Reinforced wear-resistant roller with in-situ composite carbide granules and preparation method thereof

A technology of carbide particles and in-situ compounding, which is applied in the field of steel rolling, can solve the problems of aggravated roll wear, agglomeration of wear-resistant particles, and insufficient strengthening effect of wear-resistant particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

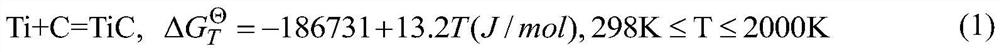

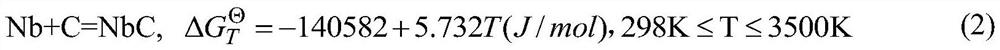

[0029] An in-situ composite carbide particle reinforced wear-resistant roll and a preparation method thereof, characterized in that (Nb,Ti)C composite carbide particles are generated in-situ in the roll matrix and evenly distributed in the roll matrix to promote the wear resistance of the roll Significantly improved, the specific preparation process steps are as follows:

[0030] ① Melt molten iron containing elements such as niobium, chromium, cobalt, manganese and nickel in a 1000 kg intermediate frequency induction furnace, and control the chemical composition and mass fraction of the molten iron in the furnace to 3.63%C, 4.74%Mn, 2.69%Co, 12.27% Cr, 2.83% Nb, 0.86% Si, 1.16% Al, 3.29% Ni, 0.027% S, 0.030% P, the balance Fe; and the temperature of the molten iron is raised to 1569°C, and then 9.5% of the mass fraction of the molten iron in the furnace is added FeTi70 (the chemical composition and mass fraction of FeTi70 is 70.82% Ti, 1.95% Al, 0.25% Si, and the balance Fe),...

Embodiment 2

[0035] An in-situ composite carbide particle reinforced wear-resistant roll and a preparation method thereof, characterized in that (Nb,Ti)C composite carbide particles are generated in-situ in the roll matrix and evenly distributed in the roll matrix to promote the wear resistance of the roll Significantly improved, the specific preparation process steps are as follows:

[0036] ① Melt molten iron containing elements such as niobium, chromium, cobalt, manganese and nickel in a 1500 kg intermediate frequency induction furnace, and control the chemical composition and mass fraction of the molten iron in the furnace to 3.78%C, 4.51%Mn, 2.79%Co, 12.06% Cr, 2.90% Nb, 0.77% Si, 1.27% Al, 3.07% Ni, 0.025% S, 0.032% P, the balance Fe; and raise the temperature of the molten iron to 1575°C, and then add 10% of the mass fraction of the molten iron in the furnace FeTi70 (the chemical composition and mass fraction of FeTi70 is 70.95% Ti, 0.97% Al, 0.28% Si, and the balance Fe), FeTi70 is...

Embodiment 3

[0041] An in-situ composite carbide particle reinforced wear-resistant roll and a preparation method thereof, characterized in that (Nb,Ti)C composite carbide particles are generated in-situ in the roll matrix and evenly distributed in the roll matrix to promote the wear resistance of the roll Significantly improved, the specific preparation process steps are as follows:

[0042] ① Melt molten iron containing elements such as niobium, chromium, cobalt, manganese and nickel in a 1000kg medium-frequency induction furnace, and control the chemical composition and mass fraction of the molten iron in the furnace to 3.44%C, 4.86%Mn, 2.55%Co, 12.39% Cr, 2.74% Nb, 0.95% Si, 1.27% Al, 3.07% Ni, 0.028% S, 0.031% P, the balance Fe; and the temperature of the molten iron is raised to 1558°C, and then add 9% of the mass fraction of the molten iron in the furnace FeTi70 (the chemical composition and mass fraction of FeTi70 is 70.36%Ti, 2.82%A1, 0.27%Si, the balance Fe), FeTi70 was baked at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com