Hot-rolled steel strip, preparation method thereof and application of hot-rolled steel strip in double-metal band saw back material

A technology of steel strip and molten steel, which is applied in the composition design and production field of hot-rolled steel strip for bimetal band saw back material, can solve the problems affecting the service life of the finished saw blade, poor fatigue life, low alloy composition, etc. The effect of hardness, fatigue life improvement, and high steel purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] In yet another aspect, the present invention also provides a method for preparing a hot-rolled steel strip, comprising the following steps:

[0046] (1) The molten iron is smelted by converter, LF refining and RH refining to obtain molten steel;

[0047] (2) Carry out continuous casting of molten steel to obtain a continuous casting slab, and the continuous casting slab is sent to the next process after hot delivery and hot charging;

[0048] (3) Heating the continuous casting slab, performing rough rolling after high-pressure water descaling, and then performing finish rolling after high-pressure water descaling to obtain a steel strip; wherein, the heating temperature is 1180°C-1290°C, and the The termination temperature of the rough rolling is 1000°C-1200°C; the termination temperature of the finish rolling is 780°C-950°C;

[0049] (4) performing cooling, coiling, and softening annealing steps on the steel strip in sequence to obtain a hot-rolled steel strip product...

Embodiment 1

[0076] The technical characteristics of the steel strip of the present invention will be described in detail below with this embodiment. The mass percent of the chemical composition of the hot-rolled coil for the back material of the bimetallic band saw in this embodiment is:

[0077]C: 0.33% Si: 0.28 Mn: 0.80 P: 0.008 S: 0.002 Al: 0.041 Cr: 3.60 Mo: 2.20 Ni: 0.86 Nb: 0.045 V: 0.35 N: 0.0046 O: 9.0ppm; H: 1.2ppm; the balance is Fe and inevitable impurity elements.

[0078] The coiled plate of this embodiment has a thickness of 4.0mm, a width of 1015mm, and a length of 462m.

[0079] The yield strength of the hot-rolled state is 1061MPa, the tensile strength is 1367MPa, the elongation is 8.5%, the hardness is HRC52.0, and the thickness of the decarburized layer is 0.00mm. The yield strength of the soft annealed state is 660MPa, the tensile strength is 816MPa, the elongation is 22.0%, the hardness HRB is 97.5, and the total decarburization layer depth of one side is 0.02mm. M...

Embodiment 2-4

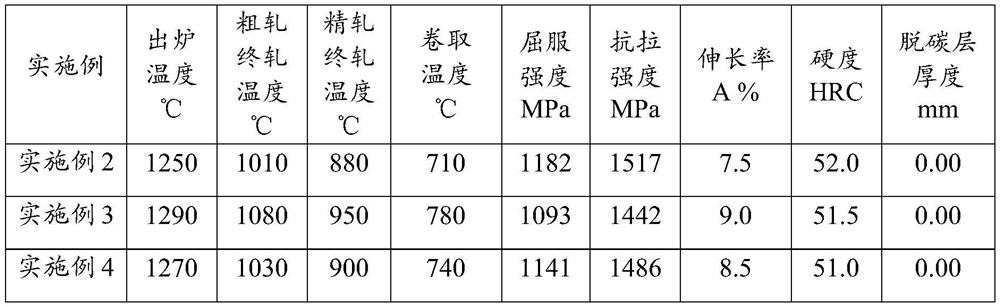

[0125] Prepare the hot-rolled steel strip in embodiment 2-4 according to the technical process identical with embodiment 1, wherein, the composition of the hot-rolled steel strip of embodiment 2-4 is shown in Table 1, and the concrete process parameter that embodiment 2-4 adopts, heat The properties of the rolled steel strip are shown in Table 2.

[0126] Composition (wt %) except iron and unavoidable impurity in table 1 embodiment 2-4 hot-rolled strip

[0127] Example C Si mn P S Cr Mo Ni Nb V Al Example 2 0.33 0.24 0.76 0.008 0.001 3.57 2.23 0.85 0.053 0.37 0.051 Example 3 0.32 0.28 0.83 0.006 0.001 3.60 2.28 0.78 0.031 0.38 0.057 Example 4 0.34 0.22 0.74 0.007 0.002 3.54 2.31 0.83 0.038 0.40 0.047

[0128] The process parameters and strip properties of other manufacturing method embodiments of hot-rolled steel strip are shown in Table 2

[0129] The performance (hot-rolled state) of the processing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com