Patents

Literature

94results about How to "Good hardness uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-molybdenum non-nickel middle chrome wear resistant steel casting and heat treatment method thereof

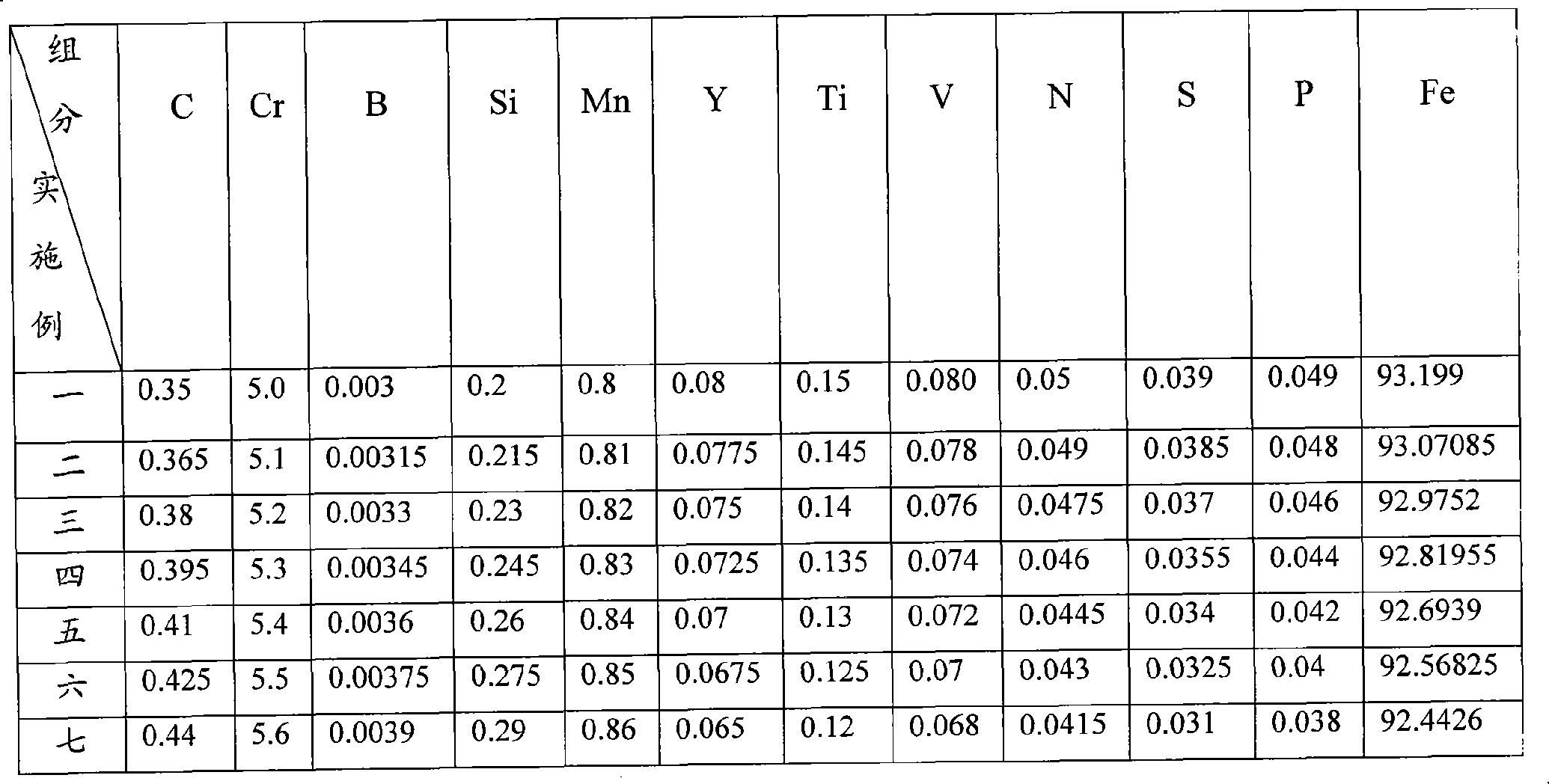

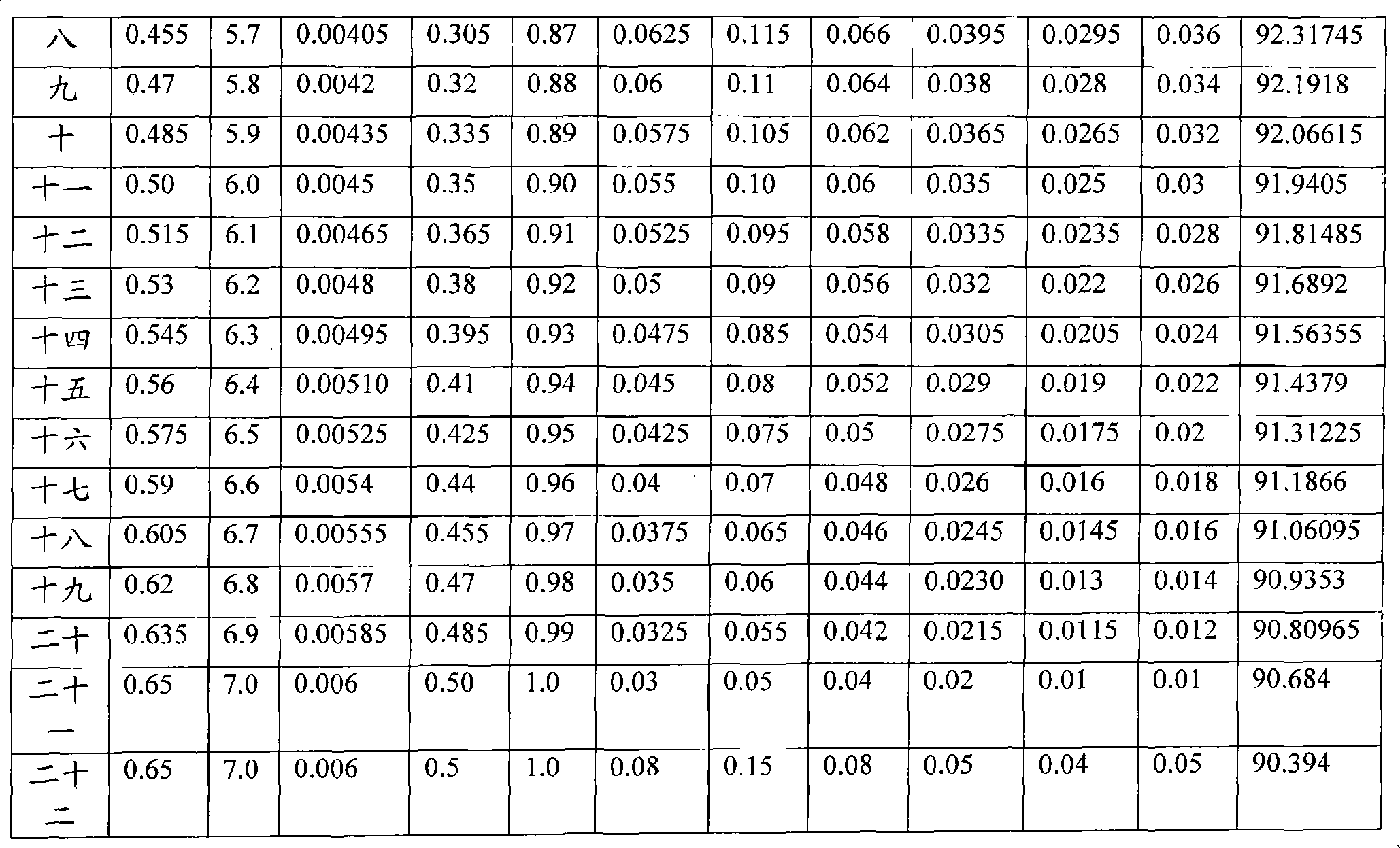

The invention belongs to the technical field of metal wear-resistant materials and particularly relates to a wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium and a heat treatment method thereof. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium comprises the components of the following mass percentages: 0.35 to 0.65 wt percent of C, 5.0 to 7.0 wt percent of Cr, 0.003 to 0.006 wt percent of B, 0.2 to 0.5 wt percent of Si, 0.8 to 1.0 wt percent of Mn, 0.03 to 0.08 wt percent of Y, 0.05 to 0.15 wt percent of Ti, 0.04 to 0.08 wt percent of V, 0.02 to 0.05 wt percent of N, less than 0.04 wt percent of S, less than 0.05 wt percent of P and the balance of ferrite. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium can be manufactured by an electric furnace using a sand casting. The invention carries out step quenching by using two types of quenching oils with different temperatures, thus leading to depth of more than 60mm of the quenching full hardening layer of the cast steel, high hardness, good uniformity of the hardness, and no cracks in the heat treatment. The casting steel is free of expensive alloying elements such as molybdenum or nickel, raw materials resource is rich, the manufacture cost is low and economic benefit is good.

Owner:SHENZHEN UNIV

Preparation method for cold rolls of super hardness wide width light gauge aluminum foils

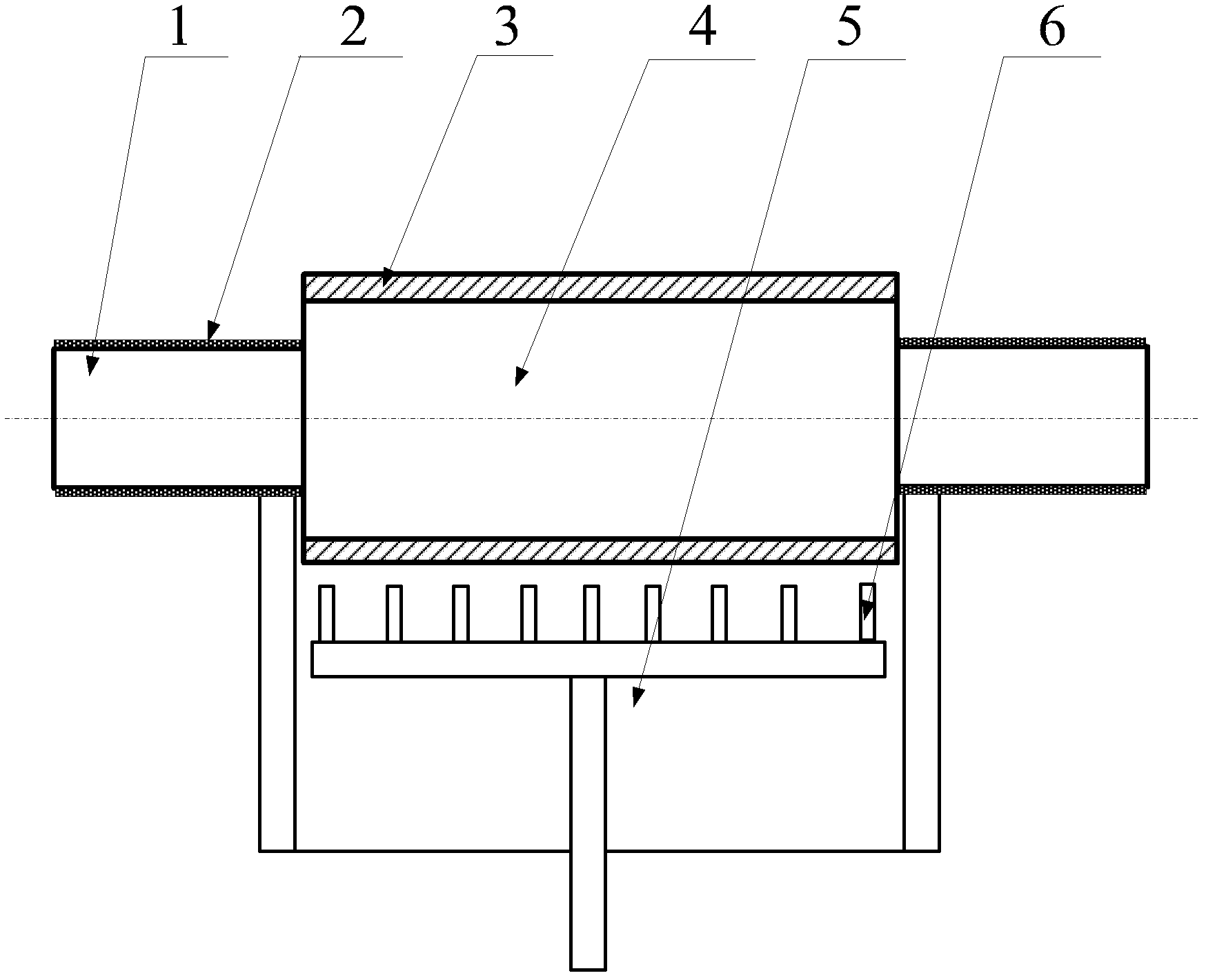

ActiveCN103100829AExcellent hardening performanceExcellent hardenabilityFurnace typesHeat treatment furnacesNumerical controlTemperature control

The invention relates to the technical field of cold rolls, in particular to a preparation method for cold rolls of super hardness wide width double-zero aluminum foils. The method particularly comprises the following steps: firstly, carrying out anneal process on a blank roll which is made of high chromium alloy materials in a forged mode, then carrying out rough turning process, thermal refining, semi fine turning process and heat treatment, and finally carrying out fine turning process on the blank roll to repair a die until a finished product is obtained. According to the preparation method for the cold rolls of the super hardness wide width double-zero aluminum foils, the high chromium alloy materials and a four-pillar sunken downwards type double-power-frequency heat treatment technology are adopted, the cold rolls are manufactured through full numerical control four-area temperature-controlled liquid nitrogen processing cryogenic treatment, the hardness of roll bodies of the cold rolls can reach 102-104 HSD, the depth of a hardening layer is larger than or equal to 25mm, uniformity of the hardness is within HSD+ / -0.5, length of roll faces exceeds 2300mm, high-grade wide width aluminum foils with width of the finished aluminum foils reaching 2300mm and thickness of 0.0065mm or below 0.0065mm can be rolled, and the preparation method is widely applied to industries such as cigarettes, food, medicine, electrons, photographic apparatuses and chemicals for daily use.

Owner:CHANGZHOU ECCO ROLLER

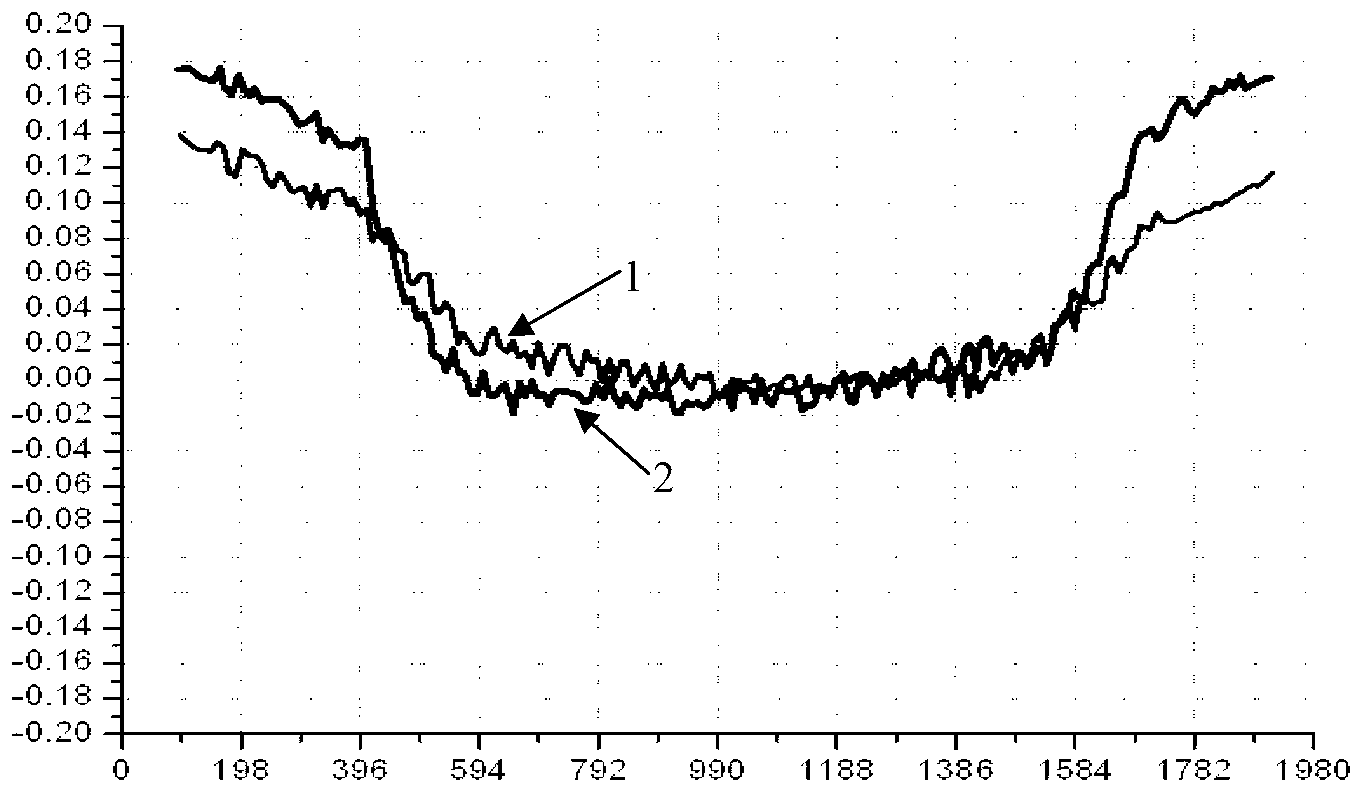

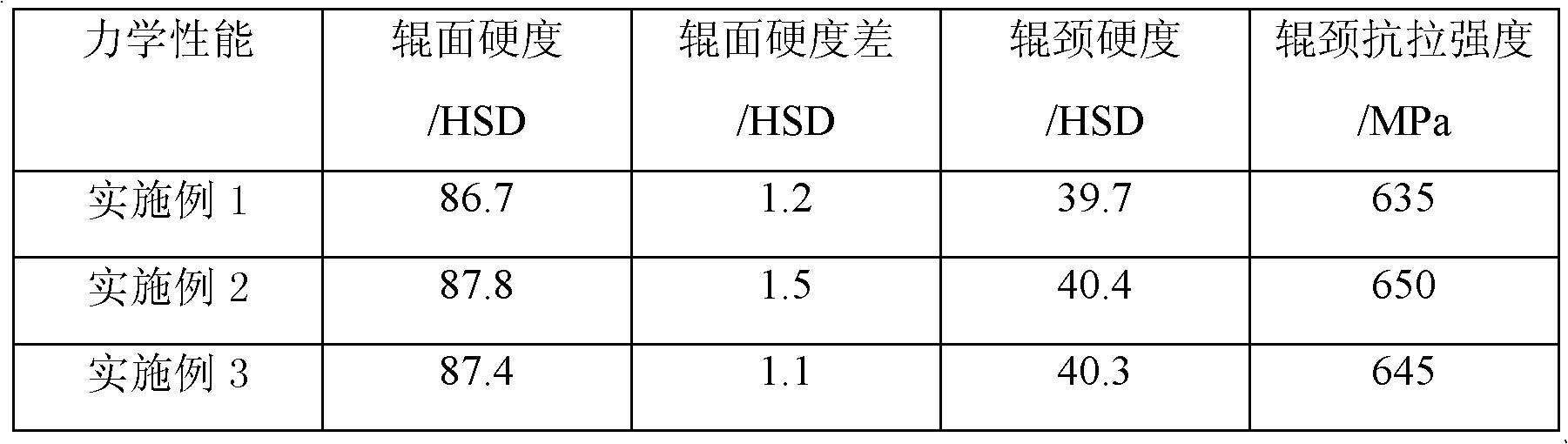

Manufacture method of composite milling roller with good roller surface rigidity uniformity

InactiveCN101760603AGood hardness uniformityHigh strengthFurnace typesHeat treatment furnacesEconomic benefitsRoom temperature

The invention discloses a manufacture method of a composite milling roller with good roller surface rigidity uniformity, which is characterized in that the method comprises the following steps: firstly, heating the composite milling roller to a temperature 80 to 150 DEG C higher than the critical point AC1 in a heating furnace; placing the composite milling roller into a cold controller after heat preservation; firstly, spraying and cooling the composite milling roller for 5 to 15 minutes; then, cooling the composite milling roller for 20 to 60 minutes by gas; finally, cooling the composite milling roller by air until the roller surface temperature is lower than 300 DEG C; putting the composite milling roller into a furnace for tempering treatment at the tempering heating temperature between 450 and 580 DEG C; cooling the furnace to the temperature lower than 200 DEG C after heat preservation; and cooling the composite milling roller to the room temperature by air. The rigidity of the rolling surface of the composite milling roller of the invention is uniform, the service life is obviously prolonged, and the invention has good economic benefits when being popularized and applied.

Owner:BEIJING UNIV OF TECH

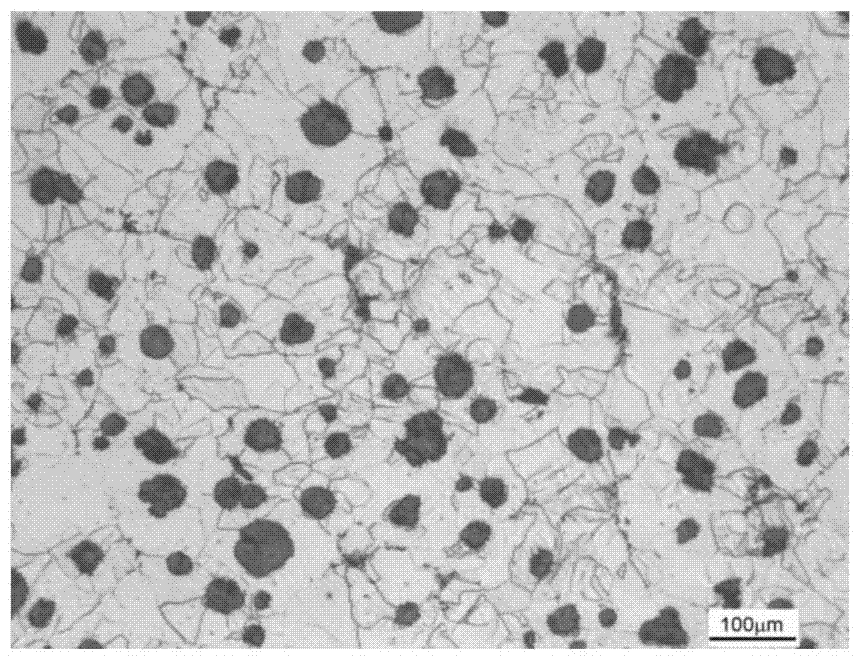

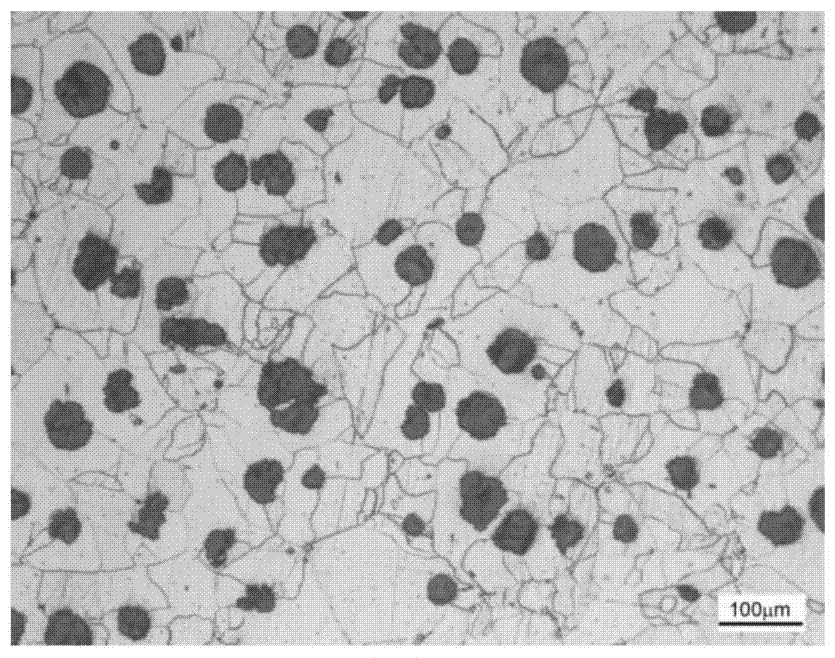

Centrifugal composite high-nickel-niobium wear-resisting cast iron roll and casting method thereof

ActiveCN103074539AReduced ability to split metal substratesGood anti-cracking effectRollsMetal rolling arrangementsCast ironNickel

The invention relates to the field of cast iron rolls, in particular to a centrifugal composite high-nickel-niobium wear-resisting cast iron roll and a casting method thereof. The centrifugal composite high-nickel-niobium wear-resisting cast iron roll comprises a working layer and a core layer, and is characterized in that the working layer is composed of the following chemical components by weight percentage: 2.9-3.6% of C, 0.6-1.5% of Si, 0.4-1.2% of Mn, less than 0.10% of P, less than 0.05% of S, 3.01-4.8% of Ni, 1.0-2.0% of Cr, 0.2-2.0 % of Mo, 0.1-2.0% of Nb, 1.0-4.0% of V, 0.05-2.0% of W, and the balance of Fe. Compared with the prior art, the invention has the benefits that bulk wear-resisting particles are distributed in a dispersing way and embedded in a roll metal matrix in dot and bulk shapes, and graphite exists in a dot shape; the wear-resisting particles are distributed in a dispersing way and are firm and not easy to fall off by being embedded into the matrix, so that the whole wear-resisting performance of the matrix structure of the roll is greatly prompted; and wear of the whole roll surface of the roll is uniform.

Owner:鞍钢轧辊有限公司

Corrosion-resistant easy cutting plastic mold steel

InactiveCN1920085AImprove corrosion resistanceEasy to processHeat treatment process controlStructure propertyMachinability

The invention relates the plastic mold steel. The weight percents of the components are as follows: C0.25-0.35, Mn0.50-1.00, Si0.30-0.60, S0.04-0.10, P<=0.025, Cr15.00-18.00, Mo0.05-0.03, V0.06-0.35, Ni0.60-1.00, N0.03-0.07, and the left are steel furnace burden. The method comprises the following steps: using electric furnace, vacuum degasification and electroslag remelting smelting. The invention also adopts the electric furnace and vacuum degasification smelting technology. The plastic mold steel has plastic mold steel, free-cutting machinability, homogeneous structure property and good deformability. The plastic mold steel is used to make large-scale plastic mold.

Owner:WUXI CHICHENG SPECIAL STEEL VENDITION

Method for preparing high-chromium wear-resistant alloy through laser cladding

The invention discloses a method for preparing a high-chromium wear-resistant alloy through laser cladding. The method is characterized by comprising steps of: firstly, uniformly mixing 80-82% of Fe-Cr-B powder, 5.5-6.0% of wolfram carbide powder, 1.0-1.2% of nickel-coated graphite powder, 8-10% of high-carbon ferrochrome powder and 2.5-3.5% of ferrovanadium powder according to mass fractions; utilizing a fiber optic laser and adopting a synchronous power feeding method to carry out laser cladding on a basic material of a Crl2Move steel, wherein the power feeding rate is 12-15g / min, the laser power is 2.0-2.5KW, the scanning velocity is 4-6mm / s, and the number of the cladding layers is 4-6; and finally, obtaining a high-chromium wear-resistant alloy laser cladding layer with high hardness, good wear resistance, surface without cracks, impurities and pores and smooth surface.

Owner:BEIJING UNIV OF TECH

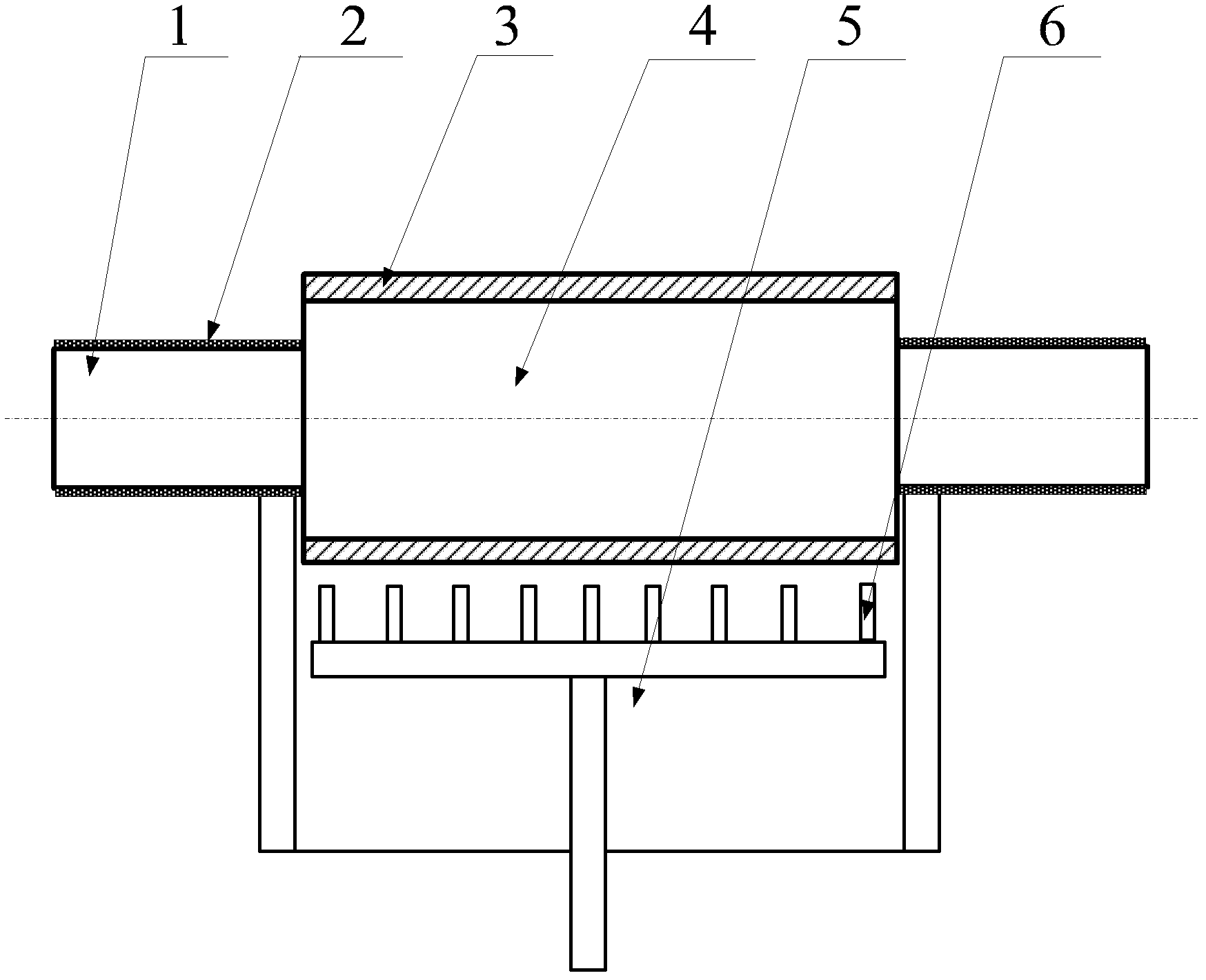

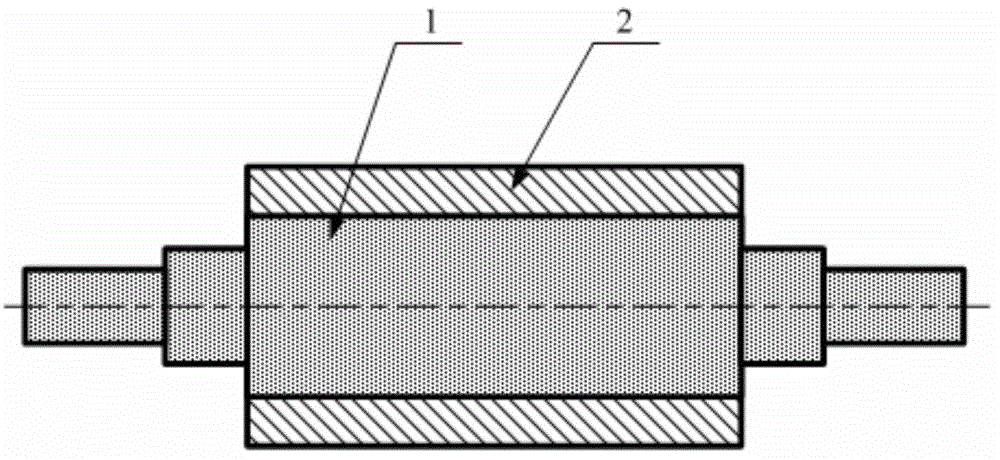

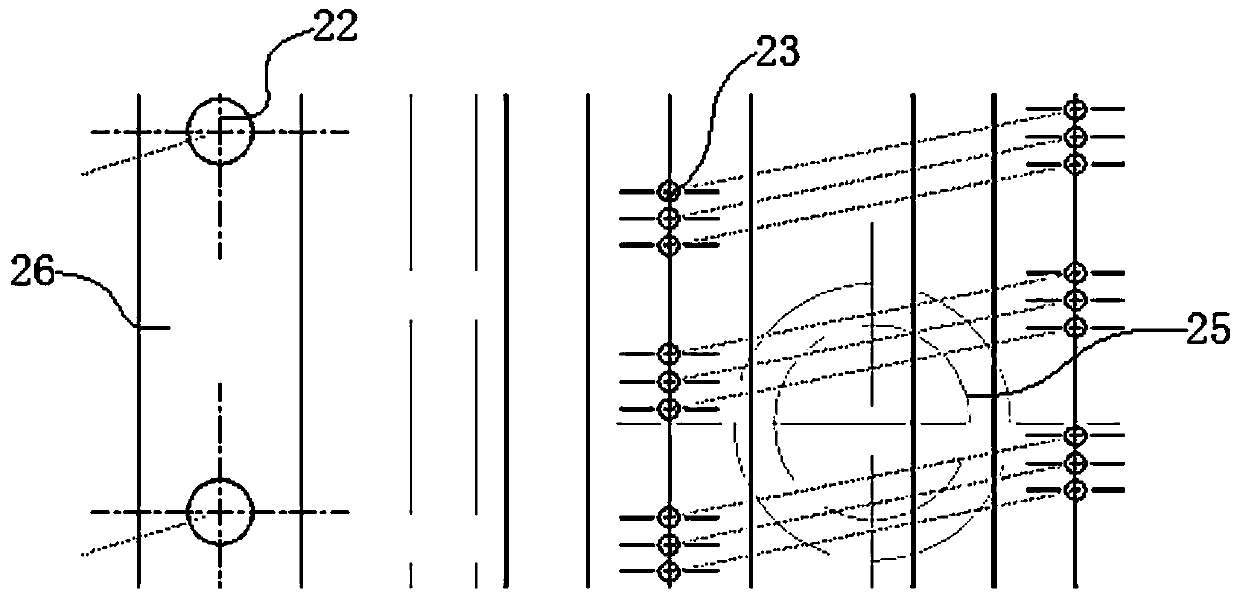

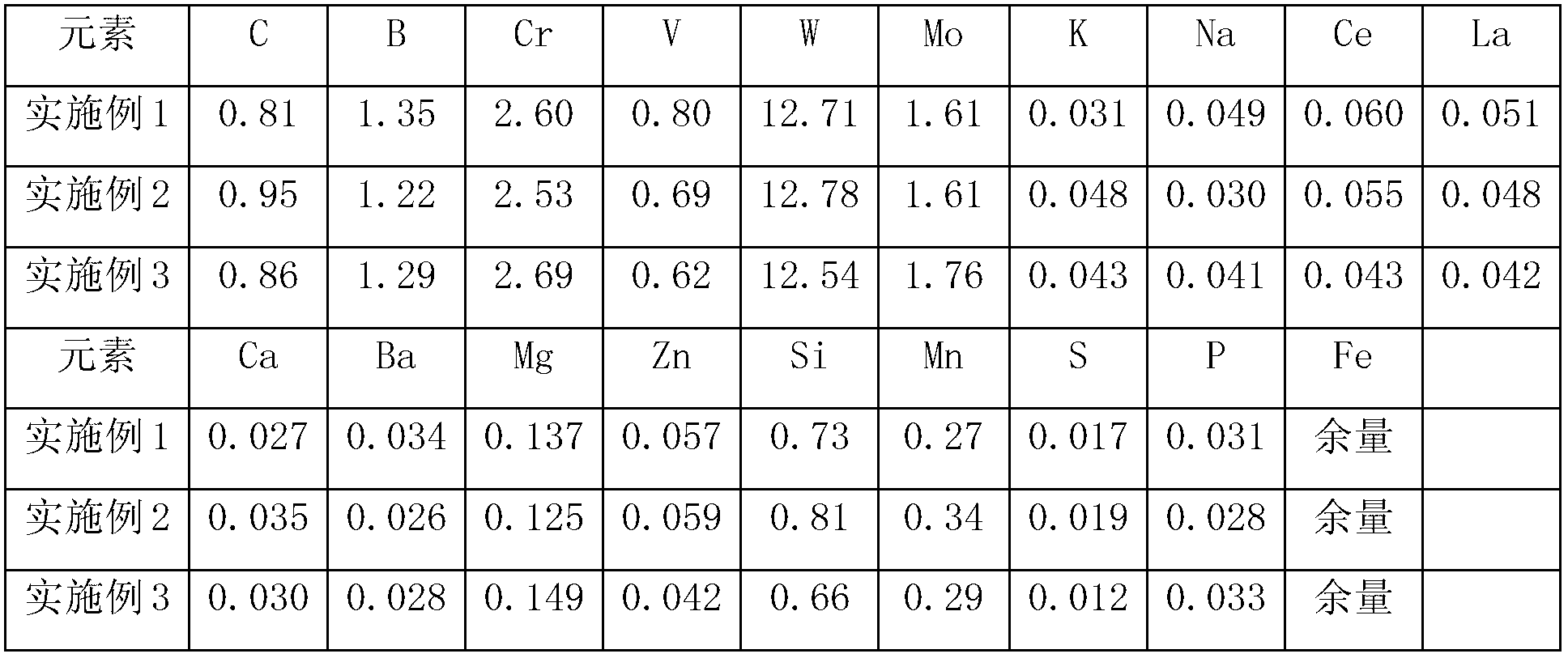

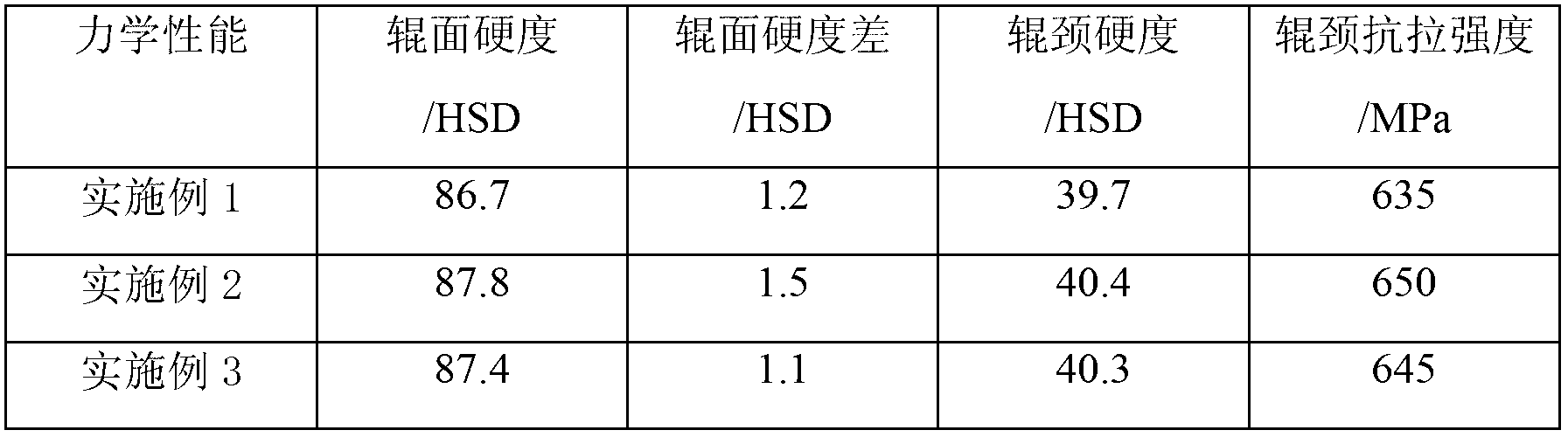

Composite roll having uniform roll surface hardness and made of high-speed steel containing boron and method for manufacturing composite roll

InactiveCN102634733AHigh roller surface hardnessHigh hardnessFurnace typesRollsDuctile ironLanthanum

A composite roll having uniform roll surface hardness and made of high-speed steel containing boron and a method for manufacturing the composite roll belong to the technical field of manufacture of rolls. A roll body is made of the high-speed steel containing boron, a roll core is made of spheroidal graphite cast iron, the roll body and the roll core are centrifugally cast in a compounded manner,and metallurgical bonding is realized. On the basis of high-tungsten high-speed steel, the chromium content of the roll body is reduced, and the boron and a proper quantity of trace alloying elementssuch as potassium, sodium, calcium, barium, zinc, magnesium, lanthanum, cerium and the like aer added into the roll body. The roll body is heated in a heating furnace, stays warm and then is placed in a cooling control device, a roll neck is coated with a heat-insulating material and is placed outside the cooling control device, the roll body is in spray cooling according to a spray quenching process 1, then is in spray cooling according to a spray quenching process 2 until the temperature of the roll body is lower than 160 DEG C, and is in natural air cooling, when the temperature of the roll surface rises to 300 DEG C, the roll body is in spray cooling according to the spray quenching process 2 again, spray cooling is performed repeatedly until the rising temperature of the roll surfacedoes not exceed 300 DEG C, and then the roll body is in air cooling to the room temperature. The roll surface hardness of the composite roll is high, hardness uniformity of the roll surface is good, wear resistance of the roll is fine, and the service life of the composite roll is long.

Owner:BEIJING UNIV OF TECH

Roll induction quenching process method

ActiveCN105063285AFew parametersEasy to operateFurnace typesIncreasing energy efficiencyInductorQuenching

The invention discloses a roll induction quenching process method. The roll induction quenching process method comprises the following steps that (1) a roll to be quenched is preheated, the preheating temperature is 220-250 DEG C, and the preheating holding time is 6-12 h; (2) the preheated roll to be quenched is hoisted into a quenching inductor and clamped in place, so that the two axial ends of the roll to be quenched extend out of the quenching inductor by 25-40 mm respectively; (3) a roll rotary mechanism is started and is powered on to be heated, and the temperature of a roll body is rapidly increased to 900-960 DEG C and is preserved; and (4) the roll obtained after heating and temperature preservation is rapidly hoisted into a spray quenching tank, the roll body is subjected to spray quenching and cooling, and then the induction quenching process is completed. The whole induction quenching is conducted on the roll body by setting the corresponding parameters, the purpose of controlling the depth of a quench-hardened layer of the roll is achieved, and as the quenching process parameters are reduced, the process operability of quenching and the product quality are improved.

Owner:YIXING YONGCHANG ROLL

Wear resistance rolling roll for strip steel cold rolling and manufacturing method of wear resistance rolling roll

InactiveCN104438337AReduce manufacturing costHigh hardnessRollsMetal rolling arrangementsMetallic aluminumAdditive ingredient

The invention provides a wear resistance rolling roll for strip steel cold rolling and a manufacturing method of the wear resistance rolling roll, and belongs to the technical field of cold-rolling strip steel. The cold rolling roll is formed by compositing a wear resistance roll sleeve and a machined roll shaft in a hot charging mode. GGr15 waste steel, Q235 low-carbon waste steel, low-carbon chromium iron, ferro-molybdenum, ferroniobium, ferro manganese nitride, metallic aluminum and boron iron ingredients are adopted for the roll sleeve, electric-furnace smelting is conducted, microalloy treatment is conducted on molten steel, and pouring is conducted on a centrifugal casting machine. After quenching and tempering are conducted on the rolling roll, the rolling roll is high in hardness and good in toughness and wear resistance, and a good using effect is achieved.

Owner:SHANDONG SHIYU BEARING

High-tungsten-vanadium high-speed steel wear-resistant roller and manufacturing method thereof

ActiveCN110000362AGood metallurgical bondReduce hardnessRollsMetal rolling arrangementsAlloyMolten steel

The invention discloses a high-tungsten-vanadium high-speed steel wear-resistant roller and a manufacturing method thereof, and belongs to the technical field of steel rolling. An electric furnace isadopted for smelting outer-layer high-speed steel molten steel and roller core molten iron, outer-layer high-speed steel of the roller is smelted in the electric furnace firstly, the molten steel in the furnace is controlled to comprise the chemical components of, by mass percent, 10.23%-10.67% of W, 1.76%-1.94% of Mo, 2.81%-2.97% of C, less than 0.035% of P, less than 0.030% of S, 6.15%-6.42% ofCr, 2.27%-2.46% of Nb, 2.24%-2.41% of Si, 0.64%-0.83% of Mn, and the balance Fe and other inevitable impurities, then the molten steel is heated to 1653-1677 DEG C, aluminum and ferrovanadium are sequentially added, multi-element alloy particles are added into a ladle, and then the molten steel is poured into a roller on a vertical centrifuge. After heat treatment, the roller has good toughness and excellent wear resistance, is used for rolling high-strength low-alloy hot-rolled threaded steel, and is excellent in use effect.

Owner:安徽环渤湾高速钢轧辊有限公司

High-speed steel roller special for cold-rolled high-strength car plate and manufacturing method thereof

ActiveCN106435370AIncreased accident resistanceMeet the requirements of rolling conditionsFurnace typesHeat treatment furnacesManganeseQuenching

The invention discloses a high-speed steel roller special for a cold-rolled high-strength car plate. The chemical components of the high-speed steel roller special for the cold-rolled high-strength car plate comprise, by weight, 0.80-0.90% of carbon, 0.20-0.45% of silicon, 0.15-0.40% of manganese, 3.55-3.70% of chromium, 4.25-4.40% of molybdenum, 1.50-1.70% of vanadium, 5.30-5.45% of tungsten, 0.030% or less of phosphorus, 0.030% or less of sulphur, and the balance iron and inevitable impurities. A manufacturing method of the high-speed steel roller special for the cold-rolled high-strength car plate comprises the following steps that a roller blank is smelted and forged according to the chemical components and weight percentage, and preheat treatment and ultimate heat treatment are conducted; and the ultimate heat treatment comprises the following methods that sub-temperature quenching plus oil cooling and twice tempering treatment are conducted by a protective atmosphere oven. The overall hardness of the high-speed steel roller special for the cold-rolled high-strength car plate is equal to or larger than 64HRC, the high-speed steel roller has high abrasion resistance and good accident resistance, and thus the demands of the rolling working conditions of high-strength steel and super high-strength steel can be met.

Owner:BAOSTEEL ROLL SCI & TECH

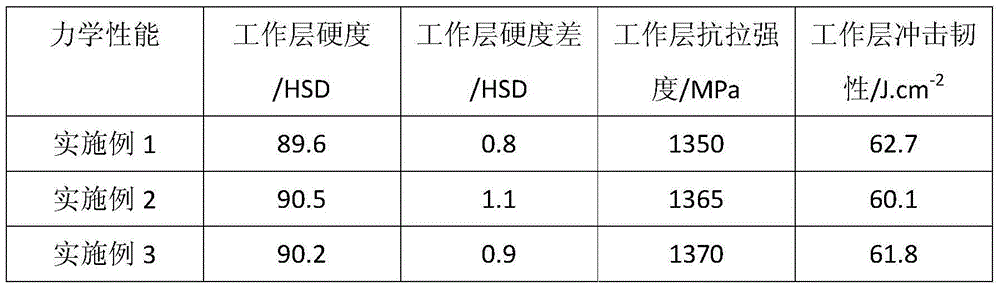

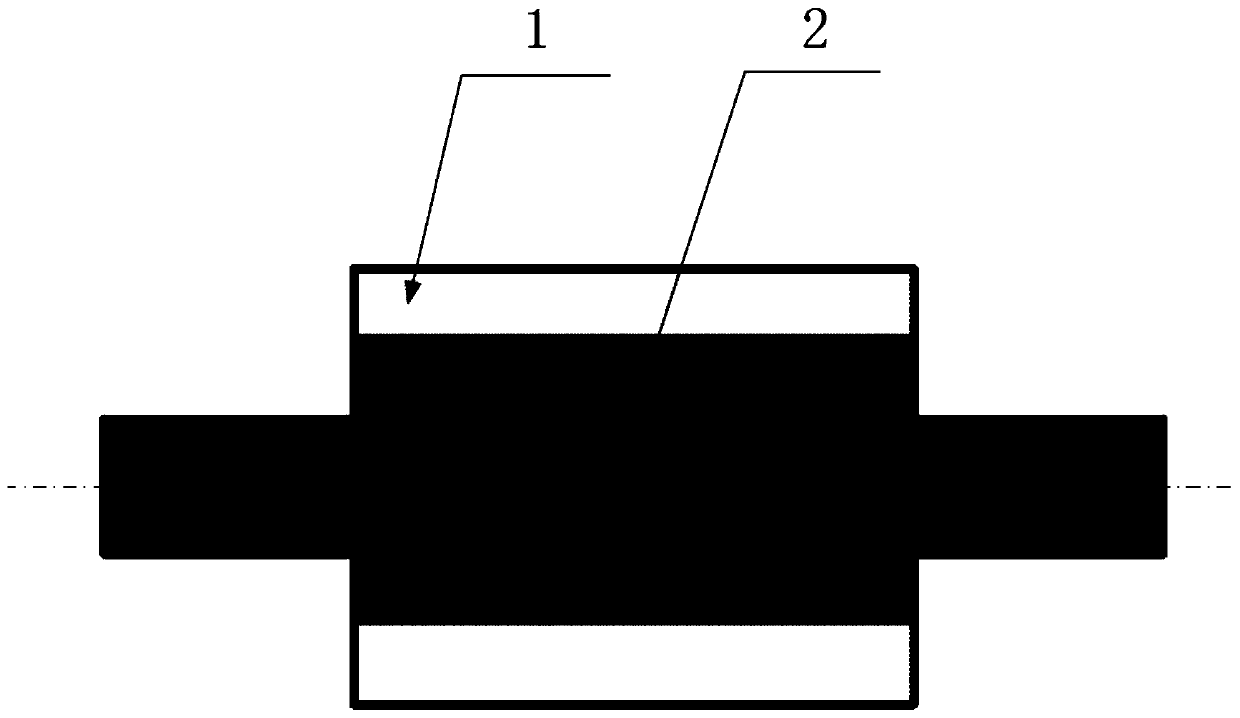

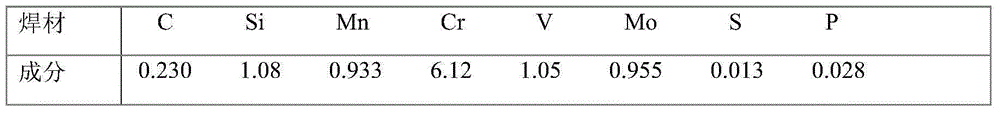

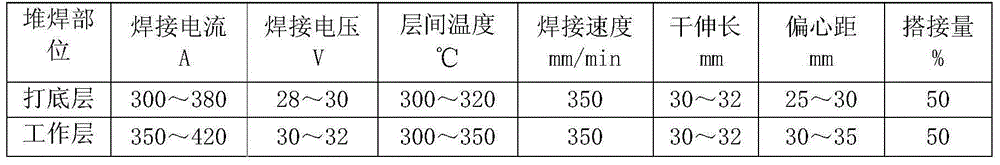

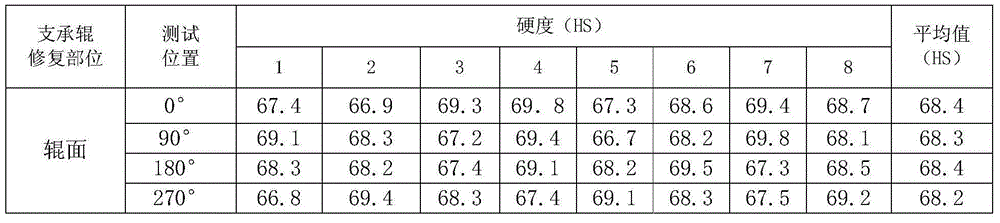

Build up welding method for repairing cold rolling and leveling supporting rollers

InactiveCN105215510ALow costImprove the value of economic useArc welding apparatusEngineeringHardness

The invention discloses a build up welding method for repairing cold rolling and leveling supporting rollers in the technical field of welding. The method includes the following steps of firstly, removing fatigue layers and cracks on the surfaces of the rollers; secondly, preheating the rollers to a certain temperature; thirdly, conducting welding, wherein in the welding process, working layers are welded after base layers are welded, and dehydrogenation is conducted after welding is completed; fourthly, conducting machining to polish build up welding layers. The method has the advantages that the rollers which lose efficacy are processed through ordinary flux-coated wires, the specific build up welding method and specific build up welding conditions, cost is low, the method is simple and easy to implement, the roller surface hardness of the rollers repaired through the method is between HS66.7 and HS69.8, the hardness uniformity is + / -HS1.55 and is superior than that of new rollers, the service life of the repaired rollers is equivalent with that of the new rollers, the repaired rollers completely meet use conditions, the rollers which lose efficacy are used again, cost is saved, and economization use value of metallurgy waste of the type is improved.

Owner:PANZHIHUA GANGCHENG GRP XIELI

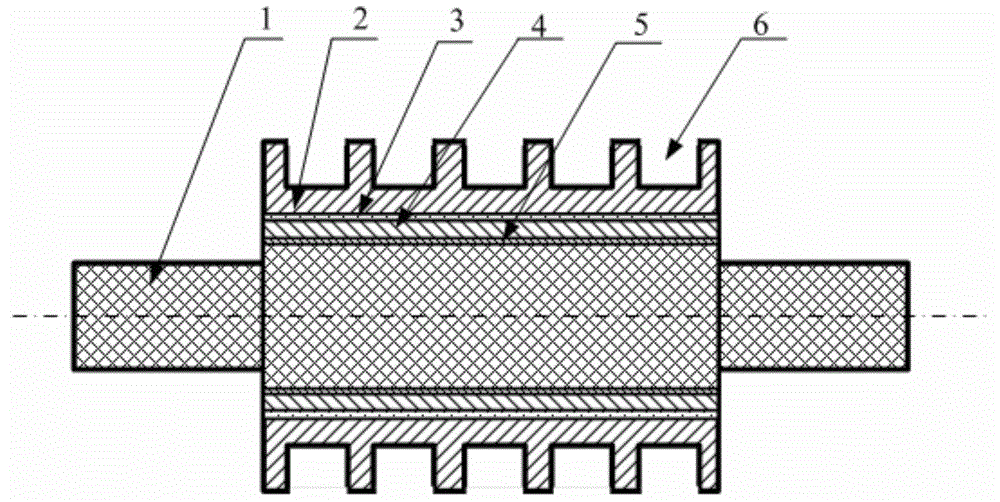

Wearable alloy profile steel bushing combined roller with groove and manufacturing method thereof

ActiveCN104646424AHigh roller surface hardnessGood hardness uniformityRollsMetal rolling arrangementsWear resistantEconomic benefits

The invention discloses a wearable alloy profile steel bushing combined roller with groove and a manufacturing method thereof and belongs to the technical field of a wearable material. The wearable alloy profile steel bushing combined roller with groove is formed by combining a roller shaft and a bushing into a whole in a hot charging and cementation composite way; the outer layer of the bushing is made from a multi-element high chromium wear-resistant alloy; the inner layer of the bushing is a low-alloy steel pipe; the roller shaft is arranged in the low-alloy steel pipe and coaxially penetrates through the low-alloy steel pipe. The roller shaft is high in strength; the roller shaft and the bushing are well combined; the roller shaft can be repeatedly used and is simple and convenient to detach. The profile steel bushing combined roller with groove has excellent wear resistance and has good economic benefit after being popularized and applied.

Owner:娄底市巨能高新耐磨材料有限公司

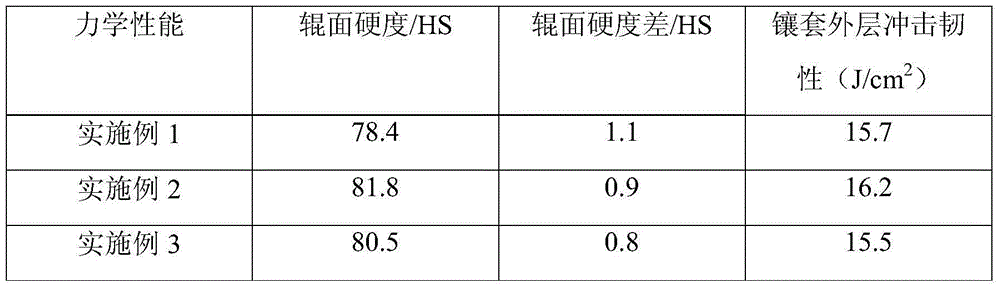

Heat treatment method for inlaid backup roll sleeve

InactiveCN105543451AImprove wear resistanceHigh contact fatigue strengthFurnace typesIncreasing energy efficiencyHardnessIngot

The invention discloses a heat treatment method for an inlaid backup roll sleeve. The heat treatment method comprises the following steps: A, smelting a steel ingot, and then forging a roll sleeve blank, followed by rough machining and flaw detection; B, performing hardening and tempering on the roll sleeve blank, heating the roughed roll sleeve, and performing tempering on the roll sleeve; C, performing semi-finish turning machining and flaw detection on the roll sleeve; D, hoisting the semi-finish turning machined roll sleeve to a power-frequency quench machining tool, carrying out overall induction heating by using a dual-power frequency power source, adopting a water quenching method; subsequently, carrying out tempering; E, detecting metallographic structures of inner and outer surfaces of the roll sleeve, and detecting residual stress and hardness of the outer surface; F, performing finish machining on the roll sleeve; and G, assembling a roll shaft, and performing finish machining on the assembled roll. The heat treatment method for the inlaid backup roll sleeve of the present invention meets the requirements in structure, hardness and residual stress aspects, and meanwhile, such properties as abrasive resistance and contact fatigue strength of the roll sleeve also are improved.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Special working roller for tin-plating finishing machine and manufacturing method thereof

ActiveCN110656294AEfficient crushingIncreased effectiveness of high temperature homogenizationRevolution surface grinding machinesIncreasing energy efficiencyIngotImpurity

The invention discloses a special working roller for a tin-plating finishing machine and a manufacturing method thereof. The working roller is prepared from the following chemical components in percentage by weight: 0.70-0.90% of carbon, 0.40-0.80% of silicon, 0.20-0.50% of manganese, less than or equal to 0.020% of phosphor, less than or equal to 0.008% of sulfur, 4.00-4.90% of chromium, 0.20-0.60% of nickel, 0.10-0.50% of molybdenum, 0.05-0.30% of vanadium and the balance iron and inevitable impurities. The manufacturing method for the working roller comprises the following steps of smeltingelectroslag ingot blank, forging roller blank, preparing for thermal treatment, performing final thermal treatment, and finish-machining. Problems such as component segregation, carbide segregation and the like are effectively controlled by optimizing the components and optimizing the manufacturing links, so that abnormal grains caused by follow-up chromium-plating or roughening due to componentsegregation or carbide segregation are avoided, and therefore, working condition requirements of the tin-plating finishing machine are met.

Owner:BAOSTEEL ROLL SCI & TECH

Manufacturing method for abrasion-resistant steel casting

The invention discloses a manufacturing method for an abrasion-resistant steel casting. The abrasion-resistant steel casting free of molybdenum and nickel and containing a proper amount of chromium comprises the following ingredients: 0.35-0.45 wt% of C, 1.2-2.3 wt% of Cr, 0.003-0.006 wt% of Nb, 0.2-0.5 wt% of Si, 0.5-1.0 wt% of Mn, 0.05-0.15 wt% of Ti, 0.04-0.08 wt% of V, 0.03-0.05 wt% of N, less than 0.04 wt% of S, less than 0.05 wt% of P, and the balance being Fe. The manufacturing method comprises the following steps: 1) according to parts by weight, scrap steel, pig iron, ferrochrome, sponge iron and a smelting additive with an amount of 1-1.5% based on the total mass of the above raw materials are added to an induction furnace for mixing and heating to melt, wherein the smelting additive is prepared from 10-15 parts of sodium oxide, 3.5-4.5 parts of aluminum oxide, 3-5 parts of potassium oxide, 6-8 parts of sodium carbonate, 4-6 parts of silicon dioxide, 11-15 parts of iron oxide, 0.5-2 parts of titanium dioxide, and 5-10 parts of anhydrous borax, and the contents of the chemical ingredients are adjusted according to requirements. The problem in the prior art that abrasion-resistant steel has high production cost because of containing molybdenum and nickel is solved.

Owner:湖北襄阳金磊环保科技有限公司

Casting method of anti-corrosion wear-resisting low-chromium alloy material

InactiveCN106191637AImprove wear resistanceImprove corrosion resistanceFoundry mouldsFoundry coresImpurityChromium Alloys

The invention discloses a casting method of an anti-corrosion wear-resisting low-chromium alloy material. The casting method comprises the following steps that raw materials are added into a smelting furnace, heat is preserved until the raw materials are melted completely, then deslagging is carried out, melted alloy liquid is obtained, and all elements comprise C, Si, Cr, Cu, Ca, Mn, Mo, N, Ni, Mg, Ti, Zr, S, P and the balance iron and unavoidable impurities; the alloy liquid is poured into a sand mould cavity with the surface coated with nanometer paint, the nanometer paint is prepared from a nanometer material and refractory aggregate, and a casting green body is obtained; and the casting green body is subjected to thermal treatment to obtain the anti-corrosion wear-resisting low-chromium alloy material. According to the casting method of the anti-corrosion wear-resisting low-chromium alloy material, the alloy material obtained through casting can be used in multiple environments and has good corrosion resistance and wear resistance, the hardness can reach over 70 HRC, and the requirement for the wear-resisting alloy material in the actual using process is met.

Owner:蚌埠市北晨微型机床厂

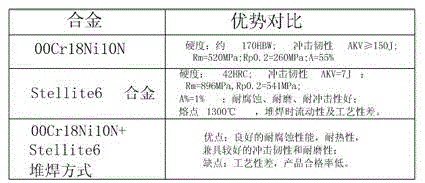

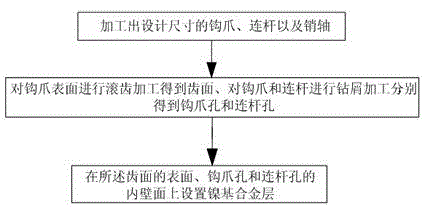

Reactor claw-link mechanism and manufacturing method thereof

InactiveCN104637552AFavorable refuelingFavorable retirementNuclear energy generationReactors manufactureAlloyEngineering

The invention discloses a reactor claw-link mechanism and a manufacturing method thereof. The reactor claw-link mechanism comprises a claw, a link and a pin shaft, wherein the claw has a toothed surface; more than one claw hole and more than one link holes for pin connection of the claw and the link are formed in the claw and the link respectively; and nickel base alloy layers are arranged on the toothed surface, the inner wall surfaces of the claw holes and the inner wall surfaces of the link holes. The manufacturing method of the reactor claw-link mechanism comprises the following steps: processing the claw, the link and the pin shaft in design sizes, hobbing or turning the surface of the claw to obtain the toothed surface, drilling the claw holes and the link holes in the claw and the link respectively, and laying the nickel base alloy layers on the toothed surface, the inner wall surfaces of the claw holes and the inner wall surfaces of the link holes. Through the manufacturing method, the reactor claw-link mechanism with favorable corrosion resistance, abrasion resistance, impact resistance and manufacturability can be manufactured. The invention provides a corresponding processing method.

Owner:李泽文 +1

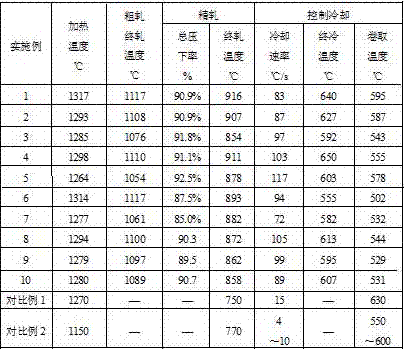

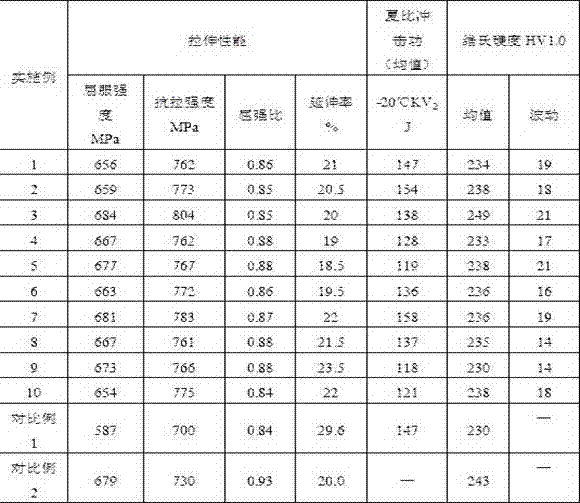

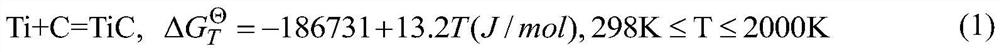

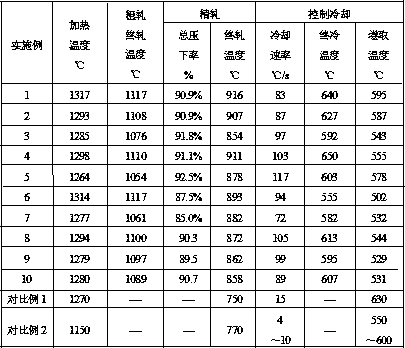

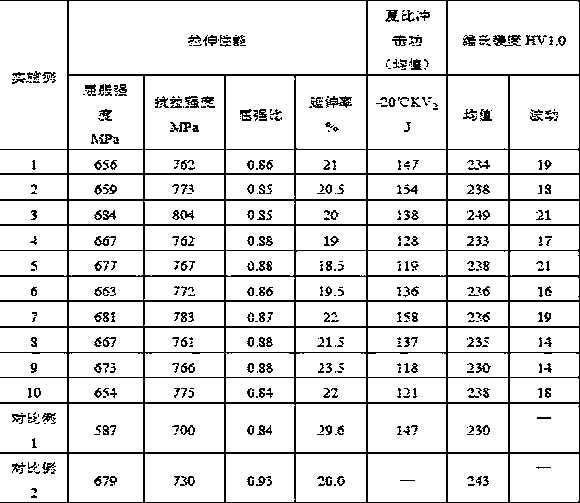

Hot rolled steel strip for CT100 level continuous pipe and production method

The invention discloses a hot rolled steel strip for a CT100 level continuous pipe and a production method. The hot rolled steel strip comprises the components of 0.10-0.14wt% of C, 0.10-0.30wt% of Si, 1.10-1.50wt% of Mn, less than or equal to 0.015wt% of P, less than or equal to 0.0020wt% of S, 0.25-0.40wt% of Cu, 0.15-0.35wt% of Ni, 0.60-1.00wt% of Cr, 0.020-0.050wt% of Nb, less than or equal to0.010wt% of V, 0.010-0.030wt% of Ti, less than or equal to 0.0050wt% of N, 0.015-0.060wt% of Al, and 0.0008-0.0025wt% of Ca. The production method comprises the steps that a blank is formed by continuous casting after rotary furnace smelting and other processes are completed; the casting blank is heated; rough rolling is carried out; finish rolling is carried out; and cooling and coiling are carried out. The theoretical working depth can reach 7000 m, the practical working depth is at least increased by 450 m, the underground working pressure reaches 90 MPa, the yield strength of the hot rolled steel strip is greater than or equal to 640 MPa, the tensile strength is greater than or equal to 740 MPa, the whole plate thickness and rigidity fluctuations are less than or equal to 23 HV1.0, the yield ratio is less than or equal to 0.88, the elongation percentage is greater than or equal to 18%, the cross section vickers hardness HV1.0 is less than or equal to 270, the low temperature toughness at minus 20 DEG C is higher than 100 J, and the hot rolled steel strip has no surface copper brittleness tendency.

Owner:武汉钢铁有限公司

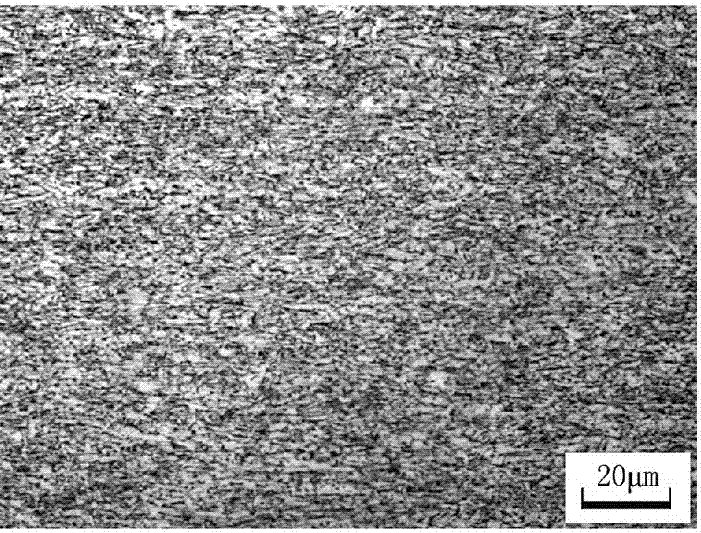

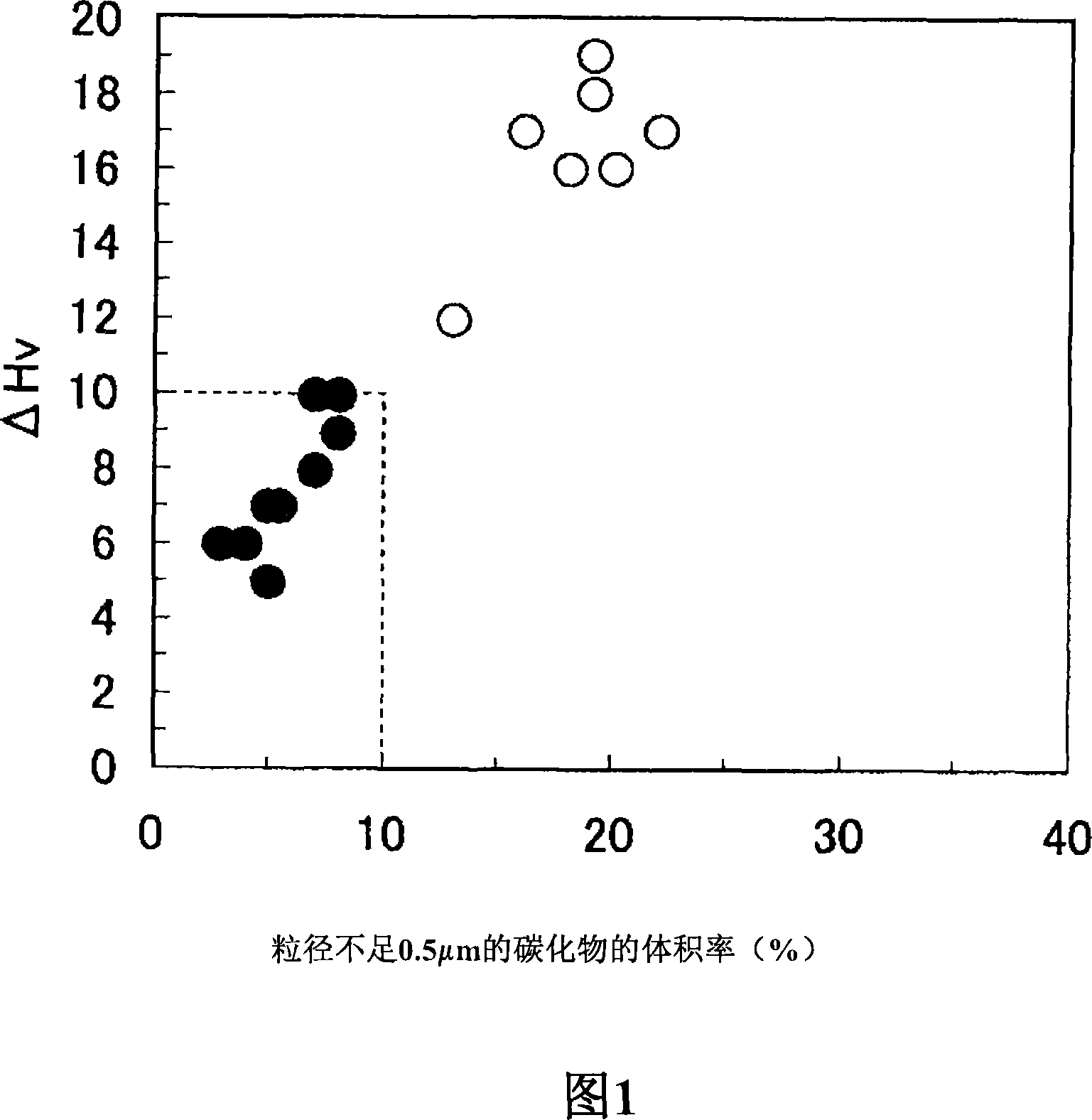

Cold-rolled high-carbon steel plate and process for manufacturing method therefor

InactiveCN101208441AGood hardness uniformityReduce the burden onFurnace typesHeat treatment furnacesCarbon steelSteel plates

A process for manufacture of a cold-rolled high-carbon steel plate comprising the steps of: hot-rolling a steel containing 0.2 to 0.7% by mass of C at a finishing temperature lower by 20 DEG C than a Ar3 transformation point or higher to produce a heat-rolled plate; cooling the heat-rolled plate to a temperature of 650 DEG C or lower at a cooling rate of 60 DEG C / sec or higher and lower than 120 DEG C / sec; taking-up the cooled hot-rolled plate at a take-up temperature of 600 DEG C or lower; cold-rolling the resulting hot-rolled plate at a pressure reduction rate of 30% or more to produce a cold-rolled plate; and annealing the cold-rolled plate at an annealing temperature ranging from 600 DEG C and an Ac1 transformation point inclusive. The process can produce a cold-rolled high-carbon steel plate which is excellent in stretch-flange formalibity and evenness in hardness in the thickness-wise direction.

Owner:JFE STEEL CORP

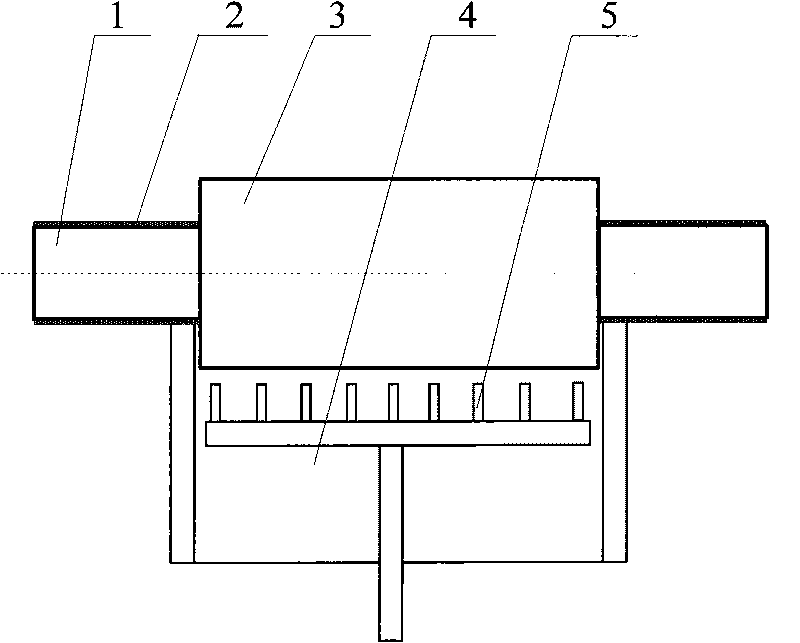

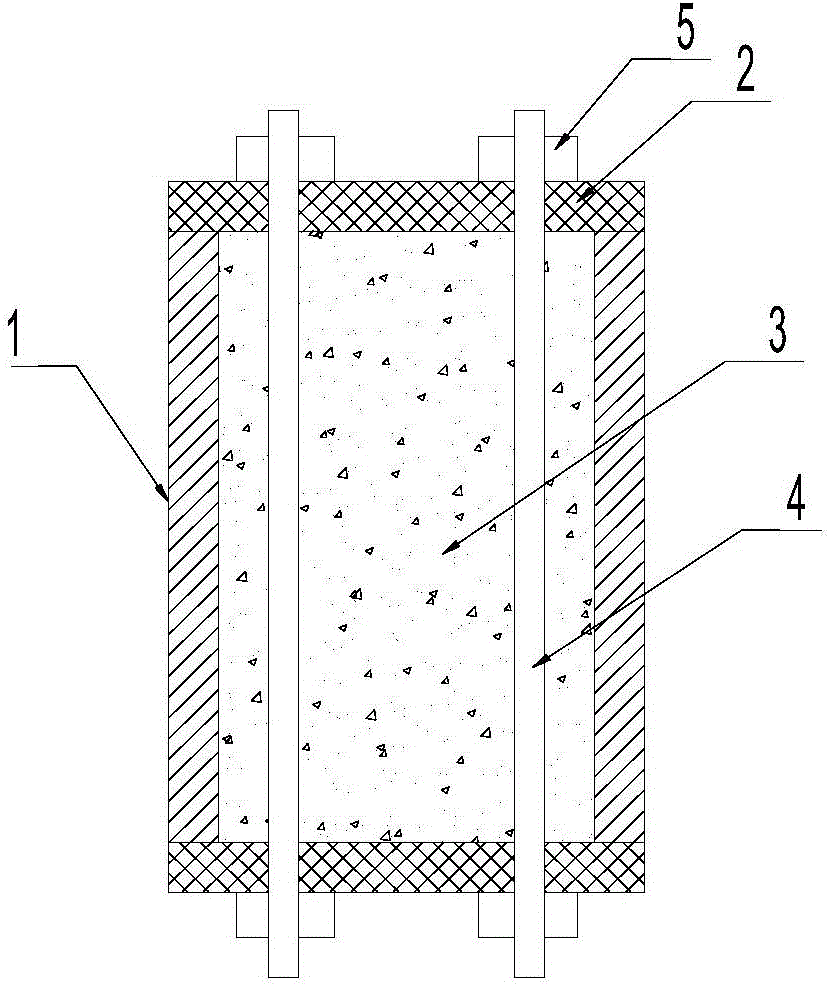

Surface quenching structure and quenching process of large-diameter cylindrical workpieces

InactiveCN104309172AGood hardness uniformityControl Hardening DepthFurnace typesHeat treatment furnacesThermal insulationQuenching

The invention relates to the technical field of workpiece quenching and particularly to a surface quenching structure and a quenching process of large-diameter cylindrical workpieces. The quenching structure comprises a cylindrical workpiece, a sealing cover and a thermal insulation material, wherein the thermal insulation material is filled in the cylindrical workpiece, and the end part of the cylindrical workpiece is sealed by the sealing cover. The quenching process of the cylindrical workpieces comprises the following steps: a. heating the quenching structure of the cylindrical workpieces to quenching temperature; b. throwing the quenching structure of the cylindrical workpieces into a quenching medium for quenching and cooling; c. annealing. The surface quenching structure and quenching process provided by the invention has the beneficial effects that compared with the existing temperature difference quenching process, the hardening depth which can be achieved by the quenching scheme is larger and can exceed by about 10%, the hardness uniformity is better, and the hardening depth can be accurately controlled by controlling the quenching and cooling times.

Owner:常州泉汇机械制造有限公司

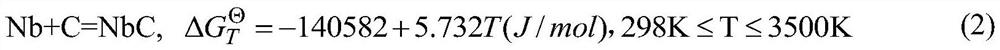

Wear resistant steel plate with 350-380 HBW hardness level, thick specification and high toughness and preparation method

The invention relates to the technical field of wear resistant steel plate preparation, in particular to a wear resistant steel plate with 350-380 HBW hardness level, thick specification and high toughness and a preparation method. The steel plate comprises the following chemical components: 0.15-0.19% of C, 0.20-0.60% of Si, 1.10-1.50% of Mn, 0.01-0.05% of Nb, 0-0.80% of Ni, 0.30-0.50% of Cr, 0.30-0.50% of Mo, 0.015-0.030% of V, P not more than 0.015%, S not more than 0.002%, 0.050-0.070% of Alt, and the balance of Fe and trace impurities. The method comprises the steps of smelting, heating of continuous-cast blanks, rolling, slow cooling of steel plates, offline quenching, and tempering heat treatment. The method is low in limiting condition on finished steel plates, high in thick specification of the steel plates and high in 40-DEG C low-temperature impact toughness.

Owner:贝斯山钢(山东)钢板有限公司 +1

Melting technique for producing QT450-18 nodular cast iron through silicon solid solution reinforced ferrite

ActiveCN106929746AImprove processing performanceGood hardness uniformityProcess efficiency improvementYttriumScrap

The invention discloses a melting technique for producing QT450-18 nodular cast iron through silicon solid solution reinforced ferrite. In the melting process, 60-70% of nodular iron pig iron by weight is added firstly, then 15-25% of scrap returns by weight are added, finally, 8-20% of carbon steel scrap by weight is added, and the temperature is 1320-1390 DEG C; a pouring process is adopted for nodularizing-inoculating treatment, specifically, auxiliary materials are added in a nodulizing ladle according to the weight percentage of the auxiliary materials accoundting for the total amount of nodulizing iron liquid, 1.20-1.40% of a yttrium-based heavy rare earth nodulizing agent is evenly laid on one side of the bottom, the nodulizing agent is evenly covered with 1.60-1.90% of a high-calcium-barium nucleating agent, and 0.003-0.006% of an antimony ingot is added before discharging; and according to the original iron liquid analysis result, 0-0.20% of ferromanganese is additionally added, and the temperature is 1450-1480 DEG C. A casting prepared through the melting technique is good in hardness uniformity and cutting performance, and the machining cost of the casting is reduced.

Owner:德阳广大东汽新材料有限公司

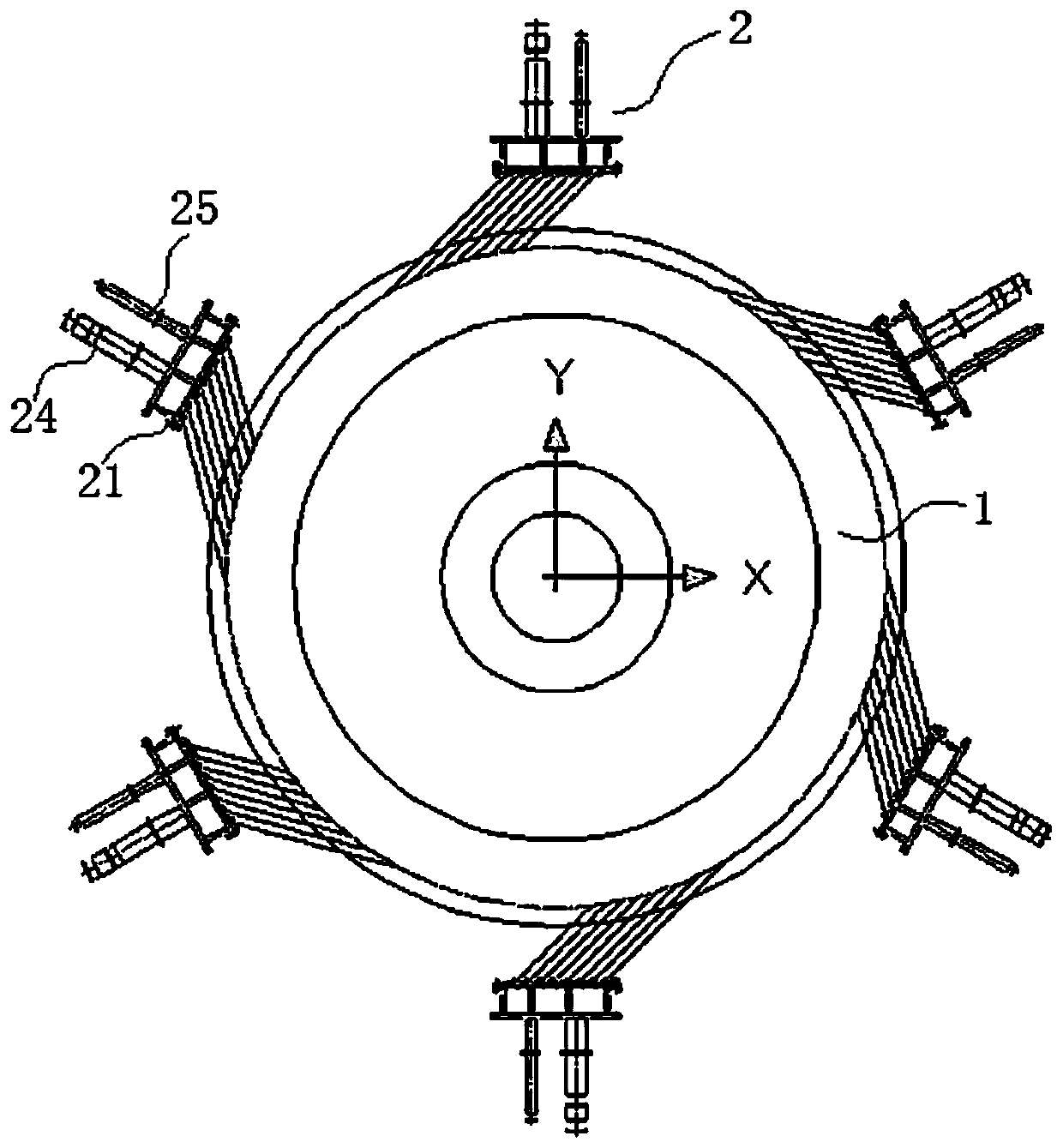

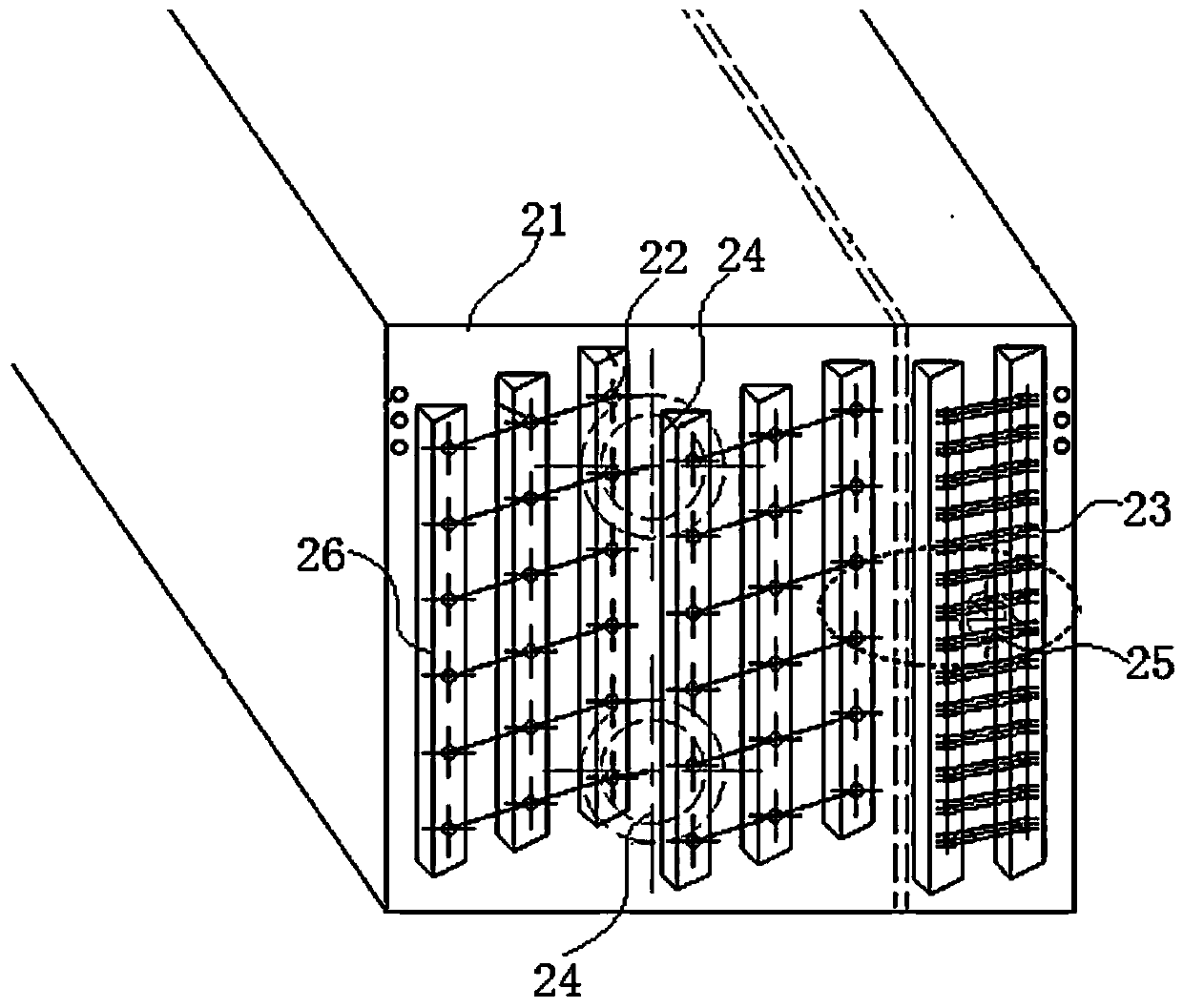

Train wheel cooling device and method and preparation method

PendingCN110777241AAdjust the spray volumeImprove cooling uniformityFurnace typesHeat treatment furnacesControl theoryMechanical engineering

The invention discloses a train wheel cooling device and method and a preparation method, and belongs to the technical field of train wheels. The device comprises a quenching table and a plurality ofspray guns which are uniformly arranged in the circumferential direction of the quenching table, and each spray gun comprises a water outlet panel and a water inlet branch pipe. Large and small spraying holes which are different in diameter are formed in the water outlet panels, wherein outlet water from the small spraying holes is separately controlled by a branch pipe, the large spray holes aredivided into the upper large spray holes and the lower large spray holes, and outlet water from the upper large spray holes and outlet water from the lower large spray holes are controlled by different branch pipes. According to the train wheel cooling device, the intensity of the cooling water jetted to the train wheels can be easily adjusted, and the uniformity of cooling, in the radial direction and in the axial direction, of wheel rims is improved. The cooling method is used for cooling of heat treatment of the train wheels by using the cooling device when the train wheels are prepared, the hardness uniformity of the wheel rims is effectively enhanced, and the using performance of the train wheels is improved. The preparation method is used for cooling of the heat treatment of the train wheels in the process of preparation using the cooling method, and the train wheels which are high in wheel rim hardness uniformity can be prepared.

Owner:MAANSHAN IRON & STEEL CO LTD

Thick working layer roller outer layer centrifugal casting and molding method

The invention discloses a thick working layer roller outer layer centrifugal casting and molding method. Variable-speed casting is adopted in the method, and the whole outer layer is changed from simultaneous solidification to layer-by-layer solidification. The specific casting method comprises the steps that molten iron of the whole outer layer is subjected to continuous casting in sequence according to the rapid-slow-rapid mode, 20% of the total amount of molten iron is cast at first, and the casting speed is controlled to be 5+ / -0.5 t / min; the casting speed is decreased, 50% of the total amount of molten iron is cast, and the casting speed is controlled to be 2+ / -0.5 t / min; the speed is increased, 30% of the total amount of molten iron is cast, and the casting speed is controlled to be 7+ / -0.5 t / min; an outer layer molding agent is added in the centrifugal casting process, and the adding amount is 0.5% of the total weight of molten iron. The whole outer layer is cast at different casting speeds, the defects of slag inclusion and looseness caused by low temperature of molten iron in the later casting period are eliminated, the composition segregation problem caused by long time of solidification in a mold is eliminated, the molding time is shortened, the molding inoculation fade phenomenon is eliminated, and the outer layer is good in hardness uniformity.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Composite roll having uniform roll surface hardness and made of high-speed steel containing boron and method for manufacturing composite roll

InactiveCN102634733BHigh roller surface hardnessHigh hardnessFurnace typesRollsDuctile ironLanthanum

A composite roll having uniform roll surface hardness and made of high-speed steel containing boron and a method for manufacturing the composite roll belong to the technical field of manufacture of rolls. A roll body is made of the high-speed steel containing boron, a roll core is made of spheroidal graphite cast iron, the roll body and the roll core are centrifugally cast in a compounded manner,and metallurgical bonding is realized. On the basis of high-tungsten high-speed steel, the chromium content of the roll body is reduced, and the boron and a proper quantity of trace alloying elementssuch as potassium, sodium, calcium, barium, zinc, magnesium, lanthanum, cerium and the like aer added into the roll body. The roll body is heated in a heating furnace, stays warm and then is placed in a cooling control device, a roll neck is coated with a heat-insulating material and is placed outside the cooling control device, the roll body is in spray cooling according to a spray quenching process 1, then is in spray cooling according to a spray quenching process 2 until the temperature of the roll body is lower than 160 DEG C, and is in natural air cooling, when the temperature of the roll surface rises to 300 DEG C, the roll body is in spray cooling according to the spray quenching process 2 again, spray cooling is performed repeatedly until the rising temperature of the roll surfacedoes not exceed 300 DEG C, and then the roll body is in air cooling to the room temperature. The roll surface hardness of the composite roll is high, hardness uniformity of the roll surface is good, wear resistance of the roll is fine, and the service life of the composite roll is long.

Owner:BEIJING UNIV OF TECH

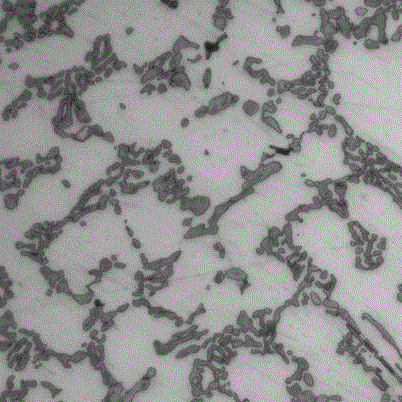

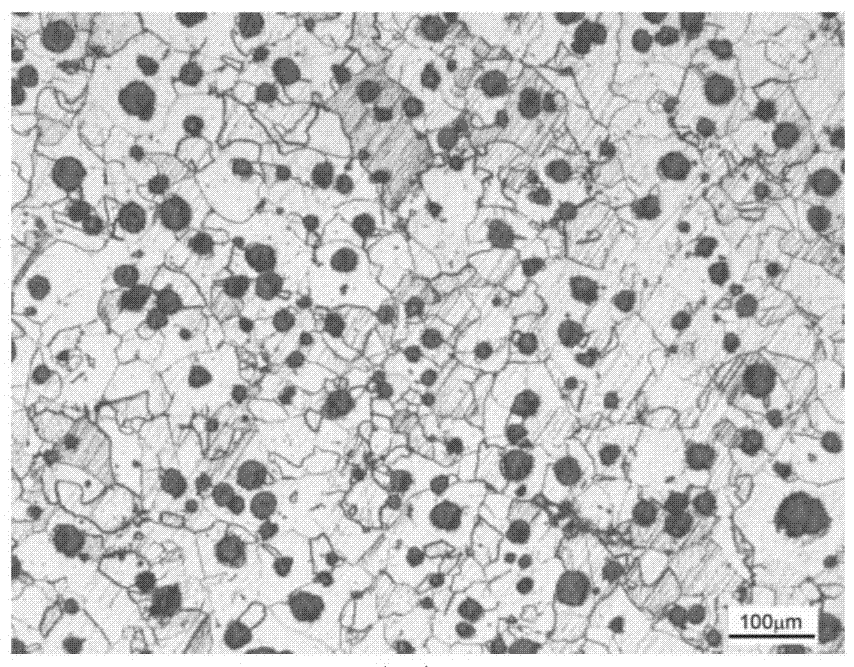

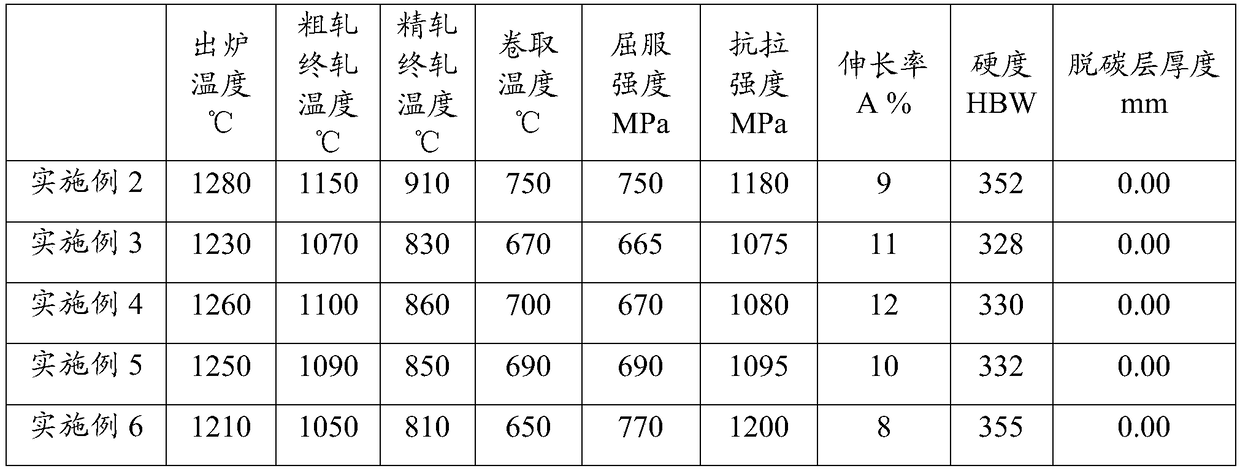

Reinforced wear-resistant roller with in-situ composite carbide granules and preparation method thereof

The invention relates to a reinforced wear-resistant roller with in-situ composite carbide granules and a preparation method thereof, and belongs to the technical field of steel rolling. The preparation method comprises the steps of generating (Nb, Ti) C composite carbide granules in situ in a roller matrix; smelting molten iron containing 3.44-3.78% of C, 12.06-12.39% of Cr, 2.74-2.90% of Nb, 0.77-0.95% of Si, 1.03-1.27% of Al, 2.55-2.79% of Co, 4.51-4.86% of Mn and 3.07-3.38% of Ni in a medium-frequency induction furnace, heating the molten iron to 1558-1575 DEG C, and then adding FeTi70; when the temperature drops to 1447-1466 DEG C, pouring the molten iron into a casting mould; and in the molten iron pouring process, adding silicon calcium barium alloy with the particle size being 2-4mm along with molten iron flow. After casting, processing and heat treatment, the roller has excellent wear resistance and a good use effect.

Owner:枣庄瑞兴机械制造有限公司

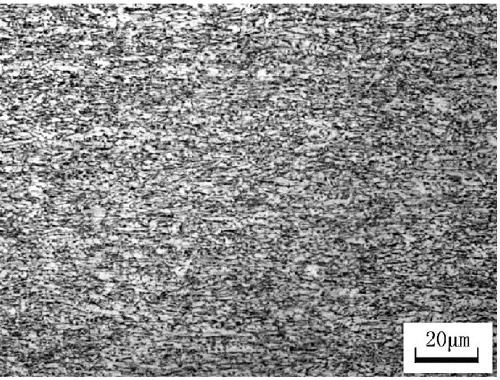

Hot-rolled coiled plate for gardening tool and manufacturing method of hot-rolled coiled plate

The invention provides a hot-rolled coiled plate for a gardening tool. The hot-rolled coiled plate comprises, by weight percent, 0.83%-1.03% of C, 0.12%-0.40% of Si, 0.25%-0.90% of Mn, 0.010%-0.070% of Al, not larger than 0.025% of P, not larger than 0.025% of S, 0.30%-0.80% of Cr, not larger than 0.55% of C and the balance Fe and inevitable impurity elements. The invention further provides a manufacturing method of the hot-rolled coiled plate for the gardening tool. The manufacturing method comprises the steps of molten iron pretreatment, converter smelting, external refining (LF+RH), slab continuous casting, hot conveying and hot charging or slab heat treatment, slab heating, high-pressure water descaling, rolling of roughing rolling unit, high-pressure water descaling, rolling of finishing mill group, cooling after rolling, coiling, cooling after coiling and heat treatment of the hot-rolled coiled plate. The hot-rolled coiled plate for the gardening tool has high hardness and wear resistance and excellent high-temperature mechanical performance and hardenability.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Production process for improving hardness stability of 22CrMoH gear steel

The invention relates to a production process for improving the hardness stability of 22CrMoH gear steel. The production process comprises the working procedures of converter smelting, LF refining, RHrefining, continuous casting, casting blank heating, rolling and cooling. The casting blank heating working procedure is that when specification of phi 50-70 mm is produced, the heating section temperature is controlled to be 1170-1200 DEG C, and the soaking section temperature is controlled to be 1180-1200 DEG C; and when the specification of phi 71-90 mm is produced, the heating section temperature is controlled to be 1140-1170 DEG C, and the soaking section temperature is controlled to be 1160-1180 DEG C. The 22CrMoH gear steel with the specification being phi 50-90 mm produced by the production process for improving the hardness stability of the 22CrMoH gear steel has the characteristics of moderate hardness and good hardness uniformity, the hot rolling state round steel hardness is 200-240 HBW, the hardness maximum discrete value of round steel in the same batch is not more than 15 HBW, an annealing working procedure can be removed for users, the direct shearing blanking machining use requirements of the users are met, and the machining cost of the users is greatly reduced.

Owner:HANDAN IRON & STEEL GROUP +1

A kind of hot-rolled steel strip for ct100 continuous pipe and its production method

The invention discloses a hot rolled steel strip for a CT100 level continuous pipe and a production method. The hot rolled steel strip comprises the components of 0.10-0.14wt% of C, 0.10-0.30wt% of Si, 1.10-1.50wt% of Mn, less than or equal to 0.015wt% of P, less than or equal to 0.0020wt% of S, 0.25-0.40wt% of Cu, 0.15-0.35wt% of Ni, 0.60-1.00wt% of Cr, 0.020-0.050wt% of Nb, less than or equal to0.010wt% of V, 0.010-0.030wt% of Ti, less than or equal to 0.0050wt% of N, 0.015-0.060wt% of Al, and 0.0008-0.0025wt% of Ca. The production method comprises the steps that a blank is formed by continuous casting after rotary furnace smelting and other processes are completed; the casting blank is heated; rough rolling is carried out; finish rolling is carried out; and cooling and coiling are carried out. The theoretical working depth can reach 7000 m, the practical working depth is at least increased by 450 m, the underground working pressure reaches 90 MPa, the yield strength of the hot rolled steel strip is greater than or equal to 640 MPa, the tensile strength is greater than or equal to 740 MPa, the whole plate thickness and rigidity fluctuations are less than or equal to 23 HV1.0, the yield ratio is less than or equal to 0.88, the elongation percentage is greater than or equal to 18%, the cross section vickers hardness HV1.0 is less than or equal to 270, the low temperature toughness at minus 20 DEG C is higher than 100 J, and the hot rolled steel strip has no surface copper brittleness tendency.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com