High-resistant chromium-nickel electric heating alloy and preparation process thereof

An electrothermal alloy and preparation process technology, applied in the field of nickel-chromium alloys, can solve the problems of lower lasting strength and service life than nickel-chromium electrothermal alloys, lower resistivity than iron-chromium-aluminum electrothermal alloys, unweldability, etc., and achieve excellent resistance to corrosion. Oxidation properties, increased lasting strength and service life, increased plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

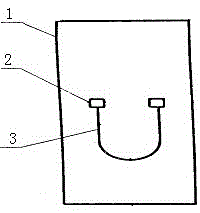

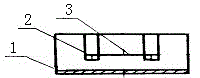

Image

Examples

preparation example Construction

[0040] The preparation process of the above-mentioned high-resistance electric heating alloy, its specific steps are as follows:

[0041] A. Firstly design ingredients according to the above;

[0042] B. Vacuum induction furnace smelting;

[0043] C. Forging;

[0044] D. Hot rolling;

[0045] E. The wire rod is annealed and pickled;

[0046] F, multi-pass: drawing-annealing-drawing;

[0047] G. Drawing is carried out by bicycle.

[0048] In the present invention, the refining temperature of step B is 1460-1500°C; refining time: more than 30 minutes, and the tapping temperature is 1500-1520°C. After the B step is completed, before the C step starts, the grinding process is carried out.

[0049] After the forging in step C is completed, ultrasonic testing is carried out before the hot rolling in step D starts. In step C, the forging start temperature is 1110°C-1130°C, and the final forging temperature is ≥960°C.

[0050] For step D, the hot rolling temperature is 1130°C-...

Embodiment

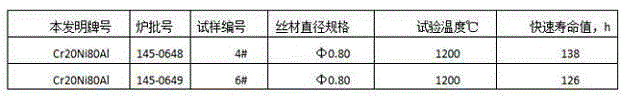

[0062] By adopting the three-level orthogonal table L 9 (3 4 )design experiment:

[0063] (1) Effect of Al, Si, Cr content on material resistivity

[0064] According to the existing experience and the description in the electrothermal alloy manual, the content of Al, Si, and Cr can directly affect the resistivity of the material. According to the upper and lower line principles of element design, three groups of variables of these three factors are used for implementation research. The detailed process is described in Table 1.

[0065]

[0066] Table 1 Effect of Al, Si, Cr content on resistivity

[0067] The preparation process of the above nine groups of embodiments is as follows: select pure metal materials with Ni, Cr, Mn, Fe, Si, Al, Ti, Zr content greater than 99% as raw materials for production, and control the rest of the elements in proportion.

[0068] (2) Material preparation

[0069] According to the five groups of embodiments of the present invention, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com