Passive degassing device as well as tank body and slurry treating element thereof

A technology of degassing device and processing body, which is applied in the direction of liquid degassing, wellbore/well components, earthwork drilling and production, etc. It can solve the problem of unsuitable degasser driven by no power supply, affecting degassing efficiency, and not suitable for gas collection And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0111] Below in conjunction with preferred embodiments, the specific implementation, features and effects provided by the present invention are described in detail as follows; for the purpose of simplicity and clarity, the description of known technologies is appropriately omitted below to avoid unnecessary details Affect the description of this technical solution.

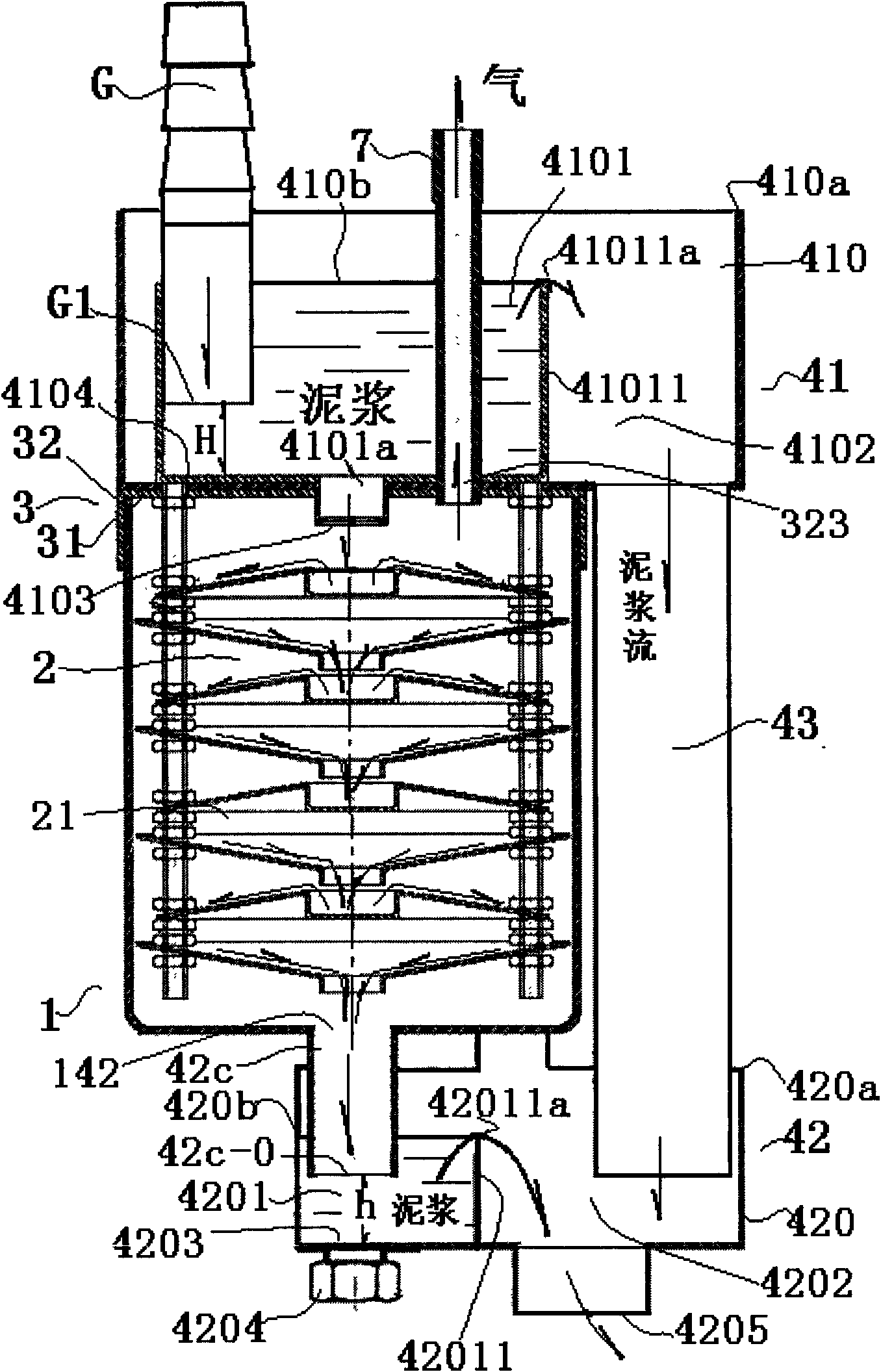

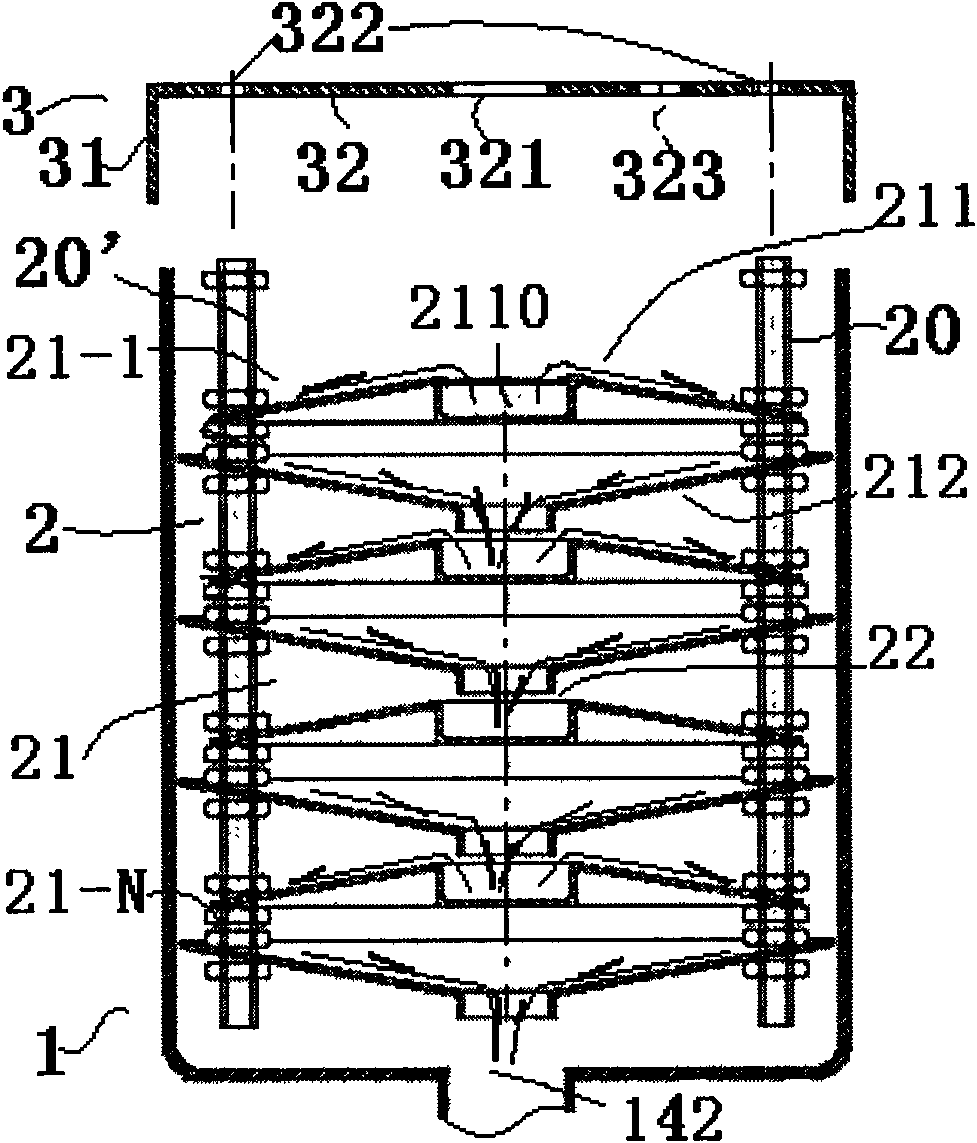

[0112] see Figure 1-4 As shown, a passive degassing device includes a tank body 1, the tank body has a mud inlet and a mud outlet 142, the upper part of the tank body is the mud inlet end, and the lower part of the tank body is the mud outlet end, wherein,

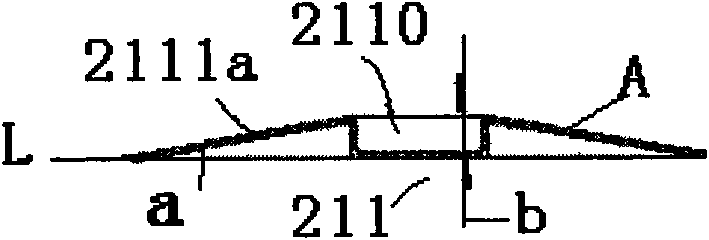

[0113] see figure 1 A mud treatment body 2 is installed in the tank body 1, and the mud treatment body is used to diffuse the mud as much as possible, so that the gas is separated from the mud;

[0114] The upper part of the tank body is provided with an assembly end cap 3, which is composed of an end cap airtight seam 31 and an assembly end face 32. On th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com