High-concentration vacuum oil-gas separation device and method for online monitoring transformer oil

A transformer oil and separation device technology, applied in measuring devices, material separation, instruments, etc., can solve problems such as low gas utilization rate, high failure rate, and large environmental impact, so as to improve sampling efficiency, solve high failure rate, The effect of short degassing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

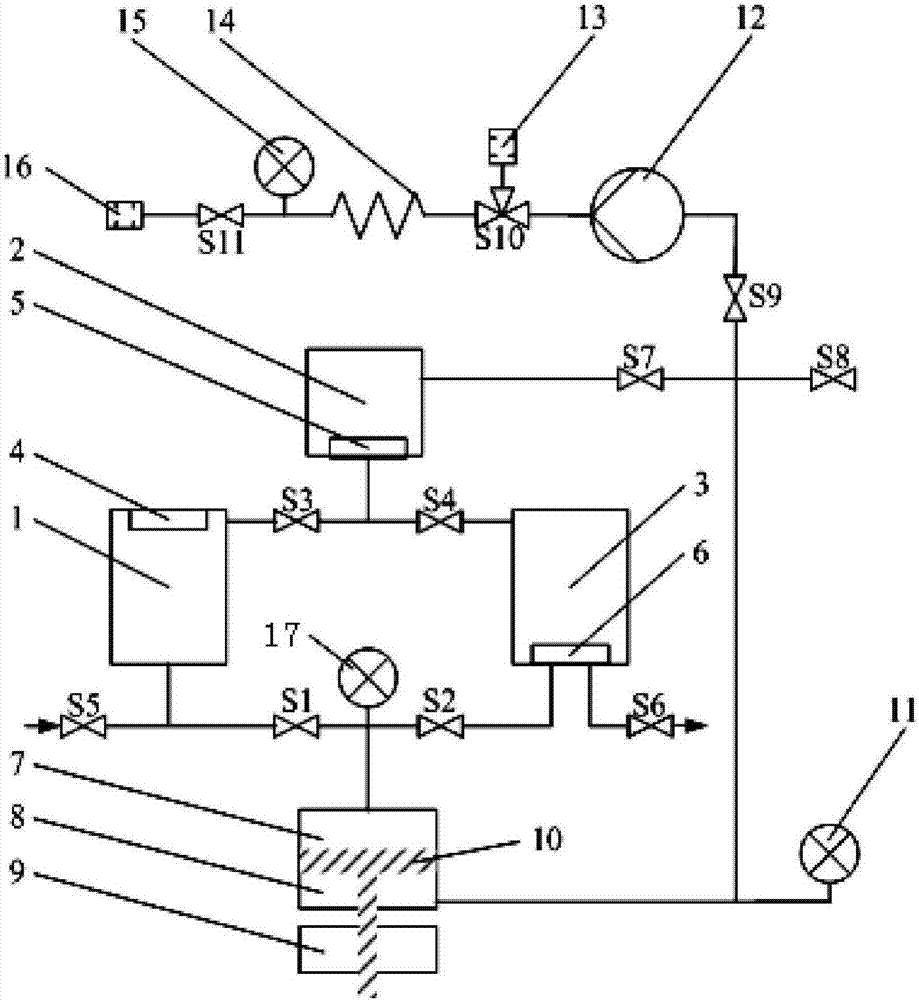

[0030] The present invention will be further elaborated below in conjunction with the accompanying drawings of the description.

[0031] Such as figure 1 As shown, a transformer oil online monitoring high-concentration vacuum oil-gas separation device of the present invention has a quantitative chamber 1, a gas well 2, an oil well 3, a degassing chamber 7, a gas collection chamber 8, a quantitative pipe 14, a vacuum-resistant air pump 12, and a driving motor 9 and the pipelines connecting the above components, wherein the gas collection chamber 8, the vacuum-resistant air pump 12, and the quantitative tube 14 form the gas path part of the vacuum degasser; the lower end of the quantitative chamber 1 is respectively connected to the oil outlet of the transformer oil tank and the degassing chamber 7 , the upper end is connected to the gas well 2; the upper end of the gas well 2 is connected to the gas collection chamber 8, and the lower end is connected to the upper end of the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com