Patents

Literature

46results about How to "No flaking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

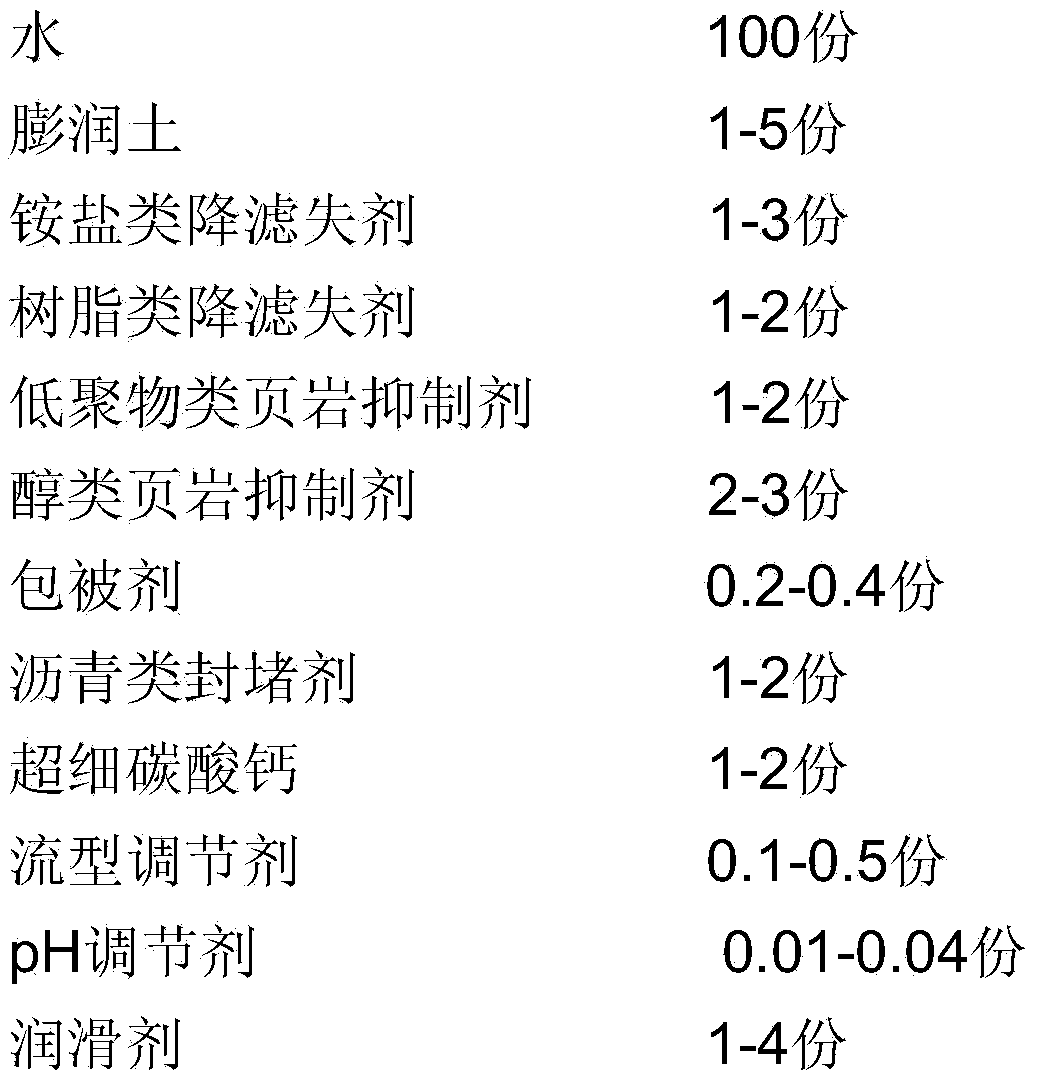

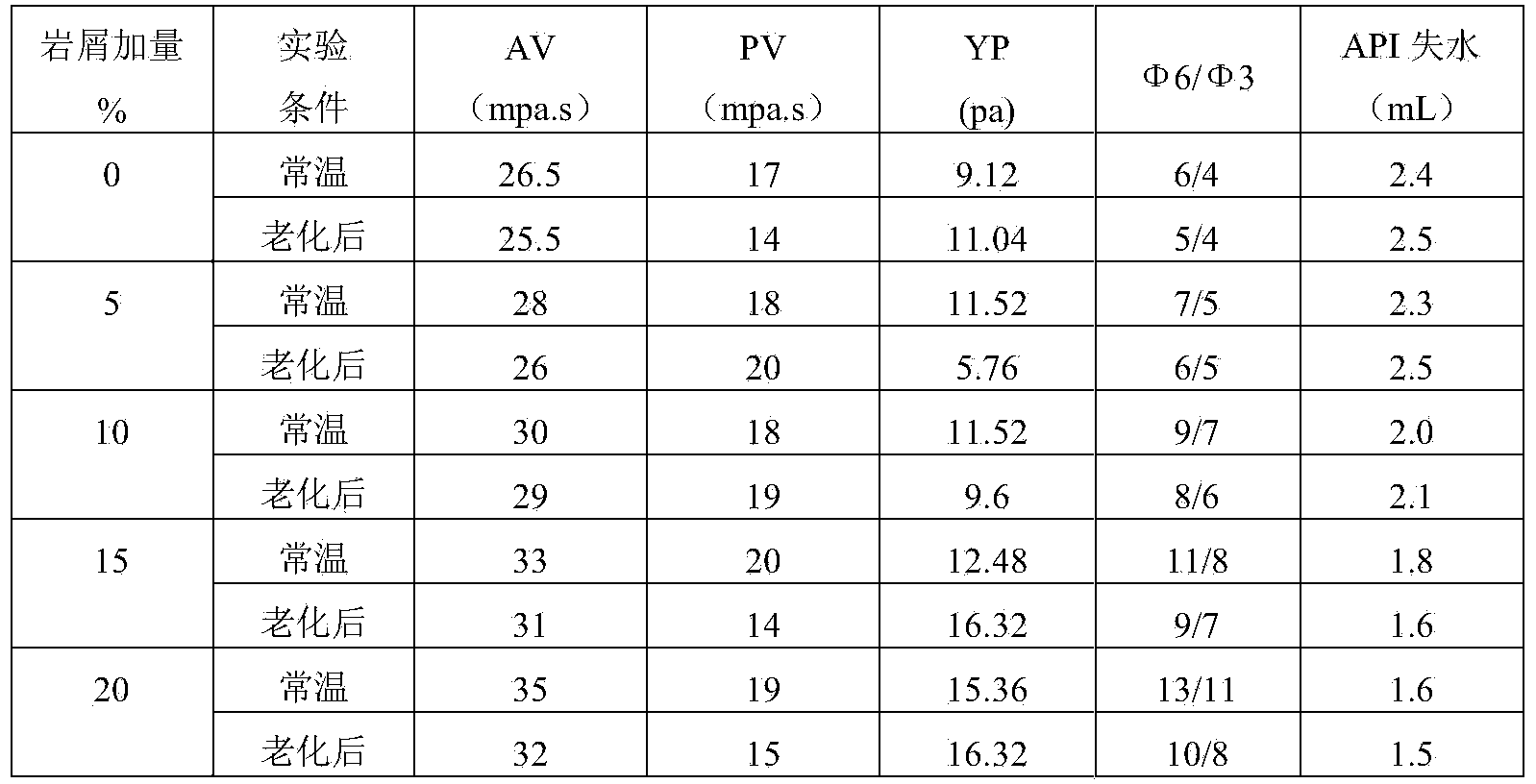

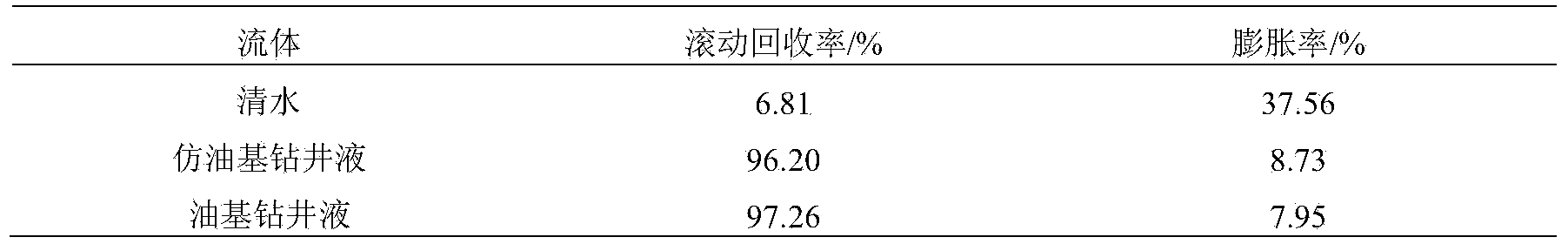

Oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity

InactiveCN104388065AEnhanced inhibitory effectStrong blockingDrilling compositionWater basedUltra fine

The present invention relates to an oil-base imitating drilling fluid with characteristics of strong inhibition, strong blocking and high lubricity. In the prior art, the existing amine compound-containing water-base drilling fluid provides the weak blocking capability for the mud shale micro-crack, and the lubricity can not completely meet the construction requirement. With the oil-base imitating drilling fluid of the present invention, the problems in the prior art are mainly solved. The oil-base imitating drilling fluid comprises, by weight, 100 parts of water, 1-5 parts of bentonite, 1-3 parts of an ammonium salt filtrate reducer, 1-2 parts of a resin filtrate reducer, 1-2 parts of an oligomer shale inhibitor, 2-3 parts of an alcohol shale inhibitor, 0.2-0.4 part of a coating agent, 1-2 parts of an asphalt blocking agent, 1-2 parts of ultra-fine calcium carbonate, 0.1-0.5 part of a flow type adjusting agent, 0.01-0.04 part of a pH value adjusting agent, and 1-4 parts of a lubricant. According to the present invention, the oil-base imitating drilling fluid of the present invention is the water-base drilling fluid having the performance equivalent to the oil-base drilling fluid, the safe, rapid and efficient drilling construction in the mud shale stratum and the unconventional dense oil reservoir is ensured, and the new technical support is provided for the effective development of the oil and gas reservoir.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

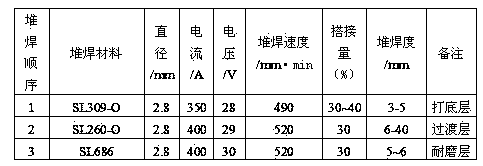

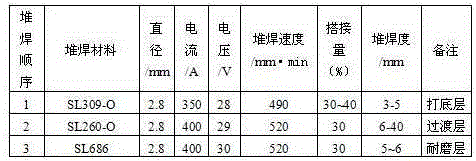

Novel full-automatic online cold welding repairing process for roll squeezers

ActiveCN103481010AReduce workloadSimplify your workflowArc welding apparatusWelding/cutting media/materialsPre treatmentEngineering

The invention discloses a novel full-automatic online cold welding repairing process for roll squeezers. The novel full-automatic online cold welding repairing process is characterized by comprising steps of (1), pre-treating roll surfaces of cement squeeze rolls to remove fatigue layers, welding check rings at two ends of each roll surface and enabling the corresponding check rings and each roll surface to be located on the same curved surface; (2), checking the roll surfaces to determine whether cracks are formed on the roll surfaces or not, grinding crack positions of the roll surfaces to remove the cracks, and performing repair welding on pits until the pits are filled; (3), performing buildup welding on the roll surfaces by means of automatic open arc welding; (4), removing the check rings and grinding and leveling the roll surfaces. The novel full-automatic online cold welding repairing process has the advantages that the buildup welding repairing quality can be guaranteed, the rolls of the roll squeezers do not need to be detached, stress relieving measures such as heating and heat insulation are omitted in buildup welding procedures, accordingly, working procedures can be greatly simplified, the construction cost can be greatly reduced, and energy can be saved.

Owner:柳州市三龙耐磨焊接科技有限公司

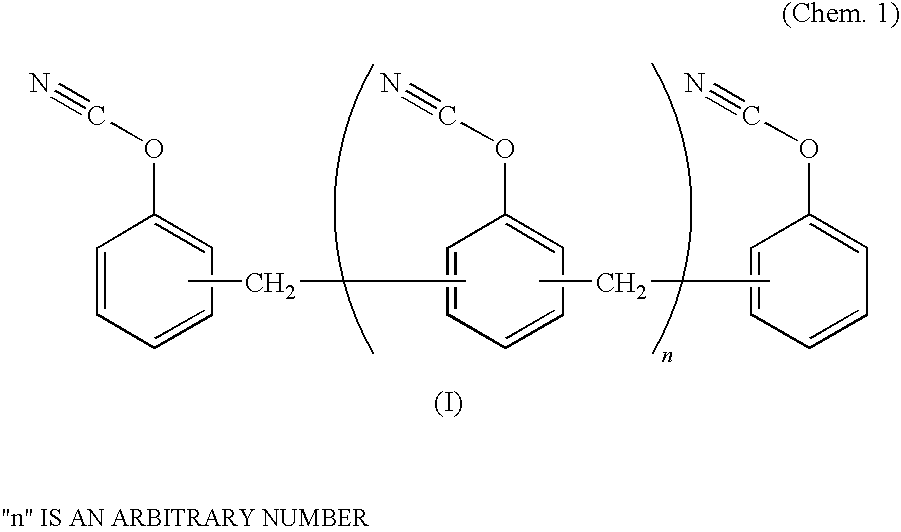

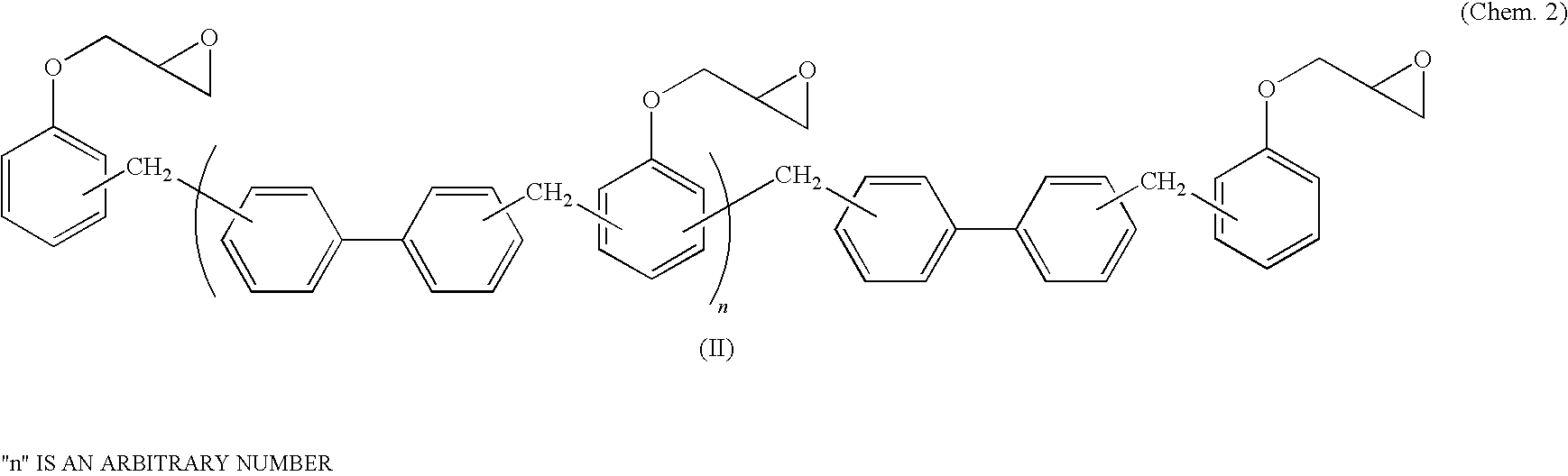

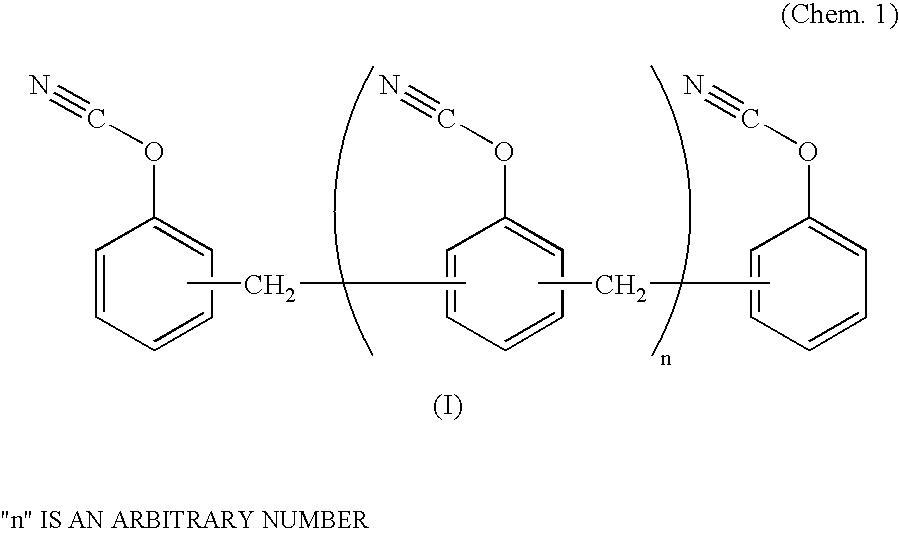

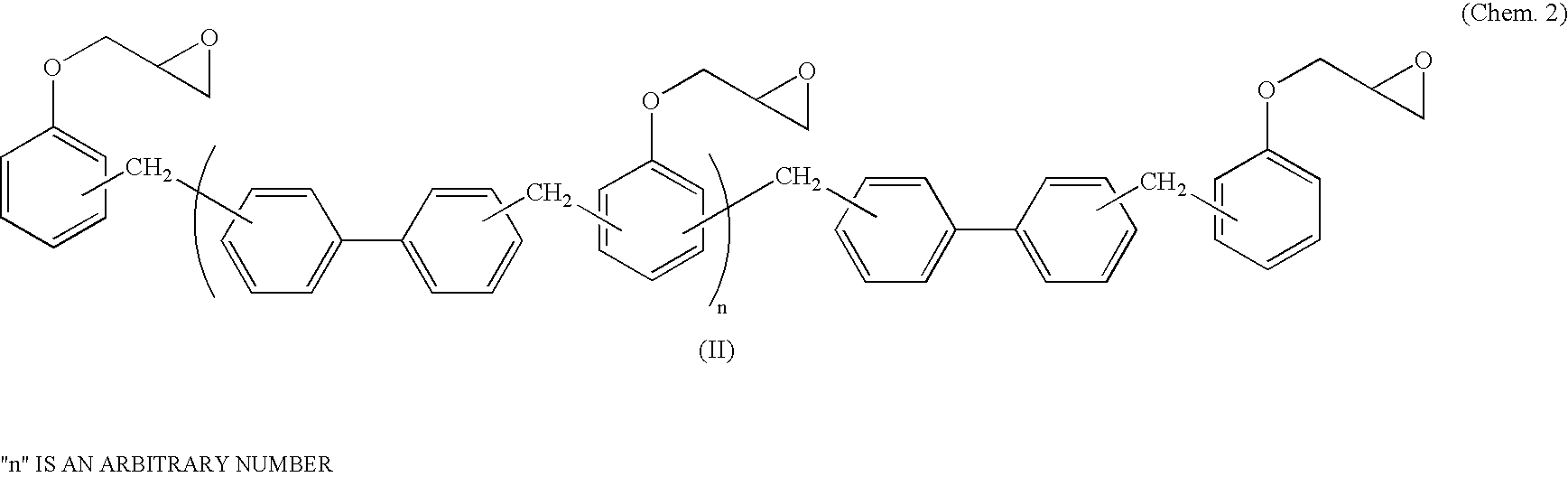

Resin composition, resin-attached metal foil, base material-attached insulating sheet and multiple-layered printed wiring board

InactiveUS7655871B2Improve heat resistanceLow thermal expansionSynthetic resin layered productsPrinted circuit aspectsMetal foilEngineering

A multiple-layered printed wiring board is manufactured, which exhibits higher thermal resistance and lower thermal expansion so that no flaking and / or no crack would be occurred in a thermal shock test such as a cooling-heating cycle test and the like, in addition to exhibiting a fire retardancy. The resin composition is capable of being employed for forming a resin layer of a resin-attached metal foil or an insulating sheet of a base material-attached insulating sheet, and includes: a cyanate resin and / or a prepolymer thereof; an epoxy resin substantially containing no halogen atom; a phenoxy resin substantially containing no halogen atom; an imidazole compound; and an inorganic filler, and also directed to a resin-attached metal foil formed by cladding a metal foil with such resin composition, a base material-attached insulating sheet formed by cladding an insulating base material therewith, and a multiple-layered printed wiring board, formed by laying such resin-attached metal foil(s) or such base material-attached insulating sheet(s) on a single side or both sides of an internal layer circuit board, and hot pressure forming thereof.

Owner:SUMITOMO BAKELITE CO LTD

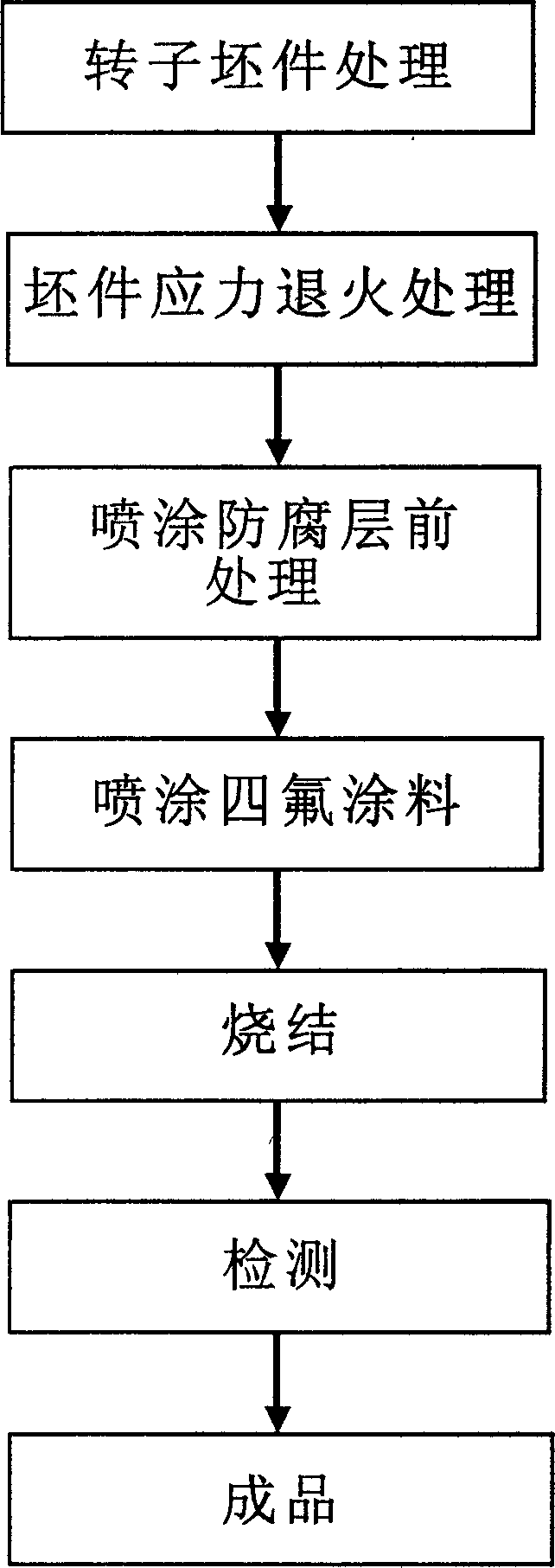

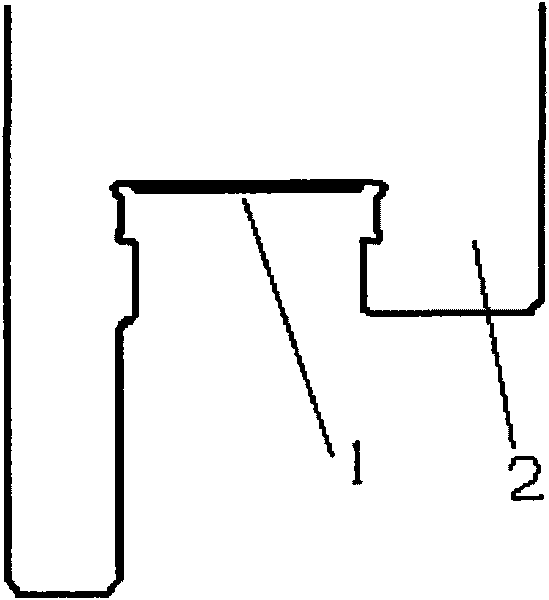

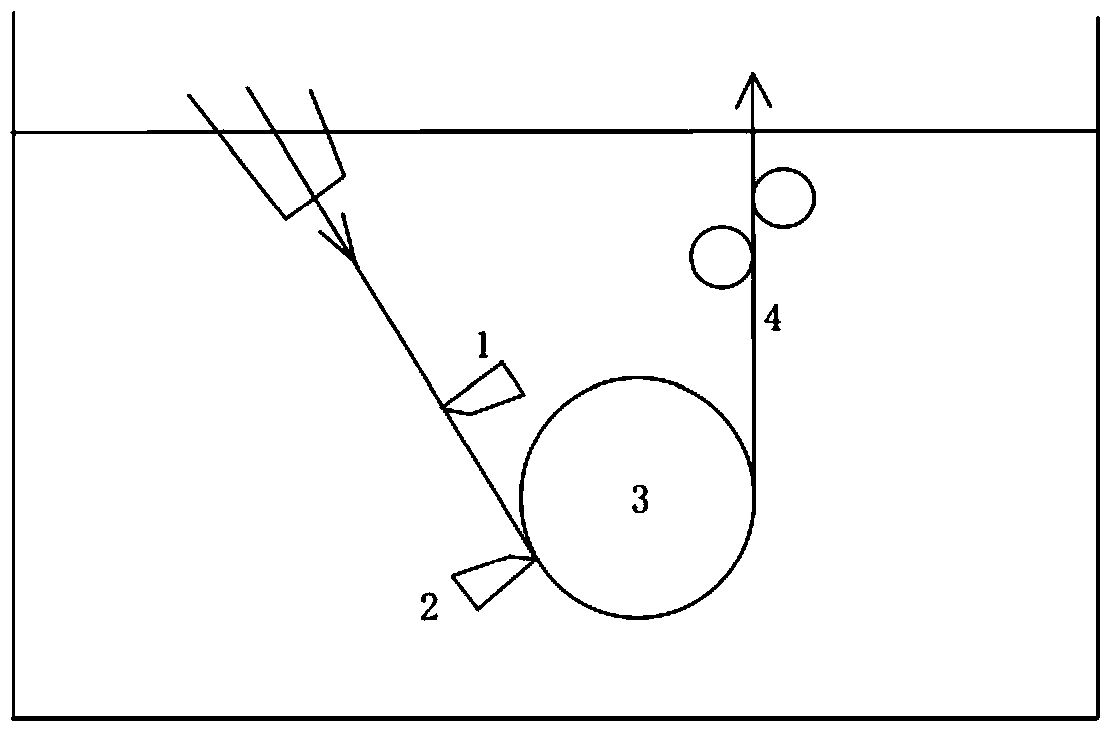

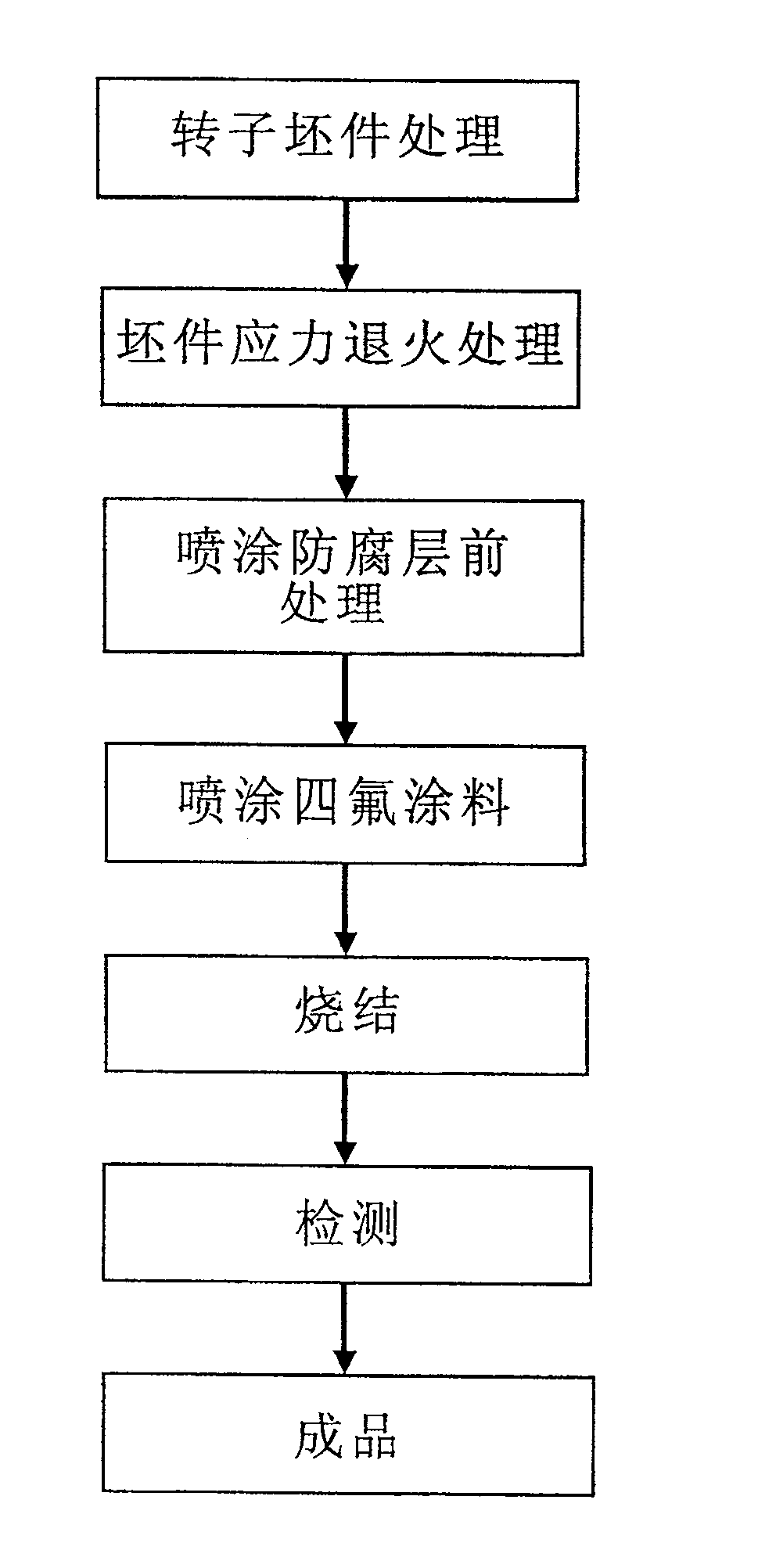

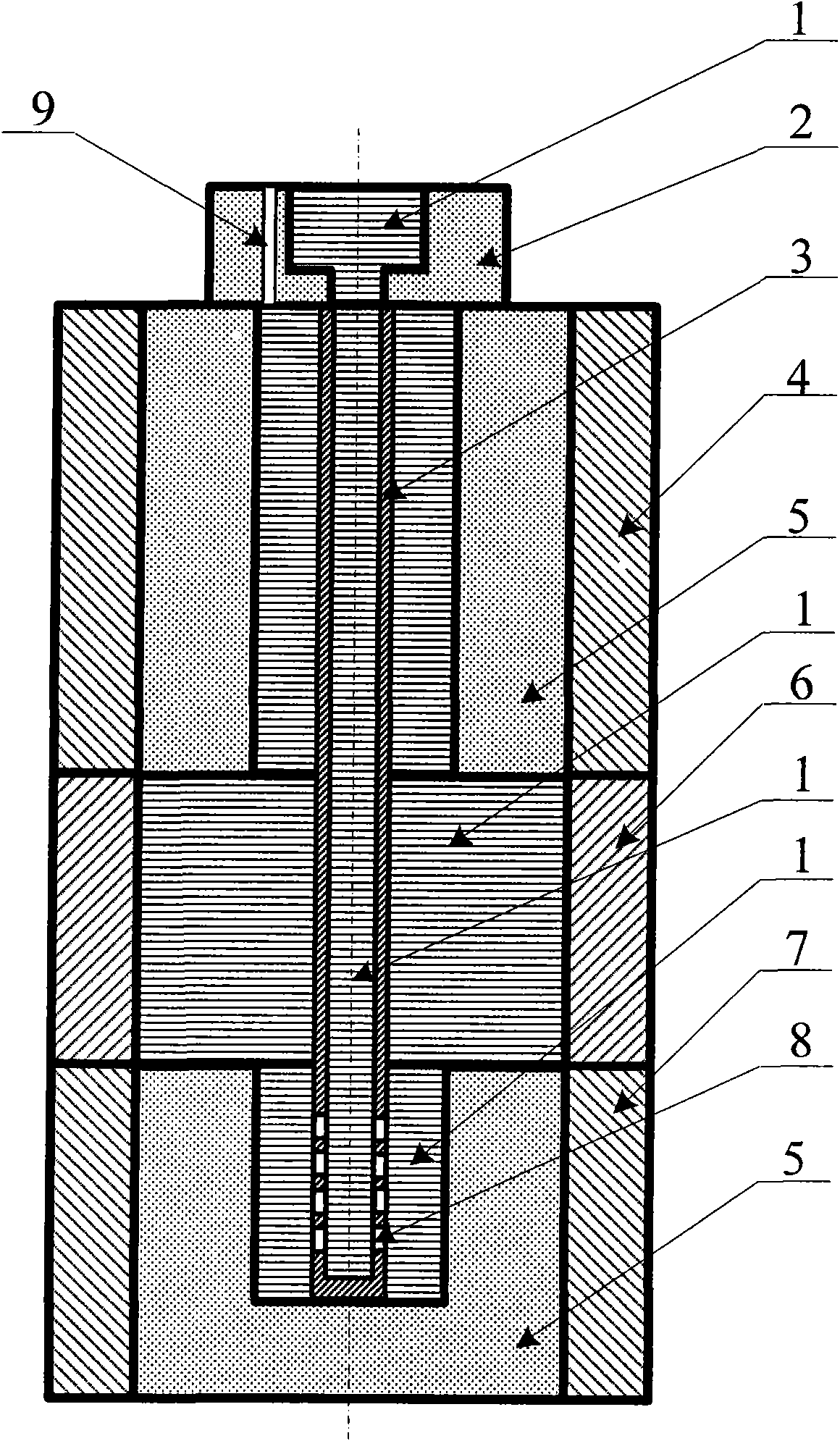

Tech. for spraying corrosion resistant coating on dry screw compressor rotor

InactiveCN1786476AUniform thicknessImprove heat resistanceRotary piston pumpsRotary piston liquid enginesHeat resistanceStress relief

An anticorrosive coating spraying process for a dry-screw compressor rotor belongs to a technical field of mechanical spraying process, which includes the following steps: first, pretreating the rotor parent material and stress relief annealing heat treating the rotor blank; then pretreating the spray anticorrosive coating and spraying polytetrafluoroethylene coating and at last sintering treating and detecting to be the rotor finished products. The inventive coating thickness is uniform and its colour is black. When the dry-screw compressor is in a normal state, the service life of the coating can reach more than 24000 hours.

Owner:WUXI COMPRESSOR CO LTD

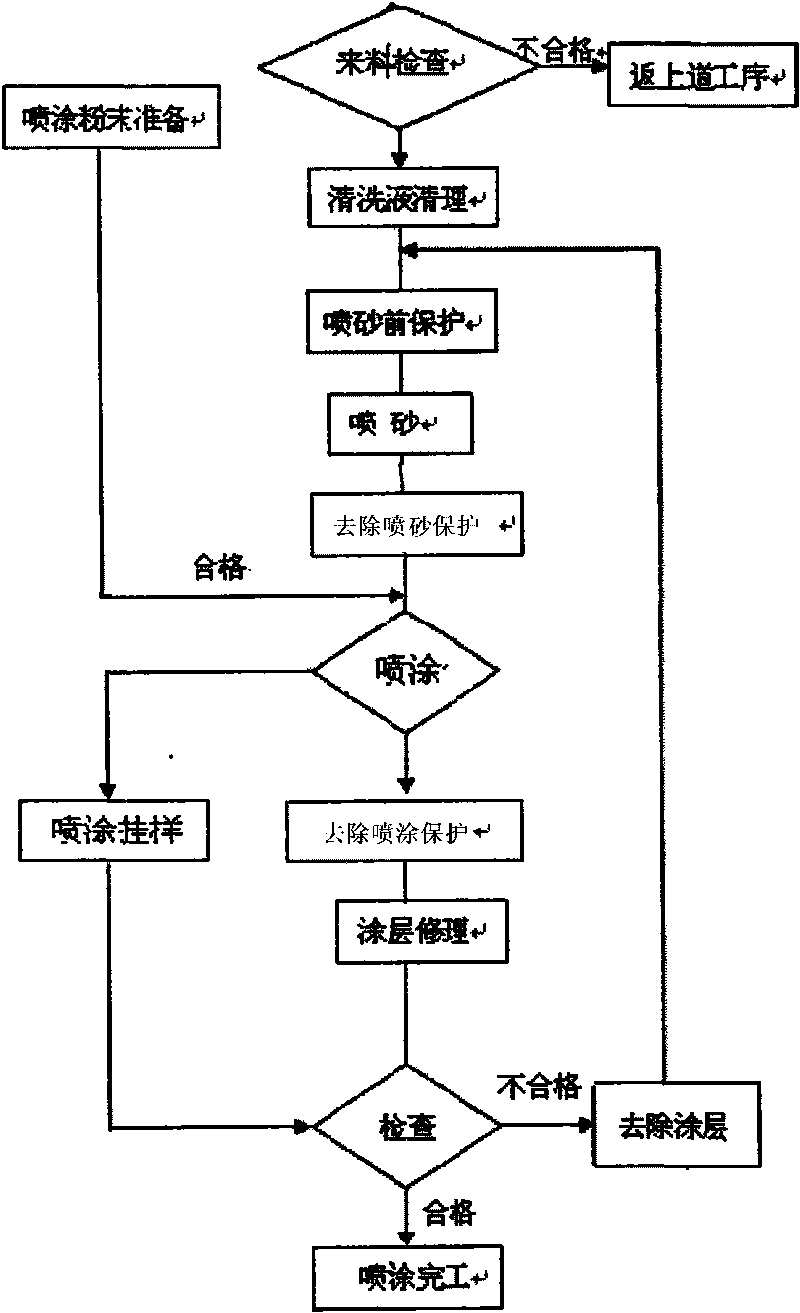

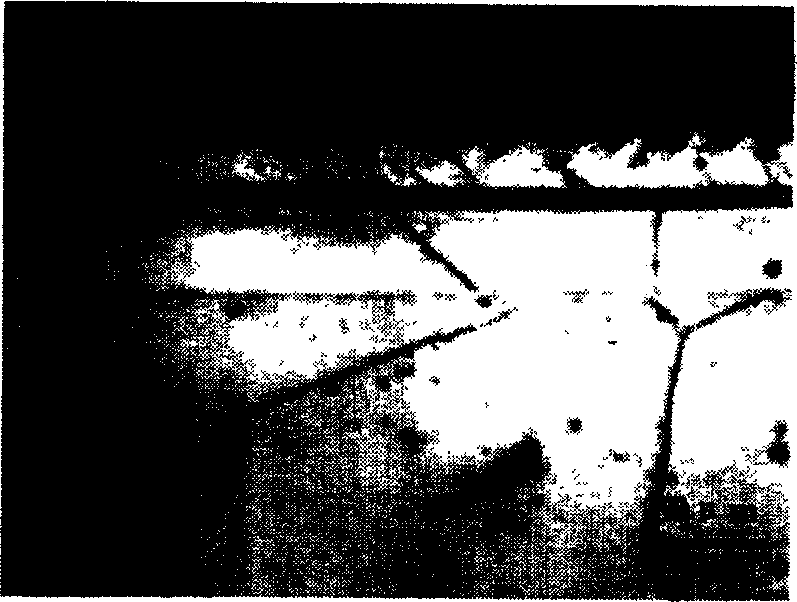

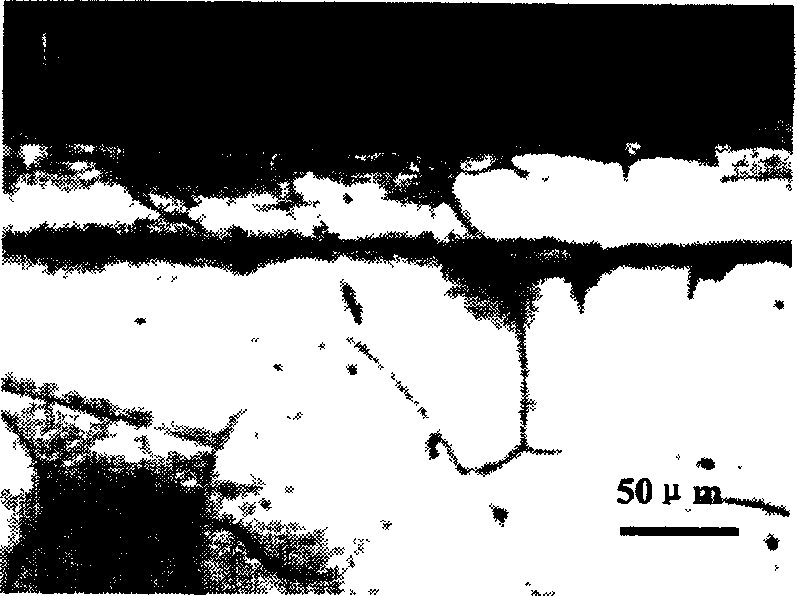

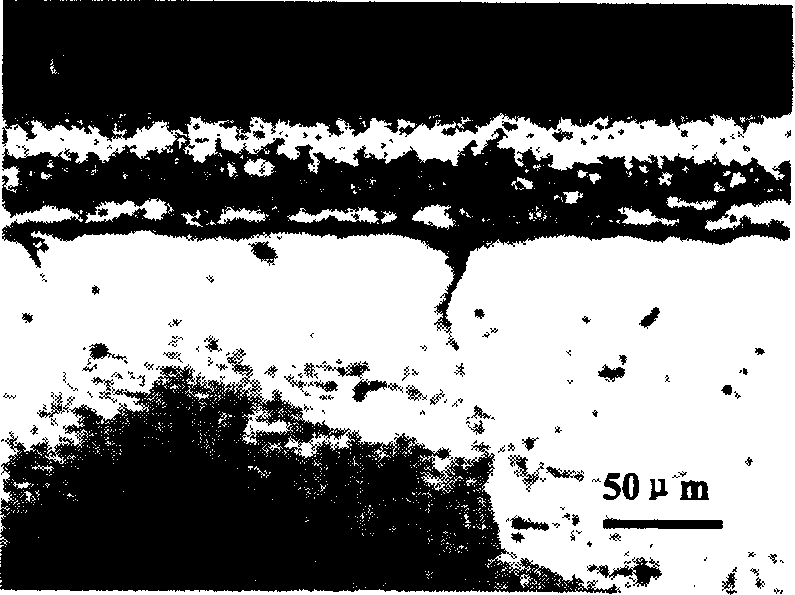

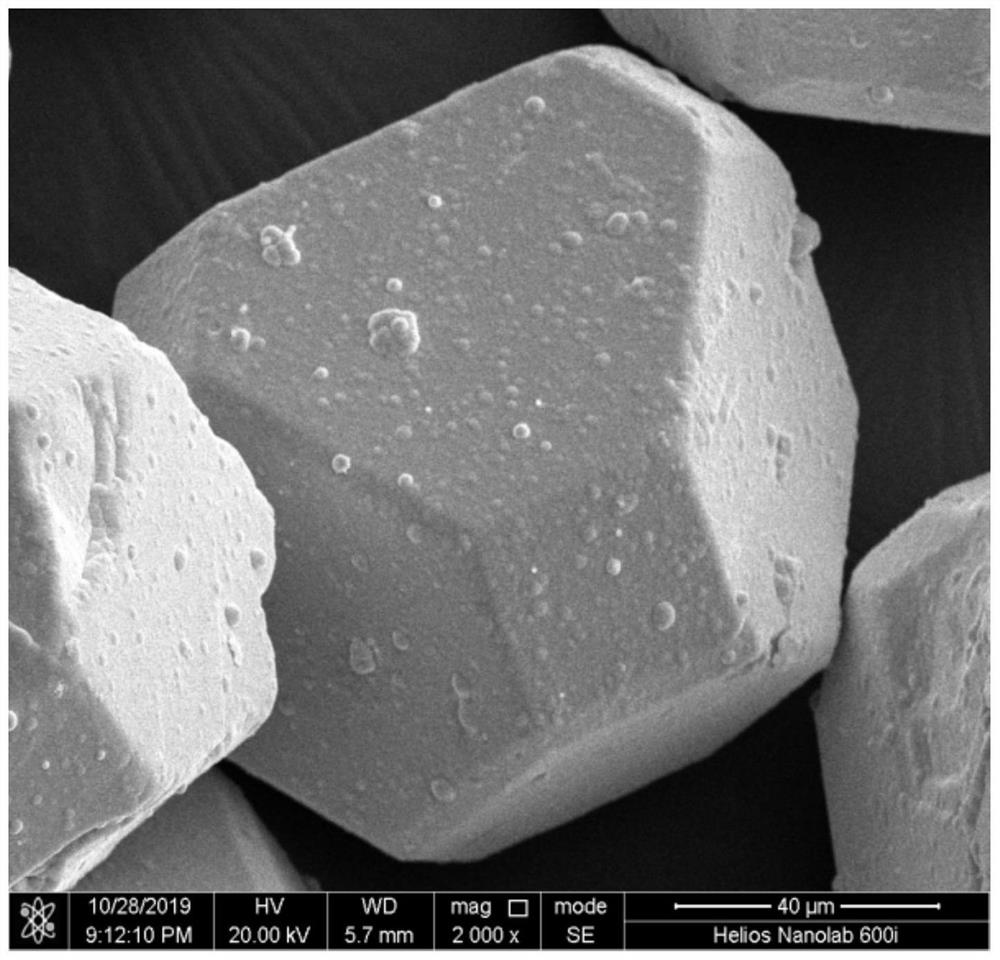

Metal composite ceramic thermal barrier coating preparation method

ActiveCN104775087AReduce porosityHigh bonding strengthMolten spray coatingComposite ceramicSuperalloy

The invention discloses a metal composite ceramic thermal barrier coating preparation method, belongs to the technical field of thermal spraying, and mainly aims to solve the problem of low structural strength and poor toughness of zirconia coating which is stabilized by yttrium oxide. The metal composite ceramic thermal barrier coating preparation method is mainly characterized in that: 1, cleaning high temperature alloy matrix surface, 2, sand-blasting roughening the cleaned high temperature alloy matrix surface, 3, spraying the sand-blasting roughened matrix surface with nickel chromium aluminum cobalt yttrium powder by plasma to use as a bottom layer, and 4, spraying the nickel chromium aluminum cobalt yttrium bottom layer with a plasma spraying material to obtain a metal composite ceramic thermal barrier coating, wherein the plasma spraying material comprises 25%-27% of Ni, 5-7% of Cr, 0.5%-2% of Al and 64%-66% ofZrO2.Y2O3. The metal composite ceramic thermal barrier coating prepared by the method has the characteristics of being high in combination strength, good in toughness, and capability of working in hot and cold alternating environment of 950 DEG C to room temperature for 1500h, and the method is mainly used for the preparation of metal composite ceramic thermal barrier coatings with good toughness and high strength of combination with the matrix.

Owner:襄阳航泰动力机器厂

High tenacious polypropylene material for manufacturing central conditioner air-discharge hose and its preparation method

The invention discloses a high-flexibility polypropylene material and making method, which comprises the following steps: allocating raw material with 100g PP resin, 10-30g POE elastic bulk, 10-30g flexibilizer, 0.1-1. 0g microfine talcum powder, 0.1-0.5g anti-oxidant and 0.1-0.5 lubricant; blending raw material in the high-speed mixer for 3-5min; placing mixed raw material in the double-screw squeezer; fusing; graining; obtaining the product.

Owner:SHENZHEN KEJU NEW MATERIAL

Hot-corrosion-resistant enamel coating and preparation method thereof

The invention belongs to the technical field of enamel materials and particularly relates to a hot-corrosion-resistant enamel coating and a preparation method thereof. For solving the problems that anenamel coating in the prior art is liable to strip off and is poor in heat resistance at high temperature, the invention provides the hot-corrosion-resistant enamel coating and the preparation methodthereof, wherein the method includes steps of: firing the surface of a metal base body to form a enamel base glaze layer, then spray-coating the surface of the enamel base glaze layer with enamel surface glaze slurry; drying the coating at 130-150 DEG C and enameling the coating at 900-950 DEG C for 12-15 min to form the hot-corrosion-resistant enamel coating belonging to the series of inert oxides. The coating has good fullness and very low oxygen migration rate, excellent thermal stability and anti-oxidizing performance, and is good in anti-acid / alkali and anti-corrosion performances.

Owner:PANZHIHUA UNIV

Wear-resistance layers on surfaces of inner ring and outer ring of bypass variable mechanism of gas turbine and preparation method thereof

ActiveCN101705842AHigh hardnessReduce coefficient of frictionMolten spray coatingMachines/enginesCorrosionAluminium

The invention discloses wear-resistance layers on the surfaces of an inner ring and an outer ring of a bypass variable mechanism of a gas turbine and a preparation method thereof. The wear-resistance layers are positioned on the inner bottom surface of the outer ring and the outer top surface and the lateral surfaces of the inner ring; and the wear-resistance layers are molybdenum coatings and are made by an air plasma spraying method. The molybdenum coatings have high hardness, low friction coefficient and uniformly distributed ports and can store oil, improve the corrosion resistance and wear resistance of the inner ring and the outer ring of the bypass mechanism, prolong the service life of workpieces and reduce cost. The preparation method of the invention adopts the air plasma spraying process, solves the problems of difficult molybdenum melting, easy coating oxidization and low spraying efficiency and successfully applies aluminum densified coatings to the bypass mechanism of the gas turbine. At the same time, the spraying method has the advantages that: the temperature of the workpieces is below 150 DEG C in a spraying process; no post-treatment is required after spraying; and the workpieces do not deform.

Owner:DONGFANG TURBINE CO LTD

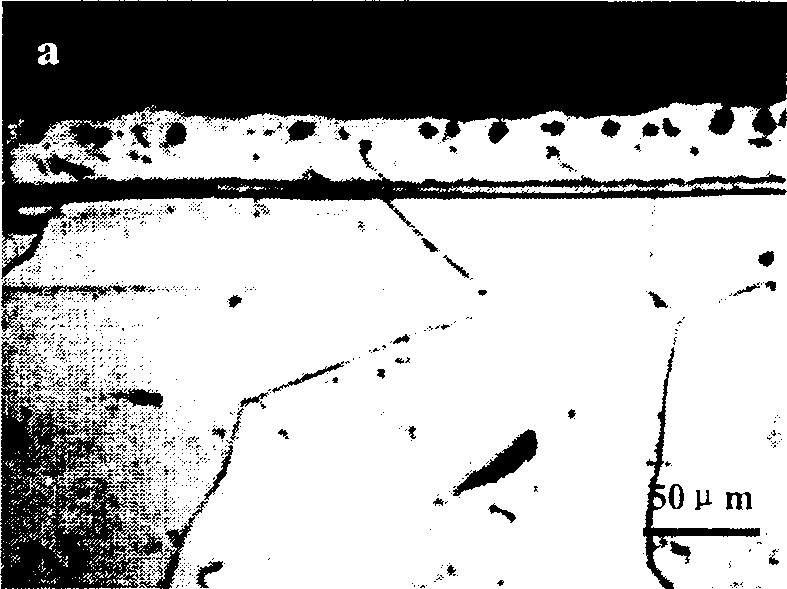

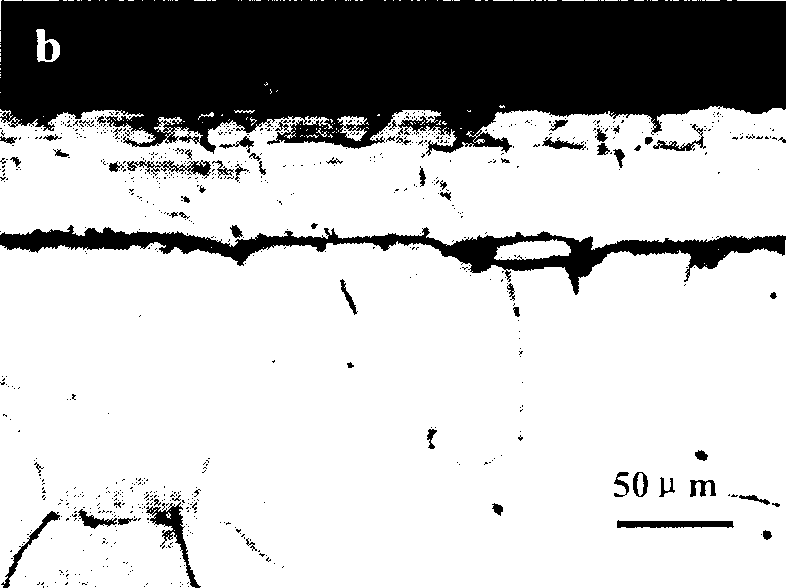

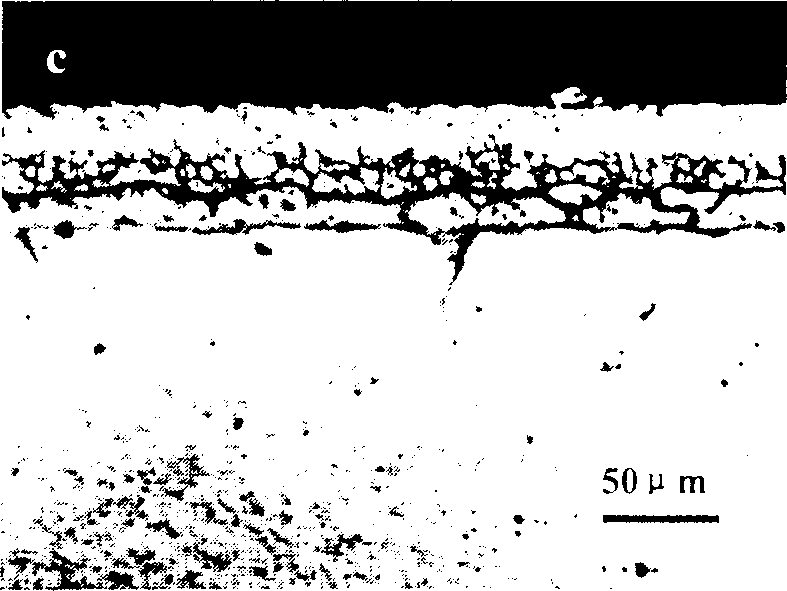

Chromizing coating modified by rare earth oxide and preparation method and application thereof

The invention discloses a rare-earth oxide modified chromizing coating and its preparation method and uses. Modified chromizing coating constituent is made up of infiltrated chrome, composite deposit metal M and minim rare-earth oxide rare-earth oxide Re#-[x]O#-[y]is Re=Ce, Y, La etc. According to mass percent, chrome content of chromizing coating surface layer is 35-55 portion, and others are M and minim rare-earth oxide, in which M coming from M-Re#-[x]O#-[y] composite deposit. The process is as follows: using metal Ni, Fe , Co, carbon steel or low-alloy steel as base material, making M-Re#-[x]O#-[y] composite deposit on base material using composite electric plating method, diffusing for chromizing, getting rare-earth oxide modified chromizing coating. The invention has a simple and mature process. and coating can physically grow protective compact Cr#-[2]O#-[3]oxidation film under high temperature, which is intensively adhesive to coating base body. Coating have good oxidation and corrosion resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Photocurable top-sticky paint

The invention is a kind of solid lacker stained withpeak,which buildup is single and made up of epoxy acrylic resin as ac oligomerization, third-hydroxymethyl-propane, and third-acryate as ac releasing agent, NO.3136 alkide resin, photosensitizer and so on. The lacker has many strongpoints, for example, high curing speed, good effect, chubby coping, high ashesion and no desquamating, because the compounding formula is advisability, especially mixed with photochromic. stainded with the top of vimineous material like pencils, the lacker will change into solid under the black light within 20 seconds and be free from the dampness, so, the drying time is shorter and surface quality and the production efficiency of the pencils will be improved. The NO.3136 alkide resin can improves the binding energy between the lacker and the coating substance, in this way, the cost will be lower.

Owner:CHINA FIRST PENCIL CO LTD

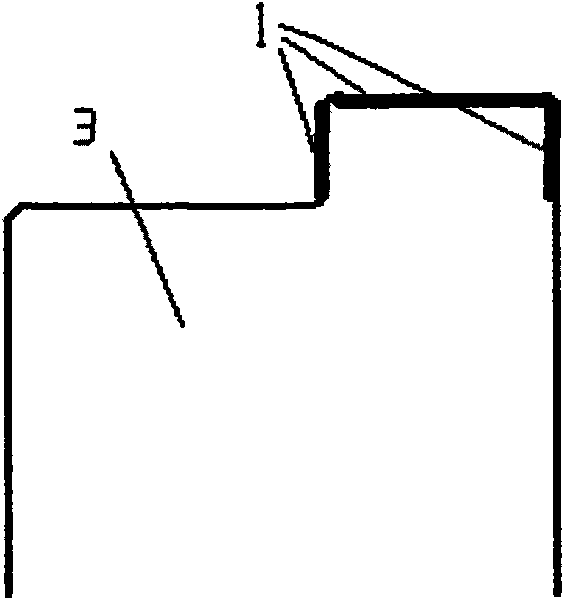

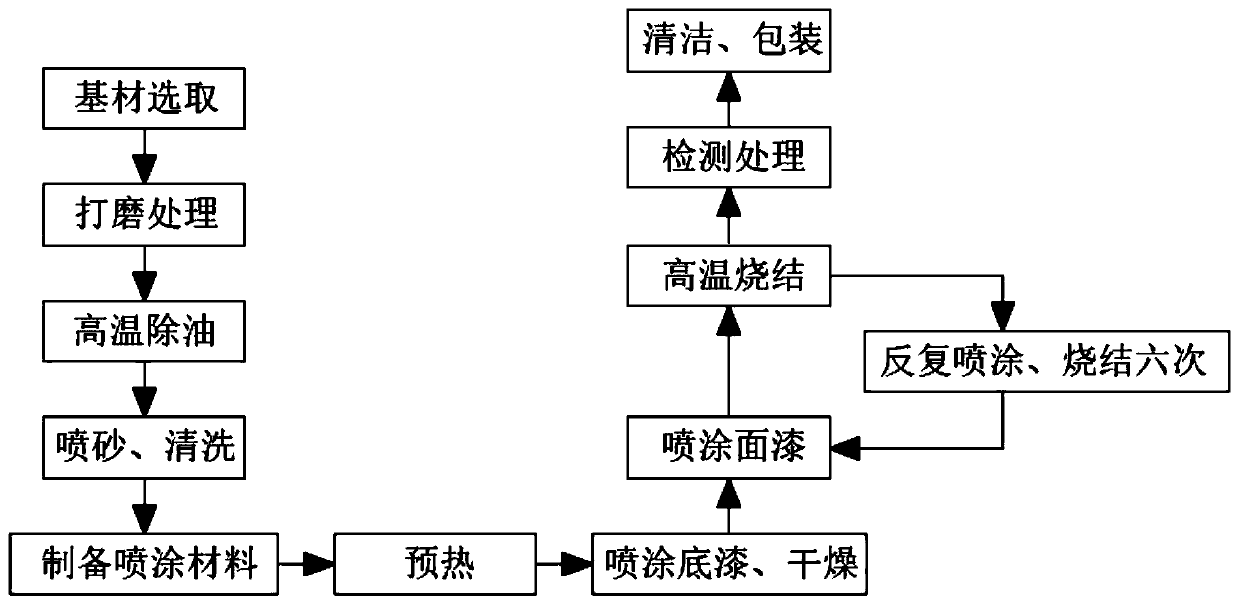

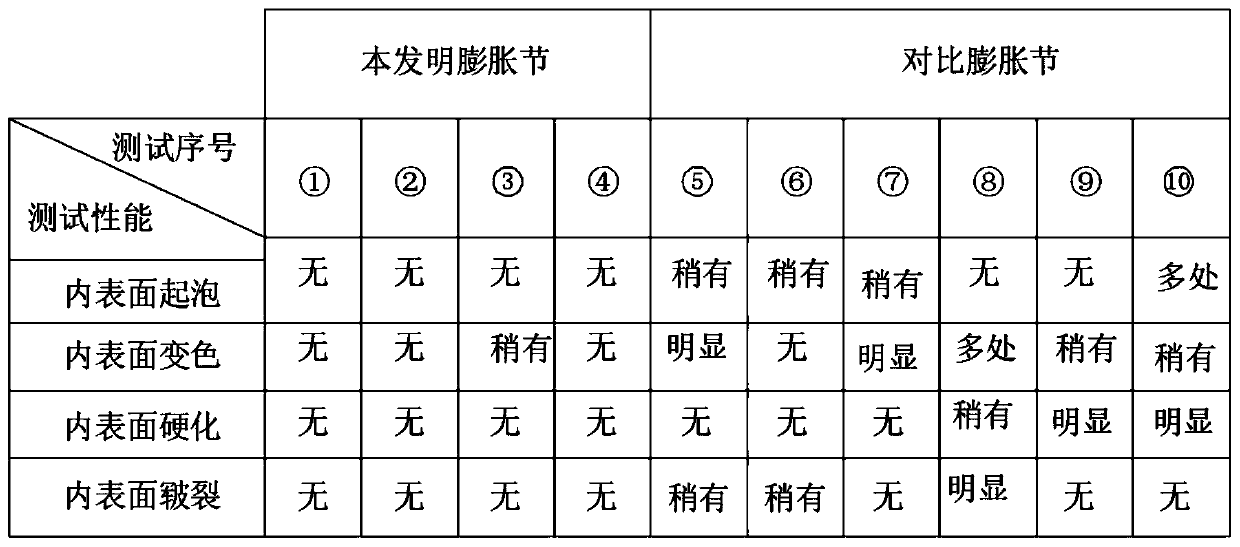

Metal expansion joint inner surface FEP electrostatic powder spraying process

InactiveCN110280469AImprove the superior characteristicsExtended service lifePretreated surfacesCoatingsMaterials preparationSand blasting

The invention discloses a metal expansion joint inner surface FEP electrostatic powder spraying process in the technical field of spraying processes. The process comprises the steps of (S1) substrate selection, (S2) polishing, (S3) high-temperature oil removal, (S4) sand blasting and cleaning, (S5) spraying material preparation, (S6) preheating, (S7) primer spraying and drying, (S8) finish coat spraying, (S9) high-temperature sintering, (S10) repeated spraying and sintering, (S11) detection and treatment and (S12) cleaning and packing; Teflon paint of fluorine paint with polytetrafluoroethylene as basal body resins is adopted, so that the excellent characteristics of metal expansion joints are improved, the service life of the metal expansion joints is prolonged, the paint spraying operation is simple, and the paint spraying is uniform; through previous polishing, high-temperature oil removal, sand blasting and cleaning, impurities and dust on the inner surfaces of the metal expansion joints are effectively removed, so that the sand blasting roughness is improved; and through later finished product appearance detection, coating film thickness detection, electrospark detection and adhesion detection, the inner surfaces of the metal expansion joints thickly sprayed are detected by multiple times, so that the coating quality is improved.

Owner:江苏苏创管业科技有限公司

Preparation method of weather-resistance tile adhesion agent for exterior wall ceramic tiles

The invention discloses a preparation method for a weather-resistance tile adhesion agent for exterior wall ceramic tiles, and belongs to the technical field of tile adhesion agent preparation. The preparation method comprises the steps that a pressure treatment is conducted with saturated steam, so that acetic acid is formed by hydrolysis of ethanoyl contained in bagasse cellulose, under the condition of acid environment, the cellulose and hemicellulose in the materials are disintegrated, then the pressure is released rapidly, the cellulose is instantaneously swelled, broken and hydrolyzed, then is frozen with liquid nitrogen, and thus ice crystals are produced among the bagasse cellulose; the ice crystals are burst by ball milling, and thus bagasse cellulose whisker is formed; the bagasse cellulose whisker is mixed with nanosilicon dioxide for carbonization under nitrogen atmosphere, after the bagasse cellulose whisker is carbonized, silicon carbide whisker is grown on the surface of the bagasse cellulose whisker, and the modified bagasse whisker is prepared as a reinforcing agent, moreover, sticky rice is cooked and beaten into a pulp liquid as an adhesion agent; the reinforcing agent, the adhesion agent and portland cement are mixed and are subjected to ball milling, then the weather-resistance tile adhesion agent for the exterior wall ceramic tiles is prepared. The preparation method has the advantages that the prepared product has good weather resistance, and is free of cracks and tile spalling after use.

Owner:郭舒洋

Resin Composition, Resin-Attached Metal Foil, Base Material-Attached Insulating Sheet and Multiple-Layered Printed Wiring Board

InactiveUS20080254300A1Improve flame retardant performanceImprove heat resistancePrinted circuit aspectsSynthetic resin layered productsMetal foilThermal expansion

A multiple-layered printed wiring board is manufactured, which exhibits higher thermal resistance and lower thermal expansion so that no flaking and / or no crack would be occurred in a thermal shock test such as a cooling-heating cycle test and the like, in addition to exhibiting a fire retardancy. The present invention is directed to a resin composition, capable of being employed for forming a resin layer of a resin-attached metal foil or an insulating sheet of a base material-attached insulating sheet, and comprises: a cyanate resin and / or a prepolymer thereof; an epoxy resin substantially containing no halogen atom; a phenoxy resin substantially containing no halogen atom; an imidazole compound; and an inorganic filler, and also directed to a resin-attached metal foil formed by cladding a metal foil with such resin composition, a base material-attached insulating sheet formed by cladding an insulating base material therewith, and a multiple-layered printed wiring board, formed by laying such resin-attached metal foil(s) or such base material-attached insulating sheet(s) on a single side or both sides of an internal layer circuit board, and hot pressure forming thereof.

Owner:SUMITOMO BAKELITE CO LTD

Waterproof heat insulating decorative imitating ceramic composite board

InactiveCN1459537AConsistent colorSmooth appearanceBuilding insulationsWater-setting substance layered productHigh weightAdhesive

A water-proof insulating decorative ceramics-like composite plate is composed of base plate and decorative layer with water-proof and insulating functions. The said base plate is made of cement, fine sand, broken sand and water through mixing. The said decorative layer is made of white jade sand, white cement, high-weight ceramics-like additive powder and polyethylene adhesive through mixing. Its advantages are beautiful and smooth appearance, high weatherability and flexible strength, and better water-proofing and insulating performance.

Owner:湖南怀化永久轻建屋面科技开发有限公司

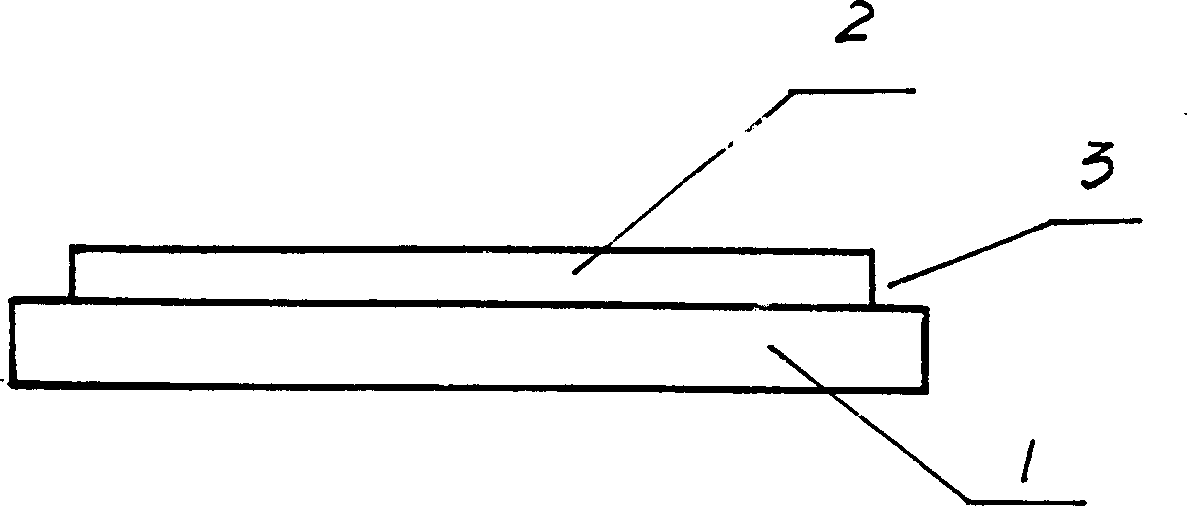

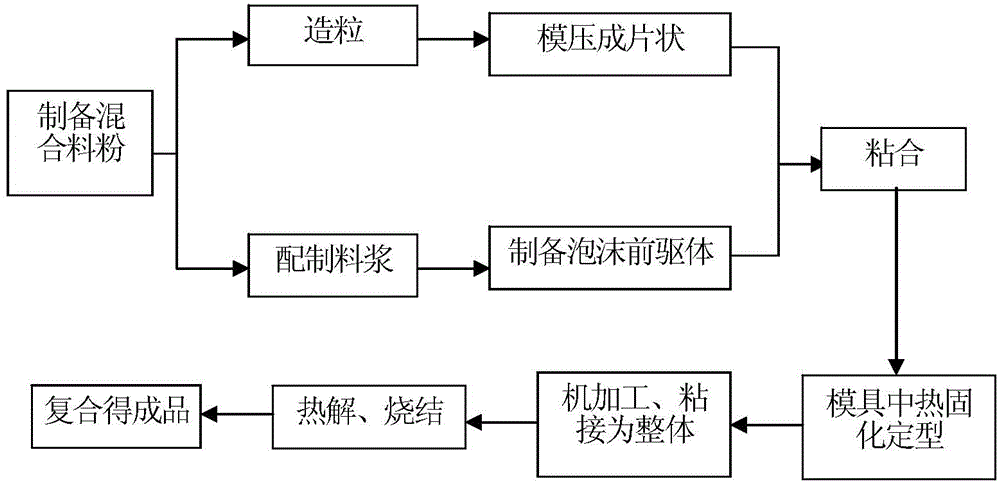

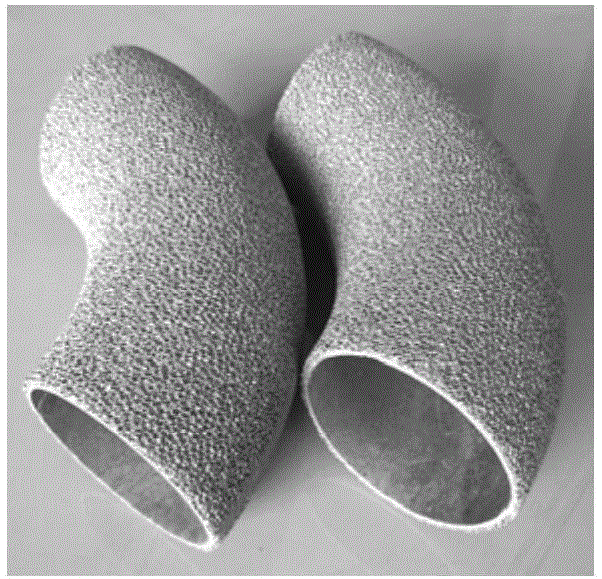

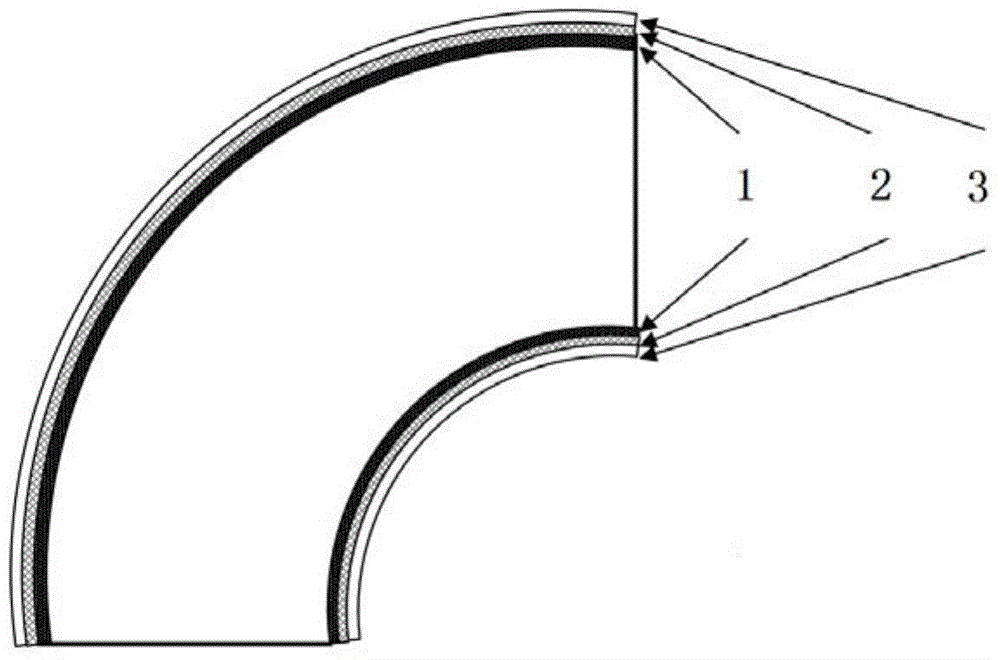

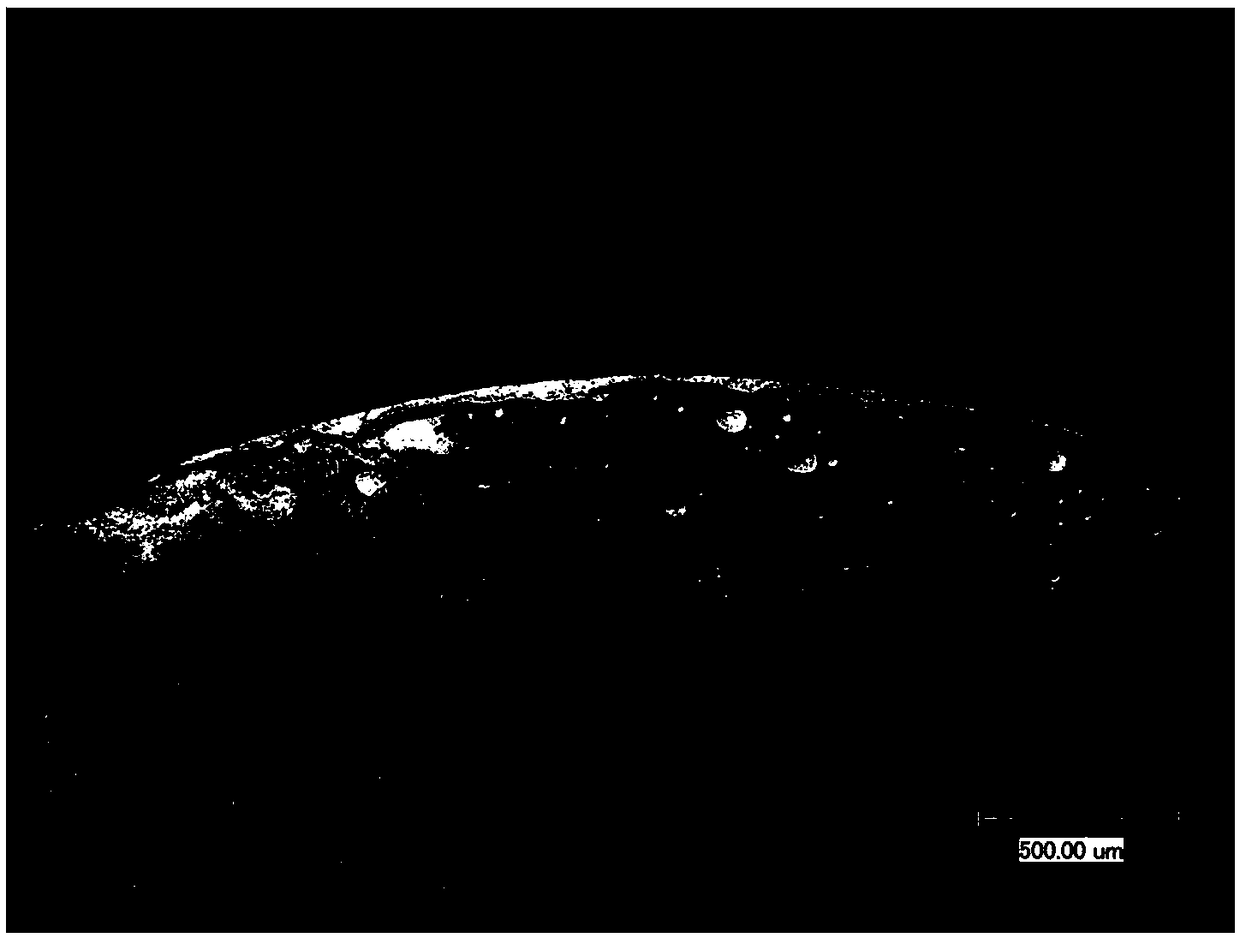

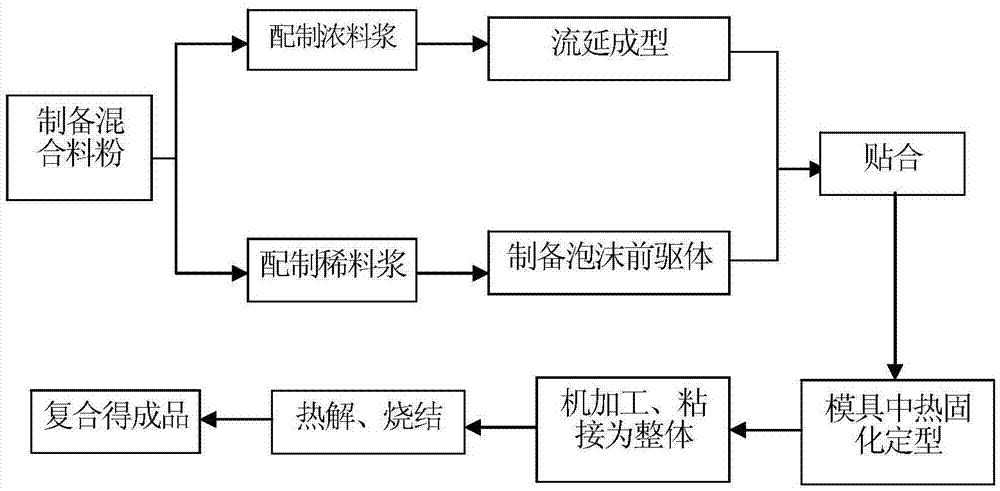

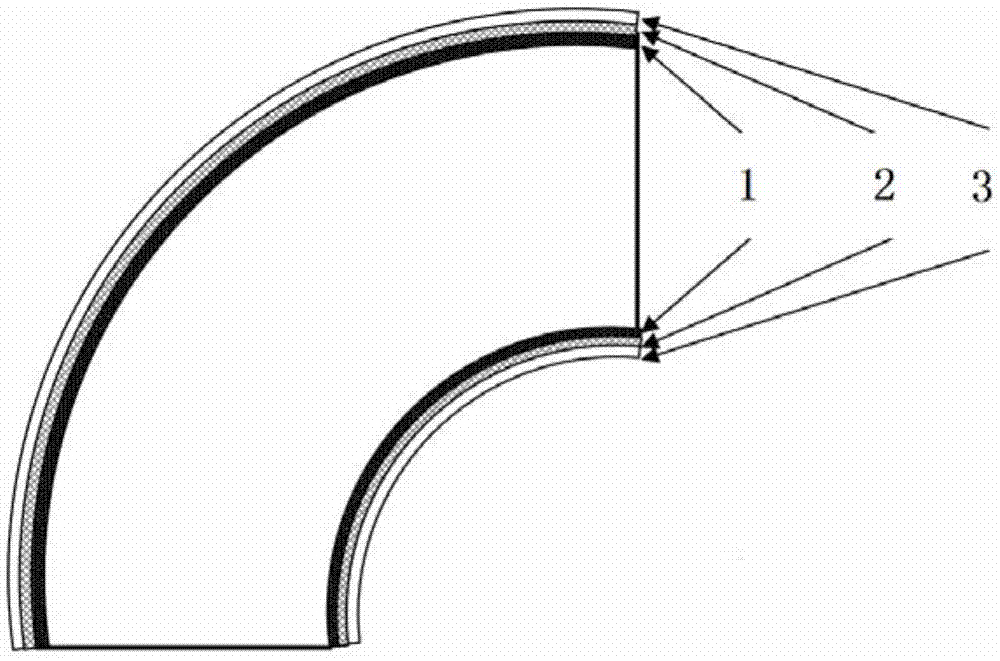

Abrasion-resistant and anticorrosion pipe or pipe fitting with double ceramic lining layers and preparation method of abrasion-resistant and anticorrosion pipe or pipe fitting

ActiveCN106321991AImprove wear resistanceImprove corrosion resistanceCorrosion preventionPipe protection against corrosion/incrustationParticulatesSurface layer

The invention relates to metal pipe or pipe fitting surface abrasion-resistant and anticorrosion protection technologies, in particular to an abrasion-resistant and anticorrosion pipe or pipe fitting with double ceramic lining layers and a preparation method of the abrasion-resistant and anticorrosion pipe or pipe fitting. The pipe or pipe fitting is composed of an abrasion-resistant and anticorrosion lining layer and a metal layer from inside to outside. The abrasion-resistant and anticorrosion lining layer is composed of a surface layer and a composite layer. The surface layer is a compact ceramic layer. The composite layer is a foamed ceramic layer. The composite layer is directly grown on the back face of the compact ceramic layer. The preparation process comprises the following steps of preparation of mixed powder, prilling and slurry preparing, sheet forming through mold pressing and preparation of a foam precursor, bonding, thermosetting forming in a mold, machining and bonding forming, pyrolyzing and sintering, and finished product obtaining through compositing. According to the ceramic lining layer abrasion-resistant and anticorrosion pipe or pipe fitting prepared through the method, the abrasion-resistant service life can be 5-10 times that of rubber lining abrasion-resistant layers, the pipe or pipe fitting has good tolerability to acid and alkali corrosion and high-temperature impact, and the replacement cycle of pipe or pipe fitting equipment can be effectively prolonged, so that the operating cost of enterprises is reduced, and emission of particulate pollutants is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Erosion-resistant acid-resistant crack-resistant zero-expansion silicon brick and preparation method thereof

InactiveCN109650860AImprove corrosion resistanceImprove creep resistanceCarboxymethyl celluloseBrick

The invention discloses an erosion-resistant acid-resistant crack-resistant zero-expansion silicon brick and a preparation method thereof. The preparation method comprises the following steps of: S1,selecting raw materials: selecting 80-90% of fused quartz, 10-20% of silicon powder, 0.1-3% of carboxymethyl cellulose and 1-5% of silica sol; S2, mixing raw materials, namely mixing the selected rawmaterials, adding SiO2, Al2O3, Fe2O3 and CaO into a stirrer to stir and mix after mixing, and obtaining a mixture after trapping materials; S3, pressing and forming: putting the mixture into a press machine, and pressing and forming by one-way pressure to prepare a cylindrical sample; S4, drying: naturally drying the prepared cylindrical sample at room temperature, placing the cylindrical sample in a drying box to heat, and drying to obtain a dried sample; S5, sintering, namely putting the dried sample into a calcining furnace to heat, preserving heat and calcining to obtain a thermal shock resistant silicon brick. Compared with other preparation methods, the method has the advantages of low technical cost, mature process, easy realization and strong practicability, and greatly improves the using quality of the silicon brick.

Owner:河北炫坤耐火材料科技发展有限公司

Wear-resistant MoSiCu laser clad layer material and preparation method thereof

InactiveCN108842152ASmall and uniform tissueStable friction and wear processMetallic material coating processesChemical compositionWear resistant

The invention discloses a wear-resistant MoSiCu laser clad layer material and a preparation method thereof. The clad layer comprises the elements including Mo, Si and Cu and comprises the following chemical components by atomic percent: 20% to 40% of Mo, 20% to 40% of Si and 40% of Cu; an alloy layer is prepared by adopting a laser cladding process; the laser machining parameters are that the laser power is 2500-3000 W; the scanning speed is 600-1800 mm / min; the defocusing amount is 25 mm; the argon protective air flow rate is 15-25 L / min; and a stainless steel surface can be coated with a wear-resistant MoSiCu ternary alloy coating which has certain thickness and is good in metallurgical quality.

Owner:SHANGHAI UNIV OF ENG SCI

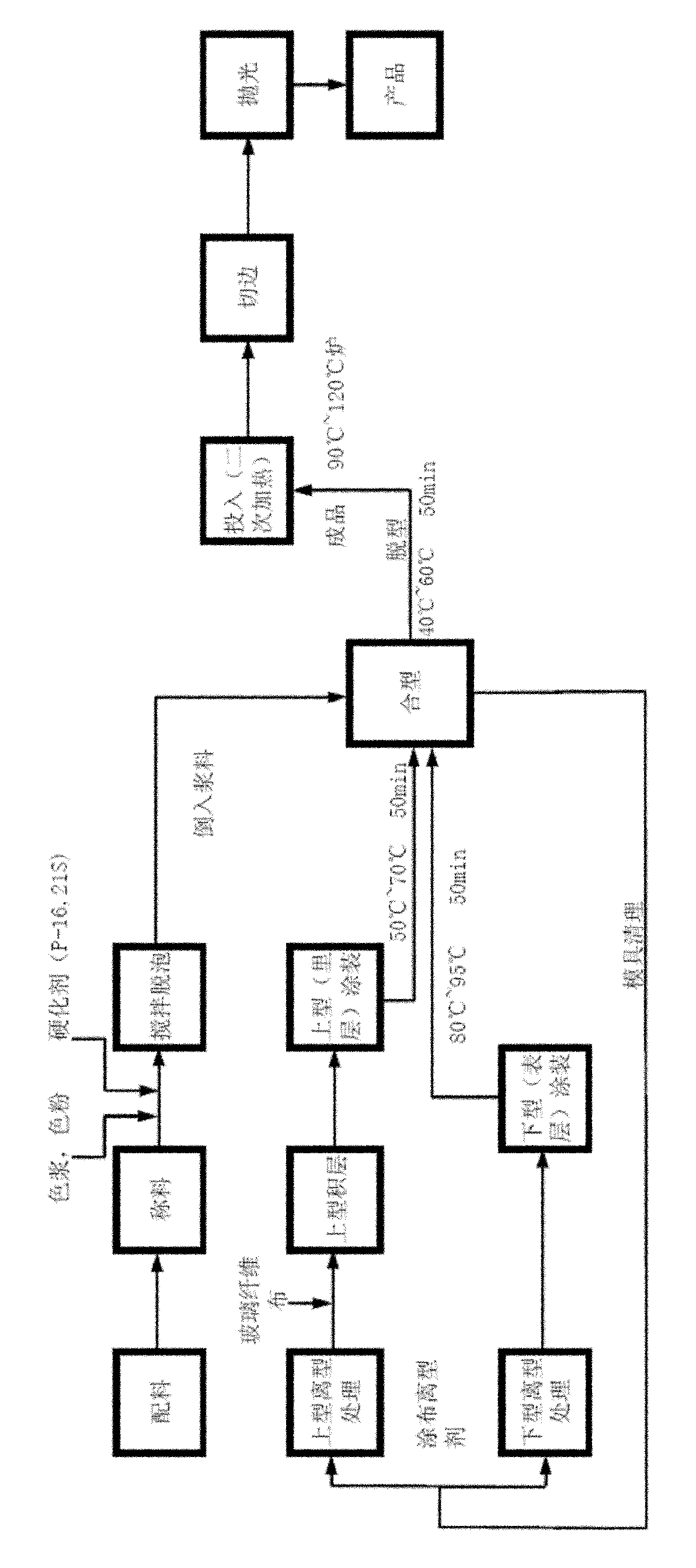

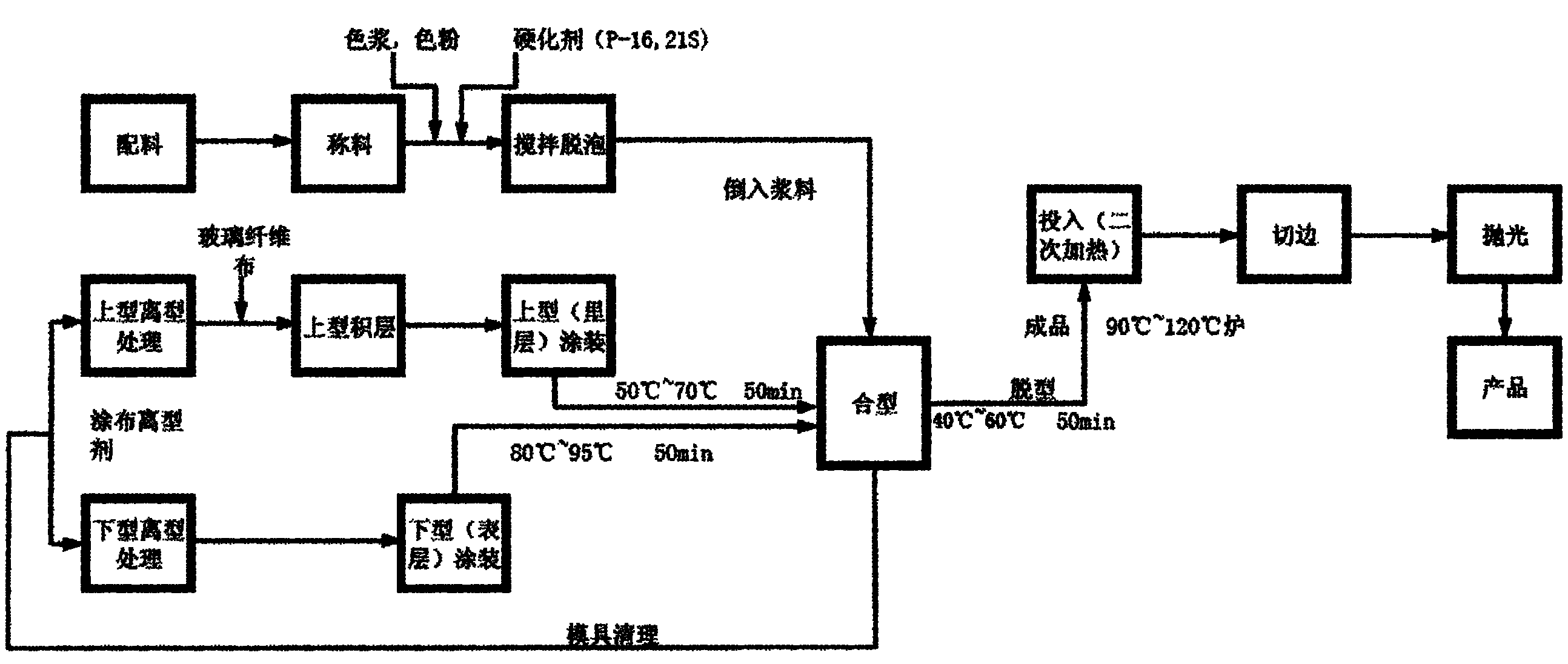

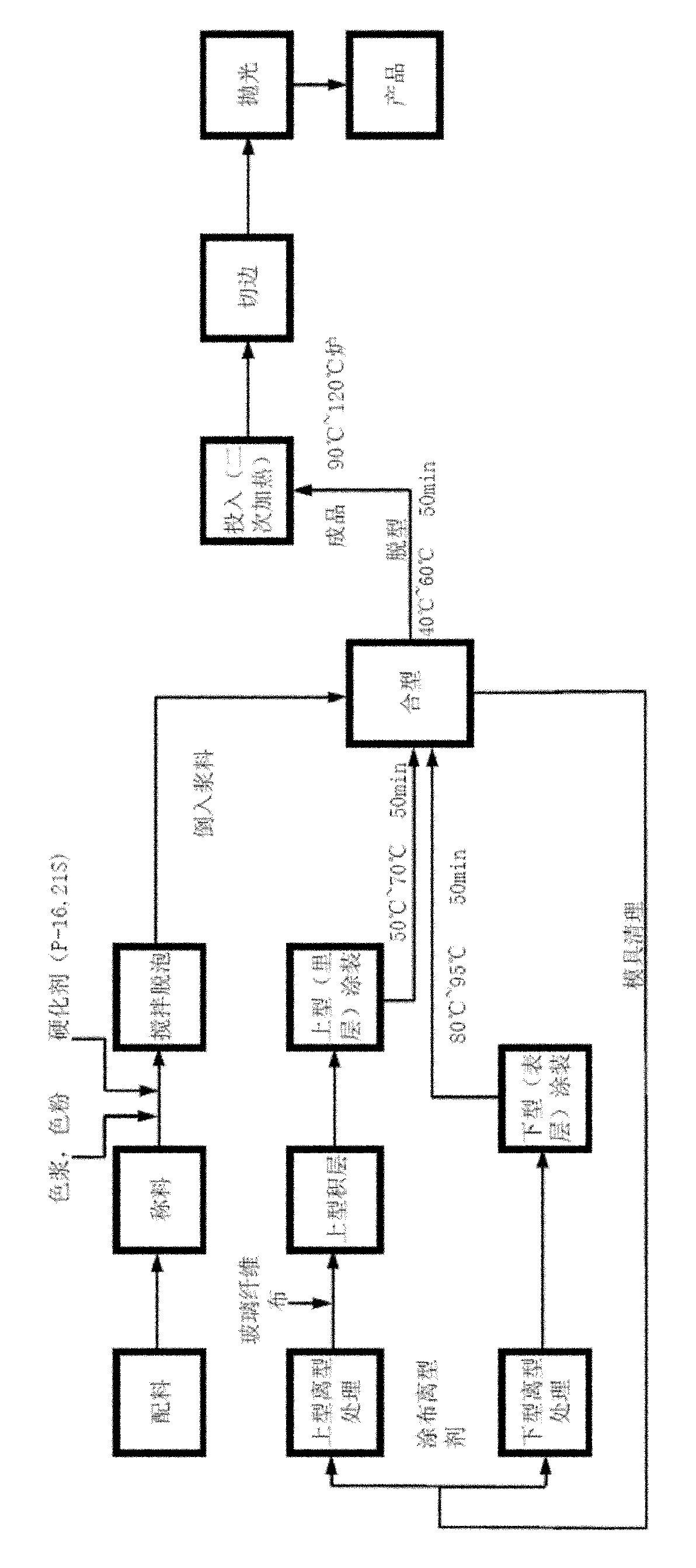

Imitation marble and method for manufacturing bathroom equipment by using same

InactiveCN101954769AGuaranteed smooth productionShorten the timeSynthetic resin layered productsCoatingsSurface layerBathroom Equipment

The invention relates to imitation marble, which comprises a waterproof surface layer, an unsaturated polyester resin middle layer and a reinforcing bottom layer. A method for manufacturing bathroom equipment by using the imitation marble comprises the following steps of: preparing unsaturated polyester resin slurry, namely coating the reinforcing bottom layer on an upper die, and coating the waterproof surface layer on a lower die; when the temperature of upper and lower dies is reduced to be between 45 and 60 DEG C, starting to close the dies, namely fixing the lower die on a die closing machine, pouring the prepared slurry into the upper die, and pushing the upper die into the die closing machine to close the dies; and screwing screws on both sides of the dies simultaneously by using apneumatic tool, overturning the dies, and conveying the dies to a ripening furnace with the temperature of between 40 and 70 DEG C for hardening molding. The imitation marble has the advantages of compact combination among materials, high waterproofness and long service life. The method for manufacturing the bathroom equipment by using the imitation marble has the advantages of simple equipment, smooth production, only 5 to 7 hours of one equipment from die preparation to finished product packaging, short time and low cost, and is suitable for large-scale production.

Owner:YAMAMOTO SANITARY FUJIAN

High-strength wear-resistant material for mechanical arm and preparation method of high-strength wear-resistant material

The invention discloses a high-strength wear-resistant material for a mechanical arm and a preparation method of the high-strength wear-resistant material and relates to the field of composites. The high-strength wear-resistant material is prepared from the following raw materials: 20-30 parts of polyester, 2-6 parts of powdered rubber, 20-30 parts of molybdenum-phenolic resin, 1-3 parts of a coupling agent, 5-10 parts of mica powder, 10-15 parts of wollastonite, 0.5-1 part of epoxy fatty acid butyl ester, 20-30 parts of carbon fibers, 2-5 parts of boron nitride fibers, 1-2 parts of triethylenetetramine and 0.5-1 part of an antioxidant. The high-strength wear-resistant material has high strength and wearing resistance, is light in weight and has better performance than the traditional carbon fiber materials; the mechanical arm prepared from the material has no peeling on the surface layer after long-time operation, is wear-resistant and long in service life and has good popularizing and applying values.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

Imitation marble and method for manufacturing bathroom equipment by using same

InactiveCN101954769BTightly boundImprove waterproof performanceSynthetic resin layered productsCoatingsSurface layerBathroom Equipment

Owner:YAMAMOTO SANITARY FUJIAN

Pipeline or pipe fitting provided with silicon carbide ceramic abrasion-resisting and corrosion-resisting liner and preparation method thereof

ActiveCN106917918AImprove wear resistanceHigh strengthCorrosion preventionPipe protection against corrosion/incrustationCarbide siliconPipe fitting

The invention relates to a metal pipeline or pipe fitting surface abrasion-resisting and anticorrosion protection technology, in particular to a pipeline or pipe fitting provided with a silicon carbide ceramic abrasion-resisting and corrosion-resisting liner and a preparation method thereof. The pipeline or the pipe fitting is composed of the abrasion-resisting and corrosion-resisting liner and a metal layer from inside to outside. The abrasion-resisting and corrosion-resisting liner is composed of a surface layer and a compounded layer. The surface layer is a compact ceramic layer. The compounded layer is a foam ceramic layer and directly grows on the back face of the compact ceramic layer. The preparation process comprises the following steps of preparation of mixed powder, preparation of slurry, preparation of a foam precursor in a tape casting mode, bonding, thermocuring forming in a mould, machining, bonding forming, pyrolysis, sintering, and compounding to obtain afinished product. According to the ceramic liner abrasion-resisting and corrosion-resisting pipeline or pipe fitting prepared through the preparation method, the abrasion-resisting service life can be five to ten times that of a rubber-lined abrasion-resisting layer, the resistance to acid and alkaline corrosion and high-temperature impact is excellent, the replacement period of the pipeline or pipe fitting can be effectively prolonged, accordinglythe operation cost of enterprises is lowered, and emission of particulate pollutants is reduced.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

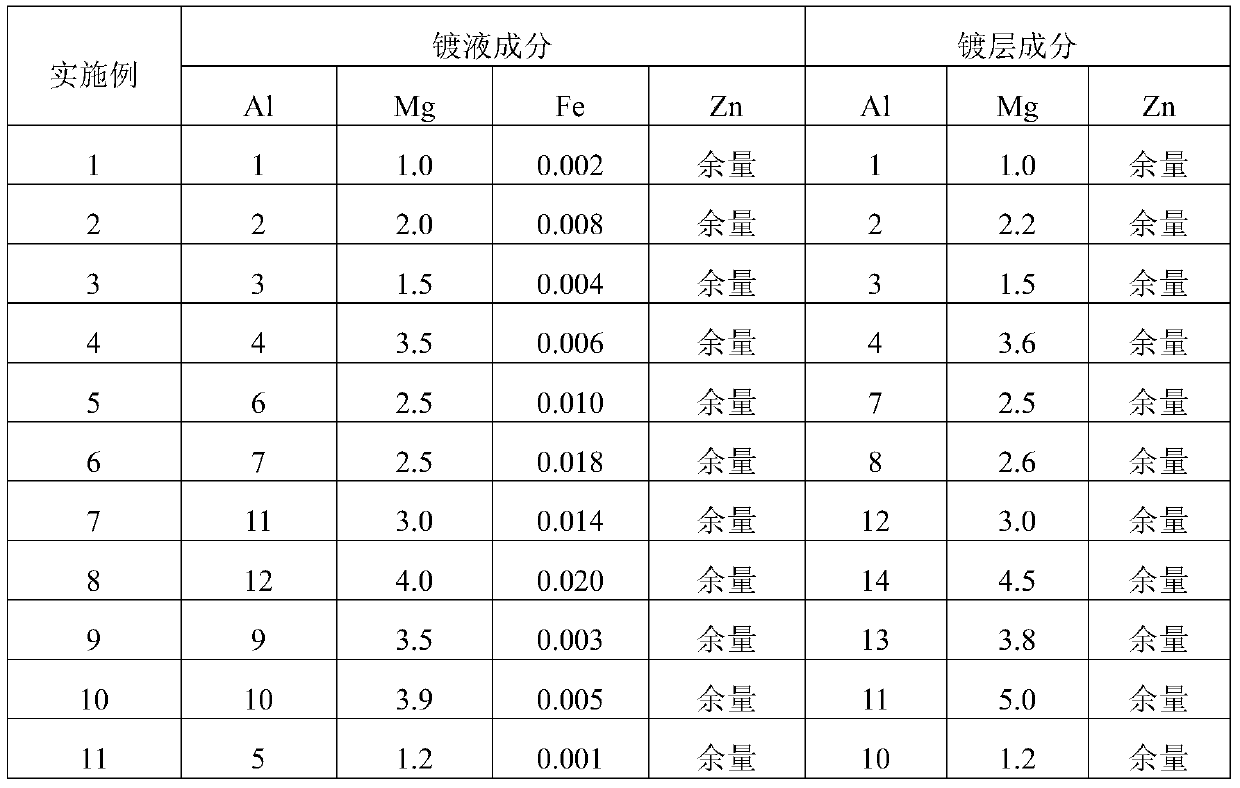

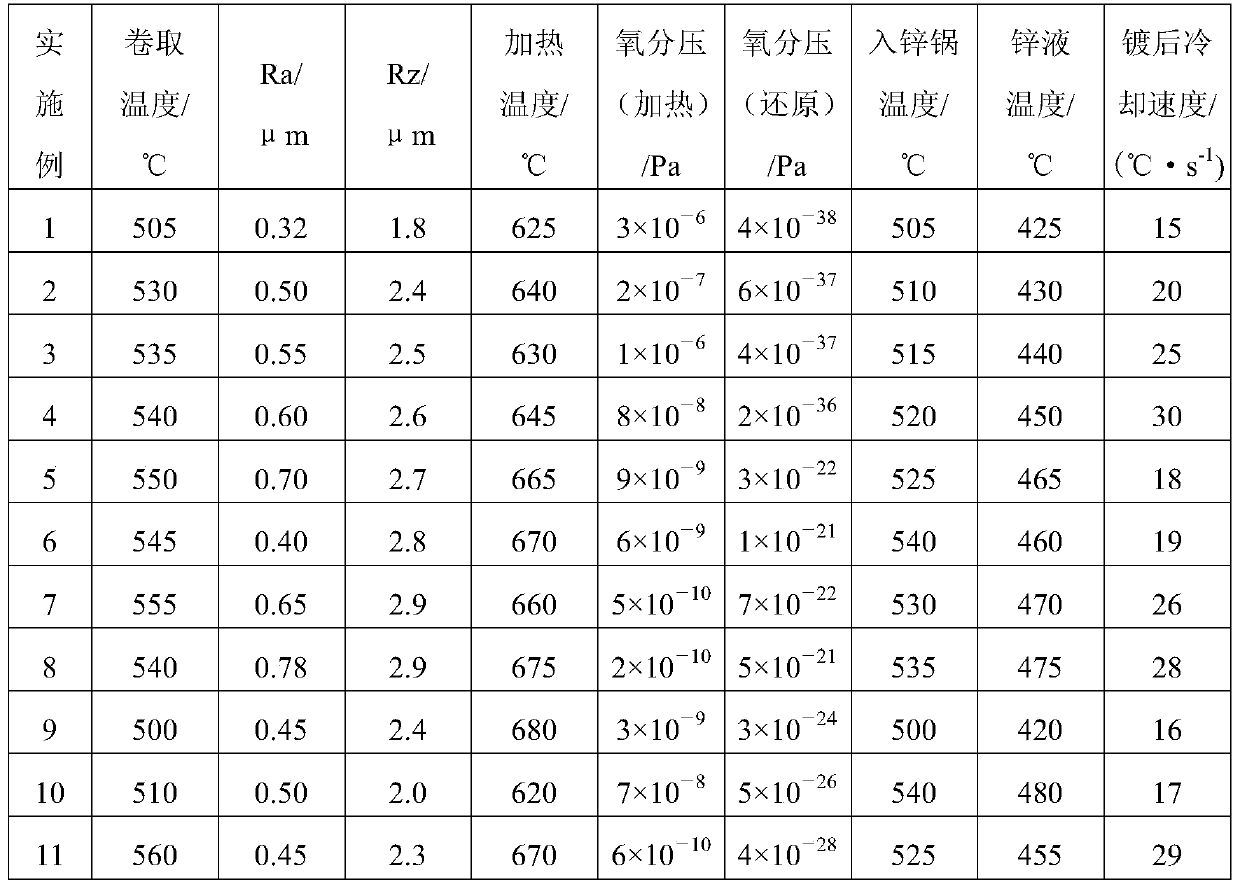

High-strength zinc-aluminum-magnesium-coated steel sheet with good surface quality and manufacturing method thereof

ActiveCN106811686BImprove surface qualityImprove corrosion resistanceHot-dipping/immersion processesHeating temperatureImpurity

Owner:ANGANG STEEL CO LTD

Technology for spraying corrosion resistant coating on dry screw compressor rotor

InactiveCN100516529CUniform thicknessImprove heat resistanceRotary piston pumpsRotary piston liquid enginesTetrafluoroethyleneHeat resistance

The invention relates to a processing method for spraying an anticorrosion layer on a rotor of a dry screw compressor, in particular to spraying a polytetrafluoroethylene anticorrosion layer on the outer surface of the rotor screw of a dry screw compressor, and belongs to the technical field of mechanical spraying technology. It mainly pre-treats the rotor matrix material, anneals the rotor blank for stress relief, then pre-treats the anti-corrosion layer by spraying it, sprays the polytetrafluoroethylene anti-corrosion layer, and finally performs sintering treatment and testing for the finished rotor. The coating thickness of the invention is uniform, the color is black, and has no corrosive effect on the base material of the substrate, the hardness is pencil hardness H-2H, the heat resistance is good, the meshing gap is reasonable, and the tetrafluoro layer is intact; the coating and the base have excellent adhesion Adhesion, no blistering, oxidation, and peeling; under normal operating conditions for dry screw compressors, the service life of the coating can reach more than 24,000 hours, which can ensure that the compression cavity (airway) of the rotor casing does not rust and Can provide pure compressed air.

Owner:WUXI COMPRESSOR CO LTD

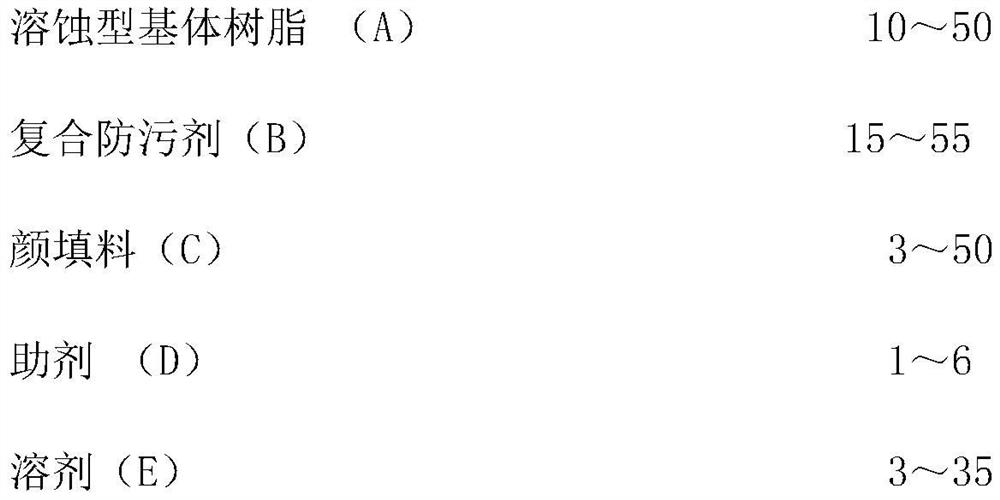

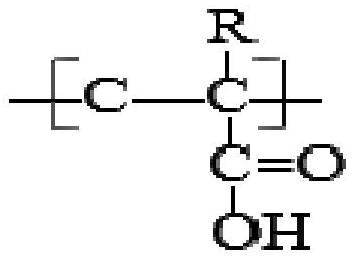

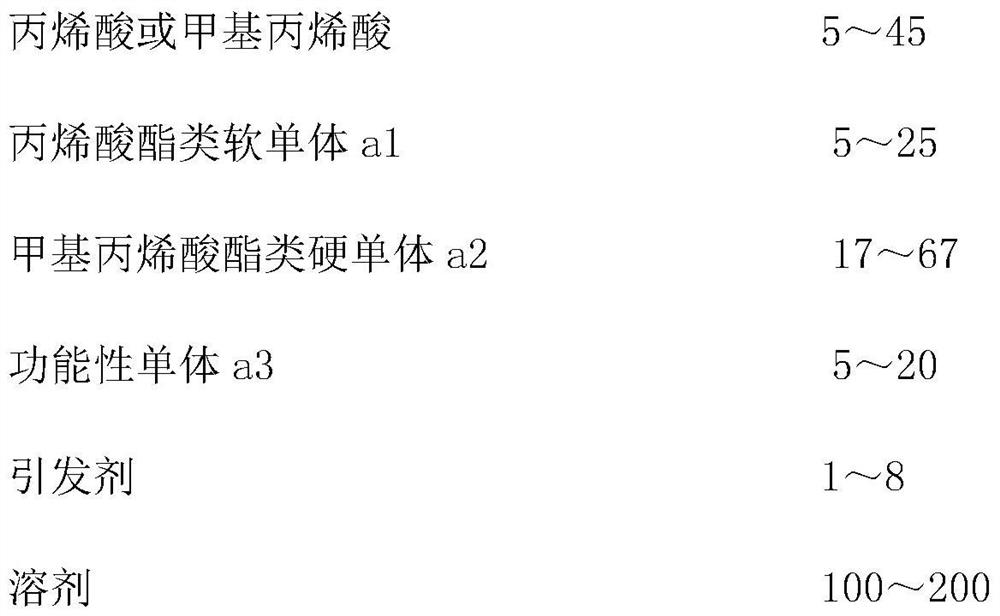

Corrosion type marine anti-fouling paint, corrosion type matrix resin and preparation method

InactiveCN112143318ALow costCost is easy to controlAntifouling/underwater paintsPaints with biocidesSeawaterCorrosion

The invention discloses a corrosion type marine anti-fouling paint, a corrosion type matrix resin and a preparation method. The paint comprises the following basic components in parts by weight: 10-50parts of corrosion-type matrix resin (A), 15-55 parts of a composite anti-fouling agent (B), 3-50 parts of a pigment filler (C), 1-6 parts of an assistant (D) and 3-35 parts of a solvent (E). Hydrogen ions (H<+>) electrolyzed from carboxylic acid groups contained in matrix resin in the anti-fouling paint and hydroxide ions (OH<->) in seawater are slowly dissolved, so that an anti-fouling agent inthe anti-fouling paint is slowly dissolved in the seawater, the anti-fouling purpose is achieved, the anti-fouling paint has 18-24 anti-fouling period effects, and the requirements of underwater facilities in the sea on medium-short-term-effect and low-cost anti-fouling paint can be met; and the cost is low and easy to control.

Owner:MARINE CHEM RES INST

A fully automatic online cold welding repair roll press technology

ActiveCN103481010BReduce workloadEasy automatic weldingArc welding apparatusWelding/cutting media/materialsStress relievingEngineering

The invention discloses a novel full-automatic online cold welding repairing process for roll squeezers. The novel full-automatic online cold welding repairing process is characterized by comprising steps of (1), pre-treating roll surfaces of cement squeeze rolls to remove fatigue layers, welding check rings at two ends of each roll surface and enabling the corresponding check rings and each roll surface to be located on the same curved surface; (2), checking the roll surfaces to determine whether cracks are formed on the roll surfaces or not, grinding crack positions of the roll surfaces to remove the cracks, and performing repair welding on pits until the pits are filled; (3), performing buildup welding on the roll surfaces by means of automatic open arc welding; (4), removing the check rings and grinding and leveling the roll surfaces. The novel full-automatic online cold welding repairing process has the advantages that the buildup welding repairing quality can be guaranteed, the rolls of the roll squeezers do not need to be detached, stress relieving measures such as heating and heat insulation are omitted in buildup welding procedures, accordingly, working procedures can be greatly simplified, the construction cost can be greatly reduced, and energy can be saved.

Owner:柳州市三龙耐磨焊接科技有限公司

Wear-resisting casting for mechanical arm and preparation method thereof

The invention discloses a wear-resisting casting for a mechanical arm and a preparation method thereof. The casting comprises, by mass, 0.8-1.05% of C, 5.1-7.2% of Mn, 0.8-1.2% of Si, 0.3-0.5% of Cr, 1.2-1.5% of V, 1.2-1.4% of Ti, 0.25-0.63% of Zr, 0.2-0.3% of Ce, 0.16-0.34% of Hf, and the balance Fe and inevitable impurities. By reasonably regulating the ratio of all the elements to enable the elements to generate the synergistic effect, the comprehensive mechanical performance of the mechanical arm is remarkably improved, so that the wear-resisting casting has high strength, high toughness and high wear resistance. After long-time operating, the surface of the mechanical arm is free of peeling and is resistant to wear.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

Chromizing coating modified by rare earth oxide and preparation method and application thereof

InactiveCN1296512CStable growthSlow growth rateSolid state diffusion coatingRare-earth elementOxidation resistant

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of preparation method of wear-resistant casting for mechanical arm

The invention discloses a wear-resisting casting for a mechanical arm and a preparation method thereof. The casting comprises, by mass, 0.8-1.05% of C, 5.1-7.2% of Mn, 0.8-1.2% of Si, 0.3-0.5% of Cr, 1.2-1.5% of V, 1.2-1.4% of Ti, 0.25-0.63% of Zr, 0.2-0.3% of Ce, 0.16-0.34% of Hf, and the balance Fe and inevitable impurities. By reasonably regulating the ratio of all the elements to enable the elements to generate the synergistic effect, the comprehensive mechanical performance of the mechanical arm is remarkably improved, so that the wear-resisting casting has high strength, high toughness and high wear resistance. After long-time operating, the surface of the mechanical arm is free of peeling and is resistant to wear.

Owner:HEXIAN LONGSHENG PRECISION MACHINERY CO LTD

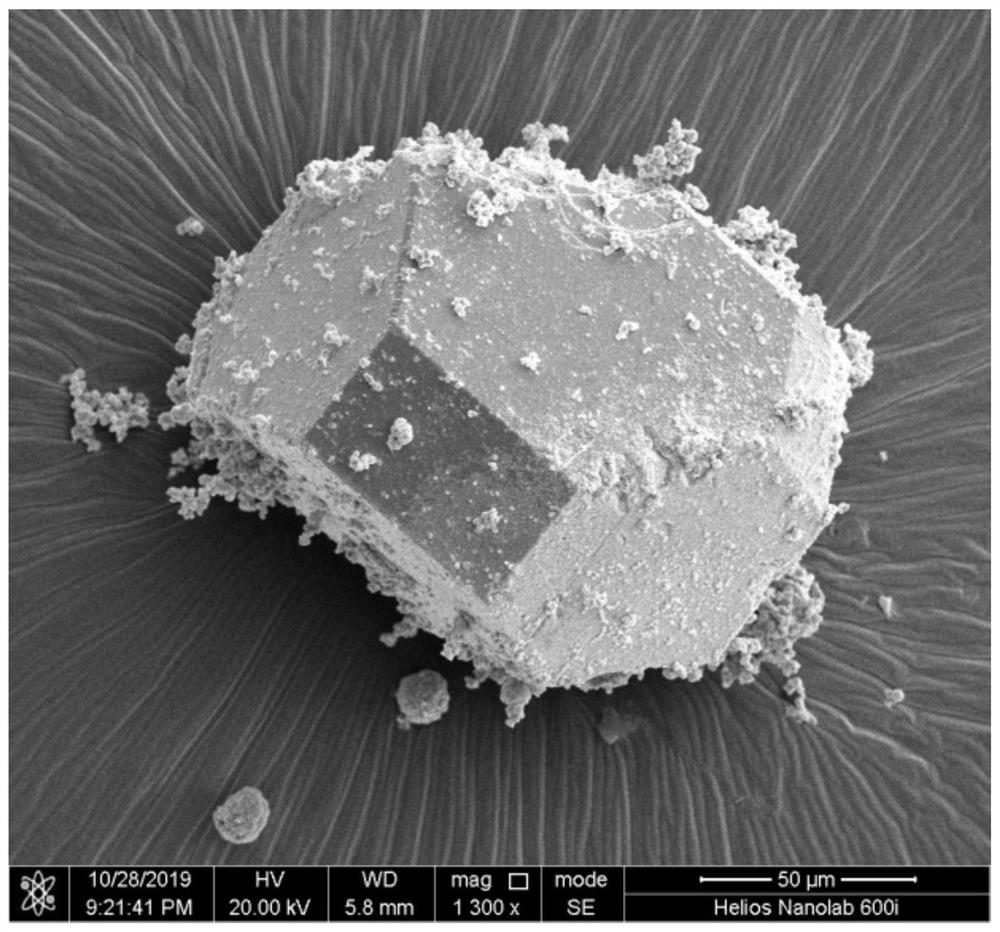

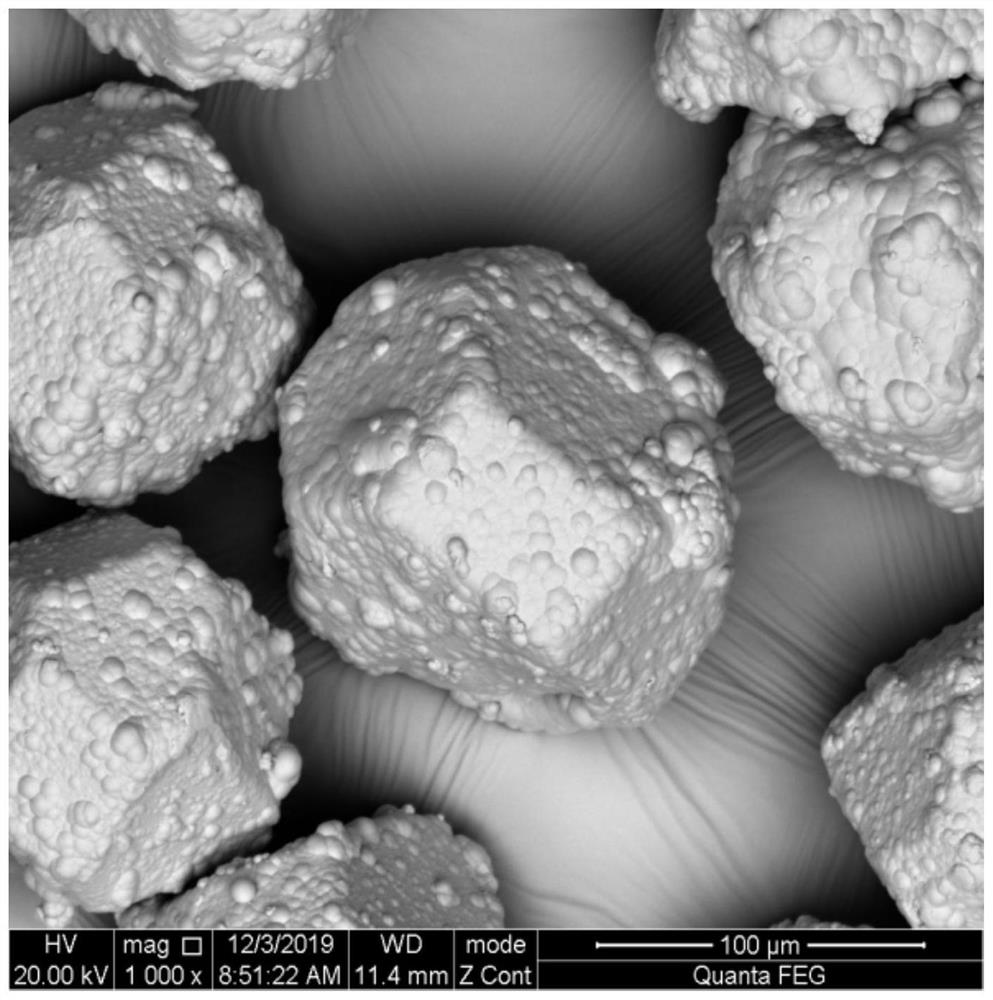

A method for nickel-plating on the surface of diamond micropowder

ActiveCN111705311BOvercome the defect of easy sheddingTightly boundTransportation and packagingMetal-working apparatusPlasma etchingDiamond

Owner:HARBIN INST OF TECH

Preparation method for cast steel roller

The invention discloses a preparation method for cast steel roller. A casting pipe is installed at the central part of a casting mould firstly. The upper end of the casting pipe is directly connected with a pouring cup. The lower end of the casting pipe is directly connected with sand mould in a bottom box casting mould. The upper end of the casting pipe is open and the lower end of the casting pipe is closed. Fifteen to forty circular holes with diameter of 6mm-20mm are arranged at the lower end of the casting pipe. Molten steel with required components, which is well smelted, is poured into the roller casting mould. During molten steel casting, the molten steel enters the casting pipe through the pouring cup and then enters the lower end of the casting mould cavity through the circular holes at the lower end of the casting pipe, the molten steel is filled into the casting mould from bottom up till the casting mould is filled with the molten steel, and finally the casting pipe is inlaid at the central part of the roller. The invention has the advantages of compact roller structure, less impurity, high strength, good wear resistance, long service life and good economic benefit after popularization.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com