A kind of production method of the steel wire rod used for the railway clip fastener of direct cold bending forming

A cold-bending forming and production method technology, applied in the manufacture of converters, etc., can solve problems such as poor fatigue performance, affecting the compactness of steel structure, and large energy consumption, and achieve good plasticity, good uniformity, and high purity of steel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention.

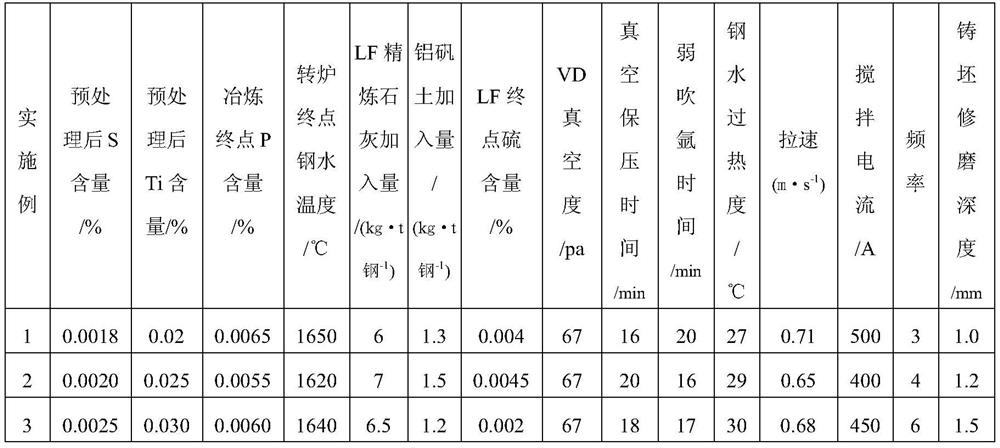

[0022] Table 1 is the smelting process of the steel of the embodiment, Table 2 is the rolling process of the steel of the embodiment; Table 3 is the performance of the steel of the embodiment.

[0023] Table 1 The smelting process of the steel in the example

[0024]

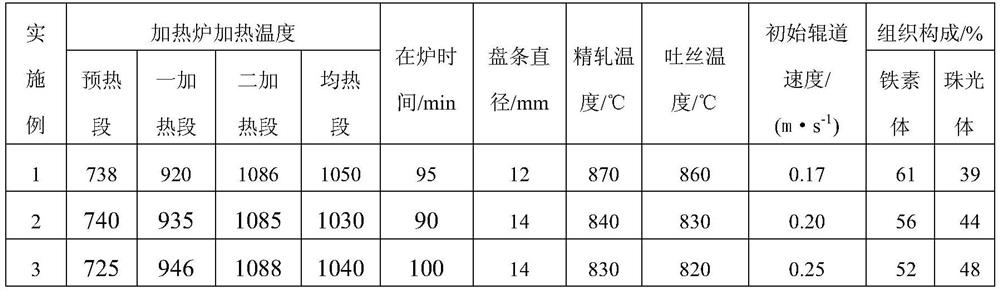

[0025] The rolling process of table 2 embodiment steel

[0026]

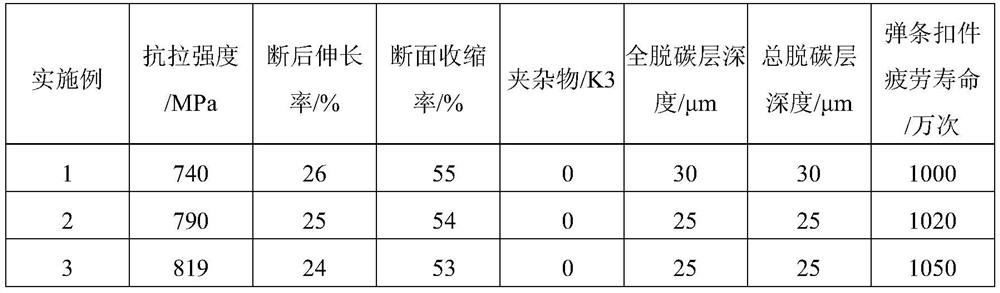

[0027] Table 3 Properties of Example Steels

[0028]

[0029] As can be seen from Tables 1 to 3, adopting the production process of the present invention, the steel wire rod for railway clip fasteners that can be directly cold-formed can be produced, the tensile strength is 700-820MPa, the elongation after breaking is ≥ 23%, and the cross-section The shrinkage rate is ≥52%, and the fatig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| fatigue bending times | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com