Cold-rolled high-carbon steel plate and process for manufacturing method therefor

A technology of cold-rolled steel sheets and manufacturing methods, which is applied in the field of manufacturing high-carbon cold-rolled steel sheets, and can solve the problems of not being able to satisfy both uniformity and stretch flangeability at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Continuously cast slabs of steels A to D having the chemical compositions shown in Table 1 were heated to 1250°C, and hot-rolled, cold-rolled, and annealed under the conditions shown in Table 2 to manufacture steel sheets No. .1~16. In addition, the hot-rolled sheet annealing was performed under the conditions shown in Table 2 under several conditions. Each anneal was performed in a non-nitriding atmosphere (Ar atmosphere).

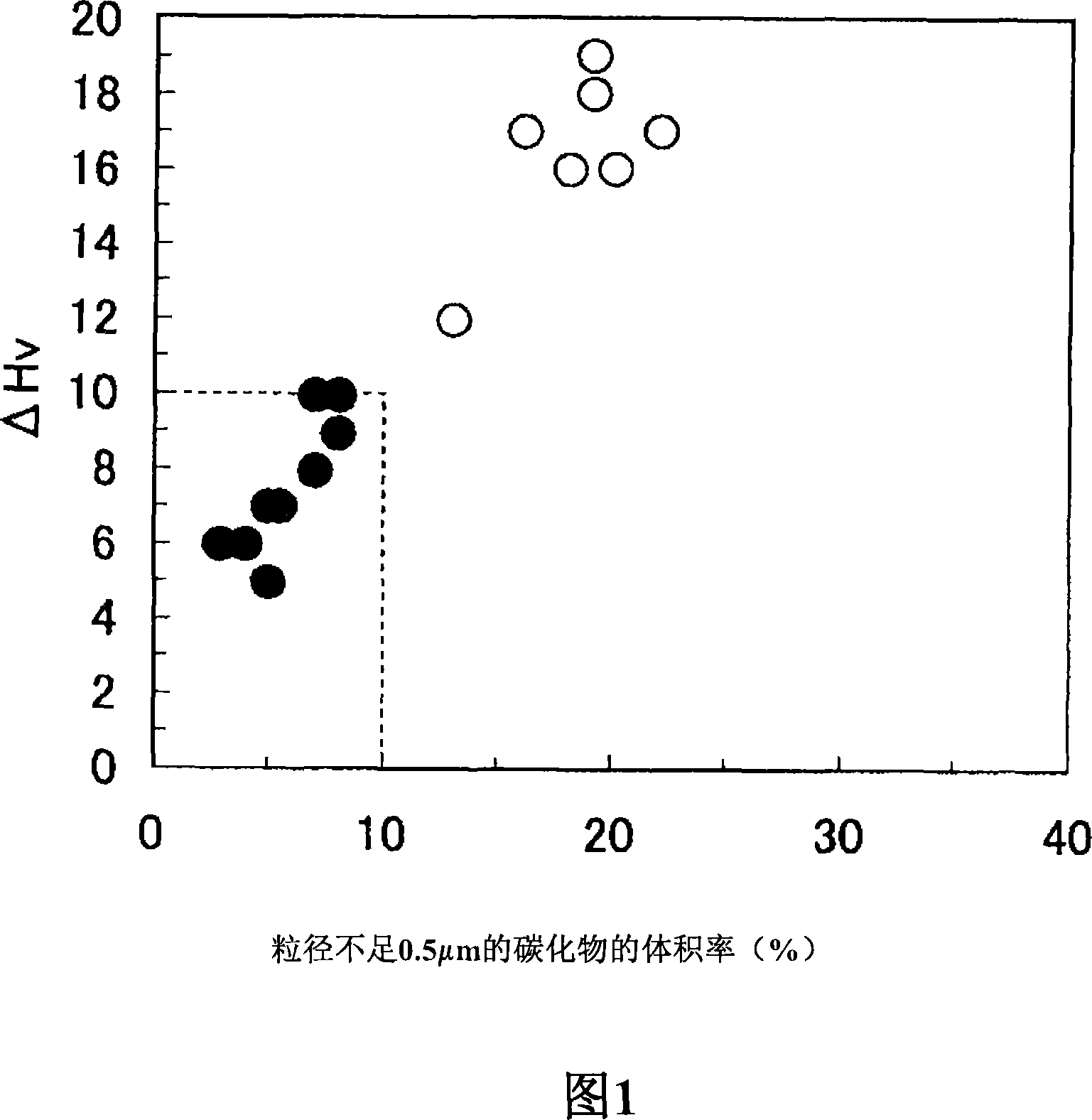

[0104] Here, steel plate Nos. 1 to 9 are examples of the present invention, and steel plate Nos. 10 to 16 are comparative examples. Then, the particle size and volume ratio of carbides, the hardness in the plate thickness direction, and the hole expansion ratio λ were measured by the following methods. Here, the hole expansion rate λ is used as an index for evaluating the stretch-flangeability. Then, the hardness in the sheet thickness direction of the hot-rolled sheet after coiling (after performing hot-rolled sheet annealing on the hot-rolled ...

Embodiment 2

[0130] E steel (C: 0.30 mass%, Si: 0.23 mass%, Mn: 0.77 mass%, P: 0.013 mass%, S: 0.0039 mass%, Sol.Al: 0.028 mass%, N: 0.0045 mass%, Ar 3 Phase transition point: 786°C, Ac 1 Phase transition point: 737°C),

[0131] F steel (C: 0.23 mass%, Si: 0.18 mass%, Mn: 0.76 mass%, P: 0.016 mass%, S: 0.0040 mass%, Sol.Al: 0.025 mass%, N: 0.0028 mass%, Cr: 1.2 Mass %; Ar 3 Phase transition point: 785°C, Ac 1 Phase transition point: 759°C),

[0132] G steel (C: 0.33 mass%, Si: 0.21 mass%, Mn: 0.71 mass%, P: 0.010 mass%, S: 0.0042 mass%, Sol.Al: 0.033 mass%, N: 0.0035 mass%, Cr: 1.02 % by mass, Mo: 0.16% by mass, Ar 3 Phase transition point: 775°C, Ac 1 Phase transition point: 755°C),

[0133] H steel (C: 0.36 mass%, Si: 0.20 mass%, Mn: 0.70 mass%, P: 0.013 mass%, S: 0.009 mass%, Sol.Al: 0.031 mass%, N: 0.0031 mass%, Ar 3 Phase transition point: 776°C, Ac 1 Phase transition point: 73 5°C),

[0134]And the D steel shown in 1 was continuously cast into a slab, heated to 1210° C., ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com