Reactor claw-link mechanism and manufacturing method thereof

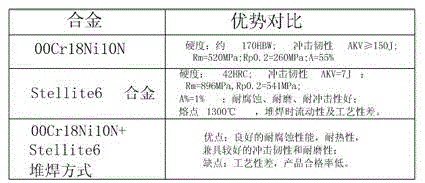

A technology of a connecting rod mechanism and a manufacturing method, which are applied in the field of a reactor hook connecting rod mechanism and its manufacturing, can solve the problems of easy occurrence of pores and cracks, high scrap rate, poor forming effect, etc. The effect of easy welding and high product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Such as figure 1 , figure 2 with Figure 5 As shown, the application provides a reactor claw 1 link 2 mechanism, including claw 1, connecting rod 2 and a pin for pin connection between claw 1 and connecting rod 2, the surface of the claw 1 is set There is a tooth surface, the claw 1 and the connecting rod 2 are respectively provided with a claw hole 11 and a connecting rod hole 21 for the pin connection of the two, and the number of the claw hole 11 and the connecting rod hole 21 is more than one, and the tooth surface Nickel-based alloy layer 3 is provided on the surface of the hook hole 11 and the inner wall surface of the connecting rod hole 21 .

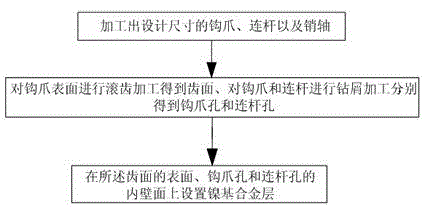

[0048] The present invention also provides a method for manufacturing the hook 1 connecting rod 2 mechanism of the reactor. This method is used to manufacture the above-mentioned hook 1 connecting rod 2 mechanism. The method includes processing the hook 1, the connecting rod 2 and the designed size The pin shaft, hobbi...

Embodiment 2

[0058] The present embodiment is further limited on the basis of embodiment 1, as Figure 2 to Figure 4 , Figure 7 to Figure 10 As shown, a method for manufacturing a reactor hook 1 connecting rod 2 mechanism includes a step of laying a nickel-based alloy layer 3, and the laying step is on the surface of the tooth surface, the inner wall surface of the hook hole 11 and the connecting rod hole 21 Nickel-based alloy layer 3 is surfacing on top.

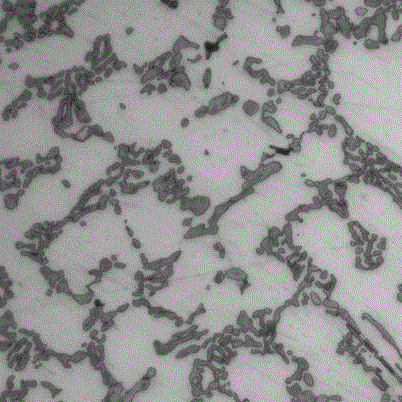

[0059] As can be seen from Example 1, the melting point of the nickel-based alloy is low, so that the nickel-based alloy layer 3 is well combined with the base of the claw 1 connecting rod 2 mechanism, so that the nickel-based alloy layer 3 and the claw 1 connecting rod 2 mechanism The joint surface of the two substrates can withstand the shear stress applied on the joint surface generated by the claw 1 connecting rod 2 mechanism during the working process. In this embodiment, the nickel-based alloy layer is selected in the form of su...

Embodiment 3

[0079] The present embodiment is further limited on the basis of embodiment 1 or 2, as Figure 5 with Image 6 As shown, this embodiment further limits the mechanism of the reactor claw 1 connecting rod 2. In order to prevent the nickel-based alloy layer 3 on the connecting rod hole 21 and the hook hole 11 from falling off as a whole during use, the connecting rod hole 21 and claw hole 11 are concentric different-diameter holes, and the minimum diameter points of connecting rod hole 21 and claw hole 11 are all located between respective two ends. The connecting rod hole 21 and the claw hole 11 of the above structure can prevent the nickel-based alloy layer 3 from moving axially along the connecting rod hole 21 or the claw hole 11 even after the nickel-based alloy layer 3 and the base layer fall off.

[0080] In order to facilitate the processing of the connecting rod hole 21 and the hook hole 11 in the above form, as a preferred structure, the connecting rod hole 21 and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com