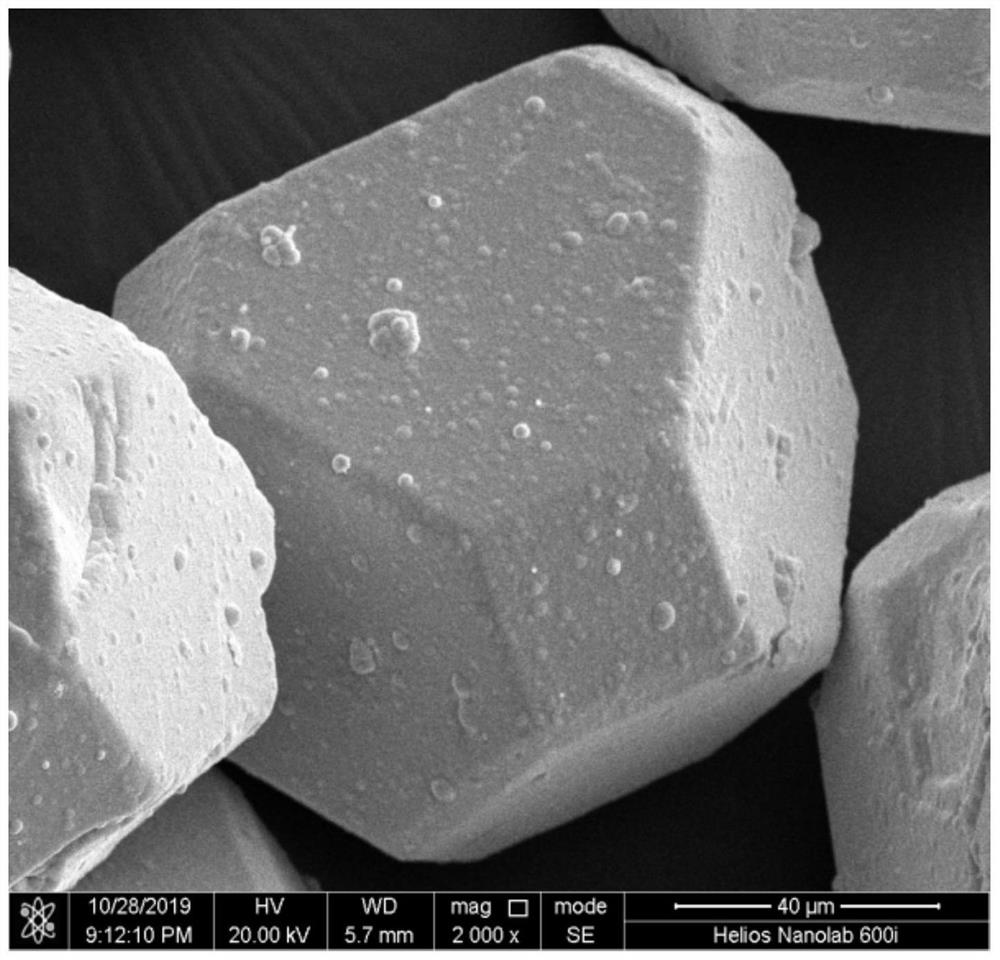

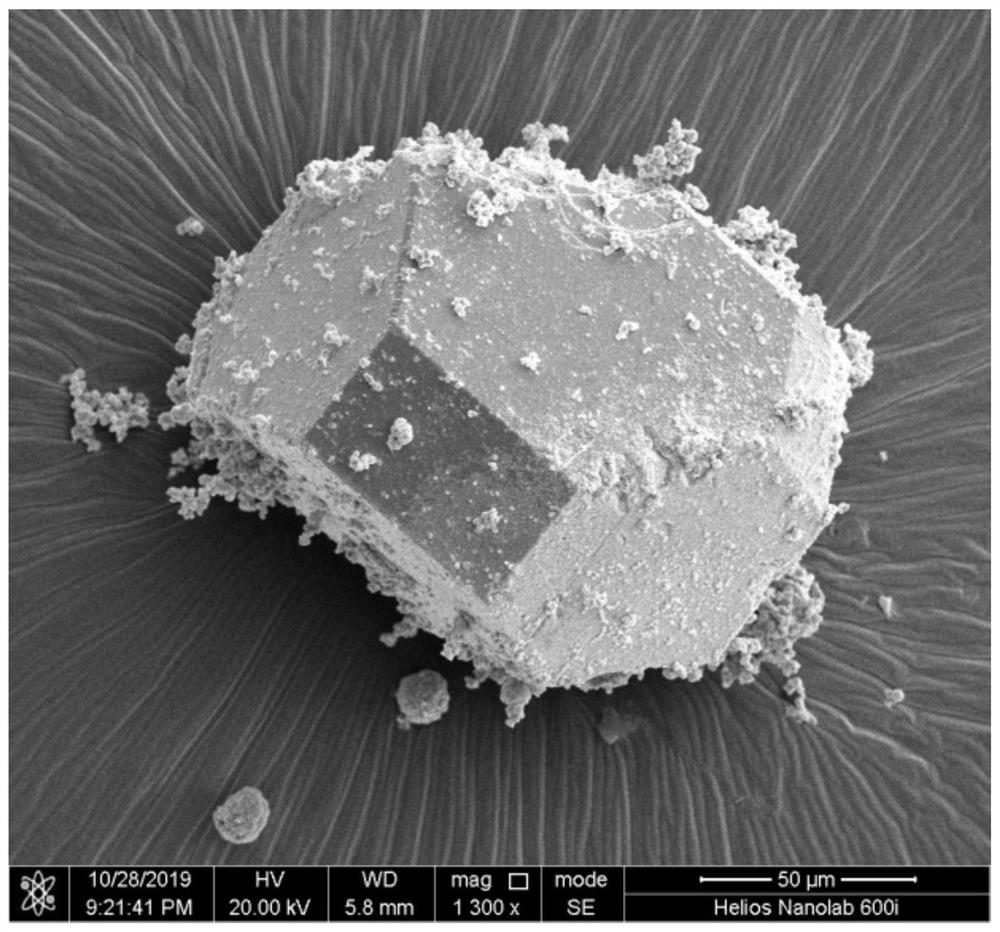

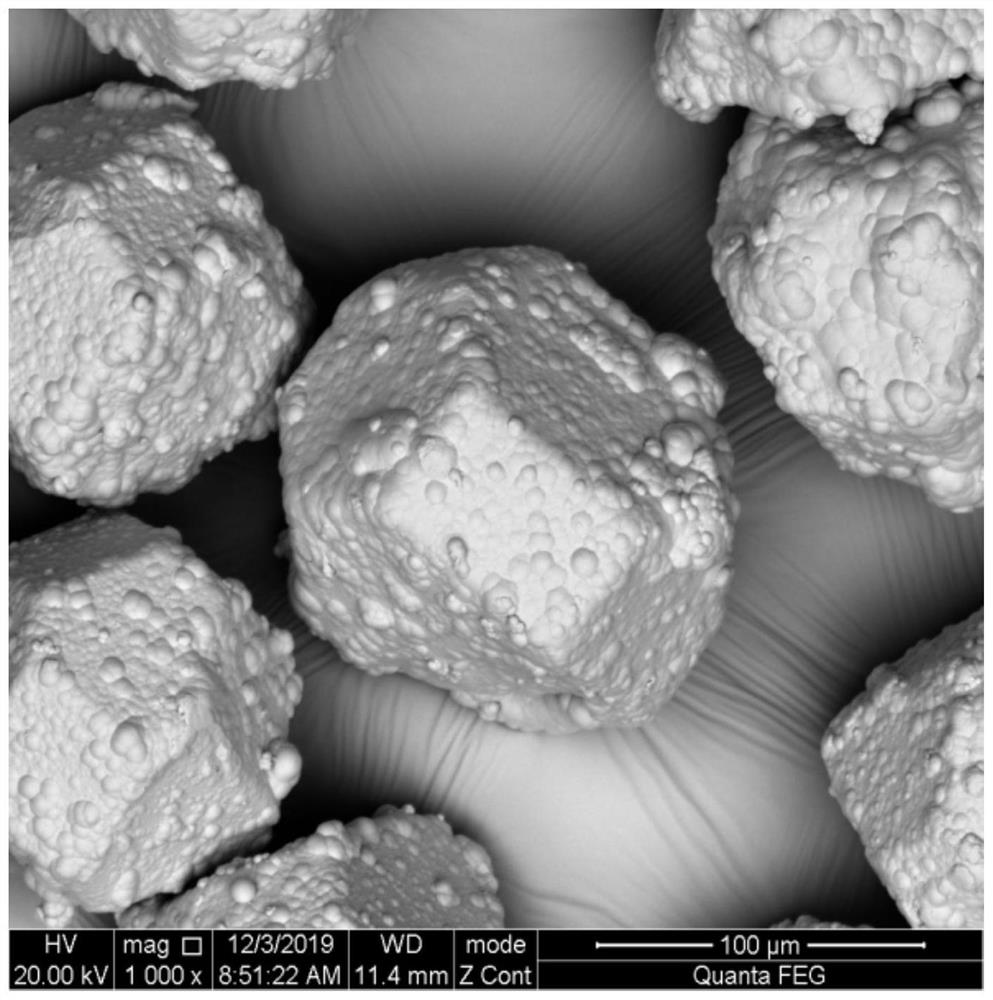

A method for nickel-plating on the surface of diamond micropowder

A diamond micropowder and nickel-plating technology, applied in liquid chemical plating, metal processing equipment, metal material coating technology and other directions, can solve the problems of many pores, non-dense, poor uniformity, etc., to achieve uniform coating, high bonding force, The effect of dense porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0033] Specific embodiment one: the method for nickel-plating on the surface of a kind of diamond micropowder described in the present embodiment, it is carried out according to the following steps:

[0034] 1. Degreasing the surface of diamond powder:

[0035] Degreasing the surface of the diamond powder to obtain the degreasing diamond powder;

[0036] 2. Plasma etching of diamond powder:

[0037] Under the condition that the air pressure is 20Pa~30Pa, the flow rate of Ar is 100sccm~200sccm and the flow rate of etching gas is 30sccm~50sccm, the diamond micropowder after degreasing treatment is subjected to plasma etching treatment for 30min~60min, and the diamond micropowder after etching treatment is obtained. ;

[0038] The etching gas is CH 4 or H 2 ;

[0039] 3. Activate the diamond powder:

[0040] PdCl 2 Added to concentrated HCl with a concentration of 5mol / L~10mol / L to obtain the activator PdCl 2 Solution, put the etched diamond powder in the activator PdCl ...

specific Embodiment approach 2

[0051] Embodiment 2: This embodiment differs from Embodiment 1 in that the particle size of the diamond micropowder described in step 1 is 120 mesh to 170 mesh. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0052] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the surface of the diamond micropowder described in step 1 carries out degreasing treatment specifically according to the following steps: put the diamond micropowder into the mass percentage of In 5%-10% NaOH solution, boil for 20min-30min and then dry; the mass ratio of the diamond micropowder to 5%-10% NaOH solution is 1:(30-50). Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com