Chromizing coating modified by rare earth oxide and preparation method and application thereof

A technology of rare earth oxides and chromizing, which is applied in coatings, metal material coating processes, solid-state diffusion coatings, etc., can solve problems such as the difficulty of adding rare earth oxides to chromizing coatings, and achieve improved oxidation resistance, Improvement of anti-oxidation performance and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

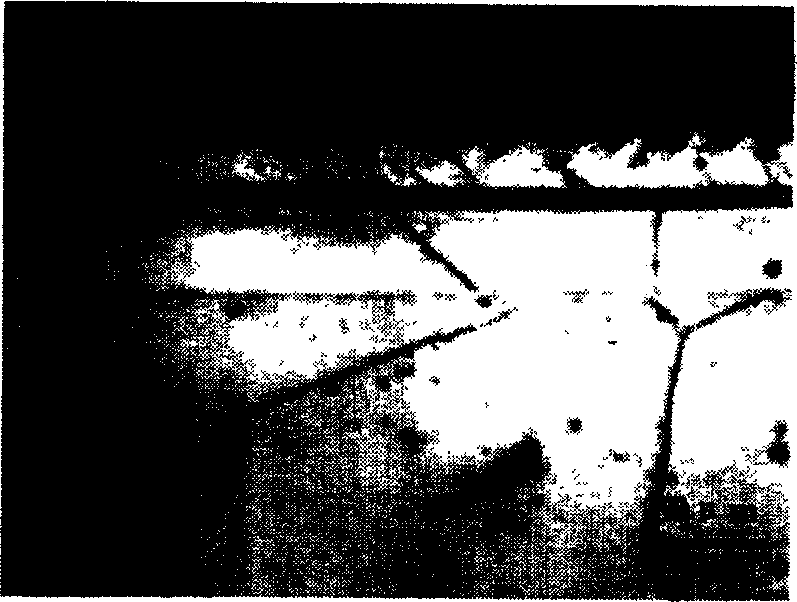

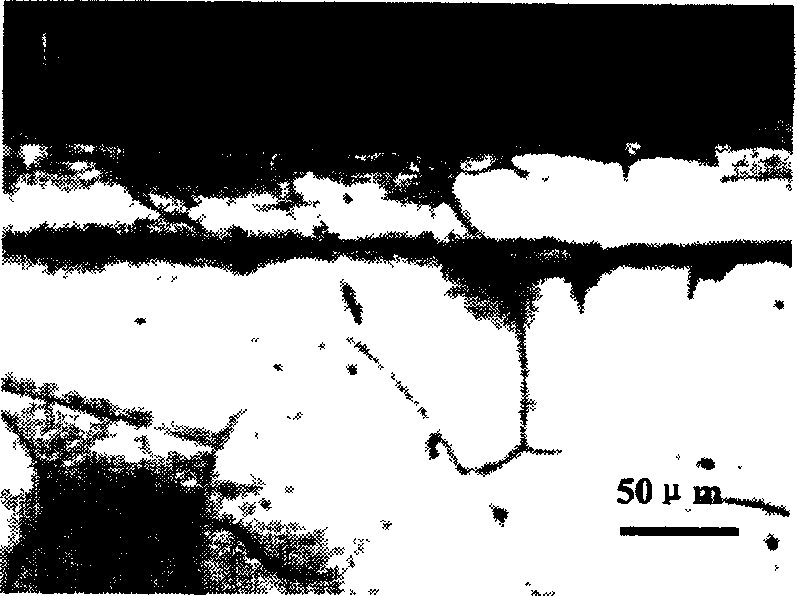

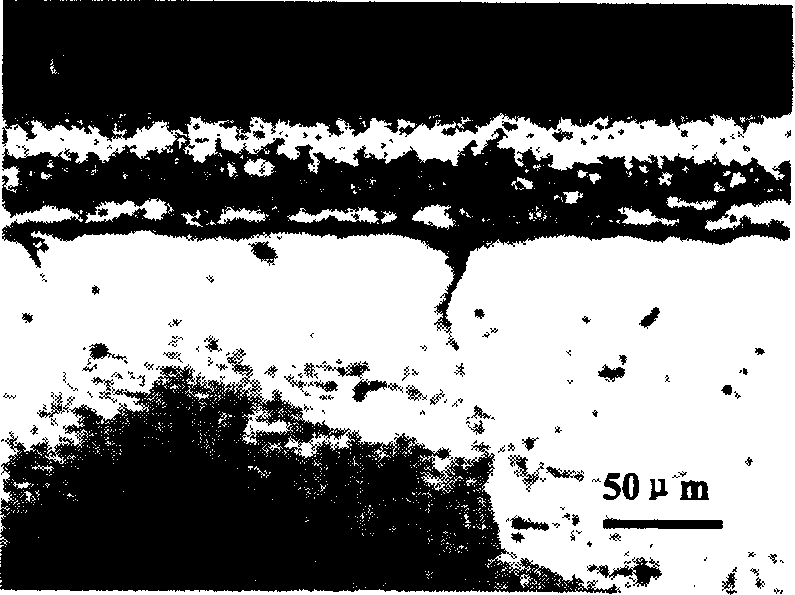

Image

Examples

Embodiment

[0044] In this embodiment, the first Ni-CeO on the low carbon steel 2 and Ni-Y 2 o 3 Preparation of CeO by Composite Electroplating and Diffusion Chromizing 2 and Y 2 o 3 Modified chromized coating as an example:

[0045] The composition of the chromized coating modified by rare earth oxides: the chromium content of the surface layer is 35-55 parts, and its composition is in a gradually decreasing distribution state from the surface to the inside. Oxide CeO 2 or Y 2 o 3 It is 1-4 parts, and the balance is M (Ni in Ni, Fe or Co), which comes from the composite coating;

[0046] The preparation method is as follows: the M-rare earth oxide composite coating is prepared by conventional composite electroplating technology. M is Ni, Fe or Co, and generally selects the same element as the main component of the matrix material. The matrix material is Fe, Ni, Co, carbon steel, alloy steel with poor oxidation resistance, commonly used sulfate system (MSO 4 ) plating solution....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com