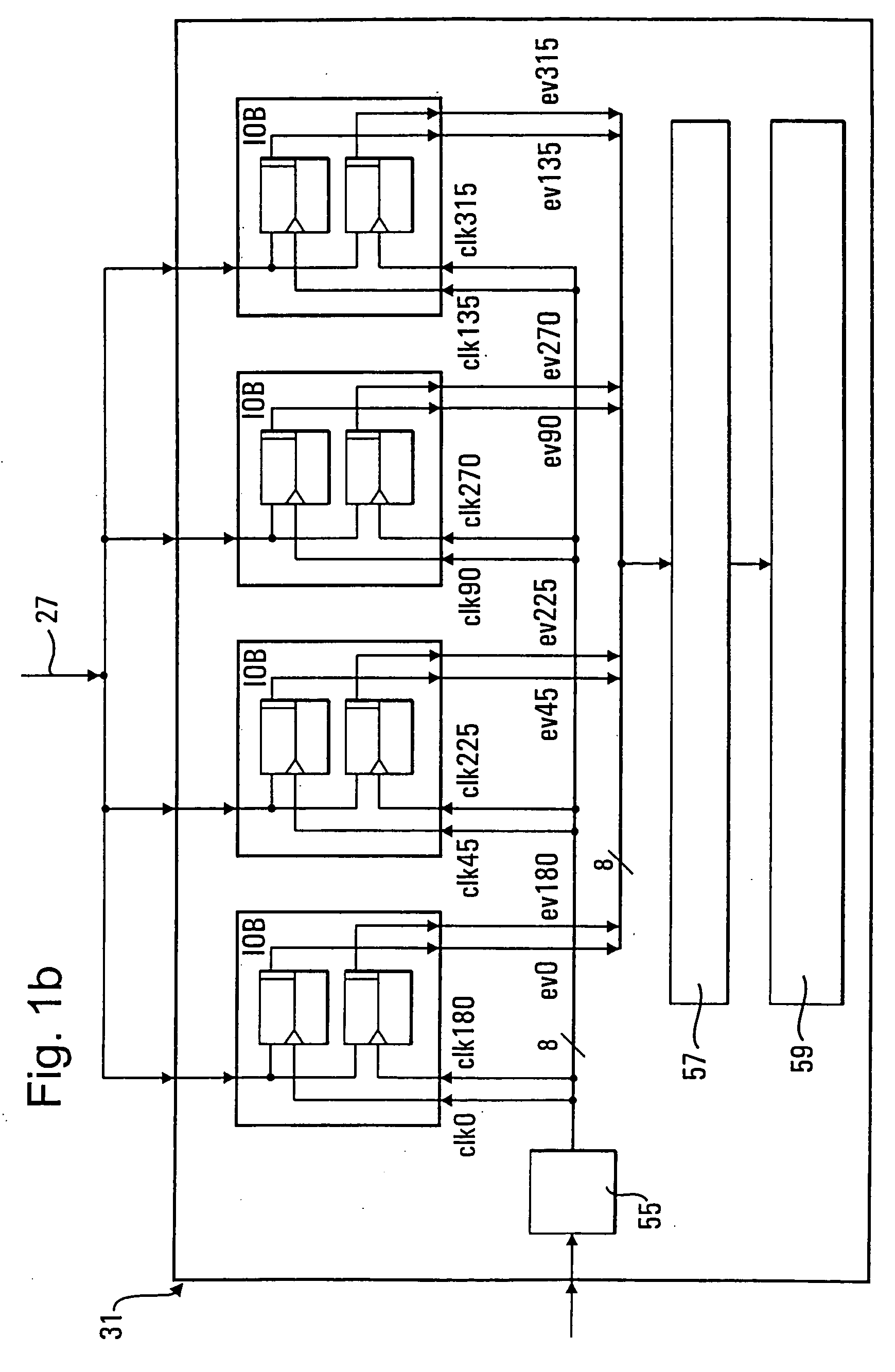

InactiveUS6987705B2Wide-ranging CAS latency modeGuaranteed uptimeDigital storageSignal generatorClock generator

A synchronous memory device which generates a data output enable signal corresponding to a set CAS latency mode including: a control clock generator for generating an A-type first control clock and a B-type first control clock; a first redundancy enable signal generator for shifting an internal read signal by a predetermined interval in synchronization with one of the A-type first control clock and the B-type first control clock and generating a plurality of first redundancy enable signals; a second redundancy enable signal generator for synchronizing the plurality of first redundancy enable signals with a DLL clock and generating a plurality of second redundancy enable signals; and an output enable signal generator for selecting one redundancy enable signal corresponding to the set CAS latency mode among the first redundancy enable signals and the second redundancy enable signals and generating the selected redundancy enable signal as the data output enable signal.

Owner:SK HYNIX INC

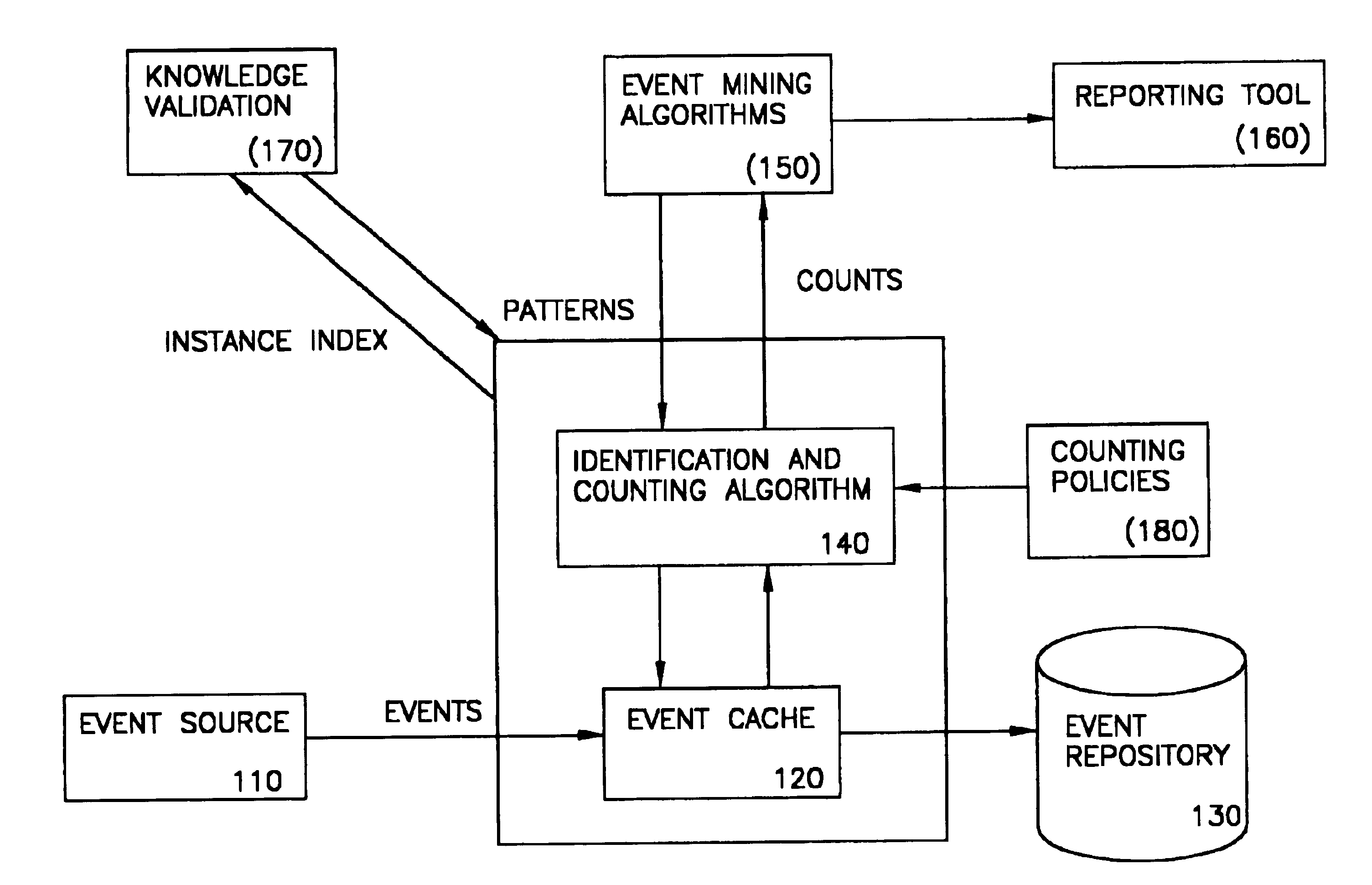

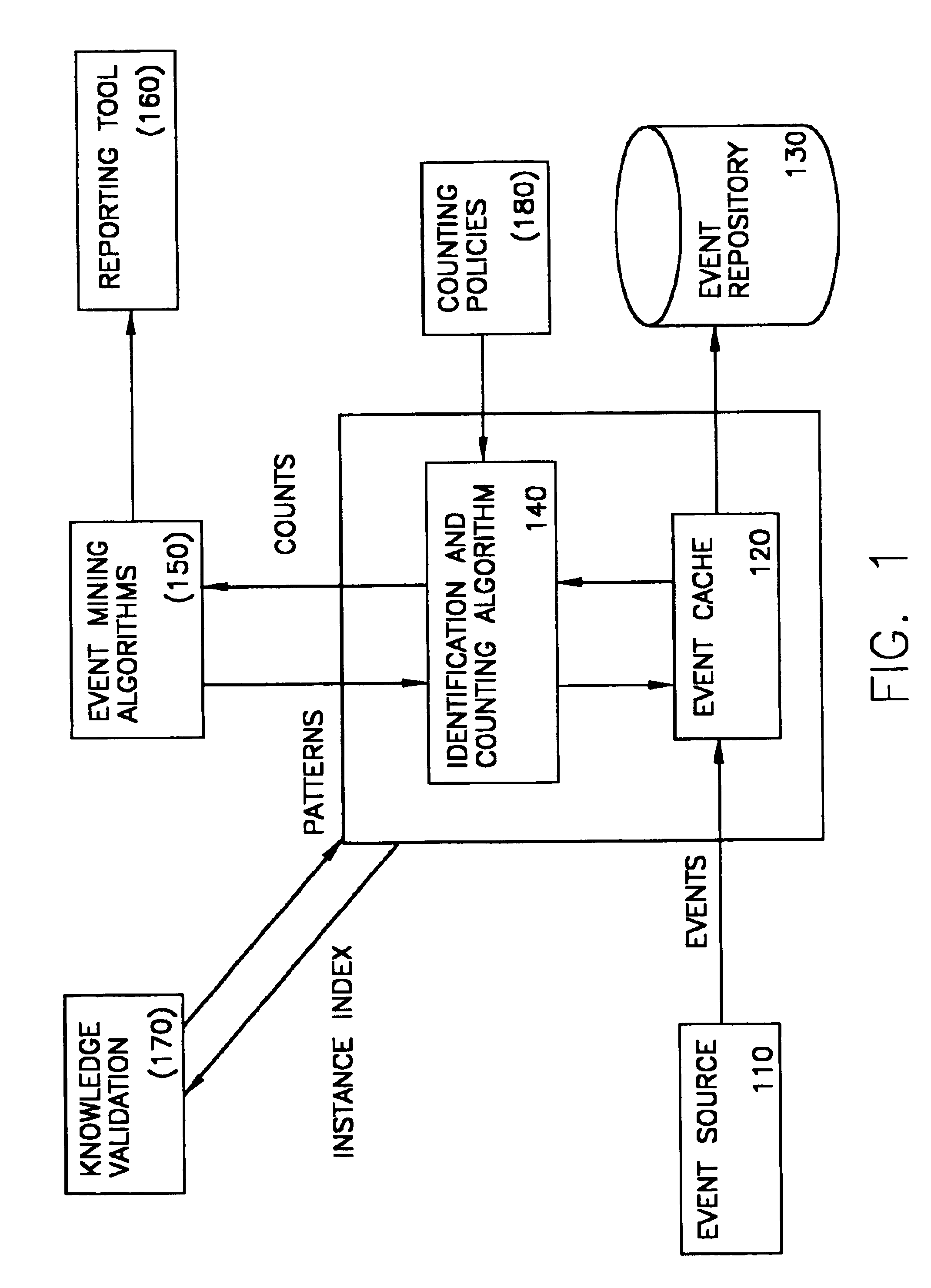

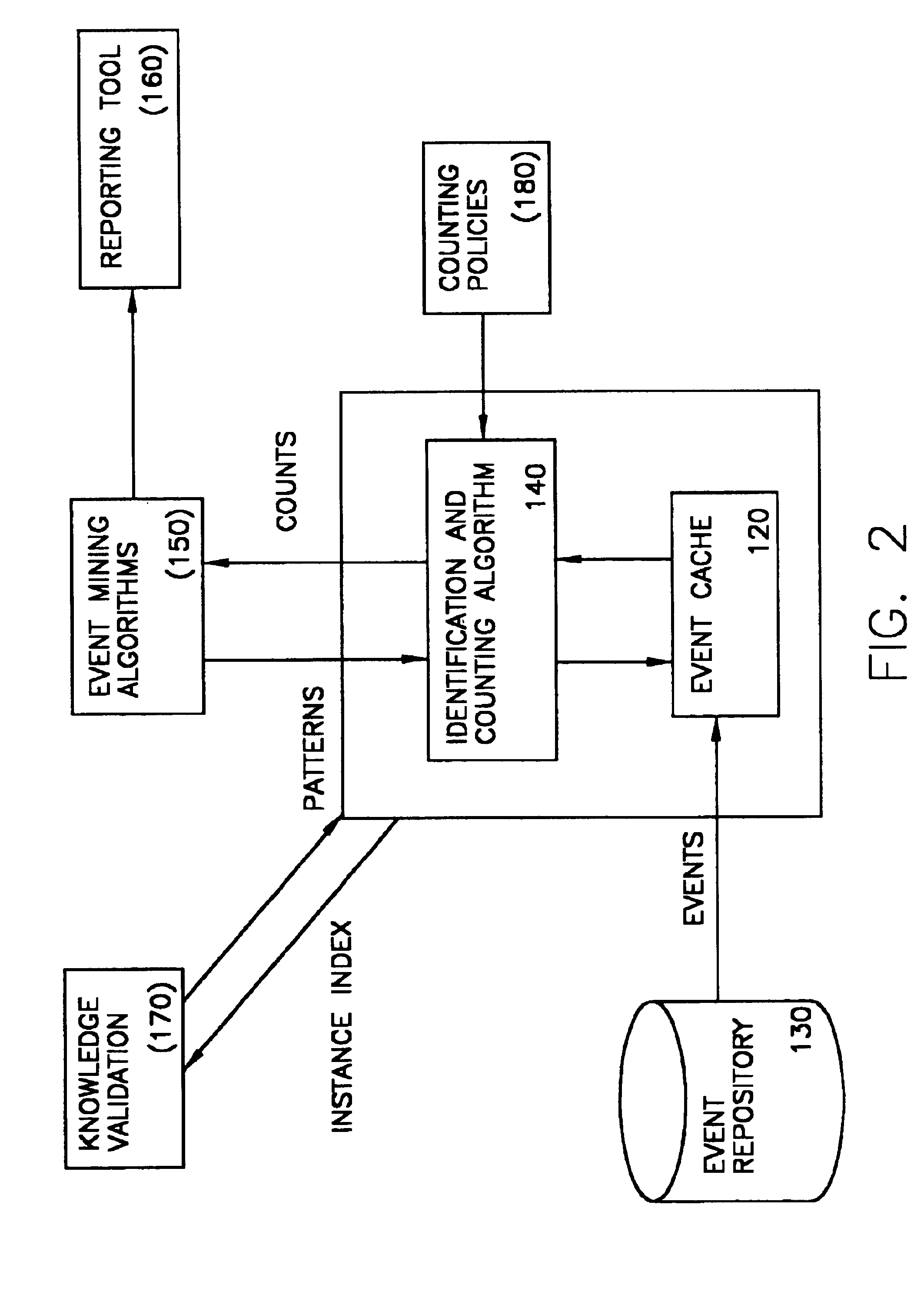

Systems and methods for identifying and counting instances of temporal patterns

InactiveUS6907426B2Accurate countImprove efficiencyData processing applicationsDigital data processing detailsComputer scienceIncremental computing

Systems and methods for instance counting and for the identification of a temporal pattern in an event sequence. The system addresses the use of “earliest-first” and “no-reuse” policies as criteria for the correctness of counting. The system also achieves higher performance than conventional methods by utilizing incremental computation.

Owner:TREND MICRO INC

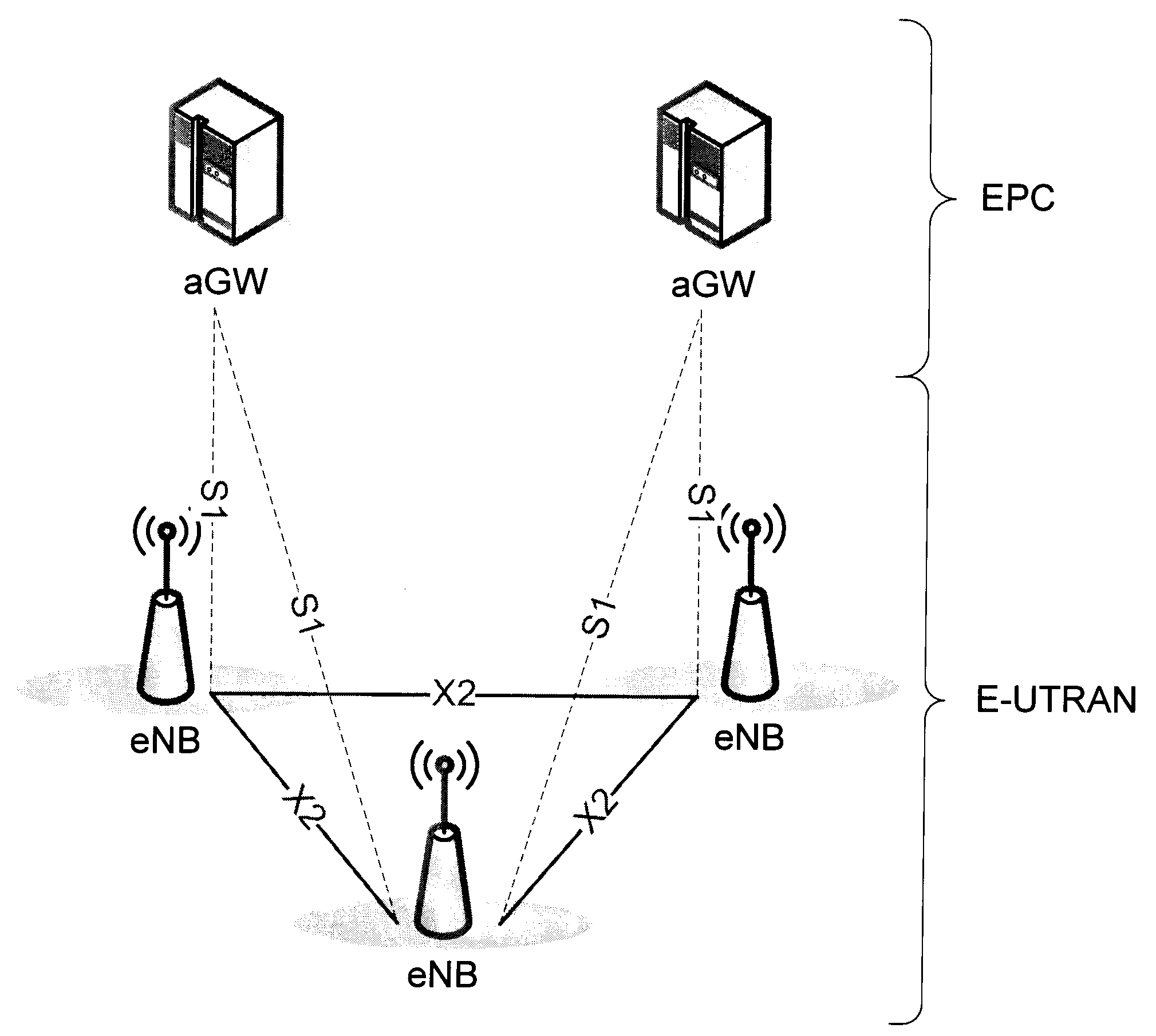

Forwarding learnt state information to target node at mobility

ActiveUS20090268689A1Resource optimizationPreserving UE batteryConnection managementWireless commuication servicesUser equipmentHandover

A method for handover in a telecommunication system is disclosed. The method determines a traffic time pattern in a handover situation where a user equipment is handed over from a source cell to a target cell in the telecommunication system. History information relating to a traffic time pattern used in the source cell by the user equipment being handed over is forwarded from a controller node of said source cell to a controller node of said target cell. In the target cell, a traffic time pattern to be used by said user equipment in said target cell after the handover is estimated by taking into consideration at least said history information.

Owner:HONOR DEVICE CO LTD

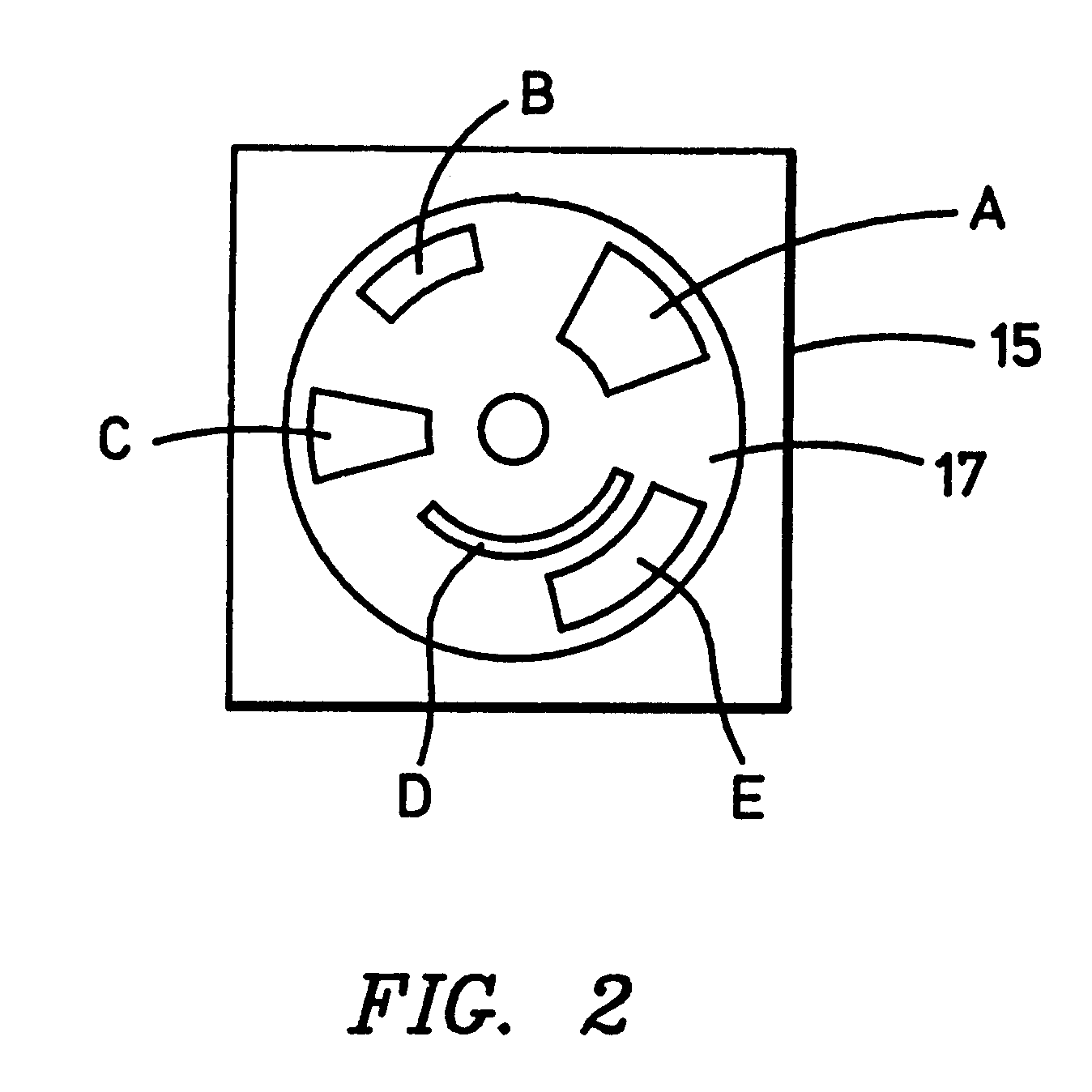

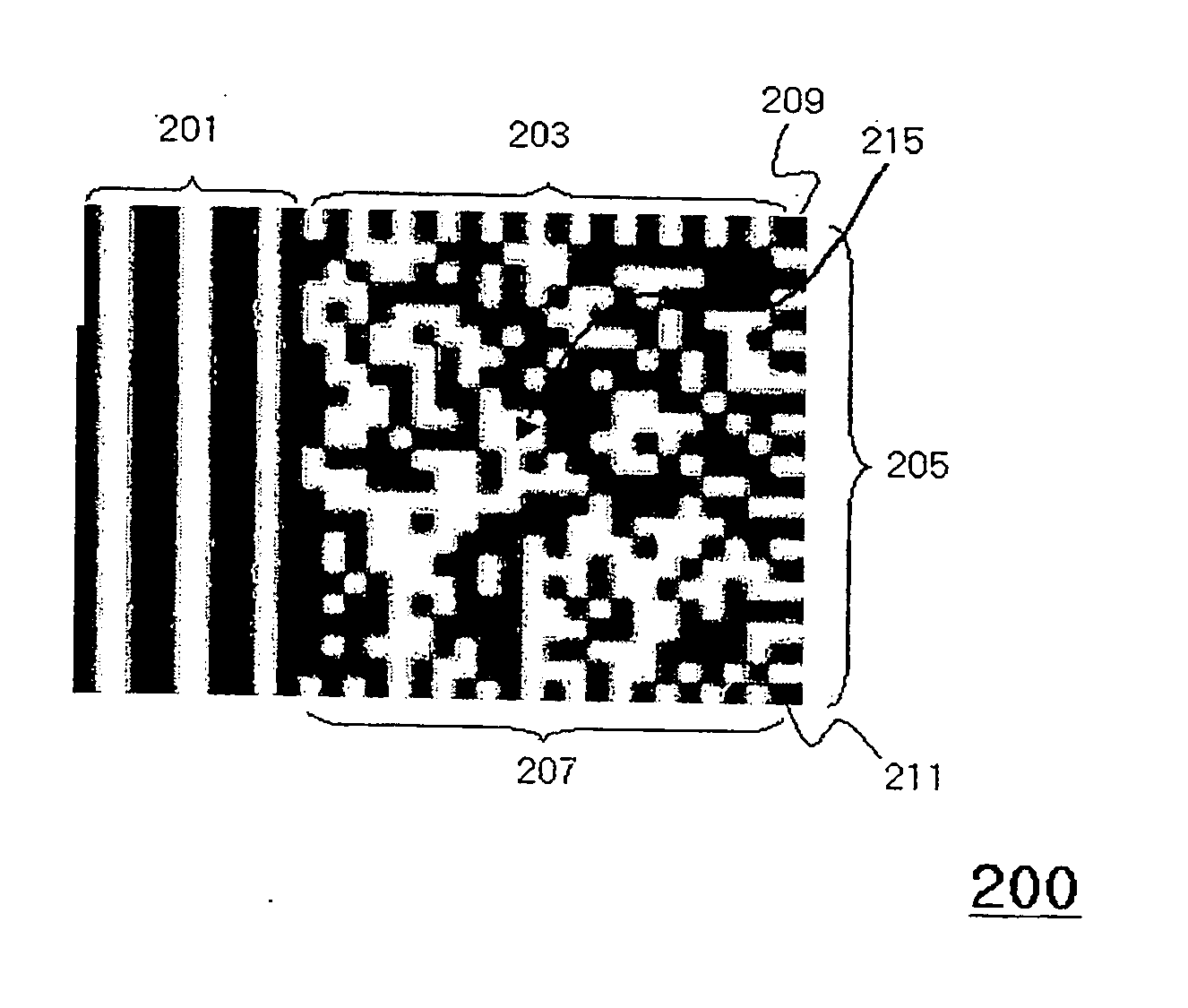

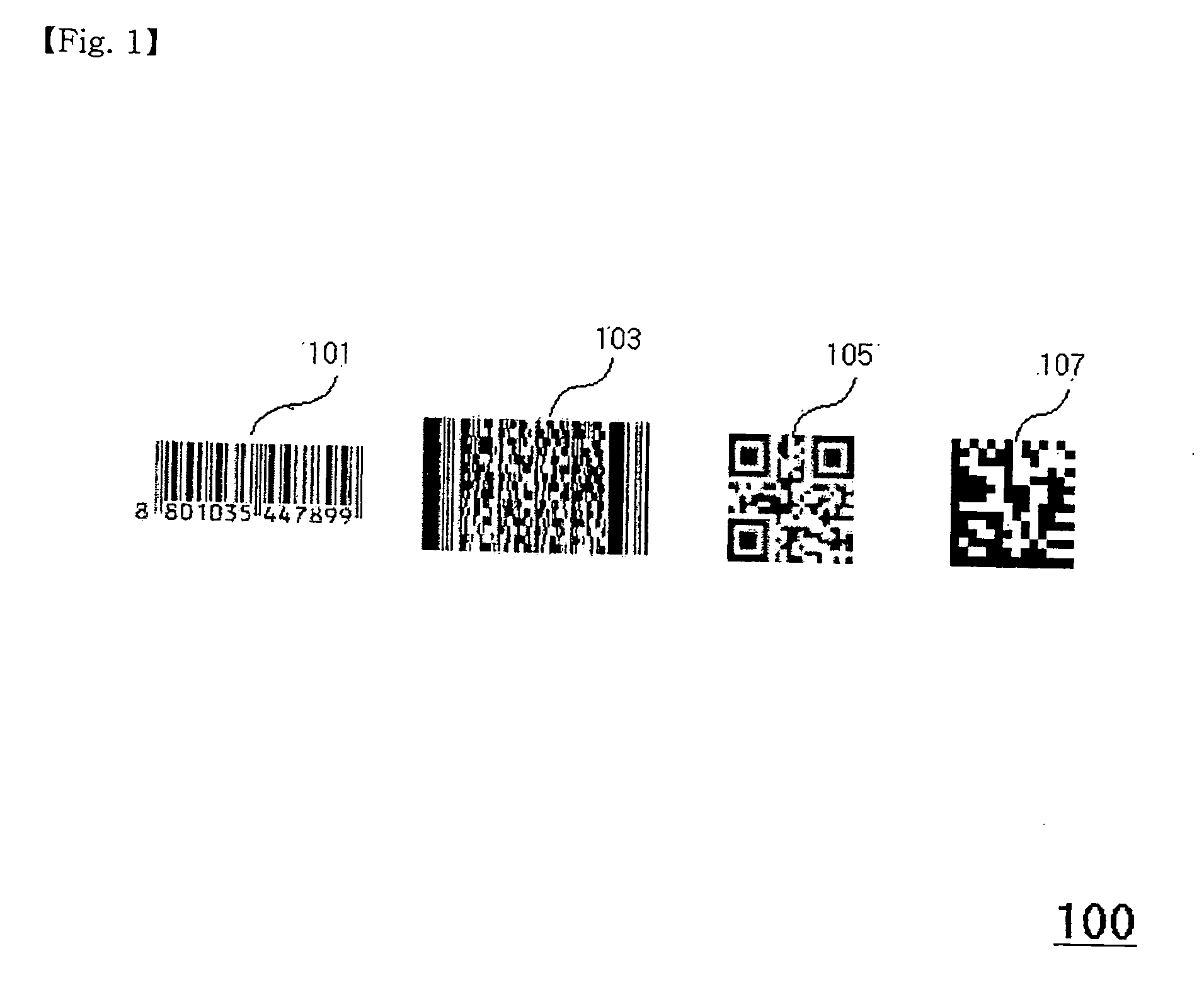

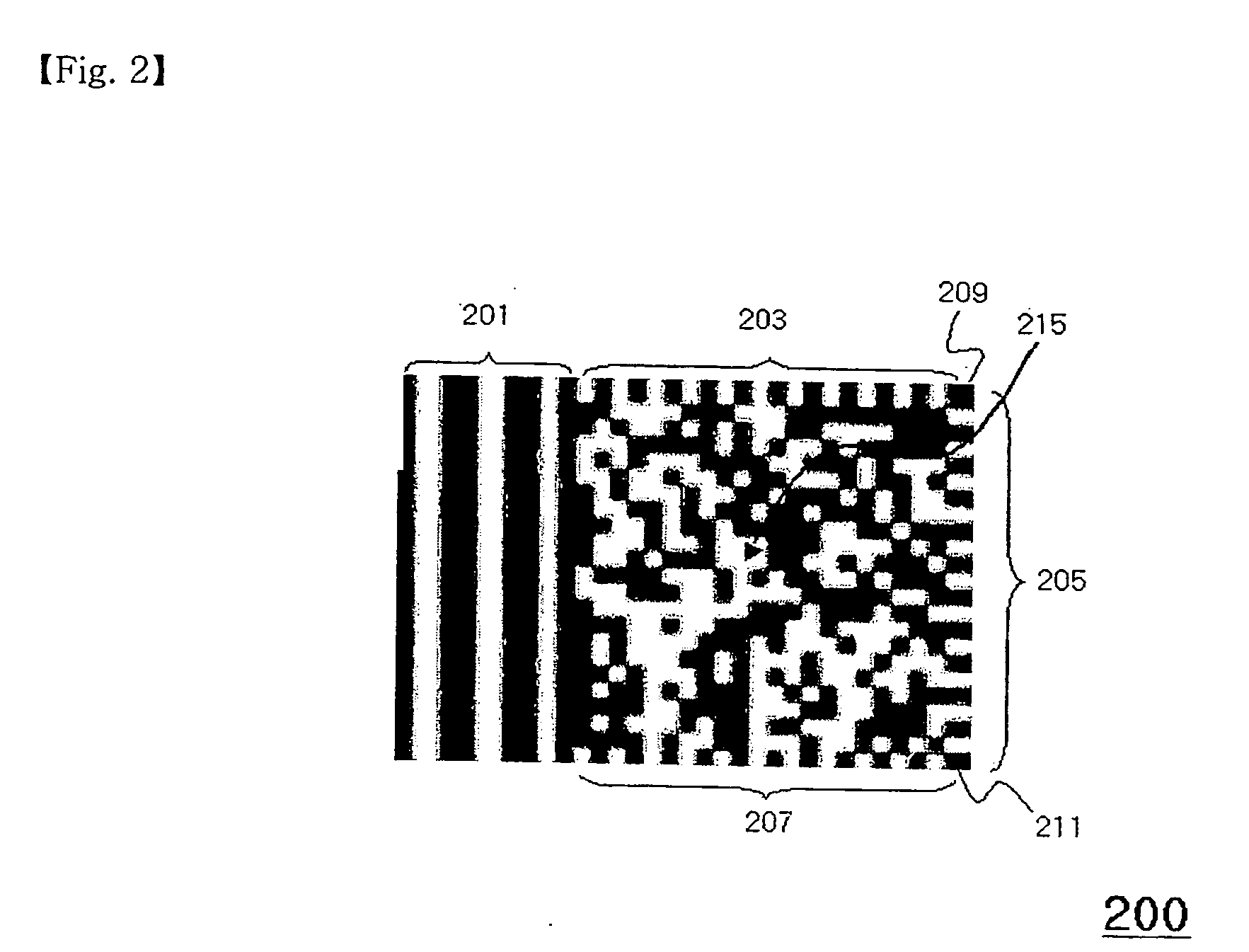

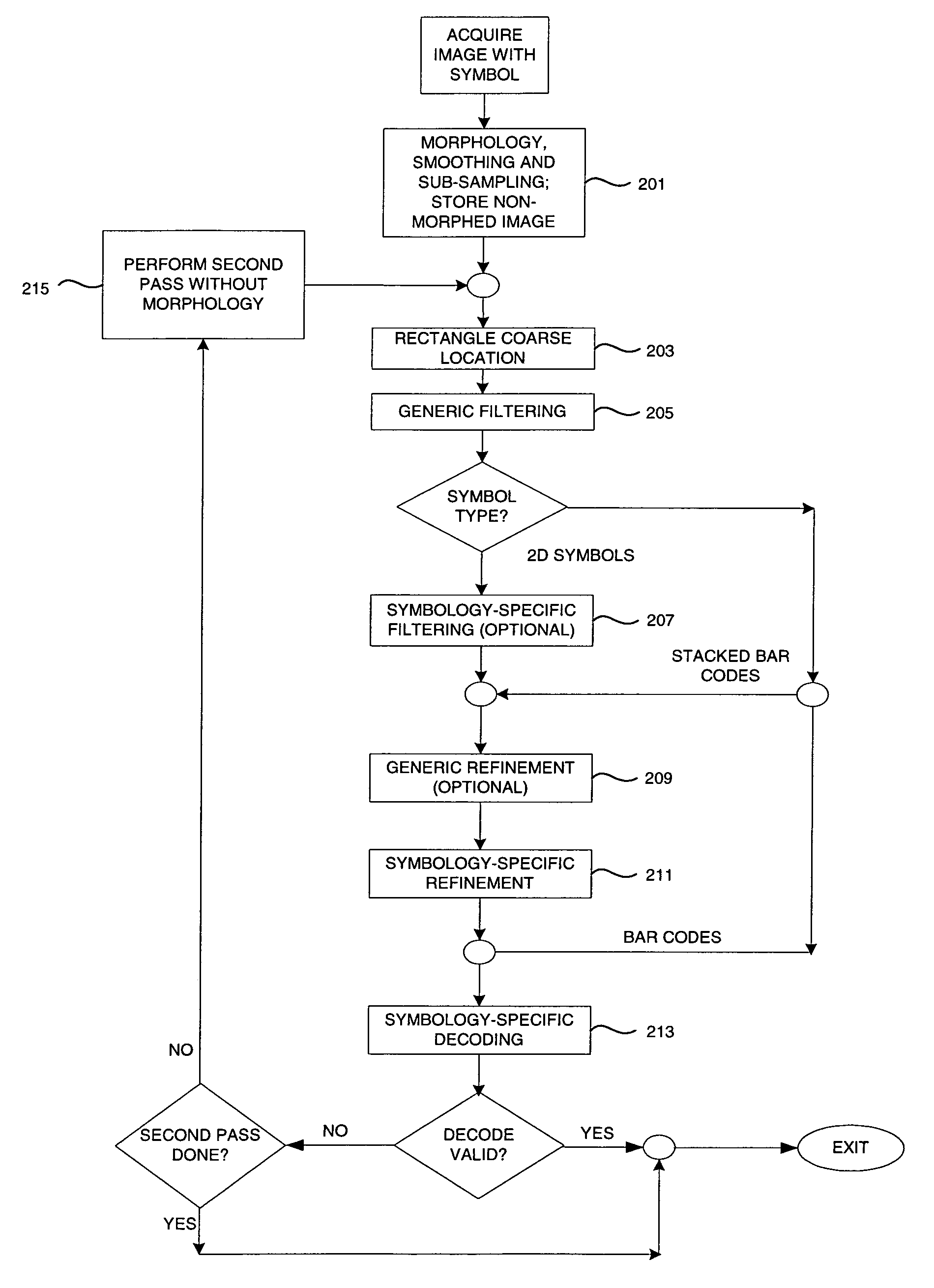

Two-dimensional code having superior decoding property which is possible to control the level of error correcting codes, and method for encoding and decoding the same

InactiveUS20060163357A1Improve decoding performanceReduce overheadCharacter and pattern recognitionRecord carriers used with machinesComputer hardwareError correcting

Two-dimensional Code having superior decoding property which is possible to control the level of error correcting codes, and method for encoding and decoding the two-dimensional Code is provided. The two-dimensional code includes finding pattern area comprised finding patterns for discriminating the code area from whole image, timing pattern area comprised timing patterns for checking a position of data area from the whole code and positions of each cells of the data area, and data area inputted various kinds of data and decoding information of data itself.

Owner:ICONLAB

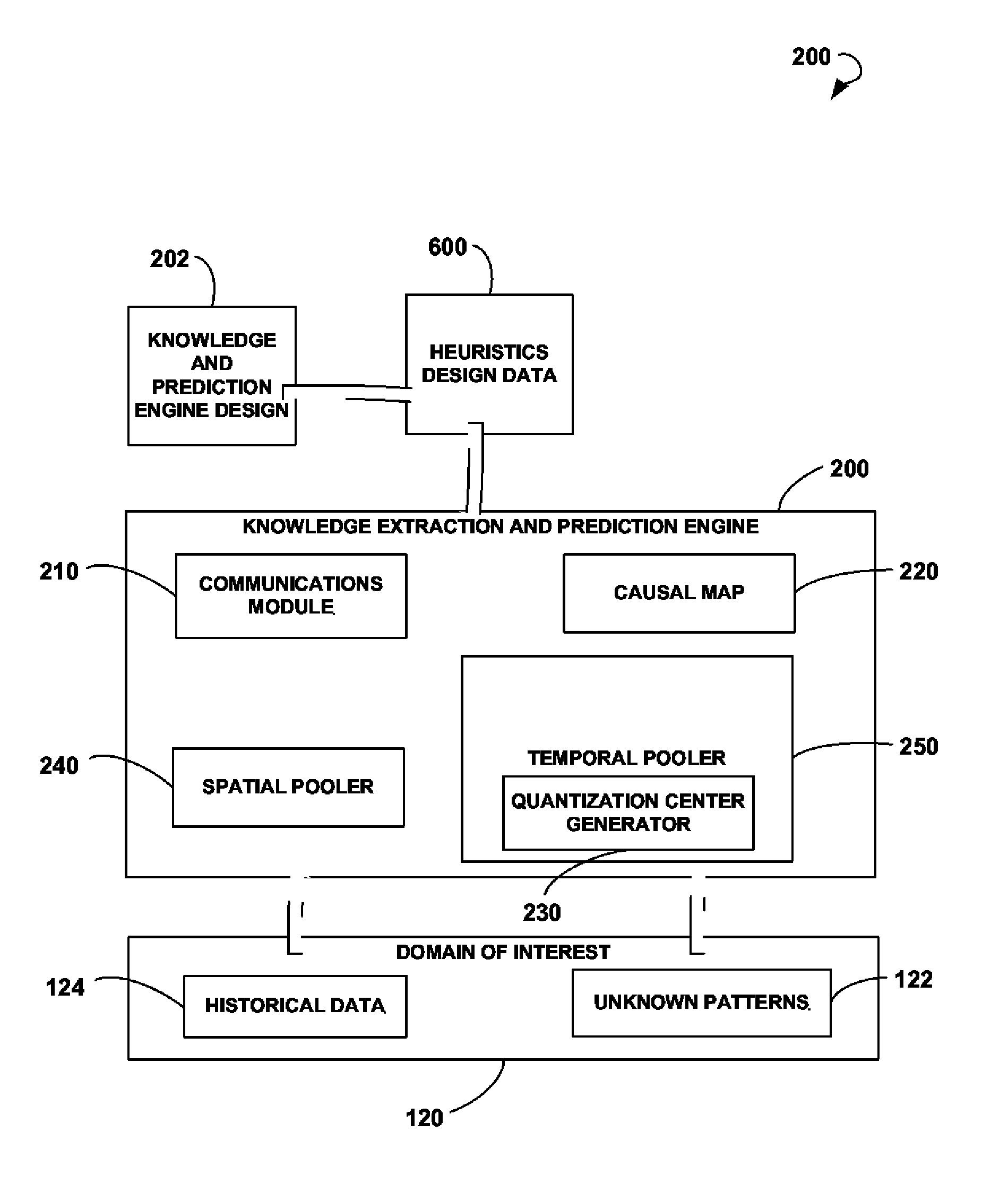

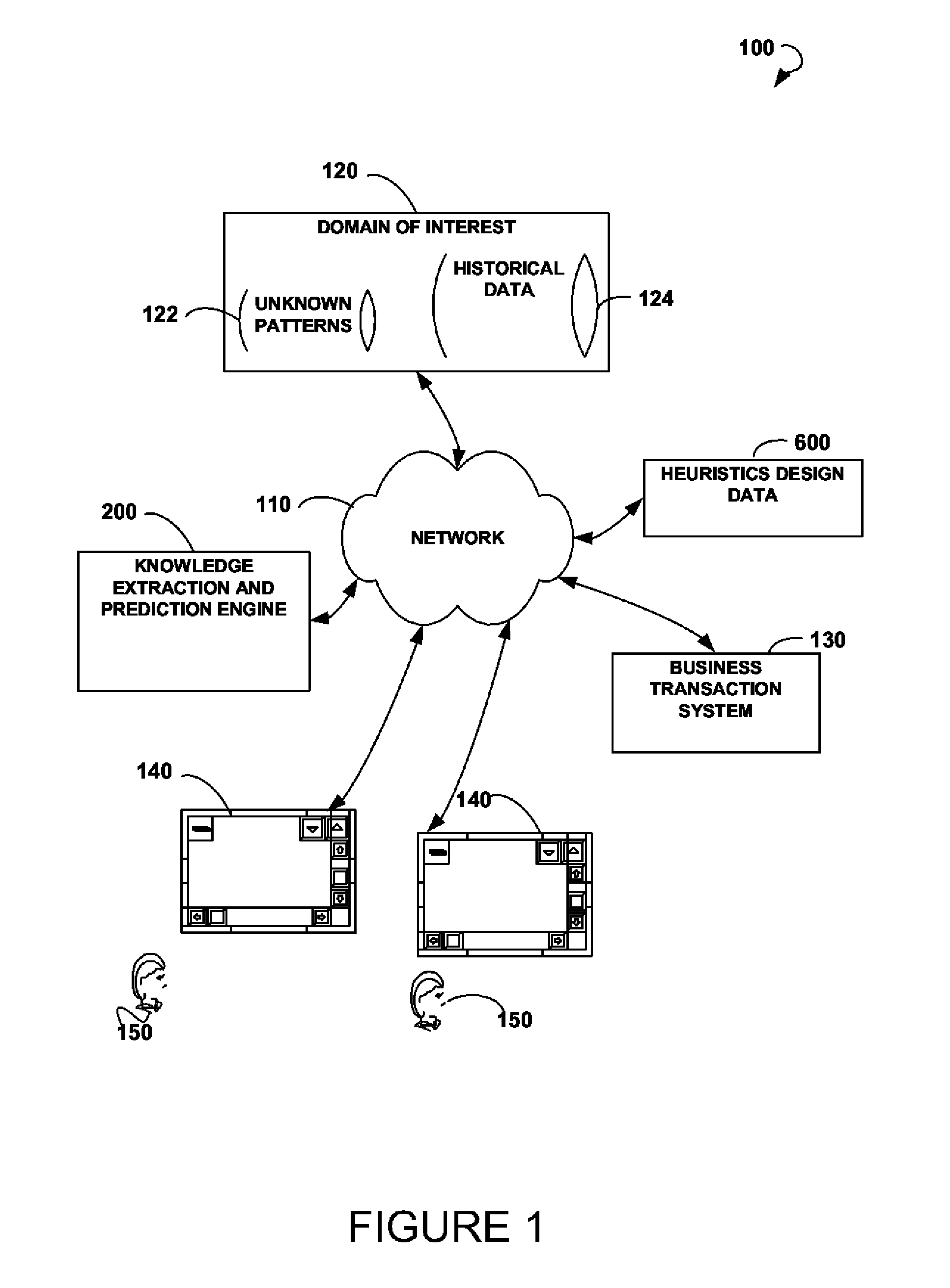

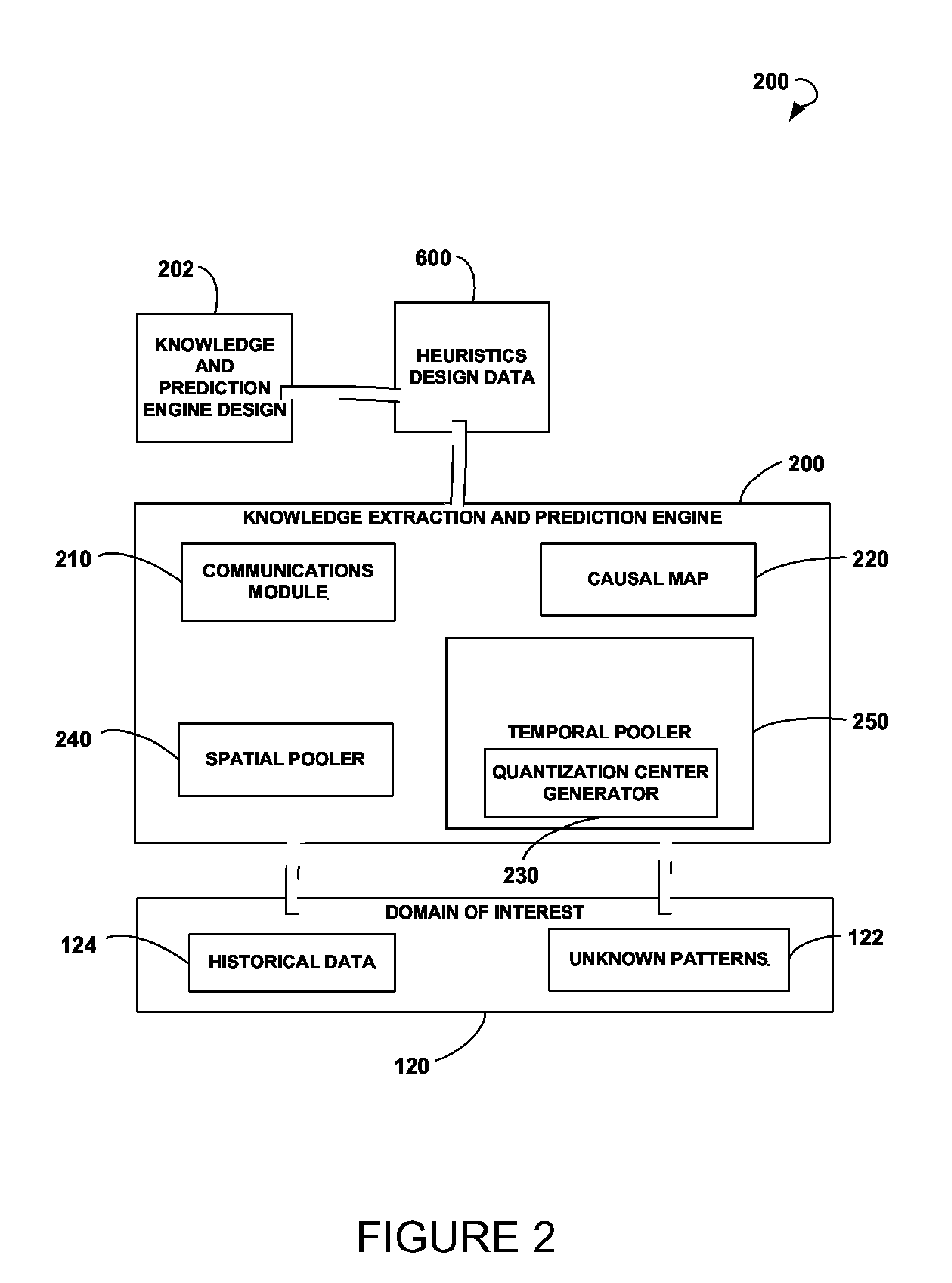

Knowledge extraction and prediction

Methods and systems for knowledge extraction and prediction are described. In an example, a computerized method, and system for performing the method, can include receiving historical data pertaining to a domain of interest, receiving predetermined heuristics design data associated with the domain of interest, and using the predetermined heuristics design and historical data, automatically creating causal maps including a hierarchy of nodes, each node of the hierarchy of nodes being associated with a plurality of quantization points and reference temporal patterns, the plurality quantization points being known reference spatial patterns. In an example the computerized method, and system for performing the method, can further include receiving, at each node, a plurality of unknown patterns pertaining to a cause associated with the domain of interest, automatically mapping the plurality of unknown patterns to the quantization points using spatial similarities of the unknown patterns and the quantization points, automatically pooling the quantization points into a temporal pattern, the temporal pattern being a sequence of spatial patterns that represent the cause, automatically mapping the temporal pattern to a reference temporal pattern, automatically creating a sequence of the temporal patterns, and automatically recognizing the cause using the sequence of temporal patterns.

Owner:USAA

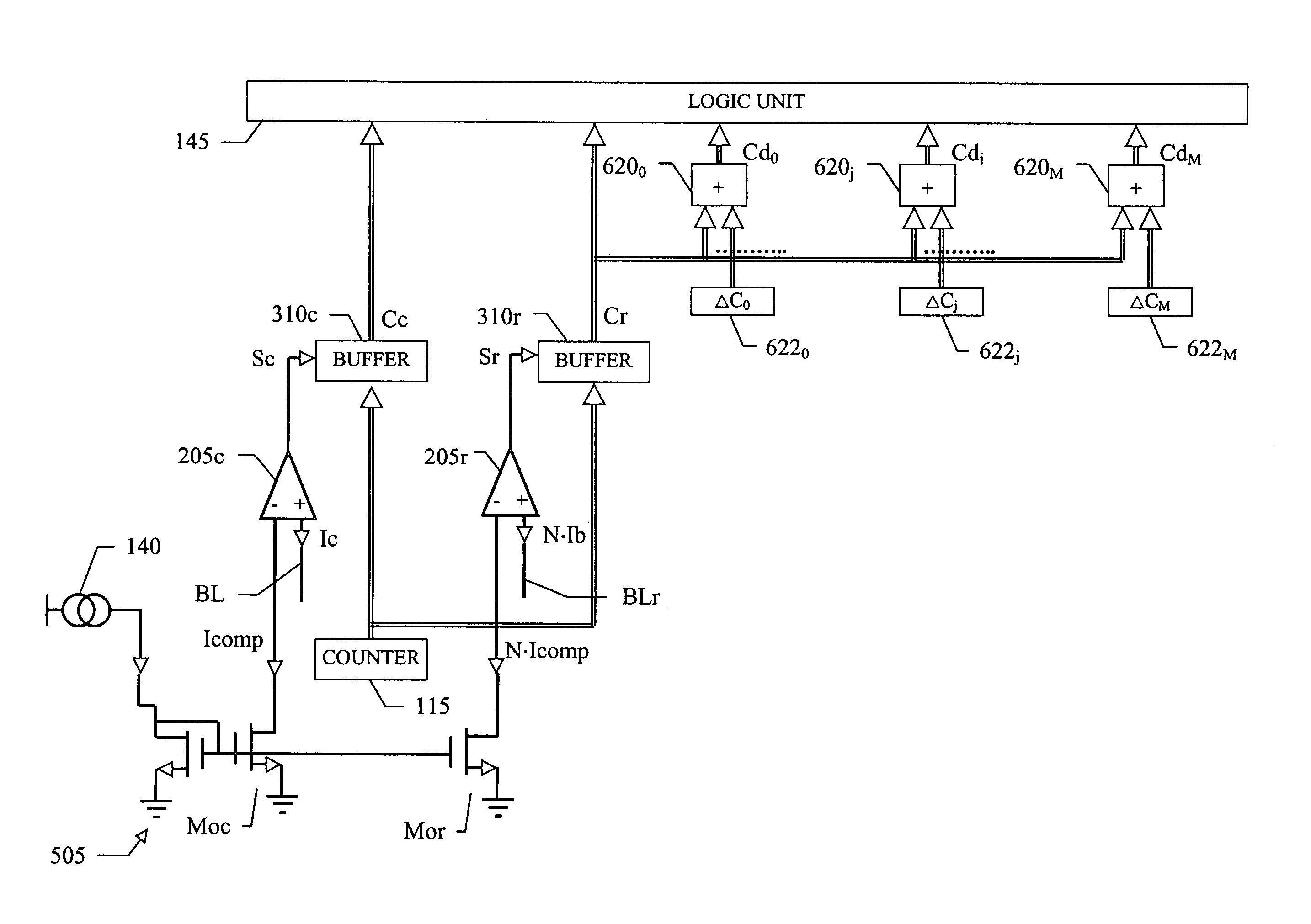

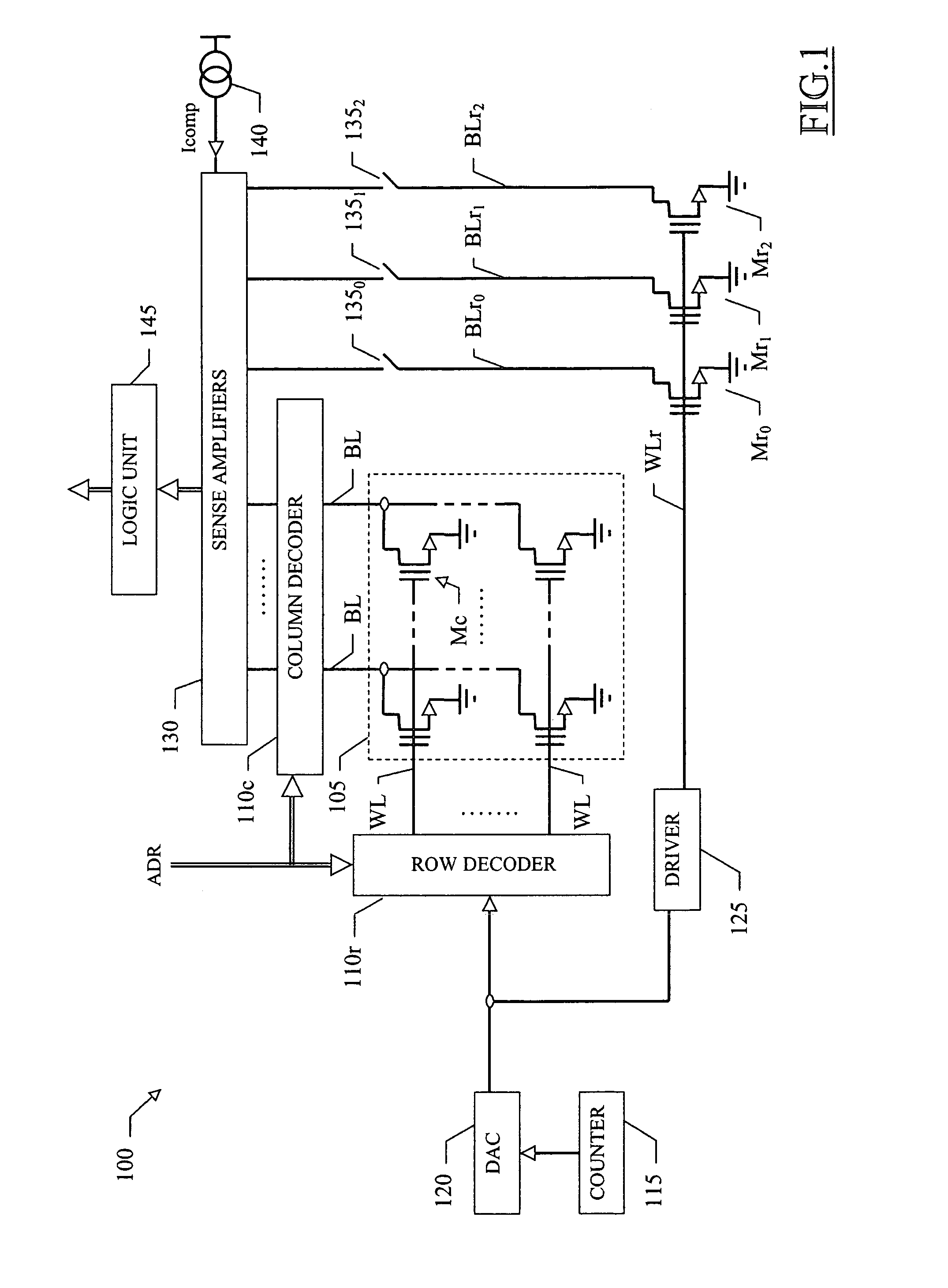

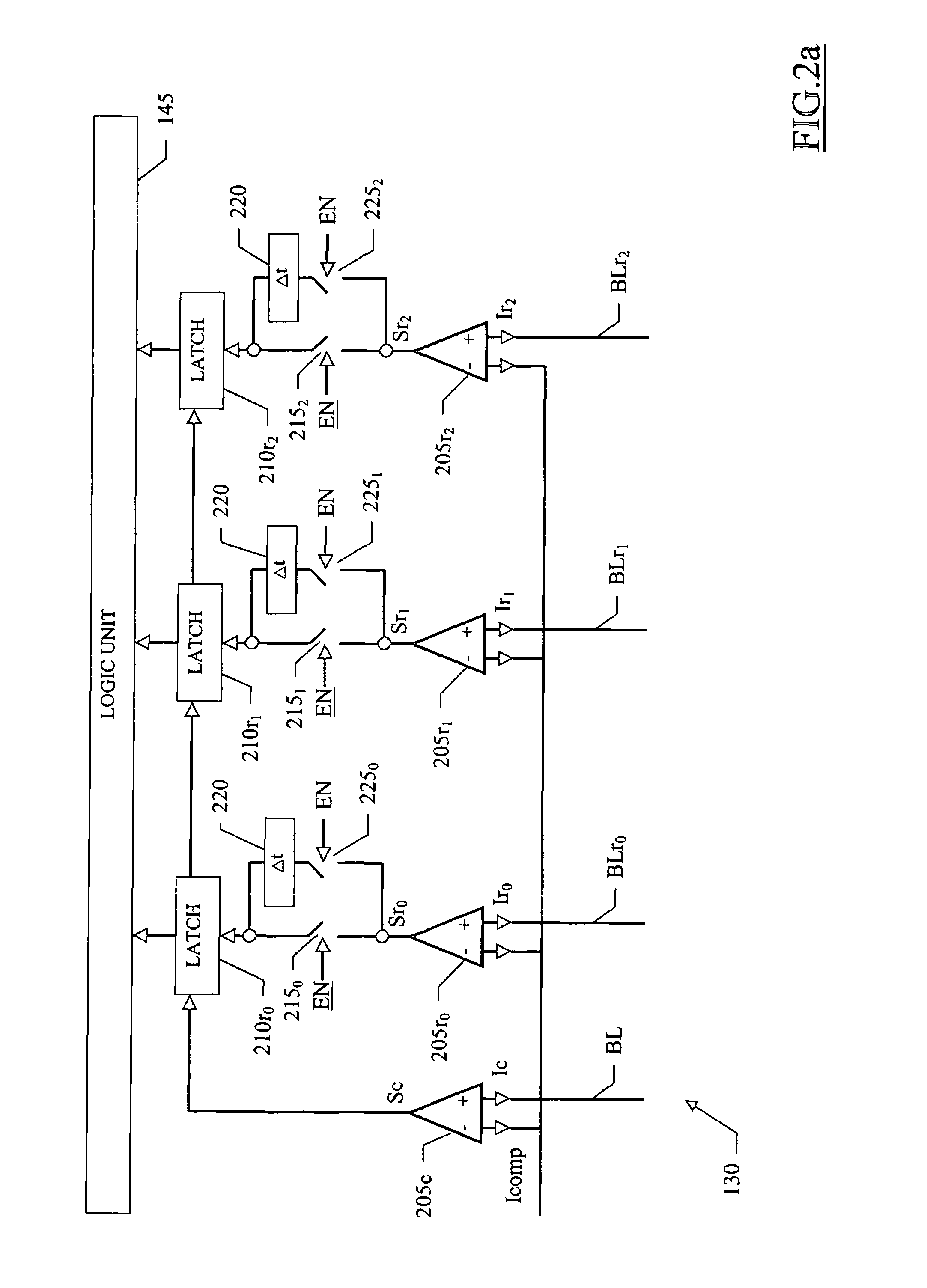

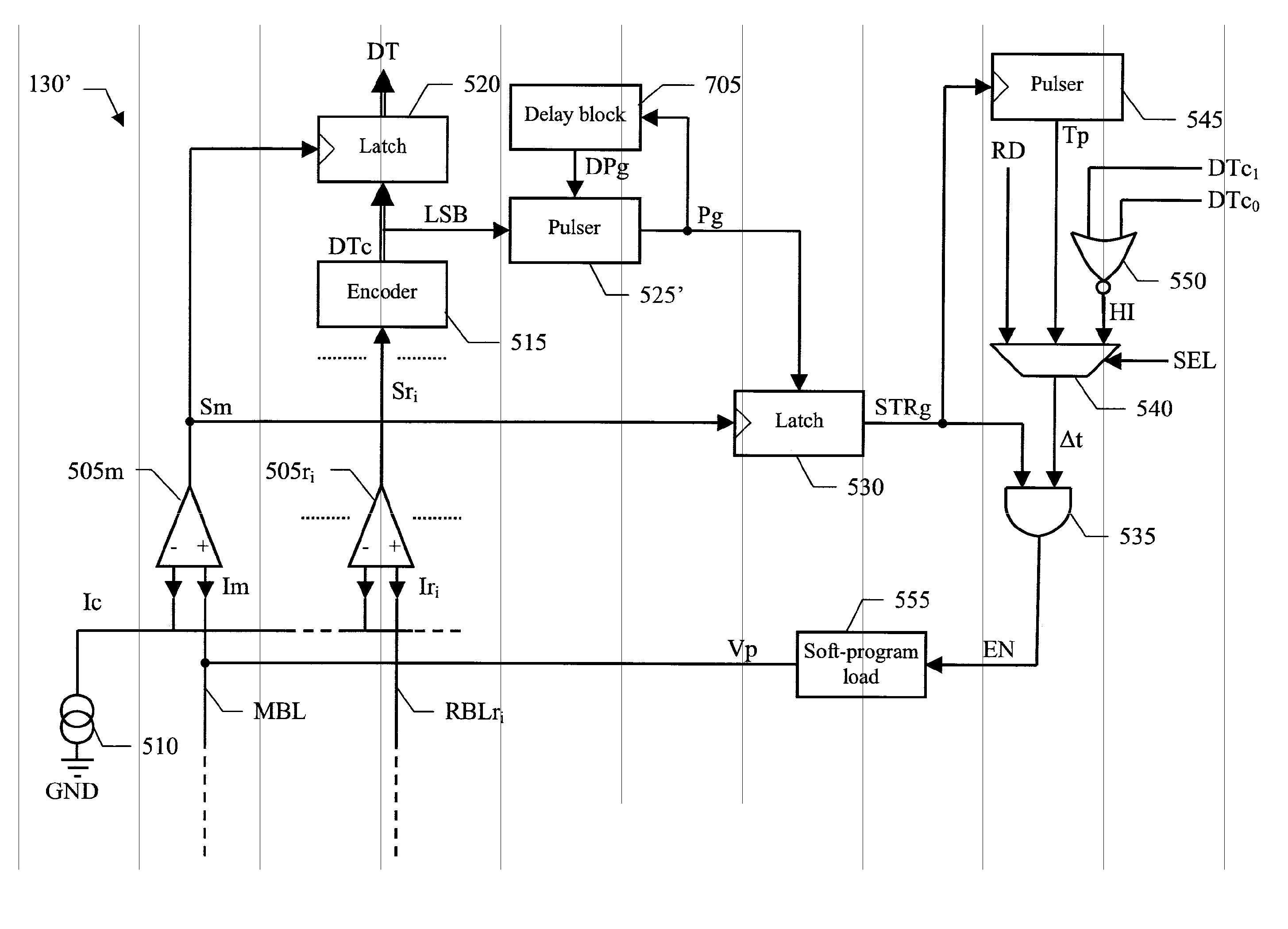

Memory device with time-shifting based emulation of reference cells

InactiveUS7345905B2High precisionReduce impactRead-only memoriesDigital storageAudio power amplifierLogic cell

Owner:MICRON TECH INC

Method and apparatus using intensity gradients for visual identification of 2D matrix symbols

InactiveUS6941026B1Accurate locationImprove reliabilityCharacter and pattern recognitionSensing by electromagnetic radiationPattern recognitionVisual perception

Owner:COGNEX CORP

Method for characterization, detection and prediction for target events

ActiveUS7292960B1Measurement arrangements for variableNuclear monitoringSliding time windowData mining

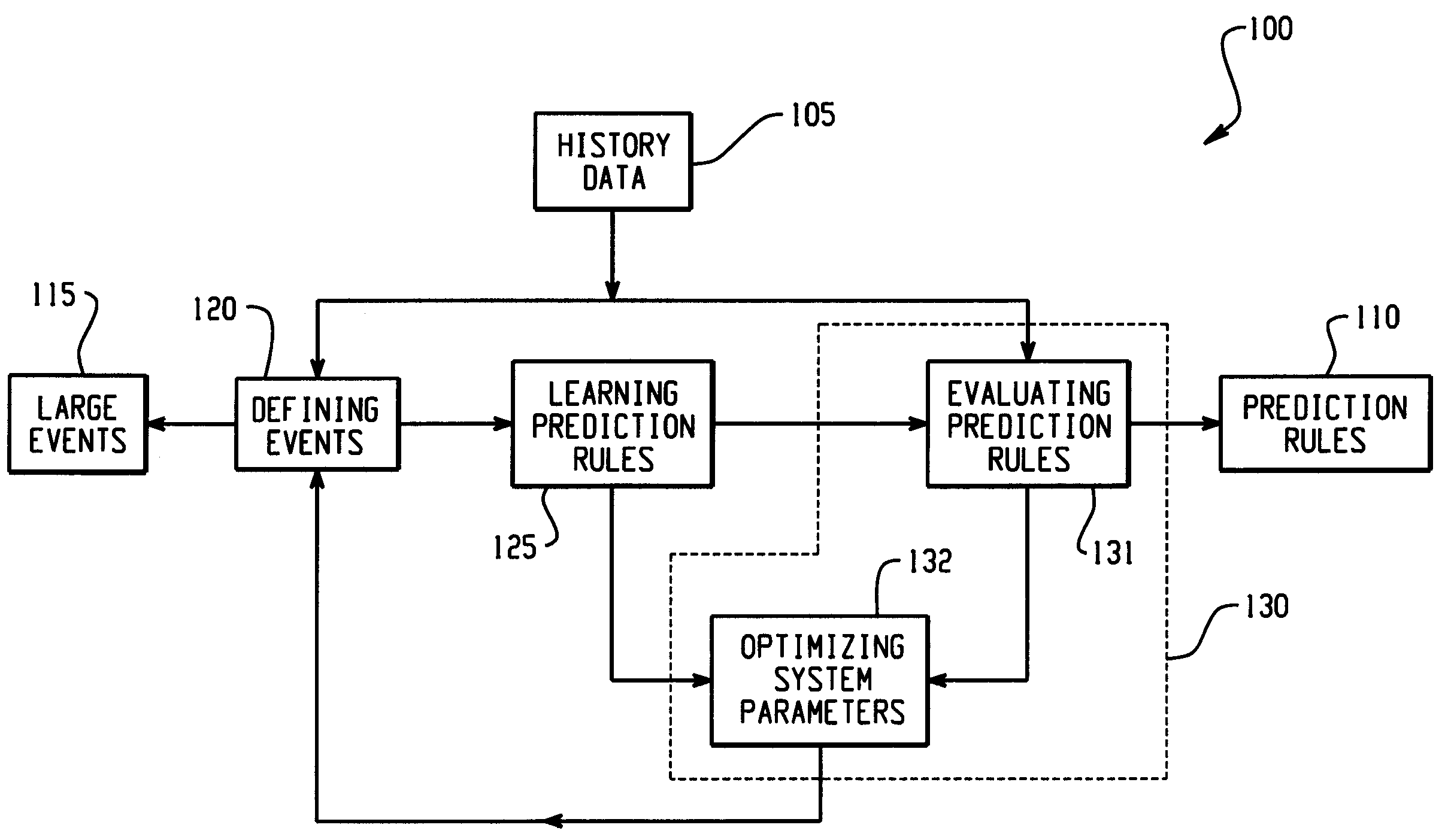

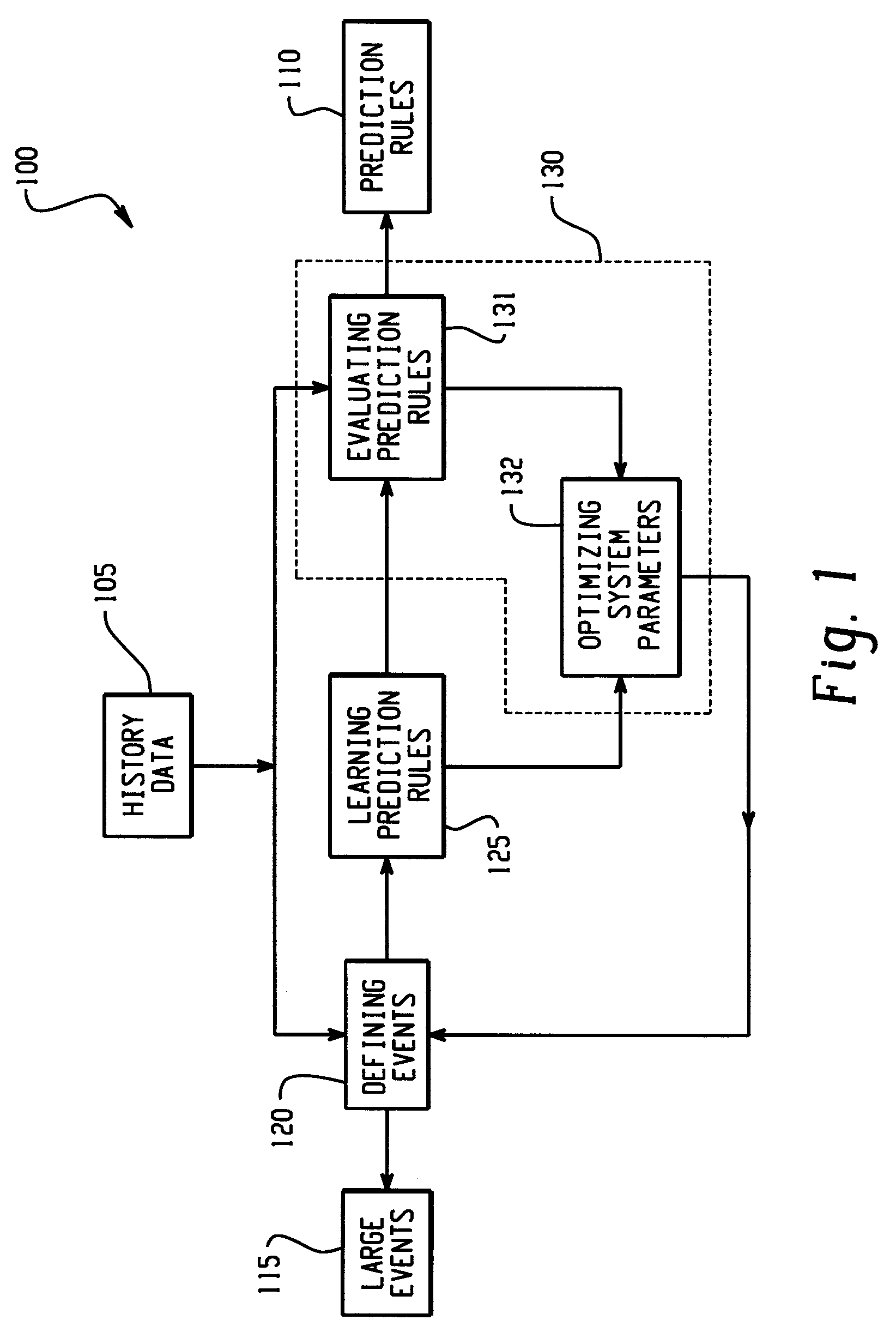

A method for characterizing, detecting and predicting an event of interest, a target event, based on temporal patterns useful for predicting a probable occurrence of the target event is disclosed. Measurable events and their features are defined and quantized into event classes. Temporal series of the event classes are analyzed, and preliminary prediction rules established by analyzing temporal patterns of the event classes that precede an occurrence of the target event using a sliding time window. The quality of the preliminary prediction rules is evaluated and parameters thereof are optimized by using a defined fitness function, thereby defining finalized prediction rules. The finalized prediction rules are then made available for application on temporal series of the event classes to forecast a probable occurrence of the target event.

Owner:GM GLOBAL TECH OPERATIONS LLC

Medical infusion pump capable of learning bolus time patterns and providing bolus alerts

ActiveUS20050278073A1Drug and medicationsPharmaceutical delivery mechanismInsulin pumpEmergency medicine

An apparatus and method are disclosed for improving a medical infusion pump. Users of medical infusion pumps, such as insulin pumps, require a bolus of a medication at predicable times of the day, such as at or near mealtimes for insulin pumps. The disclosed medical infusion pump determines bolus time intervals during which boluses are usually taken, and, alerts the user at one or more calculated alert times during an active bolus time interval when a bolus has not yet been delivered during the active bolus time interval. Advantageously, a different set of bolus time intervals are determined by day of week, to accommodate, for example, different bolus patterns during weekends versus weekdays.

Owner:TANDEM DIABETES CARE INC

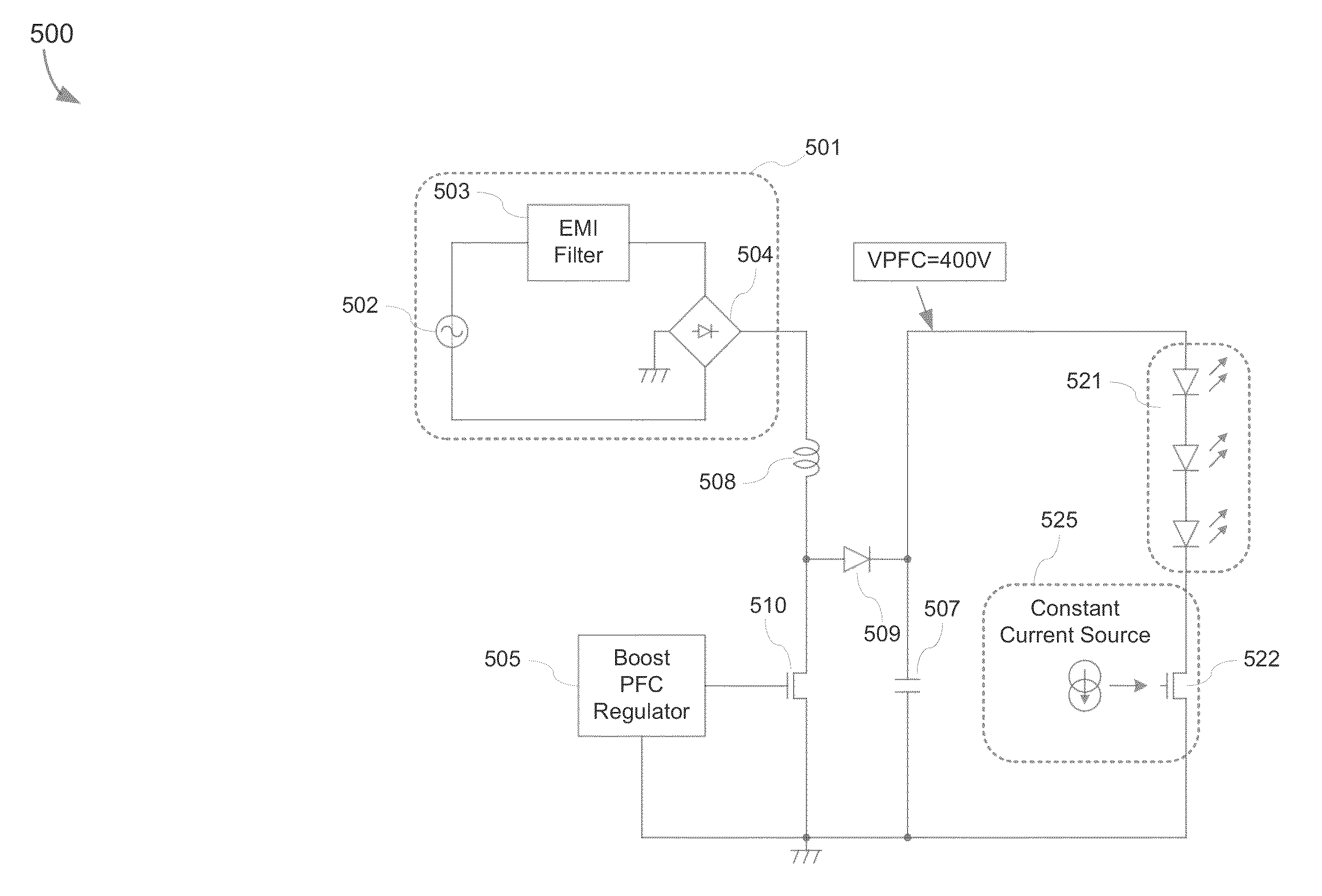

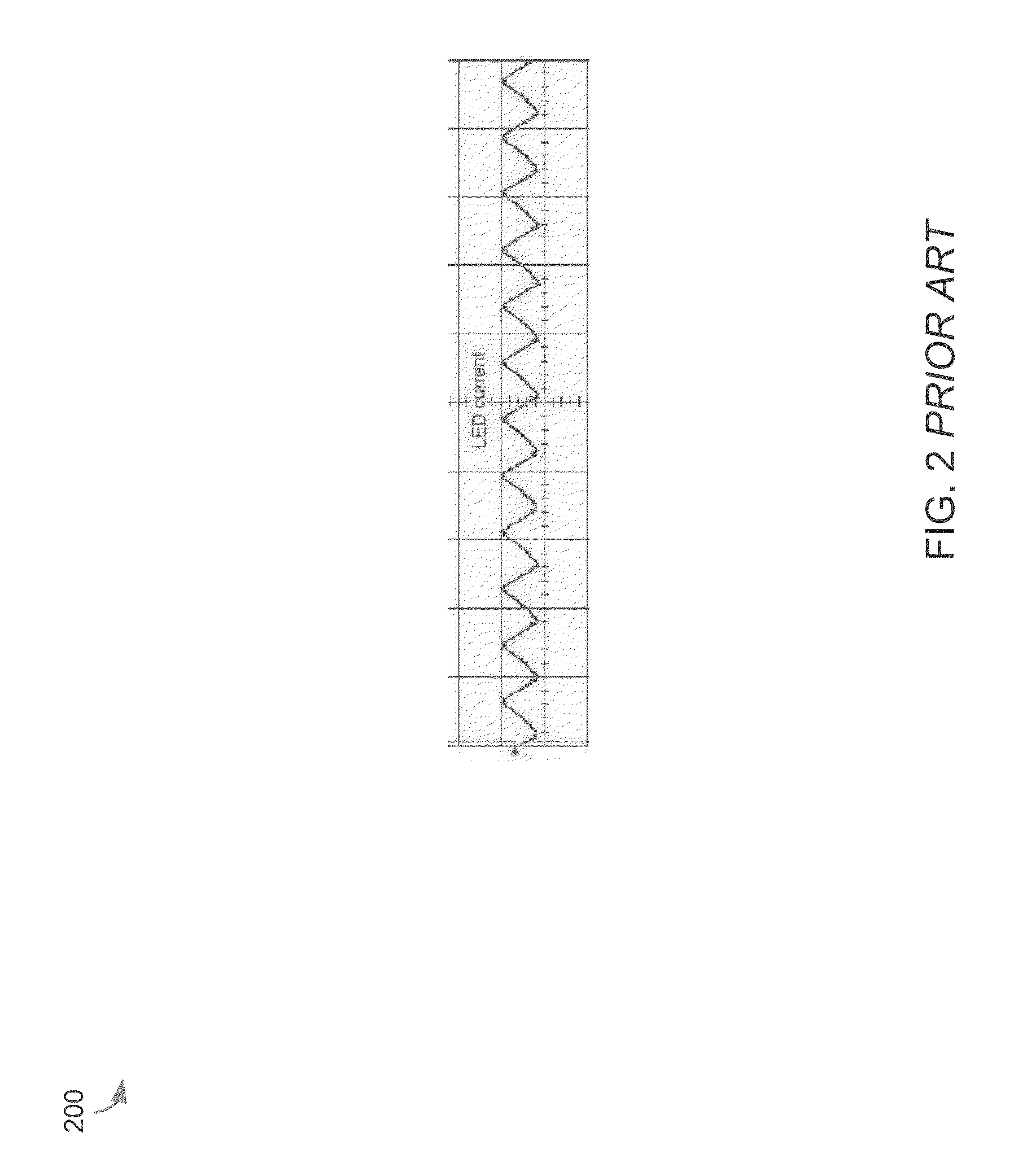

Power factor correction converter with current regulated output

ActiveUS20140239810A1Shortens duty cycleShortens the duty cycleElectric discharge tubesSemiconductor lamp usageEngineeringTime pattern

A power factor correction converter in a buck-boost configuration may include a set-up circuit configured to supply an input voltage, a buck transistor connected to the set-up circuit, and configured to receive a current from the diode bridge, a first diode connected to the buck transistor, a boost transistor, a resistor connected to the boost transistor, a coil that connects the buck transistor and the boost transistor, a buck-boost PFC regulator connected to the set-up circuit, and configured to regulate a time pattern of the on / off status of the first transistor and the second transistor synchronously, a second diode connected to the coil and the boost transistor, and configured to output a first level voltage, a capacitor connected to the second diode and a load connected to the second diode.

Owner:ASAHI KASEI ELECTRONICS CO LTD

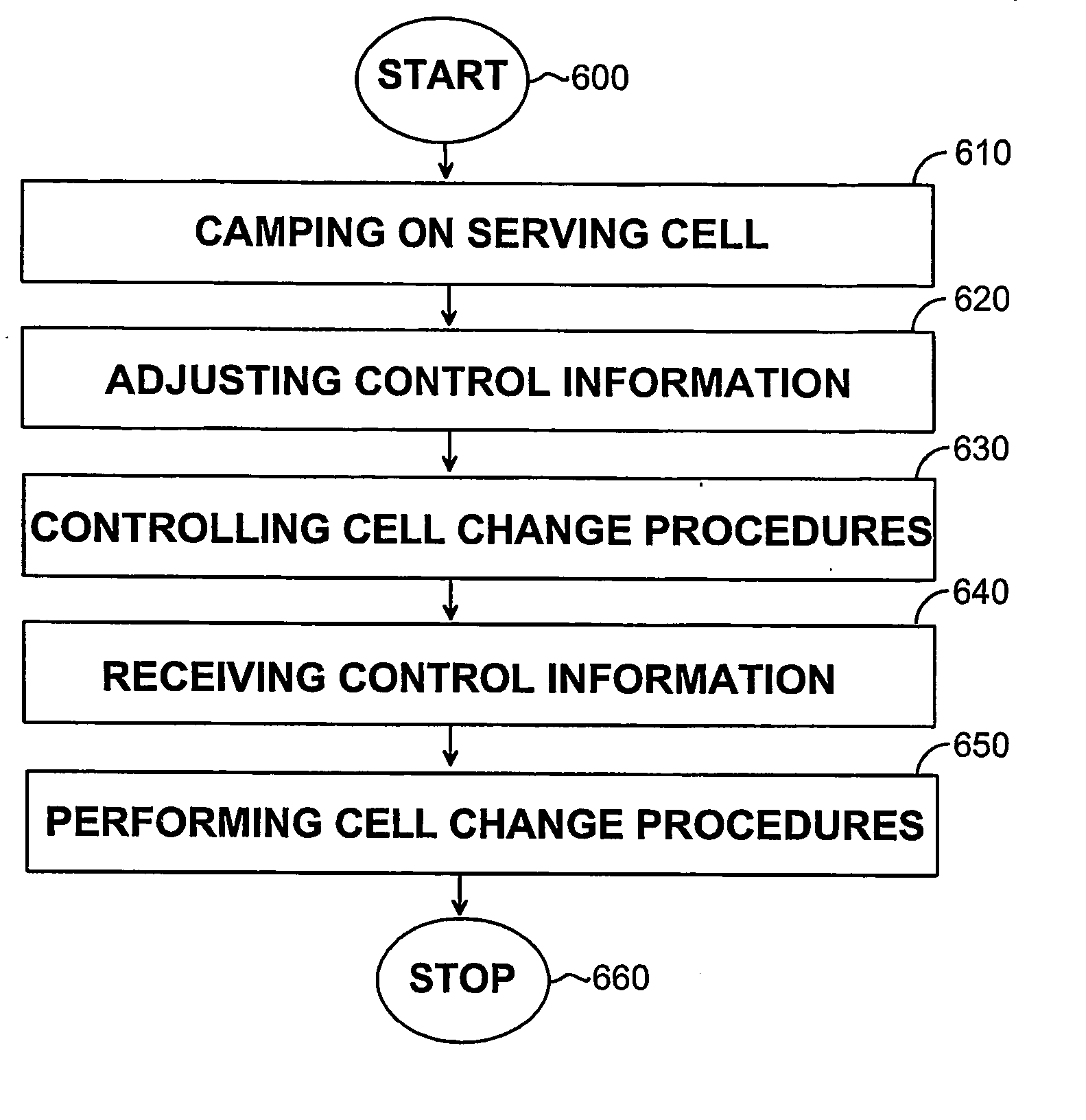

Radio resource control method in mobile communication system, mobile communication system and network element

InactiveUS7526289B2Increase capacityReduce probabilityAssess restrictionRadio transmissionCommunications systemMobile communication systems

The invention relates to a radio resource control method, a mobile communications system and a network element implementing the method. According to the invention, the cell change procedures performed by the user equipment in an idle state are controlled dynamically with control information that is adjusted according to a predetermined time pattern. The invention enables for instance an advanced cell change in an idle state, thus reducing the probability of a handover while the user equipment is in a dedicated connection to the network.

Owner:NOKIA TECHNOLOGLES OY

Super thick copper PCB plate production method and its circuit board

ActiveCN102510668ARealize the practical manufacturing processMeet basic requirementsPrinted circuit detailsConductive material chemical/electrolytical removalEpoxyScreen printing

The invention discloses a super thick copper PCB plate production method and its circuit board. The method comprises the following steps: dividing a plate substrate with a bottom copper; suspending and placing the PCB plate to be processed into an electroplating jar in a way of positive, negative clamping plates to electroplate the PCB plate for four times, until the thickness of the electroplating layer is more than 350-400Mum; etching the PCB plate; performing silk-screen printing using epoxy resin, leveling up circuit clearances by the epoxy resin and roasting the plate to solidify the epoxy resin; grinding the solidified epoxy resin and removing the residual resin layer on the surface of the circuit; drilling the plate, depositing the copper and electroplating the whole plate; performing the second time pattern electroplating and circuit etching on the plate to accomplish the circuit pattern. The super thick copper PCB plate production method and its circuit board use the multiple electroplating way and the epoxy resin leveling-up way between circuits, so as to realize the practical production technology of the super thick copper PCB plate, the copper on the circuit of the circuit board is uniform to satisfy the basis requirement of the circuit board.

Owner:SHENZHEN KINWONG ELECTRONICS

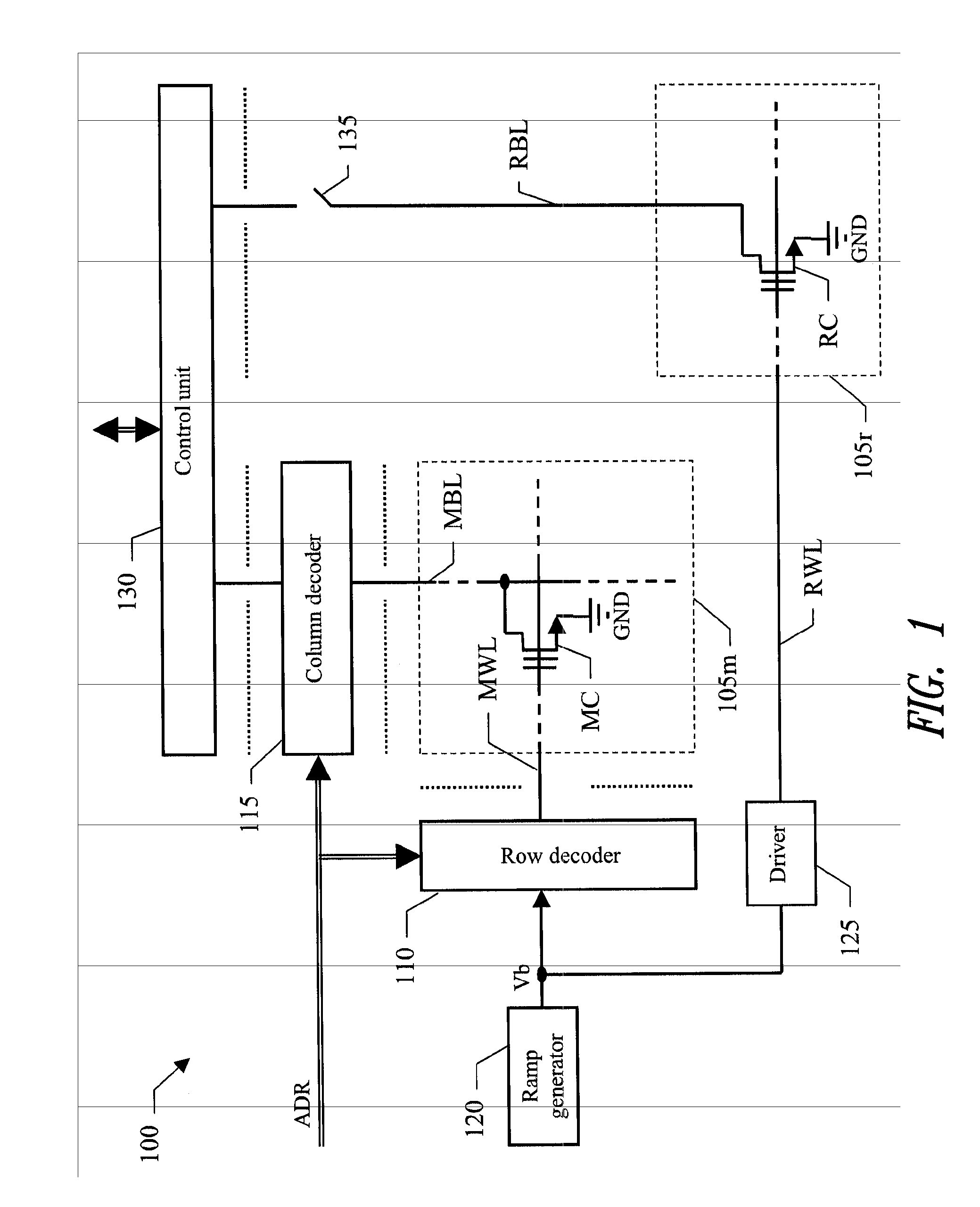

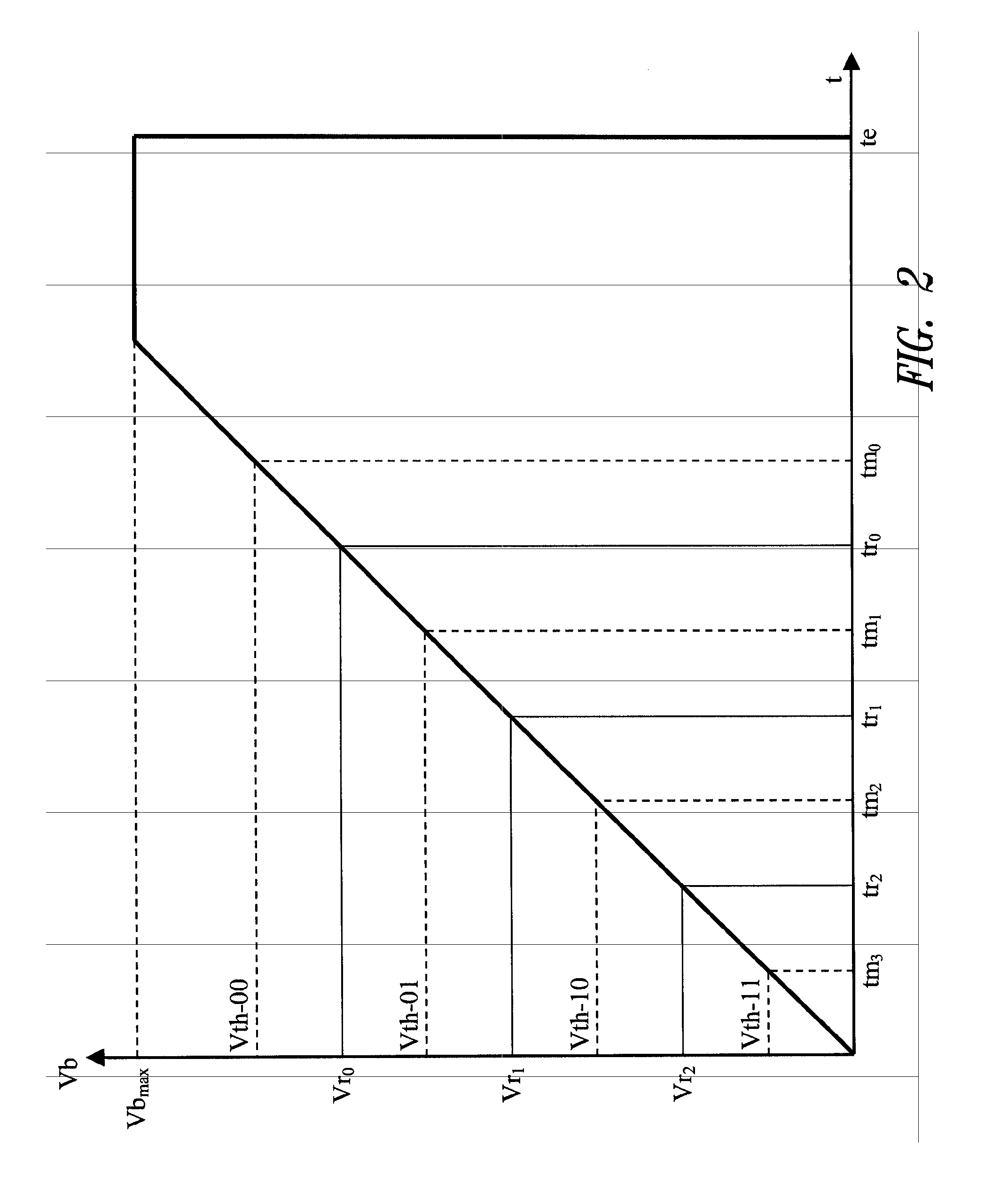

Method and system for refreshing a memory device during reading thereof

A refresh circuit for refreshing a memory device is proposed. The refresh circuit includes: reading means for reading a set of memory cells, the reading means including means for applying a biasing voltage having a substantially monotone time pattern to the memory cells and to a set of reference cells each one having a reference threshold voltage, means for detecting the reaching of a comparison current by a cell current of each memory cell and by a reference current of each reference cell, and means for determining a condition of each memory cell according to a temporal relation of the reaching of the comparison current by the corresponding cell current and the reference currents, and writing means for applying a writing voltage to at least one selected of the memory cells; the refresh circuit further includes control means for enabling the writing means during at least part of the application of the biasing voltage after the determination of the condition of each selected memory cell.

Owner:STMICROELECTRONICS SRL

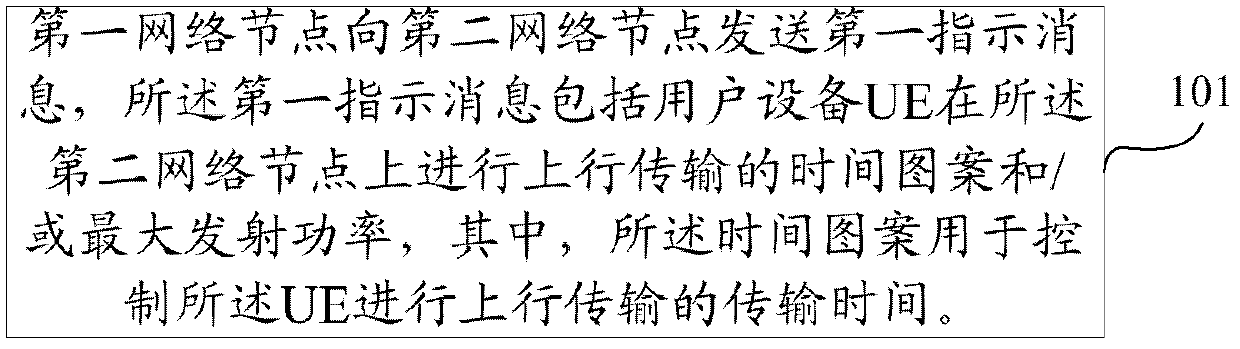

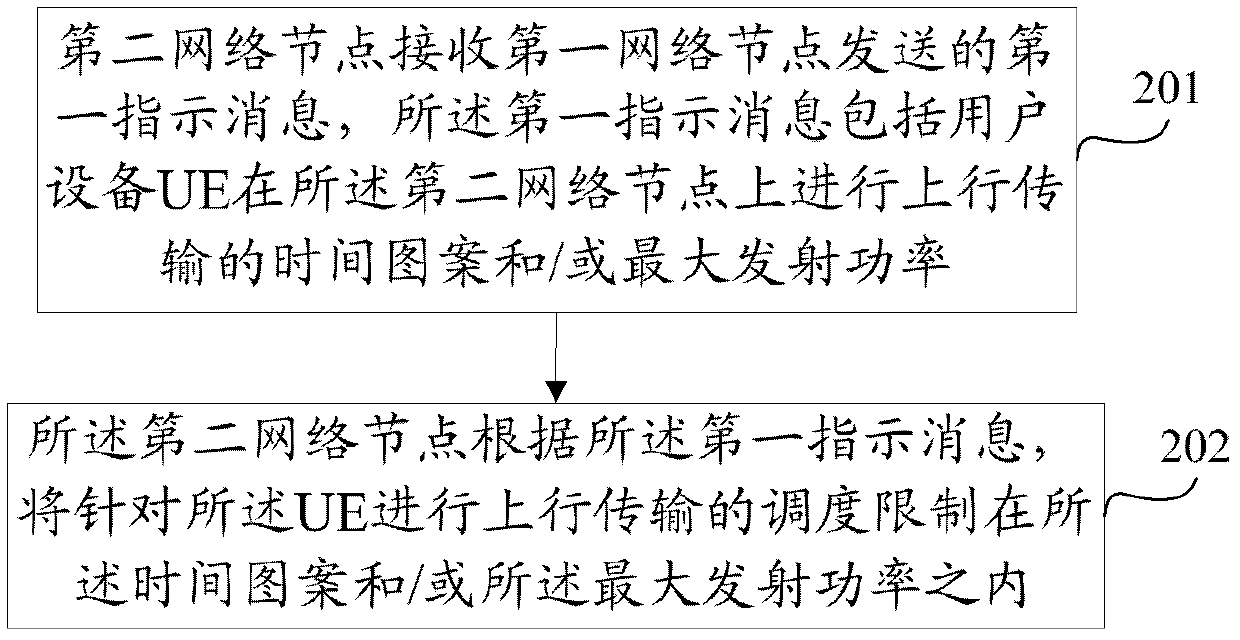

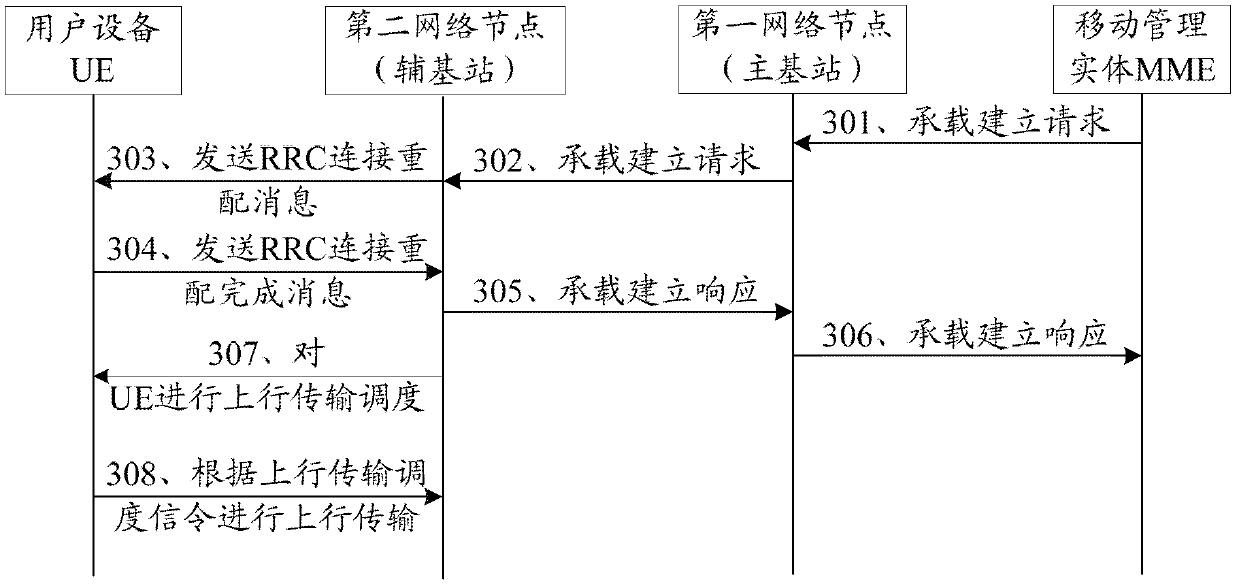

Uplink power control method, network nodes and system

ActiveCN103327595AMeet the transmit power requirementsEasy to controlPower managementUplink transmissionCarrier signal

The invention discloses an uplink power control method, network nodes and a system, and relates to the communication technical field. The uplink power control method includes the steps that a first network node sends first indicating information to a second network node, wherein the first indicating information comprises time patterns and / or maximum launching power of UE for conducting uplink transmission on the second network node, and the time patterns are used for controlling transmission time of the UE for conducting uplink transmission. The uplink power control method, the network nodes and the system are suitable for controlling the uplink power of the UE in a carrier aggregation situation.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

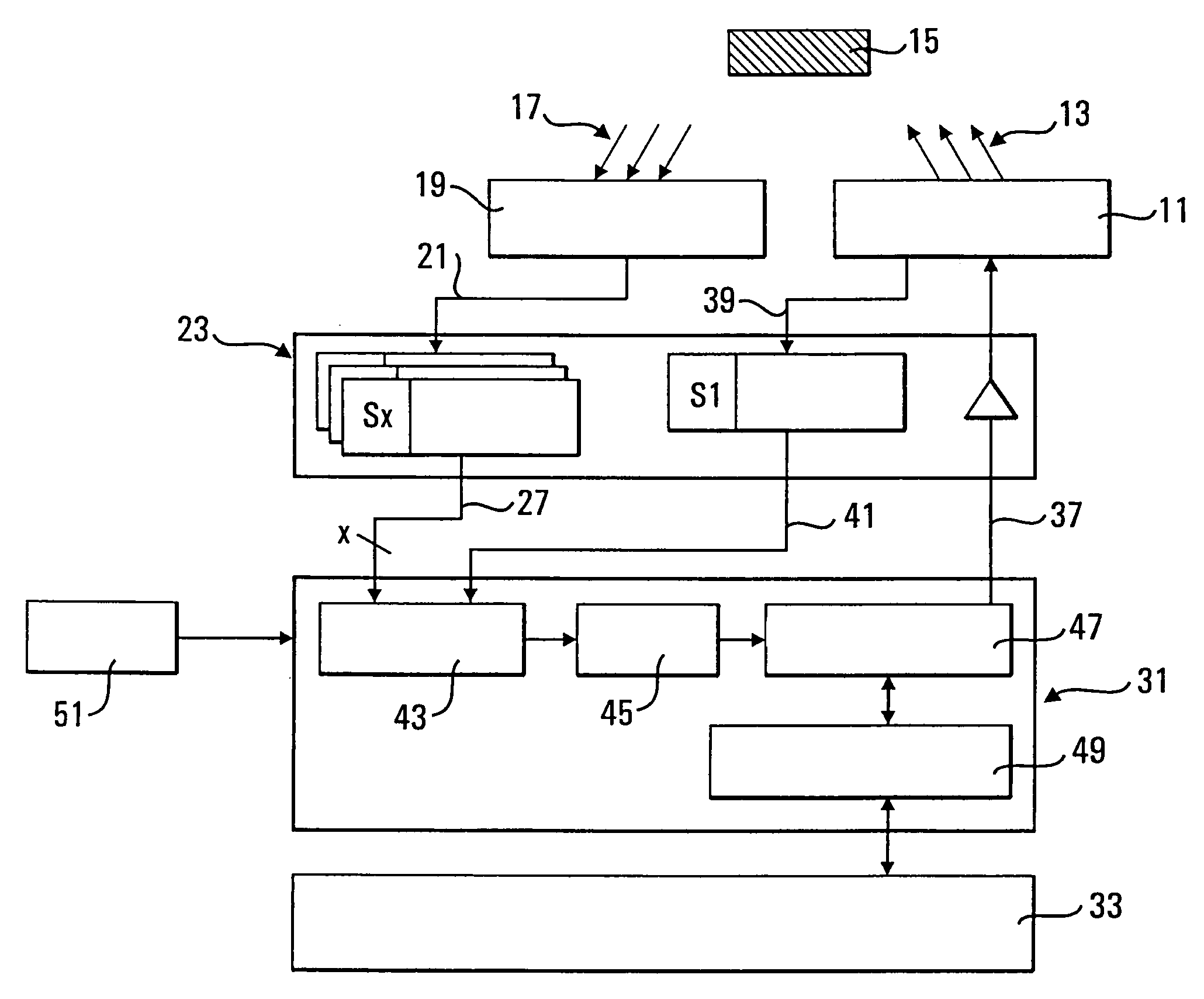

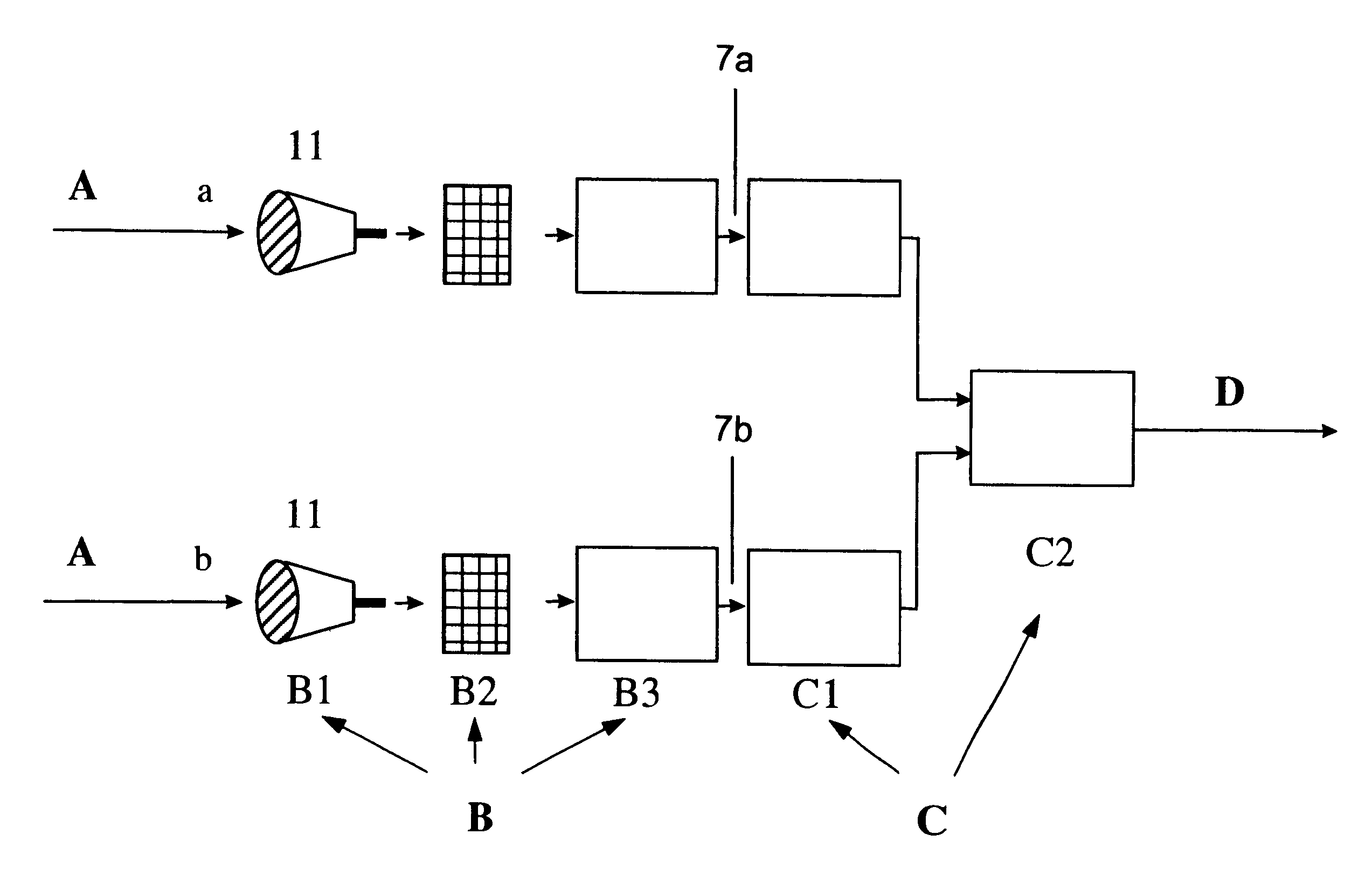

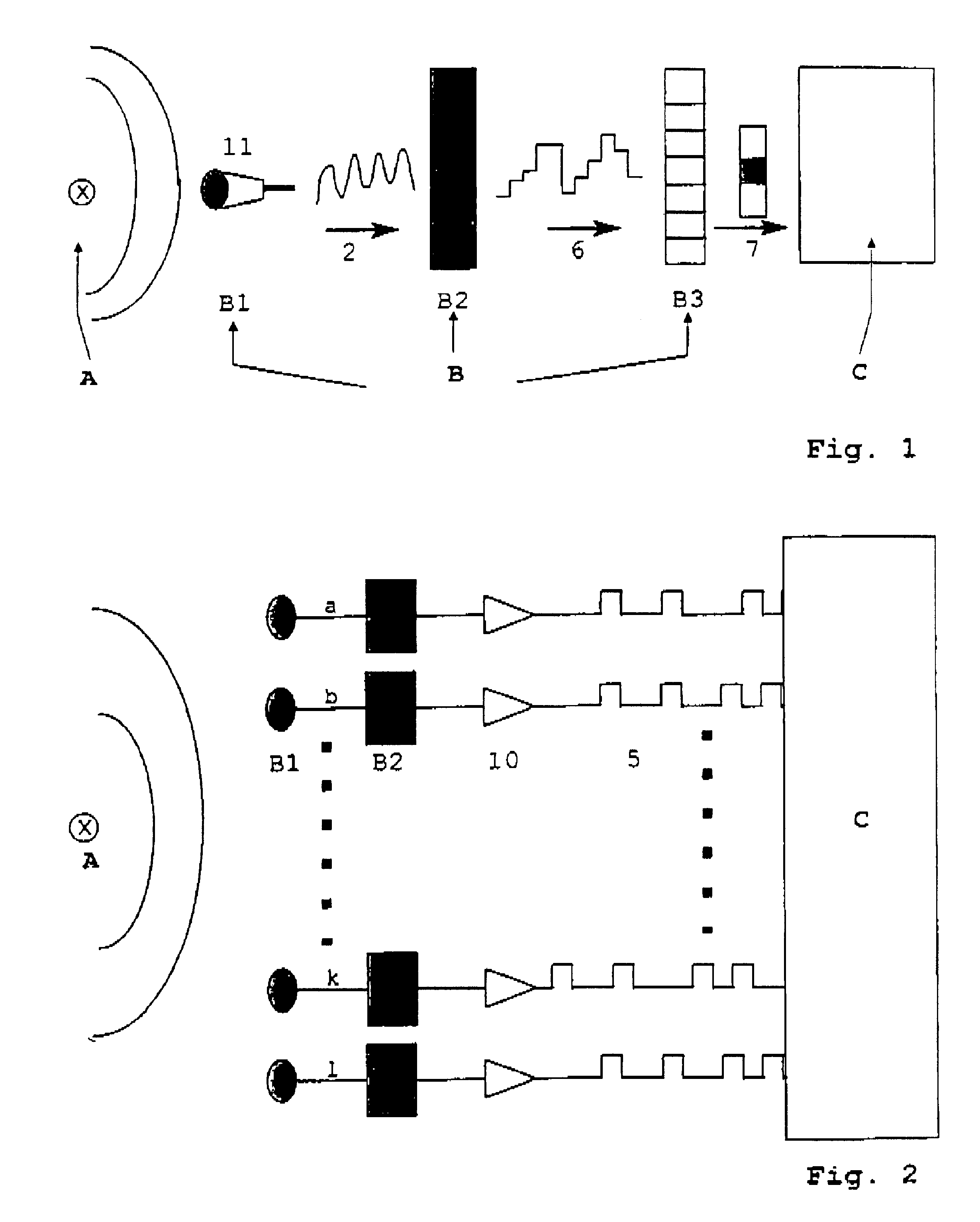

Method and apparatus for determining transit-time differentials for signal waveforms for real-time pattern recognition, localization and monitoring of optical and acoustic signals

InactiveUS6442510B1High measurement accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesVibration measurement in fluidShift registerPropagation time

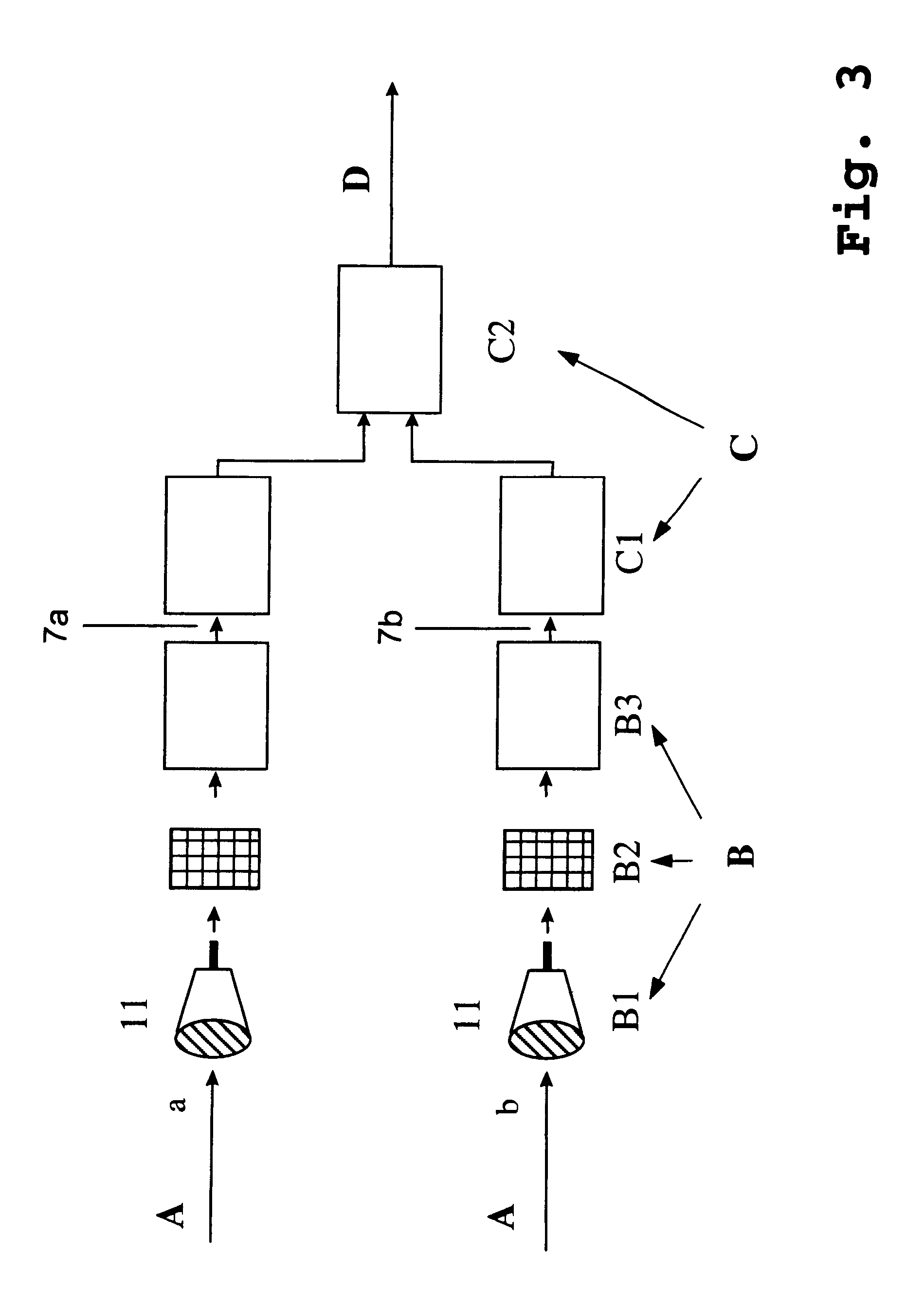

A method includes the steps of segment-wise detecting and bringing into coincidence signal waveforms for conversion into monotone and continuous trajectories for real-time pattern recognition, localization, and monitoring optical and acoustic signals. The method also determines transit-time differentials, wherein pre-programmed key signals are detected by signal sampling, data is correlated from the sampled signals, and pairs of signal combinations of given signal transit-time differentials from the coincidence of the detected signals are determined. The apparatus includes at least two receivers for generating sequences of digital values from incoming acoustic signals, vector generators to convert the digital values into input vectors (7), a signal detection unit (C1) downstream from each vector generator and having parallel, programmable signal-flow chains and adder / comparator units (1, 10) mounted perpendicularly to the signal-flow chains at equidistant spacings, and a multi-coincidence unit (C2) consisting of two antiparallel shift-register forming flipflop chains and an AND gate (20).

Owner:KLEFENZ FRANK

Array substrate, thin-film transistor and manufacturing methods thereof as well as display device

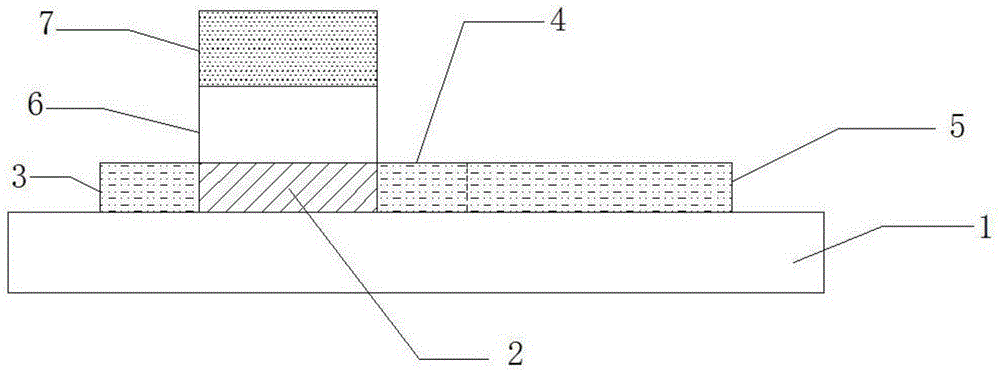

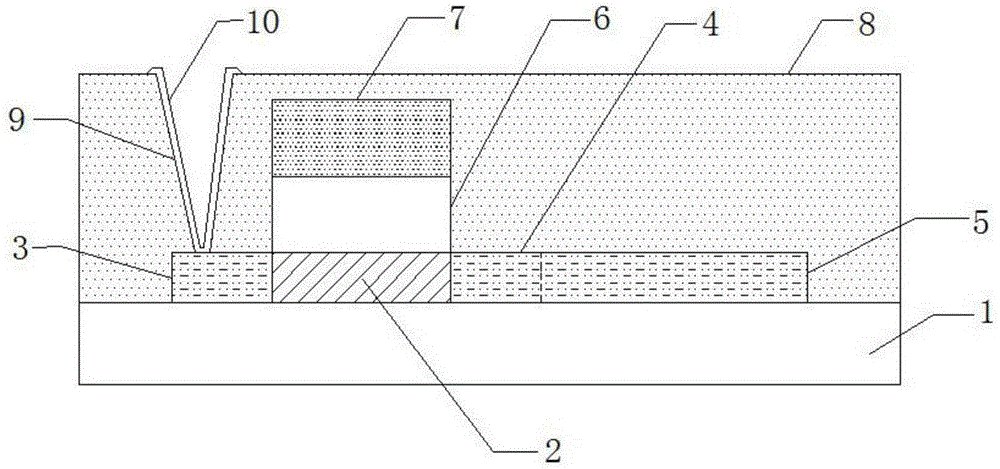

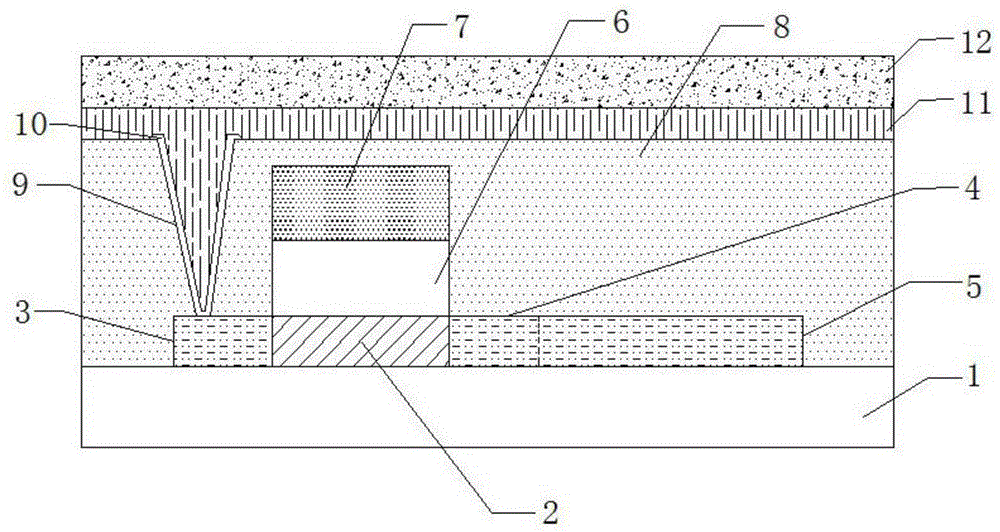

ActiveCN104681627ASimple structureReduce Mask ProcessTransistorSolid-state devicesState of artInsulation layer

The invention belongs to the technical field of display, and particularly relates to an array substrate, a thin-film transistor and manufacturing methods thereof as well as a display device. The array substrate comprises a substrate (1), and an active layer (2), a source electrode (3), a drain electrode (4) and a pixel electrode (5) which are arranged on the same layer of the substrate (1), as well as a grid insulation layer (6) positioned on the active layer (2) and a grid electrode (7) positioned on the grid insulation layer (6), wherein the active layer (2), the source electrode (3), the drain electrode (4), the pixel electrode (5), the grid insulation layer (6) and the grid electrode (7) are formed through a one-time patterning process; the source electrode (3) is connected with the drain electrode (4) through the active layer (2). The array substrate solves the technical problems that the existing array substrate is relatively complicated in structure, more in manufacturing process, low in production efficiency, relatively high in cost and the like, can substitute the existing array substrate, and is applicable to the technical field of display.

Owner:BOE TECH GRP CO LTD

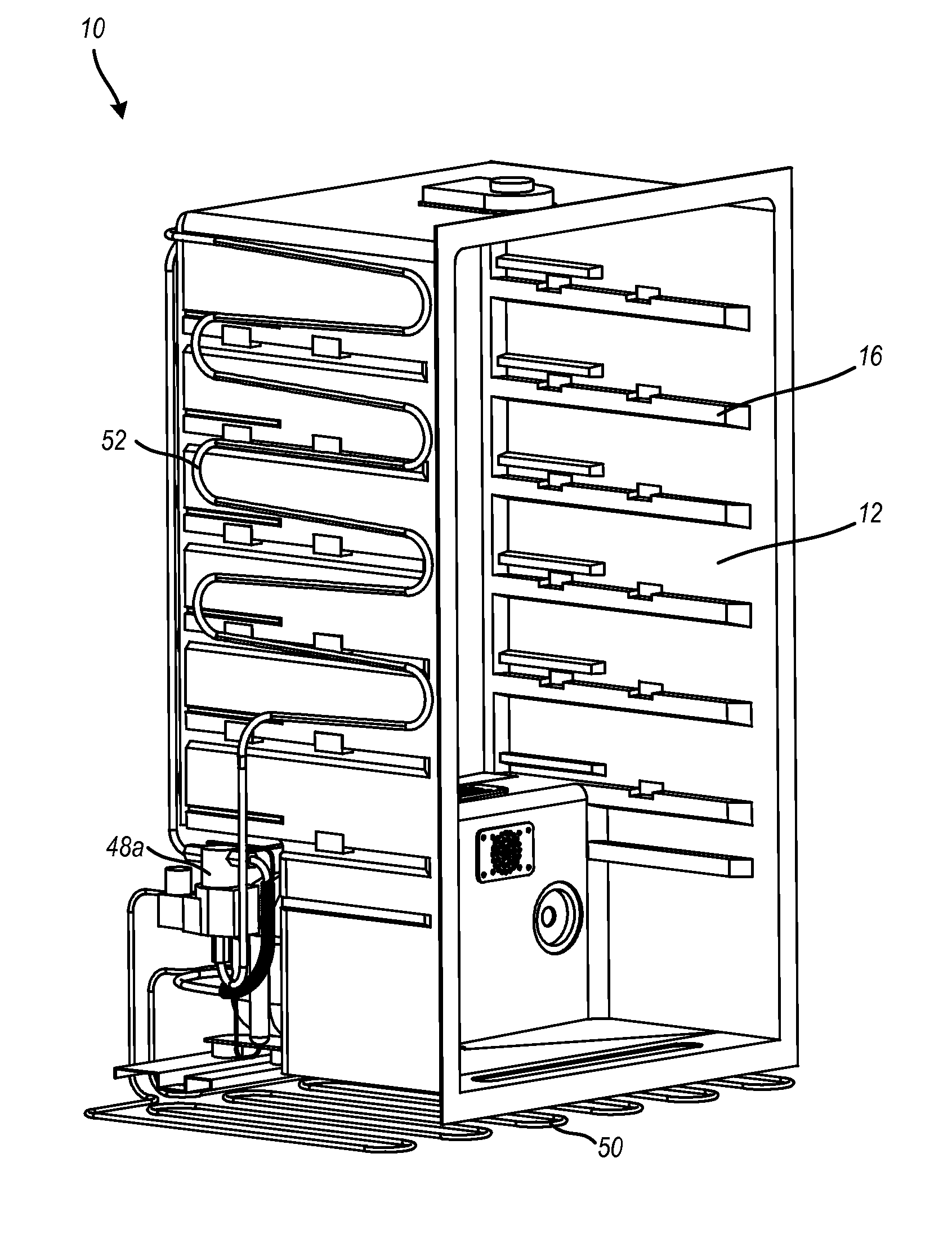

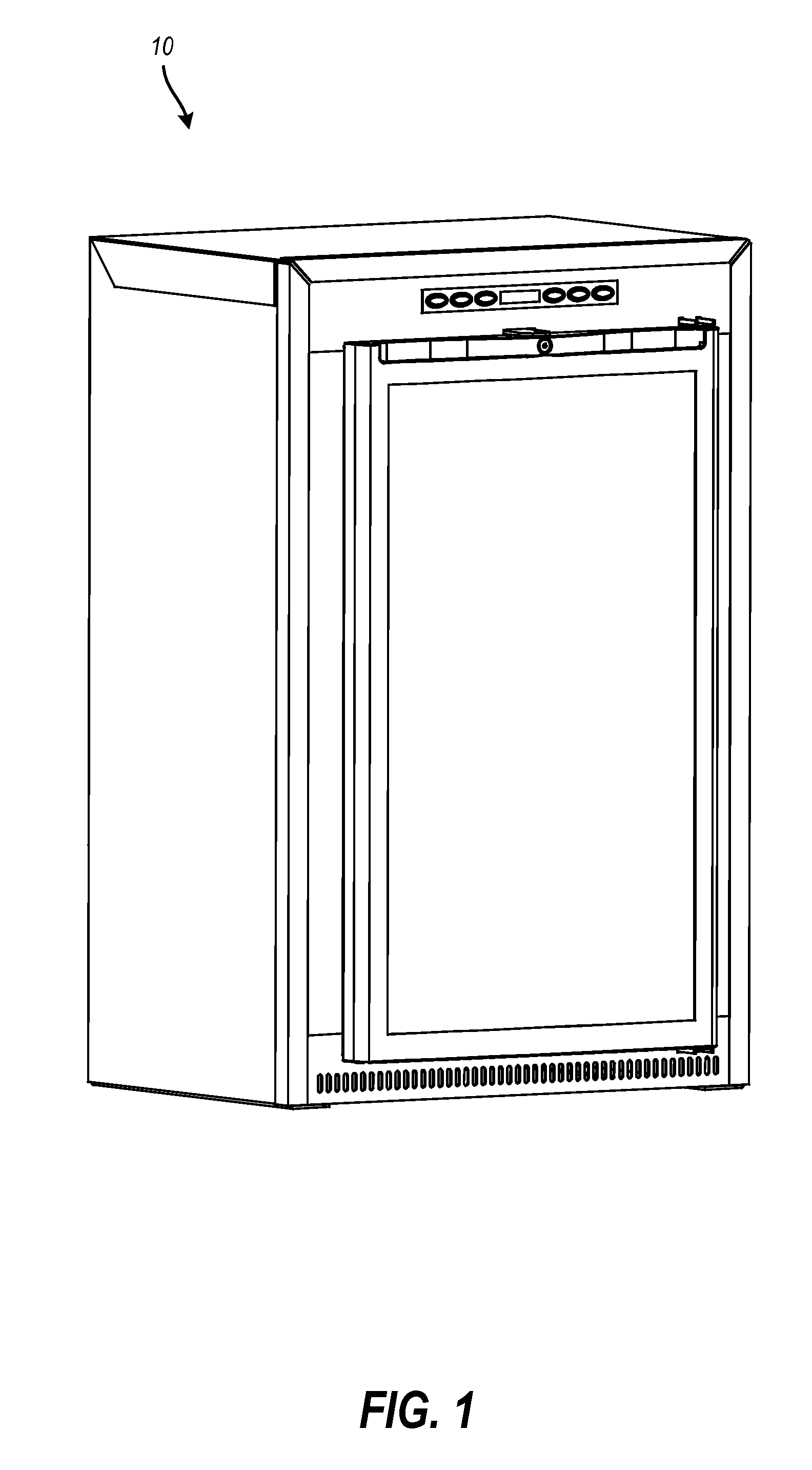

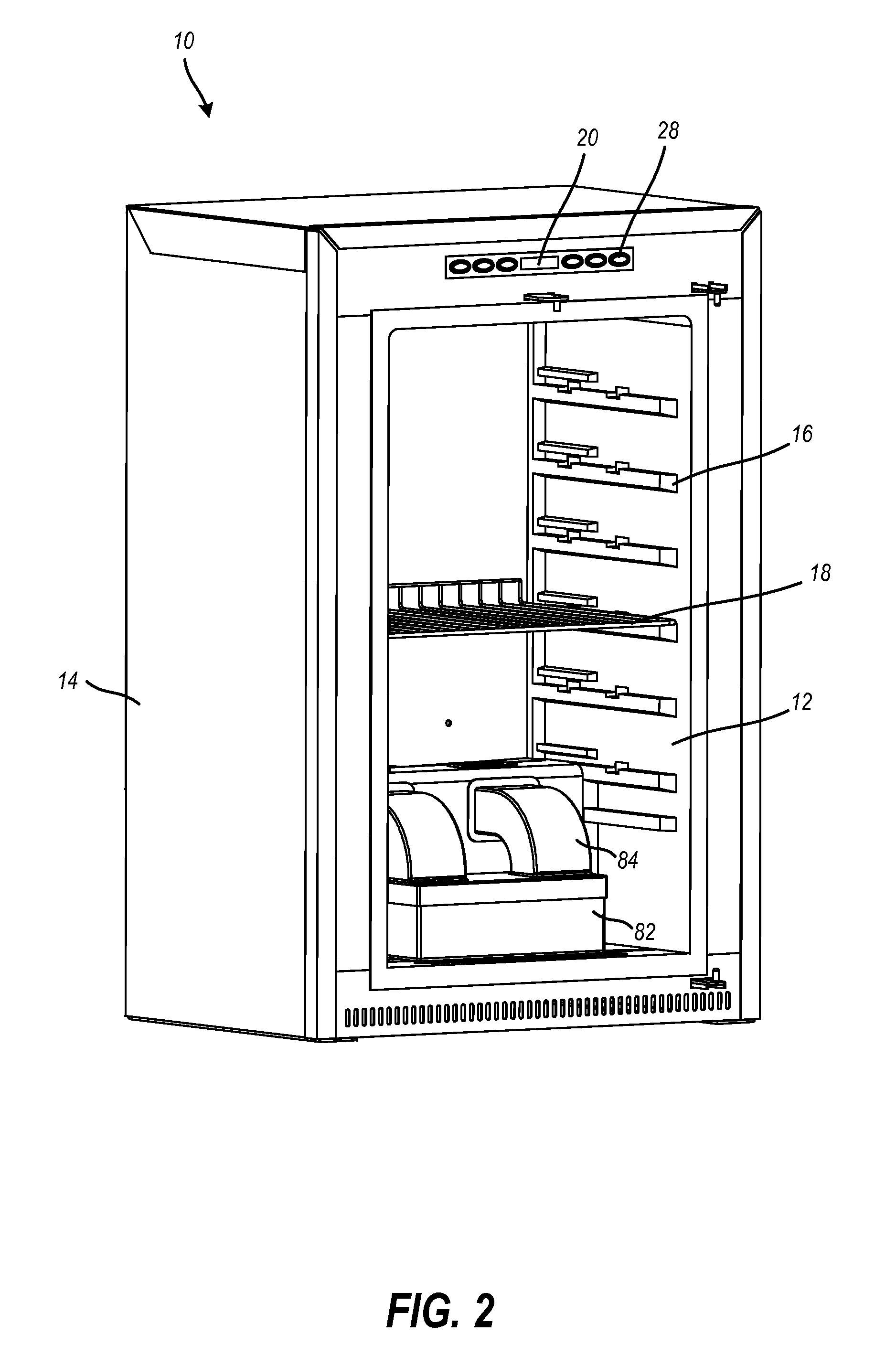

Portable electric cooler

InactiveUS20100154452A1Improve the level ofShow cabinetsMeat/fish preservationSolenoid valveCold store

The technology described herein provides a portable electric cooler for meat storage, tenderizing, and aging in a temperature and humidity controlled environment. The portable electric cooler includes a first and second sets of low pressure coils coupled to a compressor and three-way solenoid valves in order to alternate in a timed pattern the refrigerant flow in order to allow one set of low pressure coils to defrost while the other set circulates the refrigerant. The cooler includes a temperature sensor. The cooler includes a humidity system having a sensor, a controller, a water reservoir, at least one air duct coupled to the water reservoir to channel humidified air drawn from the water reservoir through the refrigeration chamber, and a solenoid configured to direct the fresh outside air being pumped in, to only travel through a set of coils that currently is in the rest mode.

Owner:MCCANN KEVIN

Data output control circuit

A data output control circuit for use in a synchronous semiconductor memory device, which has a plurality of CAS latency modes, includes a signal generating unit for generating an internal signal corresponding to an input command; a CAS latency mode control unit for outputting the internal signal as a controlled internal signal; a signal shifting unit for generating a plurality of shifted signals by synchronizing the controlled internal signal with a DLL clock signal; and a data output enable signal generating unit for outputting one of the plurality of shifted signals as a data output enable signal depending on a plurality of control signals, wherein each of the plurality of control signals corresponds to two or more continuous CAS latency modes.

Owner:SK HYNIX INC

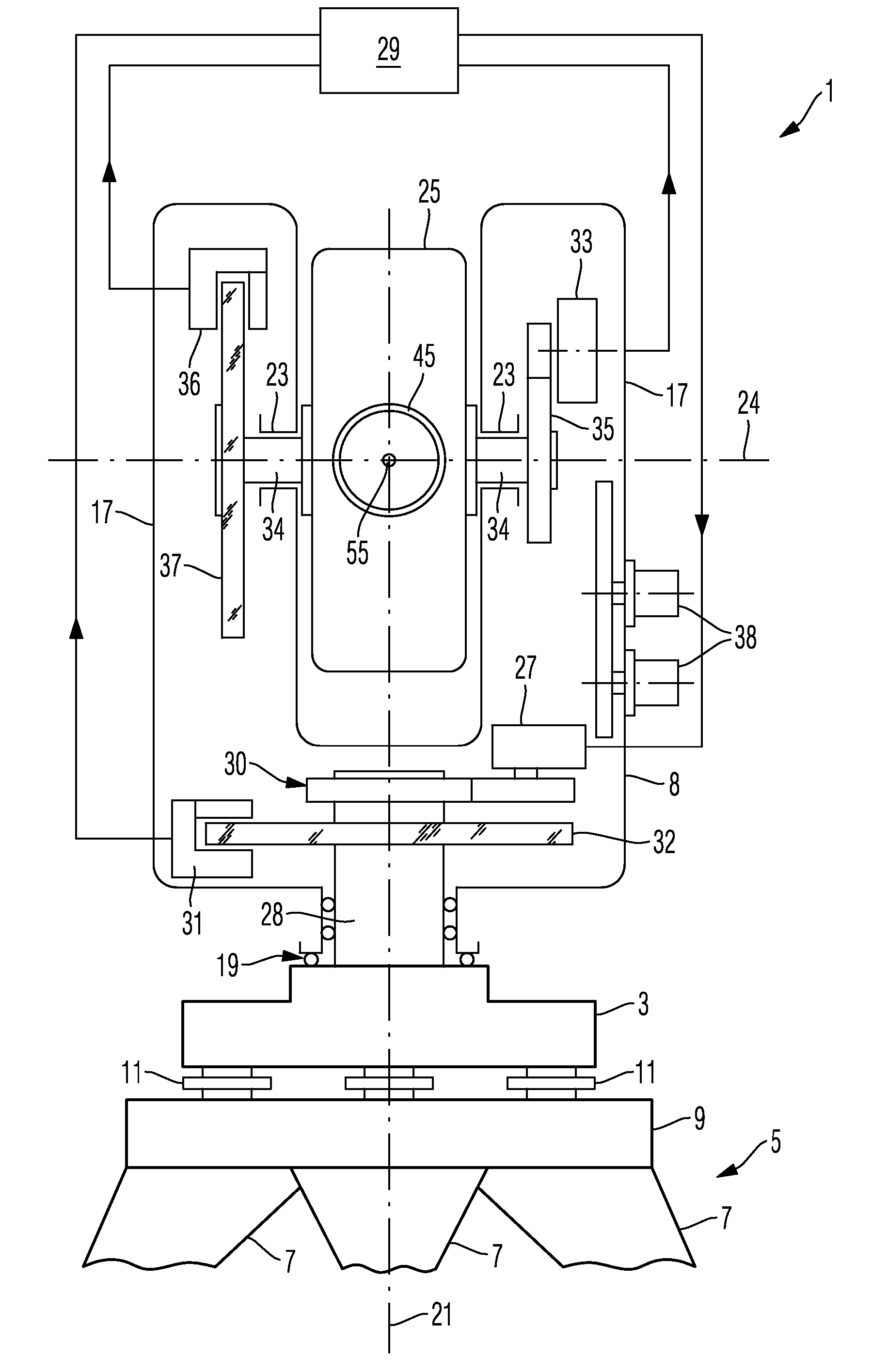

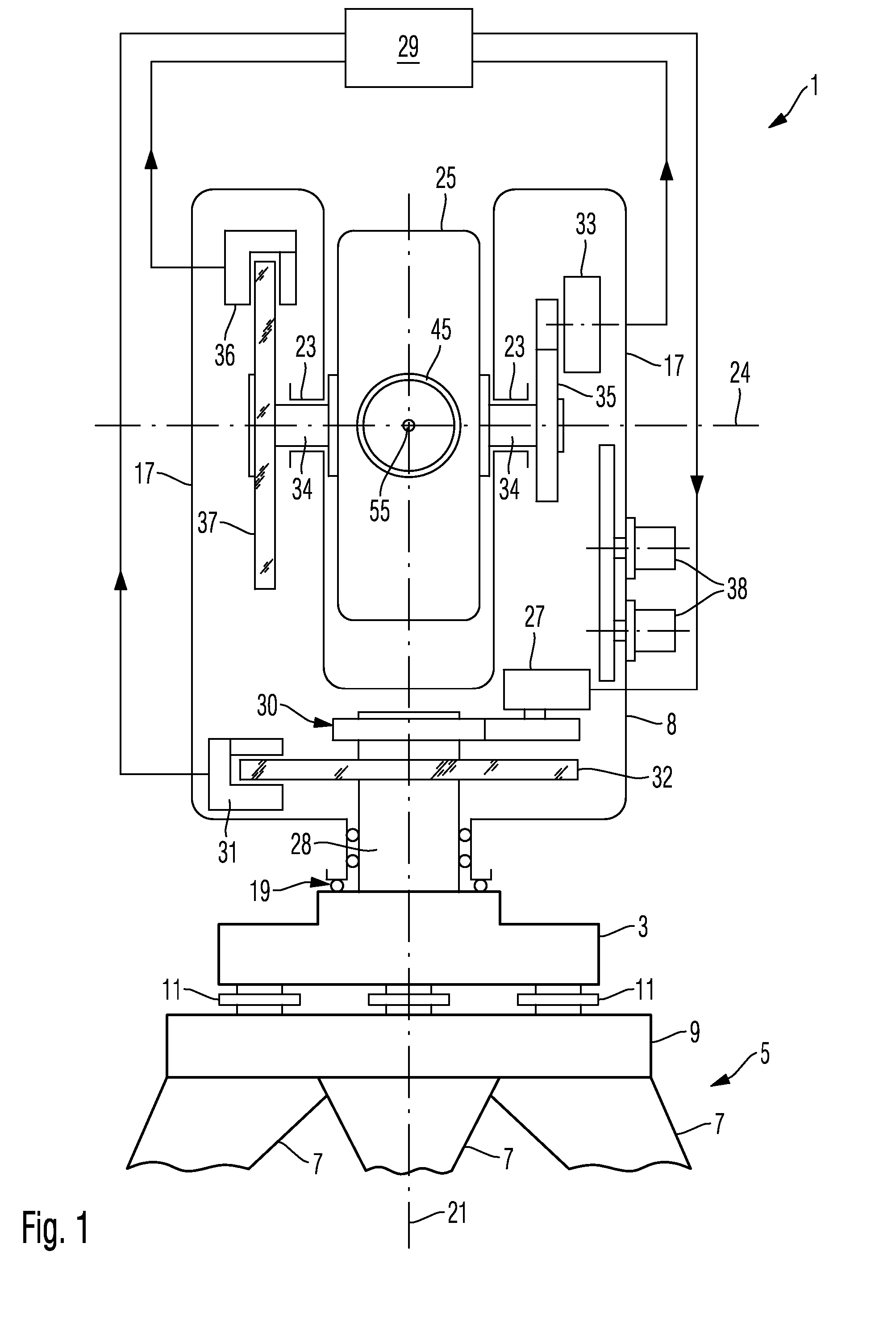

Surveying instrument and method of controlling a surveying instrument

ActiveUS7640068B2Photometry using reference valueOptical rangefindersMeasuring instrumentSurvey instrument

A surveying instrument performs tracking of a target by controlling an orientation of a measuring unit relative to the target in two different angular directions. The control in one angular direction is based on detected light intensities which are modulated according to a first time pattern, and control of the orientation in the other angular direction is based on detected light intensities modulated according to a second time pattern just different from the first time pattern.

Owner:TRIMBLE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com