Hot-rolled coiled plate for gardening tool and manufacturing method of hot-rolled coiled plate

A garden tool and manufacturing method technology, applied in the field of metallurgy, can solve problems such as short life, unfavorable technological progress, low-carbon environmental protection, waste, etc., and achieve the effects of long service life, excellent comprehensive performance, and thin decarburization layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] The percentage by weight of the chemical composition of the garden tool hot-rolled coil of the present embodiment is:

[0108]C: 0.92 Si: 0.23 Mn: 0.42 P: 0.012 S: 0.001 Al: 0.018

[0109] Cr: 0.291V: 0.15N: 0.004

[0110] The balance is Fe and unavoidable impurity elements.

[0111] The coil plate of this embodiment is 5.0mm thick, 1219mm wide, and 397.05m long.

[0112] The yield strength of the hot-rolled state is 661MPa, the tensile strength is 1064MPa, the elongation is 12%, the hardness is HBW321, and the thickness of the decarburized layer is 0.00mm. The yield strength of the hot-rolled coil in the heat-treated state is 320MPa, the tensile strength is 590MPa, the elongation is 27.0%, the hardness is HRB 87.5, and the thickness of the decarburized layer is 0.01mm. Meet the performance needs of hot-rolled coils for garden tools.

[0113] The present embodiment is carried out on a 180-ton top-bottom double-blowing converter and a 2250mm hot continuous rolling mi...

Embodiment 2 to Embodiment 6

[0167] The chemical composition of the hot-rolled coils for garden tools in Examples 2 to 6 is shown in Table 1.

[0168] The manufacturing methods of the hot-rolled coils for garden tools in Examples 2 to 6 are the same as in Example 1 except for the process parameters listed in Table 2.

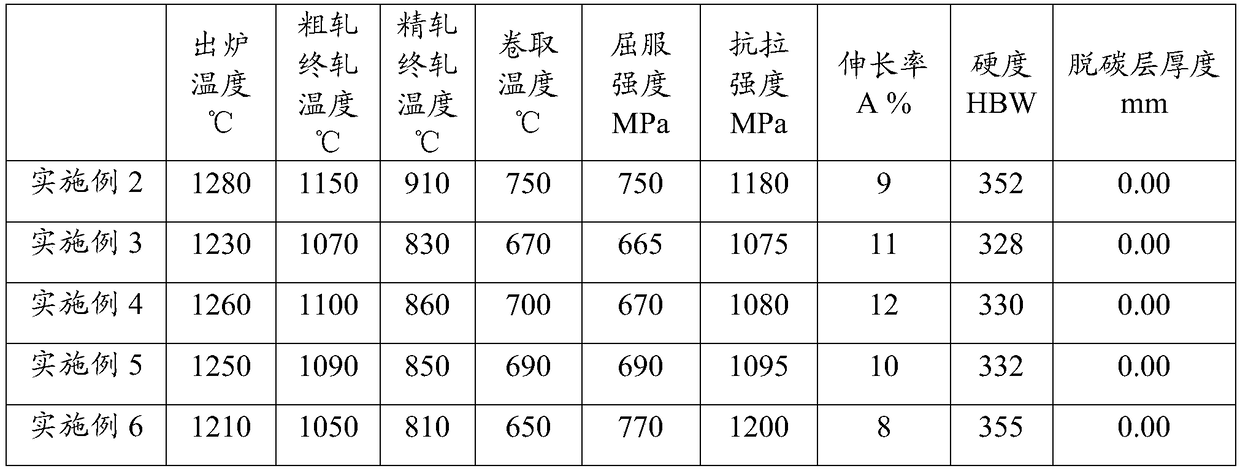

[0169] Table 2 shows the mechanical properties of the hot-rolled coils for garden tools in Examples 2 to 6 in the hot-rolled state.

[0170] Table 1

[0171]

C

Si

mn

P

S

AL

Cr

V

Example 2

0.88

0.21

0.65

0.010

0.003

0.018

0.55

0.20

Example 3

0.89

0.25

0.60

0.011

0.004

0.017

0.40

0.17

Example 4

0.91

0.26

0.35

0.013

0.002

0.022

0.35

0.10

Example 5

0.93

0.22

0.47

0.011

0.003

0.019

0.31

0.08

Example 6

0.97

0.20

0.45

0.012

0.002

0.021

0.33

0.05

[0172] Table 2

[0173]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com