Online monitoring system for gas content in transformer oil by using photoacoustic spectrum

A technology of photoacoustic spectroscopy and transformer oil, which is applied in the direction of material analysis, instruments, and measuring devices through optical means, and can solve problems such as manual correction of detection curves to increase errors, failure to find faults in real time, and human errors in degassing operations. , to achieve the effects of reducing complexity and system instability, running stably, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

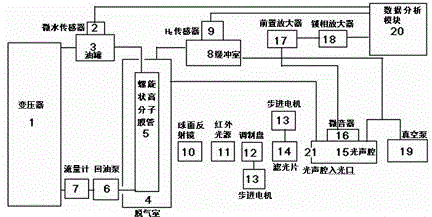

[0021] based on the following figure 1 , specifically explain the preferred embodiment of the present invention.

[0022] Such as figure 1 As shown, the system provided by the present invention for on-line monitoring of gas content in transformer oil using photoacoustic spectroscopy includes an oil circuit system, a gas circuit control module, a photoacoustic spectroscopy monitoring module, and a signal conditioning and analysis module.

[0023] The oil circuit system includes a transformer 1 , an oil tank 3 , a threaded polymer film tube 5 , an oil return pump 6 and a flow meter 7 which are sequentially connected by pipelines to form a loop.

[0024] The air path control module includes an air collection chamber 4 arranged outside the threaded polymer film tube 5 , and a buffer chamber 8 connected to the air collection chamber 4 through an air path.

[0025] The photoacoustic spectrum monitoring module includes an infrared light source 11, a spherical reflector 10 arranged ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com