Patents

Literature

267 results about "Chromium nickel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nichrome (NiCr, nickel-chrome, chrome-nickel, etc.) is any of various alloys of nickel, chromium, and often iron (and possibly other elements). The most common usage is as resistance wire, although they are also used in some dental restorations (fillings) and in a few other applications.

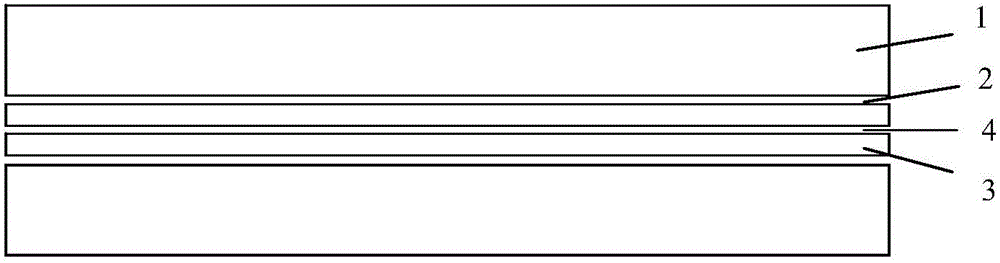

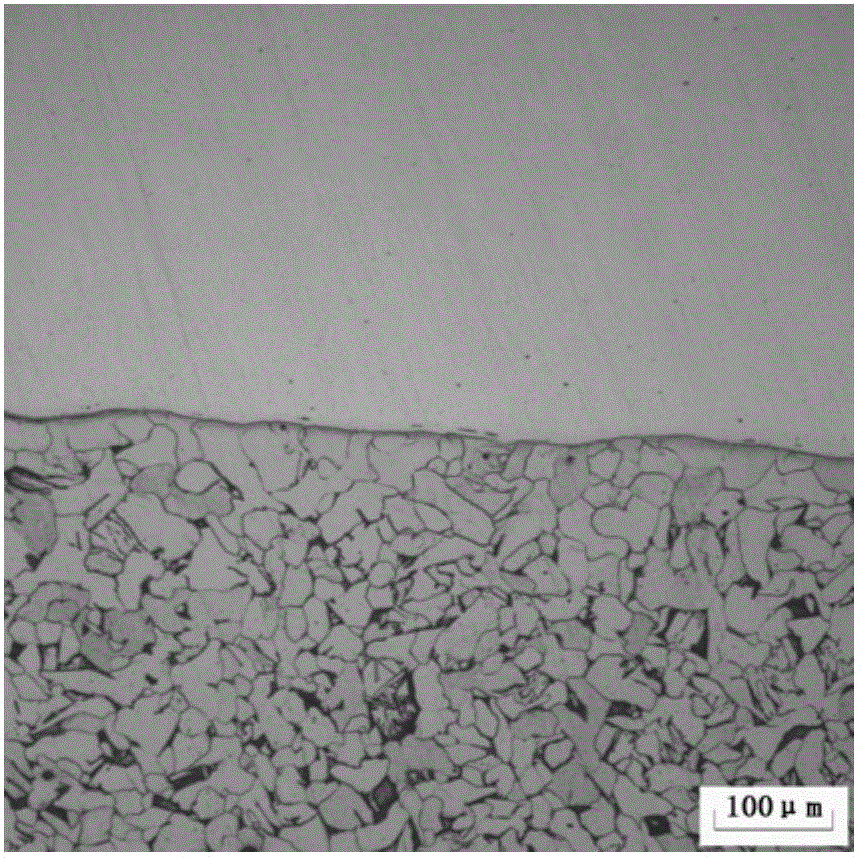

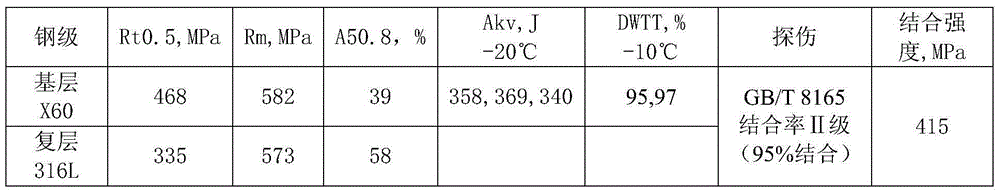

Carbon steel and stainless steel clad steel plate with toughness performance and production method

The invention discloses a carbon steel and stainless steel clad steel plate with toughness performance, and belongs to the technical field of production of metal clad plates. Carbon steel is a basal material, and satisfies the requirements of API5L "American Petroleum Pipeline Steel Specification"; 316L stainless steel is a multiple layer, and components satisfy the requirements of ASTM A240M-05 standard "Standard Specification of Chromium and Chromium Nickel Stainless Steel Plate, Sheet and Strip Steel for Pressure Vessels and General Purposes"; flux is BNi brazing filler metal; and solder resist is a mixture of magnesium oxide and aluminum oxide. The process comprises steel blank assembly, heating, rough rolling, finish rolling and heat treatment. The clad steel plate has excellent toughness performance and hydrogen induced cracking resistance, so that the use safety of crude oil conveying pipes is improved.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL

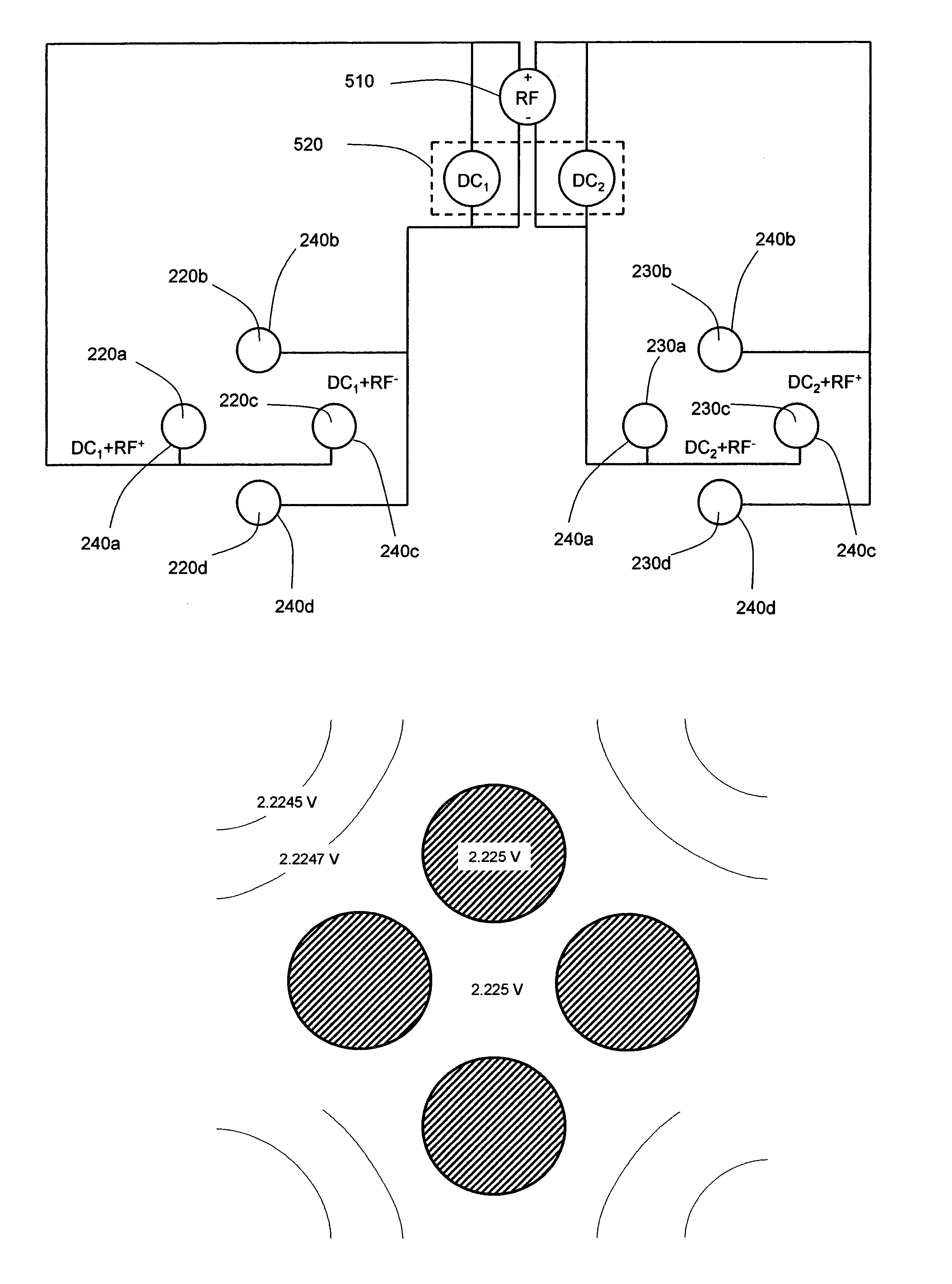

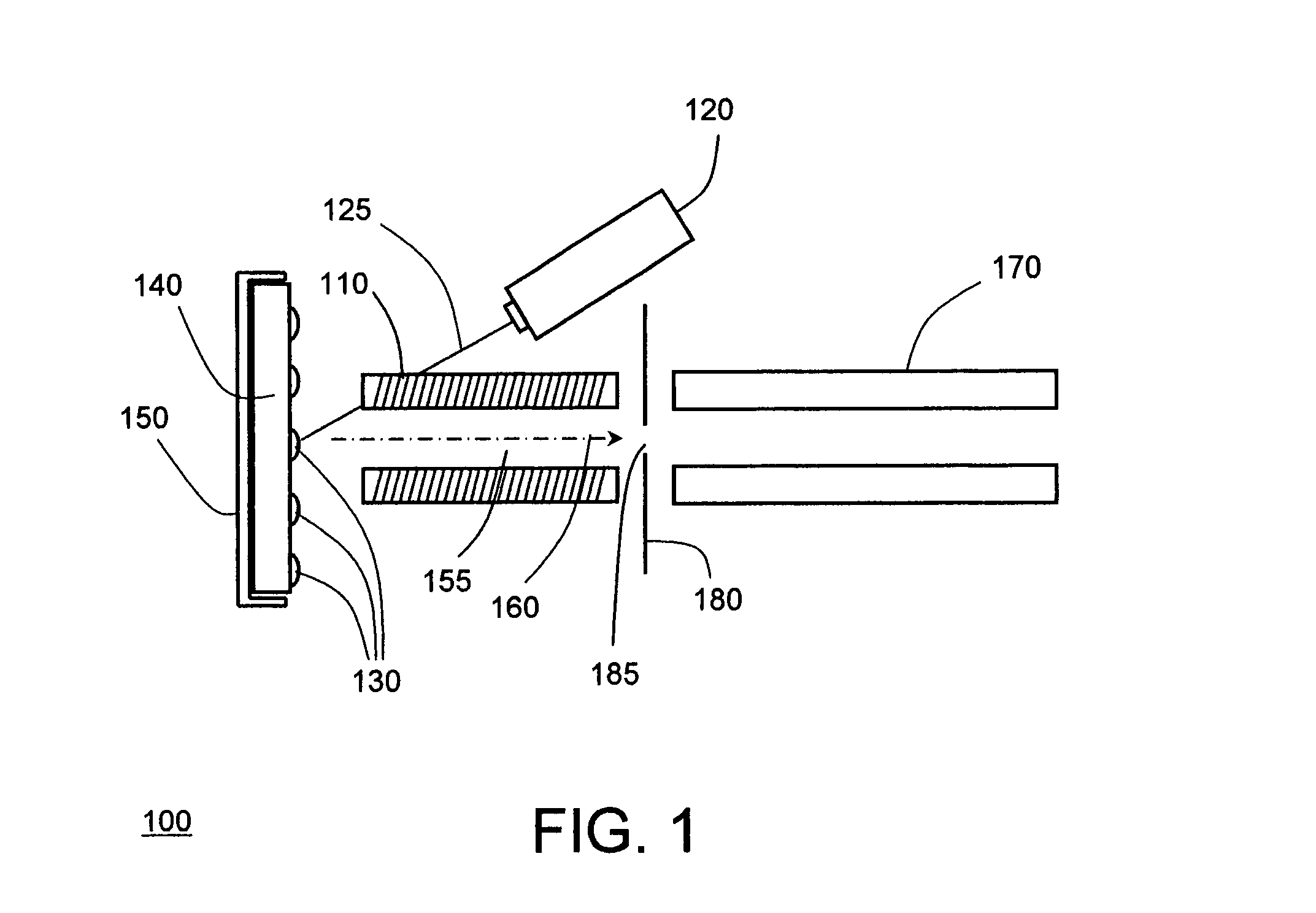

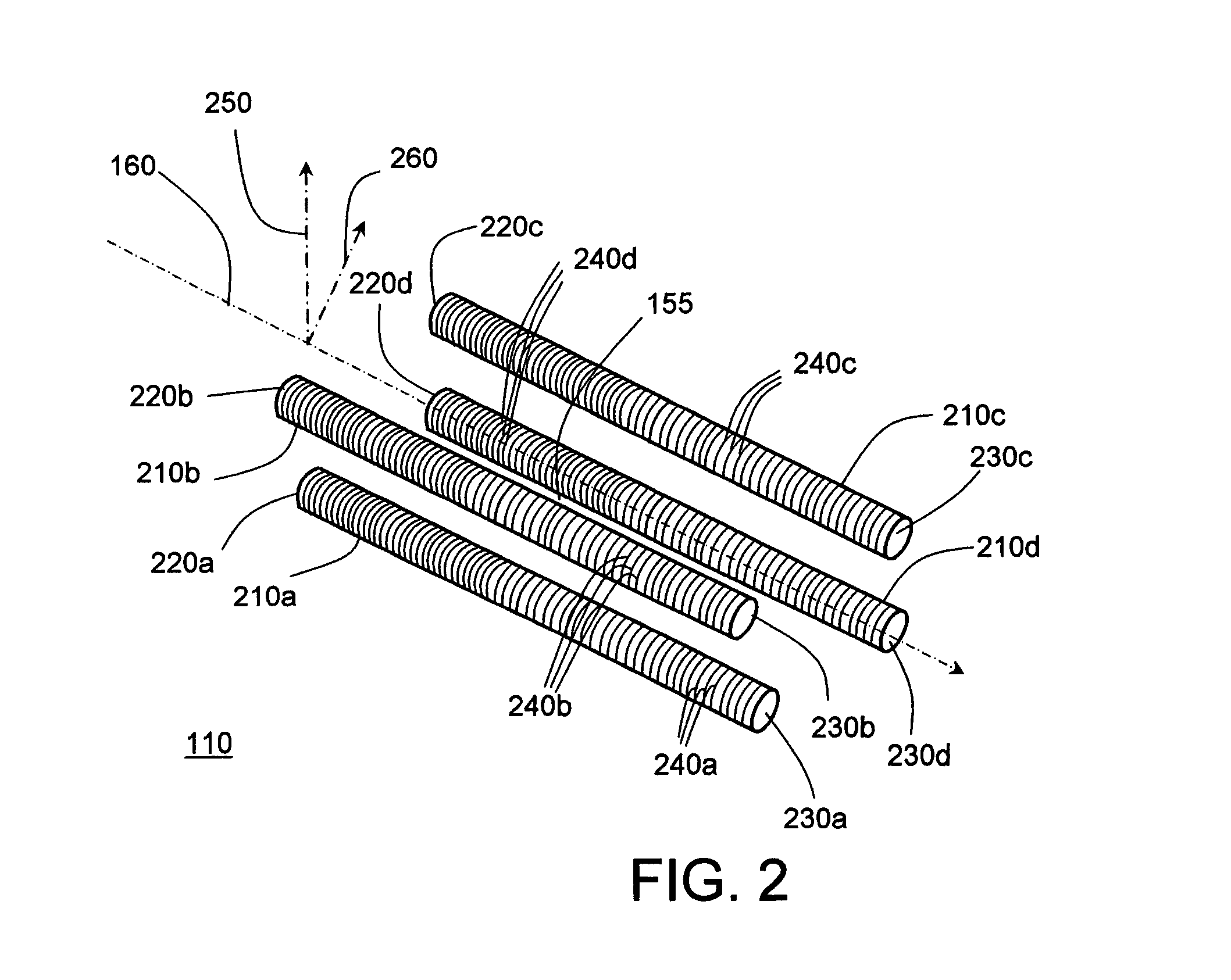

Generation of combination of RF and axial DC electric fields in an RF-only multipole

InactiveUS7067802B1Reduce usageParticle separator tubesIsotope separationRf fieldElectrical resistance and conductance

An RF-only multipole includes a spiral resistive path formed around each multipole rod body. RF voltages are applied to the rod body and resistive path, and DC voltages are applied to the resistive path, to create a radially confining RF field and an axial DC field that assists in propelling ions through the multipole interior along the longitudinal axis thereof. In one implementation, the resistive path takes the form of a wire of resistive material, such as nichrome, which is laid down in the groove defined between threads formed on the rod body. The RF-only multipole of the invention avoids the need to use auxiliary rods or similar supplemental structures to generate the axial DC field.

Owner:THERMO FINNIGAN

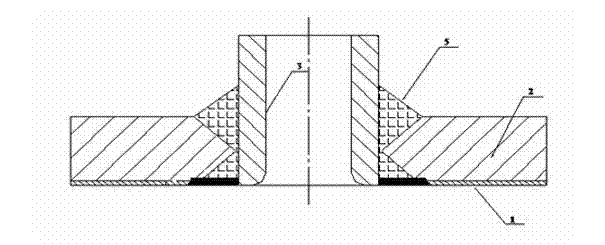

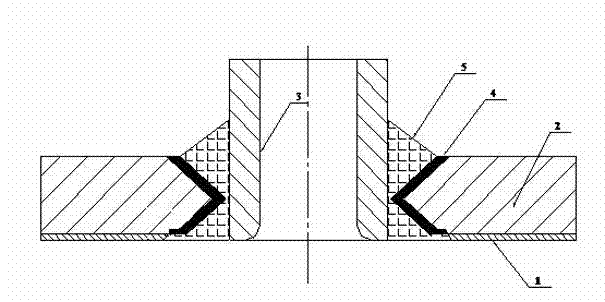

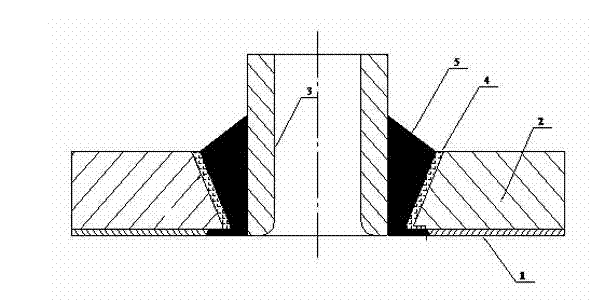

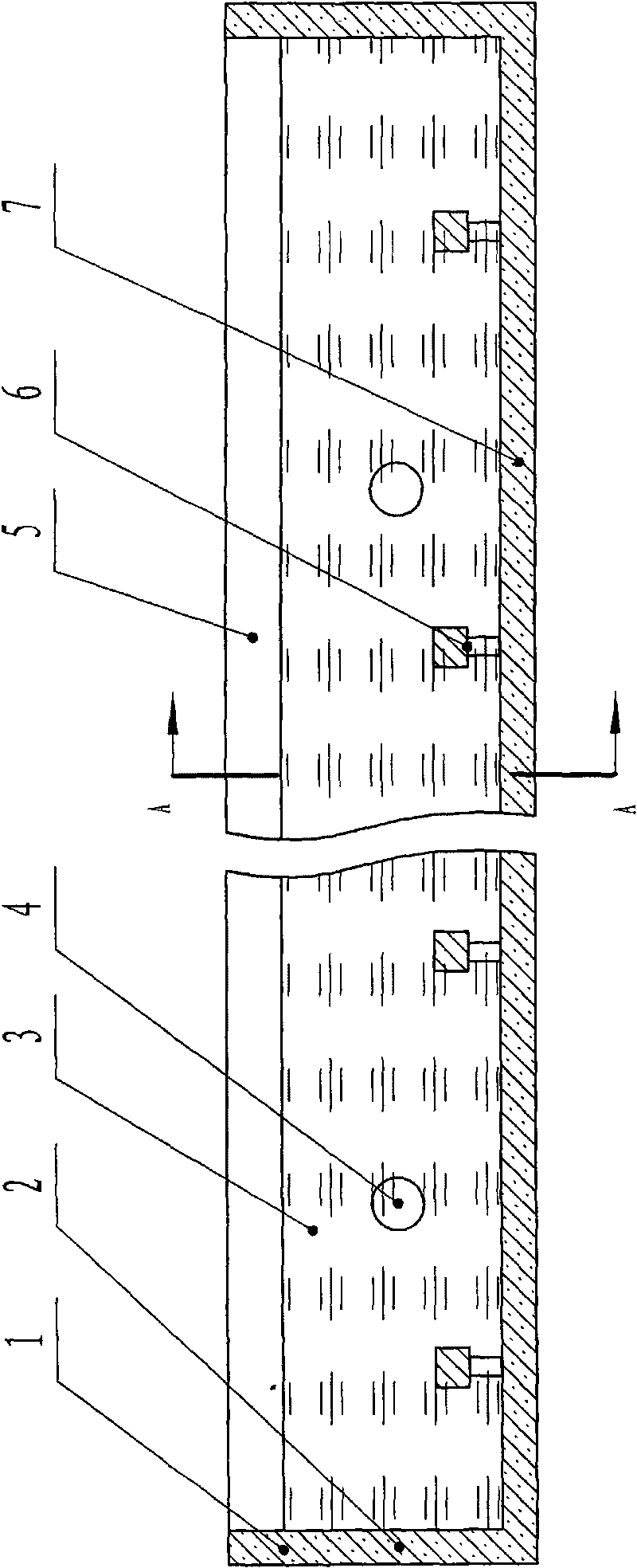

Welding method for stainless steel composite board pressure vessel shell and insert-type stainless steel connecting pipe

InactiveCN102513713AAvoid crackingEasy to useFurnace typesWorkpiece edge portionsChromium nickelStainless steel electrode

The invention discloses a welding method for a stainless steel composite board pressure vessel shell and an insert-type stainless steel connecting pipe. The method comprises the steps of a) arranging a pipe hole of the stainless steel connecting pipe in a stainless steel composite board pressure vessel shell, and manufacturing a pipe hole wall to be a primary bevel with a K shape or a single V shape; b) performing bead-welding on a primary bevel surface by using high chromium nickel stainless steel welding rods to form a transition isolating layer with certain thickness, so as to form a secondary bevel; c) carrying out stress-relief heat treatment on the stainless steel composite board pressure vessel shell after the bead welding; and d) welding corner connecting joints between the stainless steel connecting pipe and the stainless steel composite board bead-welding layer by using stainless steel welding rods with different materials according to a stainless steel composite layer on a composite board. As the transition isolating layer with the certain thickness is firstly bead-welded on the primary bevel of the basic layer side of the stainless steel composite board by using the high chromium nickel stainless steel welding rods, and then the corner connecting joints are welded by the stainless steel welding rods, so that carbon steel and low alloy steel components are transited into stainless steel components, the welding line plasticity can be transited from low to high, cracks are avoided, and the using performance is reliable.

Owner:CSSC SHENGHUI EQUIP

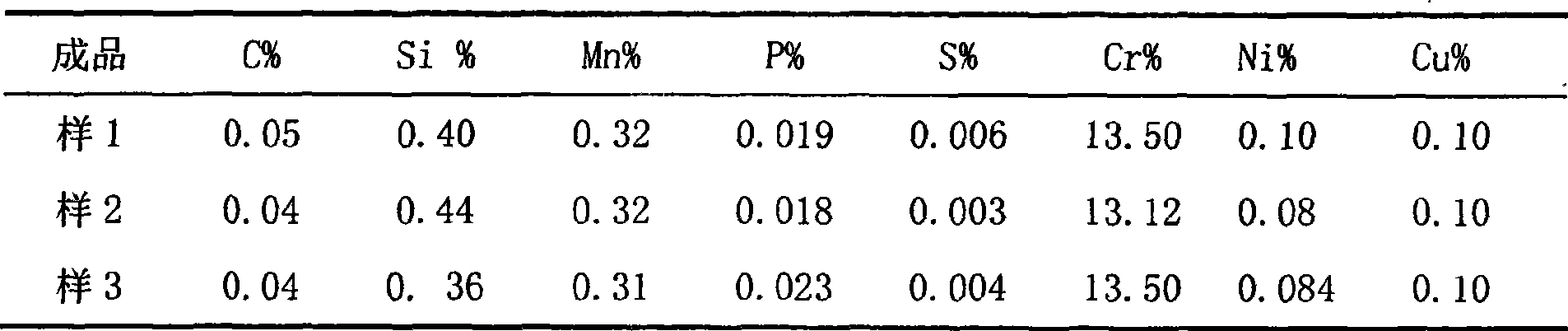

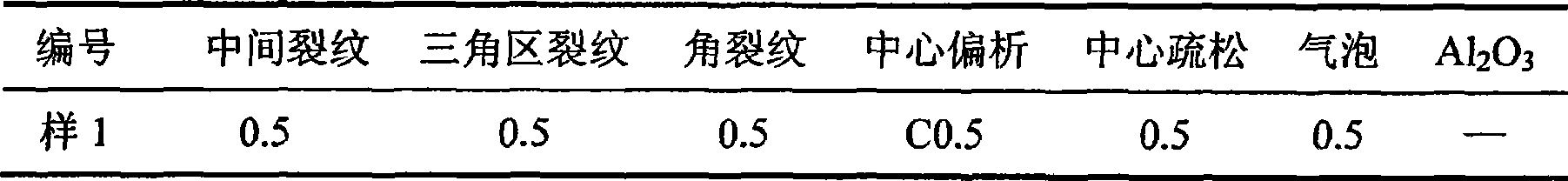

Two-step stainless steel smelting method

ActiveCN101457272AHigh recovery rateReduce consumptionProcess efficiency improvementElectric furnacePresent methodChromium nickel

The invention relates to a stainless steel smelting method by a two-step process. The method comprises the following steps: (1) smelting dephosphorized molten iron; (2) smelting semisteel; (3) lifting the semisteel to a deslagging station for deslagging treatment; (4) adding the semisteel to a GOR refining furnace for air refining; (5) refining; (6) continuous casting and (7) finishing, thinning and then rolling. Compared with the present method for producing the stainless steel by smelting, the method has the advantages of wide application scope of raw materials, low energy and resource consumption, strong variety development capacity, high recovery rate of chromium-nickel metal, high production efficiency and the like. Sulfide, oxide, silicate and punctiform non-metallic inclusion in the steel have low grade, the dephosphorized molten iron is provided by a top-bottom combined blowing converter and smelting is performed by the two-step process in an EAF+GOR refining furnace, thus the method has relatively low production cost and relatively large cost advantage, and the performance of a rolled finished product is consistent with a user quality standard.

Owner:SHANDONG TAISHAN STEEL GROUP

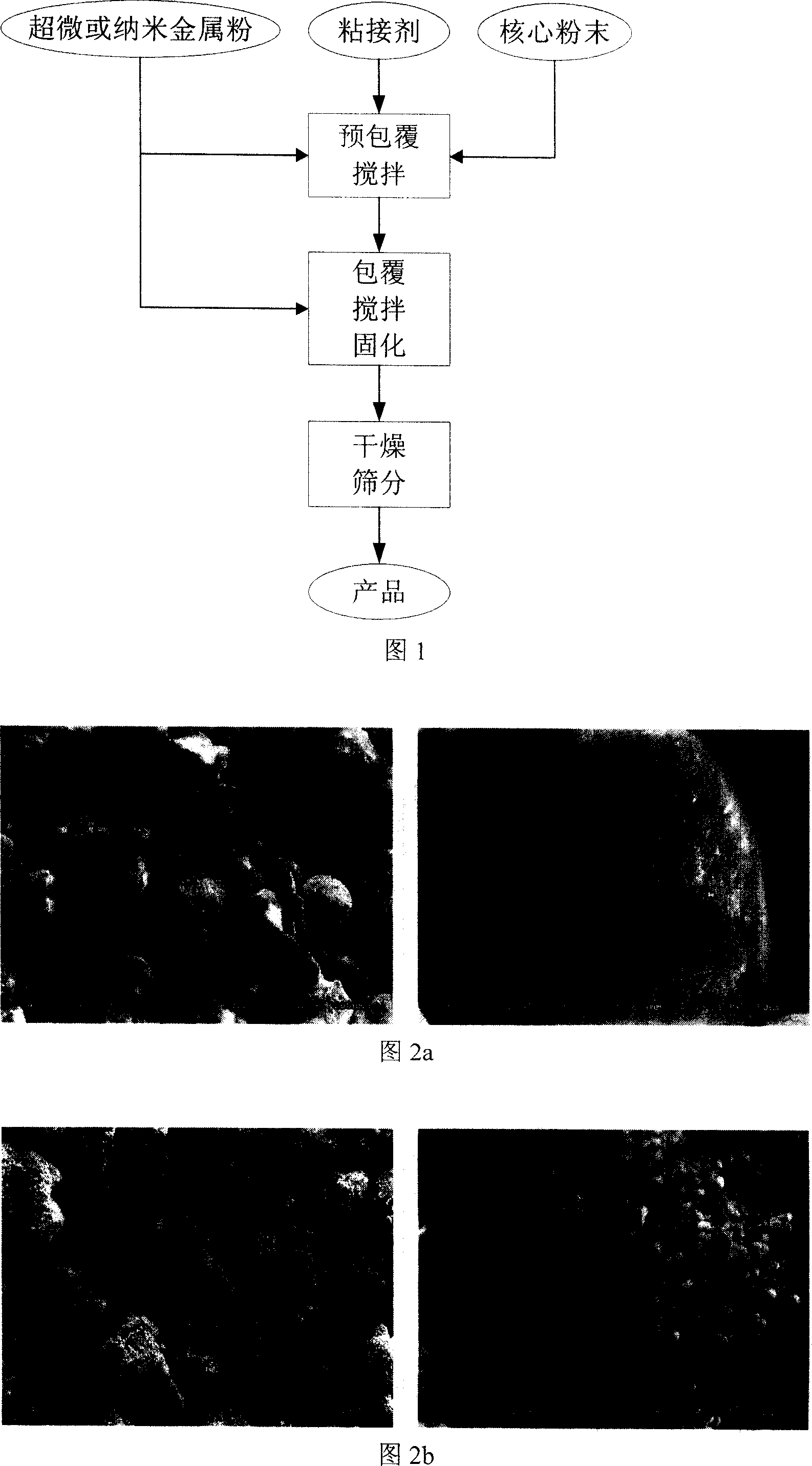

Composite powder coated by ultramicro or Nano metal powder, and preparation method

A superfine or nano-class metallic powder clad composite powder is composed of a core particle made of the metal (Ni or stainless steel), the carbide (tungsten carbide or chromium carbide), alloy (NiCr), self-smelting alloy (NiCrBSi), or their composition, and a cladding layer made of superfine or nano-class metal particles (Al, Mo, or Co). It can be used for hot spray coating or powder metallurgy. Its preparing process is also disclosed.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

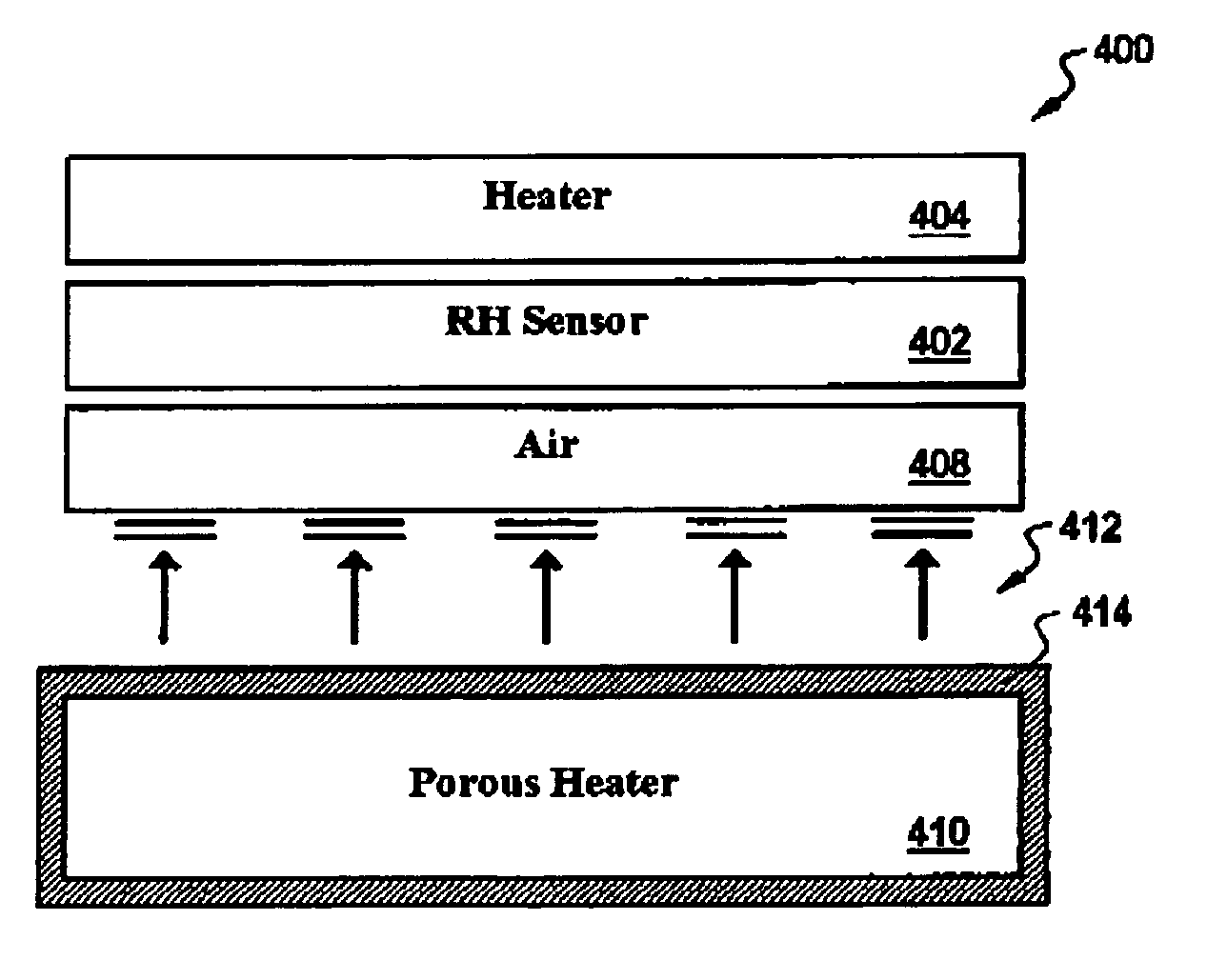

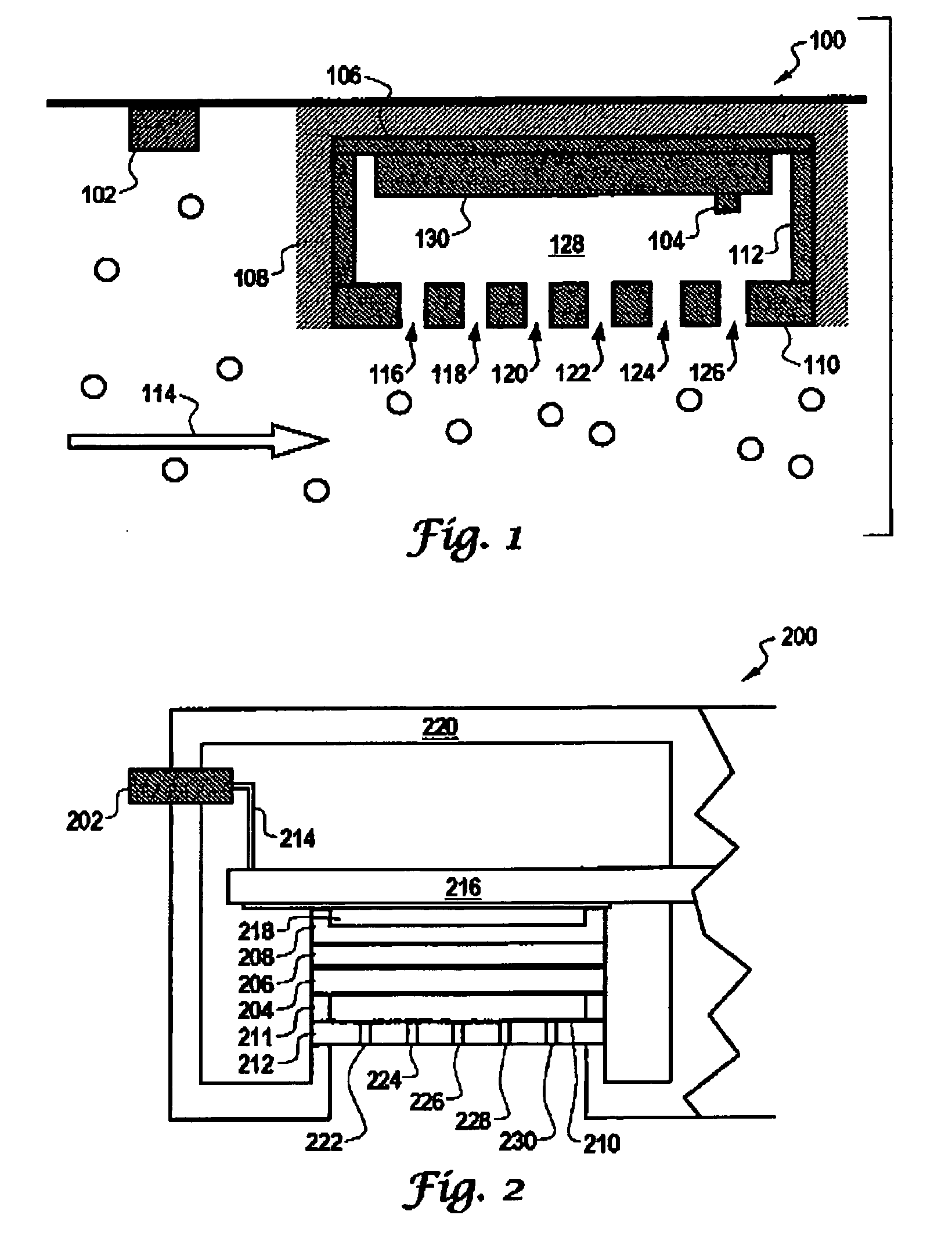

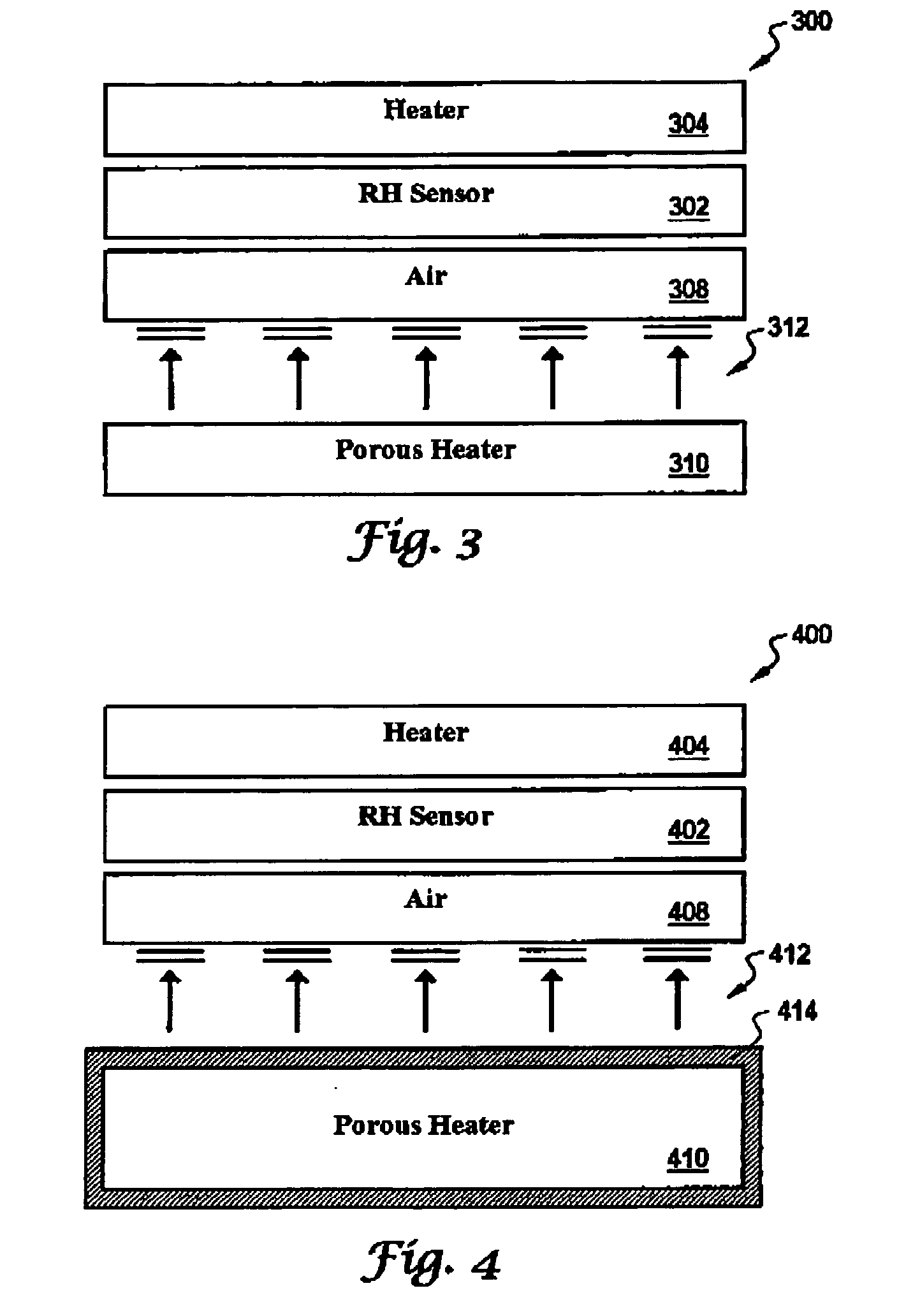

Relative humidity sensor enclosed with formed heating element

InactiveUS20060201247A1Lower the volumeSmall sizeMaterial moisture contentUsing mechanical meansElectrical resistance and conductanceChromium nickel

Sensor systems and methods are disclosed herein. A relative humidity sensor is generally associated one or more porous heating elements. A porous resistive material surrounds the relative humidity sensor. Additionally, one or more flat heating elements can be bonded to a base of the relative humidity sensor to conduct heat and insure uniform heating about the relative humidity sensor. The porous heating elements can be configured to permit humid air to pass through the porous heating elements. Also, the porous heating element(s) can be assembled slightly offset from a surface of the relative humidity sensor so that air that is saturated with water vapor passes through and is heated by the porous heating element in order to evaporate water droplets associated with the water vapor and thereby reduce relative humidity to a measurable level. The porous resistive material can be configured from a material such as, for example, tantalum or nichrome. The porous resistive material can also be configured in a sheet arranged in a woven pattern.

Owner:HONEYWELL INT INC

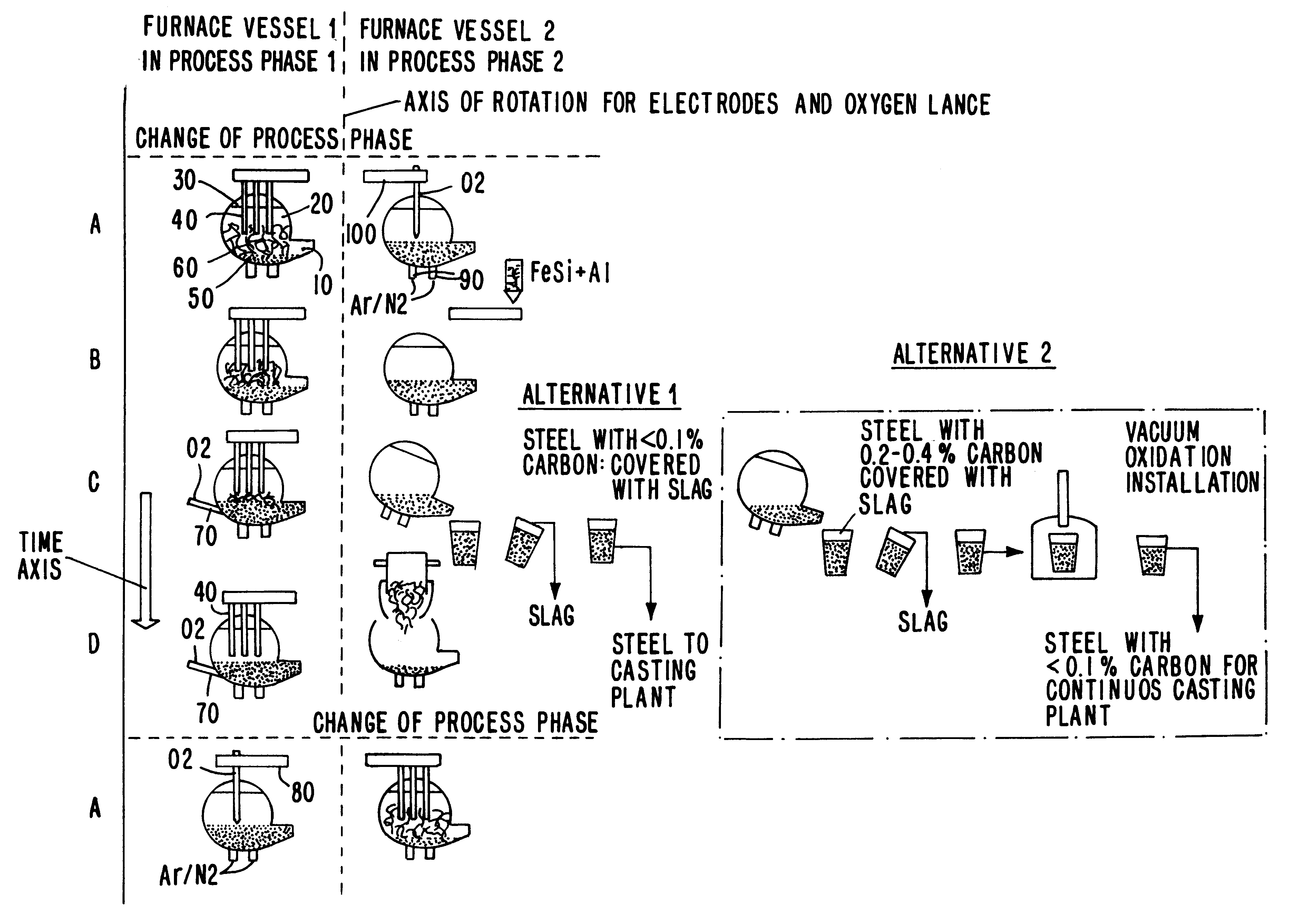

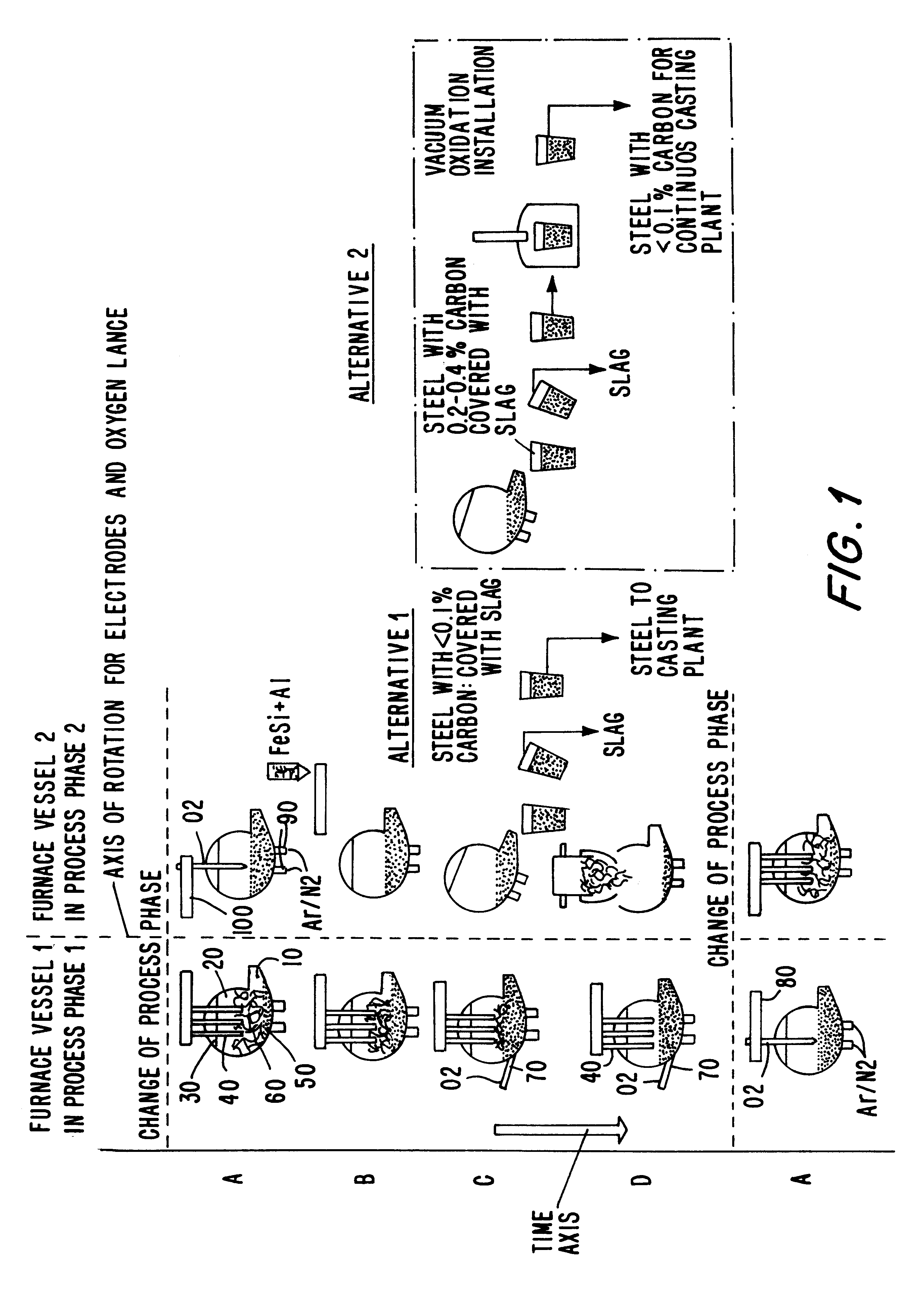

Producing stainless steels in parallel operated vessels

InactiveUS6238453B1Reduces energy consumption and electrode lossLow investment costElectric furnaceProcess efficiency improvementFoundryChromium nickel

A process for producing stainless steels, particularly special steels containing chromium and chromium-nickel, in a smelting arrangement having at least two vessels, for supplying a steel foundry. A charge having mostly iron-containing raw scrap materials and partially carbon-containing alloy carriers is melted in a first vessel. At a temperature of 1460° C., the melt is decarburized by the injection of oxygen so as to reduce the carbon content to less than 0.3%. The melt is heated to a tapping temperature of between 1620° C. to 1720° C. and the carbon content is subsequently reduced to 0.1%. A second charge is melted in a second vessel simultaneously with the decarburizing of the first charge in the first vessel.

Owner:MANNESMANN AG

Technology for producing wear-resisting compound material

The production process for forming high-alloy wear-resisting layer composite material on the surface of carbon steel or alloy steel includes the following steps: firstly, selecting and using 40-80 % of alloy powder which is formed from Cr, Mo, W, V, Ti, Ni, Co, Mn, B and C and whose grain size is 0.005-0.8 mm or selecting and using sintered hard alloy granules whose grain size is 0.4-0.8 mm and 20-60 % of nichrome alloy powder whose grain size is 0.05-0.1 mm, mixing adhesive and alloy powder and stirring them to obtain the alloy powder coating material, then applying the alloy powder coating material on the side surface of casting mould, and third step pouring and forming to form alloy layer with compact structure, and the combination of alloy layer and self-body is good.

Owner:陈振华 +2

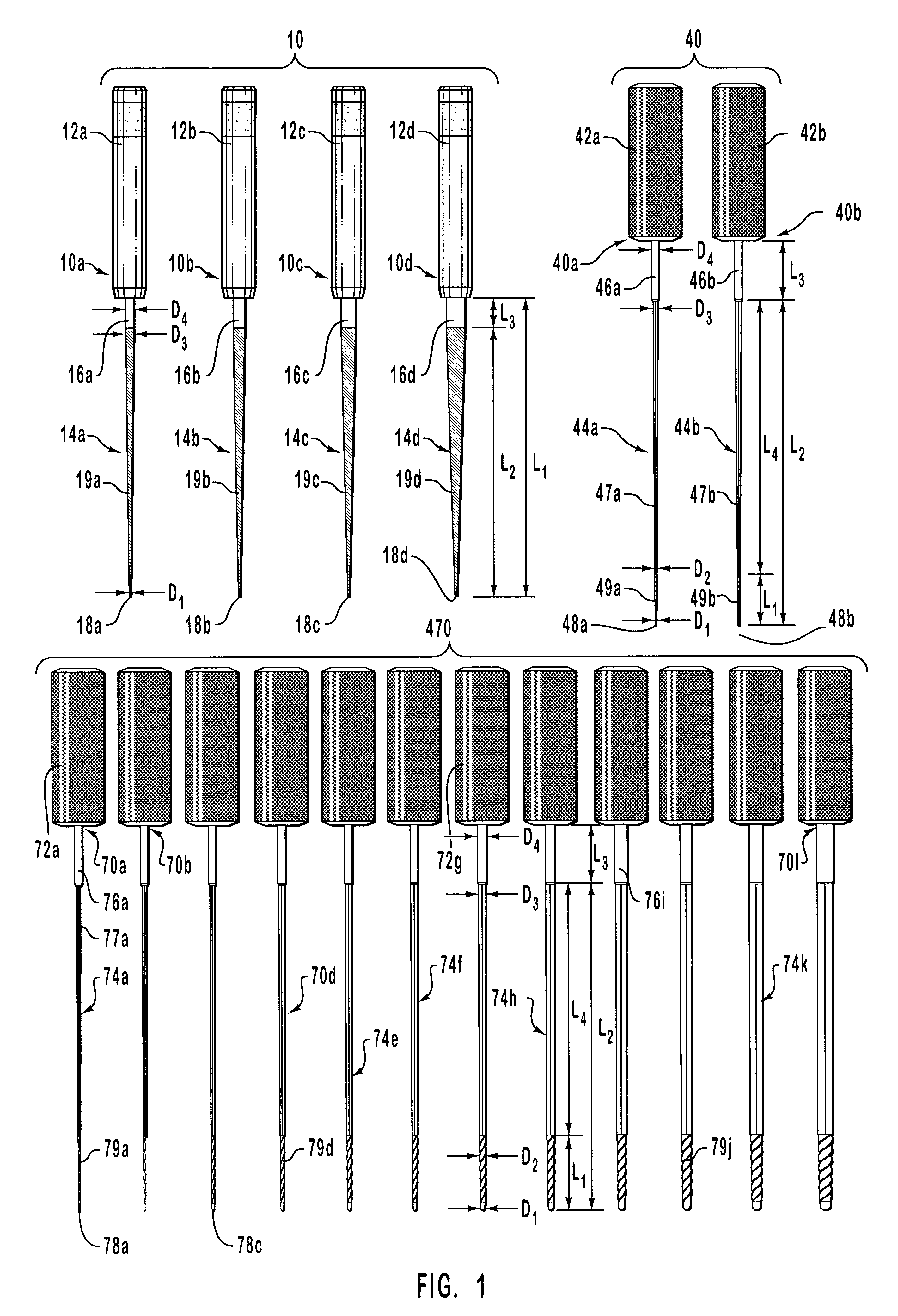

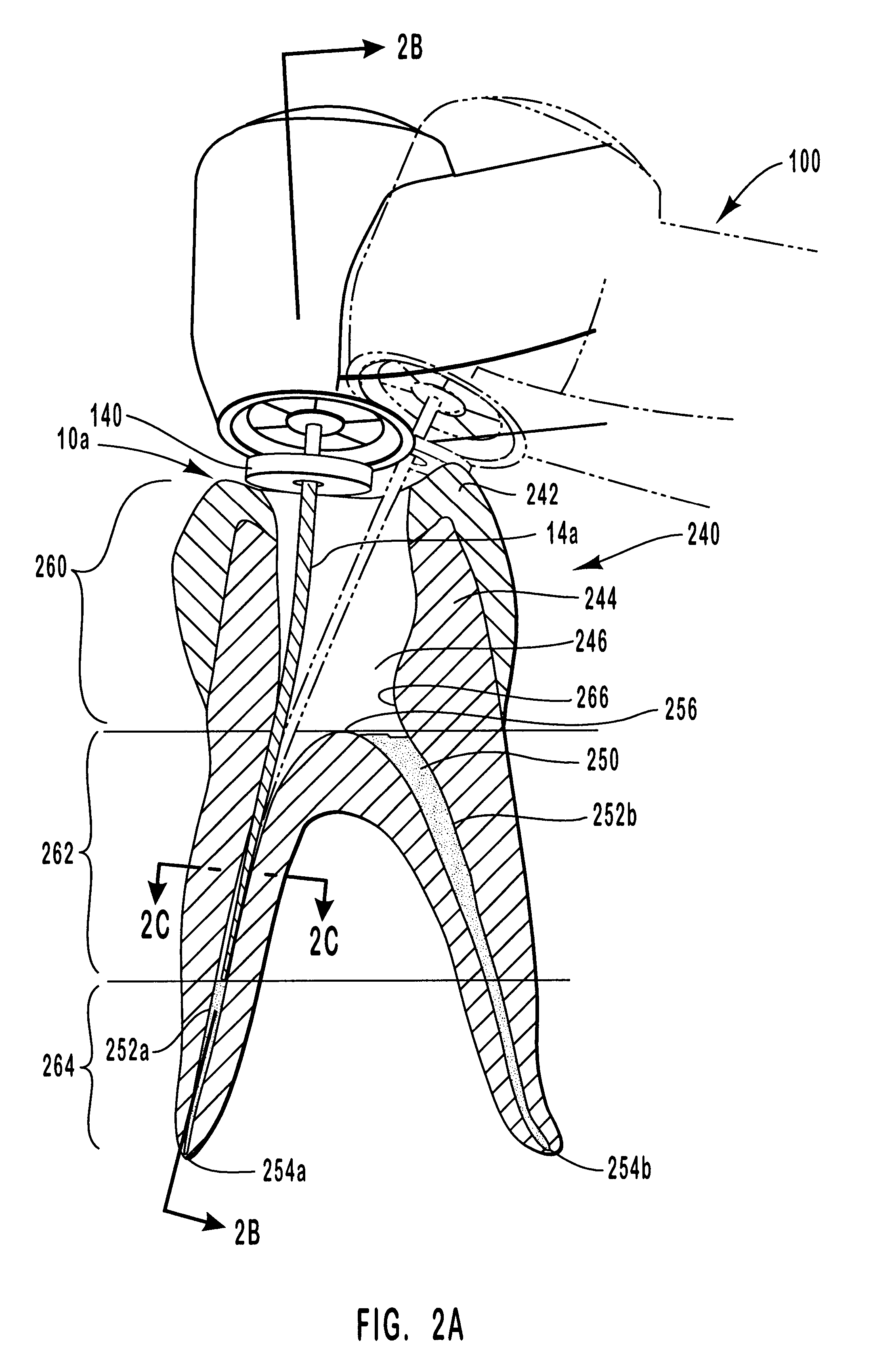

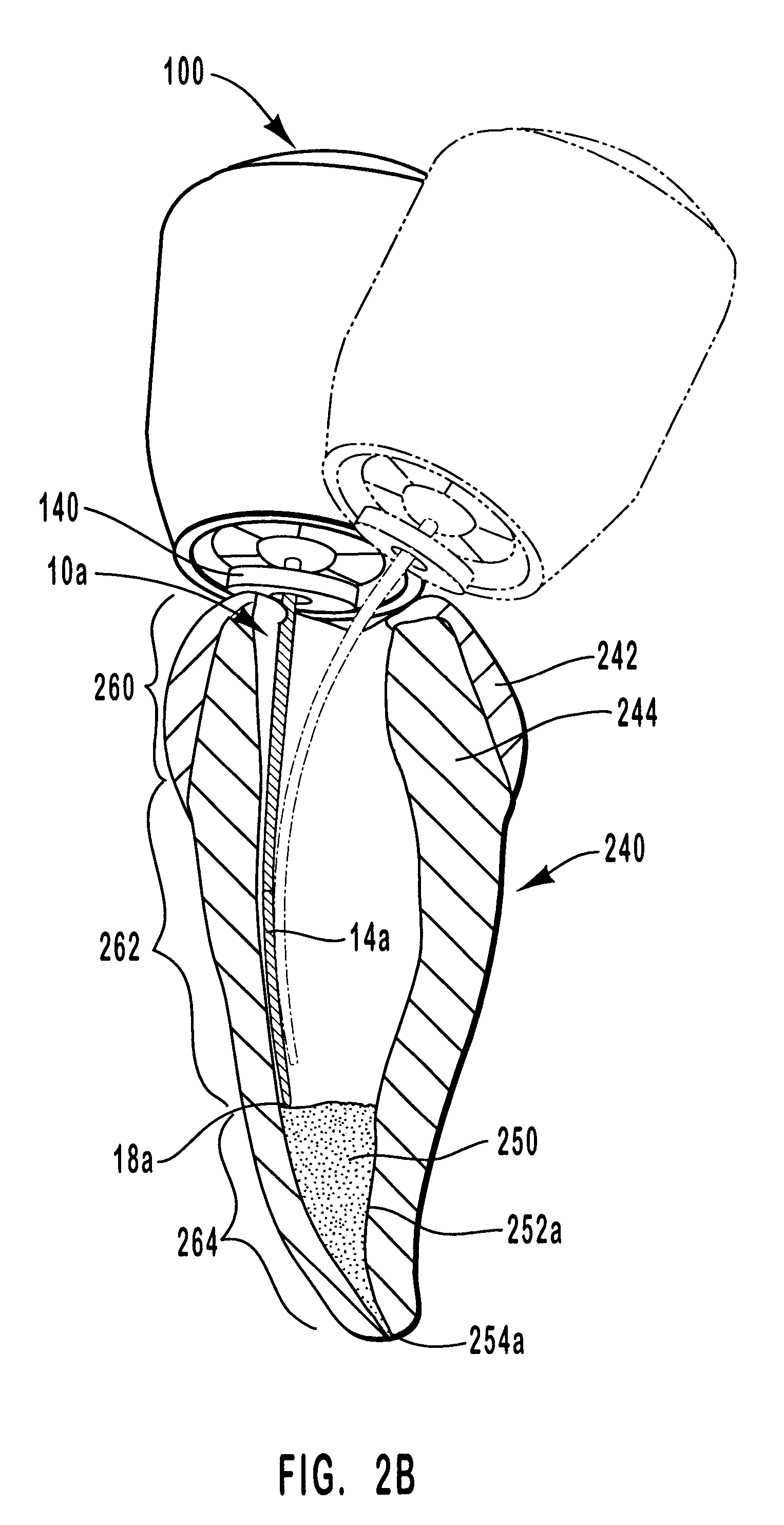

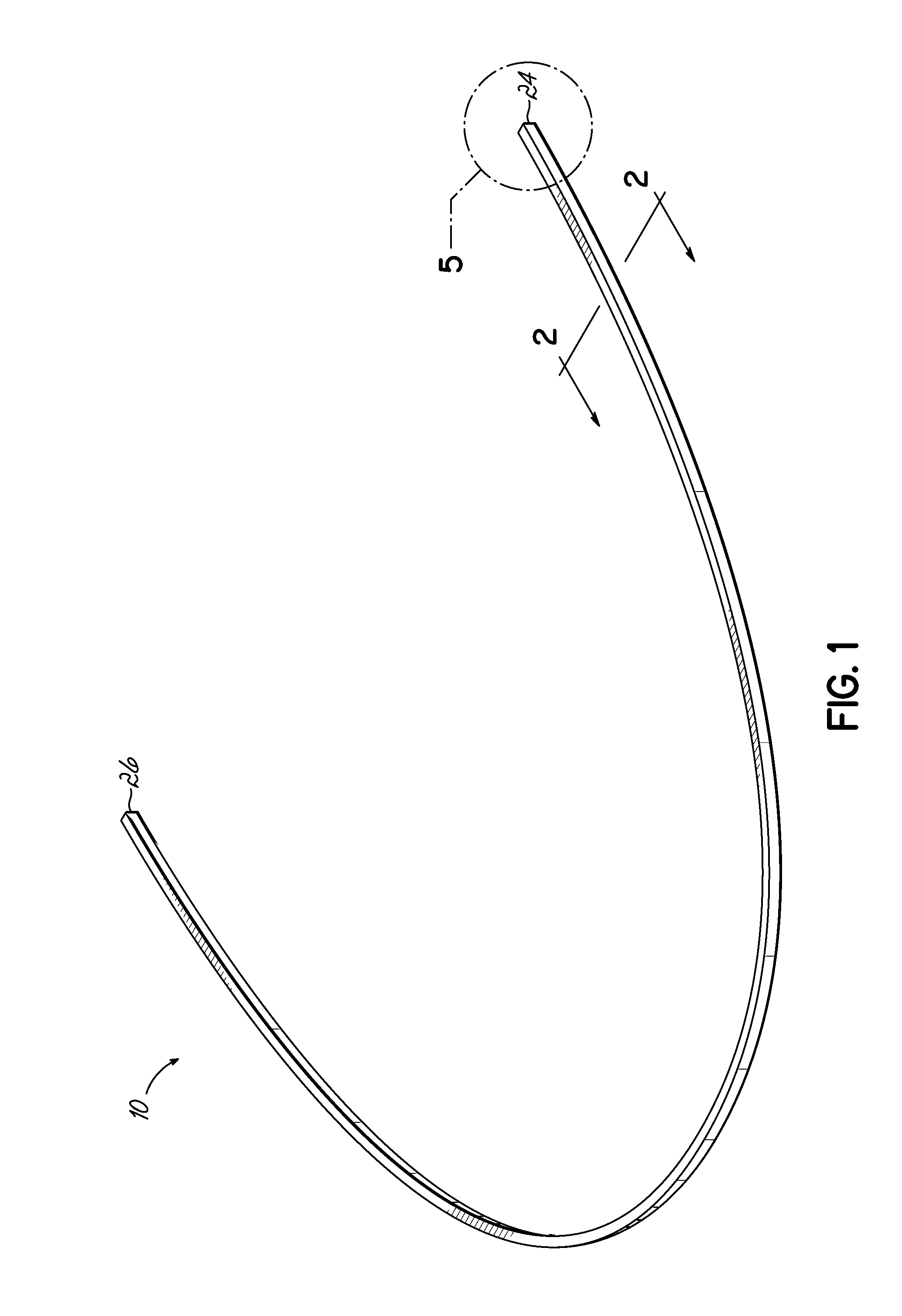

Precipitation hardenable stainless steel endodontic instruments and methods for manufacturing and using the instruments

InactiveUS6514076B1Resistant to wearEasy to useTeeth cappingTeeth nerve/root treatment implementsEndodontic filesChromium nickel

Precipitation hardenable stainless steel endodontic files and methods for their manufacture, wherein the most preferred precipitation hardenable stainless steel is 17-4PH and aging is preferably not one of the manufacturing steps. Precipitation hardenable stainless steels used in embodiments of this invention are iron-chromium-nickel grades that have the desired properties of flexibility, strength, hardness, wear resistance, stiffness, resistance to permanent deformation, resistance to variable torque, and biocompatibility for endodontic files.

Owner:ULTRADENT PROD INC

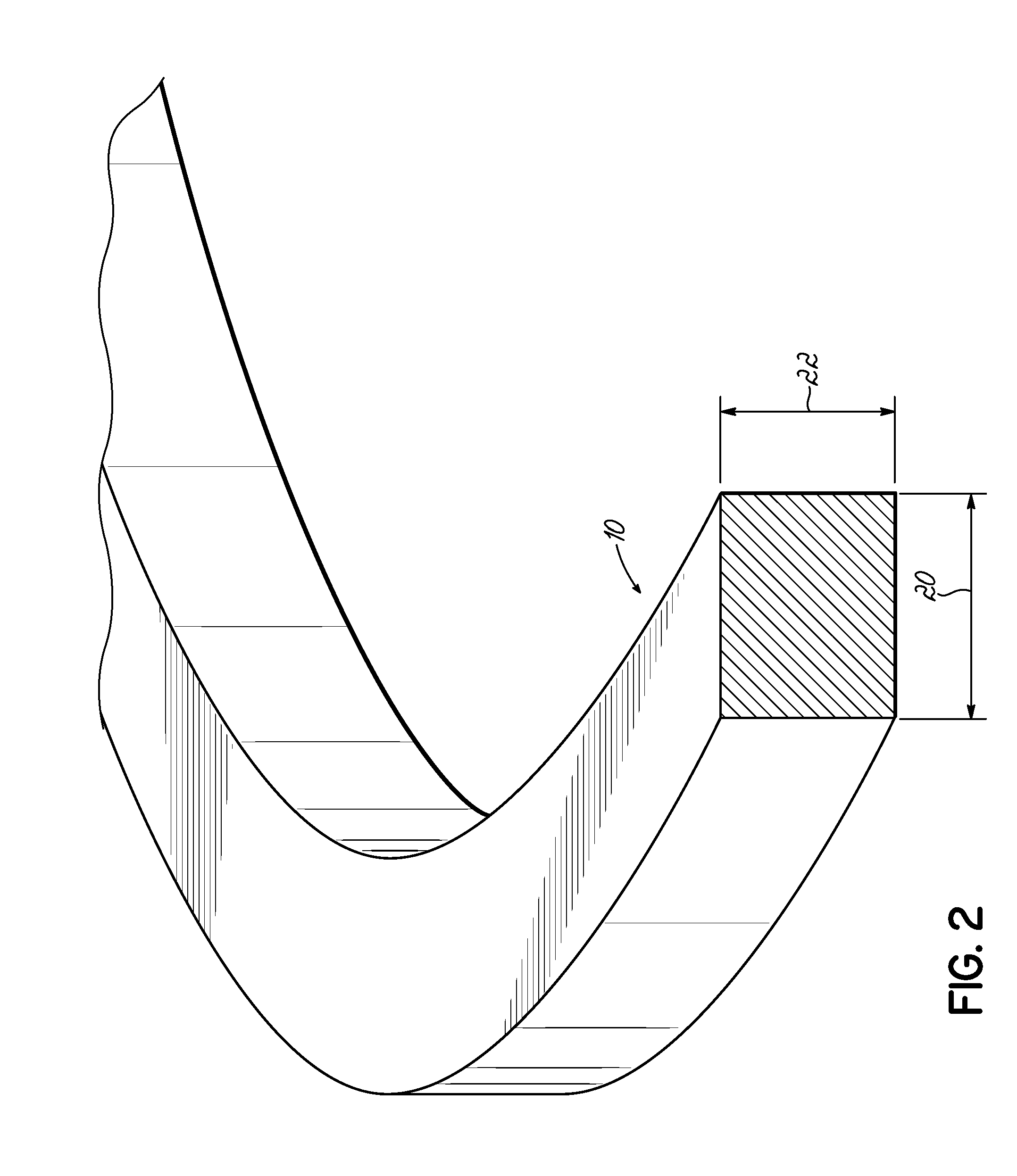

Orthodontic appliances and methods of making and using same

An orthodontic appliance includes a portion made of a shape memory alloy having a base alloy composition of at least two different metallic elements and a treated region having an alloy composition that is depleted in at least one of the metallic elements. The base alloy may include a nickel titanium alloy (NiTi), a copper chromium nickel titanium alloy (CuCrNiTi), or a copper aluminum nickel (CuAlNi) alloy. The treated region may be depleted in at least one of copper, aluminum, nickel, and titanium relative to the base alloy composition by exposing the base alloy to a source of energy. The base alloy composition has a first austenitic finish temperature and the treated region has an austenitic finish temperature that may be different than the first austenitic finish temperature. The treated region may form a part of an archwire, a stop, a hook, a crown, a band, or an orthodontic bracket.

Owner:ORMCO CORP

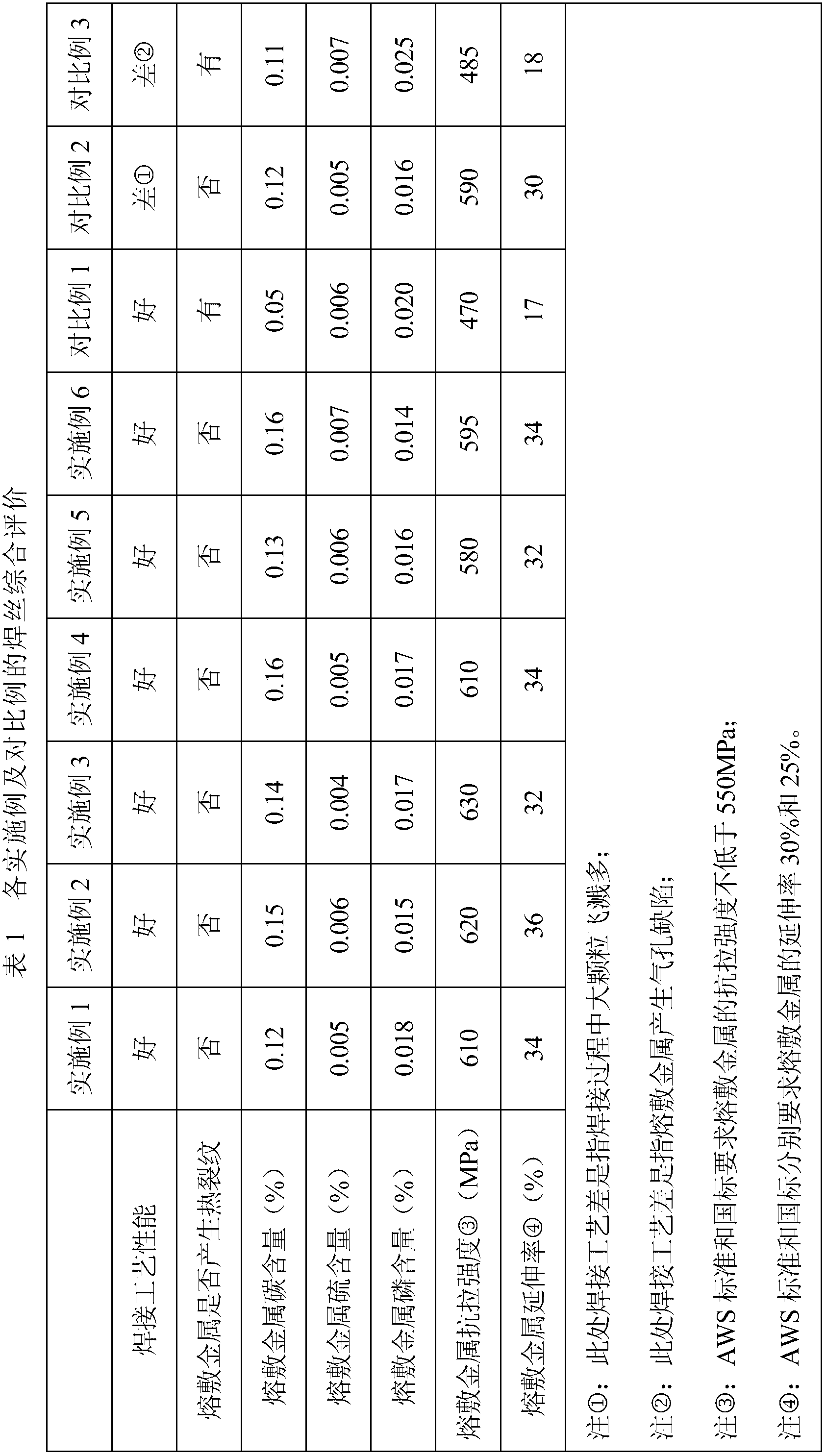

Flux-cored wire for gas-shielded welding of high-chromium-nickel all-austenitic stainless steel

InactiveCN102699579AGuaranteed processing effectIncrease widthWelding/cutting media/materialsSoldering mediaChromium nickelManganese

The invention provides a flux-cored wire for the all-position welding of an austenitic stainless steel, comprising flux powder and a stainless steel band for external use, wherein the weight of a flux core accounts for 28.0-30.0 percent of the total weight of the flux-cored wire, the flux core contains the following components accounting for the flux core in percentage by weight: 25.0%-28.0% of metallic chromium powder, 29.0%-32.0% of metallic nickel powder, 4.0%-5.0% of electrolytic metallic manganese, 2.0%-4.0% of high carbon ferro-chrome, 18.0%-20.0% of rutiles, 1.0%-2.0% of quartz, 1.0%-2.0% of zircon sands, 1.0%-3.0% of feldspars, 0.5%-1.0% of fluorspars, 0.5%-1.5% of calcium carbonate, 0.5%-1.5% of barium carbonate, and the balance of ferrous powder. The flux-cored wire has good welding process property and is suitable for the all-position gas-shielded welding of a high-chromium-nickel all-austenitic stainless steel.

Owner:CHINA JINGYE ENG +1

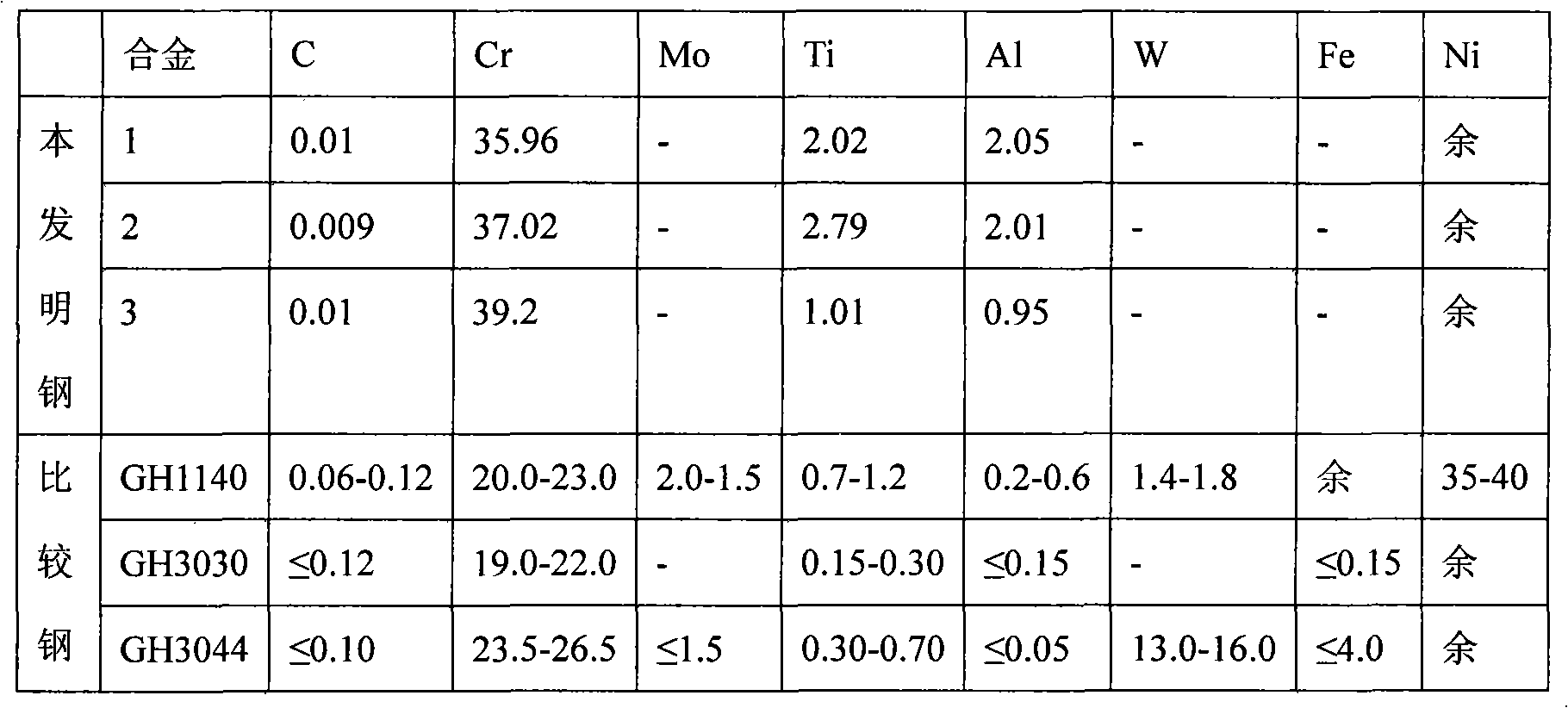

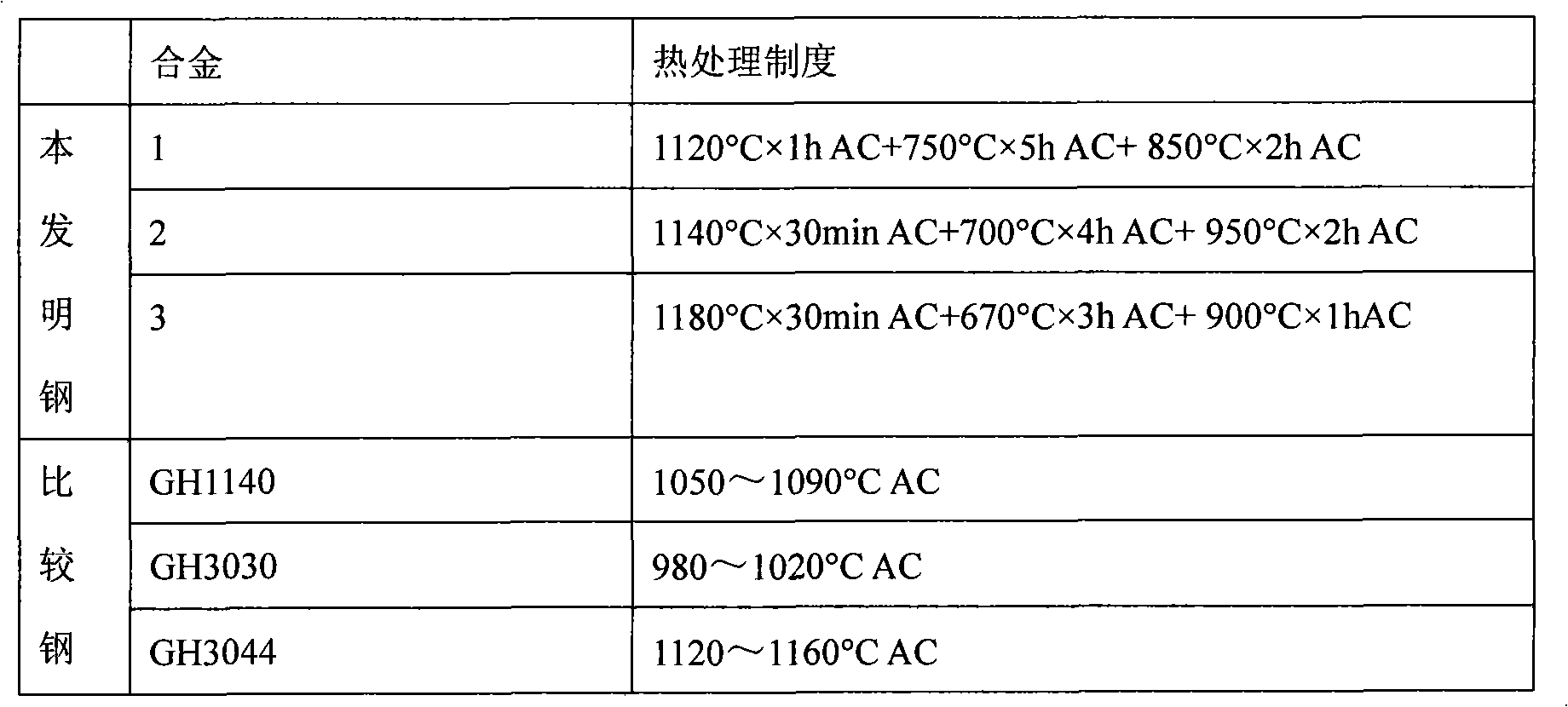

Rich chromium evolution phase reinforcing high chromated nickel base high-temperature alloy and preparation thereof

InactiveCN101270427ADoes not affect mechanical propertiesImprove stabilityChromium nickelOxidation resistant

The invention discloses a high-Chromium-Nickel based high-temperature alloy strengthened by Chromium-rich precipitated phase and a preparation method, and belongs to the field of high-temperature alloy steel, in particular to high-temperature alloy parts with high-strength and anticorrosion used below 1350 DEG C. The high-Chromium-Nickel based high-temperature alloy of the invention has the following components which are in weight percent: 35 to 40 percent of Chromium, smaller than 0.01 of Carbon, 0.01 to 3 percent of Aluminum, 0.01 to 3 percent of Titanium, and the remaining components are Nickel and other inevitable impurity elements. The preparation method thereof is carried out as follows: the compound of the raw material comprising the elements is melted, moulded, forged or rolled successively, firstly solution treatment of 1100 to 1200 DEG C in 30 minutes to 1 hour is carried out, then the compound is treated in two-stage aging treatment. After the heat treatment, the granular precipitated phase of Chromium-rich Alpha-Chromium in high density is evenly distributed in austenite matrix, the size is between 0.1 to 2 Mu meter, thus the optimal matching of organization is realized and plasticity and toughness as well as strength of alloy is assured. Compared with the prior art, the high-Chromium-Nickel based high-temperature alloy has not only the excellent performance of antioxidation and hot corrosion resistance, but also the stable microstructure and the excellent mechanical property by using Alpha-Chromium as a strengthening phase, in particular has the comprehensive performance in high-temperature and hot corrosion environment which is obviously better than that of the existing alloy.

Owner:UNIV OF SCI & TECH BEIJING

Method for smelting chromium-nickel-iron alloy from stainless steel dust-removing ash

InactiveCN101126138AEasy to recycleReduce pollutionProcess efficiency improvementChromium nickelFerrosilicon

The invention is a stainless steel ash removing method for smelting inconel. The method comprises the steps as follow; 1 make ash removing block, comprising the following three steps; 1) selective mixing; 2) extrusion molding; 3) natural drying; 2 make the master liquid by melting the normal recycled waste steel or stainless slag steel, pre-treated the molten iron, the ash removing block and the chromate nickel sponge iron inside the electric furnace; 3 batch-by- batch restoring, which comprises the following three steps: 1) add the block and the extra coke or coke breeze to smelt after the raw material used as master liquid is fully melted; 2) supply power with 15 to 20 minutes, then stop for conducting the operations of temperature measuring, exampling and analyzing, and add ferrosilicon breeze and lime; 3) the molten iron is remained between 1550 to 1600 DEG C in the smelting process; 4 finally restoring, and the main components of the metal solution after being finally restored are as follow: C percent is more than or equal to 2.50, Si percent is more than or equal to 0.20, P percent is less than or equal to 0.045, Cr percent is more than or equal to 5.0, and Ni percent is more than or equal to 1.5. The invention has the advantages of reducing environment pollution and increasing the metal yield of the ash removing.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Stainless steel welding electrode used for third-generation nuclear power main pipeline and production method of stainless steel welding electrode

ActiveCN103706963ANot prone to redness and crackingHigh tensile strengthWelding/cutting media/materialsSoldering mediaCooking & bakingNuclear power

The invention discloses a stainless steel welding electrode used for a third-generation nuclear power main pipeline and a production method of the stainless steel welding electrode, and belongs to the field of welding materials. The stainless steel welding electrode is composed of a chromium-nickel-molybdenum alloy welding core and a coating wrapped on the surface of the welding core, the welding core is composed of smaller than or equal to 0.020wt% of C, 1.00-2.50wt% of Mn, smaller than or equal to 0.30wt% of Si, 18.0-21.0wt% of Cr, 11.0-14.0wt% of Ni, smaller than or equal to 2.00-3.00wt% of Mo, smaller than or equal to 0.050wt% of Co, smaller than or equal to 0.050wt% of Cu, smaller than or equal to 0.010wt% of S, smaller than or equal to 0.015wt% of P and the rest Fe and impurities. Weight of the coating is 30-45% of that of the chromium-nickel-molybdenum alloy welding core. The method includes after uniformly mixing coating powder, adding a binder with the weight being 15-20% that of the coating for uniform mixing, feeding a mixture into a plodder to coat the mixture on the welding core, and subjecting the welding core to low-temperature baking and high-temperature baking. The stainless steel welding electrode has the advantages that content of ferrite in deposited metal is proper, and ferrite number FN of the deposited metal is 5-16; the deposited metal of the welding electrode is excellent in mechanical performance and meets nuclear power requirements; room temperature Rm is larger than or equal to 520Mpa, Rp0.2 is larger than or equal to 205Mpa, and A is larger than or equal to 35.0%; mechanical performance at high temperature of 350 DEG C includes that Rm is larger than or equal to 430Mpa, Rp0.2 is larger than or equal to 125Mpa, and A refers to actual measurement.

Owner:ATLANTIC CHINA WELDING CONSUMABLES +1

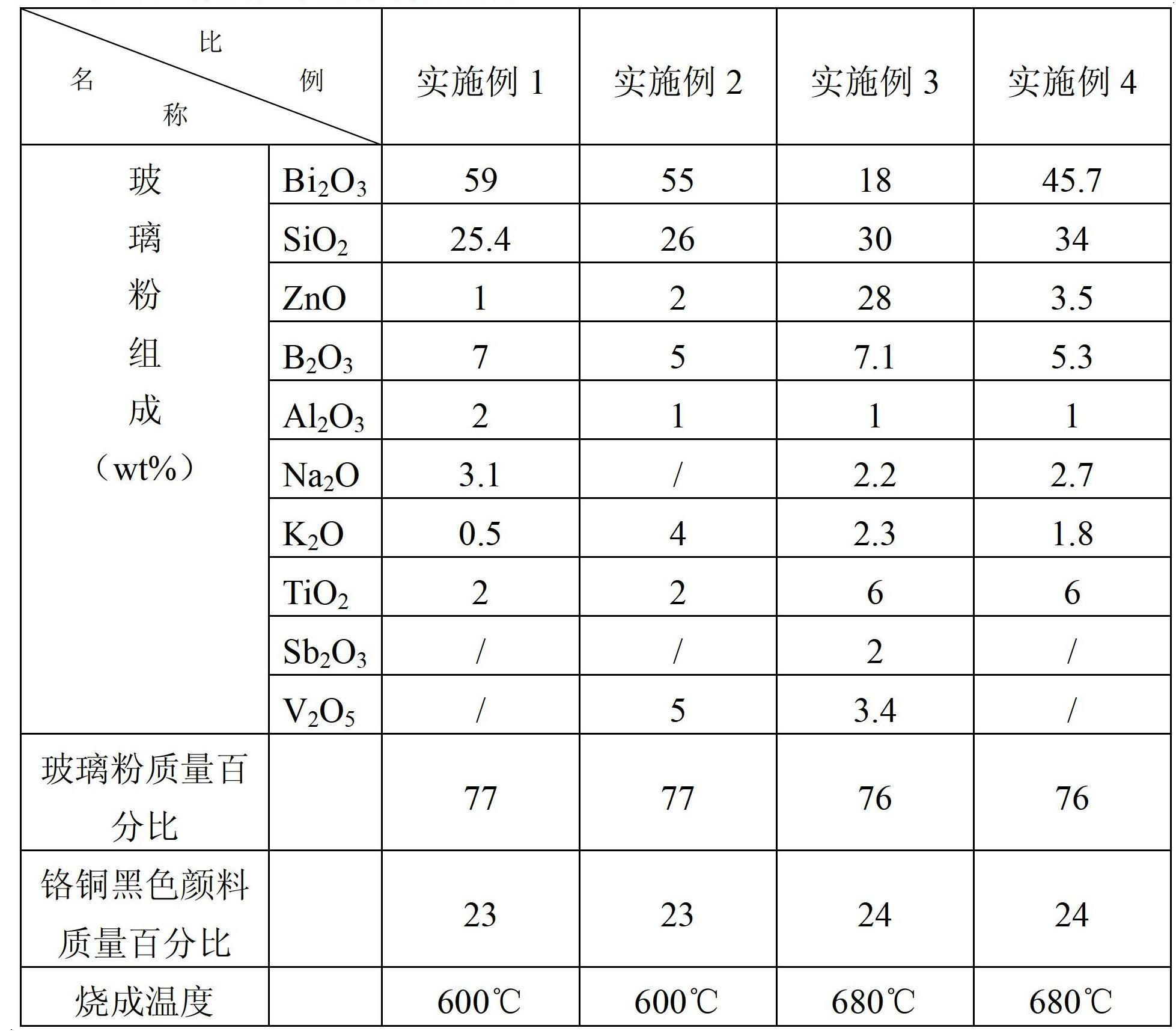

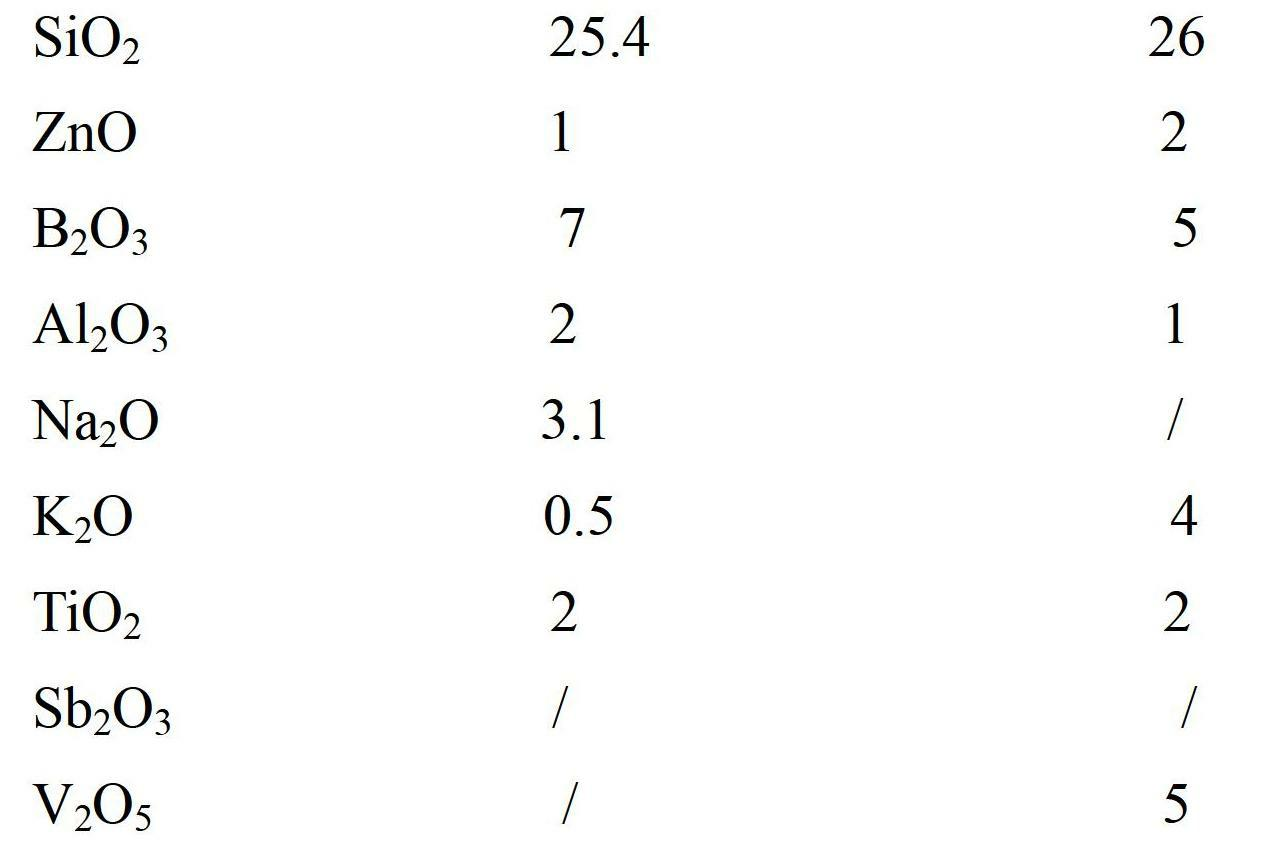

Environmental-friendly black glaze for automotive glass and preparation method of black glaze

The invention relates to a high-performance environmental-friendly black glaze for automotive glass and a preparation method of the black glaze. The invention is characterized in that the high-performance environmental-friendly black glaze for the automotive glass comprises the following compositions in percentage by weight: 75-80% of bismuth series low-melting- point glass powder and 20-25% of inorganic black pigment. The bismuth series glass powder contains ZnO without rare-earth oxides; the grain size of the glass powder is 0.5-3 um; and the inorganic black pigment is iron-chromium-nickel-manganese black pigment or chromium-copper black pigment. The glass powder and the inorganic pigment are added to a V-shaped blender mixer to be mixed in proportion, so that the black glaze for the automotive glass is obtained. And then the black glaze is blended into slurry by organic carrier, and is coated at the edge of the automotive glass through screen printing. a black framework of the automotive glass is formed through the processes such as low-temperature drying, hard fire and the like. The blackness value L is less than 7, and the shielding property Delta L is less than 1.

Owner:JIANGXI SUNFLEX LIGHT RETROREFLECTIVE MATERIAL

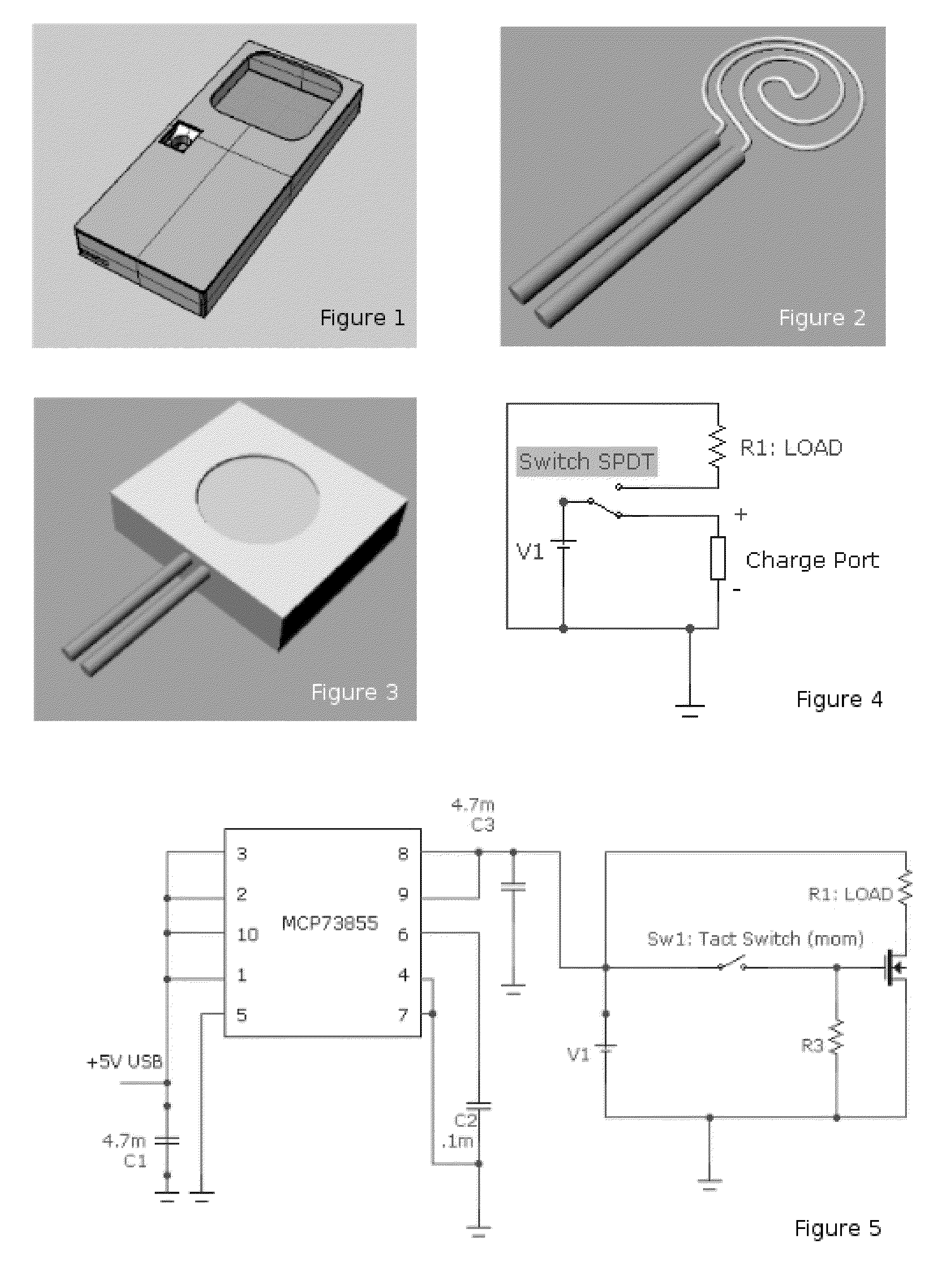

Portable Rechargeable Battery Powered Flameless Cigar Lighter

InactiveUS20100301032A1Easy to useAlter the enjoyment of the cigar's characterIncandescent ignitionChromium nickelElectrical battery

A pocket size electric lighter having a heating element made of nichrome which has been seated firmly in a material of low thermal conductivity while having a thin top coating of thermally conductive material. Power to the heating element is provided via rechargeable battery. A small charging port provides a means to recharge the battery as necessary.

Owner:JOHNSON TYLER

Cubic boron nitride superhard cutter

The invention discloses a superhard cutter with high hardness and good abrasive resistance and heat resistance. The cutter comprises the following components in percentage by weight: 75-85 percent of cubic boron nitride micro powder with the granularity of 1-10 mum, 0.5-3 percent of microlite powdered boron with the purity above 99.5 percent, 5-10 percent of microlite powdered aluminum with the purity above 99.5 percent, and 6-15 percent of carbon with a diamond structure. Because the invention is prepared by adopting the cubic boron nitride as a main raw material and adding the high-purity microlite powdered aluminum and the high-purity microlite powdered boron as well as the carbon with the diamond structure under super-high pressure and high temperature, the high hardness, the abrasive resistance and the heat resistance are obviously improved; and the superhard cutter is used for high-hardness alloy materials with turning HRC within 48-53, and has better effect particularly on chromel alloy materials.

Owner:刘书锋

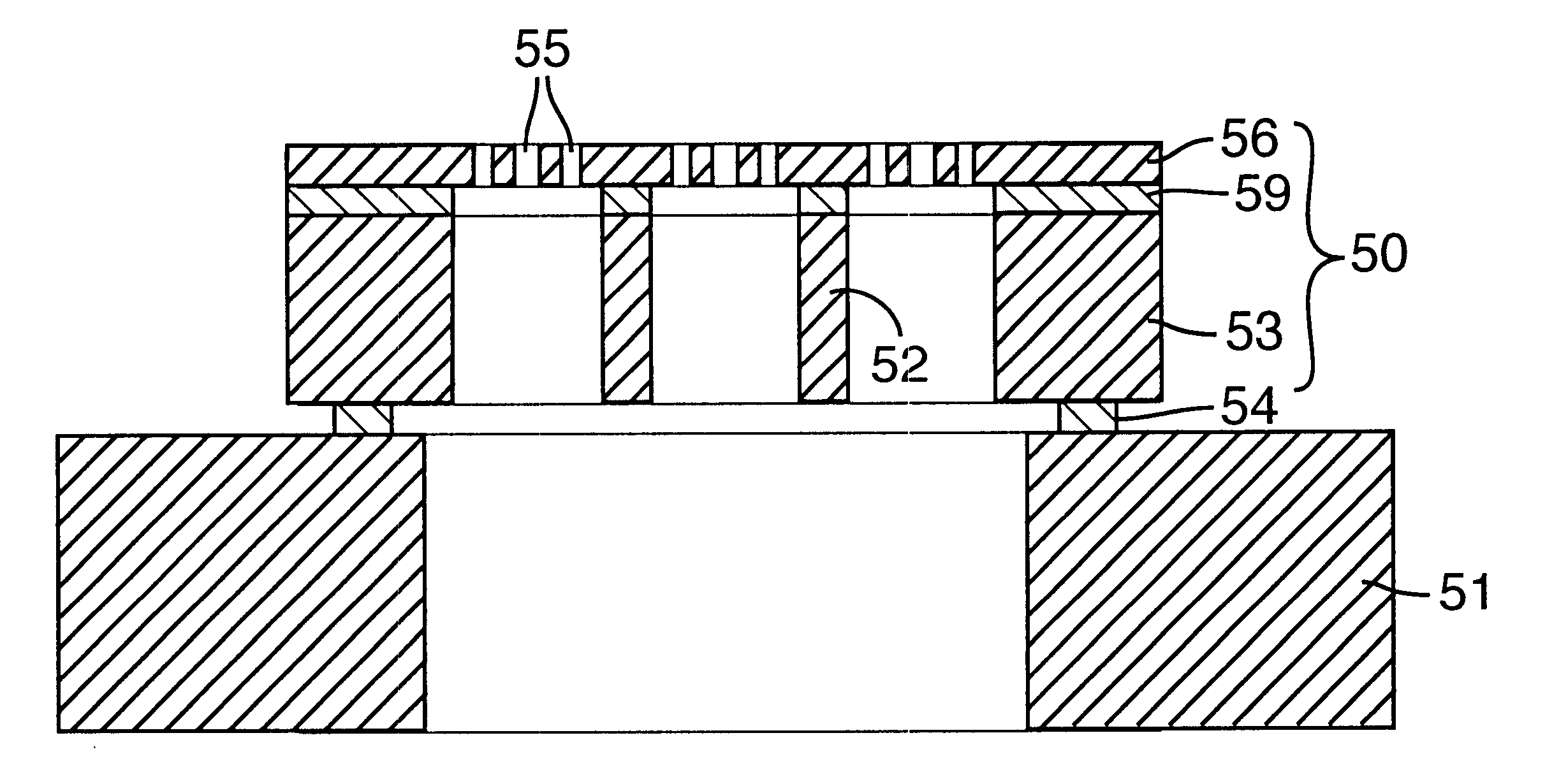

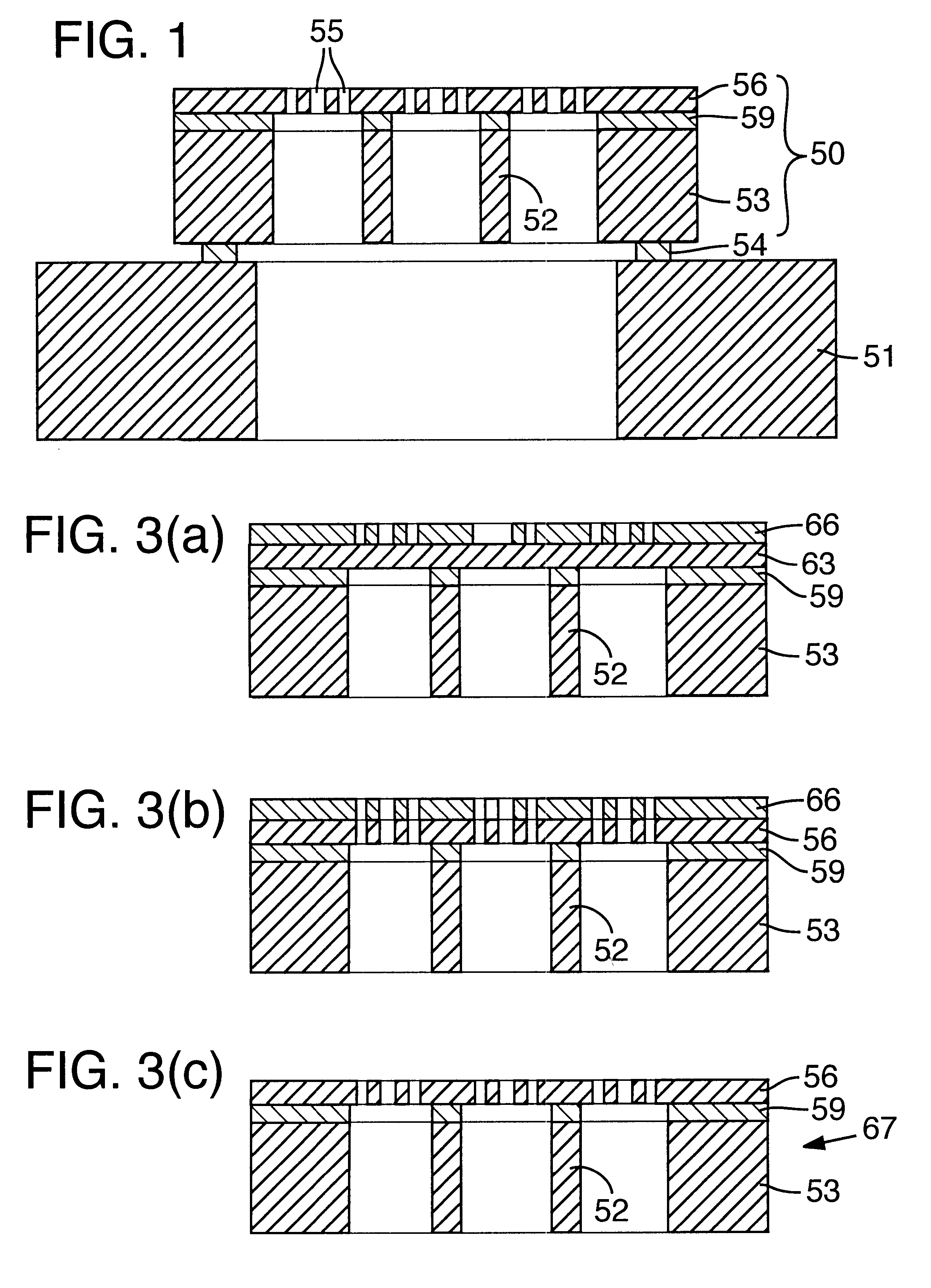

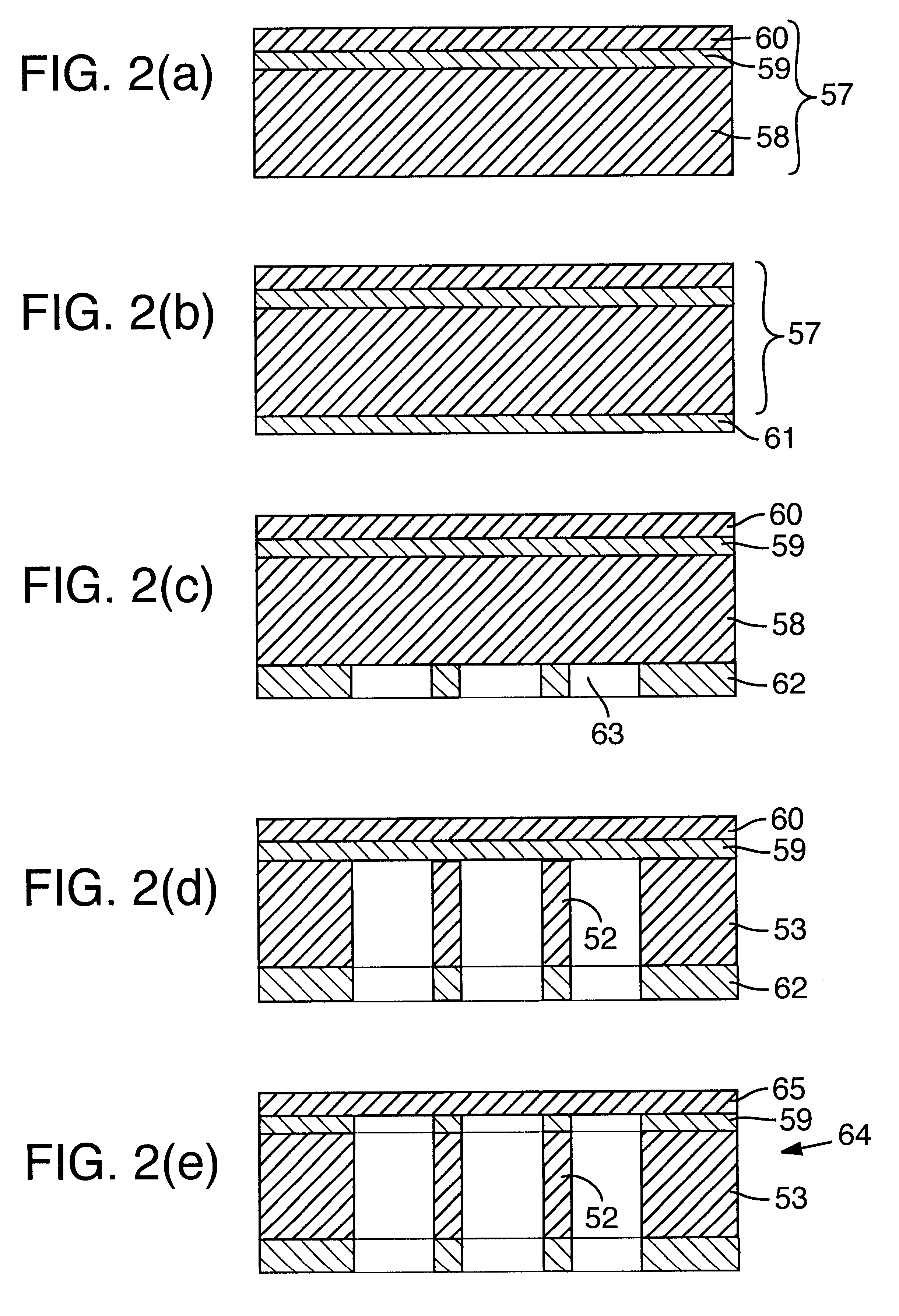

Reticles including support frame for charged-particle-beam microlithography, and methods for making same

InactiveUS6534222B1Reduce distortion problemsRelieve stressDielectric heatingPicture framesChromium nickelNichrome

Reticles and reticle blanks are disclosed, especially for charged-particle-beam microlithography, that include a peripheral frame and a support frame bonded to each other in a manner that substantially reduces distortion at the bonds as well as membrane distortion. The peripheral frame is bonded peripherally to the support frame in any of various manners including an anodic weld of glass and silicon (the glass containing mobile ions) and a eutectic metal silicon bond wherein the metal can be, e.g., gold, aluminum, germanium, or tin. The glass-silicon and eutectic bonds in which the metal is, e.g., gold, are also resistant to chlorine gas used for routine cleaning of the reticle. In the case of the eutectic metal bond, an intervening layer of chrome or nichrome can be applied between the metal layer and the bonding surface to enhance bonding. Also, the eutectic bond can be formed by incubation at a temperature profile that favors formation, in the welds, of multiple, minute bonding points in metallic island structures on the bonding surfaces. Also disclosed are methods for making reticles and reticle blanks.

Owner:NIKON CORP

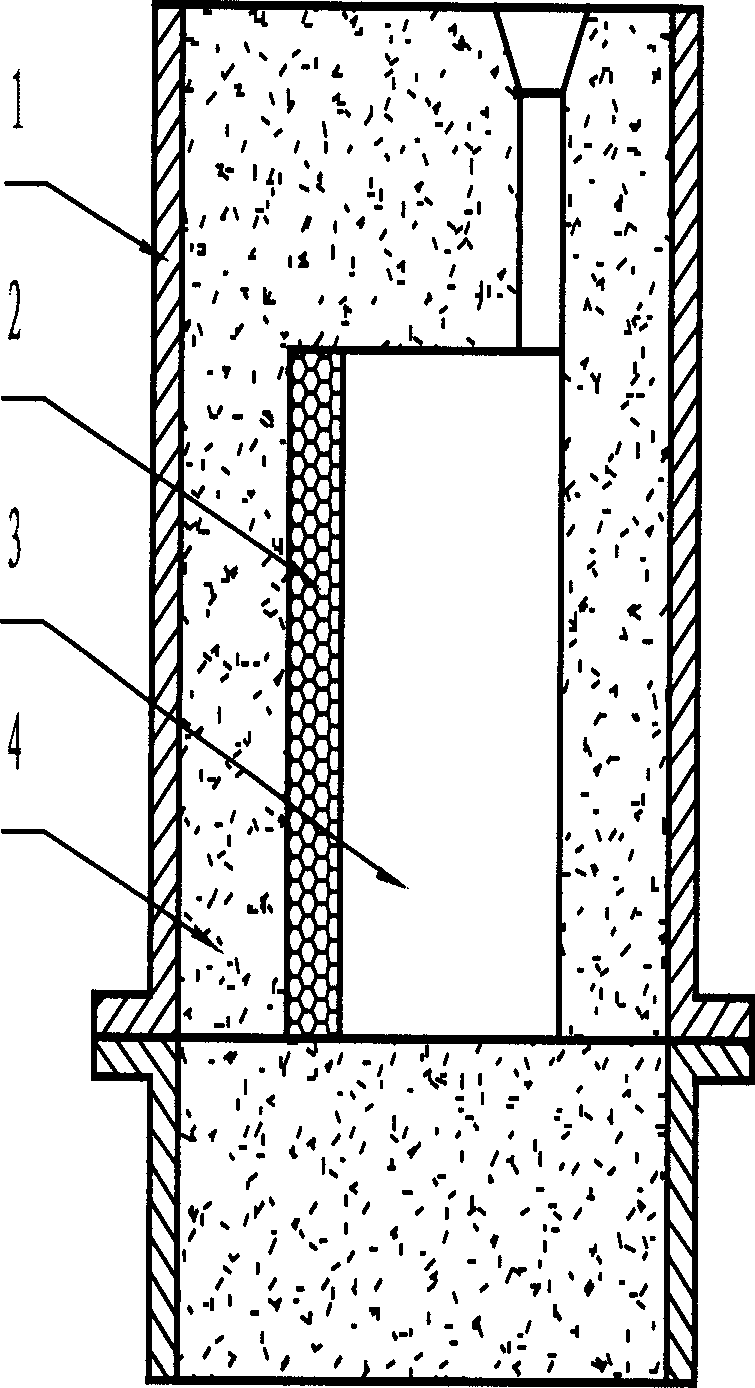

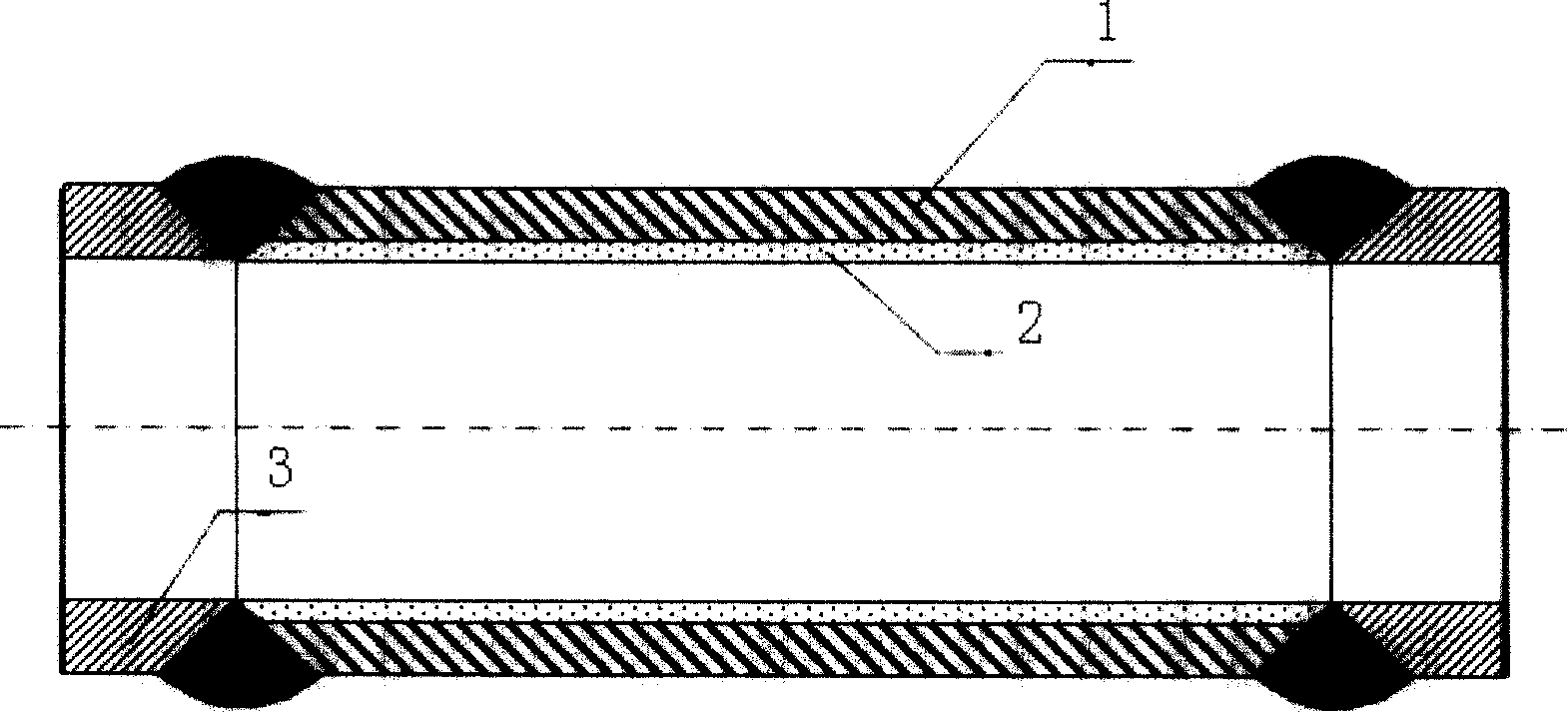

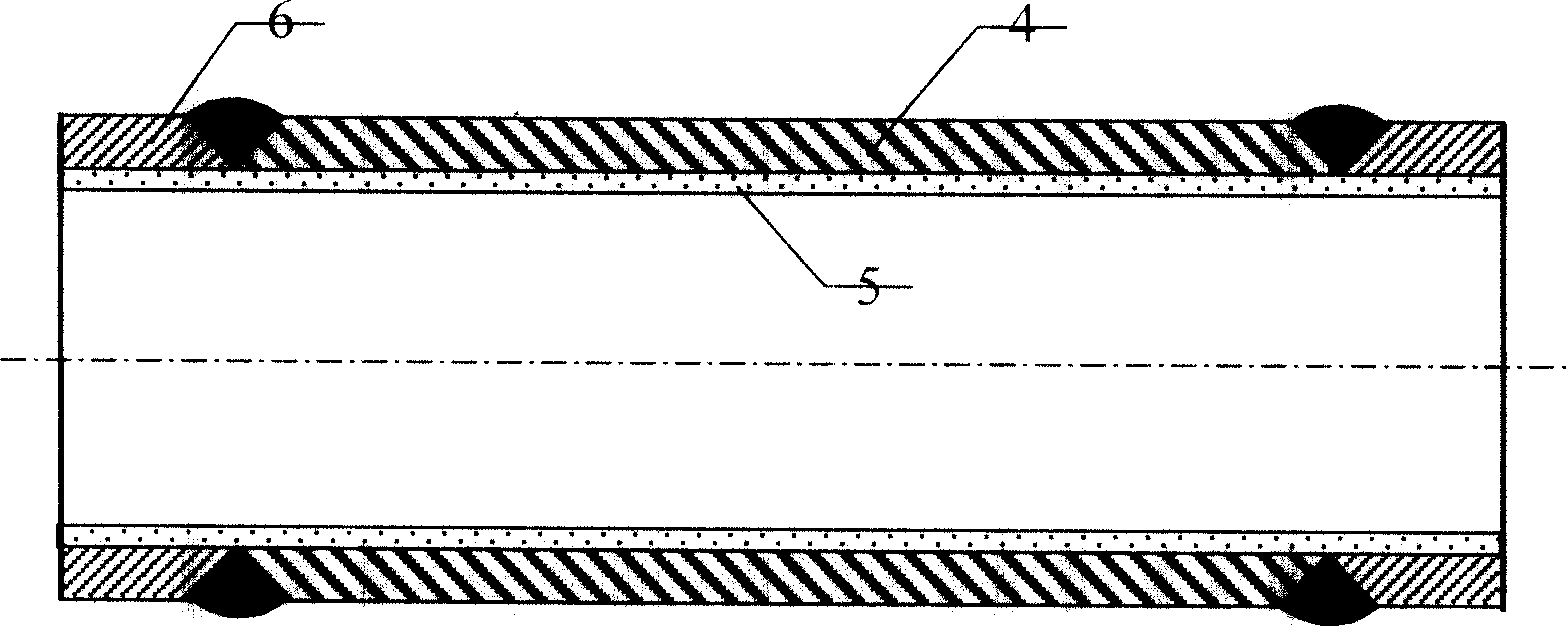

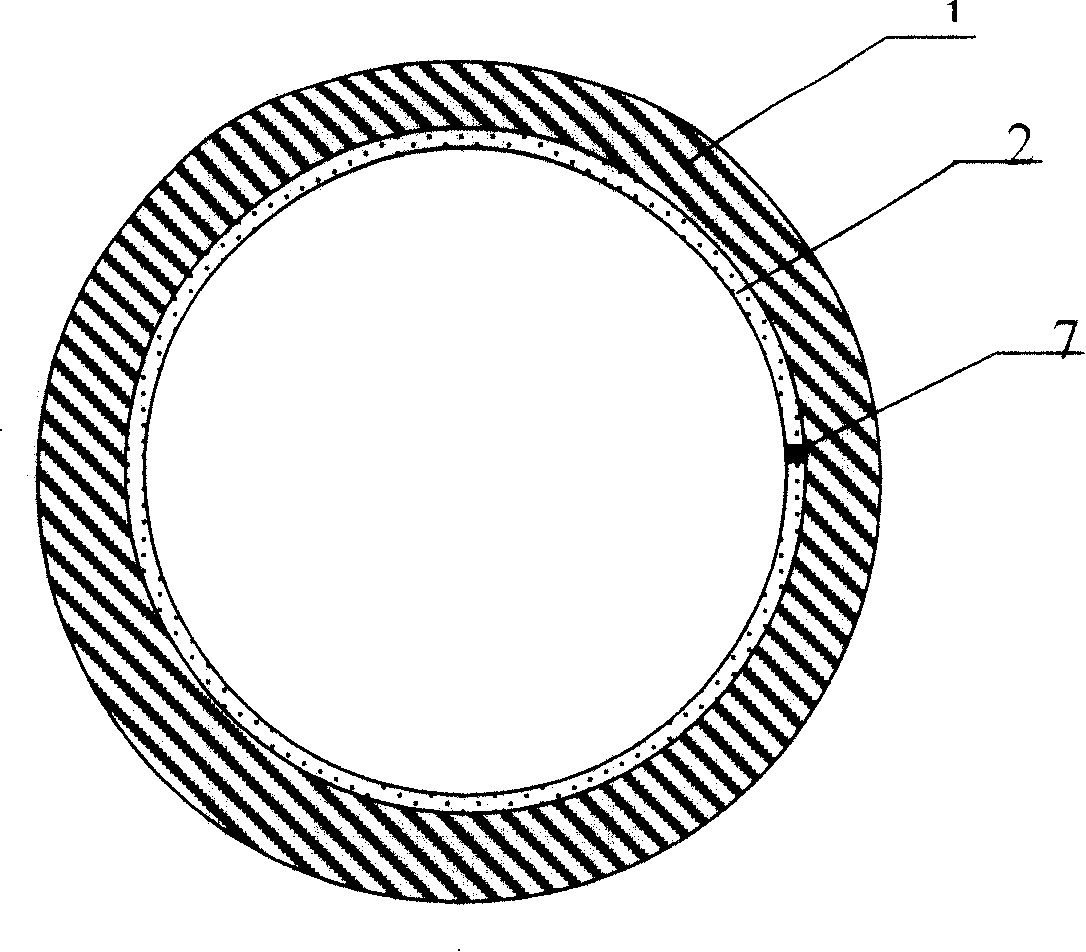

Inner lining anti-corrosion metallic composite pipeline with easy welded joint structure

InactiveCN101205994ASolve anti-corrosionImprove corrosion resistanceLayered productsCorrosion preventionChromium nickelNichrome

The invention relates to a compound tube with internal lining made of corrosion resistant metal, which has end parts and a liner tube made of corrosion resistant metal and an outer body tube made of carbon steel or low alloy steel. The corrosion resistant metal applied in the end parts and the liner tube is used for resisting medium corrosion, while the carbon steel or the low alloy steel applied in the body tube is used for ensuring mechanical strength. When two compound tubes are welded together, a continuous tube made of corrosion resistant metal is formed in the compound tube, thereby ensuring that the whole tube has the corrosion resistance property of the corrosion resistant metal. When the mechanical strength at the joint of the two compound tubes is relatively low, the mechanical strength can be reinforced by (1) improving the wall thickness of the tube joint, (2) applying fiber reinforced composite, or (3) applying clamper filling technology. The liner tube of the invention can be made of corrosion resistant metals like stainless steel, nickel-based alloy, high content nichrome, titanium alloy, etc. The compound tube provided by the invention has good corrosion resistance, easy processing and low cost.

Owner:BEIJING SAFETECH PIPELINE

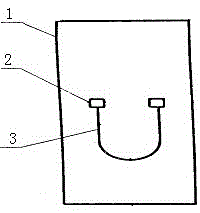

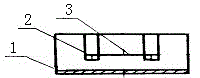

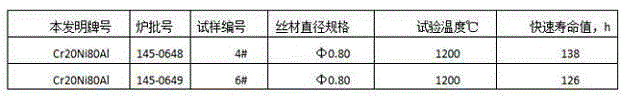

High-resistant chromium-nickel electric heating alloy and preparation process thereof

The invention discloses a high-resistant chromium-nickel electric heating alloy and a preparation process thereof. The chemical formula of the high-resistant chromium-nickel electric heating alloy is Cr20Ni80Al; the raw material formula of the high-resistant chromium-nickel electric heating alloy comprises the following components in percentage by weight: less than or equal to 0.03 percent of C, 1.40 to 1.60 percent of Si, less than or equal to 0.30 to 0.50 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, 20.5 to 21.50 percent of Cr, less than or equal to 0.10 percent of Ti, less than or equal to 3.5 to 3.7 percent of AL, less than or equal to 1.00 percent of Fe, less than or equal to 0.2 percent of Zr, and the balance of Ni and inevitable impurities. According to the high-resistant chromium-nickel electric heating alloy, the electrical resistivity of the electric heating alloy is improved; the electrical characteristics are better; the anti-oxidation performance of an alloy material is improved; the high-temperature strength of the alloy is improved; the service life of the alloy is prolonged.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

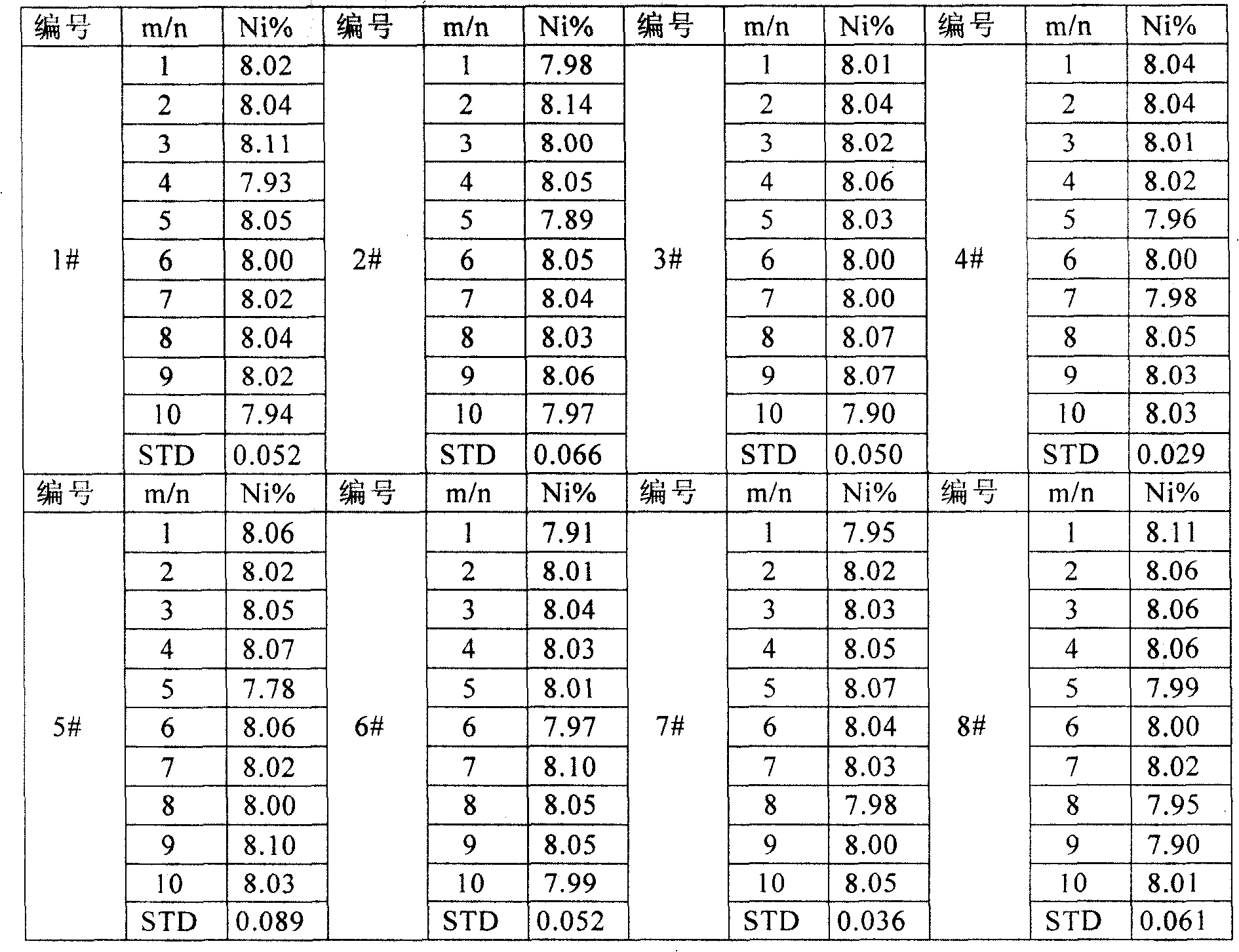

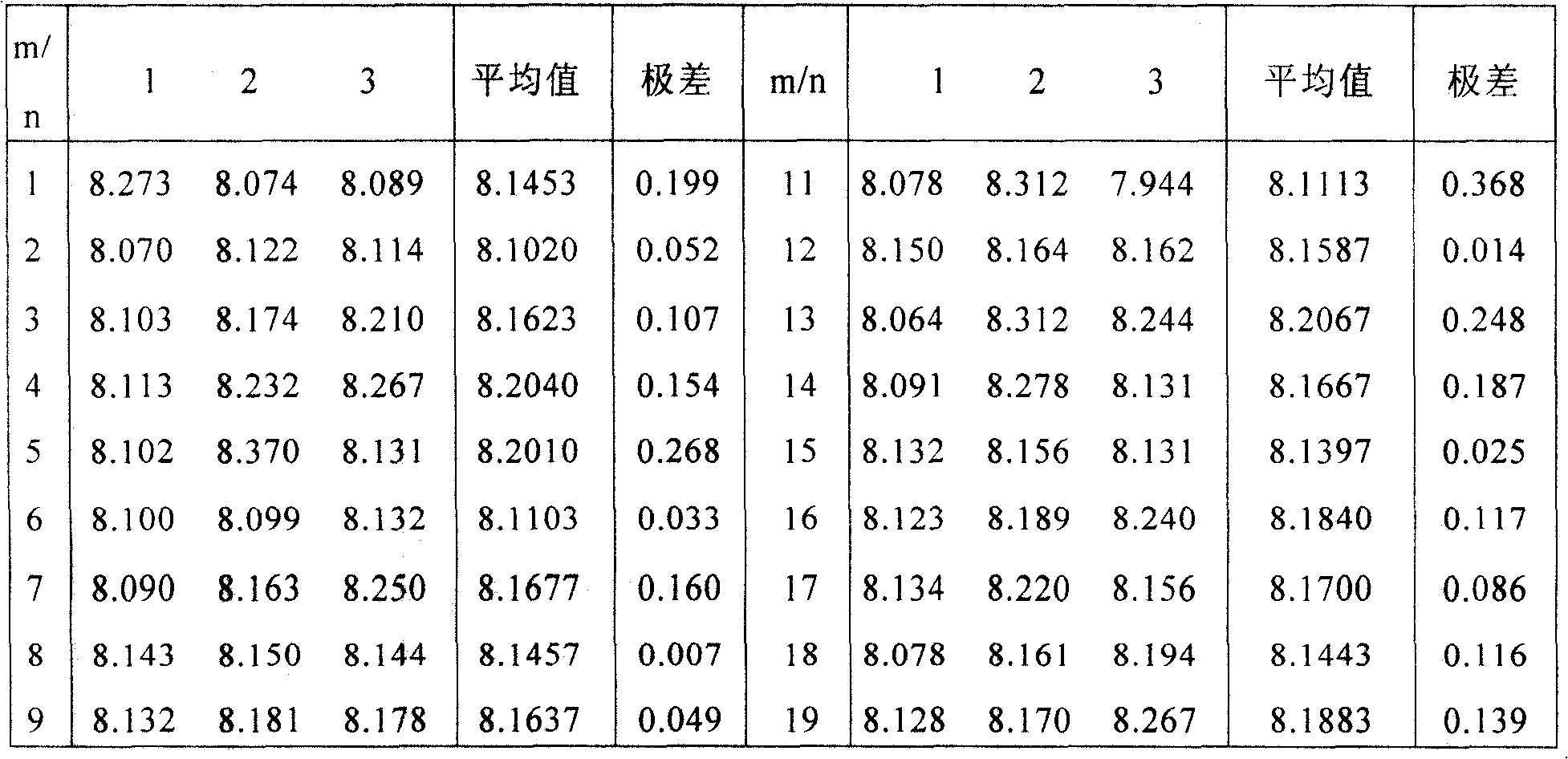

Production method of high-homogeneity chromium-nickel austenite stainless steel optical spectrum emendation example

InactiveCN101246120AImprove control analysis accuracyGuarantee the actual control accuracy targetMaterial analysis by optical meansChromium nickelIngot

The present invention discloses a method for preparing the high-homogeneity chromium-nickel austenite stainless steel optical spectrum correcting sample in order to provide a reliable optical spectrum correcting sample. The method comprises the following steps: 1) correcting the component of the sample to the following mass percentage: C<=0.20, Si<=1.0, Mn<=2.0, P<=0.035, S<=0.030, Cr 16-24, Ni 6-14, and the rest is Fe; 2) smelting and casting to steel ingot with the components; 3) smithing with the staring temperature: 1100 DEG C-1150 DEG C, and the finishing temperature: 900 DEG C-950 DEG C; 4) roller milling with staring temperature: 1100 DEG C-1150 DEG C, and the finishing temperature: 900 DEG C-950 DEG C; and 5) heat treating for solution temperature 1000 DEG C-1050 DEG C and temperature preserving time 40-50min, and at last water cooling with immersion type. The invention corrects the homogeneous austenite structure with grain fineness number larger than 7 and residual ferrite dispersed arranged in the sample block, satisfies the request of the spectrum analysis and leads to that the spectrometry obtains the best analyzing precision.

Owner:BAOSHAN IRON & STEEL CO LTD

Manufacture method for tire casing of diamond wire saw sintered type bead

InactiveCN102513539AGood bezel setting abilityLower sintering temperatureMetal sawing toolsChromium nickelCobalt

The invention discloses a manufacture method for the tire casing of a diamond wire saw sintered type bead. The method comprises the following steps: 15 parts of iron powder, 25 parts of cobalt powder and 60 parts of copper powder are taken according to parts by weight for mixing so as to form iron, cobalt and copper prealloying power under normal temperaure, then 75 to 85 parts of prealloying powder, 10 to 15 parts of bronze powder and 5 to 10 parts of nickel chromium triangle alloyed powder are taken according to parts by weight for mixing so as to form pelletizing powder, finally proper diamond is added into the pelletizing powder so as to form the raw material of the tire casting, then cold press and hot press sintering and the like are performed on the raw material of the tire casting so as to form the tire casting. The tire casing of the diamond wire saw sintered type bead, manufactured by the invention, has an excellent holding force, the tire casing is firmly adhered to a steel base, the sintering activity of the tire body is greatly improved, the sintering temperature is lowered greatly, and the energy is saved.

Owner:长沙市德天冶金科技有限公司

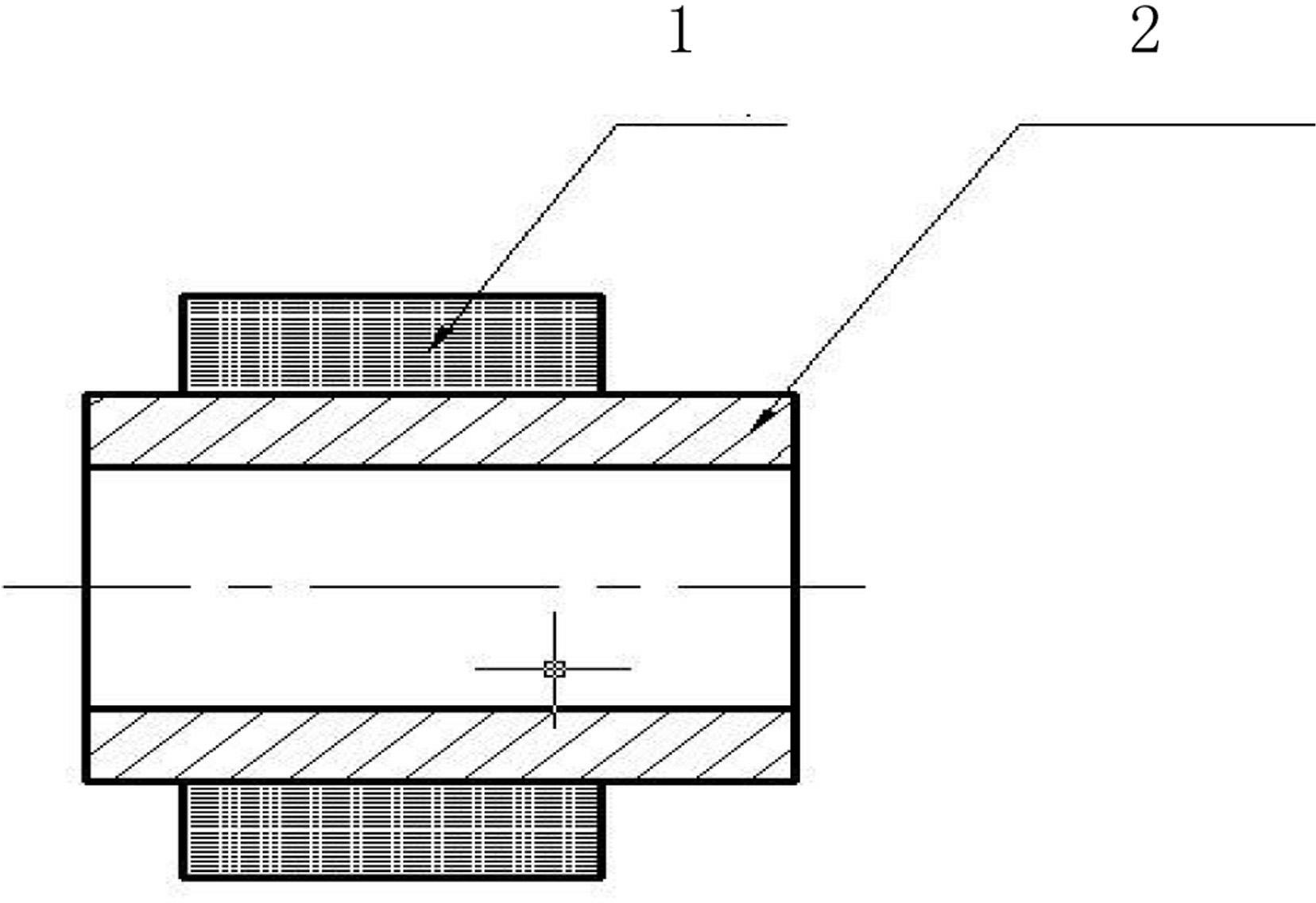

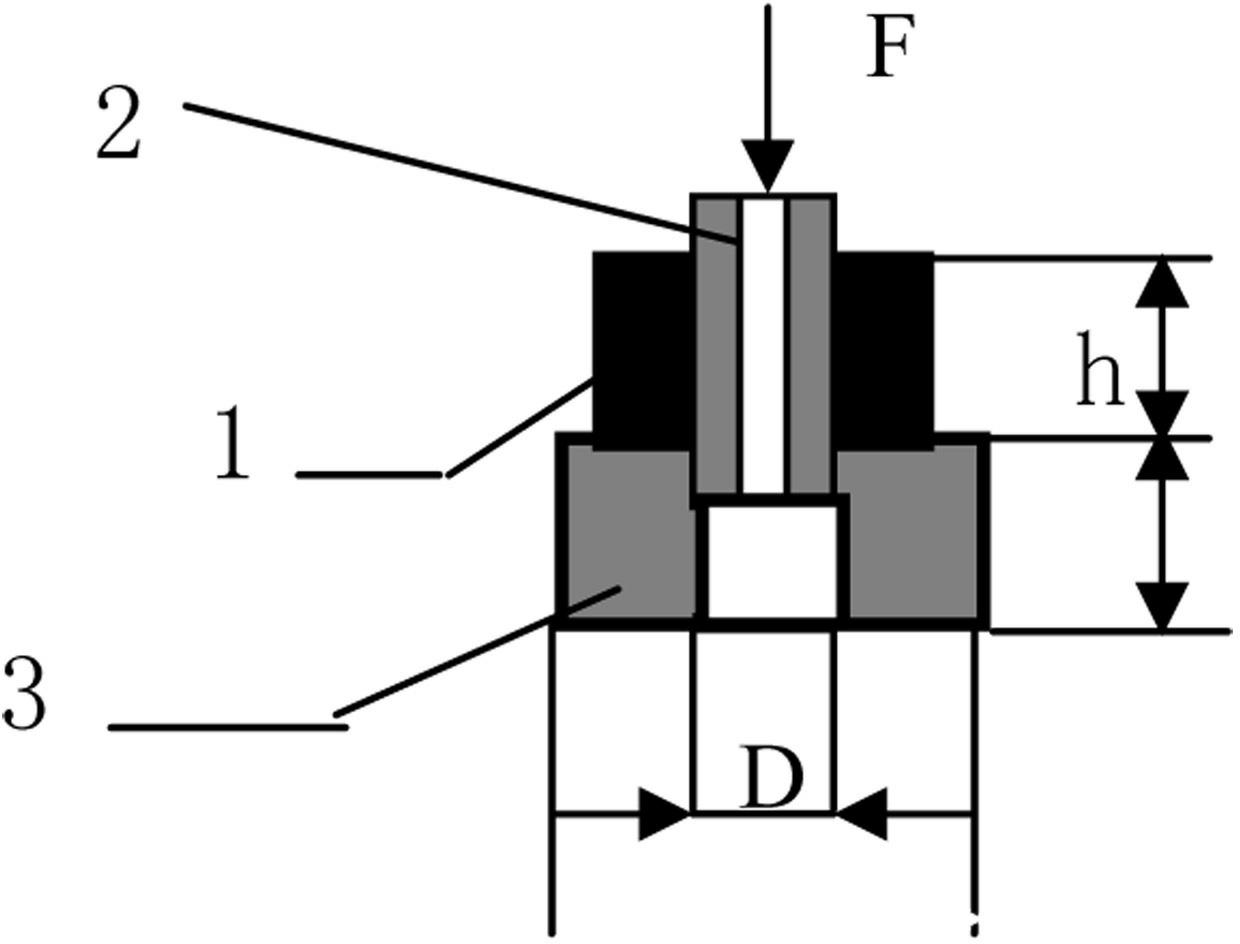

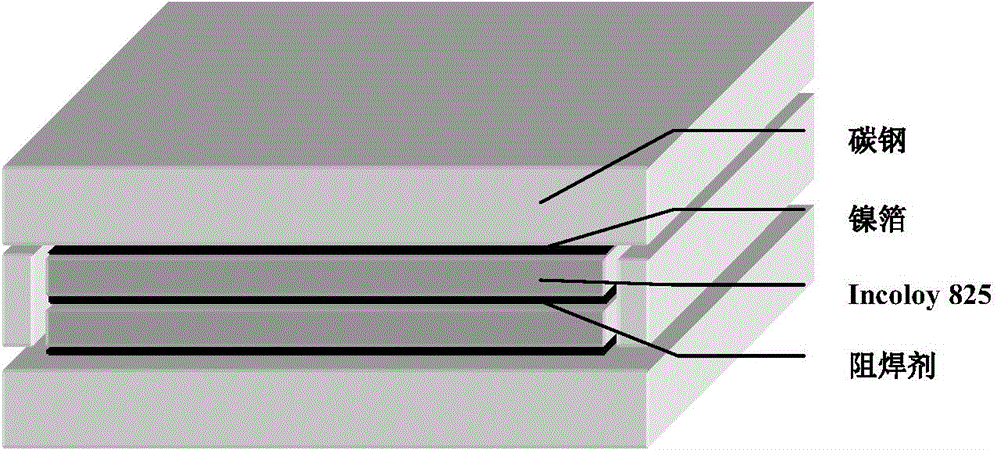

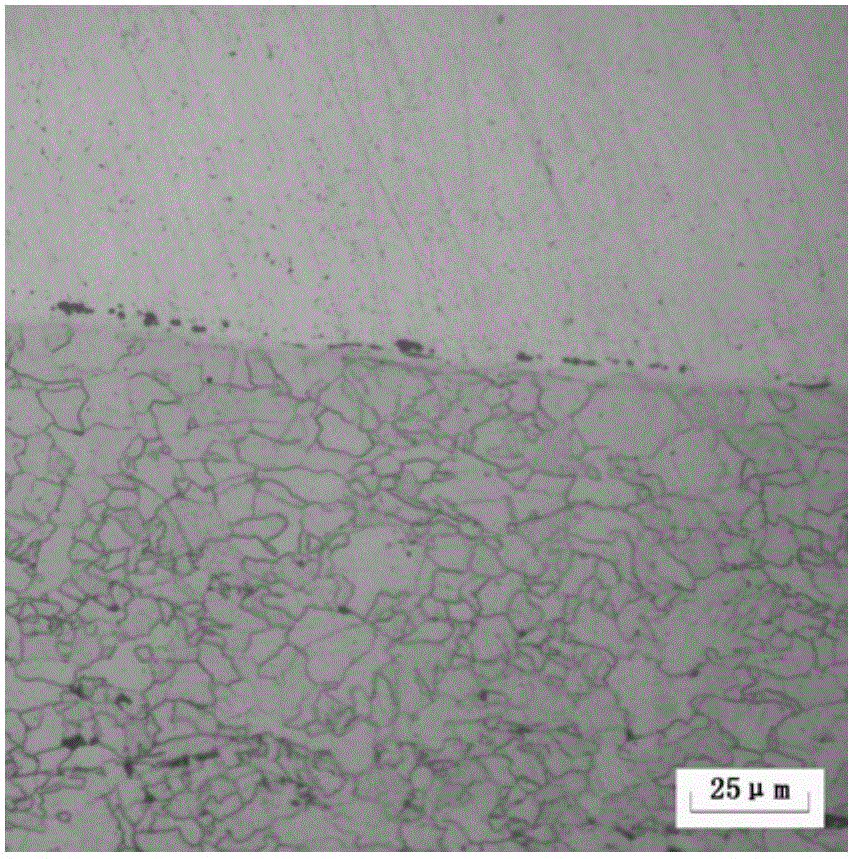

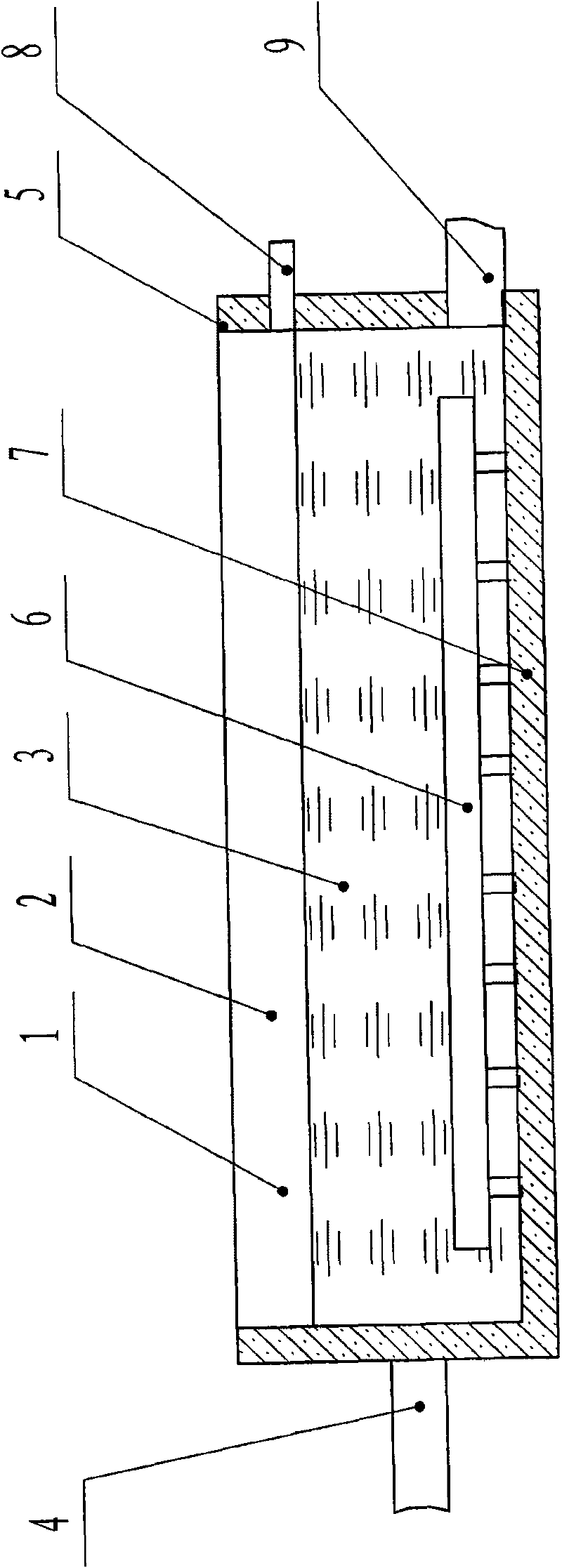

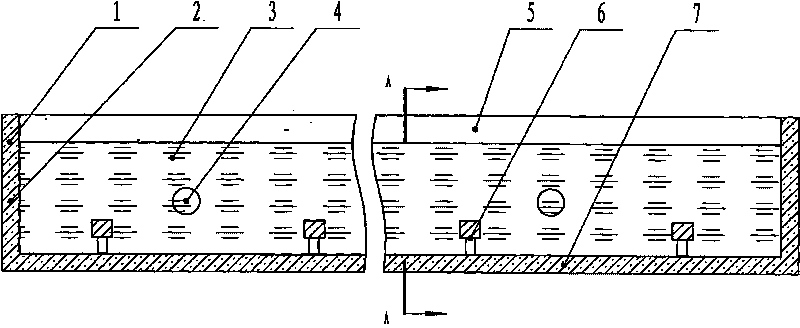

Nichrome and carbon steel composite board as well as production method thereof

The invention relates to a nichrome and carbon steel composite board as well as a production method thereof, which belong to the technical field of metal composite board production. According to the invention, the composite board is characterized in that the smelted X60MS and Incoloy 825 nichrome casting blanks enable respective cogging and rolling, the size of a designed intermediate blank can be rolled; then the polish-grinding treatment can be carried out on surface of billets, the billet are symmetrically composited, an upper layer and a lower layer are X60MS material carbon steels, the two intermediate layers are nichrome, nickel foils with different thickness can be selectively added between the carbon steel and nichrome or a soldering flux is not added, and a solder resist is added between the nichrome and the nichrome. then four edges welding for edge sealing can be carried out on the billets, and a mechanical pump is used for vacuum-pumping treatment. The composite board has the advantages that the shearing intensity of a compound interface is more than 500MPa, flaw detection can reach the requirement of grade one in standard binding rate in GB / T 8165< composite board and steel band>, which is 100% binding. When the tensile strength of nichrome reaches 760MPa, elongation percentage A50.8 can reach 30%, and tensile strength of X60MS can reach 600MPa, impact energy at -20 DEG C can reach 300-400J, and shearing area of DWTT at -10 DEG C is greater than 85%.

Owner:SHOUGANG CORPORATION

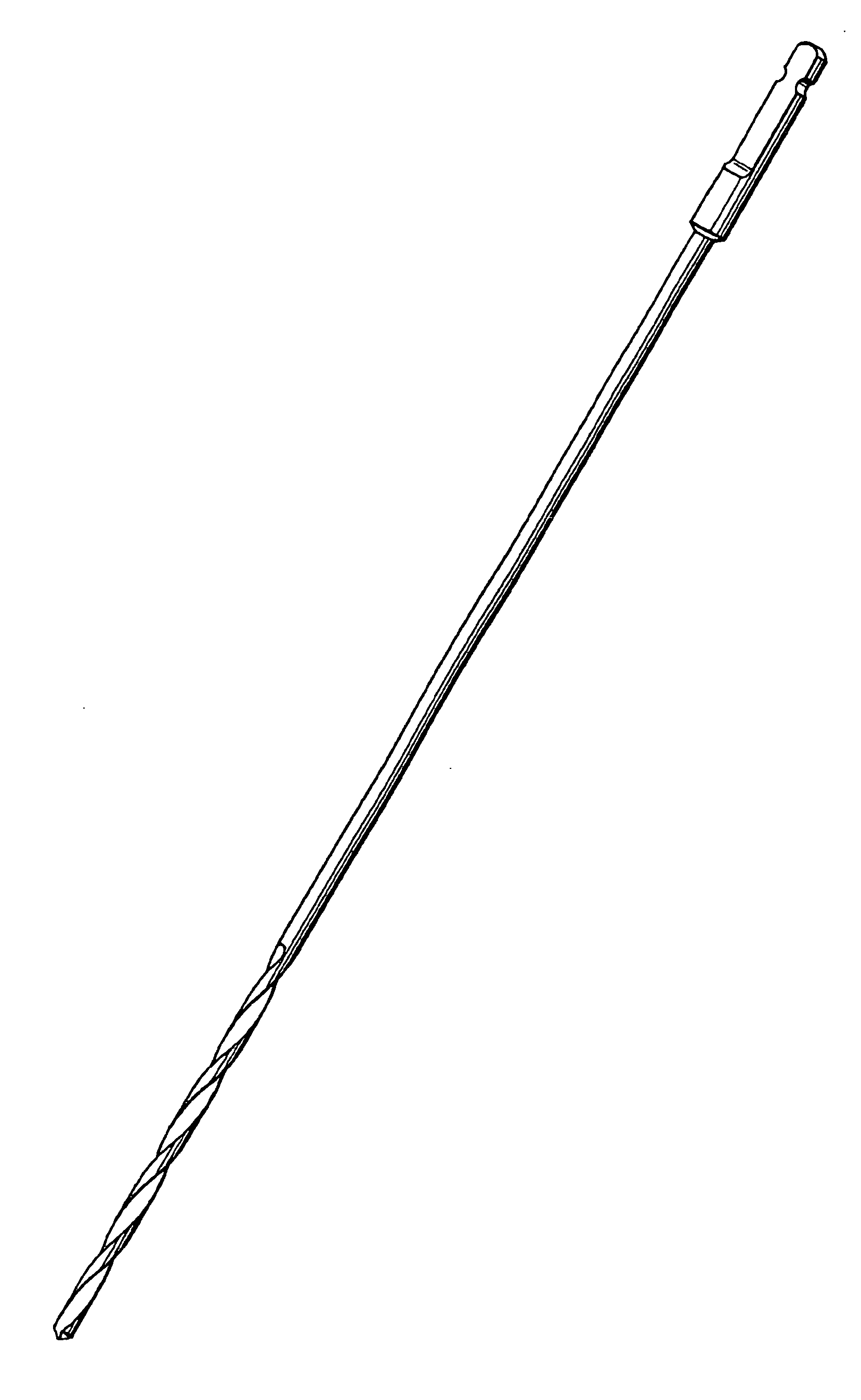

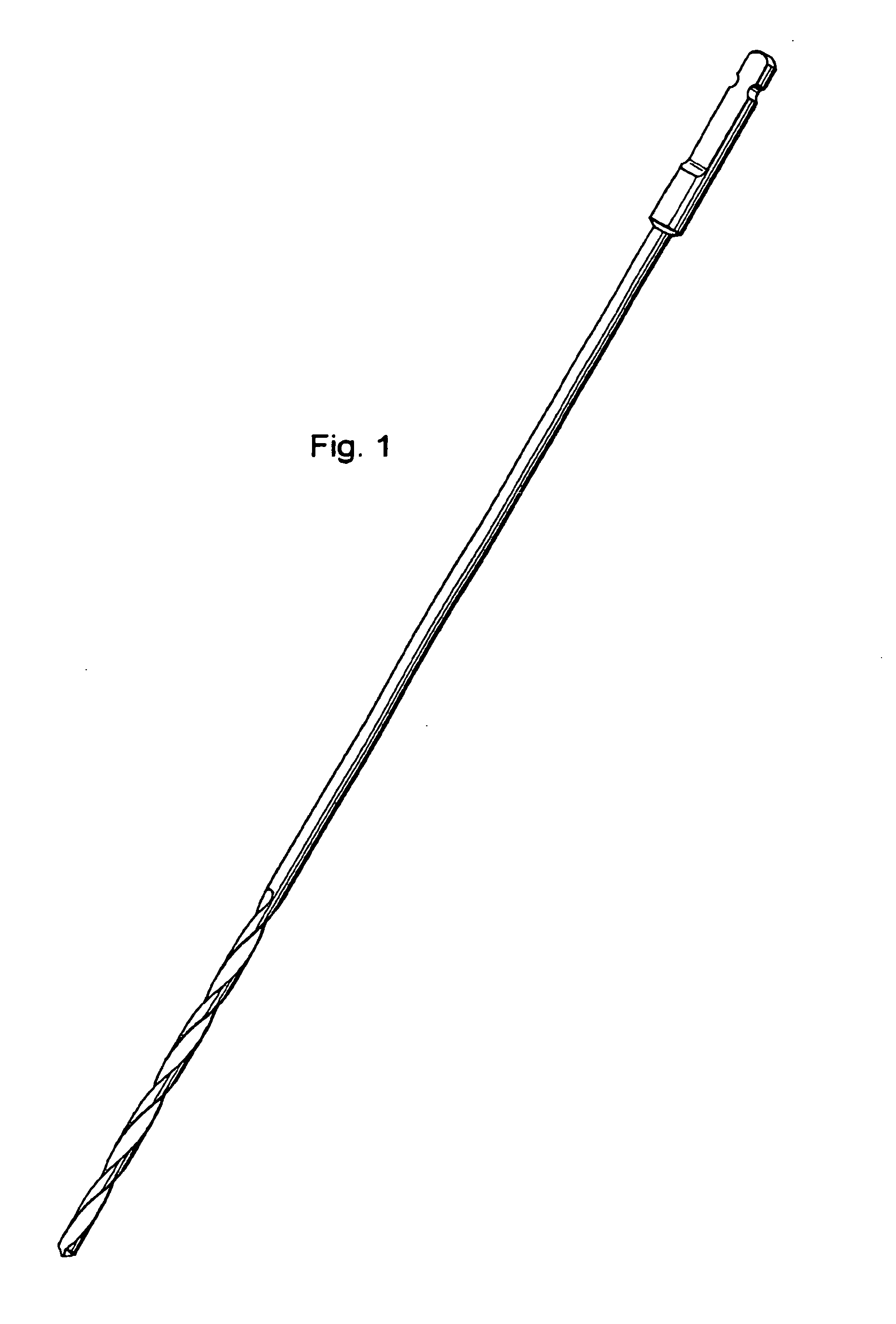

Use of a non-corrosive, martensitically hardening steel

InactiveUS20070000576A1Improve corrosion resistanceIncrease resistanceChromium nickelMartensitic stainless steel

The aim of the invention is to produce mechanically driven rotary tools, preferably boring, milling, grinding and cutting tools which are stable, non-corrosive and biocompatible and also have high mechanical strength properties, in conjunction with good ductility properties. To this end, the invention relates to the use of a precipitation-hardenable, martensitic, stainless chromium-nickel steel having the following composition (in weight %): 10 to 14 of chromium; 7 to 11 nickel; 0.5 to 6 of molybdenum; 0.5 to 4 of copper; 0.05 to 0.55 of aluminium; 0.4 to 1.4 of titanium; up to 0.3 of carbon and nitrogen; less than 0.05 of sulphur; less than 0.05 of phosphorus; up to 0.5 of manganese; up to 0.5 of silicon; respectively up to 0.2 of tantalum, niobium, vanadium and wolfram; and optionally up to 9 of cobalt; optionally 0.0001 to 0.1 of boron; the reminder consisting of iron and common impurities.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

High temperature Ni-Cr alloy and its production process

InactiveCN1974816AImprove high temperature resistanceImprove oxidation resistanceHeat resistanceChromium nickel

The present invention provides one kind of Ni-Cr alloy with high smelting point, capacity of bearing temperature of 1300 deg.c, high tensile strength and high yield strength and its production process. The Ni-Cr alloy contains C 0-0.1 wt%, Si 0-0.5 wt%, Mn 0-1.0 wt%, S 0-0.015 wt%, Cr 21-25 wt%, Ni 58-63 wt%, Al 1.0-1.7 wt%, Cu 0-1.0 wt%, and Fe for the rest. The production process includes the following steps: smelting, secondary refining, heating at 900-1200 deg.c for 10-40 min before forging, cold working and water cooling. The Ni-Cr alloy has raised heat resistance, high tensile strength, high yield strength and other advantages.

Owner:杭正奎

High-precision nickel-chromium/copper-nickel thermocouple alloy wires

InactiveCN102735361AReduce temperature measurement deviationImprove stabilityThermometers using electric/magnetic elementsUsing electrical meansMisch metalChromium nickel

The invention discloses high-precision nickel-chromium / copper-nickel thermocouple alloy wires and a production process thereof. A nickel-chromium thermocouple alloy wire comprises the components of chromium, cobalt, silicon, calcium, yttrium, carbon, sulfur, iron, nickel and a misch metal; a copper-nickel thermocouple alloy wire comprises the components of nickel, manganese, magnesium, calcium, carbon, sulfur and copper; and the process comprises the following steps of: (a), preparing raw materials; (b), performing vacuum melting; (c), performing hot rolling; (d), performing wire drawing and annealing; and (e), testing finished products, packaging the finished products to leave factory. The nickel-chromium / copper-nickel thermocouple alloy wires, which are produced according to a unique product formula and by the unique production process, can reach a high-precision I-grade level.

Owner:JIANGSU HUAXIN ALLOY

Method for preventing surface oxide film of nichrome roller from being peeling-off

InactiveCN101003053AReduce deformation rateReduce loadTemperature control deviceRolling equipment maintainenceChromium nickelSurface roughness

A method for preventing the surficial oxide film of Ni-Cr roller from being stripped includes such steps as blooming the conticast billet of ferritic stainless steel at 1150 + / - 50 deg.C to become intermediate billet at 1020-1050 deg.C and with a thickness less than 35 mm, arranging an insulating hood between blooming and finish rolling, and finishing rolling of stainless steel band at a temp higher than 950 deg.C by three passes with relative surface roughness of rollers (0.9 microns, 0.6 microns and 0.6 microns) and relative maximal deformation rate (42%, 38% and 36%).

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method of processing chromium-nickel austenite stainless steel continuous casting slab

The invention relates to a method of processing chromium-nickel austenite stainless steel continuous casting billet, comprising the following steps in sequence: (1) placing cut chromium-nickel austenite stainless steel continuous casting slab into a circulating water tank and removing the slag crusts adhered to the surface of the chromium-nickel austenite stainless steel continuous casting slab; (2) lifting the chromium-nickel austenite stainless steel continuous casting slab out of the circulating water tank and cooling the same; and (3) visually detecting the chromium-nickel austenite stainless steel continuous casting slab to decide whether the chromium-nickel austenite stainless steel continuous casting slab needs to be polished. If having smaller and less oscillation marks on the surface, the chromium-nickel austenite stainless steel continuous casting slab does not need to be polished; if having obvious oscillation marks on the surface, the defected chromium-nickel austenite stainless steel continuous casting slab needs to be artificially polished; and if having deep oscillation marks, scabs on the surface or the like on the surface, the defected chromium-nickel austenite stainless steel continuous casting slab needs to be integrally polished with a polishing machine until the oscillation marks, the scabs or the like on the surface can not be seen visually. The method of processing chromium-nickel austenite stainless steel continuous casting billet uses water to remove all the protective slag crusts adhered to the surface of the chromium-nickel austenite stainless steel continuous casting slab, thus the visual detection of chromium-nickel austenite stainless steel continuous casting slab can be detected, the polishing workload can be greatly reduced, the yield can be increased and the processing efficiency can be improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

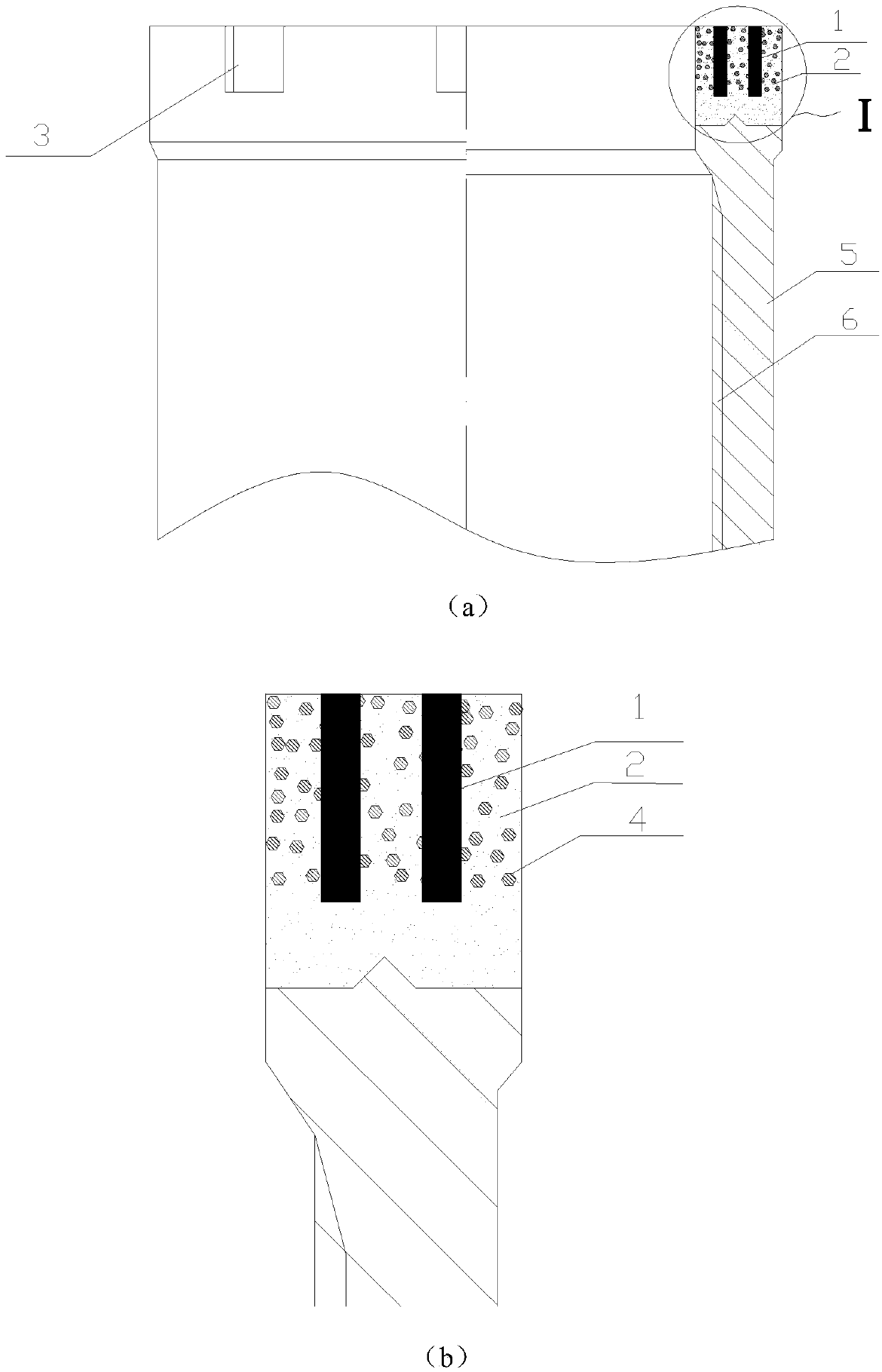

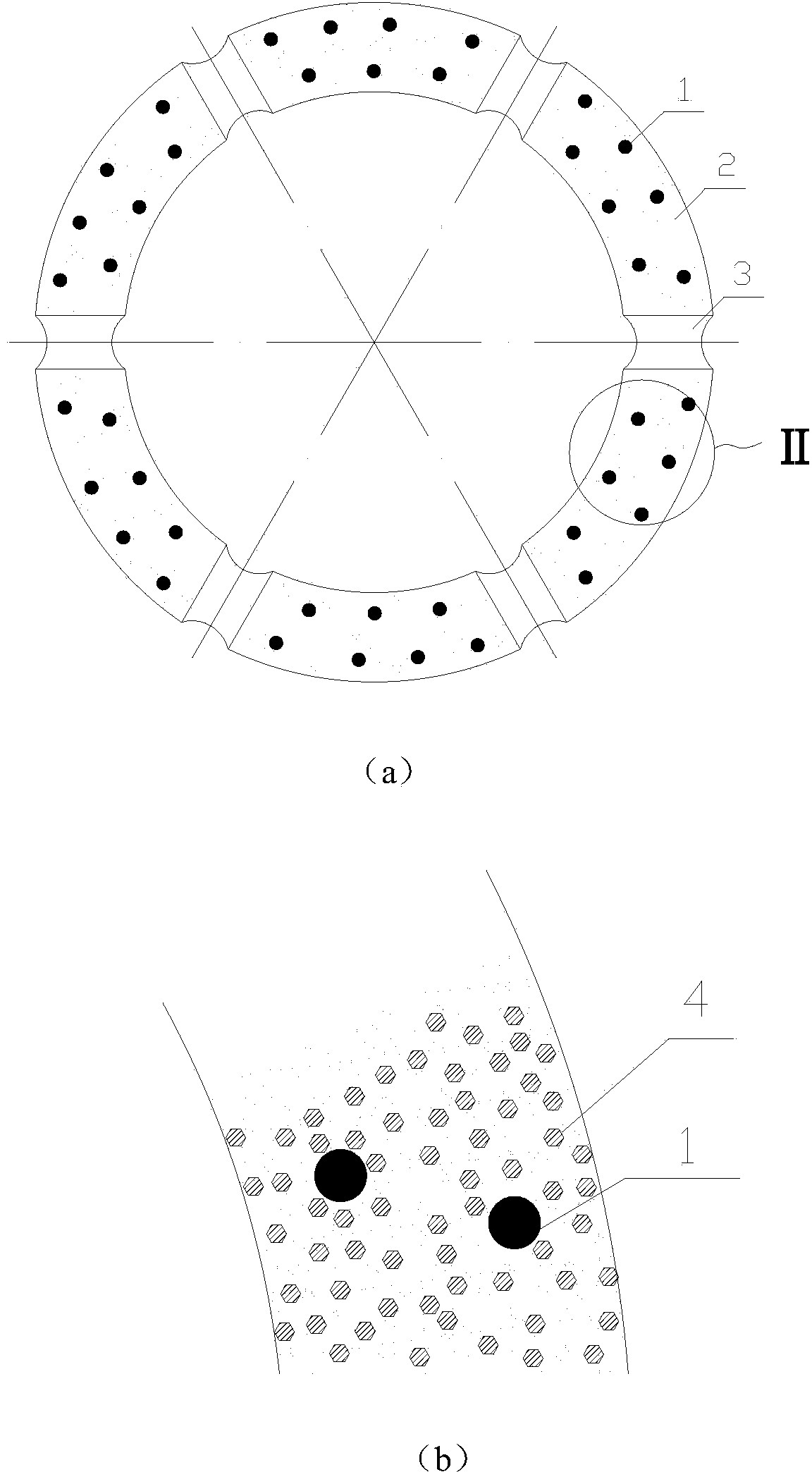

Braze welding nickel base impregnated diamond bit for deep part solid rock drilling, and manufacturing method of braze welding nickel base impregnated diamond bit

The invention discloses a braze welding nickel base impregnated diamond bit for deep part solid rock drilling, and a manufacturing method of the braze welding nickel base impregnated diamond bit. A braze welding nickel base body mixture of the braze welding nickel base impregnated diamond bit is formed by sintering a nickel base casing, a thin metal wire and diamond, the diamond is impregnated into the sintering nickel base casing, the content of diamond accounts for 30 to 80 percent by volume, and the granularity is 35 / 60 mesh; the sintering nickel base casing comprises the following components in mass percent: 35 to 75 percent of nicochrome powder and 25 to 35 percent of iron powder; the diameter of the thin metal wire is 1.0 to 1.6 mm; a nickel base prealloyed brazing filler metal is used, the performance of a drill bit is improved greatly, the sintering temperature is lowered, and the diamond damage degree is lowered; the content of the iron powder is higher, and the cost of the drill bit is lowered; the thin metal wire is embedded, so that the abrasive resistance of the casing is lowered and diamond exposure and drilling hole deviation preventing are facilitated. The braze welding nickel base impregnated diamond bit provided by the invention is particularly suitable for deep part solid rock drilling, and is also suitable for shallow slippery formation drilling.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

Method for preparing chromel alloy by stainless steel pickling sludge

ActiveCN103526029AHigh recovery rateIncrease contentProcess efficiency improvementChromium nickelSludge

The invention provides a method for preparing chromel alloy by stainless steel pickling sludge. The method comprises the steps as follows: an alkali liquor is added into the stainless steel pickling sludge, pH is adjusted to be in a range from 6.5 to 7.5, and neutral sludge is obtained; the neutral sludge is added into a rotary kiln for drying to obtain a dry basis; the dry basis is added into a ball forming machine, and coke and starch are simultaneously added for ball forming to obtain mixed particles; the mixed particles are added into the rotary kiln for reduction smelting, the smelting temperature is simultaneously controlled in a range from 1,250 DEG C to 1,400 DEG C, and an additive is simultaneously added for an early reduction reaction for 1-2 hours to obtain metallic balls; and a hot bag containing the metallic balls is placed into an electric plasma furnace for melting and smelting to obtain the chromel alloy. With the adoption of the method, waste is changed into valuable materials, the stainless steel pickling sludge which can pollute the environment is neutralized, nickel-chromium elements are reduced to obtain the chromel alloy for metal smelting; and the chromel alloy with high recovery rate and high content is obtained through addition of an NCP additive and sodium sulfate.

Owner:TAIZHOU YONGXING ALLOY MATERIAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com