A kind of aluminum alloy material and preparation method thereof

A technology for aluminum alloy materials and raw materials, applied in the field of aluminum alloy materials and their preparation, can solve the problems of low tensile strength and yield strength, and reduced surface gloss, and achieve the advantages of weakening mechanical properties, reducing linear shrinkage, and shortening life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] An aluminum alloy material, which is formed by mixing waste aluminum and component A at a weight ratio of 8:1-3;

[0035] In the aluminum waste, the iron content accounts for 0.3wt% of the total aluminum waste, the zinc content accounts for 0.2wt% of the total aluminum waste, the copper content accounts for 0.2wt% of the total aluminum waste, and the aluminum content accounts for 0.2% of the total aluminum waste. 87.0wt%;

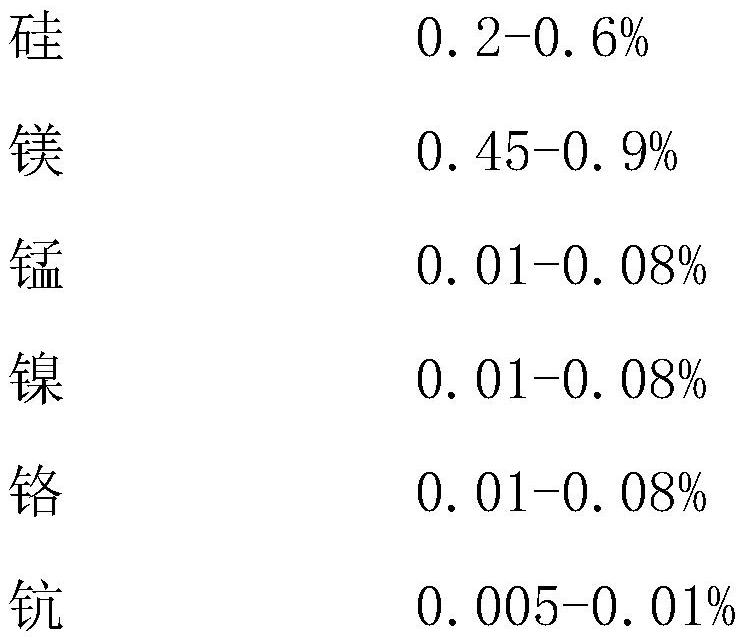

[0036] Described component A comprises the raw material of following percentage by weight:

[0037]

[0038] The preparation method of the above-mentioned aluminum alloy material comprises the following steps:

[0039] (S1), take each raw material in proportion, and set aside;

[0040] (S2), using acetone to clean the waste aluminum, then using hydrochloric acid with a concentration of 15wt% to clean the waste aluminum, then rinsing with water for 45 seconds, and drying to obtain pretreated waste aluminum;

[0041] (S3), after mixing the raw ma...

Embodiment 2

[0049] An aluminum alloy material, which is formed by mixing waste aluminum and component A at a weight ratio of 8:1;

[0050] In the aluminum waste, iron content accounts for 1.0wt% of the total amount of aluminum waste, zinc content accounts for 0.3wt% of the total amount of aluminum waste, copper content accounts for 0.3wt% of the total amount of aluminum waste, and aluminum content accounts for 20% of the total amount of aluminum waste. 80.0wt%;

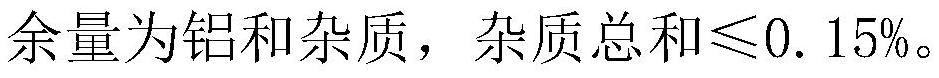

[0051] Described component A comprises the raw material of following percentage by weight:

[0052]

[0053]

[0054] The preparation method of the above-mentioned aluminum alloy material comprises the following steps:

[0055] (S1), take each raw material in proportion, and set aside;

[0056] (S2), using acetone to clean the waste aluminum, then using hydrochloric acid with a concentration of 10wt% to clean the waste aluminum, then rinsing with water for 30 seconds, and drying to obtain pretreated waste aluminum;

[00...

Embodiment 3

[0065] An aluminum alloy material, which is formed by mixing scrap aluminum and component A at a weight ratio of 8:3;

[0066] In the aluminum waste, the iron content accounts for 0.08wt% of the total aluminum waste, the zinc content accounts for 0.1wt% of the total aluminum waste, the copper content accounts for 0.1wt% of the total aluminum waste, and the aluminum content accounts for 0.1% of the total aluminum waste. 90.0wt%;

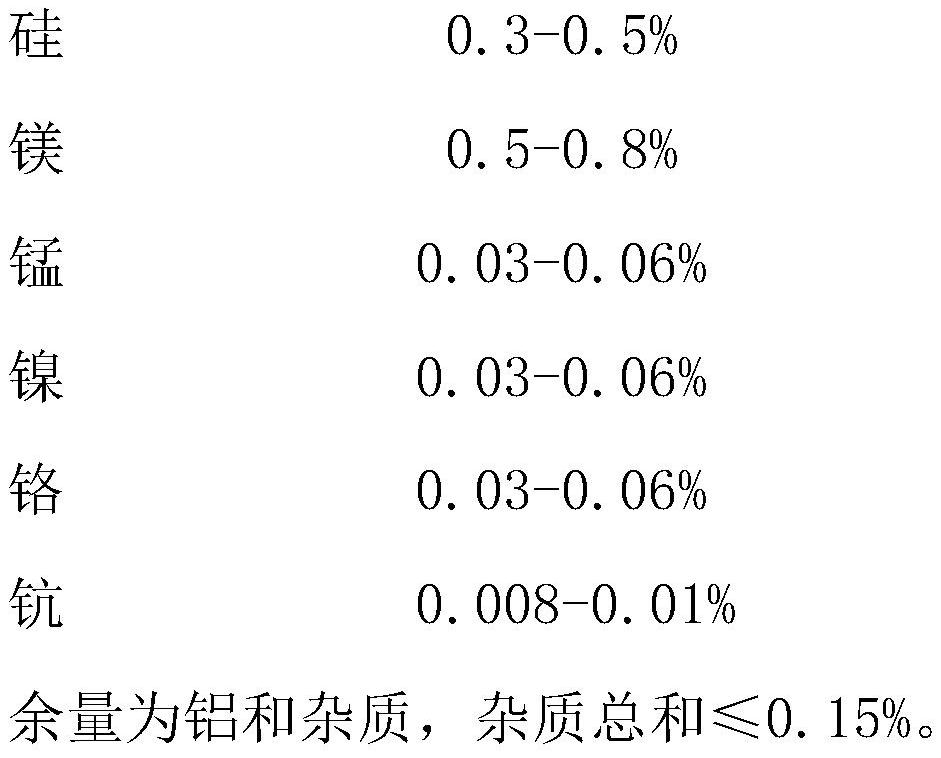

[0067] Described component A comprises the raw material of following percentage by weight:

[0068]

[0069]

[0070] The preparation method of the above-mentioned aluminum alloy material comprises the following steps:

[0071] (S1), take each raw material in proportion, and set aside;

[0072] (S2), using acetone to clean the waste aluminum, then using hydrochloric acid with a concentration of 20wt% to clean the waste aluminum, then rinsing with water for 60 seconds, and drying to obtain pretreated waste aluminum;

[0073] (S3), after mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com