Preparation method for cast steel roller

A cast steel roll and roll technology, applied in the field of casting, can solve the problems of reducing the mechanical properties and service performance of the roll, the roll is prone to pores, and the production cost of the roll is increased, so as to achieve high production rate of molten steel process and good hardness uniformity of the roll surface. , the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

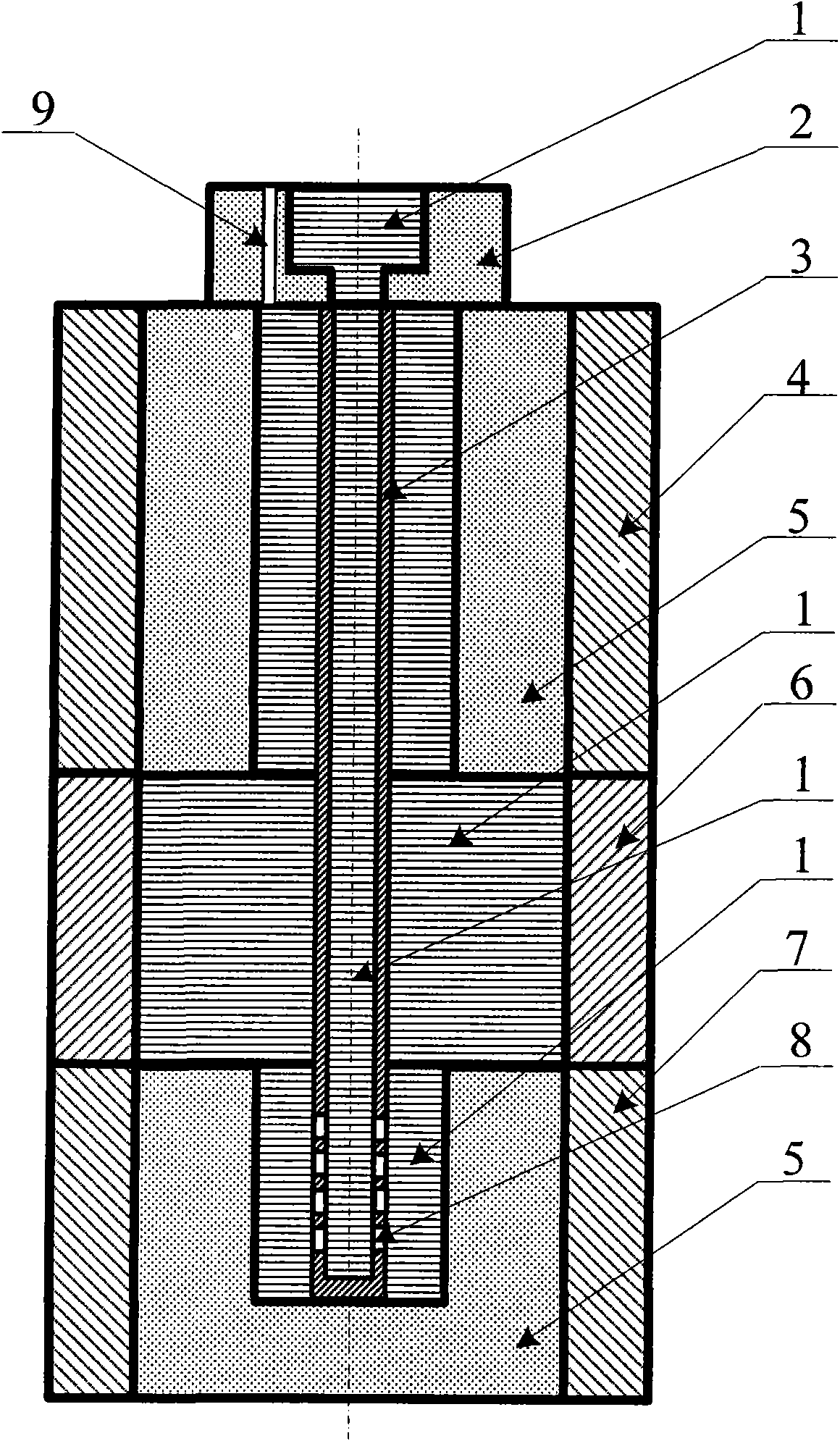

[0019] A 3-ton electric furnace is used to smelt 75CrMo cast steel roll material, and a cast steel roll with a weight of 2.8 tons is cast. When the composition of molten steel meets the requirements, it is released from the furnace. The middle box metal mold (6) is placed on the upper end of the bottom box metal mold (7), the upper box metal mold (4) is placed on the upper end of the middle box metal mold (6), and the sprue cup (2) is placed on the upper box On the top of the sand mold (5) in the metal casting mold (4), an air vent (9) is also arranged on the sprue cup (2), and the air vent (9) communicates with the mold cavity. The casting pipe (3) is installed in the center of the roll mould, the upper end of the casting pipe (3) is directly connected with the sprue cup (2), and the lower end of the casting pipe (3) is directly connected with the bottom box mold (8). The sand mold (5) is connected, the upper end of the casting pipe is open, the lower end is closed, and 15 r...

Embodiment 2

[0021]A 15-ton electric furnace is used to smelt 70Mn2 cast steel roll material, and a cast steel roll with a weight of 12 tons is cast. When the composition of molten steel meets the requirements, it is released from the furnace. The middle box metal mold (6) is placed on the upper end of the bottom box metal mold (7), the upper box metal mold (4) is placed on the upper end of the middle box metal mold (6), and the sprue cup (2) is placed on the upper box On the top of the sand mold (5) in the metal casting mold (4), an air vent (9) is also arranged on the sprue cup (2), and the air vent (9) communicates with the mold cavity. The casting pipe (3) is installed in the center of the roll mould, the upper end of the casting pipe (3) is directly connected with the sprue cup (2), and the lower end of the casting pipe (3) is directly connected with the bottom box mold (8). The sand molds (5) are connected, the upper end of the casting pipe is open, the lower end is closed, and 35 r...

Embodiment 3

[0023] A 10-ton electric furnace is used to melt 75CrNiMo cast steel roll material, and a cast steel roll with a weight of 6 tons is cast. When the composition of molten steel meets the requirements, it is released from the furnace. The middle box metal mold (6) is placed on the upper end of the bottom box metal mold (7), the upper box metal mold (4) is placed on the upper end of the middle box metal mold (6), and the sprue cup (2) is placed on the upper box On the top of the sand mold (5) in the metal casting mold (4), an air vent (9) is also arranged on the sprue cup (2), and the air vent (9) communicates with the mold cavity. The casting pipe (3) is installed in the center of the roll mould, the upper end of the casting pipe (3) is directly connected with the sprue cup (2), and the lower end of the casting pipe (3) is directly connected with the bottom box mold (8). The sand mold (5) is connected, the upper end of the casting pipe is open, the lower end is closed, and 20 r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com