A kind of normal temperature solvent type road marking paint and preparation method thereof

A road marking, solvent-based technology, used in coatings and other directions, can solve the problems of low water resistance, heat resistance and impact resistance, short service life of marking lines, and low road adhesion, etc., to promote film-forming curing, enhance Mechanical strength, effect of promoting dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

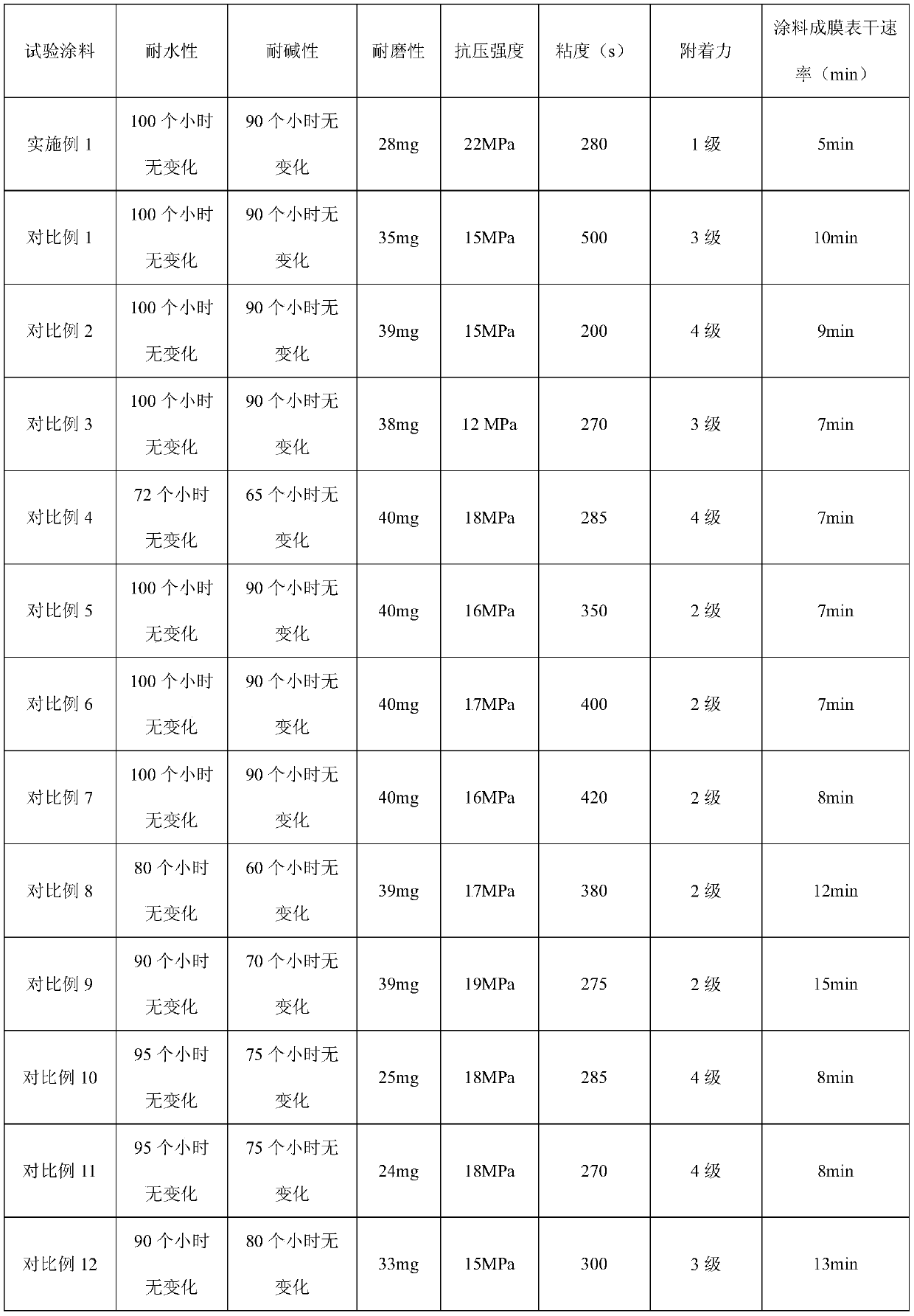

Examples

Embodiment 1

[0032] A normal temperature solvent-based road marking paint, prepared from the following raw materials in parts by weight: 360 parts of acrylic resin, 25 parts of branched modified polysulfone resin, 35 parts of epoxy resin, propylene glycol methyl cyclohexyl ether 11 parts, 9 parts of diisobutyl nylon acid, 12 parts of plasticizer, 9 parts of anti-sedimentation dispersant, 90 parts of pigment, 360 parts of filler, 9 parts of toluene, 38 parts of butyl acetate, 65 parts of butanone, 15 parts of ethanol Parts; 9 parts of lithium polysilicate;

[0033] Acrylic resin is an acrylic resin formed by polymerization of methyl methacrylate and butyl methacrylate in a ratio of 4:1;

[0034] The branched modified polysulfone resin is prepared by adding a Si-containing chain extender in the polymerization reaction of the preparation process.

[0035] The preparation method of the above-mentioned normal temperature solvent-based road marking paint comprises the following steps:

[0036]...

Embodiment 2

[0041] A normal temperature solvent-based road marking paint, prepared from the following raw materials in parts by weight: 350 parts of acrylic resin, 20 parts of branched modified polysulfone resin, 30 parts of epoxy resin, propylene glycol methyl cyclohexyl ether 10 parts, 8 parts of diisobutyl nylon acid, 10 parts of plasticizer, 8 parts of anti-sedimentation dispersant, 80 parts of pigment, 350 parts of filler, 8 parts of toluene, 35 parts of butyl acetate, 55 parts of butanone, 10 parts of ethanol Parts; 8 parts of lithium polysilicate;

[0042] Acrylic resin is an acrylic resin formed by polymerization of methyl methacrylate and butyl methacrylate in a ratio of 4:1;

[0043] The branched modified polysulfone resin is prepared by adding a Si-containing chain extender in the polymerization reaction of the preparation process.

[0044] The preparation method of the above-mentioned normal temperature solvent-based road marking paint comprises the following steps:

[0045]...

Embodiment 3

[0050] A normal temperature solvent-based road marking paint, prepared from the following raw materials in parts by weight: 380 parts of acrylic resin, 30 parts of branched modified polysulfone resin, 40 parts of epoxy resin, propylene glycol methyl cyclohexyl ether 12 parts, 10 parts of diisobutyl nylon acid, 15 parts of plasticizer, 10 parts of anti-sedimentation dispersant, 100 parts of pigment, 380 parts of filler, 10 parts of toluene, 40 parts of butyl acetate, 70 parts of butanone, 20 parts of ethanol Parts; 10 parts of lithium polysilicate;

[0051] Acrylic resin is an acrylic resin formed by polymerization of methyl methacrylate and butyl methacrylate in a ratio of 4:1;

[0052] The branched modified polysulfone resin is prepared by adding a Si-containing chain extender in the polymerization reaction of the preparation process.

[0053] The preparation method of the above-mentioned normal temperature solvent-based road marking paint comprises the following steps:

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com