Super thick copper PCB plate production method and its circuit board

A manufacturing method and PCB board technology, applied in chemical/electrolytic methods to remove conductive materials, printed circuits, printed circuit manufacturing, etc., can solve the problem of high cumulative thickness, limited batch production, and no processing technology for products with a thickness of over 400 UM, etc. problem, to achieve the effect of uniform copper coating on the line and meet the basic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Various preferred embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings.

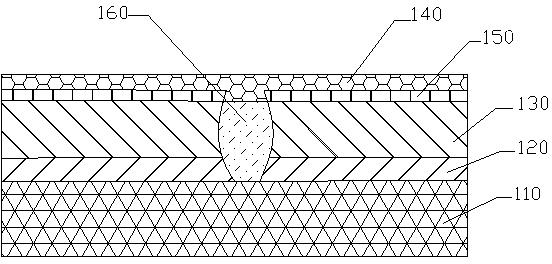

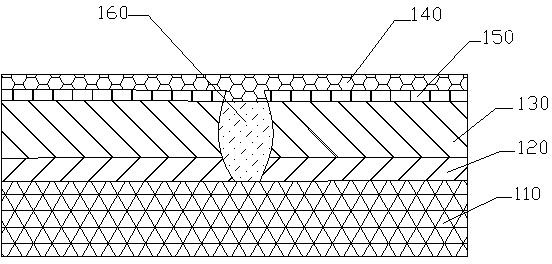

[0032] The ultra-thick copper PCB board manufacture method disclosed by the present invention and circuit board thereof, such as figure 1 As shown, it forms an ultra-thick PCB board. Specifically, on the substrate base material layer 110, the original copper clad layer is used as the bottom copper layer 120 with a thickness of 200um. Through continuous electroplating, it needs to be repeated many times. An electroplating thickening layer 130 is formed, and the thickness of the copper-clad circuit thereof exceeds 350 um, and is above 350-410 um. A circuit layer 150 and a green oil layer 140 are formed on the top of the circuit copper, and at the same time, epoxy resin 160 must be filled between the circuits to ensure the practical production process of the circuit board.

[0033] The basic process flow steps of the ultra-thick co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com