Energy-saving jet purging device

A purging device and jet technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as inability to use circulating water, small effective area for purging, deformation of nozzle openings, etc. , to achieve the effect of improving energy saving efficiency, improving load cutting capacity, and large blowing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings.

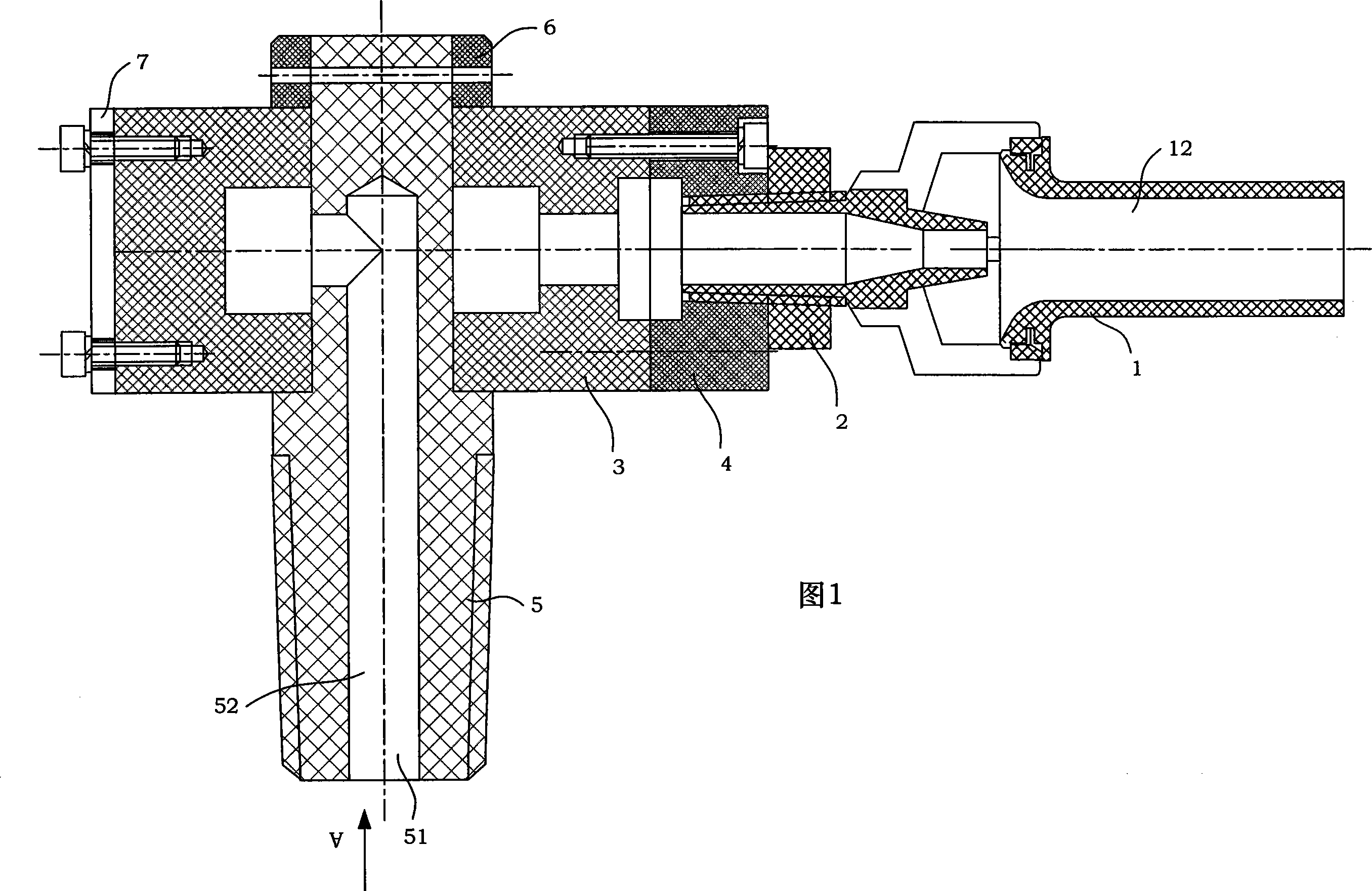

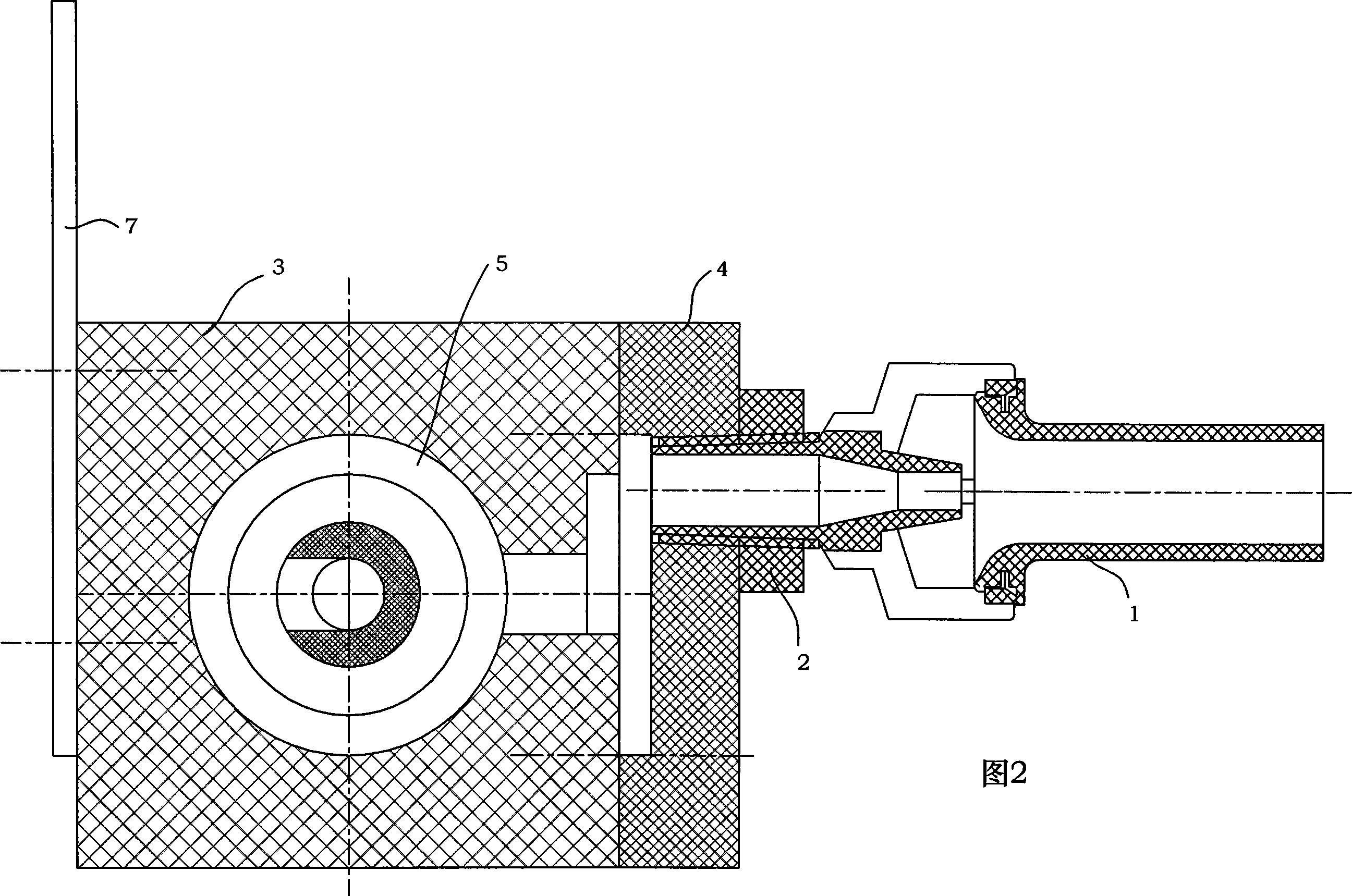

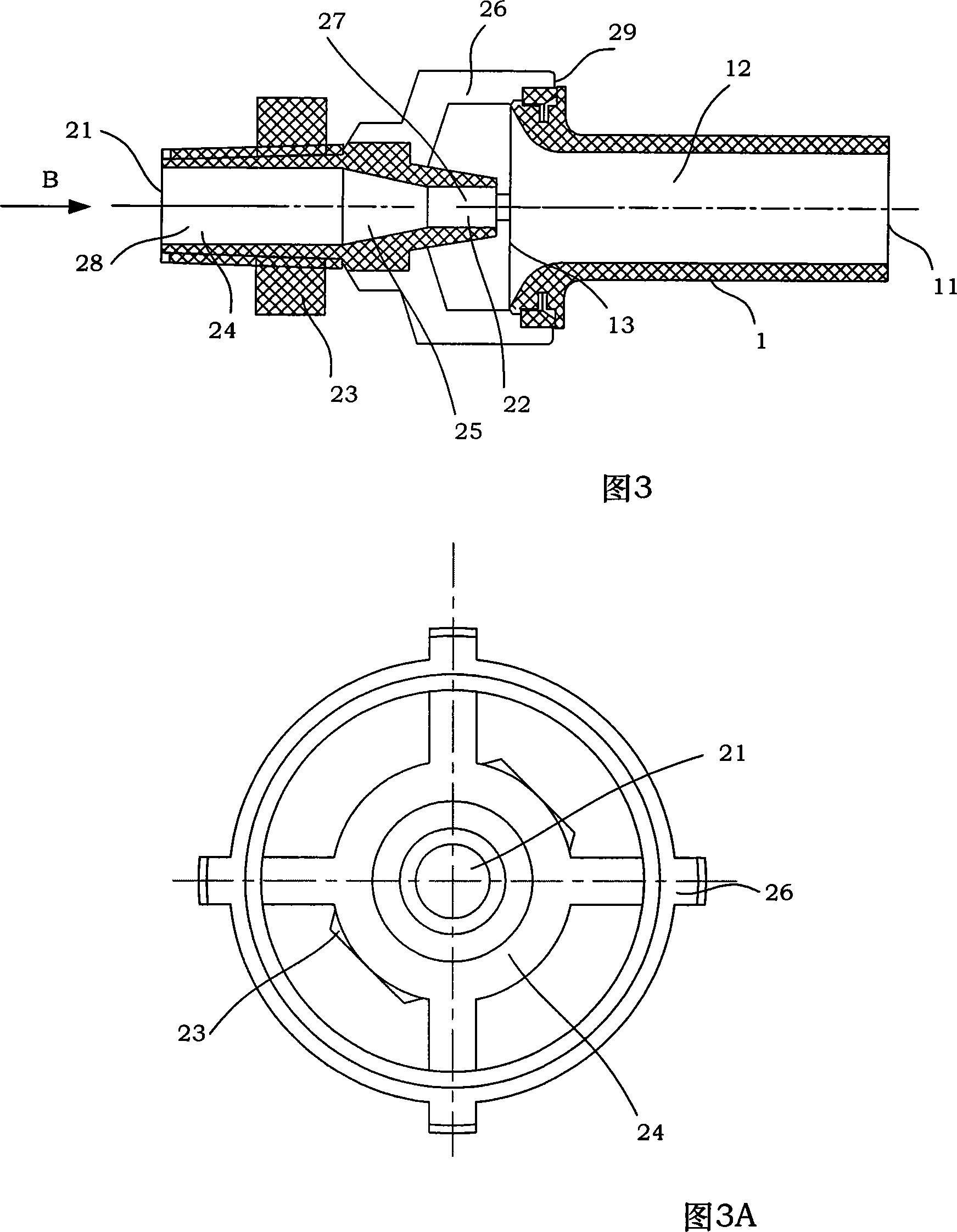

[0016] Referring to Fig. 1 and shown in Fig. 2, the energy-saving jet blower of the present invention includes a jet pipe 1, a nozzle 2, a swing body 3, a connector 4, and a water diversion bracket 5; (see Fig. 3 ) the nozzle 2 In one piece, the inner channel 28 of the nozzle 2 is divided into a smooth section 24, a convergent section 25 and an expansion section 27 in sequence, and a flange 23 is provided on the outer shell of the smooth section 24 (as the connection depth between the nozzle 2 and the connecting piece 4, Simultaneously also is to play the effect of a limit), flange 23 is provided with external thread on the inlet 21 end of nozzle 2; The shell of converging section 25 is provided with support 26, is connected with jet tube on the grasping end 29 of support 26 1. The swinging body 3 is connected to the water diversion bracket 5, the upper end o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com