Patents

Literature

151results about How to "Improve degassing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

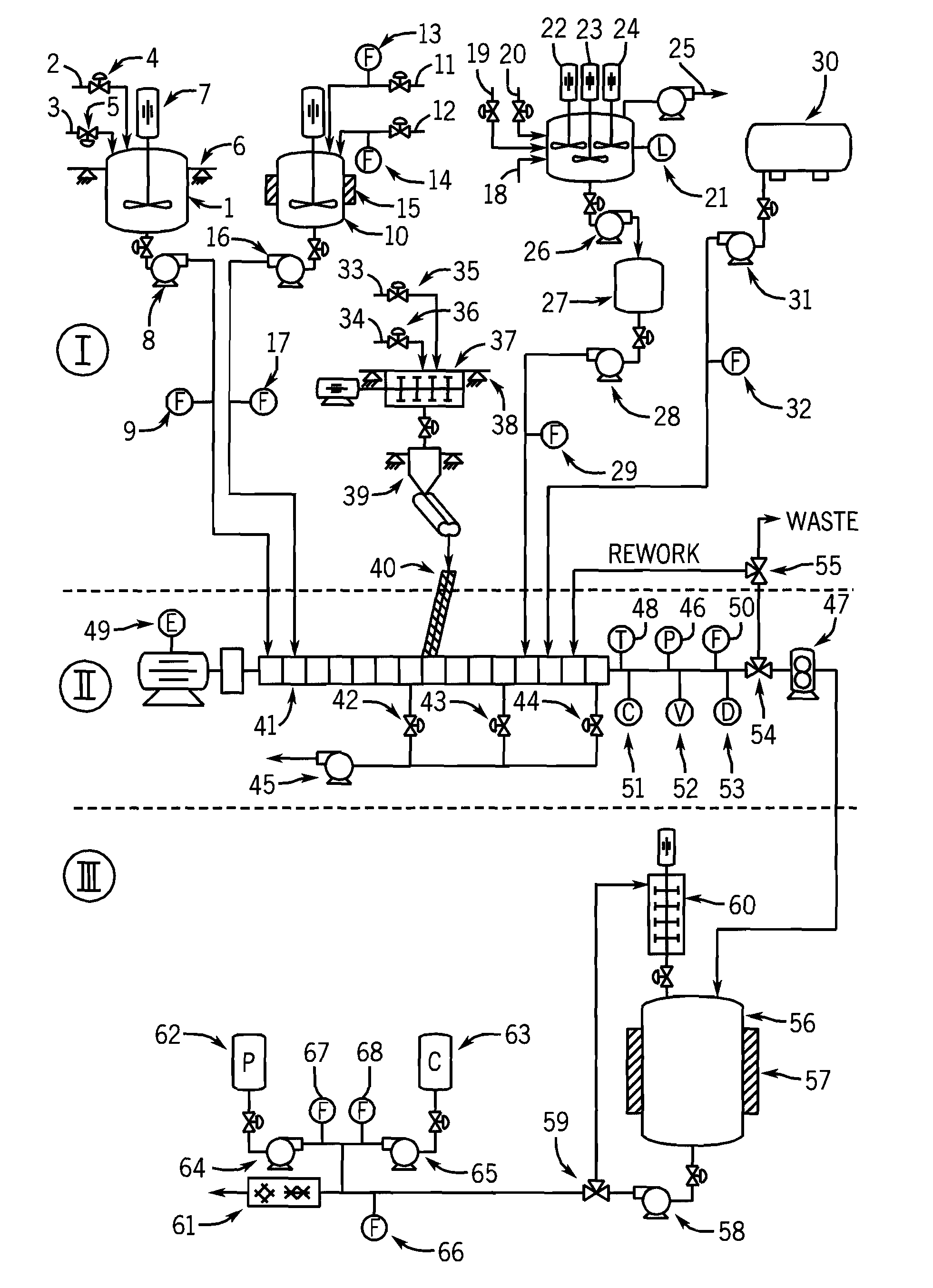

Continuous Process for the Production of Moisture-Cure, Polyurethane Sealants and Adhesives

ActiveUS20090198036A1High surface area-to-volume ratioMinimization requirementsArtifical filament manufactureChemical reactionAdhesive

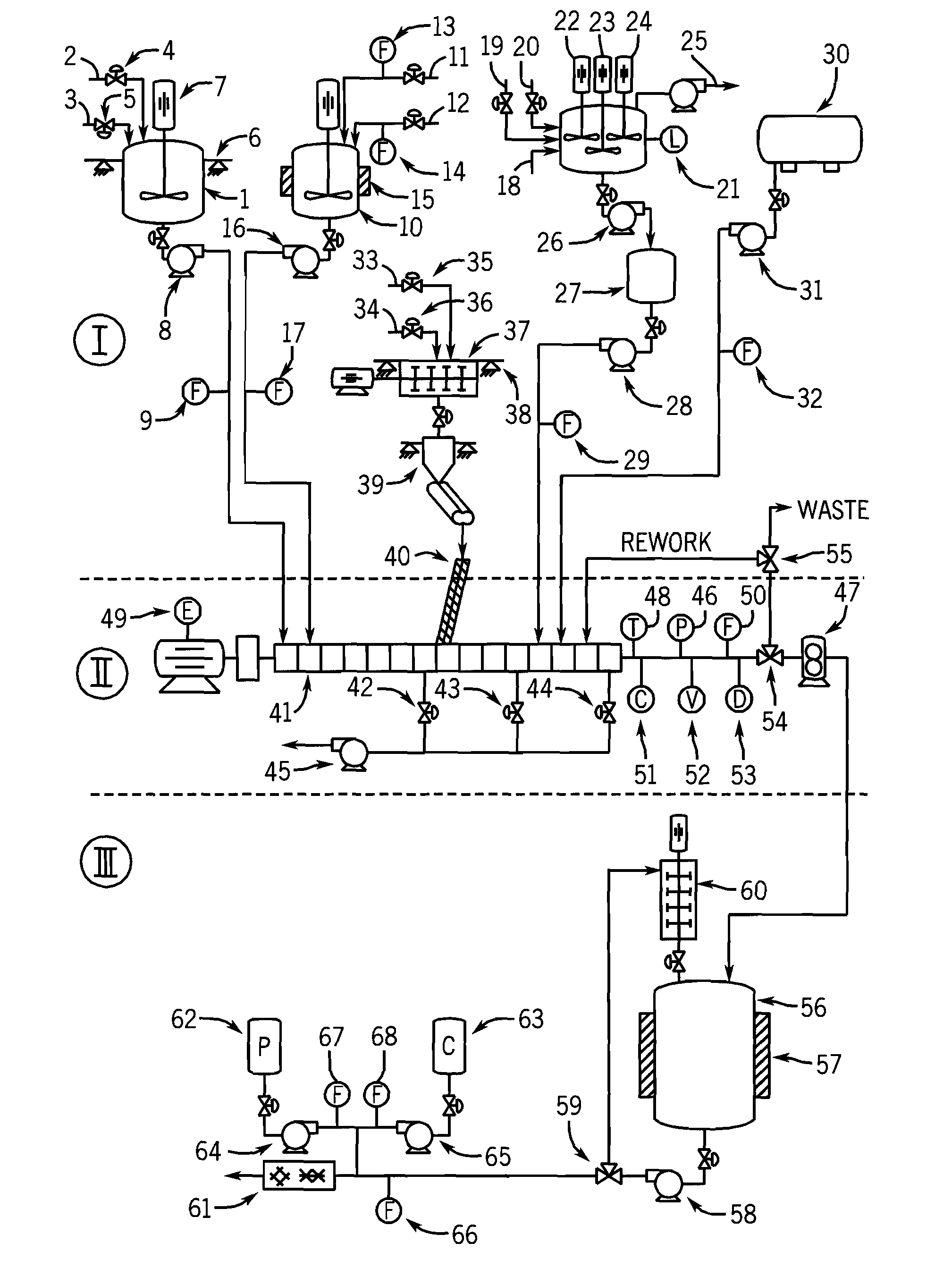

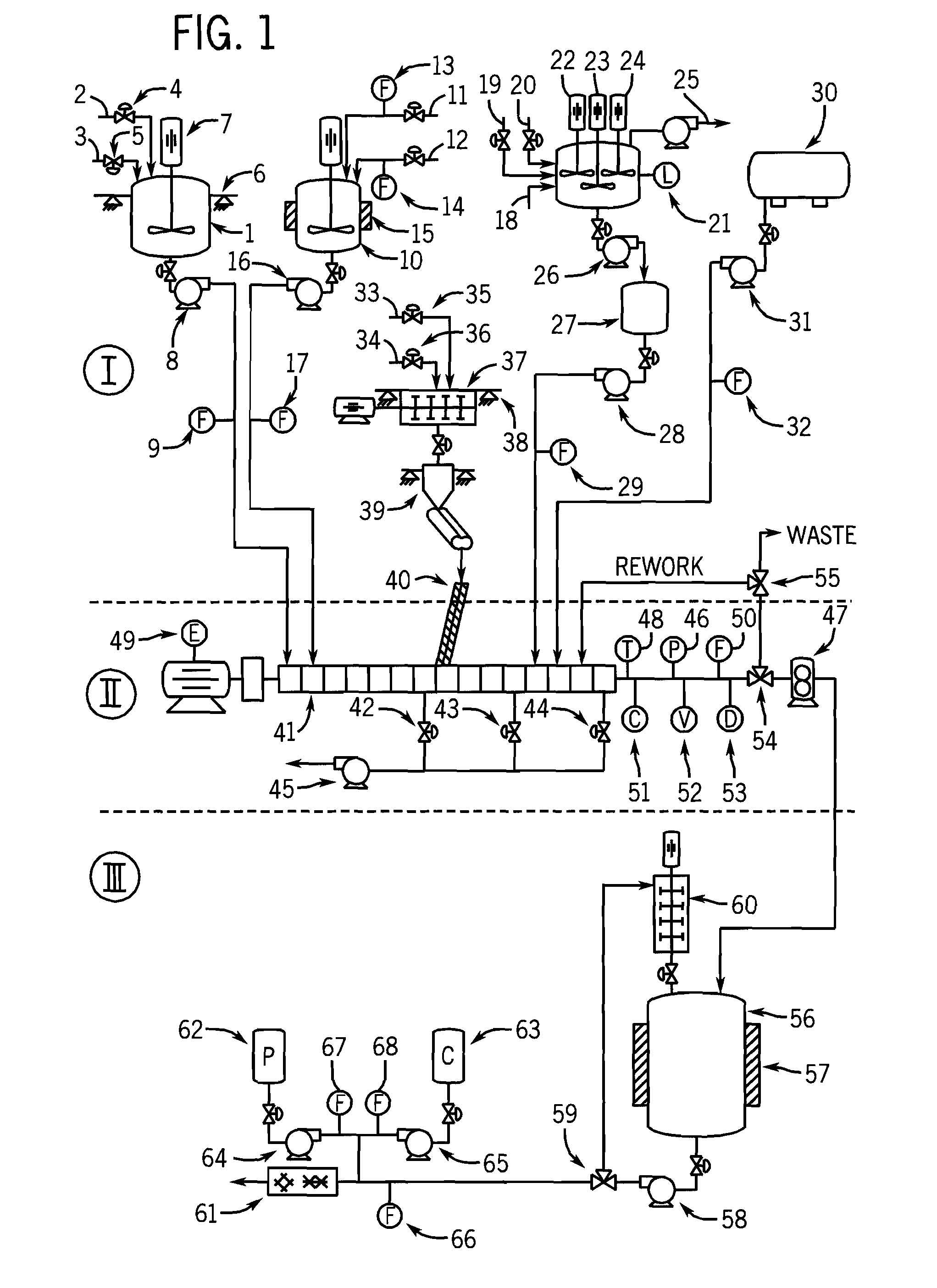

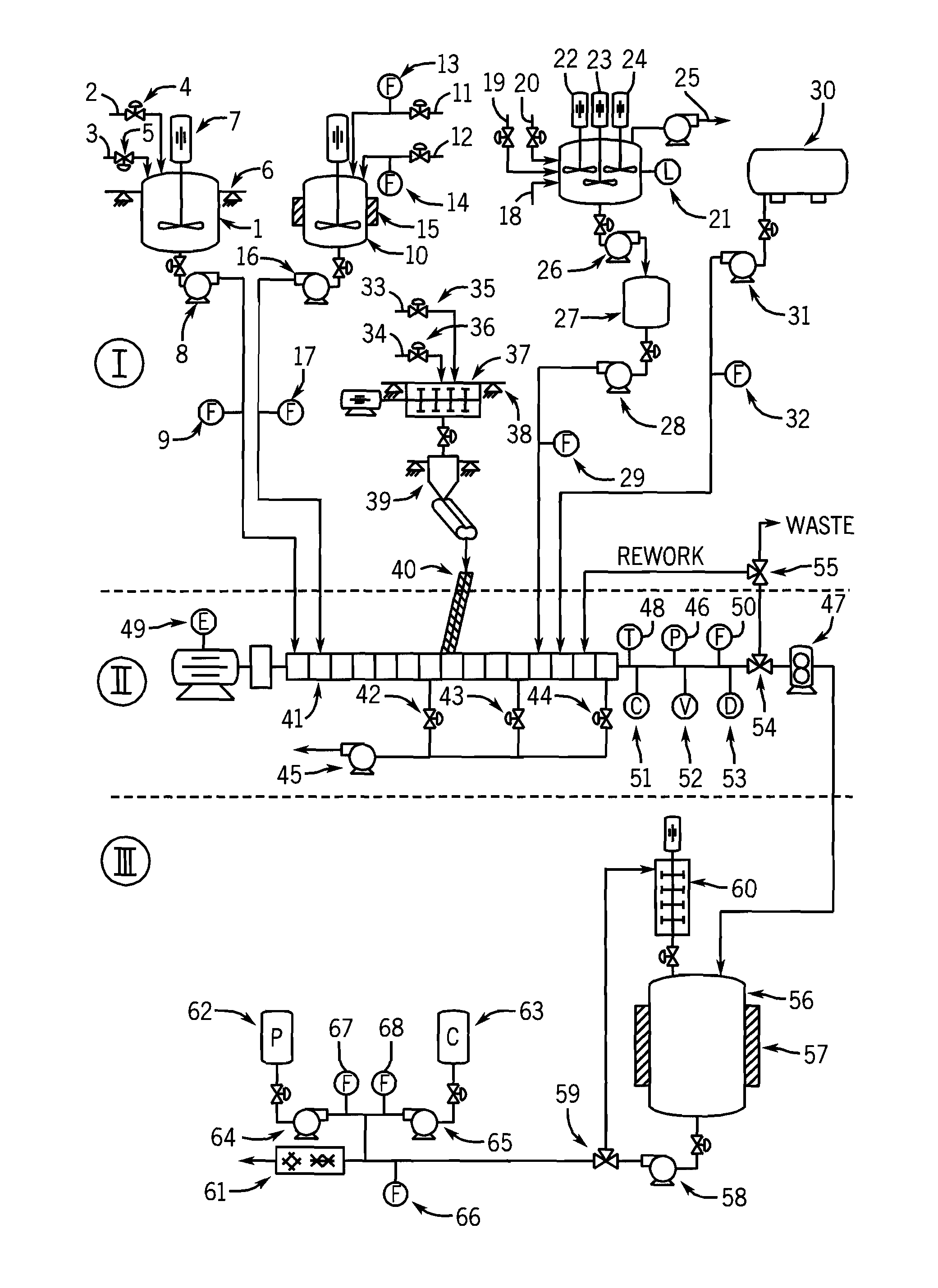

A process for continuous manufacturing of moisture-curable polyurethane formulations used as sealants and adhesives. The process is characterized by the fact that the reactive components are introduced independently, and without the need for a prepolymer, to a mixer. Solid or liquid raw materials can be either pre-blended or fed directly to the mixer, a twin-screw extruder, which provides the requisite energy to homogenously mix the raw materials and drive the chemical reaction. The process is designed so that the extruder barrel and screw allow variable feed addition and heat exchange down the length of the machine. This allows various operations to be performed at different points in the extruder, including reaction, dispersive mixing, distributive mixing and devolitization.

Owner:BOSTIK INC

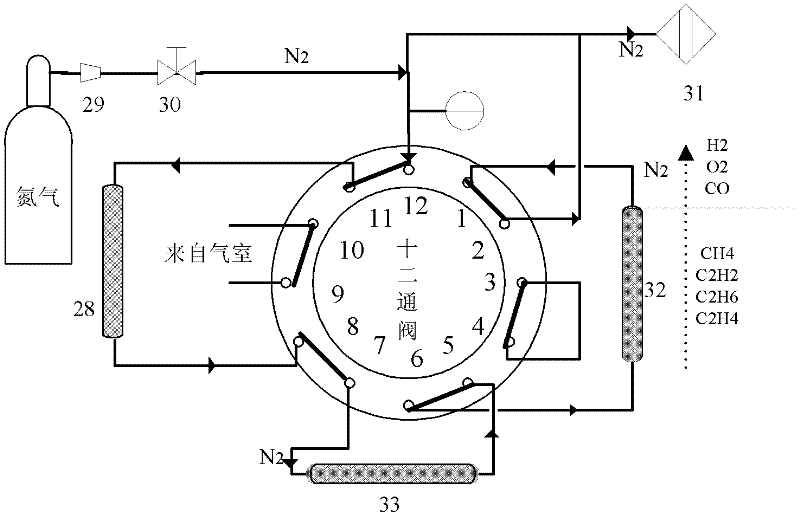

On-line detection system and method of trace dissolved gas in organic oil

InactiveCN102353724ASeparation EquilibriumEasy and quick passProgramme controlComponent separationRefluxFuel cells

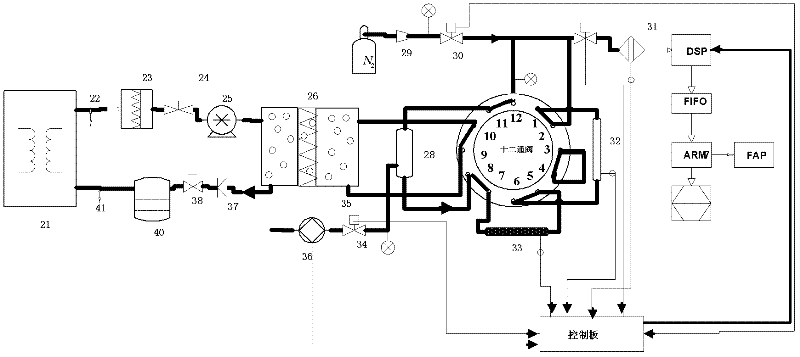

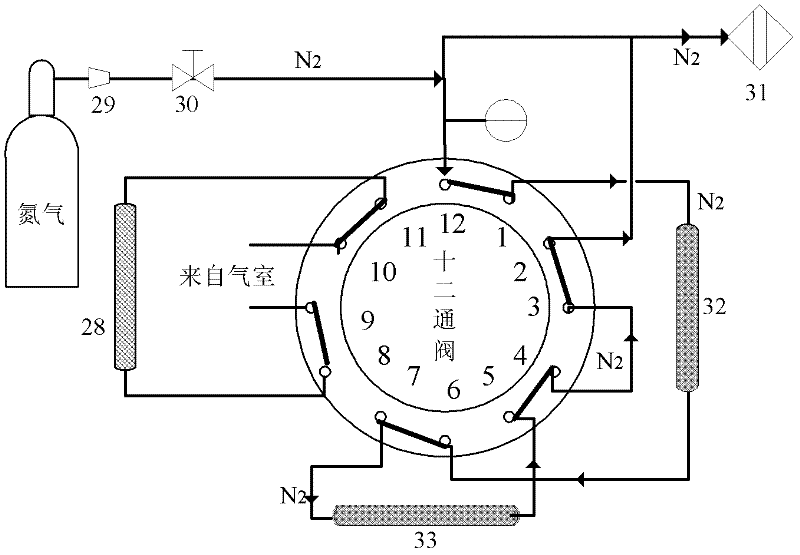

The invention discloses an on-line detection system and method of trace dissolved gas in organic oil, characterized in that: a polymer degassing film with short oil-gas balance time is used, thus the structure is simple, and degasification speed is fast; the trace dissolved gas in organic oil is separated through the dual column chromatography, thus the number of channels of traditional chromatograph is simplified; the unique twelve-way valve structure is used, and double chromatographic columns are arranged, thus the system works respectively alternately in states of reflux and sample injection, and the problem of difficult separation of O2 and CO gas existing in the traditional chromatographic system is effectively solved; a trace flammable gas detection sensor produced by using a solidoxide fuel cell technique can simultaneously detect 7 kinds of dissolved gases in organic oil with high detection accuracy and good separating degree of different component gases, and the number of gas sensor in the system is reduced. According to the invention, an oil-gas separation, a gas separation detection unit and a control unit are combined together, thus the volume of the system device isreduced, the stability of the system is increased, and the system is convenient for installation and maintenance.

Owner:CENT SOUTH UNIV

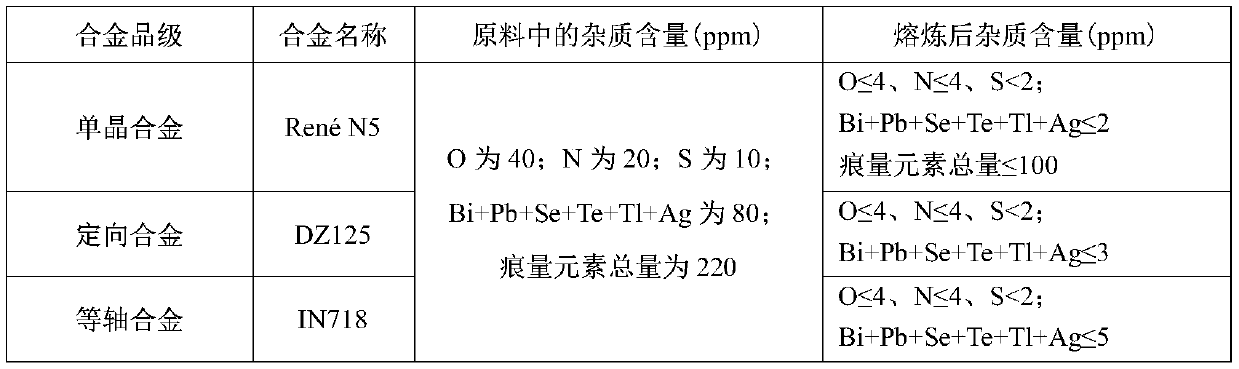

Pure purification smelting method used for nickel-based high-temperature alloy master alloy

The invention relates to a pure purification smelting method of an alloy, in particular to a pure purification smelting method for a nickel-based high-temperature alloy master alloy, and belongs to the technical field of metal smelting. According to the method, pure purification smelting of a master alloy is completed through material distributing and alloy melting, primary refining, alloying andsecondary refining, microalloying controlling and casting. The method has the advantages that the purity of vacuum melting can be effectively improved, the element segregation can be improved, and a nickel-based high-temperature alloy prepared by the method has the advantages that the purity is high, the segregation is low, the quality is remarkably higher than that of an alloy prepared through the existing technology and method, the quality of the nickel-based high-temperature alloy is improved, and the application field is expanded; nickel-based high-temperature alloys with different gradesand marks smelted by adopting the method has good effects; vacuum induction furnaces with the furnace types of 250 kg-grade and 1.5 ton-grade are adopted; and compared with an alloy before smelting and prepared through other technologies and methods, the alloy is remarkably improved in purity and uniformity.

Owner:METALINK SPECIAL ALLOYS CORP

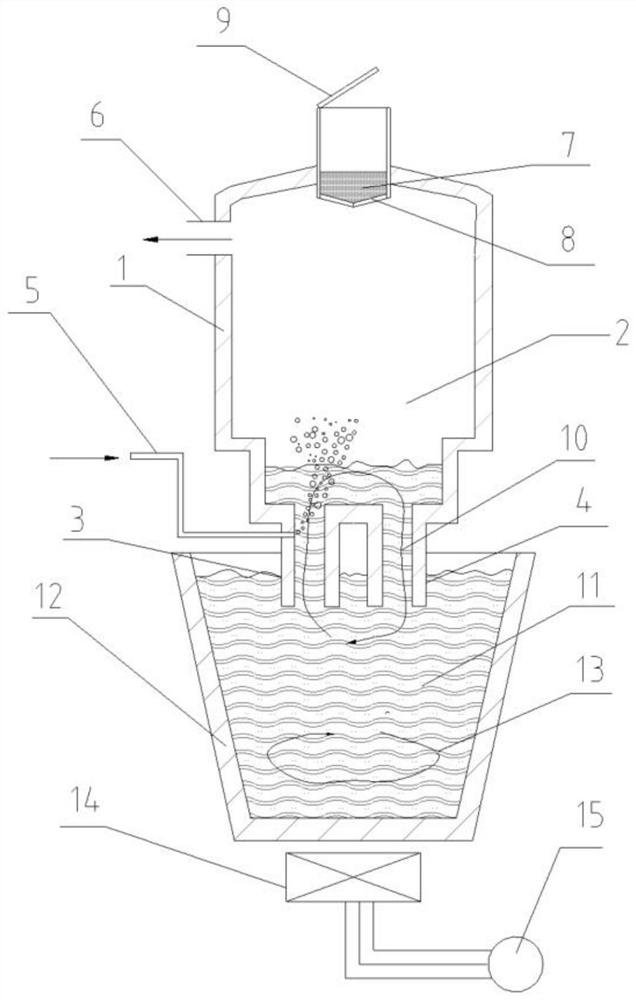

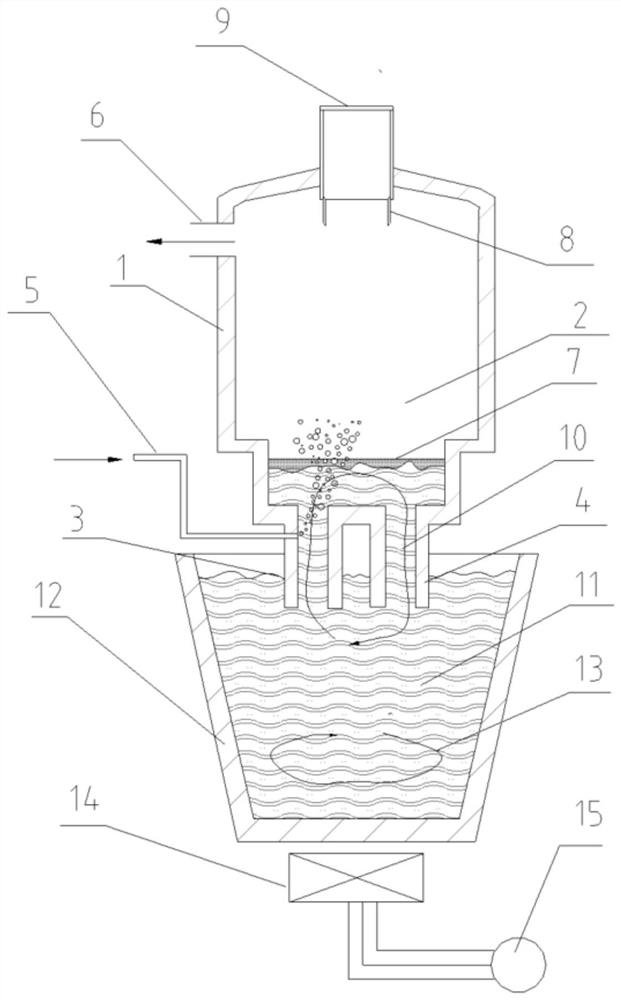

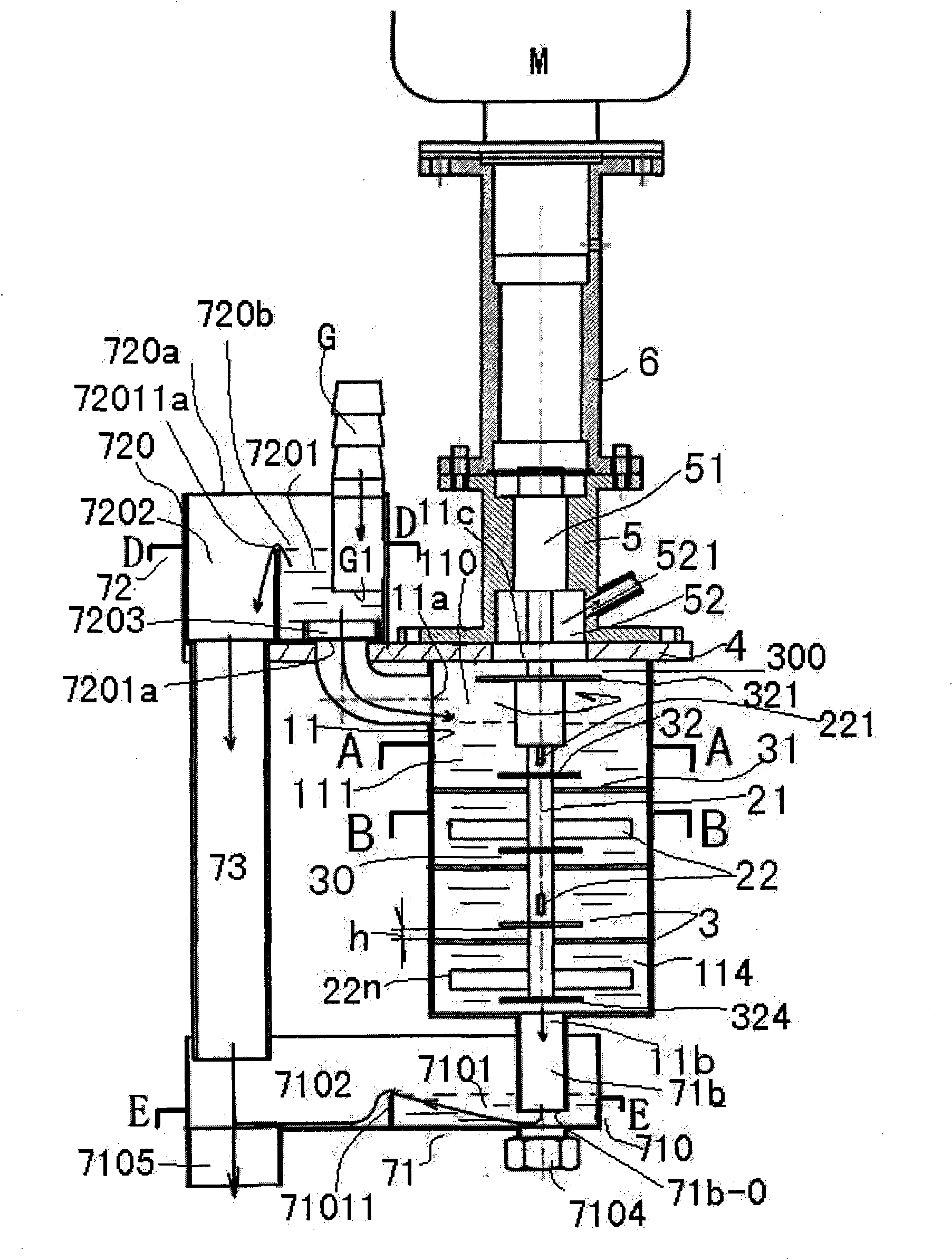

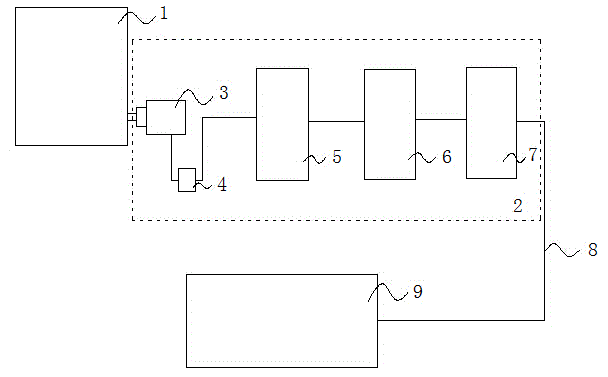

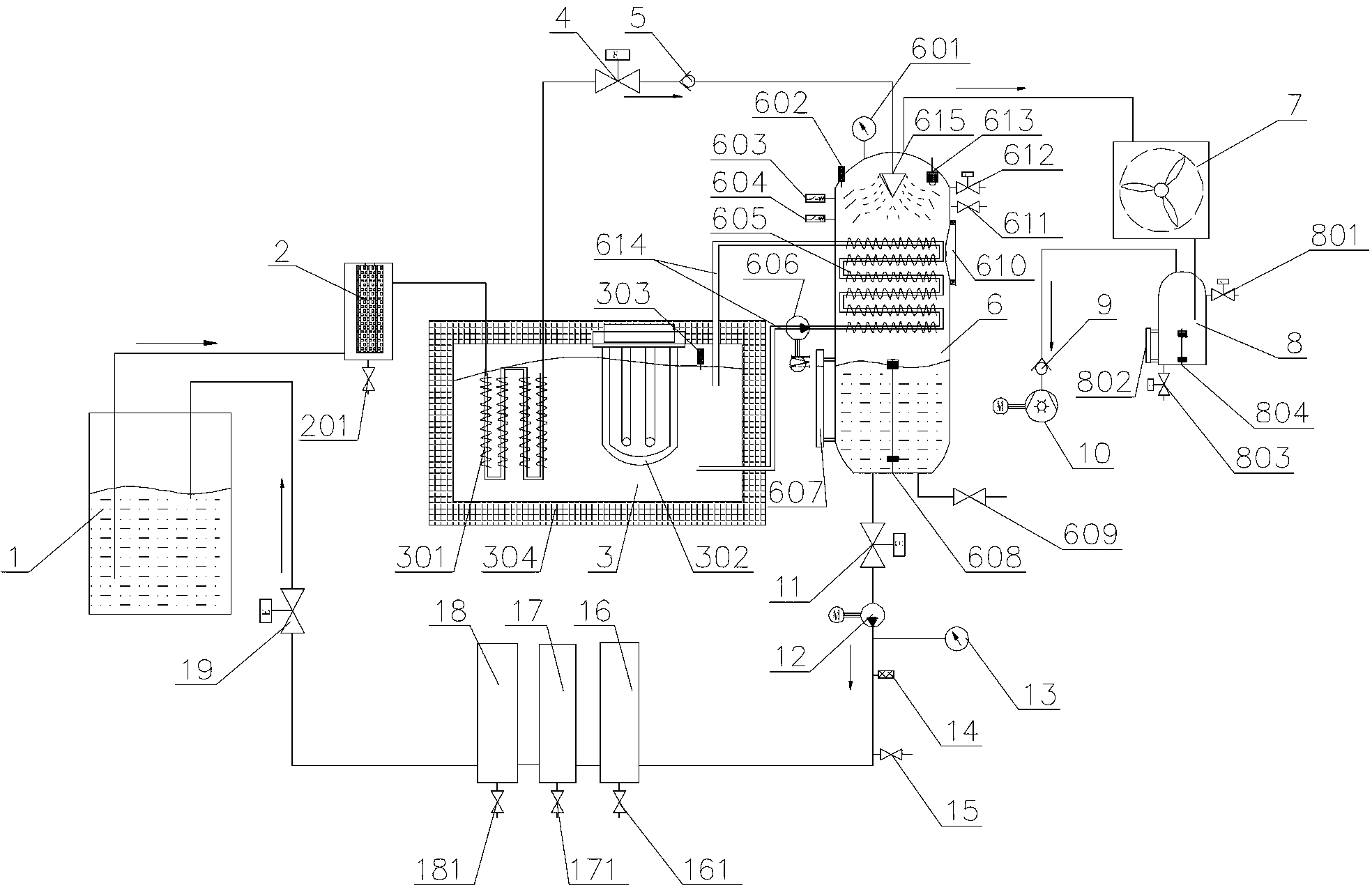

Aluminum melt vacuum treatment system and method

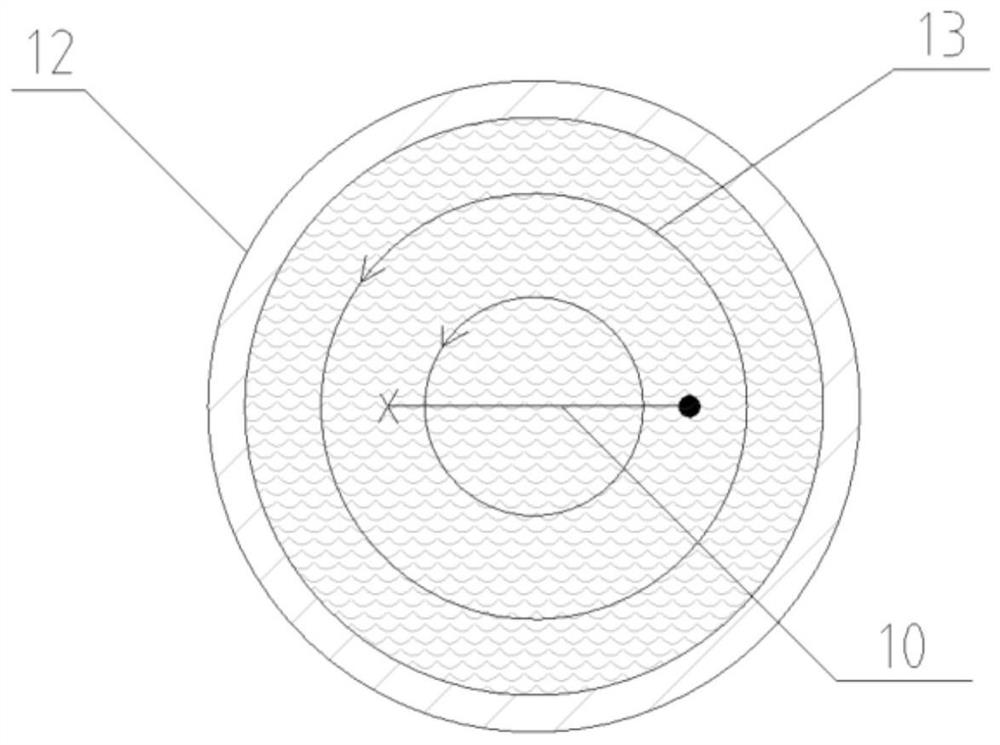

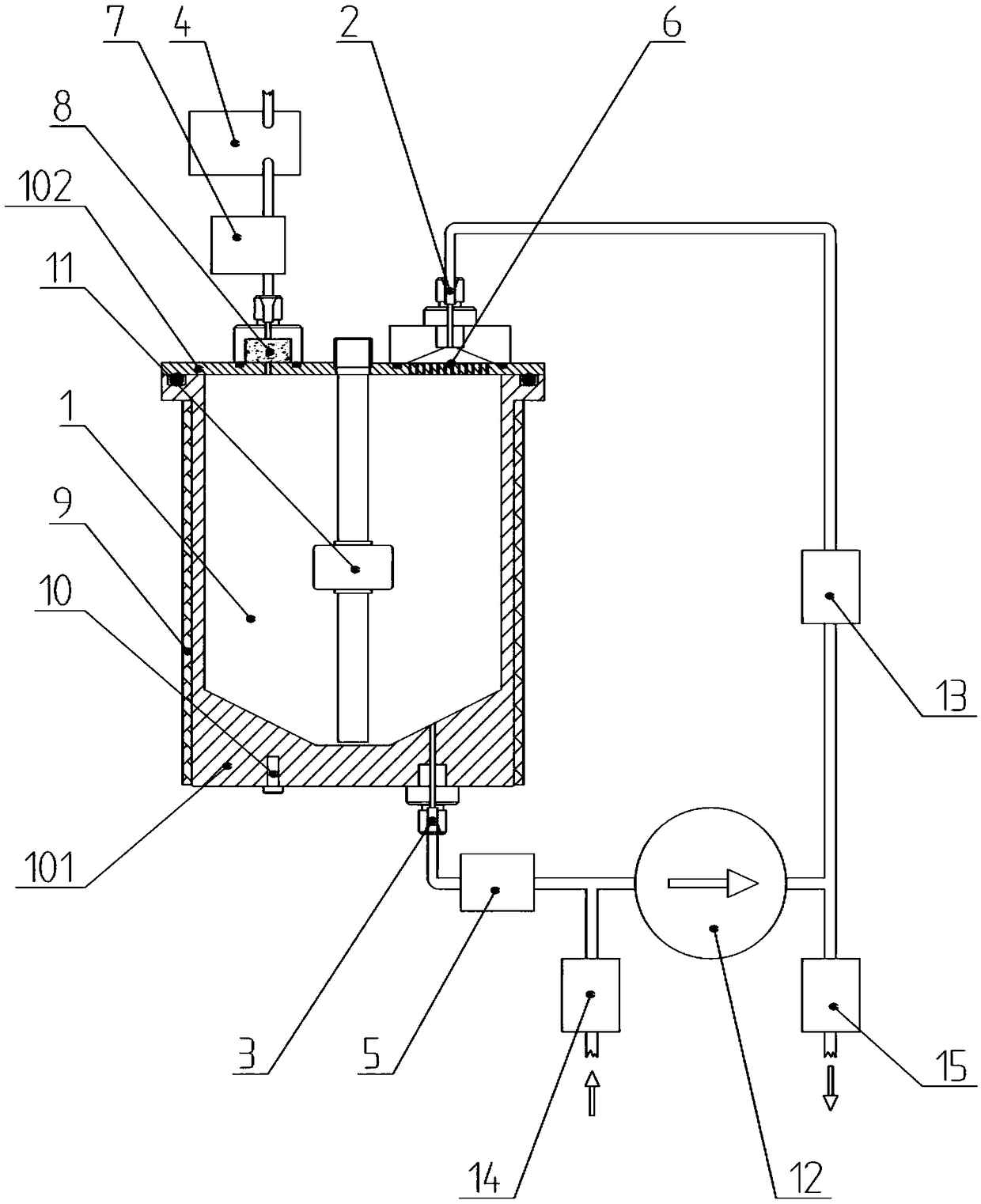

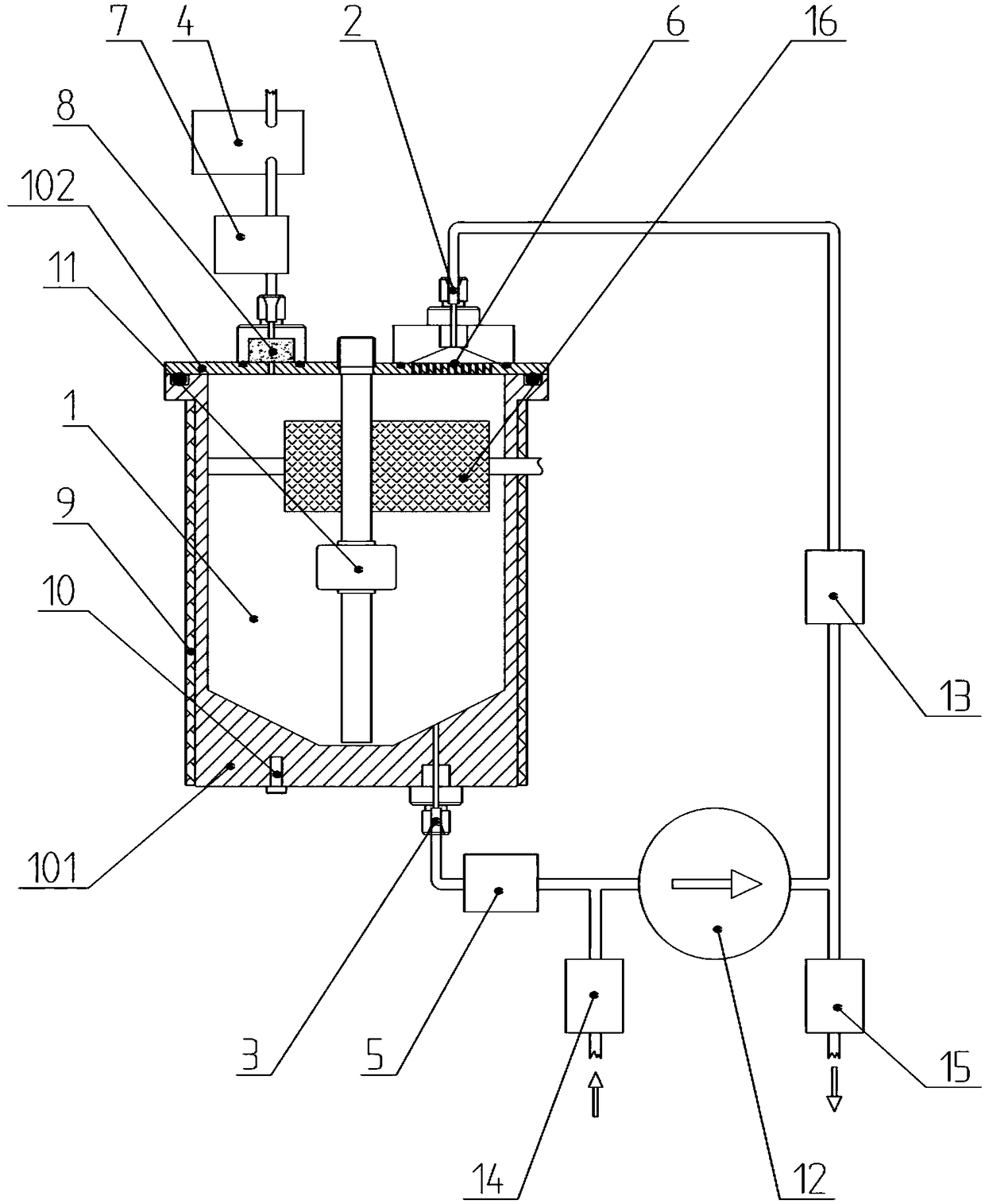

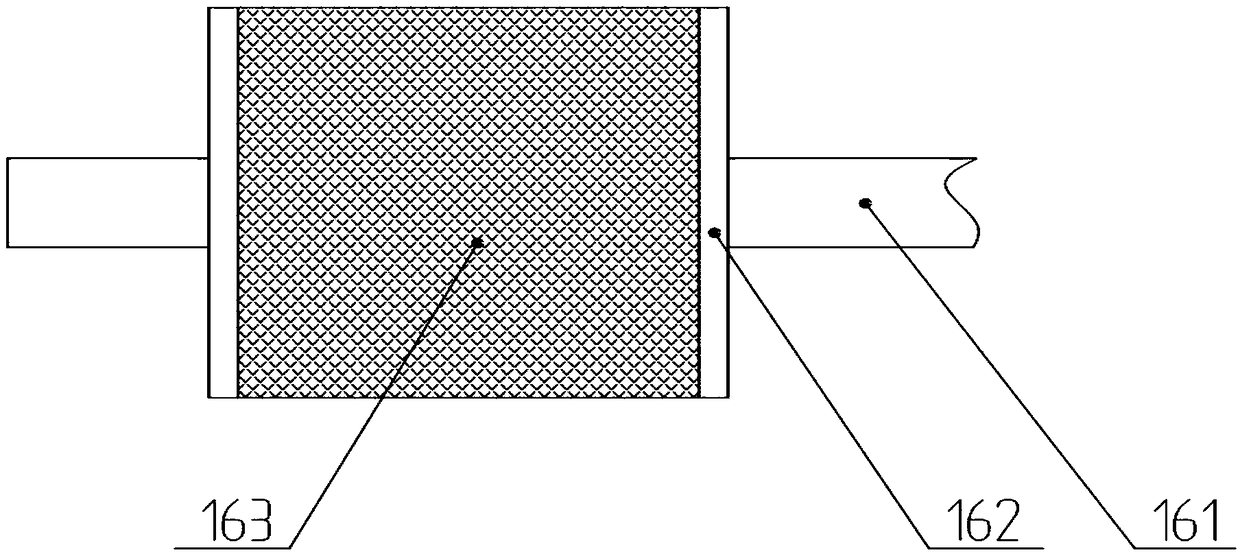

PendingCN111763831AImprove degassing conditionsImprove degassing efficiencyAluminum matrix compositesInductor

The invention discloses an aluminum melt vacuum treatment system and method. The aluminum melt vacuum treatment system comprises an aluminum melting furnace, a vacuum circulation degassing device, a permanent magnet stirring device and a feeding device, the vacuum circulation degassing device is located above the aluminum melting furnace, the top of the vacuum circulation degassing device is connected with the feeding device in a sealed mode, the vacuum circulation degassing device comprises a vacuum chamber with the side wall provided with an extraction opening and comprises a first channel and a second channel which are located at the bottom of the vacuum chamber and communicate with each other, the first channel and the second channel are inserted into the aluminum smelting furnace, aninert gas inlet is formed in the outer side wall of one of the channels, the permanent magnet stirring device is located at the bottom of the aluminum smelting furnace and comprises an inductor and afrequency converter connected with the inductor, a feeding port is formed in the top of the feeding device, a discharging port is formed in the bottom of the feeding device, and the feeding port and the discharging port can be automatically opened and closed and form an interlocking relation. When the system is used for vacuum treatment of aluminum-based alloy or aluminum-based composite materialmelt, the vacuum degassing efficiency of the aluminum melt is greatly improved, and meanwhile, uniform stirring of alloy elements in the aluminum melt can be achieved.

Owner:SHANGHAI JIAO TONG UNIV +1

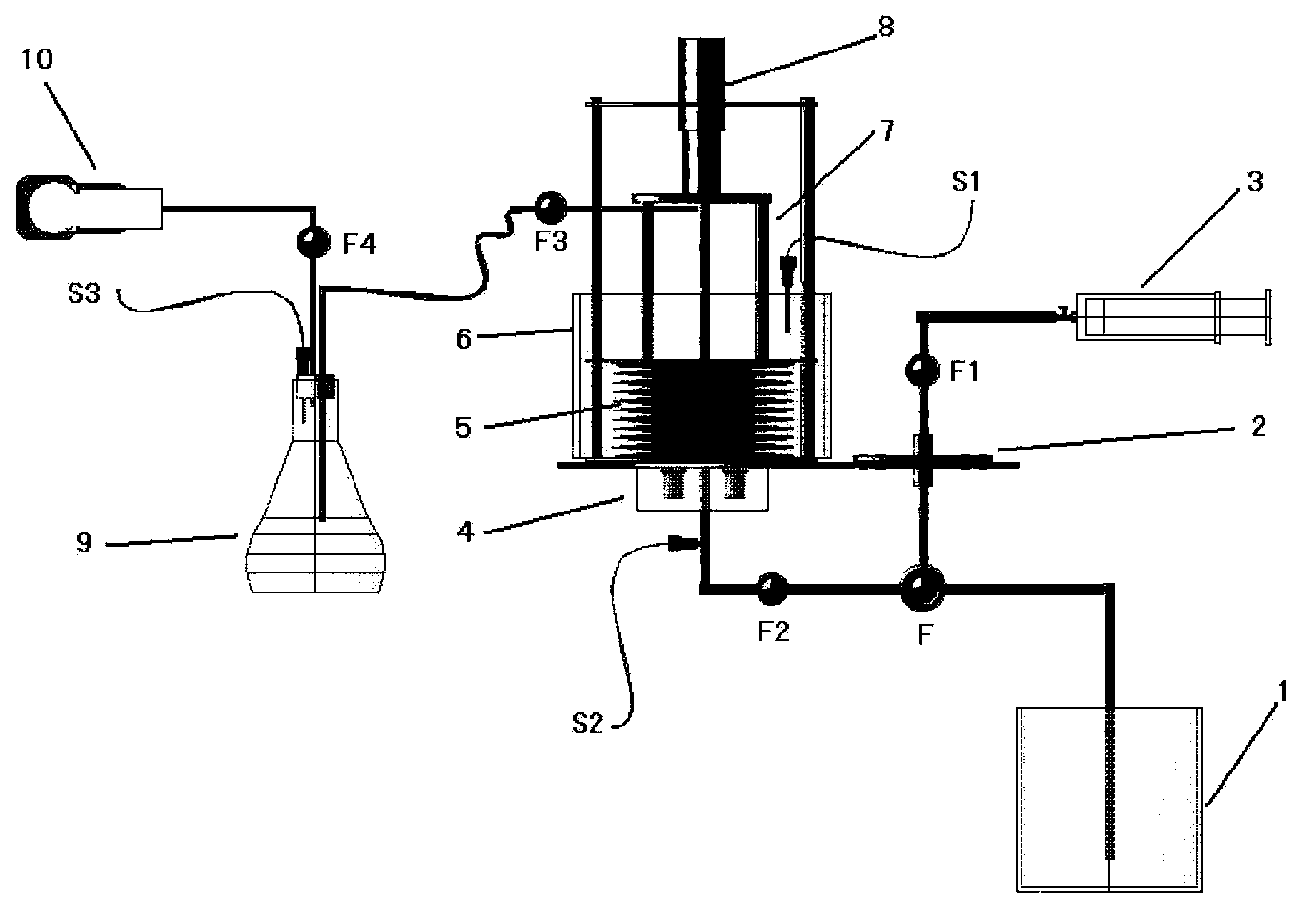

Oil spraying vacuum degassing device for online monitoring of oil chromatogram and application method

PendingCN108627601AIncrease flow rateReduce volumeComponent separationInternal pressureSolenoid valve

The invention discloses an oil spraying vacuum degassing device for online monitoring of an oil chromatogram and an application method and relates to the field of separating materials through a chromatography. The oil spraying vacuum degassing device comprises a degassing cylinder for degassing, wherein the degassing cylinder is provided with an oil feeding opening for feeding oil and an oil returning opening for discharging the oil; the oil spraying vacuum degassing device further comprises a vacuum pump for realizing negative pressure of the degassing cylinder and a circulating solenoid valve for realizing circulating oil; the oil feeding opening and the oil returning opening are connected through a pipeline provided with the circulating solenoid valve; the oil feeding opening is connected with a spraying structure. When the oil spraying vacuum degassing device is used, pressure in the degassing cylinder is pumped to a complete vacuum negative-pressure state and then transformer oilis injected; then a plurality of times of circulation are carried out and filtered gas is pumped to finish concentration detection work; finally, an oil sample is recycled. The oil spraying vacuum degassing device disclosed by the invention has the beneficial effects that the degassing efficiency is improved and the degassing time is shortened; a bottom-end side face in the degassing cylinder is set to be a reversed tapered surface, so that the volume of residual oil can be effectively reduced and a condition that impurities deposited at the bottom of the inner side of the degassing cylinder are pumped into the pipeline can be avoided.

Owner:SHANDONG WUYUE ELECTRICAL APPLIANCES

Method and apparatus for improving hydrogen utilization rate of hydrogenation equipment

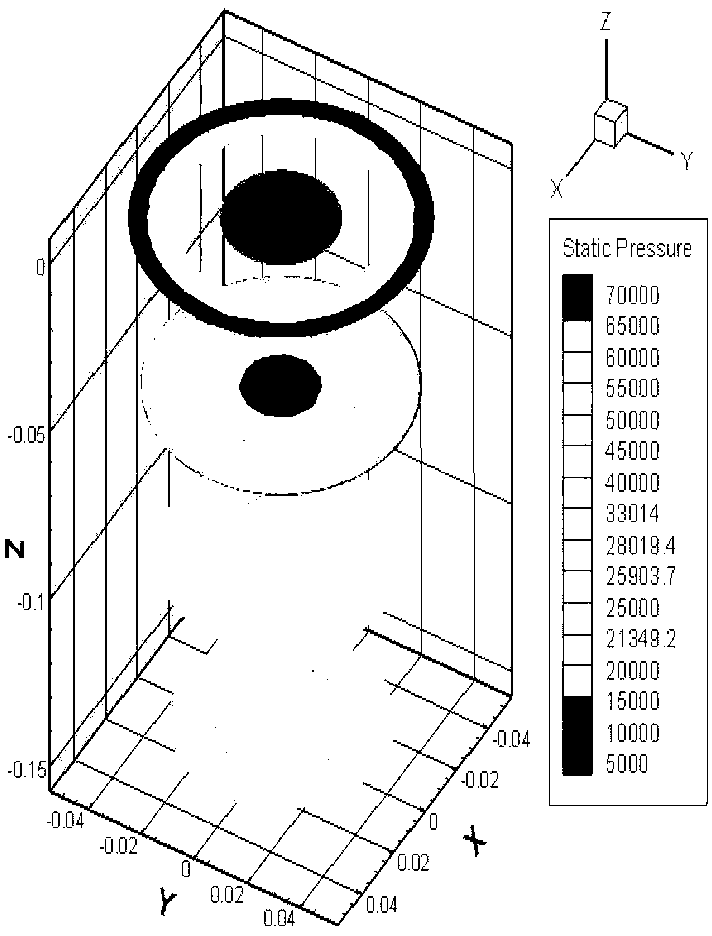

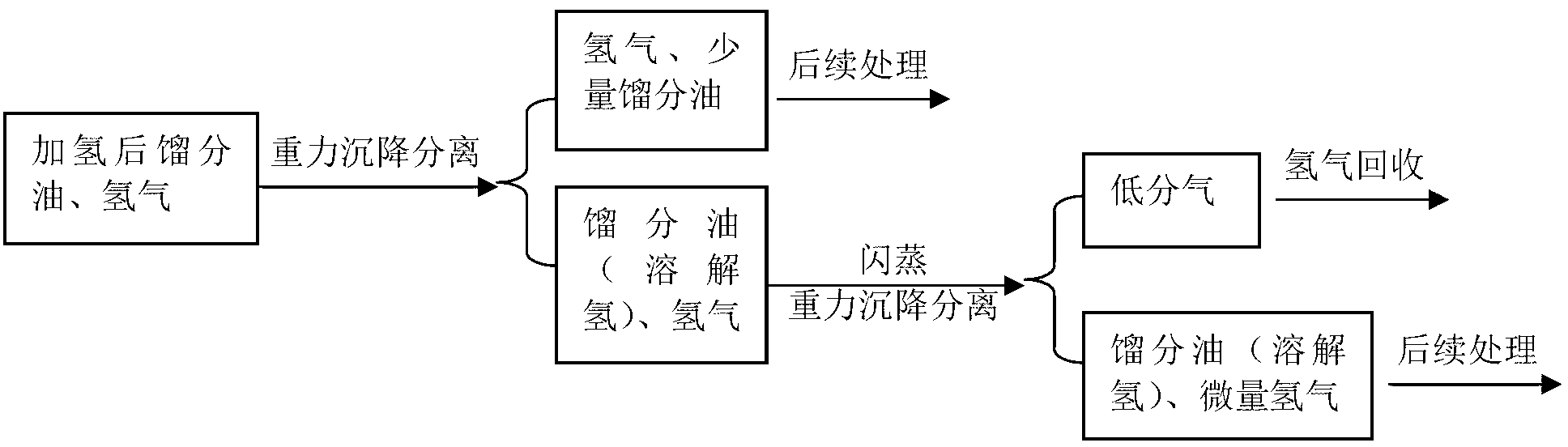

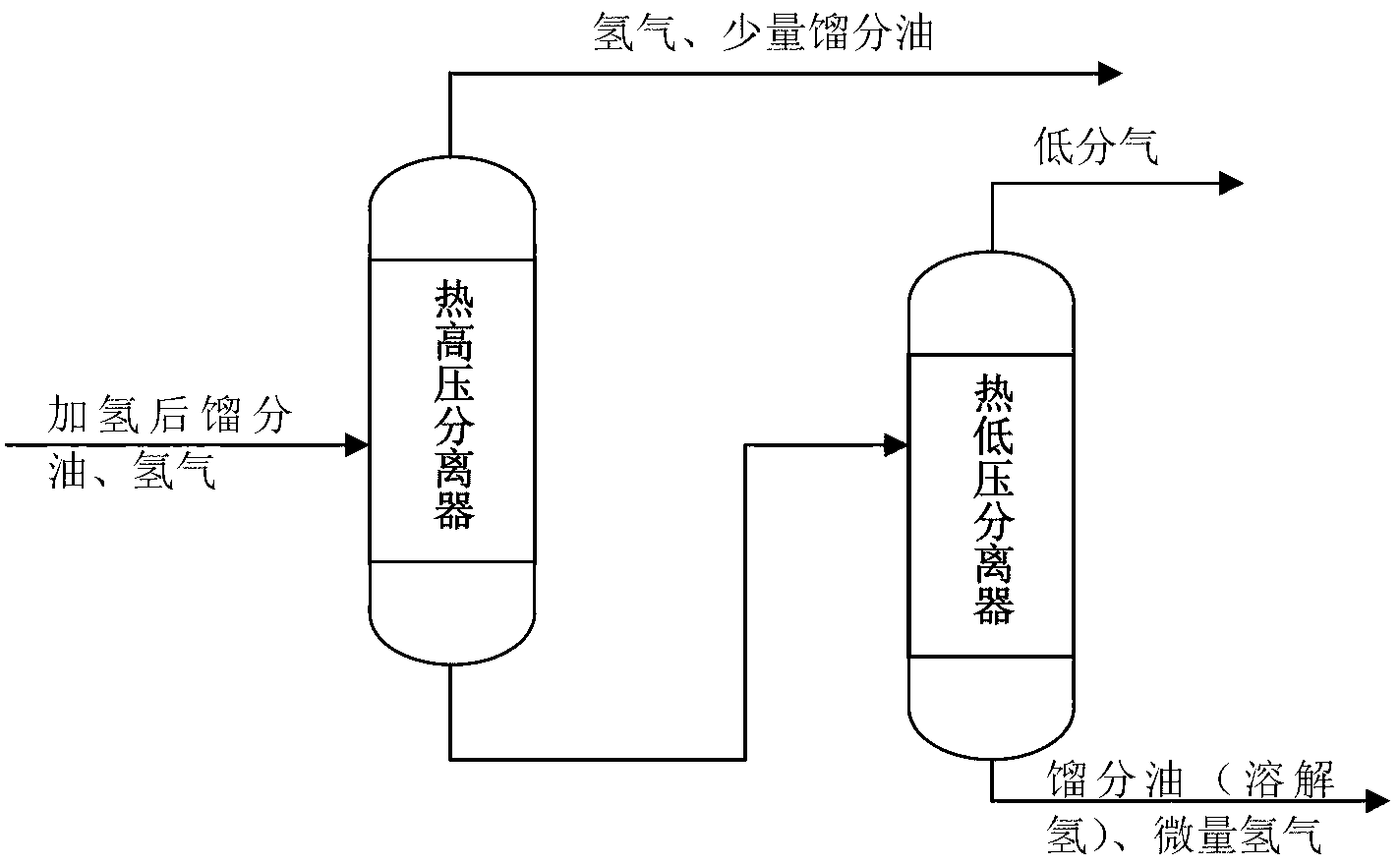

ActiveCN103320161AOvercoming lossEasy to operateTreatment with plural serial refining stagesFluid phaseGas phase

The invention relates to a method and an apparatus for improving a hydrogen utilization rate of hydrogenation equipment. The method comprises the steps of implementing primary gas-liquid separation to distillate oil, a gaseous product and hydrogen after hydrogenation under high pressure through an inertial separation distributor arranged at an inlet of a thermal high pressure separator, and delivering a gas phase to a following system; feeding a liquid phase to a thermal low pressure separator, as a first step in the thermal low pressure separator, implementing primary separation through a jet flashing technology to release a part of low gas (mainly consisting of hydrogen), and settling depending on gravity to separate the gas phase and the liquid phase; under the same pressure, separating hydrogen which is still dissolved in thermal low oil and partial small bubbles through a centrifugal deaerating method in a second step; completely removing liquid drops carried in the gas phase part through cyclone separation or coalescing separation and discharging the gas phase part out of the apparatus, and delivering the distillate oil to a following facility. The method and the apparatus can improve recovery rate of the hydrogenation equipment to the hydrogen contained in the distillate oil after hydrogenation, and can be applied to other processes for recovering the hydrogen as well.

Owner:EAST CHINA UNIV OF SCI & TECH

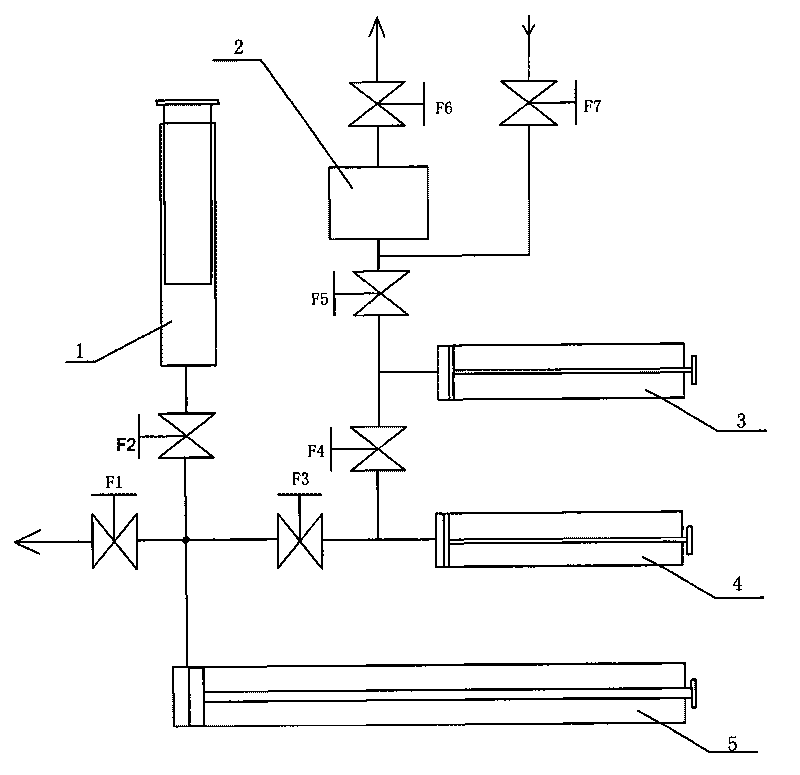

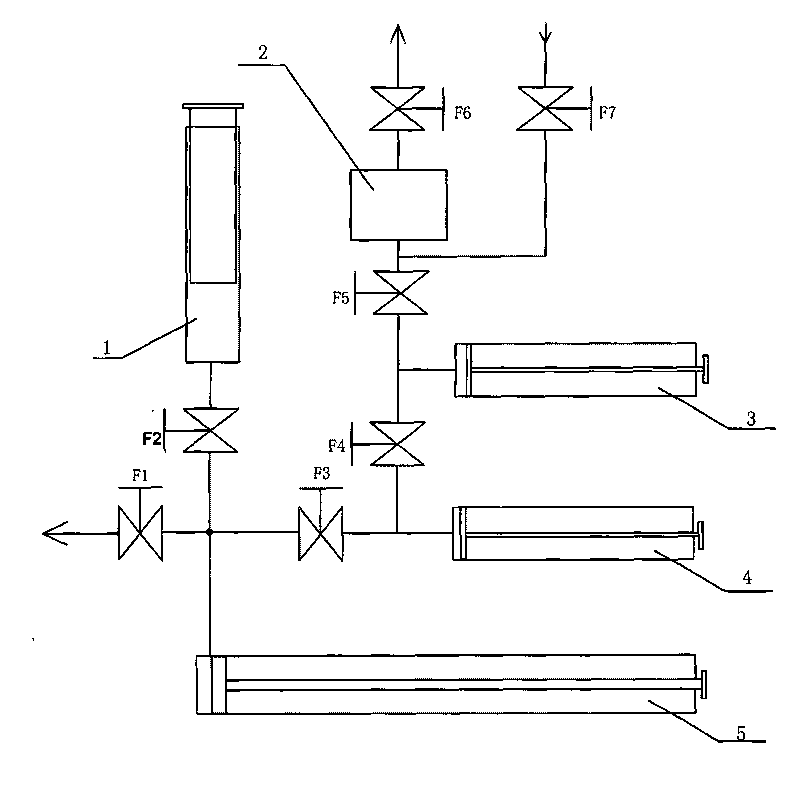

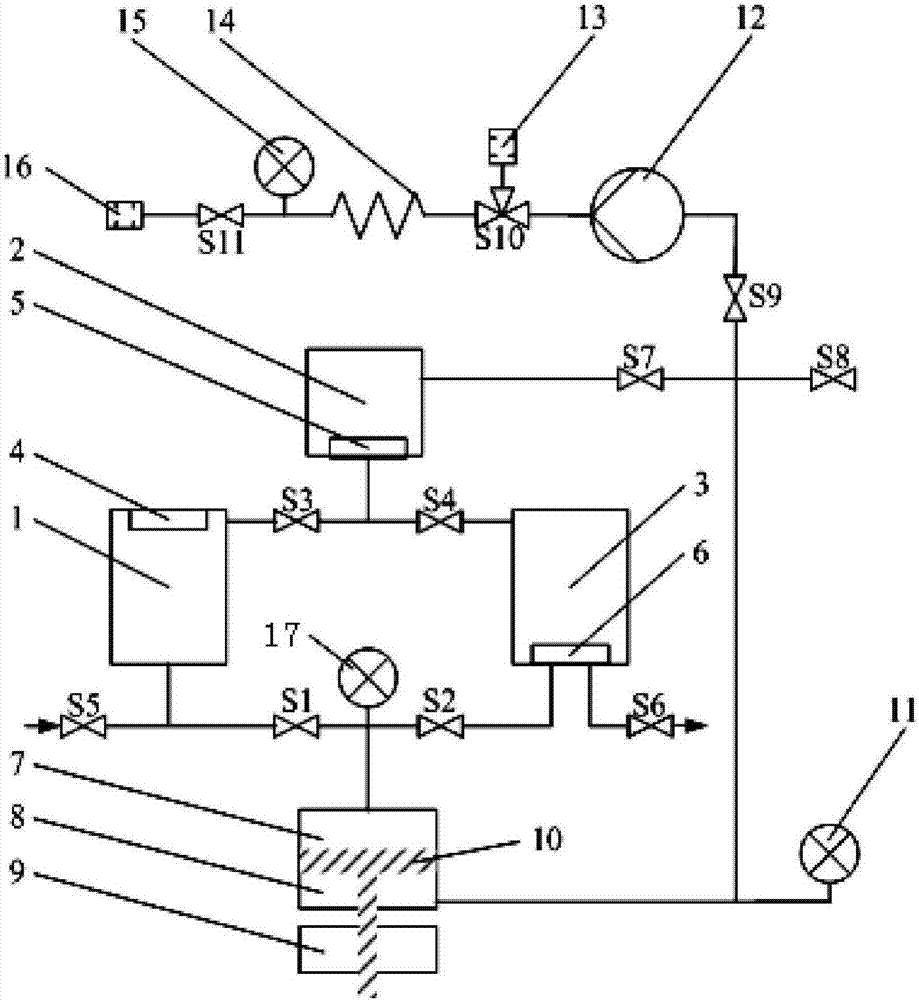

Automatic volume displaced type vacuum degasser for transformer oil

InactiveCN101762641ASimple degassing processImprove degassing efficiencyComponent separationDegasserGas phase

The invention provides an automatic volume displaced type vacuum degasser for transformer oil. The invention is characterized in that the degasser comprises a sample oil injector, a sample gas quantitative tube, a gas transfer cylinder, a gas exchange cylinder, an oil sample degassing cylinder, an oil draining valve F1 and a plurality of electromagnetic valves; the outlet of the sample oil injector is respectively connected with the oil sample degassing cylinder, the oil draining valve F1 and a third electromagnetic valve F3 by a pipe which is provided with a second electromagnetic valve F2; the other end of the third electromagnetic valve F3 is respectively connected with the gas exchange cylinder and a fourth electromagnetic valve F4; the other end of the fourth electromagnetic valve F4 is respectively connected with the gas transfer cylinder and a fifth electromagnetic valve F5; the other end of the fifth electromagnetic valve F5 is respectively connected with the sample gas quantitative tube and a seventh electromagnetic valve F7; the other end of the seventh electromagnetic valve F7 is communicated with carrier gas; and the outlet of the sample gas quantitative tube is provided with the sixth electromagnetic valve F6. As the preposing degassing device for on-line analysis and monitoring of the oil-gas phase chromatograph of a transformer, the invention has the advantages of high degassing efficiency, quick speed and simple structure, and full-automatic degassing realization.

Owner:ZIBO ZHONGHUI INSTR

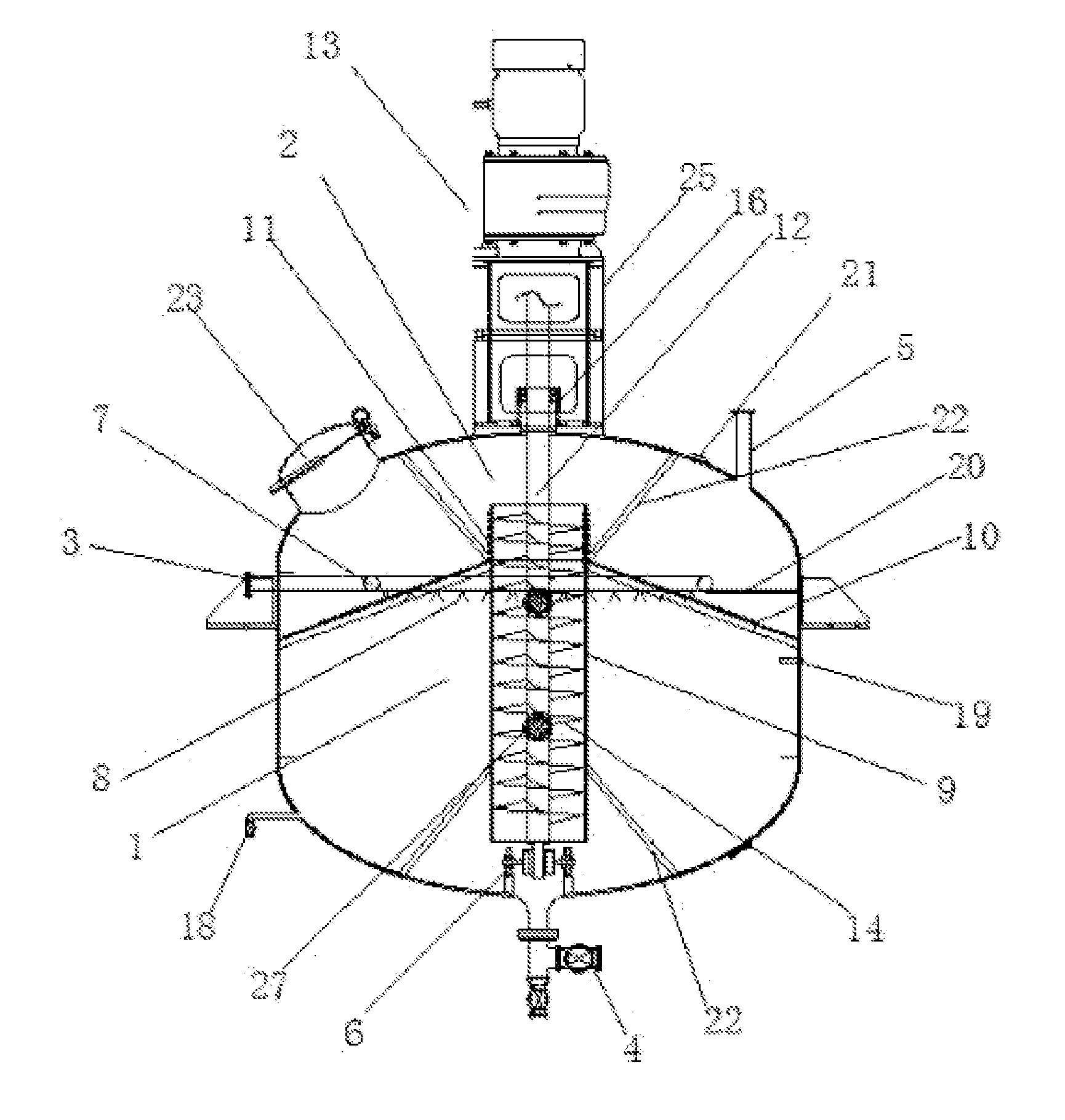

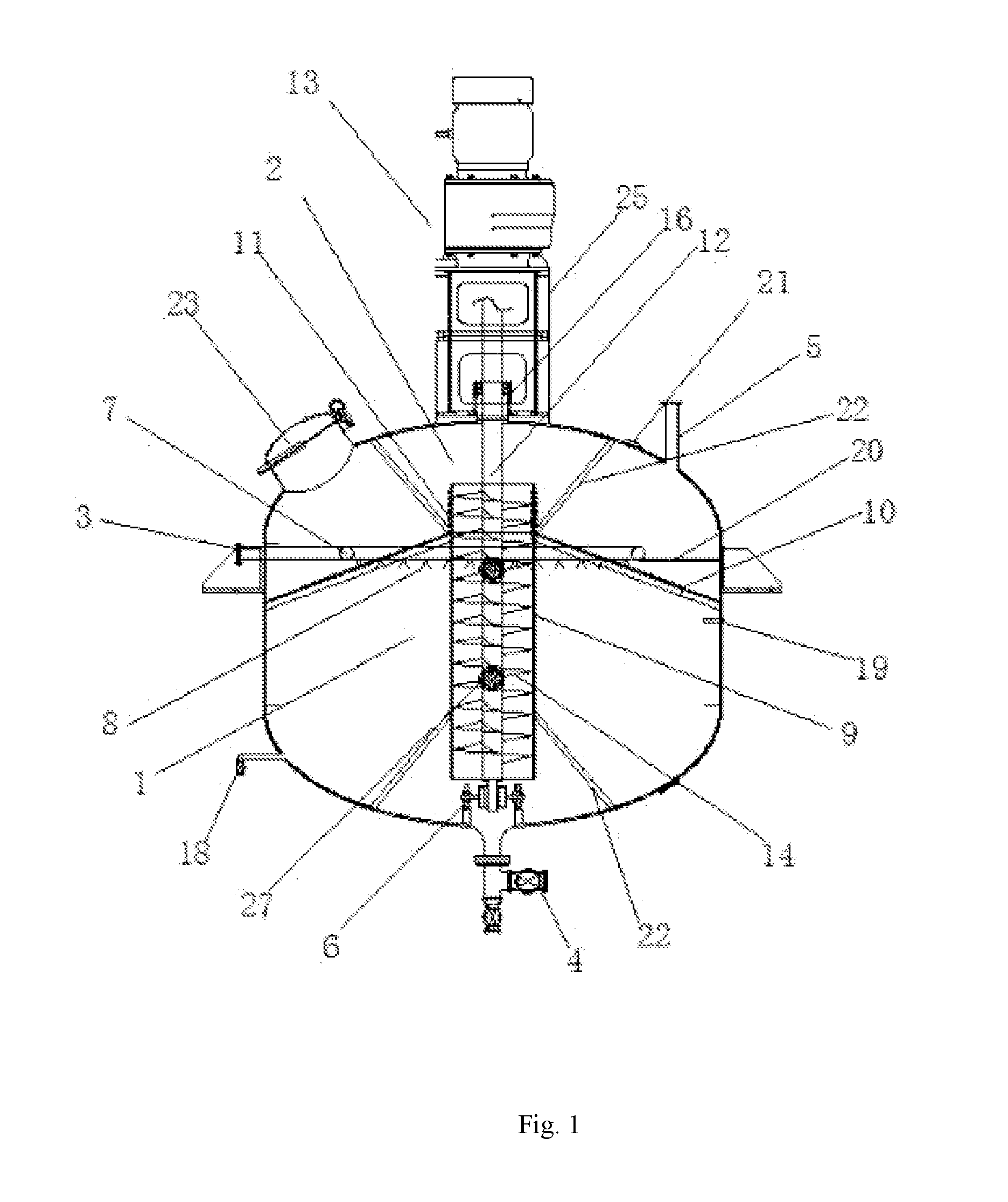

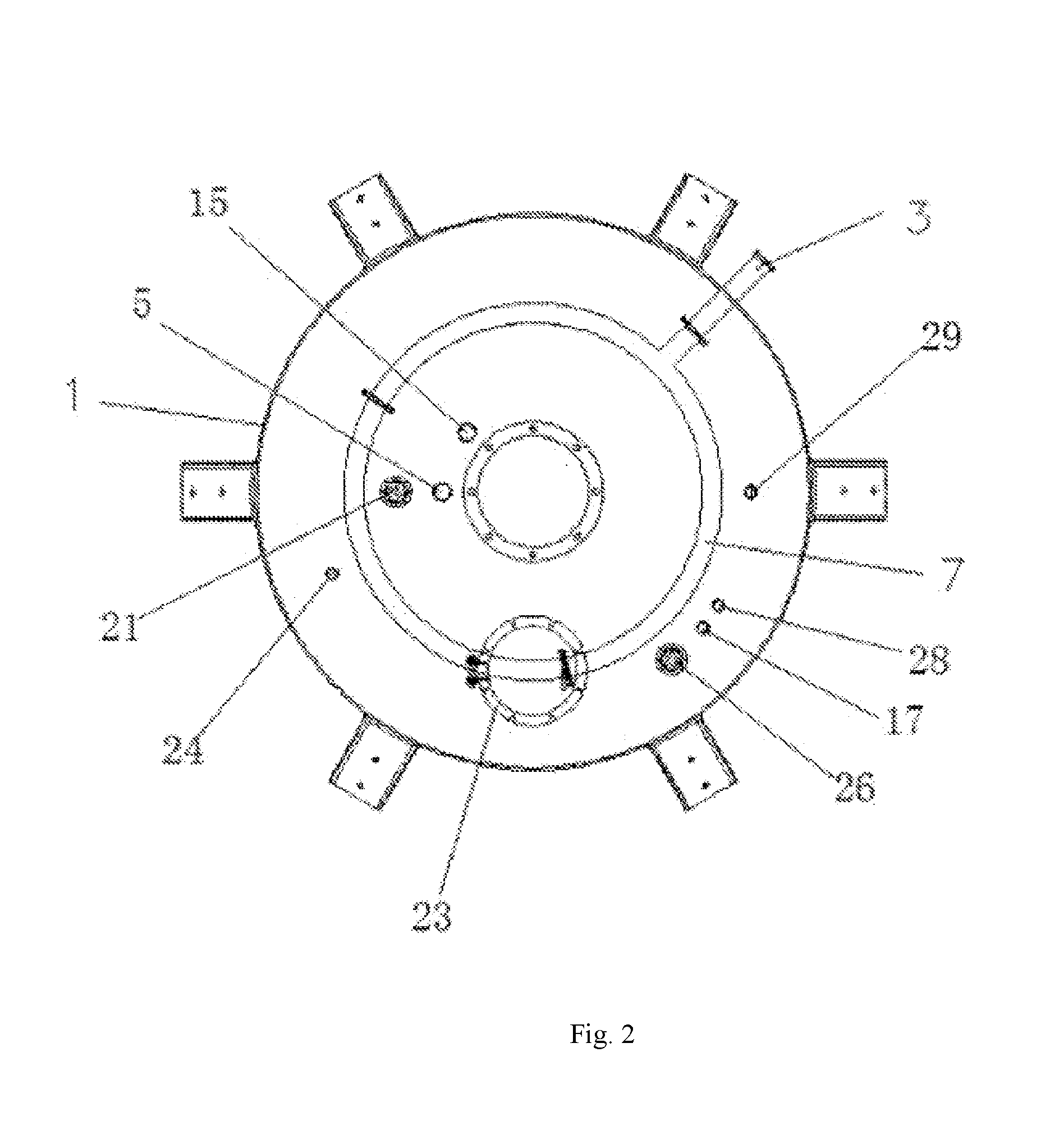

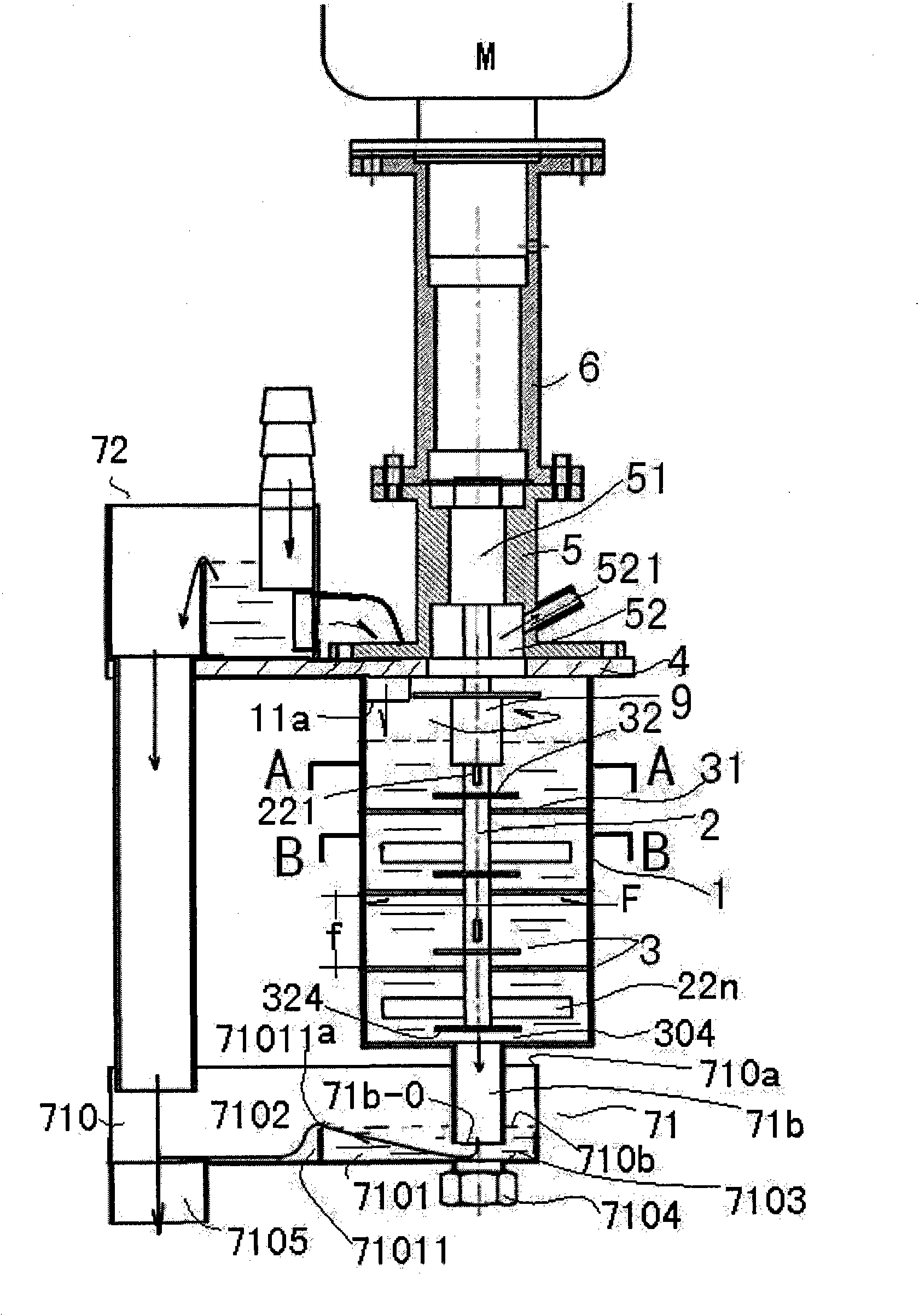

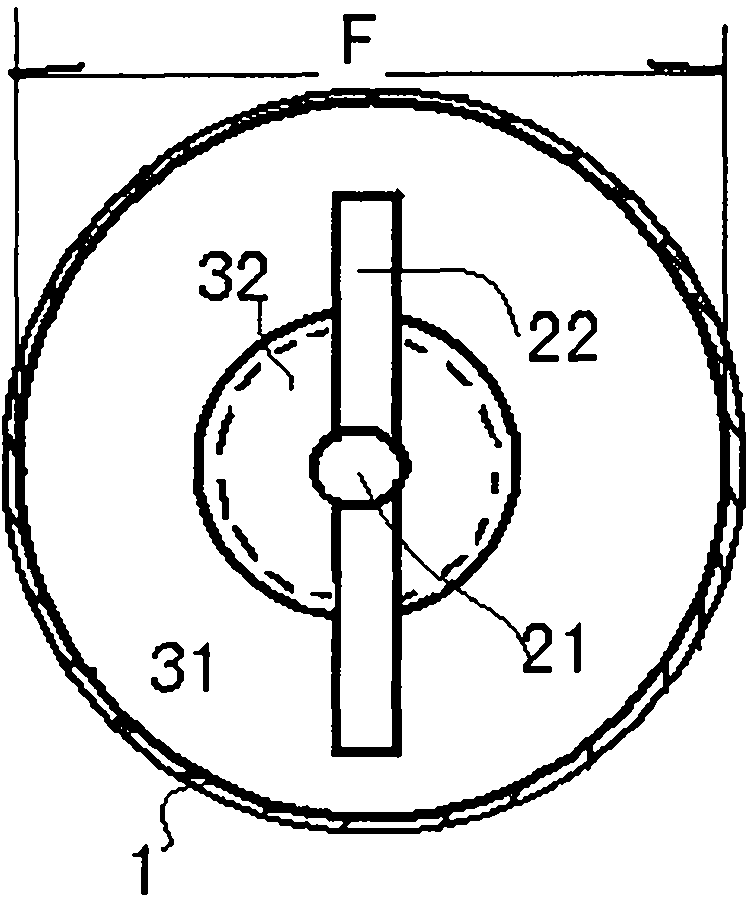

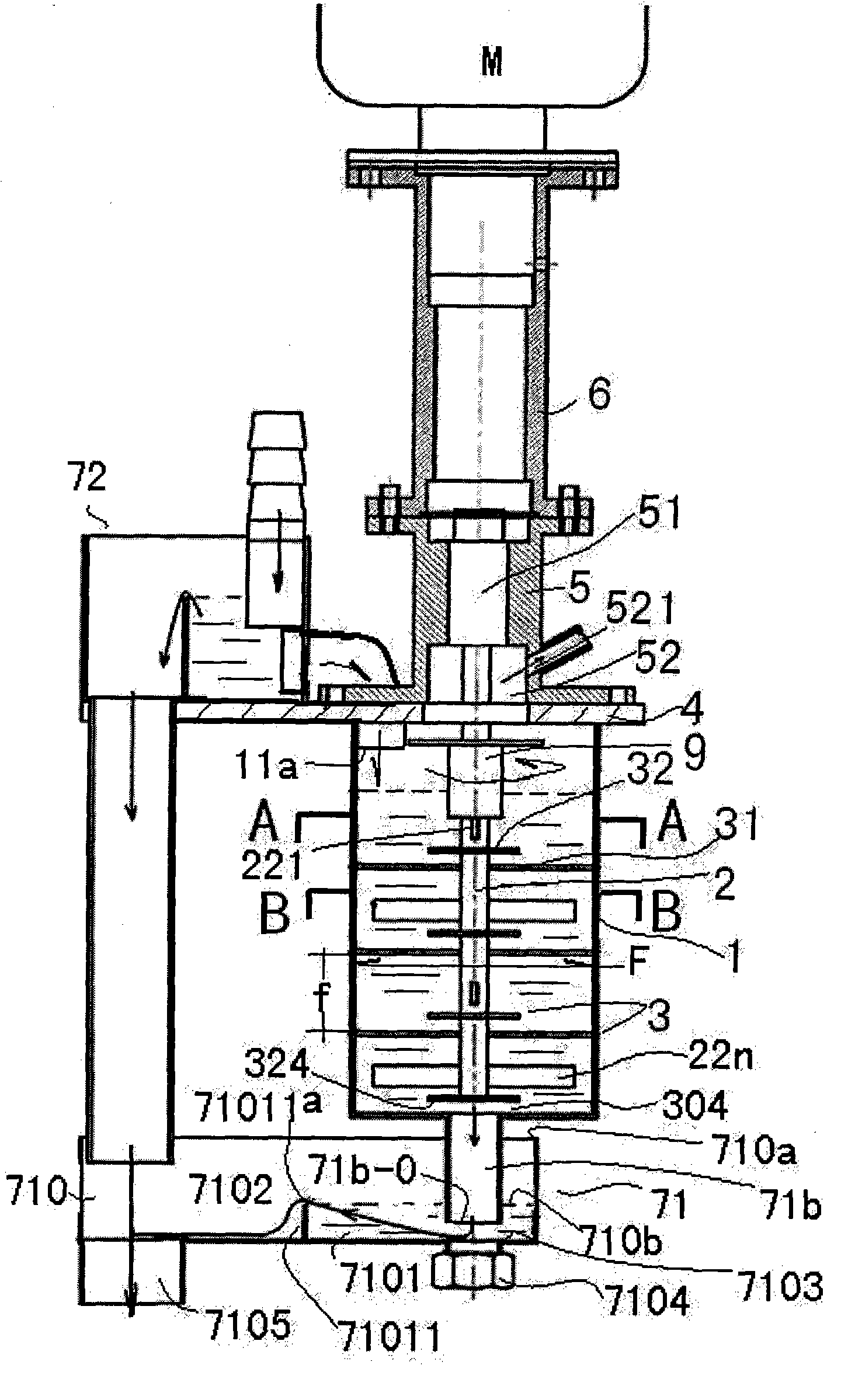

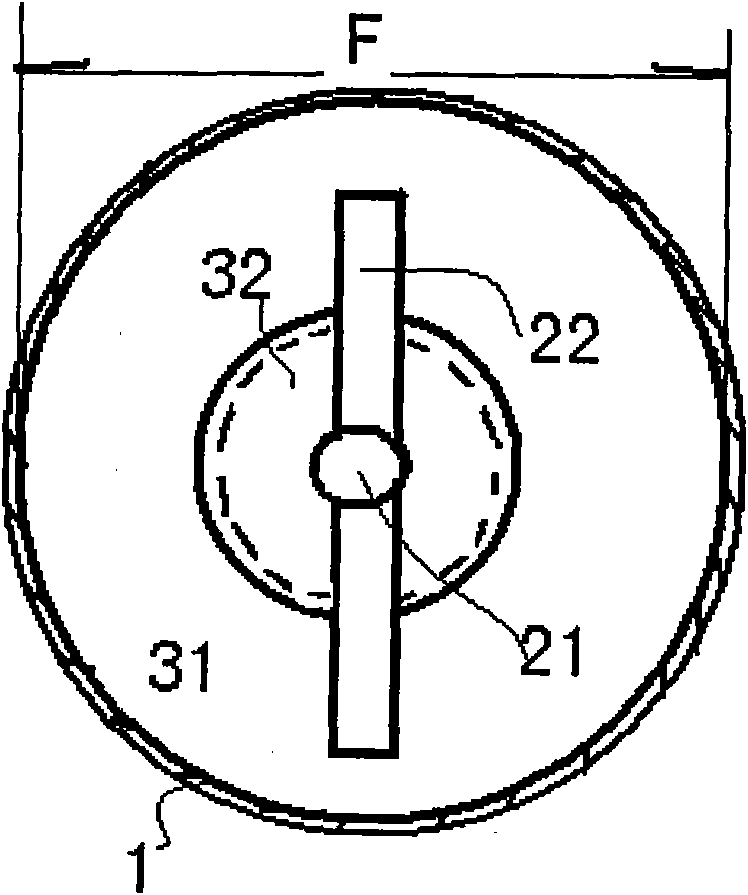

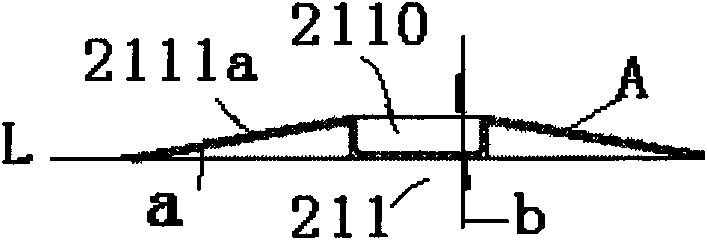

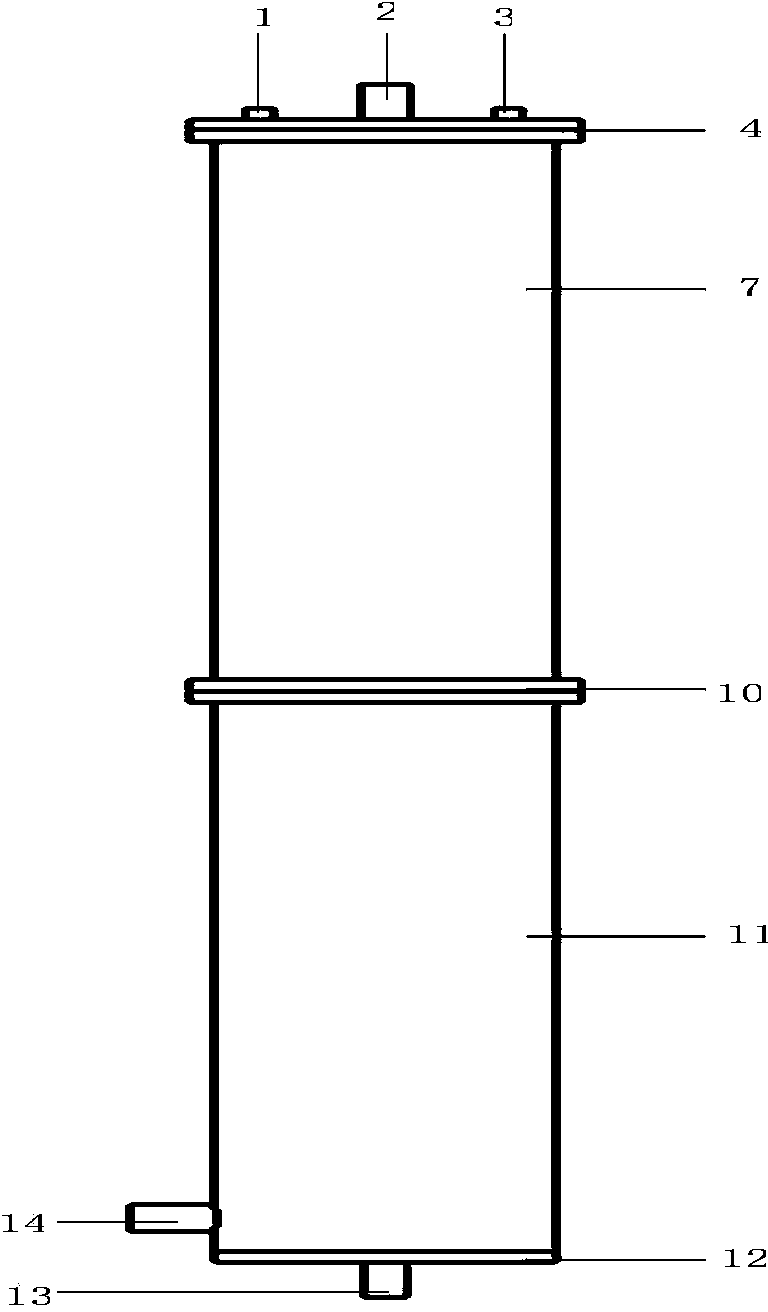

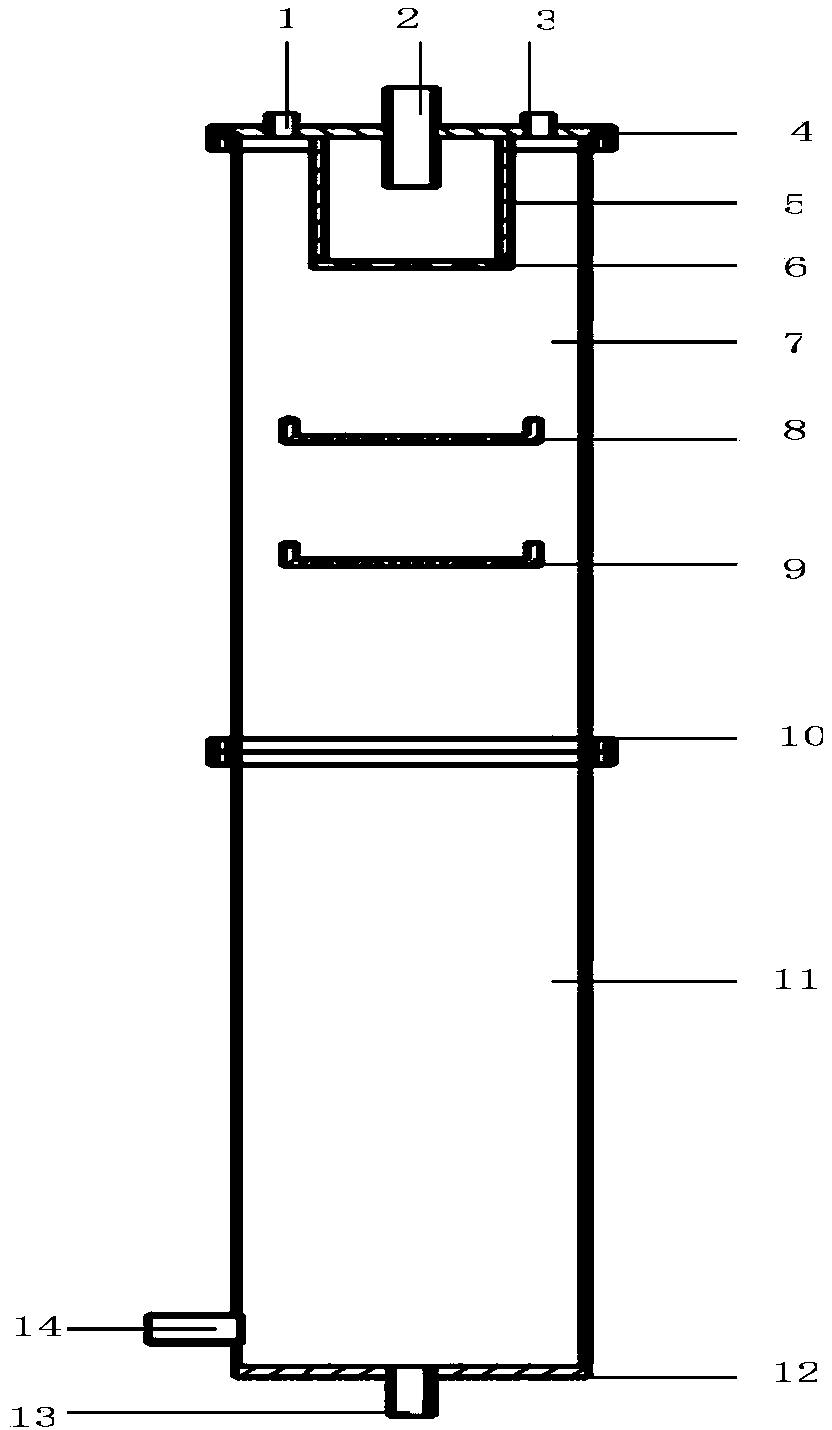

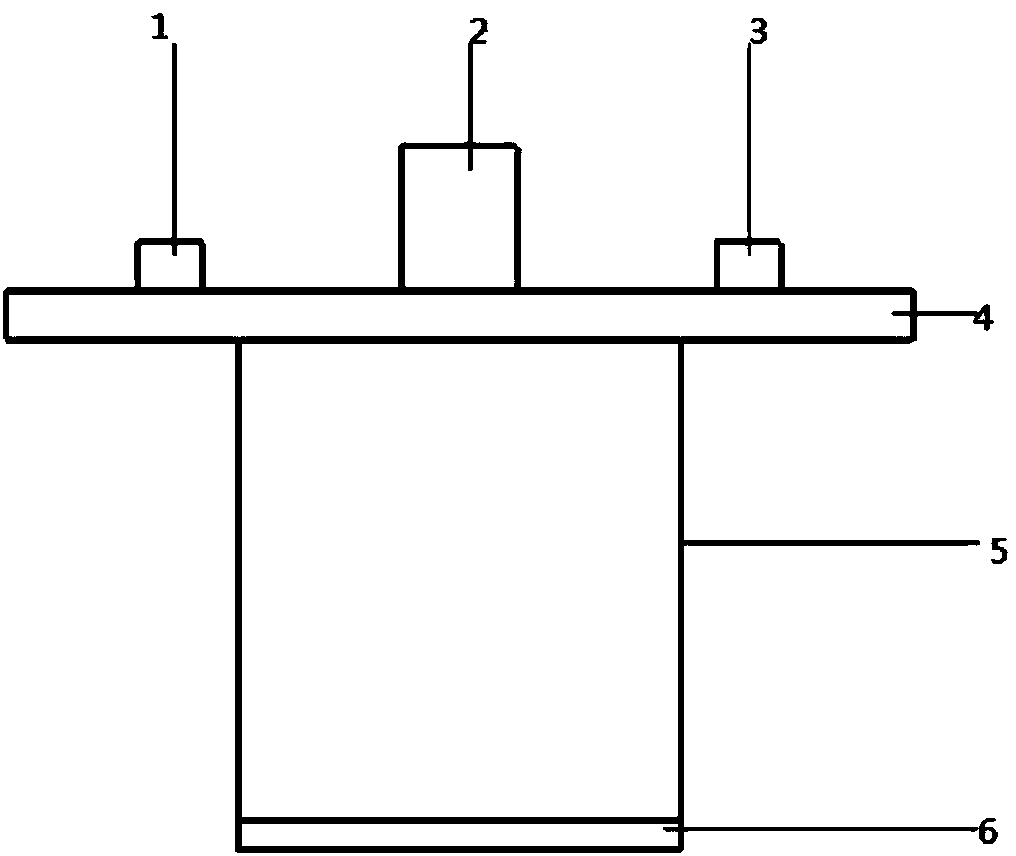

Defoaming apparatus for high-viscosity pure-chitosan spinning solution

InactiveUS20160193548A1Increase the areaHigh-efficiency high-qualitySpinning solution filteringTransportation and packagingPropellerEngineering

A degassing device for high-viscosity pure-chitosan spinning solutions having a reaction vessel and stirring device. A feed port and vacuum port are disposed at the upper part of the reaction vessel, an inner cylinder body is fixedly disposed in the center position of the reaction vessel which also has a discharge port, the upper cylinder opening of the inner cylinder body is closed and the lower cylinder opening is open, an umbrella-shaped dispersion plate is fixedly disposed at the periphery of the upper half part of the inner cylinder body, a gap is formed between the outer edge of the umbrella-shaped dispersion plate and the inner wall of the reaction vessel, and small liquid outlet holes are distributed on the part of the inner cylinder body above the umbrella-shaped dispersion plate. The stirring device has a stirring shaft with screw propeller and stirring power unit. The upper end of the stirring shaft is mounted to the stirring power unit, the stirring shaft passes through a mechanical sealing device and enters the reaction vessel with the lower end fixed on a seat-mounted bearing, the stirring shaft is superposed with the axial line of the inner cylinder body, and a gap is formed between the inner wall of the inner cylinder body and screw propeller.

Owner:HISMER BIO TECH

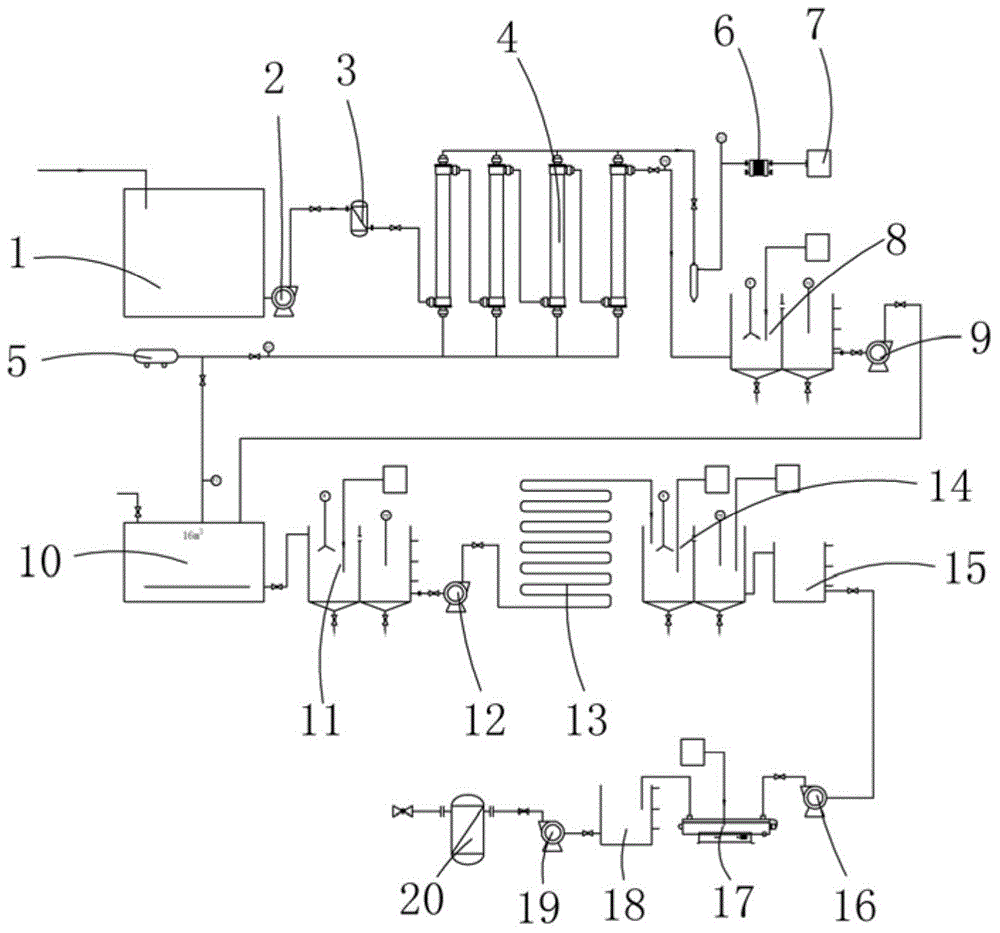

Coating wastewater treatment technology

InactiveCN105060577AReduce COD valueLarge membrane contact areaMultistage water/sewage treatmentHigh concentrationWater discharge

The invention relates to a coating wastewater treatment technology. The technology comprises the following steps: raw water enters an equalizing tank; water in the equalizing tank enters a prepositioned filter through an elevator pump and is filtered, and the filtered raw water enters a degassing and carbonizing linkage system, wherein a carbonization membrane module is arranged in the degassing and carbonizing linkage system; water discharged from the carbonization membrane module goes through a reagent adding pool a and undergoes reagent adding, the reagent added water enters a micro-electrolysis system through a pump in order to realize treatment of high-concentration organic wastewater; water discharged from the micro-electrolysis system goes through a reagent adding pool b and undergoes reagent adding, and obtained water enters a coiled tube through a pump b and undergoes a Fenton reaction, wherein reagent adding of the reagent adding pool b is carried out to adjust the pH value and the content of hydrogen peroxide; water obtained after the Fenton reaction goes through a reagent adding pool c and undergoes reagent adding, and obtained water enters a coagulation and precipitation tank and precipitates; a clear liquid at the upper portion of the coagulation and precipitation tank enters a photocatalysis system through a pump c in order to remove organic matters in the clear liquid; and water obtained after photocatalysis is collected by an intermediate water tank, and enters an enhanced filter through a pump d, and filtered water is discharged. The technology has the advantages of reduction of the COD value of coating wastewater, simple process flow and long service life.

Owner:HUZHOU SENNUO MEMBRANE TECH ENG

High-concentration vacuum oil-gas separation device and method for online monitoring transformer oil

ActiveCN107247108AFacilitate real-time online analysisShort degassing timeComponent separationAir quality improvementAir pumpDrive motor

The invention relates to a high-concentration vacuum oil-gas separation device and method for online monitoring transformer oil. The high-concentration vacuum oil-gas separation device is provided with a quantification chamber, a gas well, an oil well, a degassing chamber, a gas collection chamber, a quantification pipe, an anti-vacuum gas pump, a driving motor and oil and gas pipelines, wherein a gas path part of a vacuum degassing machine is formed by the gas collection chamber, the anti-vacuum gas pump and the quantification pipe; the lower end of the quantification chamber is connected with an oil outlet of a transformer oil tank and the degassing chamber respectively and the upper end of the quantification chamber is connected with the gas well; the upper end of the gas well is connected with the gas collection chamber through a gas pipeline and the lower end of the gas well is connected to the upper end of the quantification chamber and the upper end of the oil well; the lower end of the oil well is connected with the degassing chamber and an oil inlet of the transformer oil tank through two branch pipelines respectively; the degassing chamber and the gas collection chamber are separated through a piston and the driving motor is connected with the piston; a gas inlet of the anti-vacuum gas pump is connected with the gas collection chamber and a gas outlet of the anti-vacuum gas pump is connected with the quantification pipe. According to the high-concentration vacuum oil-gas separation device and method provided by the invention, degassing is finished by adopting a vacuum degassing principle and real-time online analysis of dissolved gas in the transformer oil is facilitated; a manner of degassing and collecting gas for a plurality of times is adopted, so that the degassing efficiency is high and the repeatability is good.

Owner:SIFANG-TBEA INTELLIGENT ELECTRICAL CO LTD

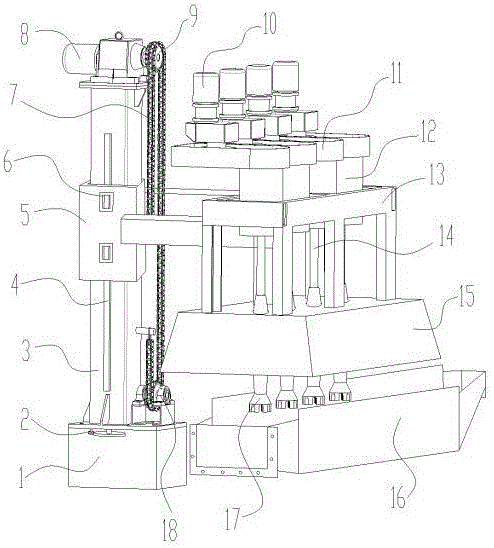

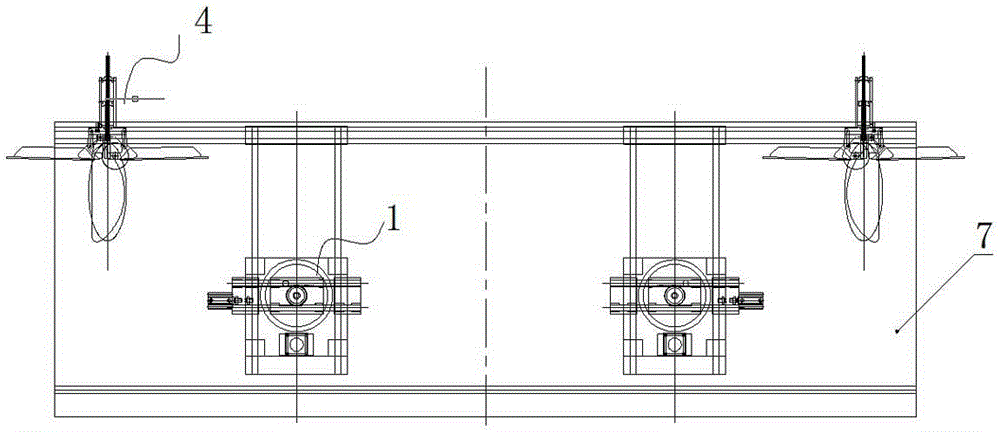

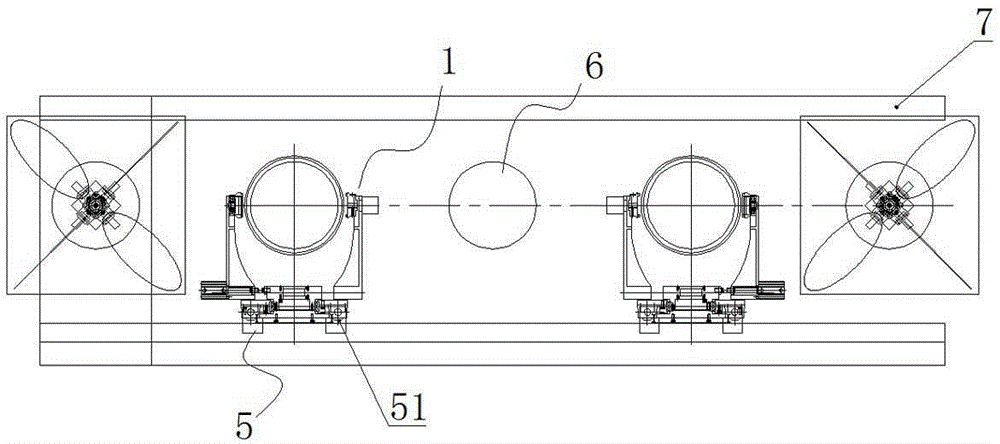

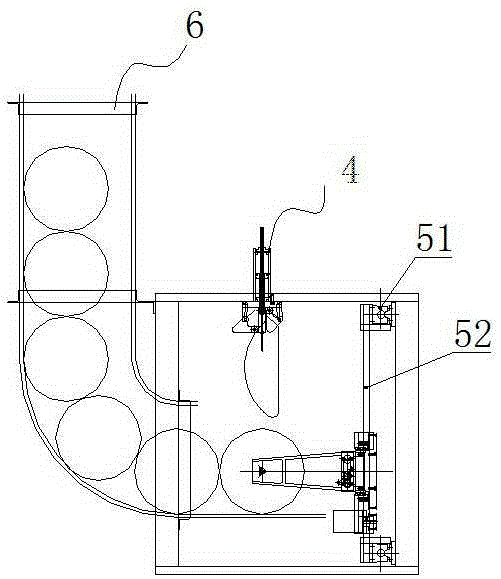

Launder-type on-line degassing device

InactiveCN105112687ASuitable for online useImprove degassing efficiencyProcess efficiency improvementEngineeringSteel frame

The invention provides a launder-type on-line degassing device which comprises a base, a rotary driving device, an upright column, guide rails, a guide bushing, a roller, a chain, a lifting motor, a duplex chain wheel, rotating motors, a transition connection disc, bearing sleeves, a steel frame, hollow shafts, a launder cover, a launder, rotor components and a lower bearing pedestal. Through the demonstration, the launder-type on-line degassing device is stable in degassing performance, high in efficiency, and low in rejection rate, and the labor intensity of workers is reduced greatly.

Owner:QUZHOU ZHENGRONG ENVIRONMENTAL PROTECTION TECH

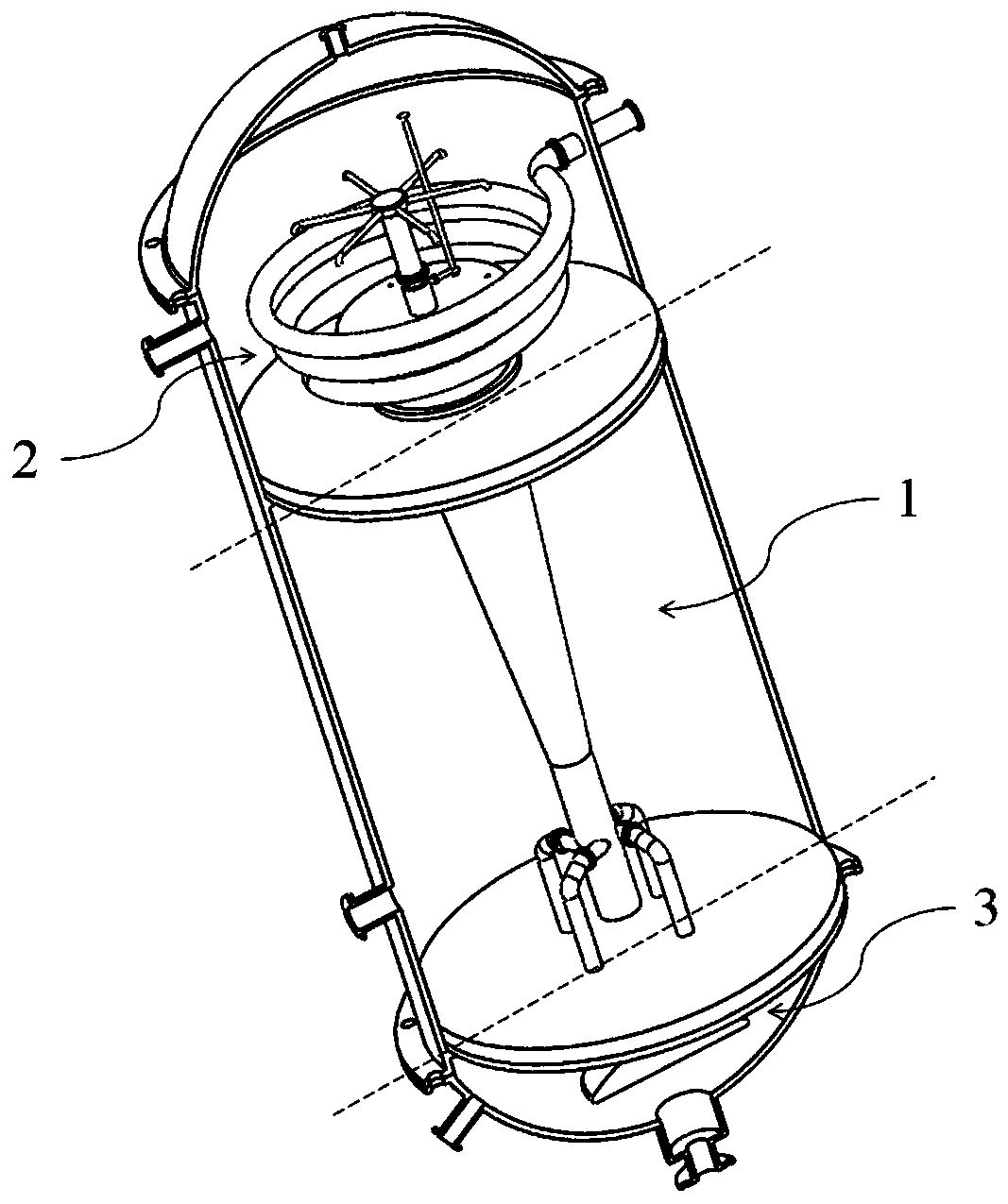

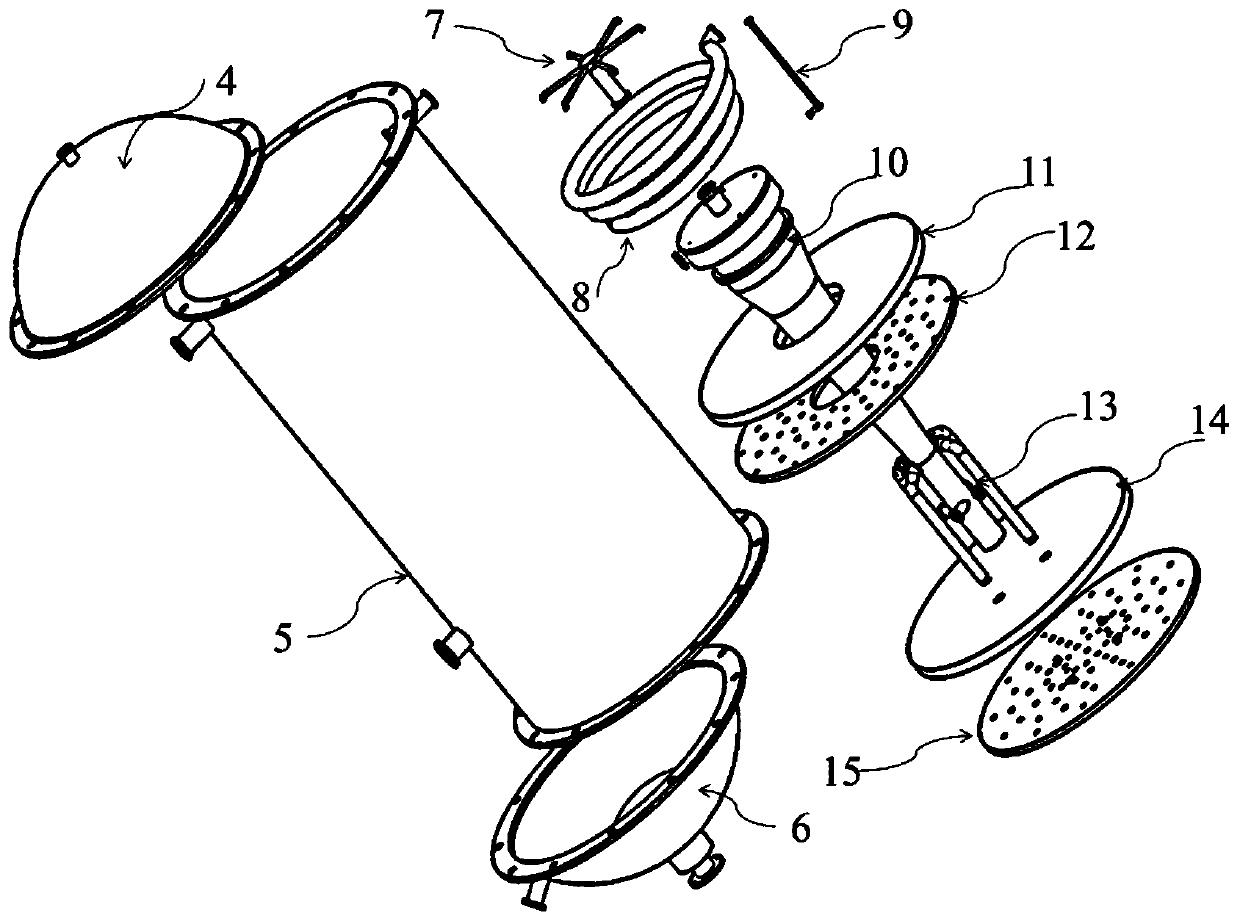

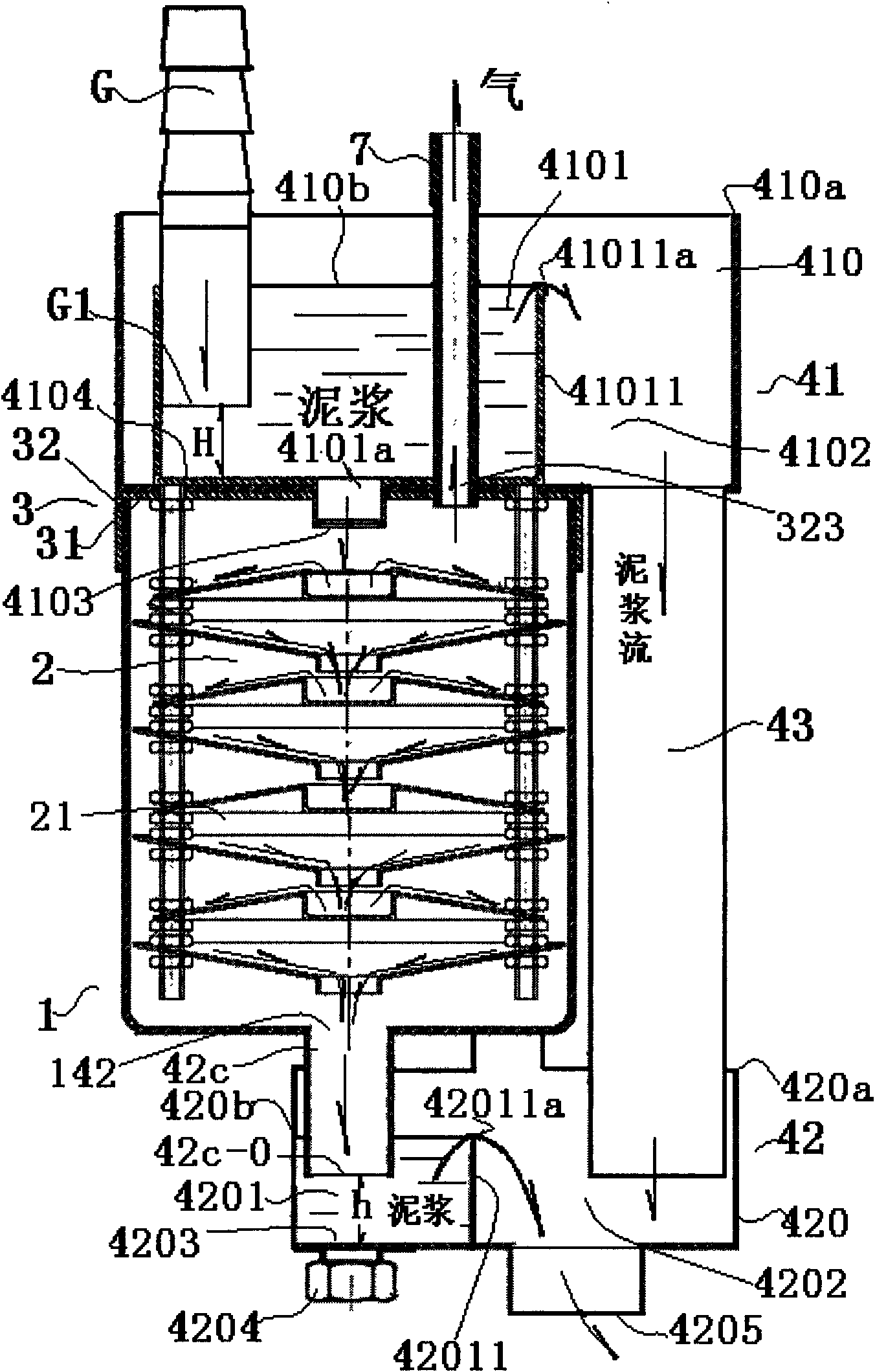

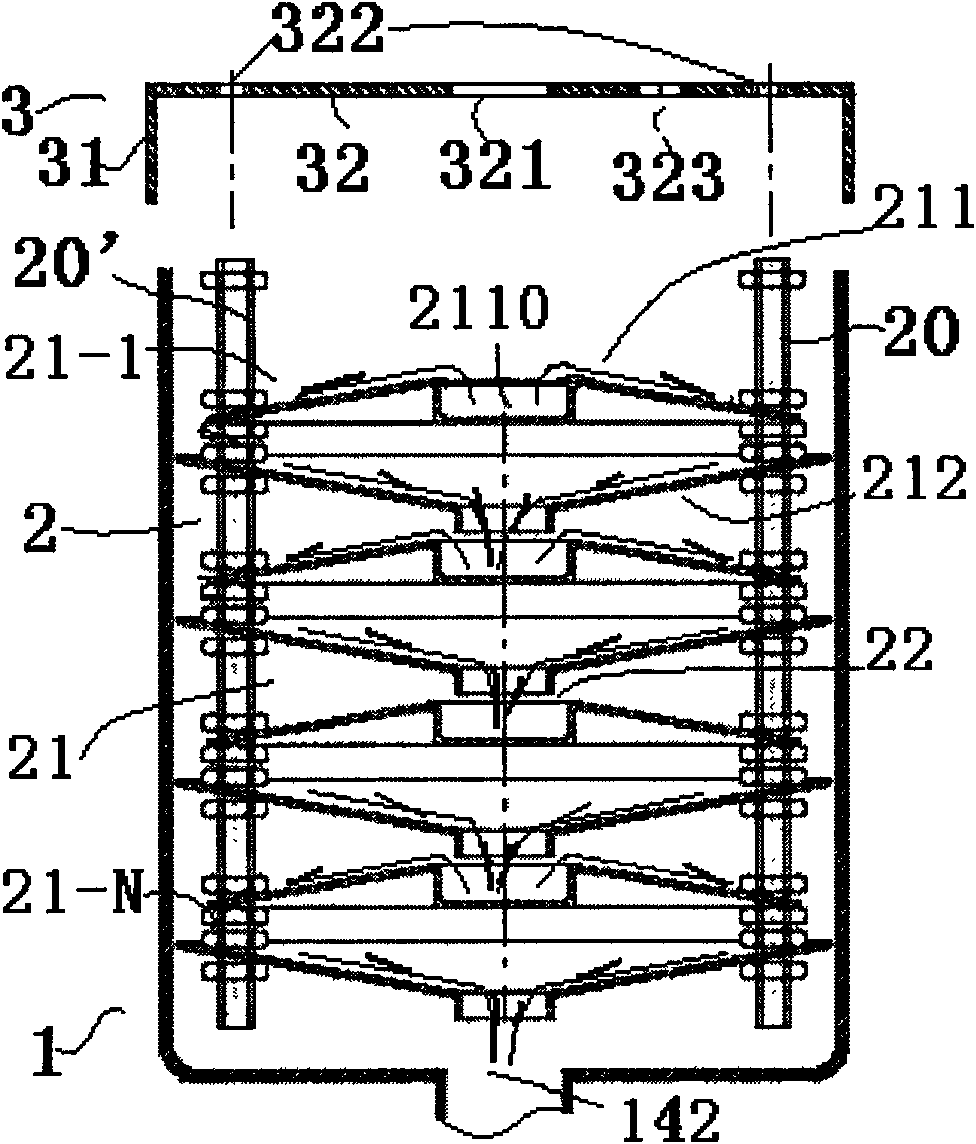

Degasser

ActiveCN102125772AStir wellAvoid it happening againLiquid degasificationBorehole/well accessoriesDegasserSlurry

The invention discloses a degasser, which belongs to the comprehensive logging and gas logging equipment and relates to a device for performing online degassing on the slurry extracted from oil exploration drilling. The degasser is provided with a tank body for containing the slurry and a stirring body, wherein the stirring body is used for extending into the tank body to stir the slurry; the tank body is provided with a slurry inlet and a slurry outlet; the inner cavity of the tank body is set as a level-by-level stirring cavity; the level-by-level stirring cavity is divided into classification chambers by a slurry blocking component in the tank body; the slurry blocking component comprises a first slurry blocking sheet and a second slurry blocking sheet; the first slurry blocking sheet is provided with an outer edge that can be closely combined with the inner wall of the tank body and a channel hole; the outer edge is combined with the tank body; and the channel hole is used for forming a channel of the leakage slurry. The tank body of the degasser is set as a drawer type chamber capable of stirring level by level; and by combining the reasonable configuration of the slurry blocking component, the degasser enables the slurry to be stirred more sufficiently in the stirring chamber of the level so as to realize level-by-level sufficient stirring and level-by-level sufficient degassing.

Owner:天津开发区利达科技发展有限公司

Ventilating air-eliminating refining method of 3104 aluminum alloy flat ingot in casting furnace

The invention relates to a method for degassing and deslag in smelting, more specially, to to a refining method of venting, degassing and deslag in 3104 aluminium alloy flat section ingot casting furnace. The refining method of venting, degassing and deslag in 3104 aluminium alloy flat section ingot casting furnace includes kettle furnace, thirteen air bricks built on the fireproofing structure of the furnace bottom, 13 venting pipelines mounted on the furnace bottom, the said refining method for venting, degassing and deslag is that inert gas or inert mixing gas enters into maintaining furnace through the venting pipelines mounted on the bottom of thirteen air bricks, the inert gas adsorbs the impurity in aluminium liquid and then floats with air bubble up to the surface of aluminium liquid and exhausts to obtain the product. The advantage of the invention is: improving the degassing and deslag efficiency; improving the product quality of aluminium alloy flat section ingot; reducing the defect for casting flat section ingot; shortening the cost for producing flat section ingot, improving the productivity and reducing the flow of gas. The invention is usable for aluminium and aluminium alloy casting industry.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

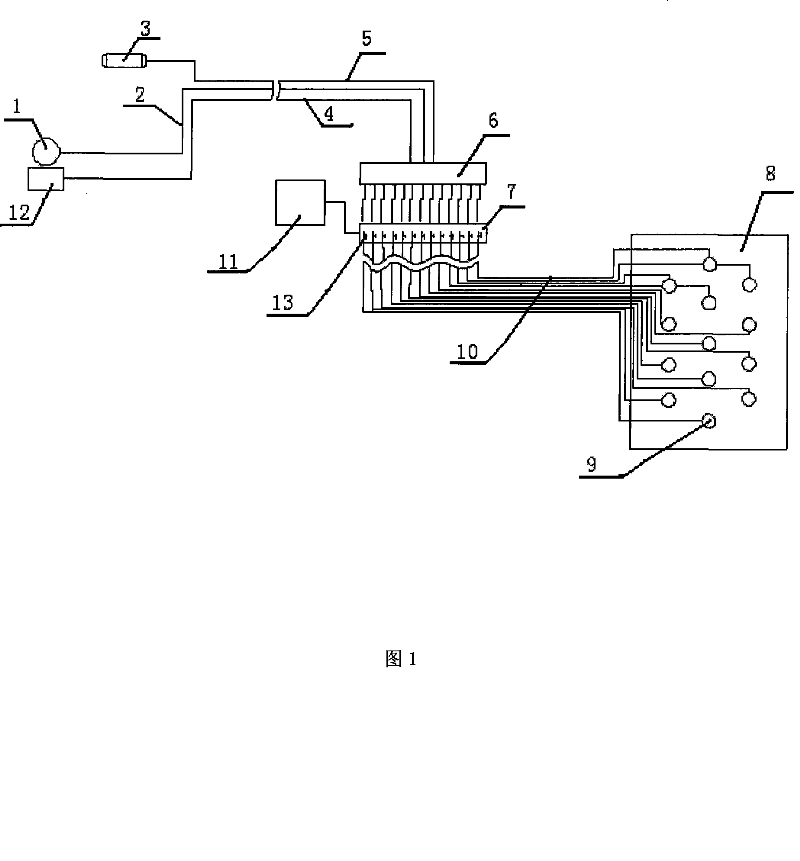

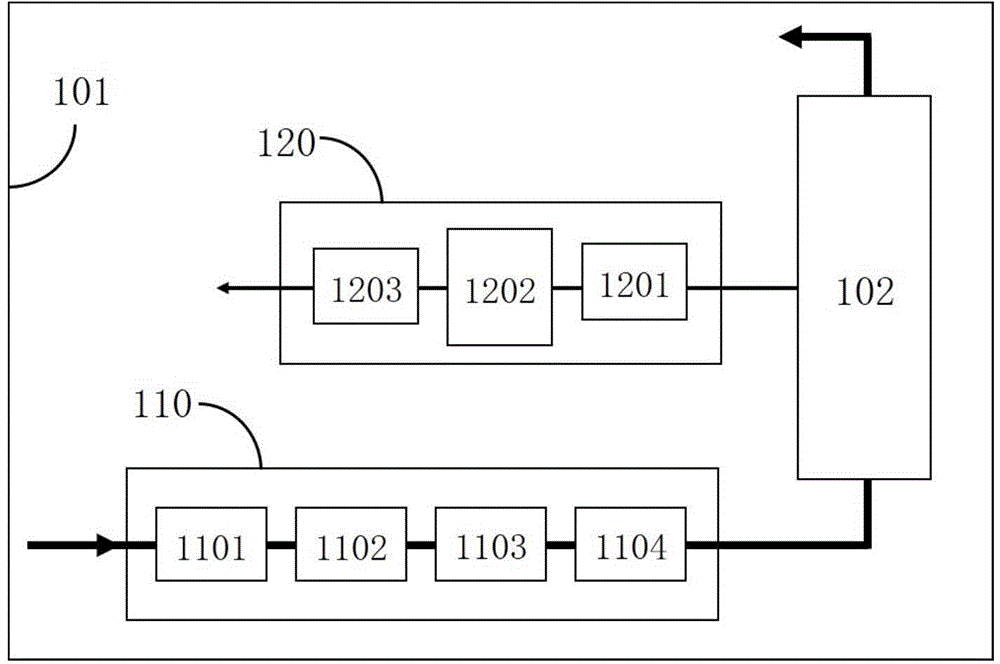

Online transformer oil chromatography monitoring system based on vacuum stirrer

InactiveCN104897816AEffective separationImprove degassing efficiencyComponent separationChromatography columnComputer data processing

The invention discloses an online transformer oil chromatography monitoring system based on a vacuum stirrer. The system comprises a data acquisition unit and a master control computer data processing and fault diagnosis system, wherein the data acquisition unit comprises an oil-gas separator, a chromatographic column, a gas sensor and a CPU (central processing unit), wherein a sampling end of the oil-gas separator is connected with a transformer, an output end of the oil-gas separator is connected to the chromatographic column through a cold trap, an output end of the chromatographic column is connected to the gas sensor, and an output end of the gas sensor is connected to the CPU; the data acquisition unit is connected to the master control computer data processing and fault diagnosis system through a communication network; a vacuum mixing and vibrating degassing device is arranged in the oil-gas separator; a carrier gas generating module is arranged in the data acquisition unit. According to the online transformer oil chromatography monitoring system, a conventional carrier-gas cylinder is replaced with the carrier gas generating module, stable carrier gas is provided for the monitoring system, the data accuracy of the monitoring system is guaranteed, frequent replacement of the carrier-gas cylinder is avoided, and the use is very convenient.

Owner:云南电网有限责任公司文山供电局

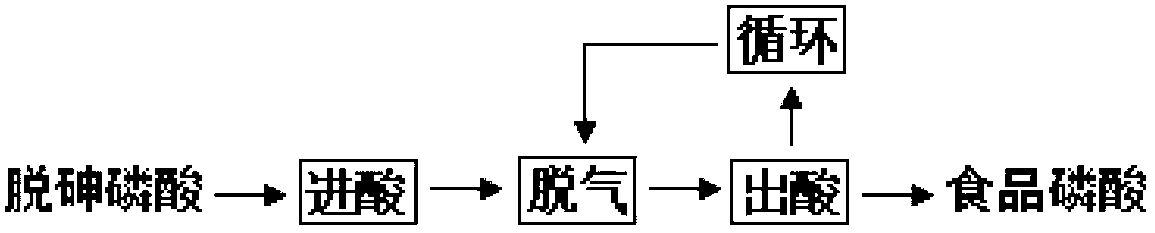

Method for removing hydrogen sulfide of food-grade phosphoric acid

The invention discloses a method for removing hydrogen sulfide of food-grade phosphoric acid. The method comprises the following steps of: vacuumizing at a tower top of a hydrogen sulfide removing tower, enabling clean gas to move from a tower bottom to the tower top, conveying industrial arsenic-removed phosphoric acid to the tower top via a circulating pump, evenly distributing the phosphoric acid via a filler layer of the hydrogen sulfide removing tower and subsequently heating hydrogen sulfide in the phosphoric acid to fully contact with rising gas flow, blowing off the hydrogen sulfide to enable the hydrogen sulfide to enter an arsenic-removing reactor from the tower top, enabling the sulfuretted hydrogen-removed phosphoric acid to fall to the tower bottom, and conveying the sulfuretted hydrogen-removed phosphoric acid to the tower top via the circulating pump for continuously removing hydrogen sulfide or conveying the sulfuretted hydrogen-removed phosphoric acid to a finished product tank to obtain the food-grade phosphoric acid according to the detection situation of the removing effect of the hydrogen sulfide. Through the method, the hydrogen sulfide in the phosphoric acid can be accelerated to fully contact with the rising gas flow, the hydrogen sulfide gas in the phosphoric acid is efficiently removed, the problems of time consumption and energy consumption while repeatedly degassing the sulfuretted hydrogen-removed phosphoric acid via the traditional hydrogen sulfide removing device are solved, the circulation time of the process of removing the hydrogen sulfide is shortened and the degassing efficiency and the production continuity of the food-grade phosphoric acid are enhanced.

Owner:GUANGXI MINGLI CHEM

Degasser and tank body and stirring body thereof

InactiveCN102166490AStir wellImprove securityLiquid degasificationRotary stirring mixersDegasserBiochemical engineering

The invention discloses a degasser and a tank body and a stirring body thereof, relating to a device for on-line degassing of slurry extracted from oil exploration drilling. The degasser is provided with the tank body for accommodating the slurry and the stirring body; the stirring body is used for stretching into the tank body to stir the slurry; the tank body is provided with a slurry inlet anda slurry outlet, wherein the tank body is also provided with a seat body; one end of the seat body connected with an installation plate is provided with a gas collecting chamber; the tank body has anairtight structure; and the airtight structure is composed of a slurry outlet structure and the slurry inlet structure and an induced draught exhaust port. The stirring body is composed of a stirringbody central shaft and a plurality of stirring rods; the stirring body central shaft is connected with a transmission shaft; the stirring rods are fixedly arranged on the stirring body central shaft at a preset interval, and the adjacent stirring rods are vertical to each other. An inner chamber of the tank body is arranged into a stepwise stirring chamber, and the stepwise stirring chamber is partitioned into graded chambers by a slurry blocking assembly arranged in the tank body; and the slurry blocking assembly consists of a first slurry blocking piece and a second slurry blocking piece.

Owner:天津开发区利达科技发展有限公司

System and method for separating and extracting dissolved gas from environmental water

ActiveCN104609583AImprove portabilityAchieve dimmingPreparing sample for investigationTesting waterEnvironmental engineeringEnvironmental water

The invention discloses a system and method for separating and extracting dissolved gas from environmental water. The system is characterized by comprising a water-quality treatment device, a membrane degassing device, a vacuum collection device and a flow control device. The treatment method is characterized by comprising the following steps of firstly removing impurity particles in the environmental water by virtue of the water-quality treatment device, degassing the dissolved gas in the environmental water by virtue of the membrane degassing device and further discharging degassed environmental water; and finally further pumping and collecting the dissolved gas generated in the membrane degassing device into an gas cylinder by virtue of the vacuum collection device. The system disclosed by the invention has the characteristics of low cost, simple operation, high degassing efficiency, convenient carrying and maintenance, low weight, small size and the like, can be carried by single people and has almost no any application limitation on the extreme field environment so that the system is very suitable for extracting dissolved gas from the environmental water.

Owner:INST OF ADVANCED TECH UNIV OF SCI & TECH OF CHINA

Integrated gas-liquid-solid continuous separation device

InactiveCN111318058AMaintain precision separation performanceSimple processLiquid degasificationCentrifugal force sediment separationPhysical chemistryOil water

The invention discloses an integrated gas-liquid-solid continuous separation device. The device comprises an upper sealing cover, an outer cylinder and a lower sealing cover, and the upper sealing cover, the outer cylinder and the lower sealing cover are connected into a whole through flanges. An upper layer, a middle layer and a lower layer are formed in an inner cavity of the outer cylinder, theupper layer is used for storing oil and gas after primary separation, the middle layer is used for storing oil after secondary separation, the lower layer is used for storing sand and water which arefinally separated, and all the layers are separated through perforated sieve plates and oil absorption felts. Mixed incoming liquid is accelerated to enter a cyclone for primary separation through atangential inlet and a spiral pipe type acceleration flow channel, and then is subjected to secondary separation by oleophylic and hydrophobic oil absorption felts, and continuous separation of a multiphase medium is realized. Multi-stage continuous separation is realized based on the combined action of cyclone separation, settling separation and membrane separation, and high-precision continuousseparation of oil-water-sand-gas four-phase media can be achieved in one device.

Owner:NORTHEAST GASOLINEEUM UNIV

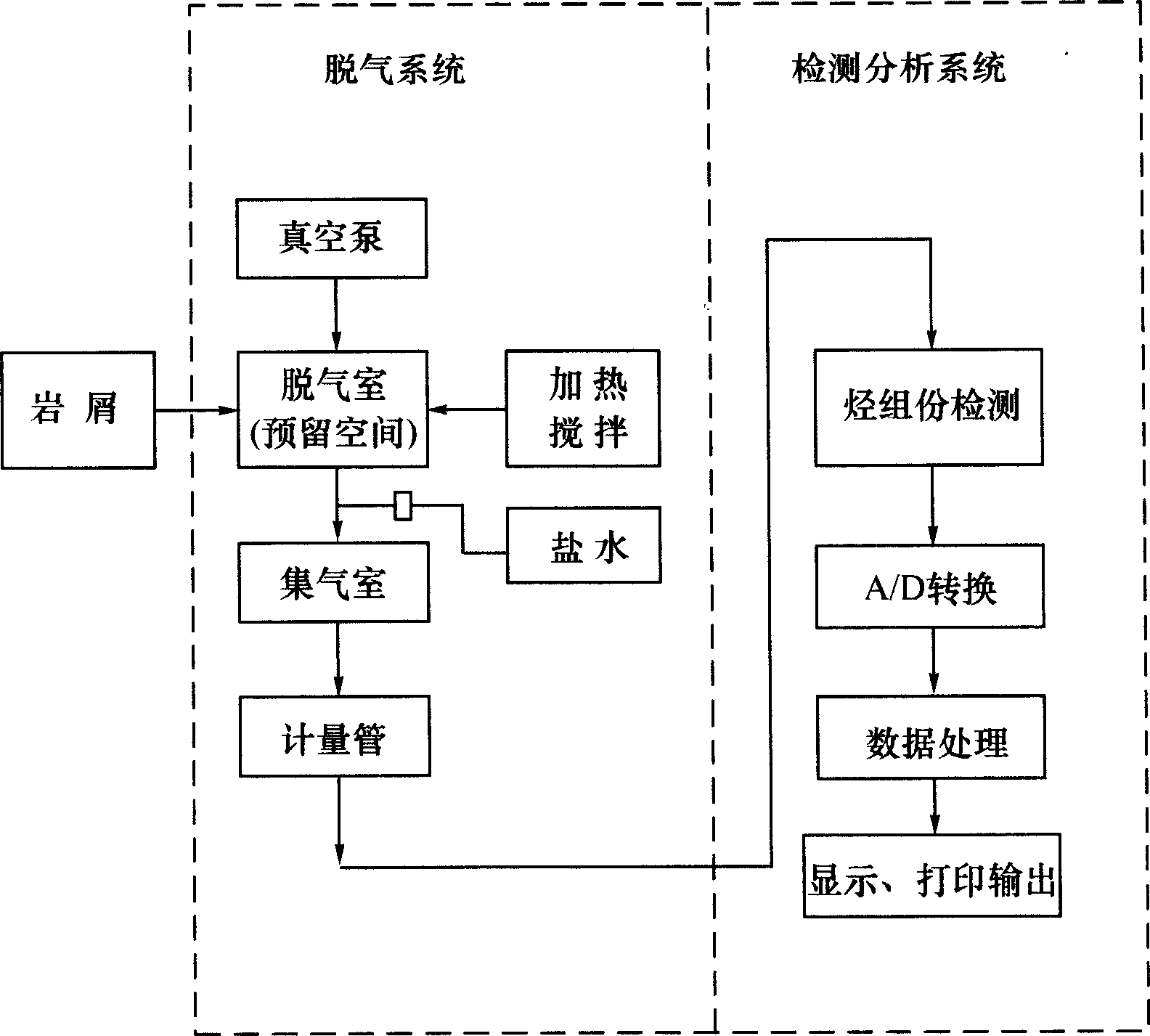

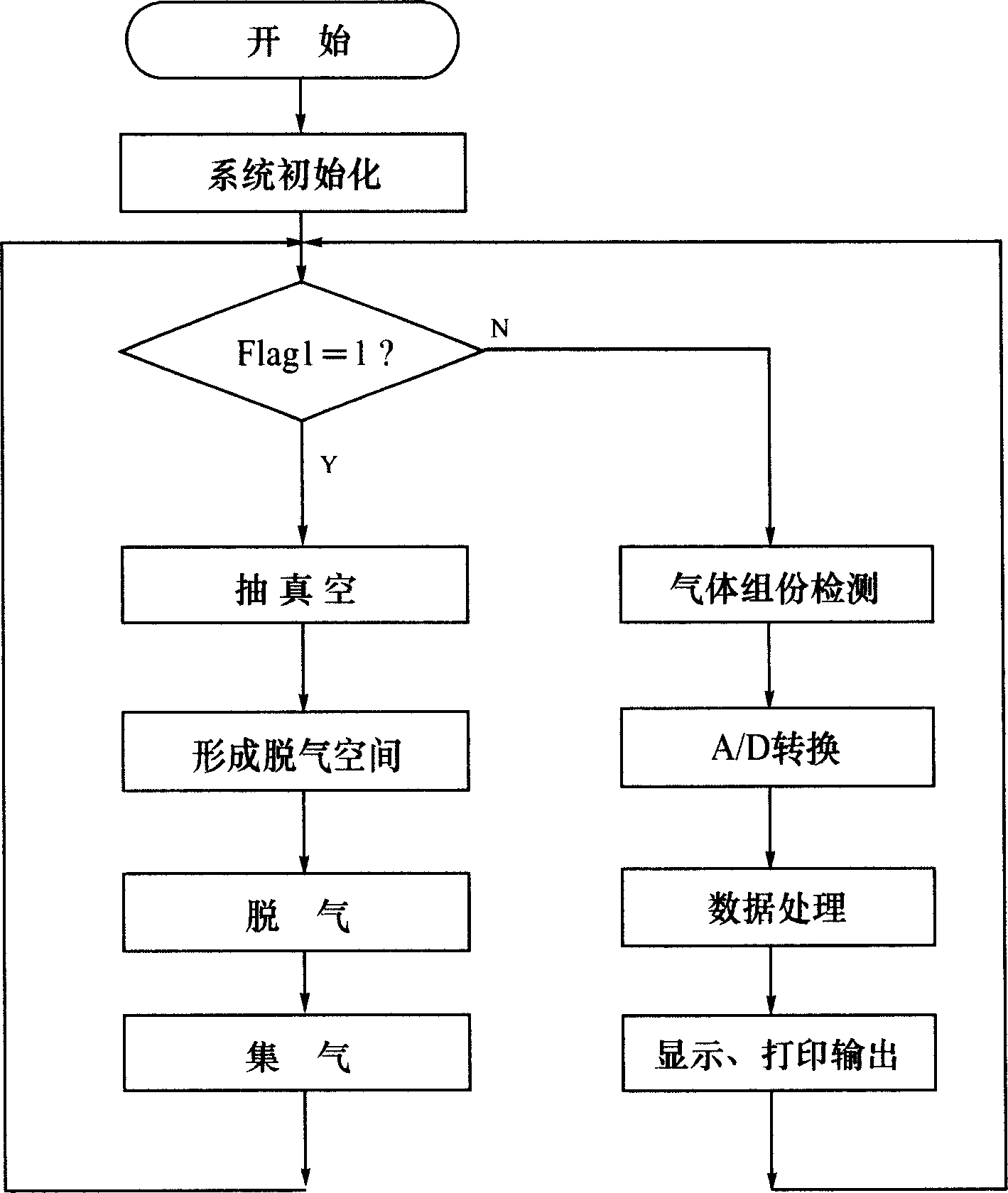

Light hydrocarbon ananlysing method for detecting rock fragments

InactiveCN1598590ASolve the problem of failure of detection and evaluation methods for oil and gas reservoirsSolve the problem of failureWithdrawing sample devicesOptimal controlData acquisition

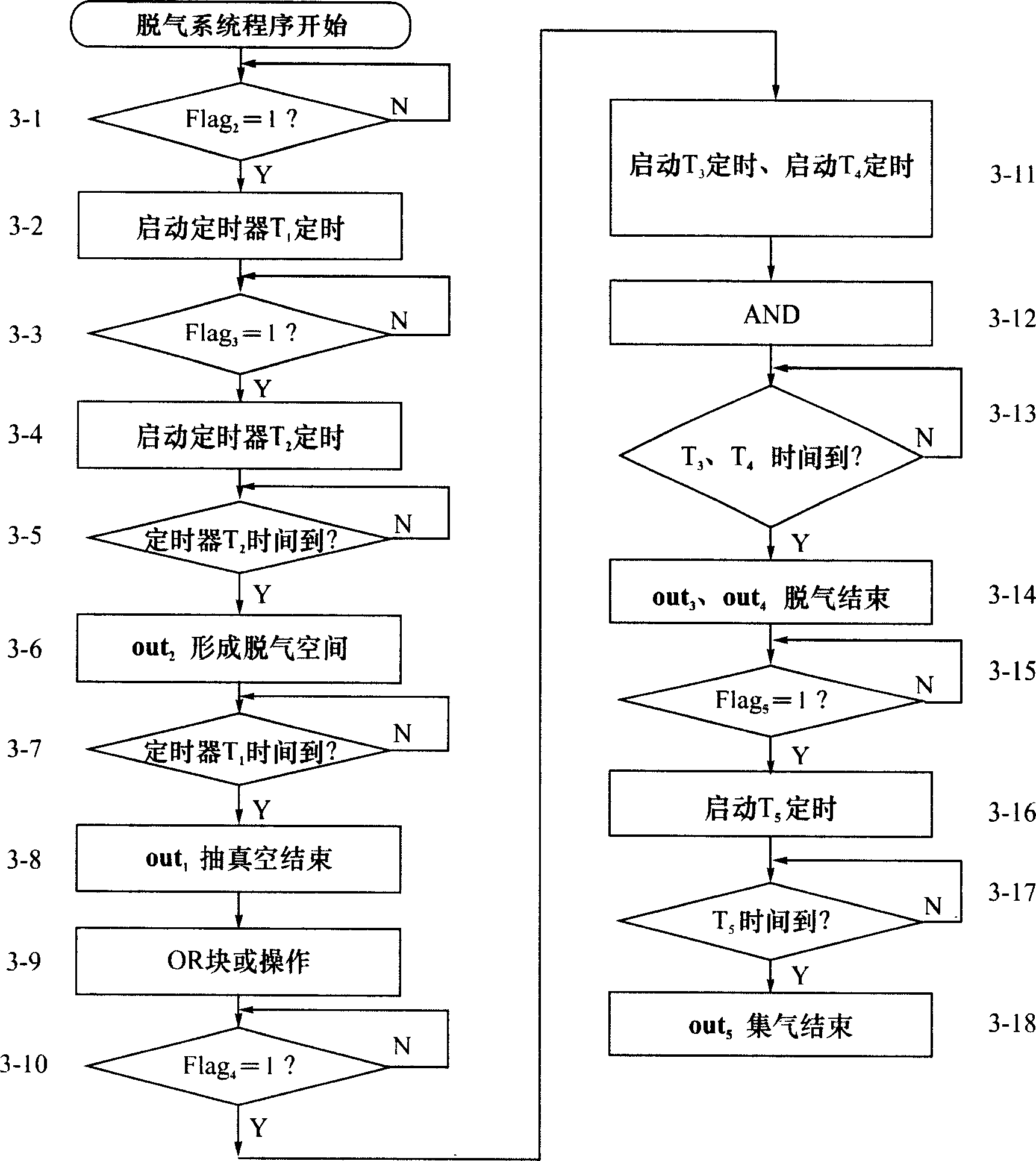

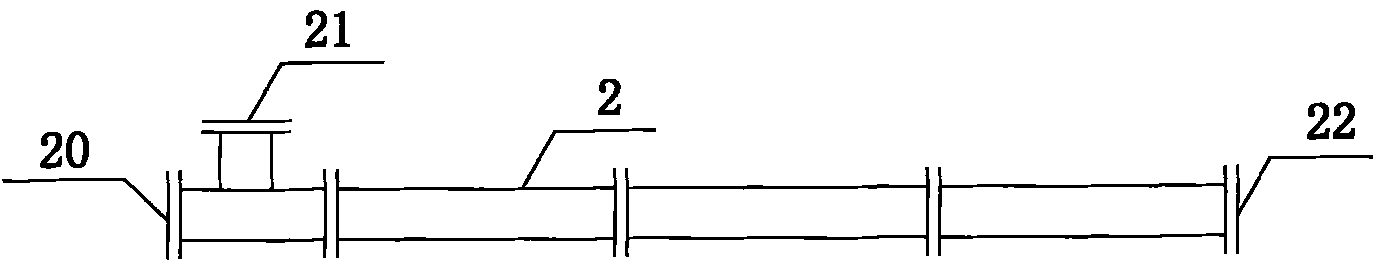

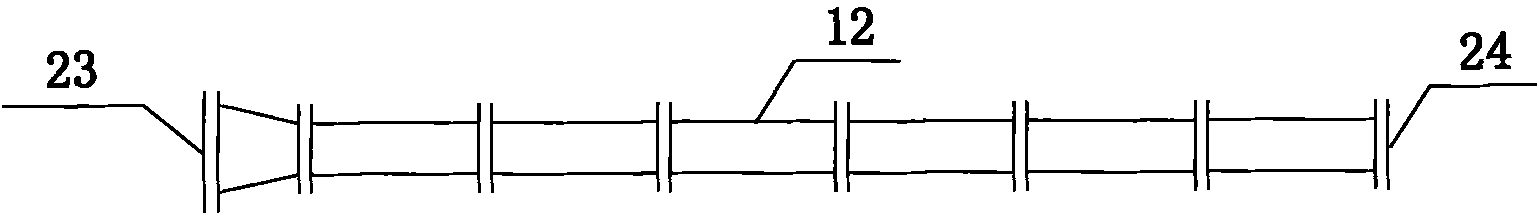

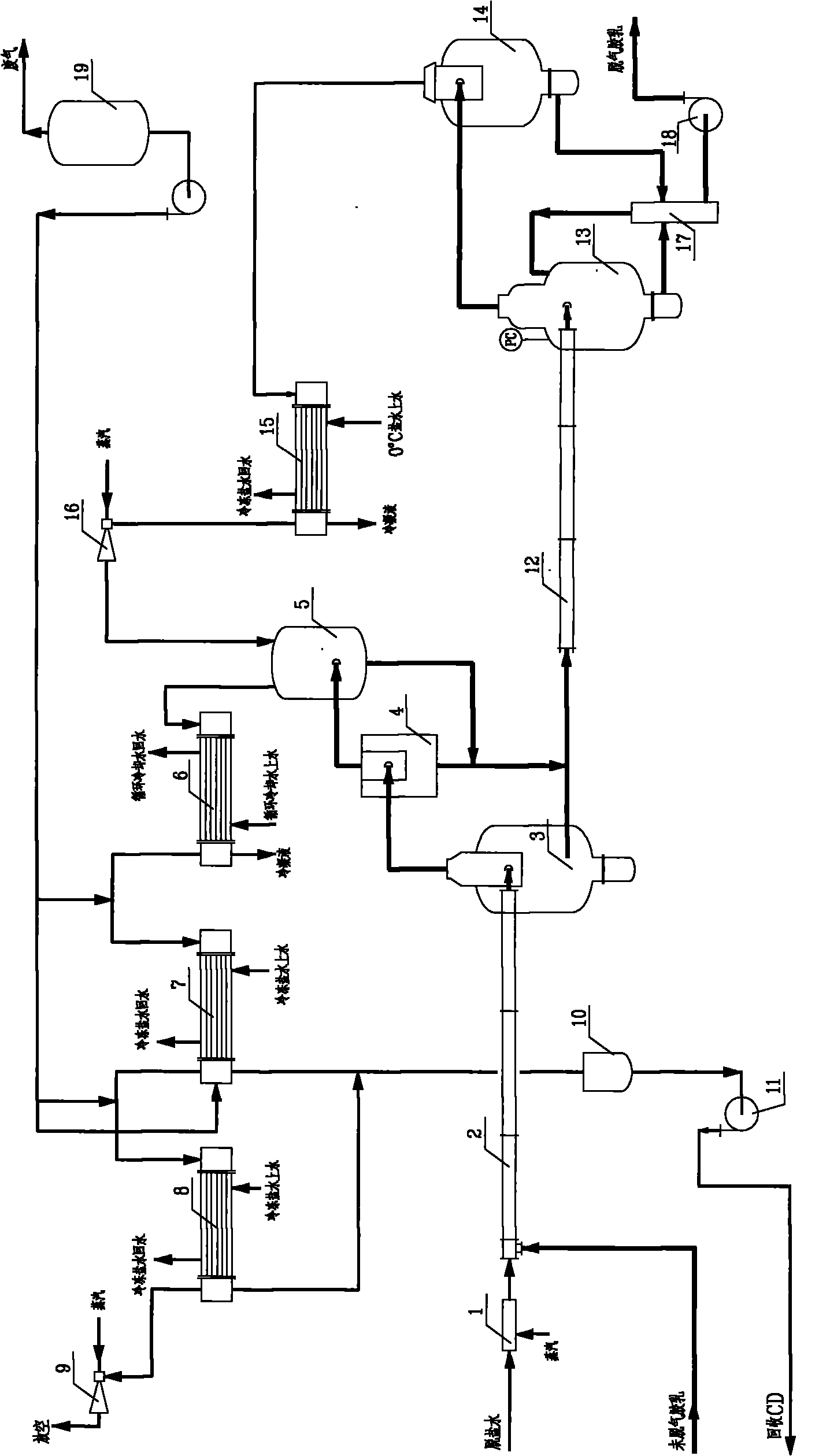

The invention discloses a bore meal detecting light hydrocarbon analysis method. It manages and controls through computer, and runs degassing system program (vacuumizing, forming degassing space, degassing, collecting gas process, and degases from bore meal) and detecting analysis system program ( detecting gas groups, A / D transferring, data collecting, and data dealing, displaying and printing gas groups). The invention applies the logging light hydrocarbon group method in earth logging. The invention solves the difficult problem of evaluating hydrocarbon reservoir method, because of using PDC aiguille, in traditional earth logging detecting method; and achieves the interlocking logical controlling of complex controlling loop and optimum controlling in program step control by the usage of computer, makes the whole process, including degassing, collecting gas, sending gas and measure, be full automatic, conquers all kinds of faults of traditional manual operation, completely removes man made factor and air influnces.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

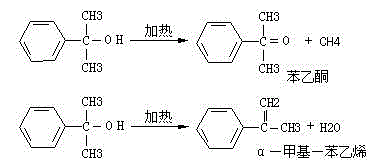

Degassing technology in synthetic process of neoprene

InactiveCN102120789AThe amount of non-condensable gas decreasesImprove heat transfer efficiencyLiquid degasificationNeopreneToluene

The invention discloses a degassing technology in the synthetic process of neoprene. The technology comprises the following steps: neoprene latex with chloroprene monomer enters a first-stage degassing pipe; under the vacuum condition, steam and neoprene latex enter a first-stage separator after steam stripping to obtain first-stage separated gas and first-stage separated neoprene latex; the first-stage separated gas enters a second-stage separator to obtain second-stage separated gas and second-stage separated neoprene latex, the second-stage separated gas enters a third-stage separator to obtain third-stage separated gas and third-stage separated neoprene latex, the third-stage separated gas passes through a water condenser, a chloroprene recycling condenser and a tail gas condenser so that water, chloroprene monomer and toluene are condensed, tail gas is sucked in a first-stage ejector, the ejector is emptied; the first-stage separated neoprene latex, the second-stage separated neoprene latex and the third-stage separated neoprene latex are mixed to enter a second-stage degassing pipe, the mixed gas is flashed under high vacuum degree and then performs first-stage separation twice to obtain final neoprene latex and twice separated gas; the twice separated gas enter first-stage separation twice to obtain final separated gas and final neoprene latex; and the final separated gas is cooled, is sucked by a second-stage ejector and enters a third-stage separator. The process disclosed by the invention has high degree of degassing and high monomer recovery rate which can be more than 90%, the process has low energy consumption; and by adopting the process, the quality of the neoprene product can be increased.

Owner:SEDIN ENG

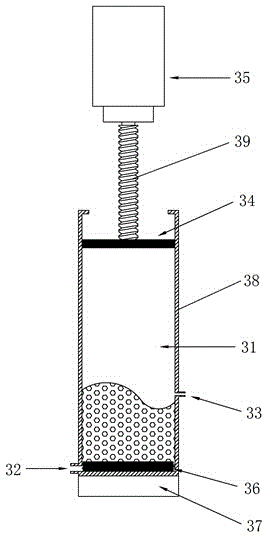

Degassing and dehydrating miniature device for transformer oil

ActiveCN103901333AImprove degassing efficiencyImprove work efficiencyElectrical testingPropellerVacuum pressure

The invention relates to a degassing and dehydrating miniature device for transformer oil. An oil storage tank is connected with a telescopic degassing tank through a three-way electromagnetic valve and a single-pass electromagnetic value B. The telescopic degassing tank is connected with a vacuum buffer tank through a single-pass electromagnetic valve C. The vacuum buffer tank is connected with a vacuum pump through a single-pass electromagnetic valve D. A sampler is connected with the three-way electromagnetic valve through the single-pass electromagnetic valve A and a thin-film filter. An ultrasonic vibrator is fixed at the lower part of a base of the telescopic degassing tank. The telescopic degassing tank is placed in a temperature-controllable air bath. The upper part of the telescopic degassing tank is connected with an electrical repeated propeller through a connection rod. A pressure sensor is installed on a connection pipe of the telescopic degassing tank and the single-pass electronic valve B. A temperature sensor is installed in the air bath. A vacuum pressure sensor is installed on the vacuum buffer tank. The degassing and dehydrating miniature device for the transformer oil uses combination of the electrical repeated propeller, the telescopic degassing tank and the ultrasonic vibration to perform vacuum degassing and dehydration on samples so that degassing efficiency is improved and degassing speed is high.

Owner:PETROCHINA CO LTD

Preparation method of poly(p-phenylene benzobisoxazole) fibers

ActiveCN112760737AReduce accumulationReduce decreaseMonocomponent synthetic polymer artificial filamentFiberSpinning

The invention belongs to the field of high-performance fibers, and particularly relates to a preparation method of poly(p-phenylene benzobisoxazole) fibers. The preparation method comprises the following steps of taking frozen polyphosphoric acid powder, phosphorus pentoxide, 4,6-diaminoresorcinol hydrochloride and terephthalic acid as raw materials, putting the phosphorus pentoxide into a reaction system step by step in a reasonable proportion in a proper time period, and detecting and regulating the apparent viscosity of the materials in real time in a prepolymerization process to ensure that a prepolymer with uniform apparent viscosity is obtained; performing post-polymerization to obtain PBO spinning slurry; and performing dry-jet wet spinning and post-spinning to obtain the finished PBO fibers. The method overcomes the defects that traditional solid raw materials are poor in solvent mixing and dispersing effect, easy to agglomerate and incapable of uniformly reacting, ensures the consistency of a prepolymerization reaction end point, and reduces the process errors. The intrinsic viscosity of the polymer in the same batch in different time periods is small in change and high, the mechanical property of the fibers can be obviously improved, and the quality stability is also improved.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

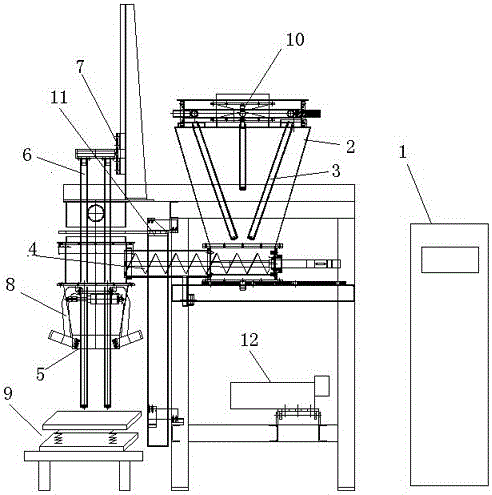

Degassing packaging machine

The invention relates to a degassing packaging machine. The degassing packaging machine comprises an electric control cabinet, a driving motor and a stock bin; the stock bin is internally provided with a first micro-pore degassing rod; the bottom of the stock bin is connected with a discharging hole through an air exhausting packing auger; a second micro-pore air exhausting rod vertically runs through the discharging hole; the second micro-pore air exhausting rod is connected with an air exhausting hoisting mechanism; a bag clamping device is further arranged at the discharging hole; and a vibration device is arranged at the lower part of the discharging hole. The packaging machine is used for automatically carrying out a plurality of times of degassing on materials and effectively reducing the air between the materials, so that the compactedness of the materials is increased; and the packaging machine has the advantages of high automatic degree, high degassing efficiency, capability of being adaptive to ultra-light materials and materials with relatively great gas content, and wide applicable range.

Owner:JIANGSU INNOVATIVE PACKAGING TECH CO LTD

Passive degasser

ActiveCN102133490AGuaranteed accuracyGuarantee the true gas contentLiquid degasificationWithdrawing sample devicesPetroleumEngineering

The invention provides a passive degasser relating to a device for on line detaching gas in slurry lifted during oil exploration drilling, which is particularly suitable for the passive degasser. The passive degasser comprises a pot body, wherein the pot body is provided with a slurry inlet and a slurry outlet; the upper part of the pot body is the slurry inlet end; the lower end of the pot body is the slurry outlet end; and a slurry treatment body is arranged in the pot body. In the invention, the slurry treatment body is arranged to disperse and degas the slurry to be treated, and under a circumstance of having no power source drive, the slurry can be further diffused, that is fully dispersed, therefore, the degassing efficiency is effectively increased; and an airtight construction is arranged on the pot body to ensure that the slurry can be under an airtight condition in the whole degassing process of the degasser and all the gases collected by a sample air pump are the gases detached in treating the slurry in the pot body so as to provide guarantee for the accuracy of sample gas collecting data and for detecting the true gas content of a stratum.

Owner:天津港保税区鑫利达石油技术发展有限公司

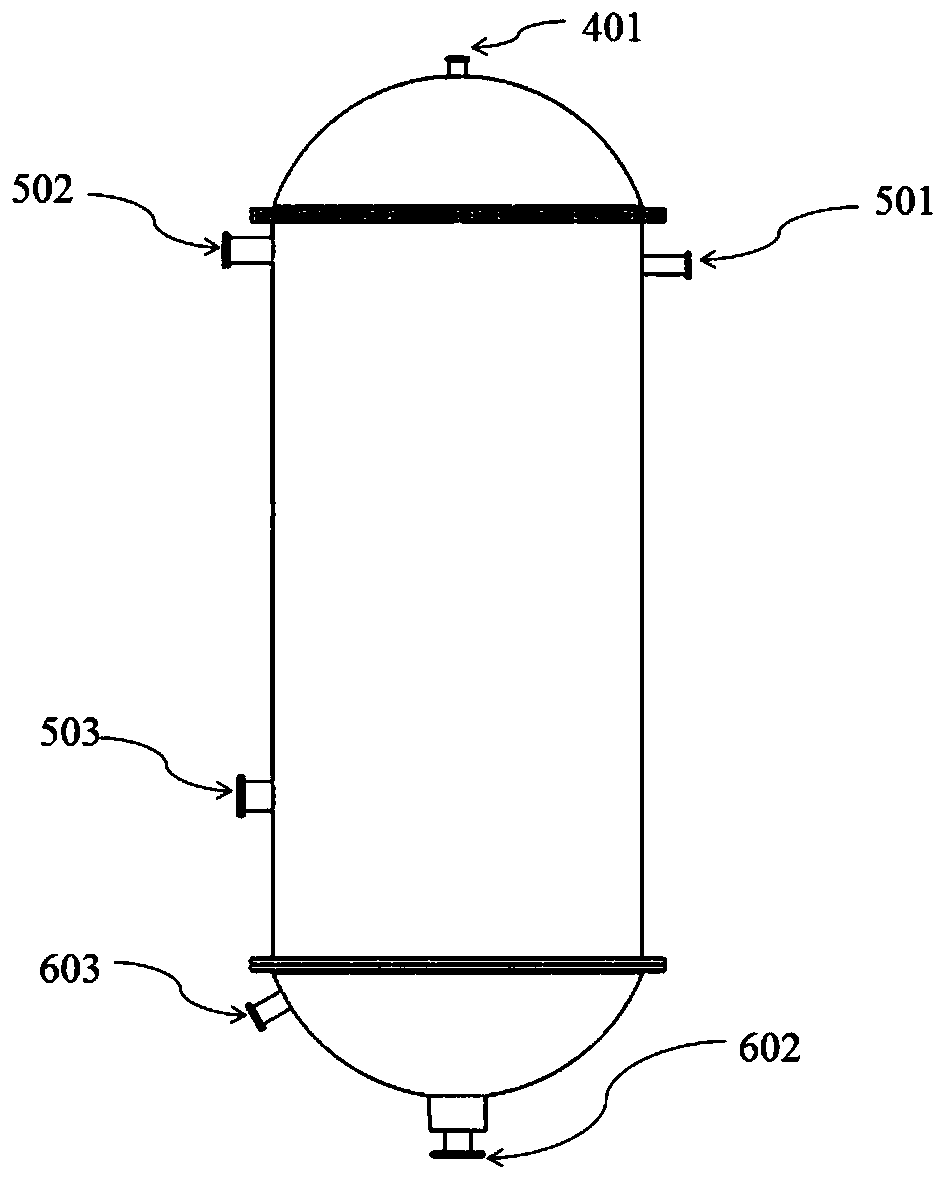

Air removal device for water tunnels

InactiveCN104174188AAvoid Cavitation Cavitation HazardsImprove degassing efficiencyLiquid degasificationPumping vacuumWater use

The invention discloses an air removal device for water tunnels, which increases the flow velocity of water and reduces the pressure of water through gravity settling and vacuumizing and by using an orifice air removal generator, so that air dissolved in the water is expanded into bubbles from air cores at low pressure, and the bubbles dissolved in the water quickly emerge from the water, thereby achieving air-liquid separation. Upper and lower barrel bodies are connected by a flange plate, a cover plate is fixedly connected with the upper barrel body, the cover plate is provided with a water inlet pipe communicated with a sleeve, the sleeve is fixed at the middle position of the downside of the cover plate, a first-level orifice is arranged at the bottom of the sleeve, a second-level orifice and a three-level orifice are fixed below the sleeve, a cleaning tube and a vacuumizing tube are located on both sides of the water inlet pipe and communicated with the upper barrel body, a discharge pipe is arranged on a chassis, and a water outlet pipe is located on one side of the lower barrel body. The air removal device can quickly carry out air removal on a large amount of experimental water for water tunnels, thereby avoiding cavitation and erosion hazards caused by air contained in the water in the process of experiments. The air removal device can be applied to the removal of air contained in oil and the air removal of water for air conditioning circulation.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

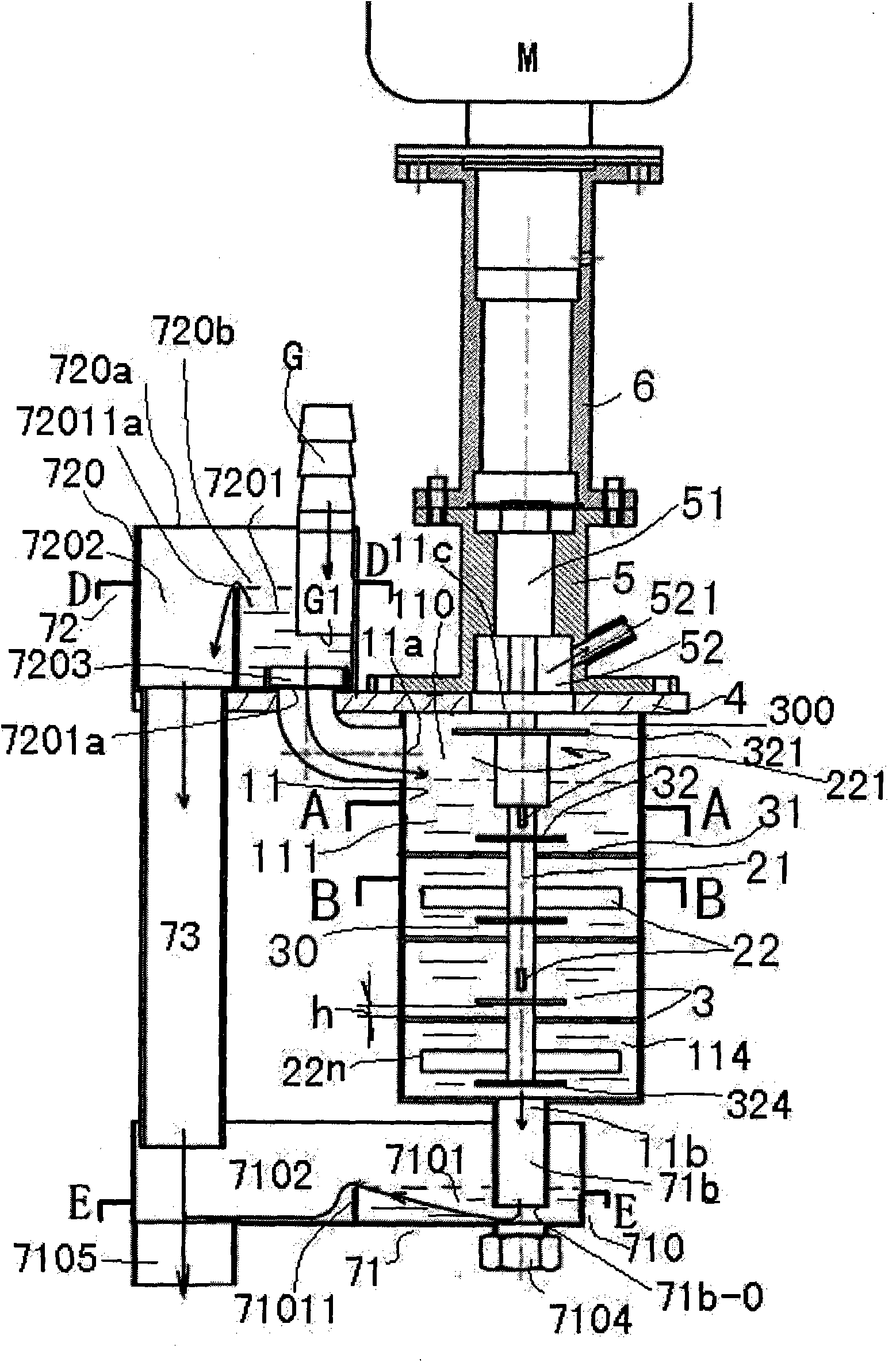

Combined Degassing and Circulation of Liquid

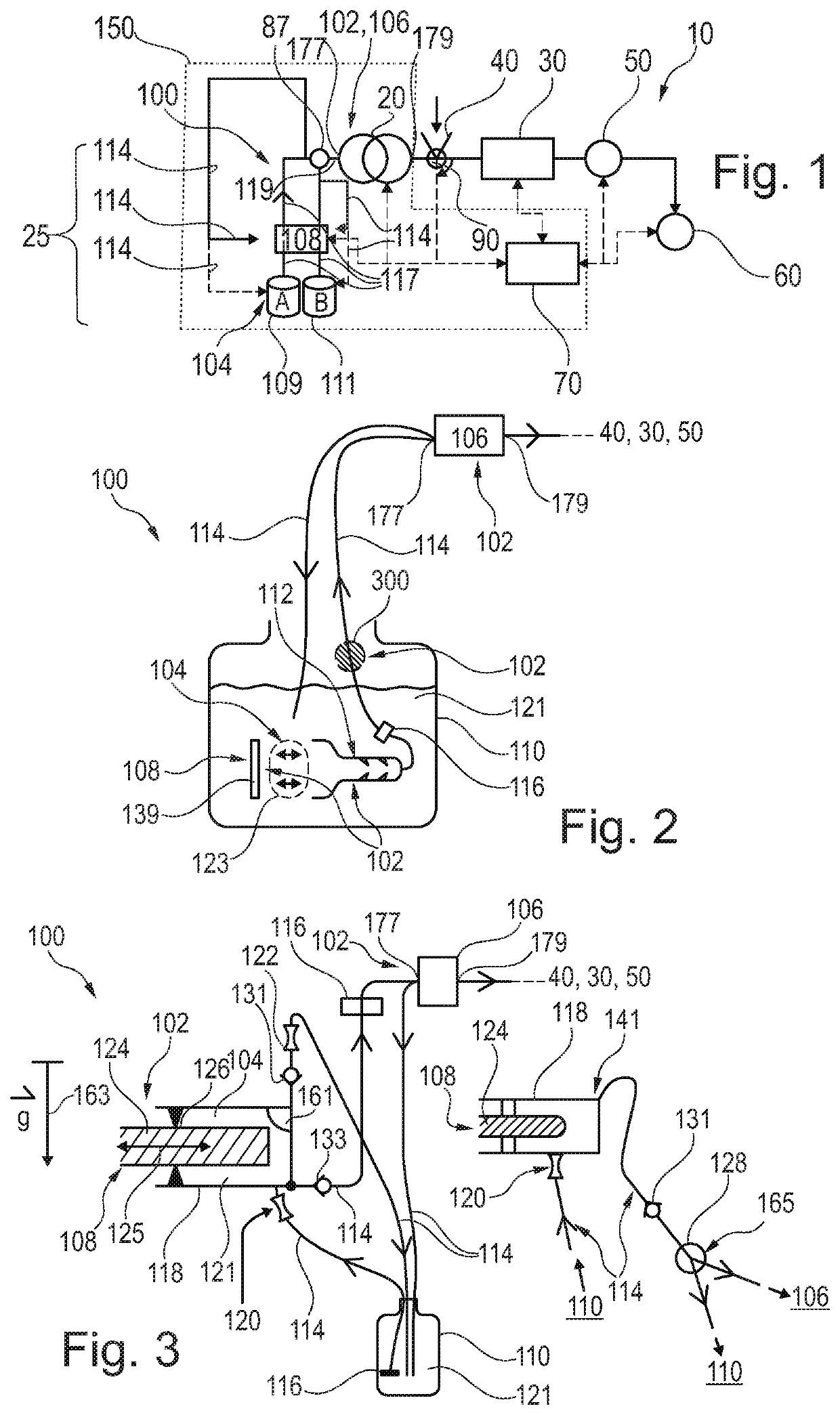

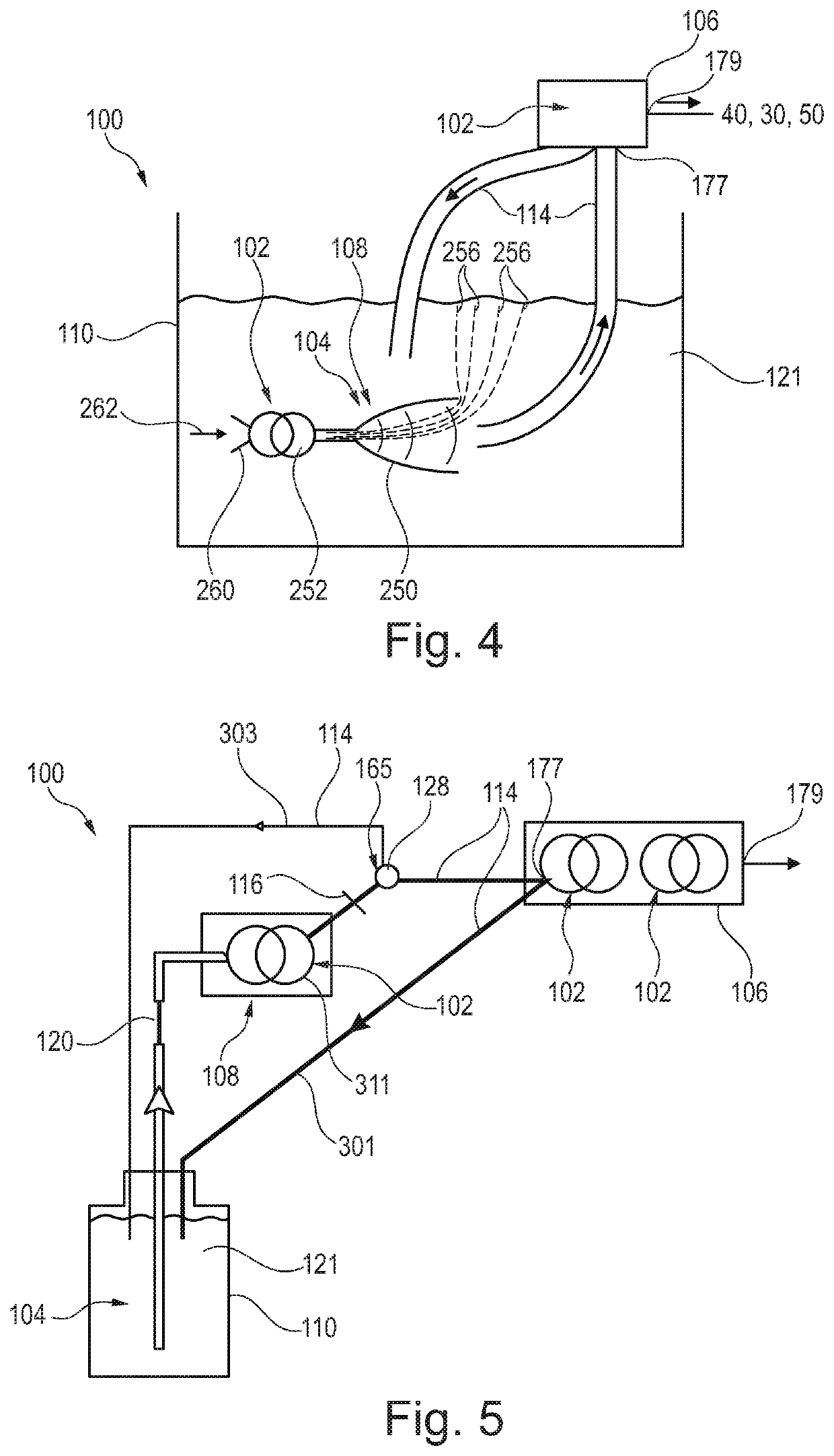

PendingUS20200246724A1Effective degassingEfficient separationComponent separationSolid sorbent liquid separationDegasserConsumer unit

A degasser for at least partially degassing a gas-containing liquid, in particular for a sample separation device, includes a circulation path along which the liquid can be circulated between a liquid accommodation volume and one of an inlet to a consumer unit consuming degassed liquid or a conduit leading to the inlet, a drive unit configured for circulating the liquid in the circulation path, and a filter in the circulation path for filtering particles or debris out of the liquid, wherein the liquid is forced through the filter by the drive unit. The drive unit includes a movable body, in particular a movable piston or a movable membrane, configured for at least partially degassing the liquid by generating a negative pressure in the liquid.

Owner:AGILENT TECH INC

Full-automatic deflating machine for plastic balls

ActiveCN105233478ARealization of automatic ball loadingReduce labor intensityHollow inflatable ballsElectric machineryDrive motor

The invention relates to a full-automatic deflating machine for plastic balls, characterized by comprising a valve nozzle finding mechanism, a deflating mechanism and a ball charging drive mechanism. The valve nozzle finding mechanism has a pair of plastic ball clamp arms. The deflating mechanism is used for deflating a plastic ball. The ball charging drive mechanism is used for driving the plastic ball clamp arms to reciprocate between a plastic ball channel exit and the deflating mechanism to hand over the plastic ball. The full-automatic deflating machine has the advantages that a ball charging mechanism drives the valve nozzle finding mechanism to move to the plastic ball channel exit, the plastic ball clamp arms and a rotary clamp head clamp the plastic ball, a valve nozzle on the plastic ball is automatically found through the fitting of a clamp arm rocking mechanism of the valve nozzle finding mechanism, a valve nozzle photographic recognition component and a rotary drive motor, the ball charging mechanism inserts the plastic ball onto the deflating mechanism, and thus the plastic ball is automatically deflated.

Owner:南通智晶塑料制品有限公司

Charge type vacuum oil filter

InactiveCN103055595AImprove dehydration efficiencyImprove degassing efficiencyFiltration circuitsCharge typeEngineering

The invention discloses a charge type vacuum oil filter which comprises an oil loop and a heat conduction oil loop, wherein the oil loop comprises an oil tank for containing oil, a heat exchanger A, an atomizer, a vacuum chamber and an oil pipeline; the heat conduction oil loop comprises a heating tank for containing heat conduction oil, a heat exchanger B and a heat conduction oil pipeline; a heating tube is arranged inside the heating tank; the heat exchanger A is positioned inside the heating tank; and the heat exchanger B is positioned inside the vacuum chamber and below the atomizer. The charge type vacuum oil filter provided by the invention adopts a heat conduction oil indirect low-temperature heating technique, and the oil is heated by using the heat exchanger A, so that damage caused by the fact that the oil is directly heated at high temperature is avoided; the heat exchanger B is used as a reactor to further heat the oil, and the oil mist sprayed on the reactor is formed into an oil film, so that the working efficiency is greatly improved; due to an additionally arranged charging flow mixer and a collector, the filtering precision is improved; and due to an additionally arranged air humidity sensor, the moisture of the oil can be detected on line.

Owner:昆山威胜达环保设备有限公司

66-500kv crosslinked cable short-degassing online treatment process

ActiveCN104979051AFast degassing rateGood effectInsulating conductors/cablesElectrical conductorNitrogen

The invention discloses a 66-500kV crosslinked cable short-degassing online treatment process. A process flow comprises conductor preparing; three-layer co-extruding and insulating and online degassing; and degassing in a drying room, wherein the step of three-layer co-extruding and insulating and online degassing specifically comprises three-layer co-extruding of a conductor shielding layer, an insulating layer and an insulating shielding layer; crosslinking; cooling; secondary heating; and cooling; the secondary heating is carried out under protection of nitrogen atmosphere, the nitrogen concentration of the nitrogen atmosphere is controlled over 98%, the nitrogen temperature is controlled at 220+ / -5 DEG C, and the conductor temperature is controlled at 90 DEG C. According to the 66-500kV crosslinked cable short-degassing online treatment process disclosed by the invention, the insulating layer is not aged during degassing, the degassing rate is high, the byproduct removal effect is good, the degassing time of the drying room can be greatly shortened, the production period is shortened, and energy is saved and emission is reduced.

Owner:浙江万马股份有限公司

Continuous process for the production of moisture-cure, polyurethane sealants and adhesives

ActiveUS8734609B2High surface area-to-volume ratioMinimization requirementsOrganic non-macromolecular adhesiveCellulose adhesivesChemical reactionAdhesive

A process for continuous manufacturing of moisture-curable polyurethane formulations used as sealants and adhesives. The process is characterized by the fact that the reactive components are introduced independently, and without the need for a prepolymer, to a mixer. Solid or liquid raw materials can be either pre-blended or fed directly to the mixer, a twin-screw extruder, which provides the requisite energy to homogenously mix the raw materials and drive the chemical reaction. The process is designed so that the extruder barrel and screw allow variable feed addition and heat exchange down the length of the machine. This allows various operations to be performed at different points in the extruder, including reaction, dispersive mixing, distributive mixing and devolitization.

Owner:BOSTIK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com