Lubricating grease film degassing film generating device

A film generating device and a technology for lubricating grease, applied in the direction of lubricating composition, etc., can solve the problems of long degassing time, low efficiency, lowering product grade, etc., and achieve large degassing surface area, good degassing effect, and short degassing time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

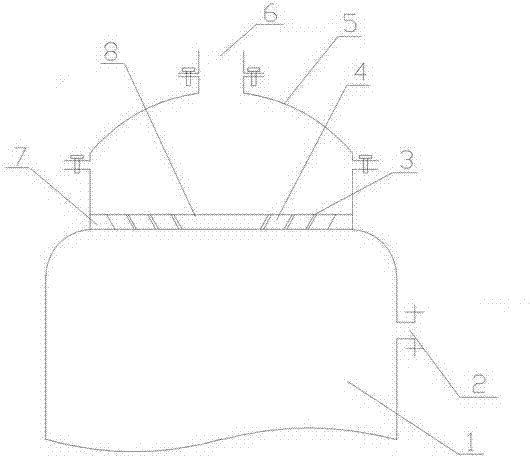

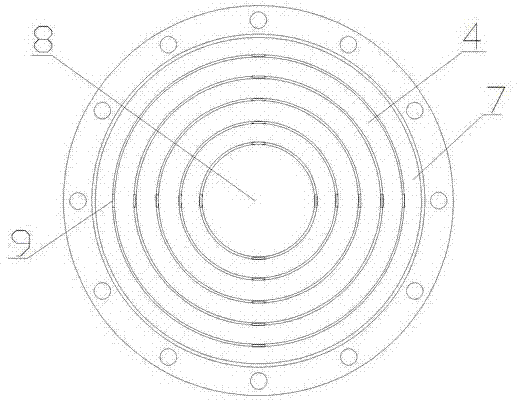

[0009] A film generating device for grease film type degassing, such as figure 1 , figure 2 As shown, it includes a negative pressure tank 1 provided with an air suction port 2, and its feature is that an inlet pipe with a connecting flange is arranged on the upper mouth of the negative pressure tank 1, and a lubricating pipe is provided on the inlet pipe through flange connection. The upper cover 5 of the grease inlet 6 is installed on the support at the lower part of the inlet pipe, and the conical composite disk with conical annular gaps 3 is evenly distributed on the disk surface, and the outer ring 7 of the conical composite disk is installed on the support in the inlet pipe. Above, the inner ring surface of the outer ring 7 is a conical ring surface shrinking inward, and the spacer rings whose diameters are uniformly arranged from large to small and whose inner and outer conical ring surfaces cooperate with each other are evenly distributed on the inner conical ring sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com