Patents

Literature

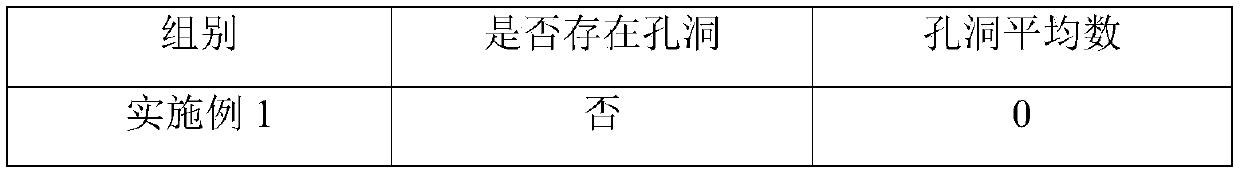

50results about How to "Effective degassing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

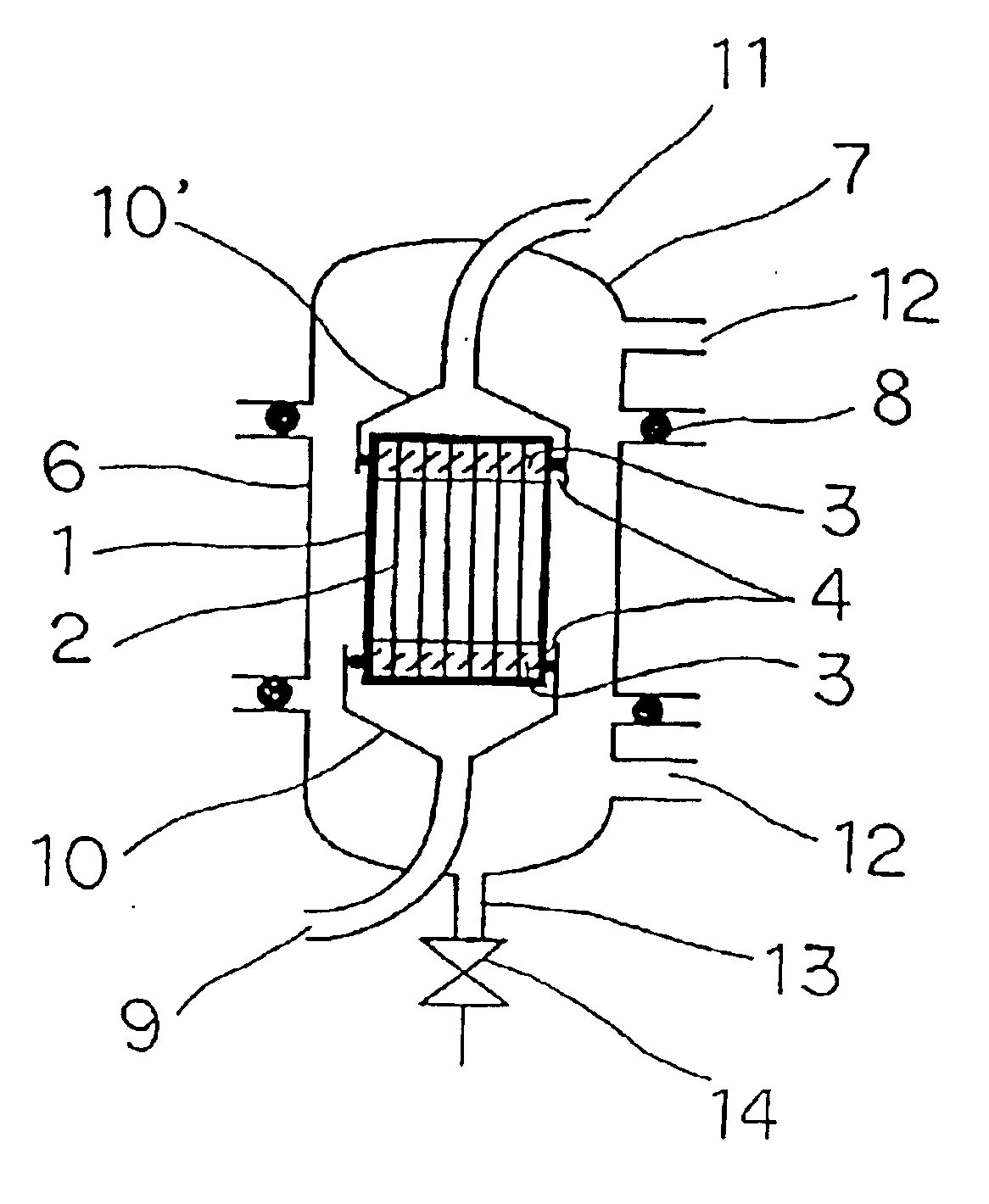

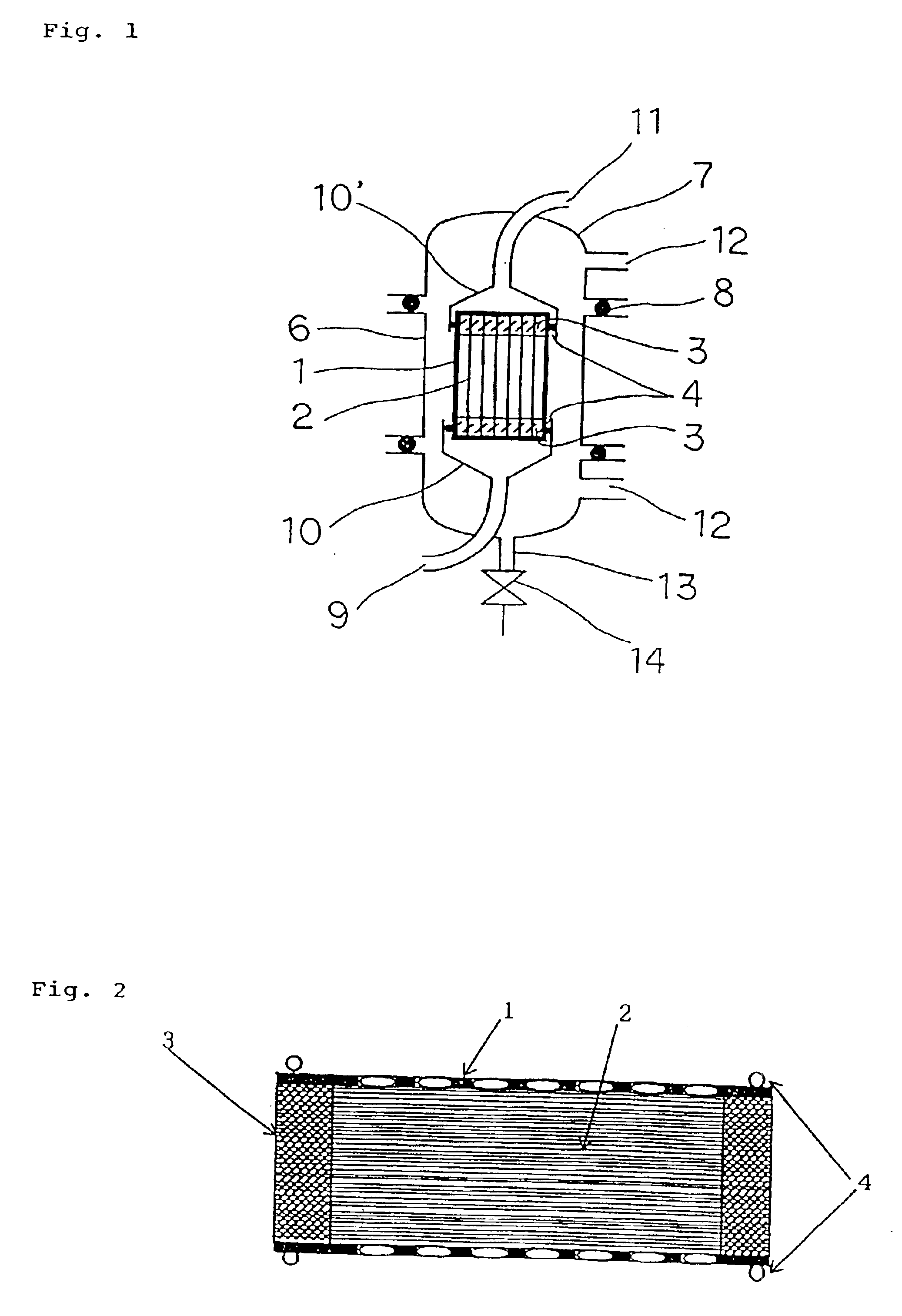

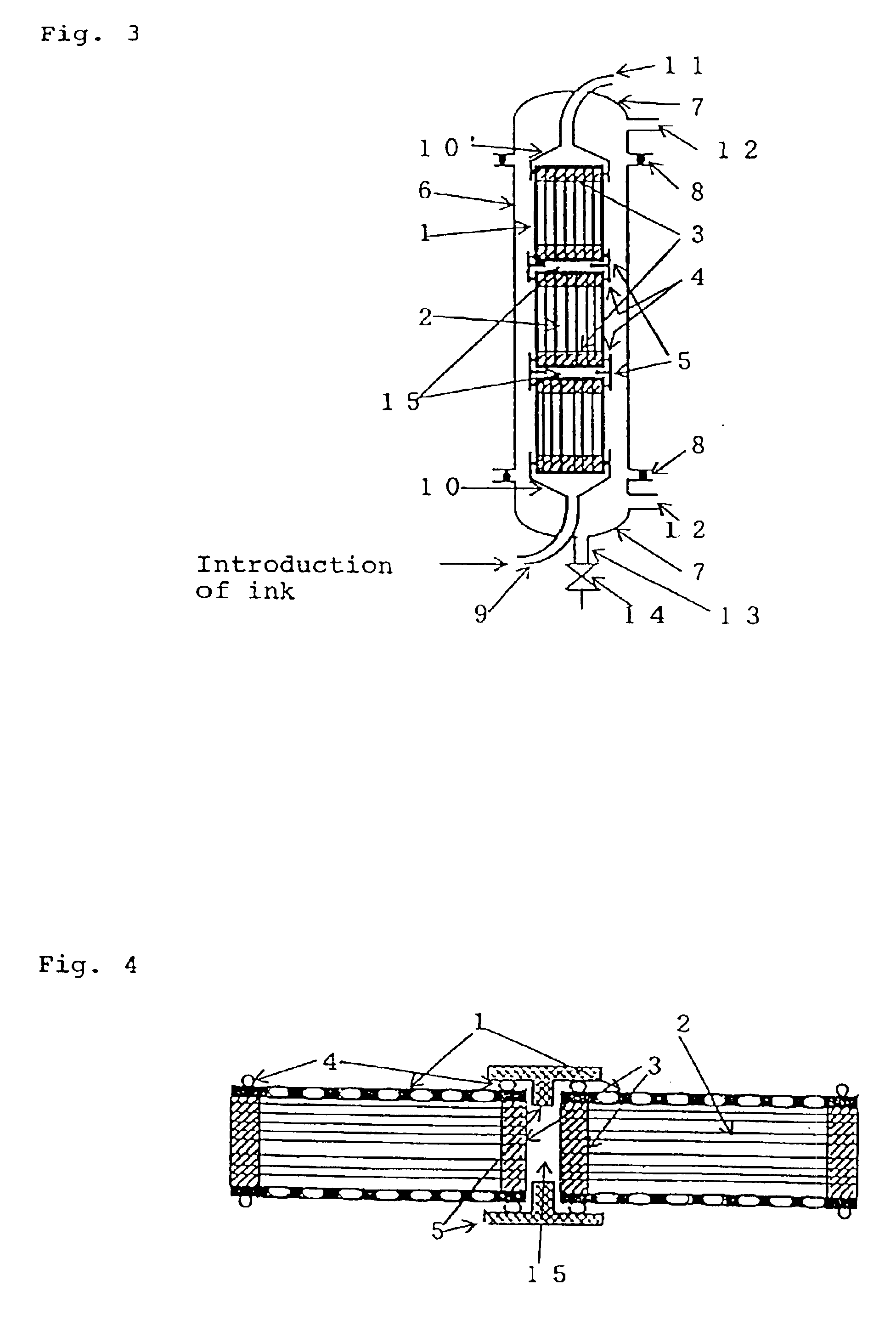

Hollow fiber membrane for the degassing of inks, ink degassing method, ink degassing apparatus, method for the fabrication of an ink cartridge, and ink

InactiveUS6860922B2Effective degassingSmall pressure lossMembranesSemi-permeable membranesHollow fibre membraneFiber

Owner:MITSUBISHI CHEM CORP

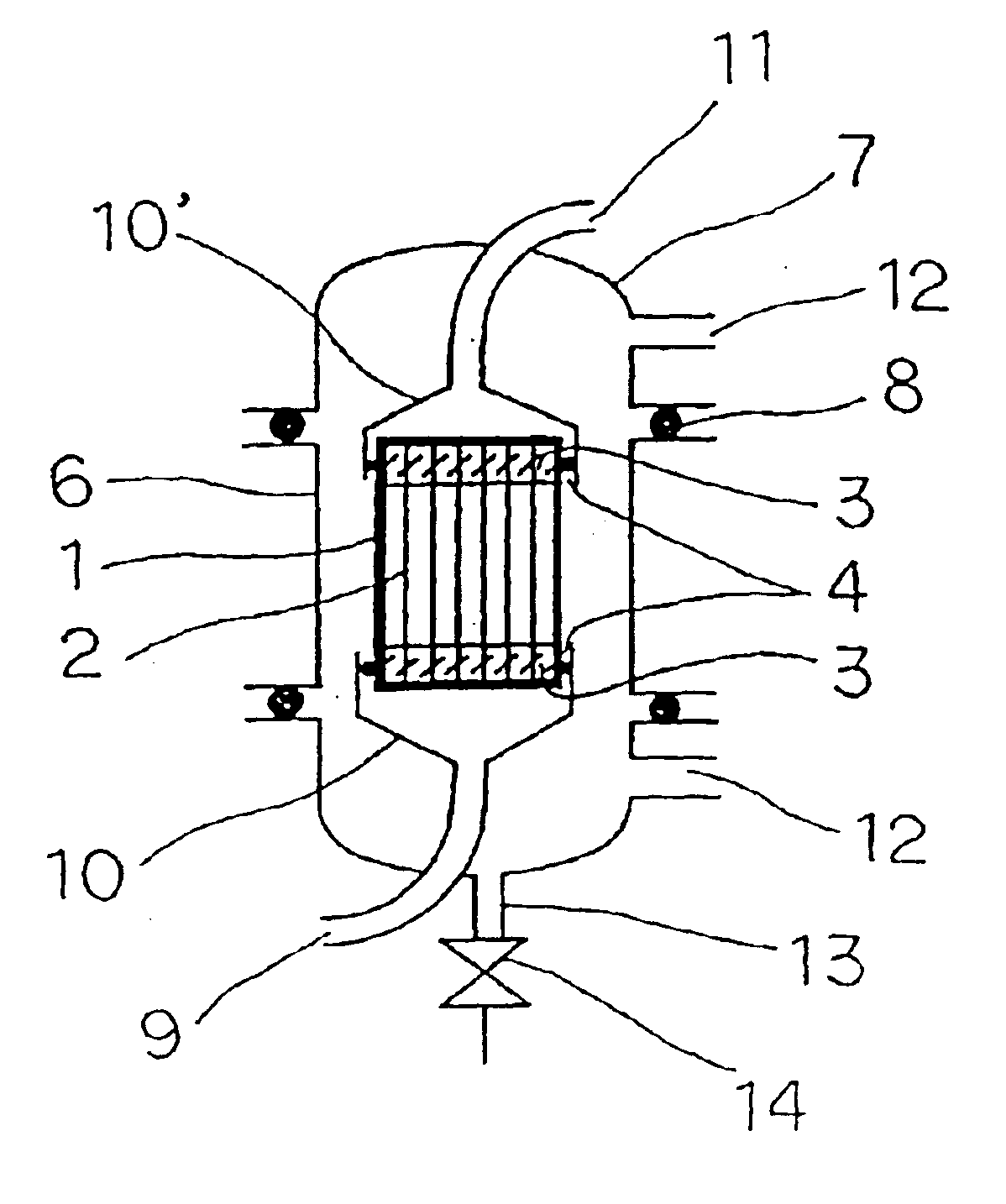

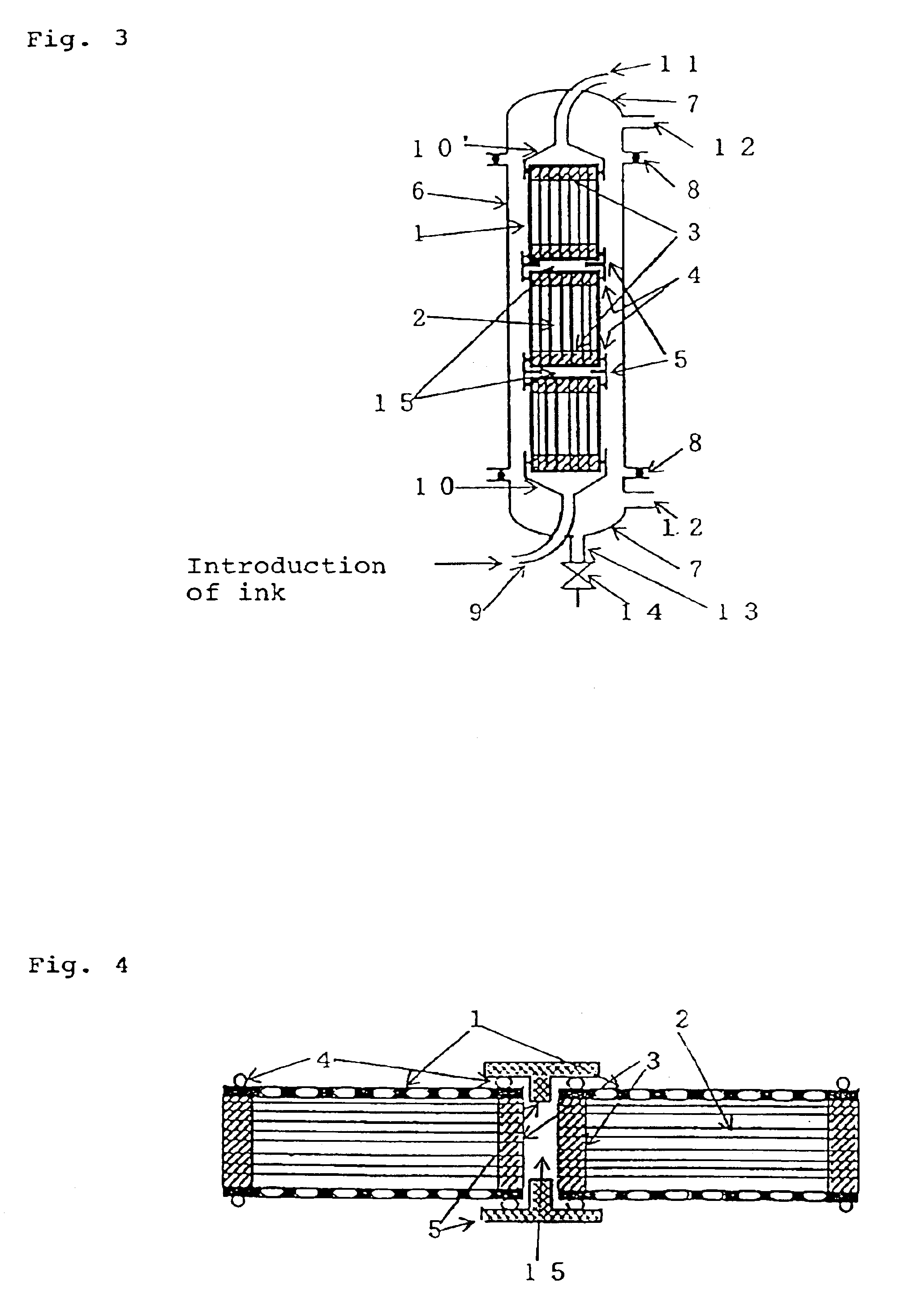

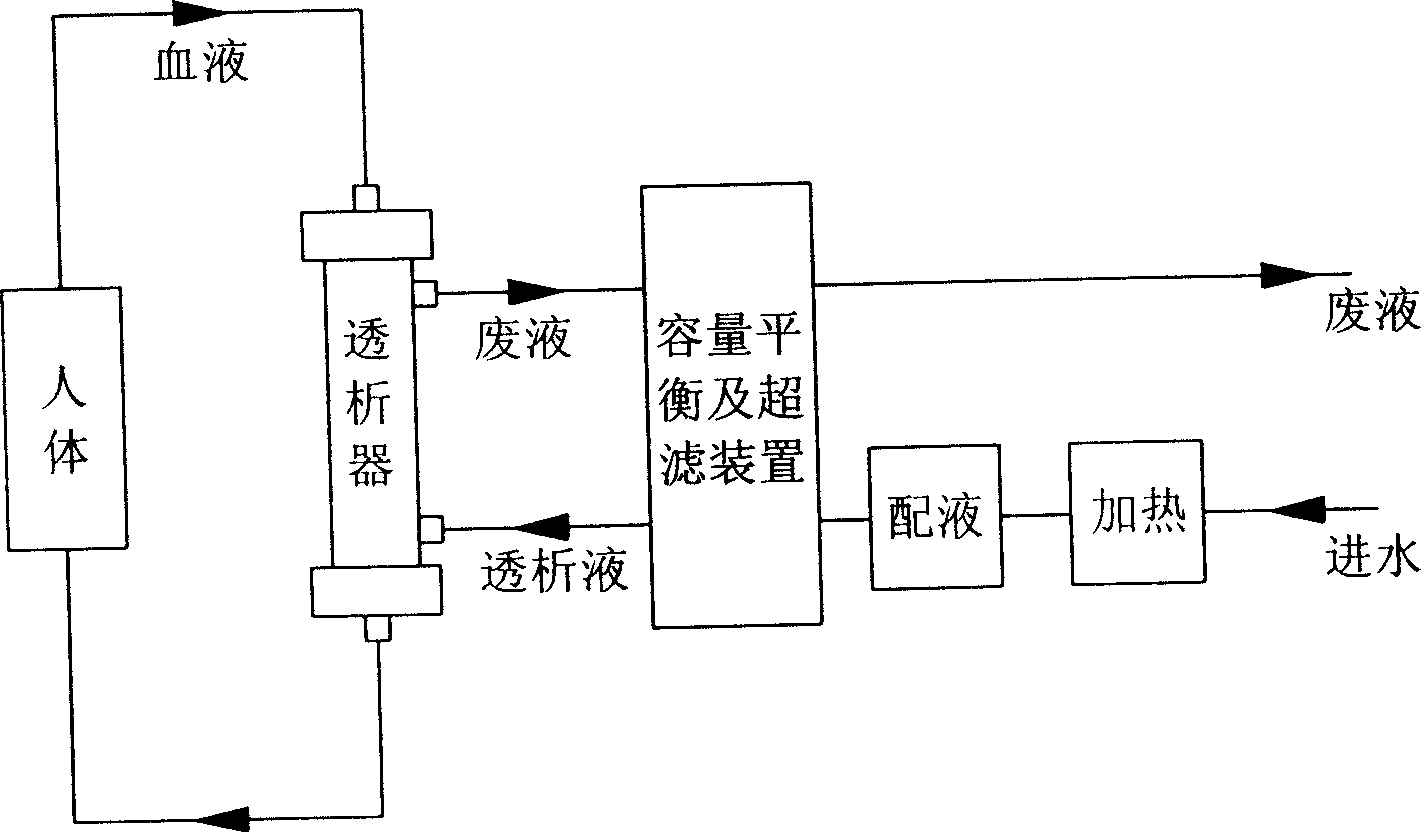

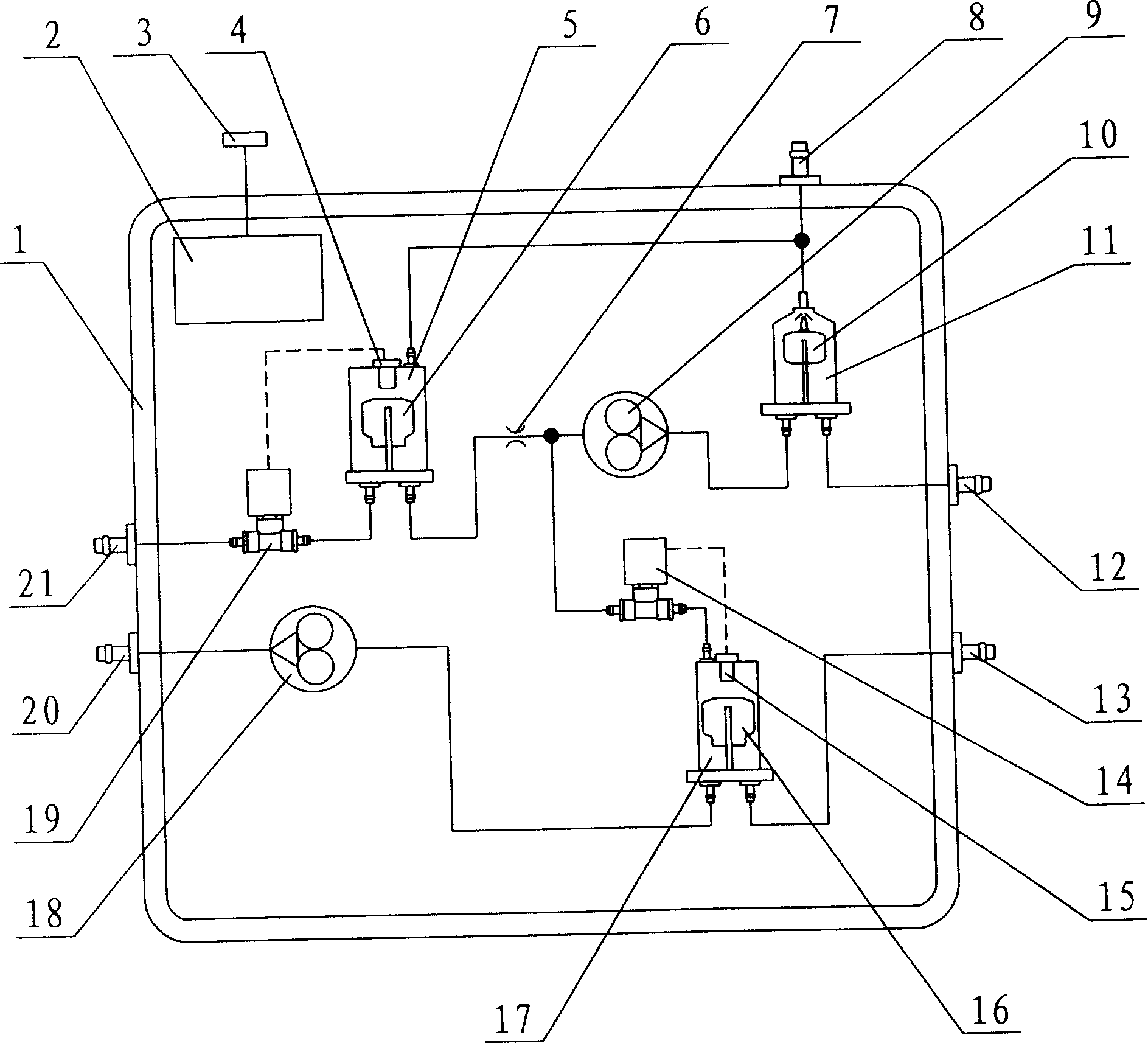

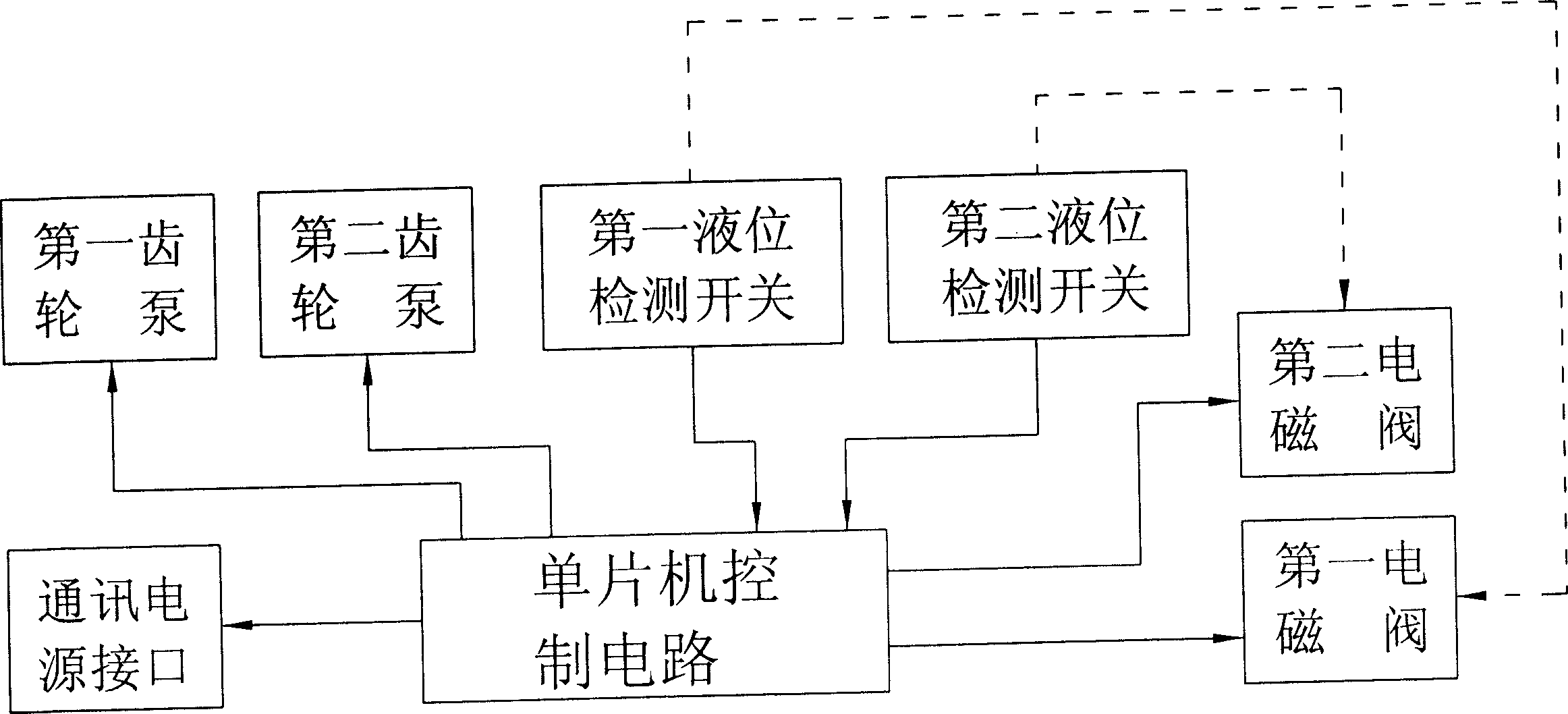

De-airing device for purifying blood

The de-airing device for purifying blood has one box with water inlet, water outlet, air exhaust, dialysate joint and waste liquid joint. The water inlet is connected to the liquid inlet of the flow controlling choke; the liquid outlet of the flow controlling choke is connected to two pipelines, including the first pipeline connected to the liquid inlet of the first de-airing tank via a gear pump and the second pipeline connected to the liquid exhaust of the second de-airing tank via a second solenoid valve; the liquid outlet and the air exhaust of the first de-airing tank are connected separately to the dialysis joint and the air exhaust joint pipeline; and the liquid inlet and the liquid outlet of the second de-airing tank are connected separately to the waste liquid joint pipeline and the water outlet joint via a second gear pump. The present invention can avoid air embolism to blood for normal dialysis treatment.

Owner:SWS HEMODIALYSIS CARE CO LTD

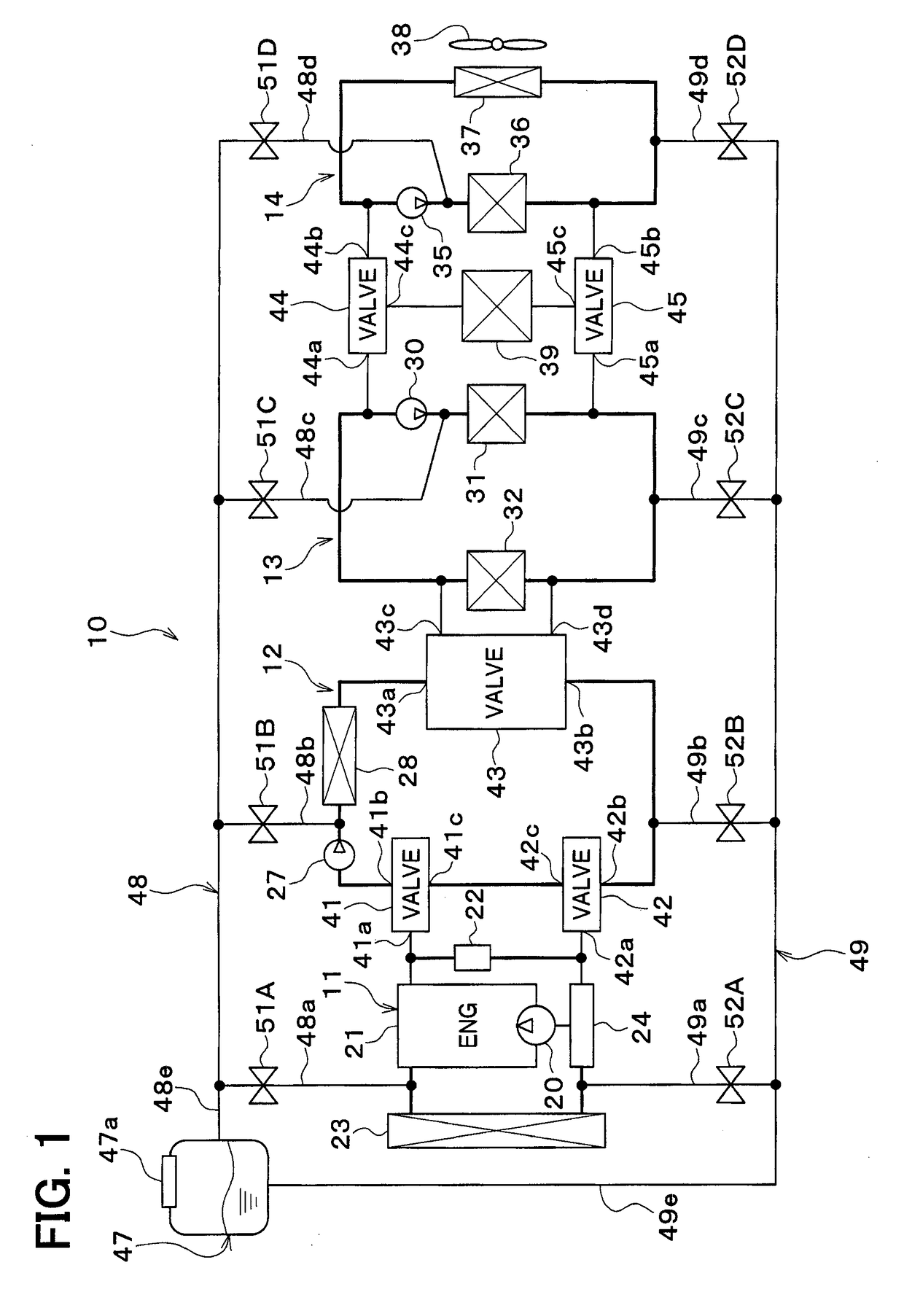

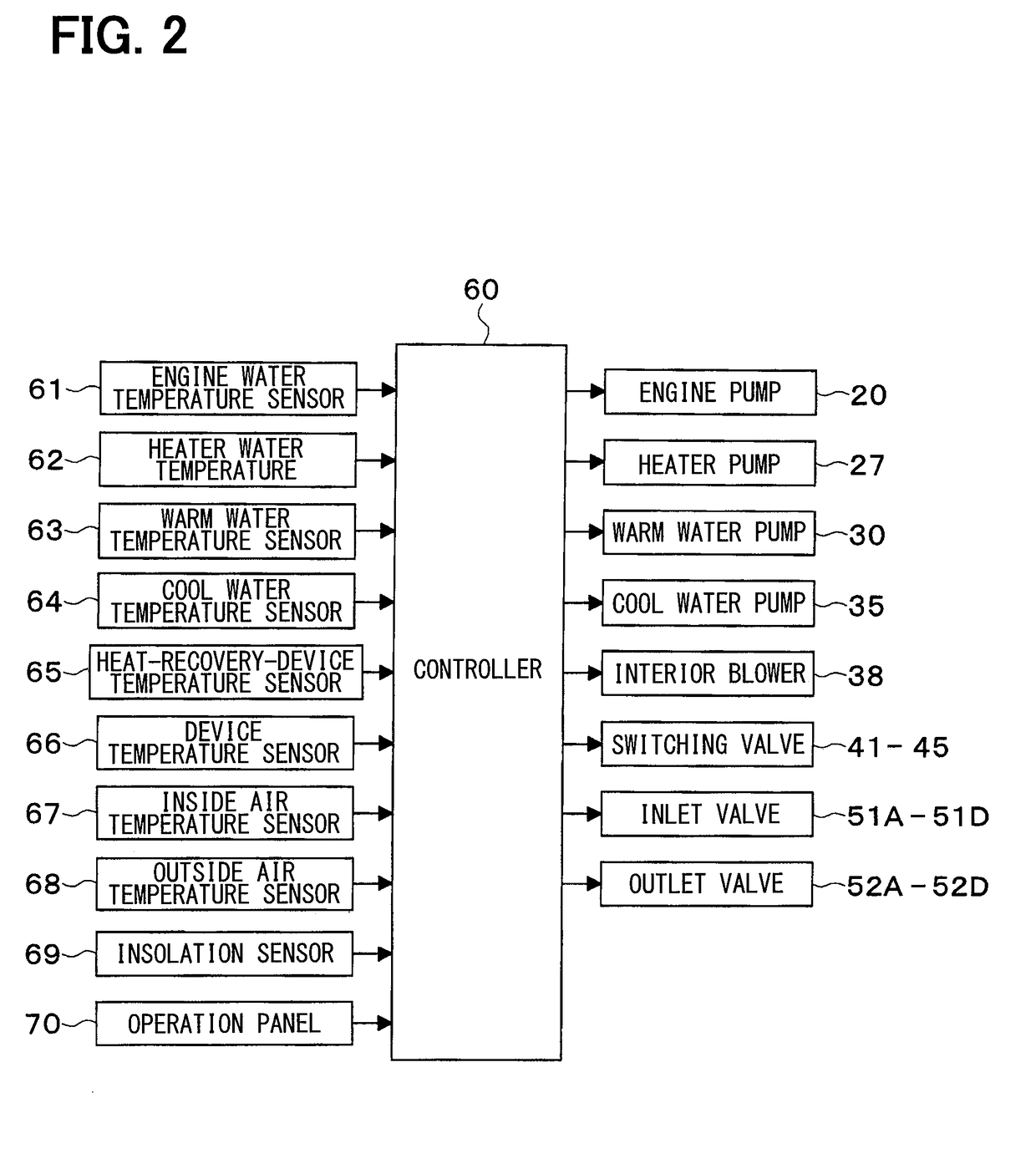

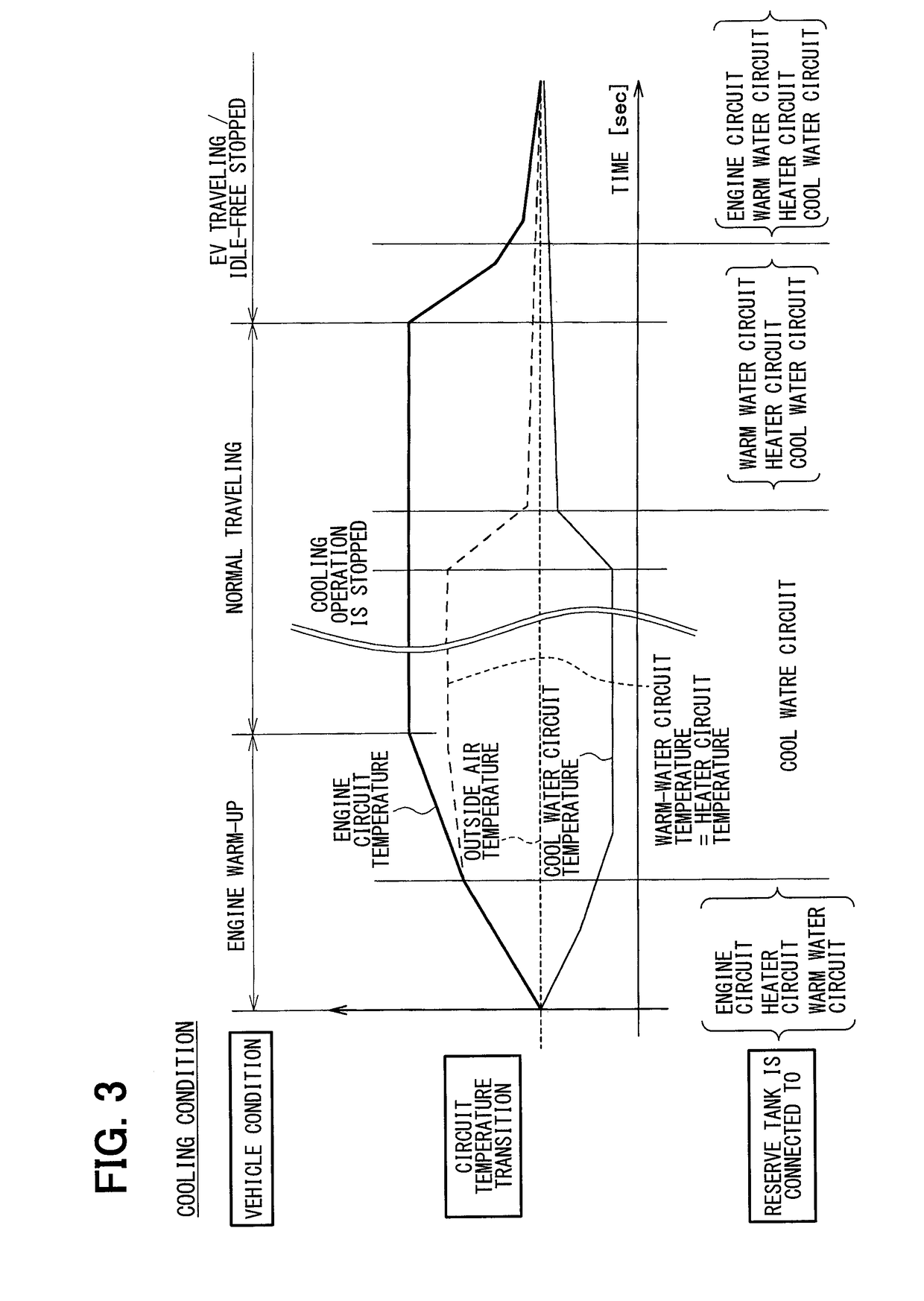

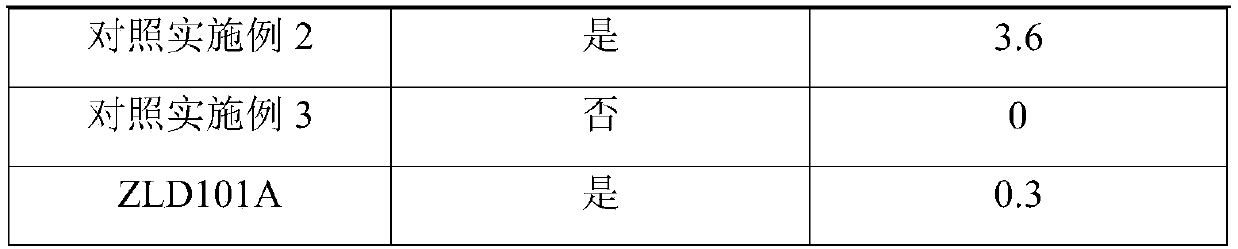

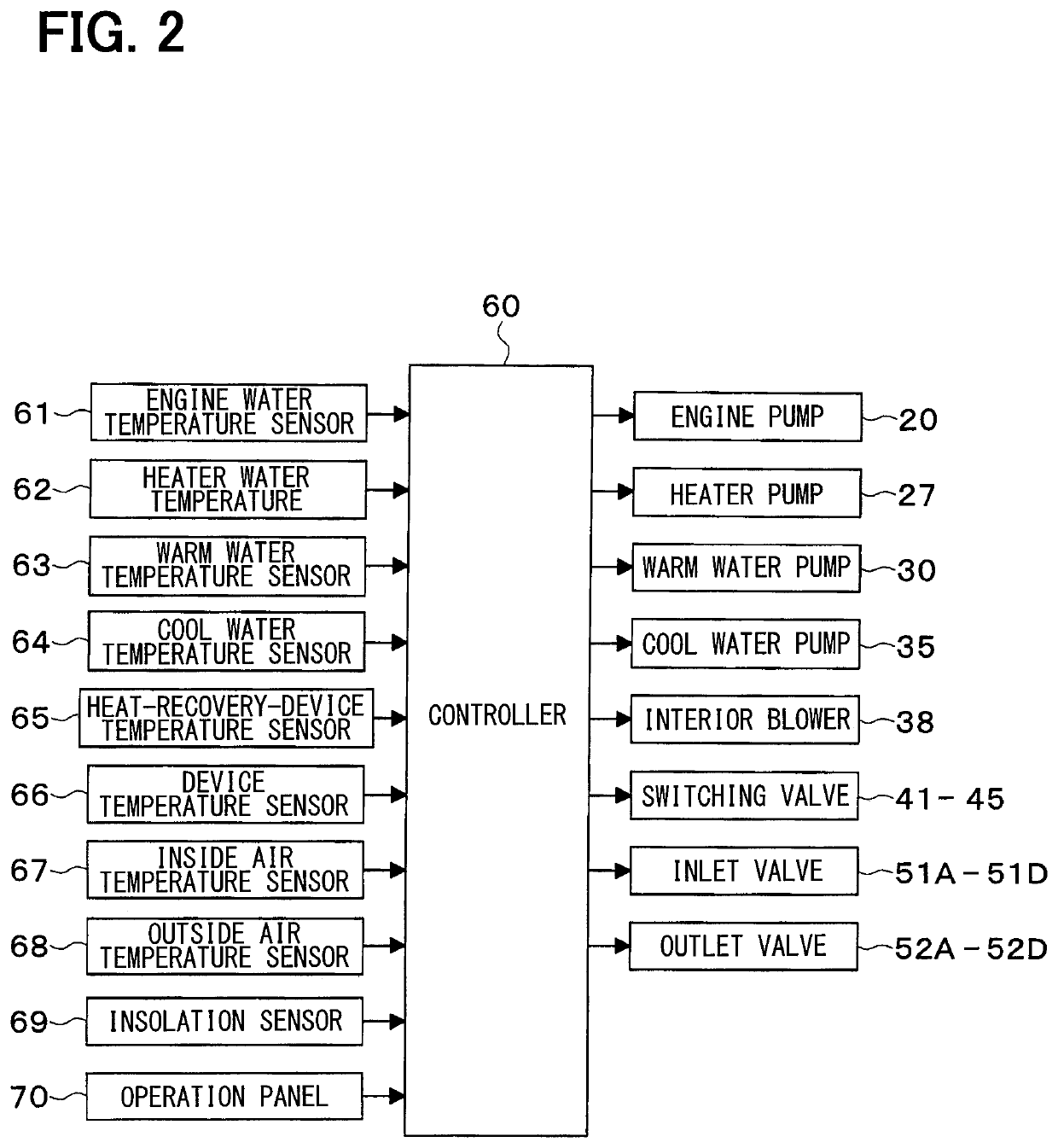

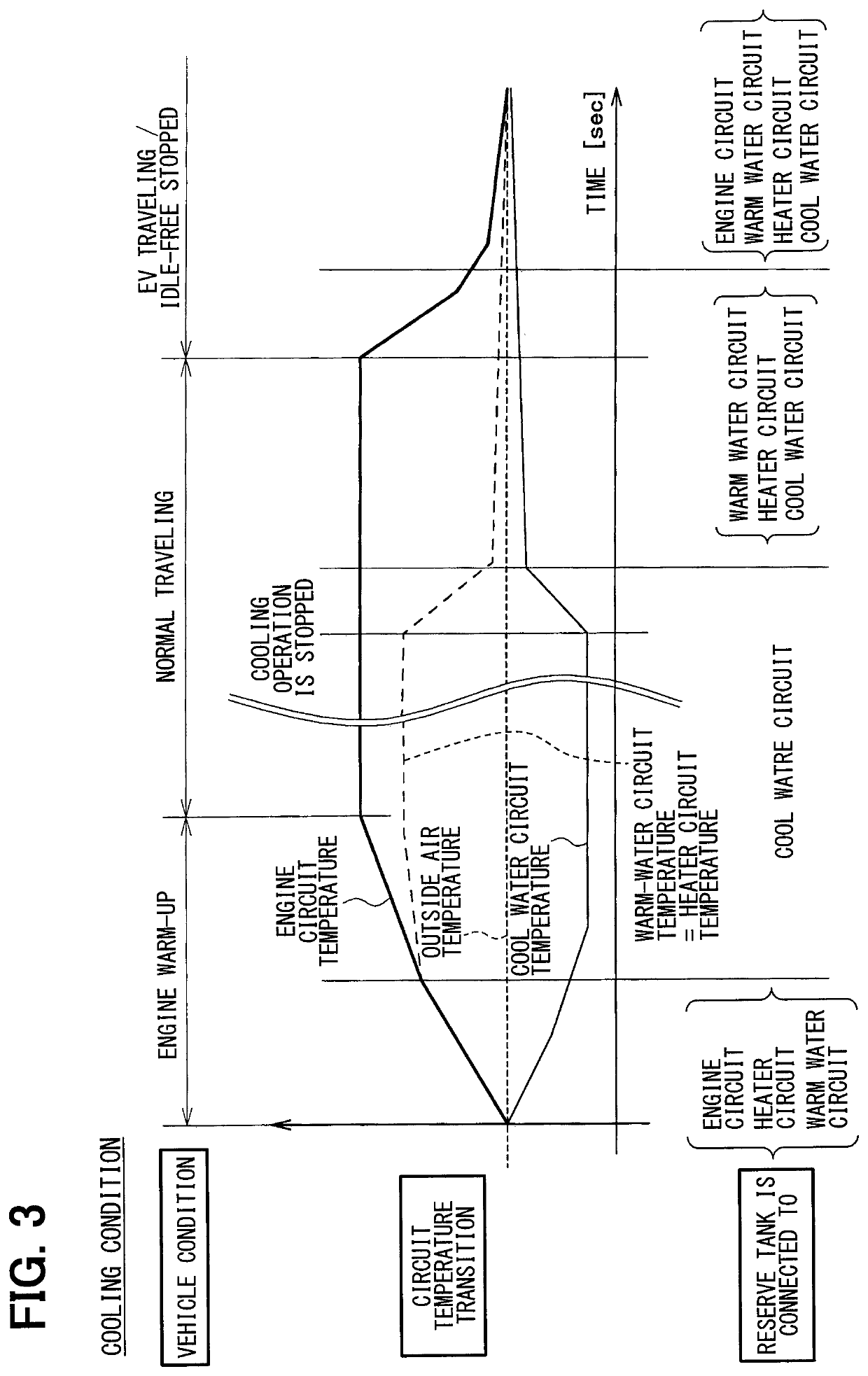

Thermal management device for vehicle

ActiveUS20190078497A1Suppress heat lossAvoid mixingLiquid coolingAir-treating devicesThermodynamicsHeat management

A thermal management device for a vehicle includes heat medium circuits, a reserve tank, and a connector. The heat medium circulates through the heat medium circuits separately. The reserve tank is configured to separate an air bubble contained in the heat medium from the heat medium. The connector allows the reserve tank to come in communication with the heat medium circuits selectively. As such, an occurrence of the heat loss in the degassing performed in the reserve tank can be suppressed with the thermal management device for a vehicle including the heat medium circuits.

Owner:DENSO CORP

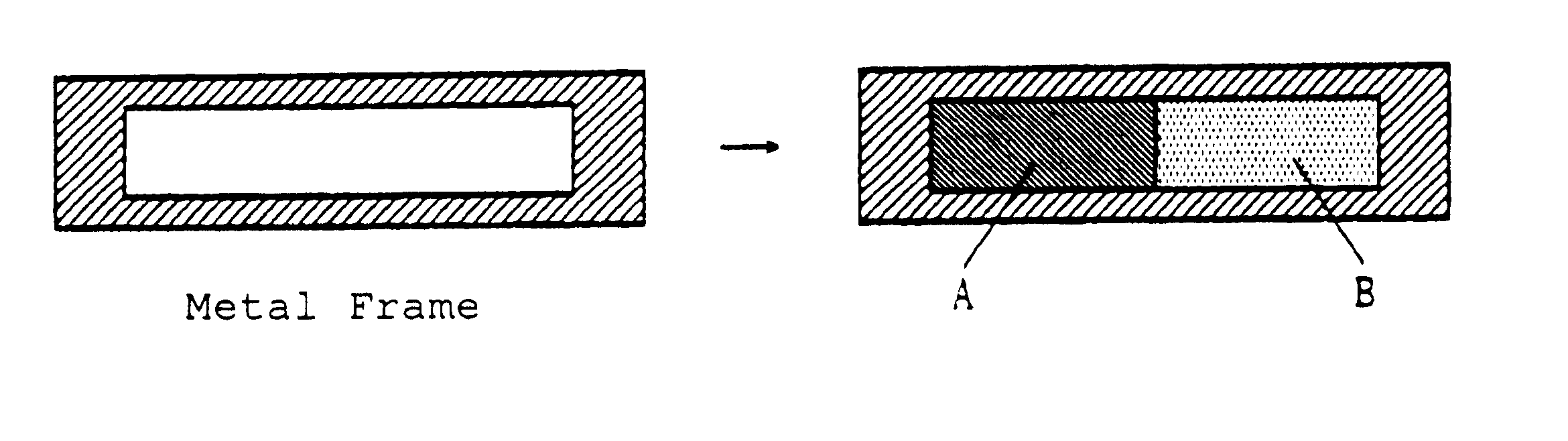

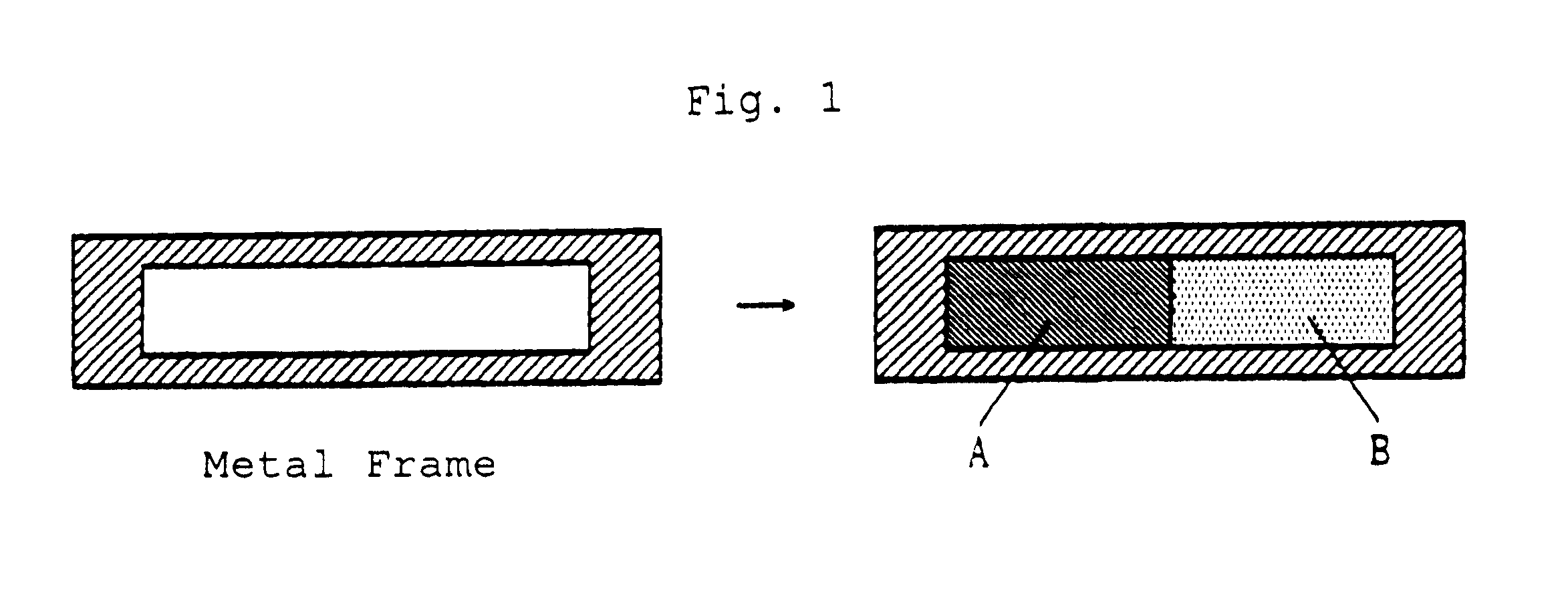

Polyacetal composite and process for producing the same

InactiveUS6517949B1Satisfactory compositeEffective degassingSynthetic resin layered productsLaminationMaleic anhydrideItaconic acid

A polyacetal composite according to the invention includes a polymer unit (A) composed of a polyacetal resin, and a polymer unit (B) composed of a thermoplastic resin or elastomer having an acidic group, and the polymer unit (A) and the polymer unit (B) directly adhere to each other. The acidic group includes, for example, a carboxyl group and a carboxylic anhydride group. The thermoplastic resin or elastomer having an acidic group includes a comonomer having at least one selected from among acrylic acid, methacrylic acid, fumaric acid, maleic acid, maleic anhydride, and itaconic acid as a comonomer, and typical examples thereof include, for example, acid-modified polystyrene and acid-modified NBR (acid-modified nitrile rubber). In this polyacetal composite, the polyacetal resin and another polymeric material are firmly fixed with each other.

Owner:DAICEL HULS

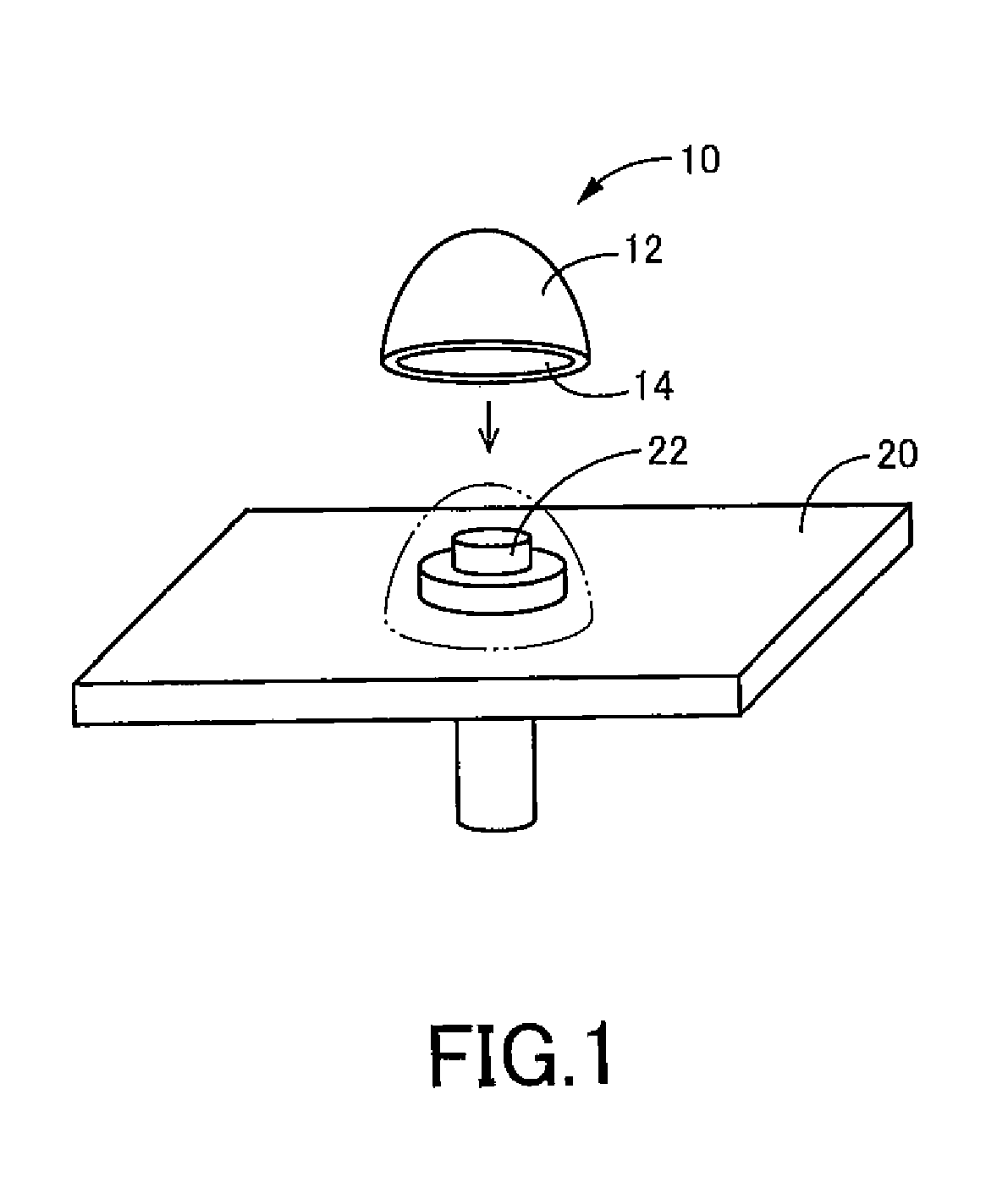

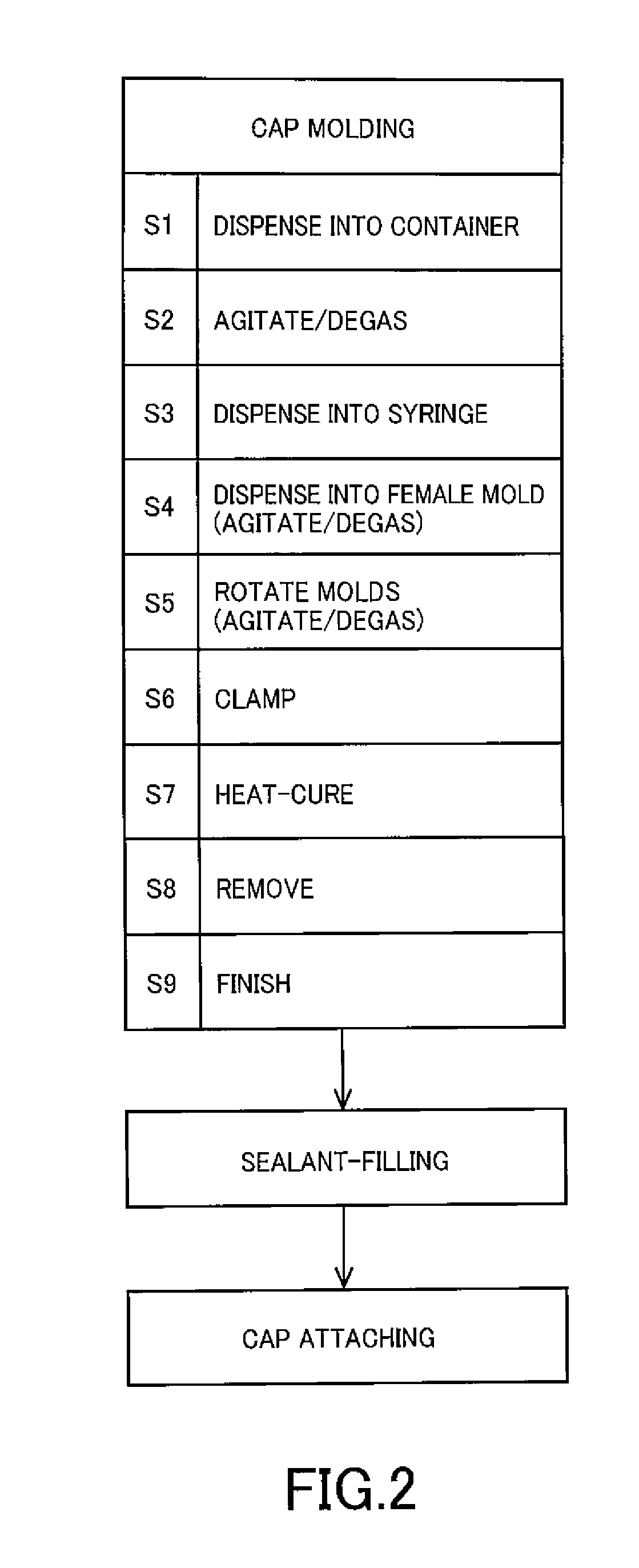

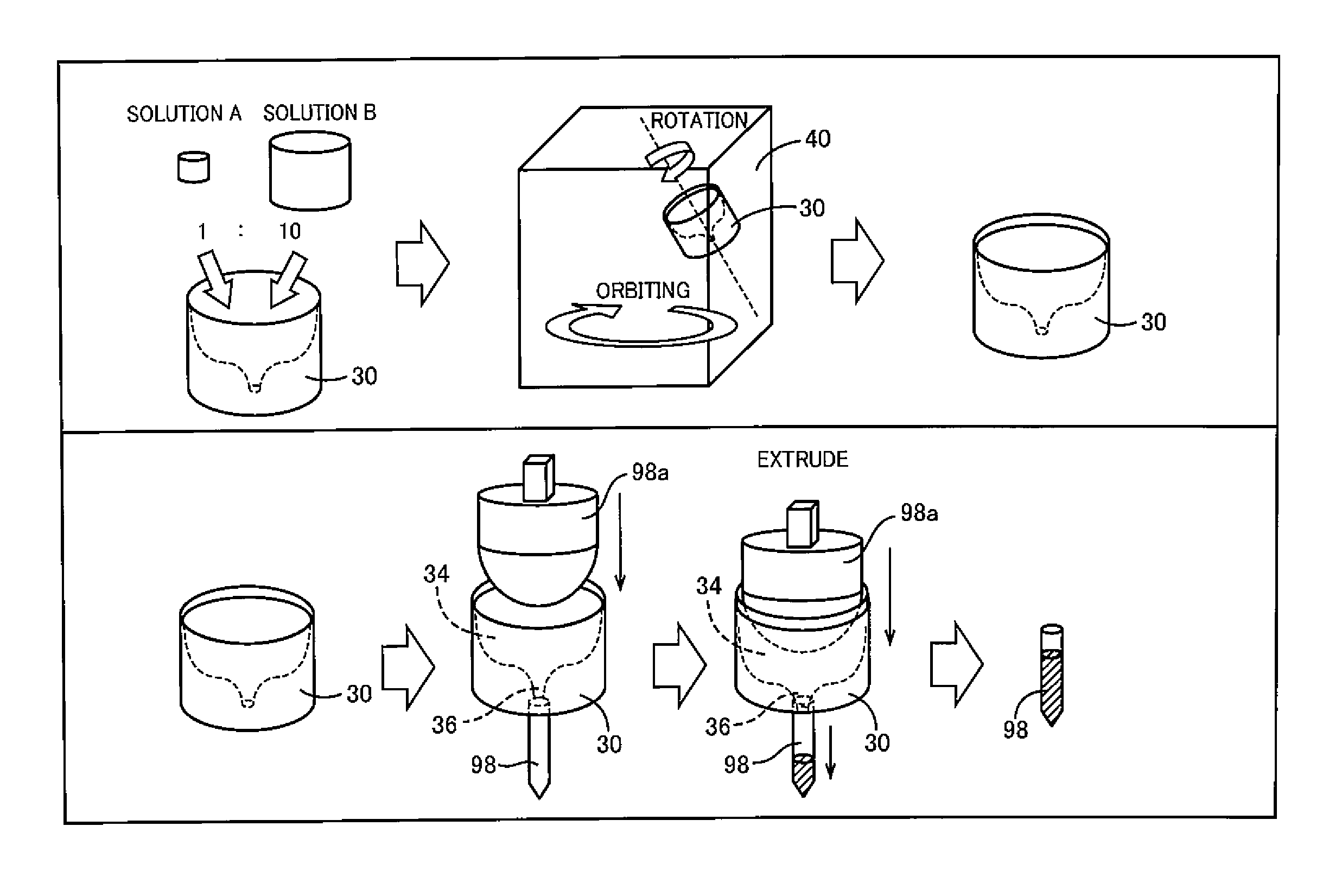

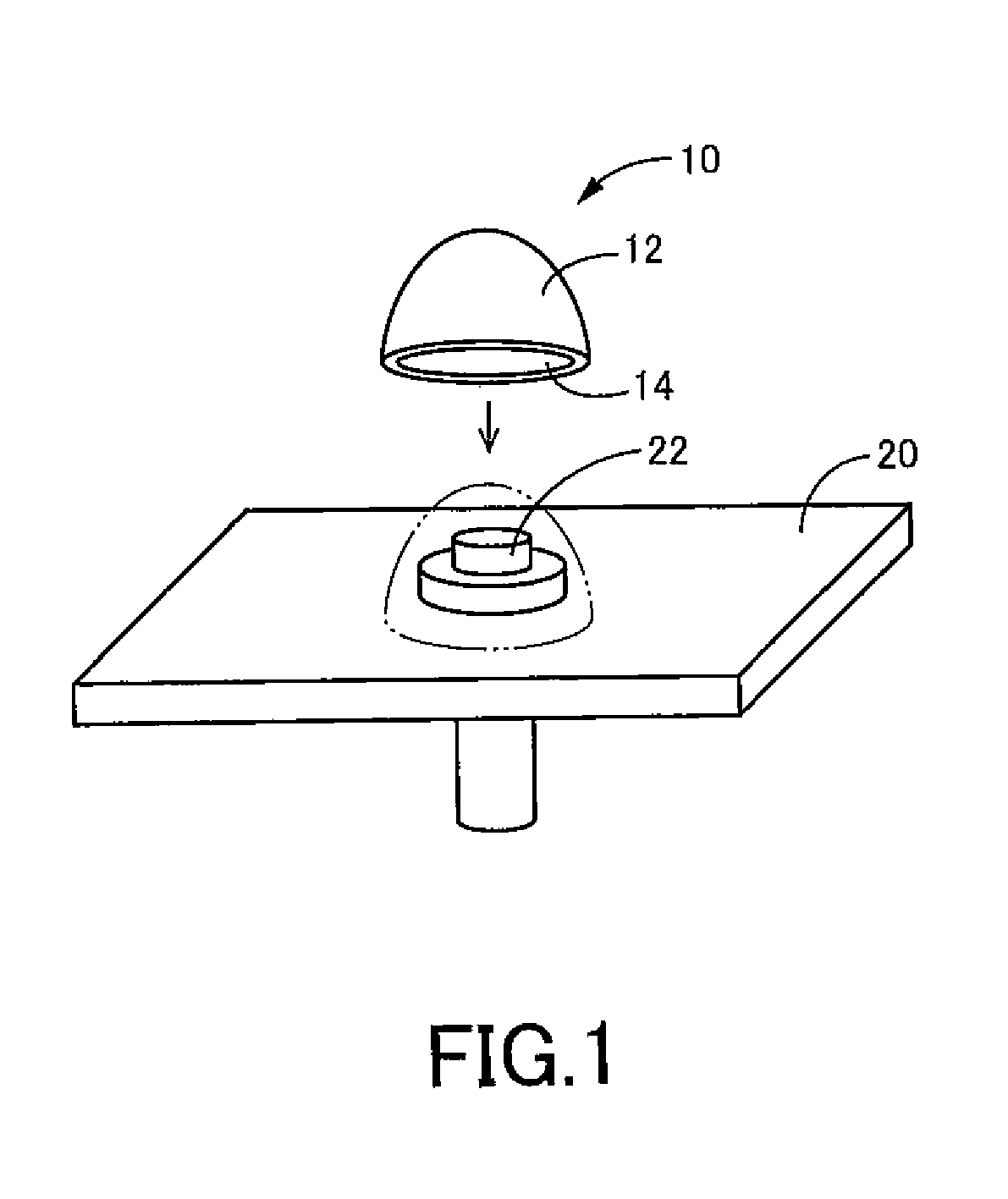

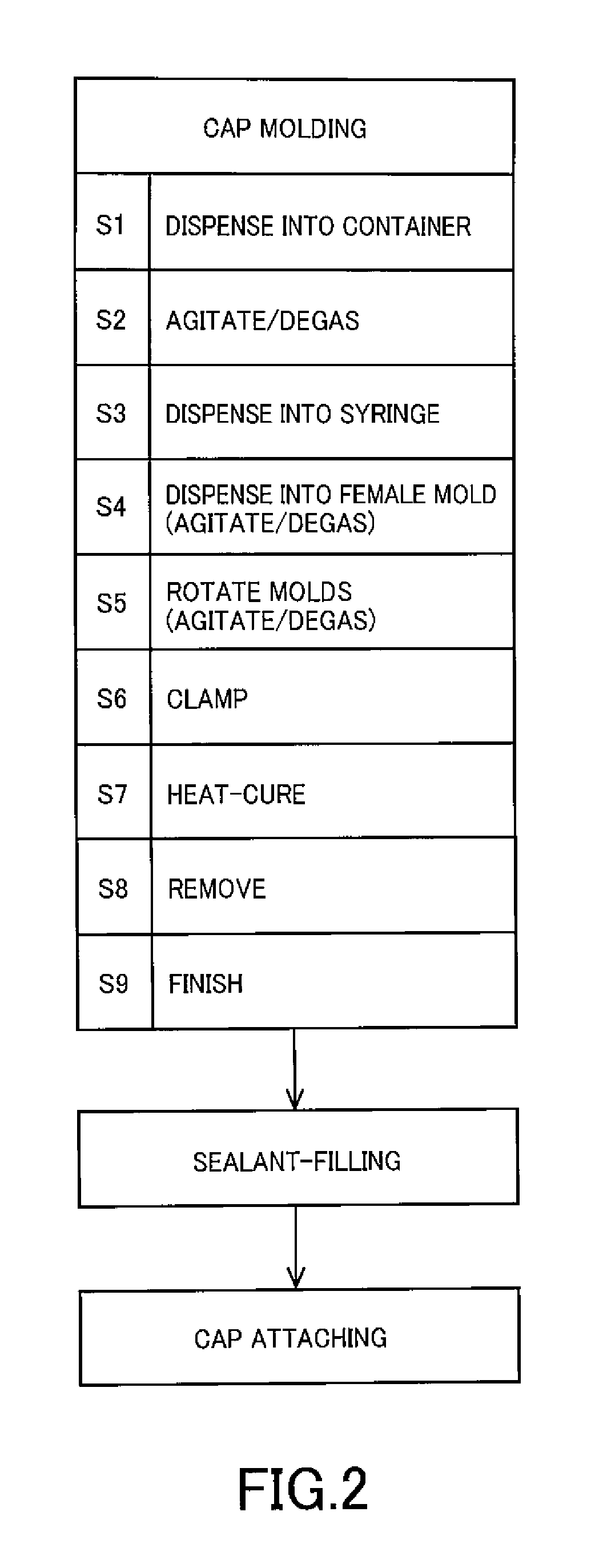

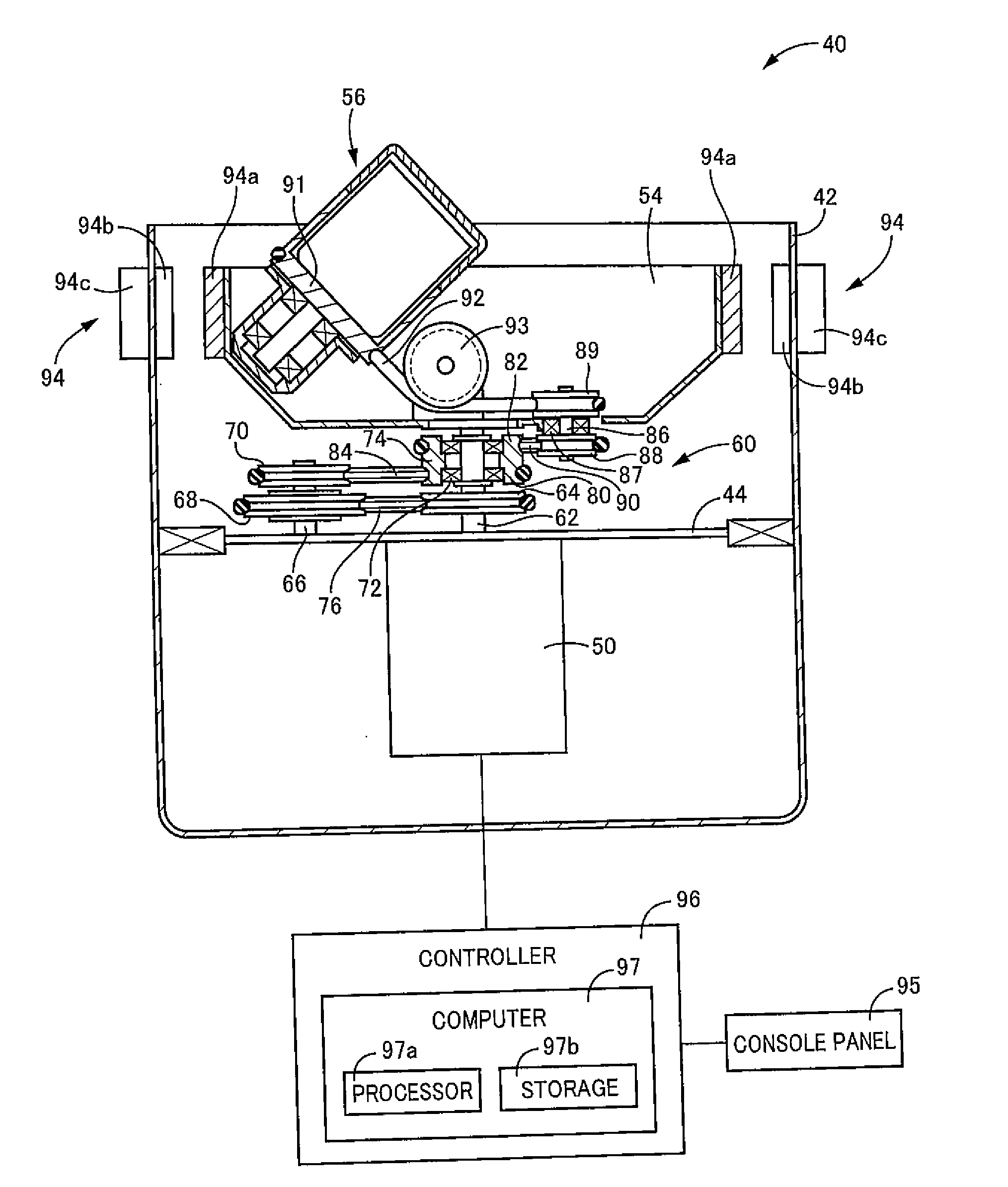

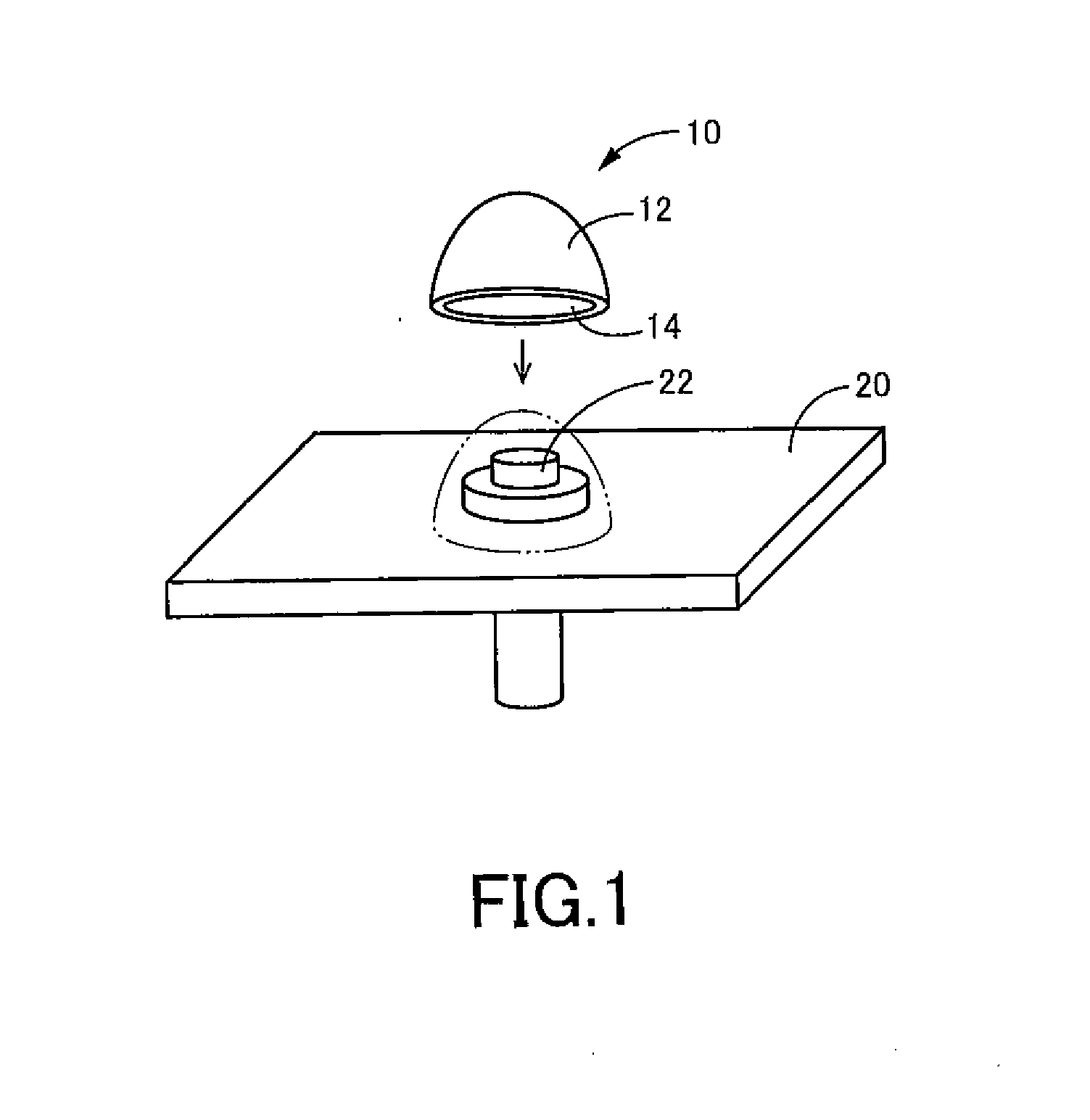

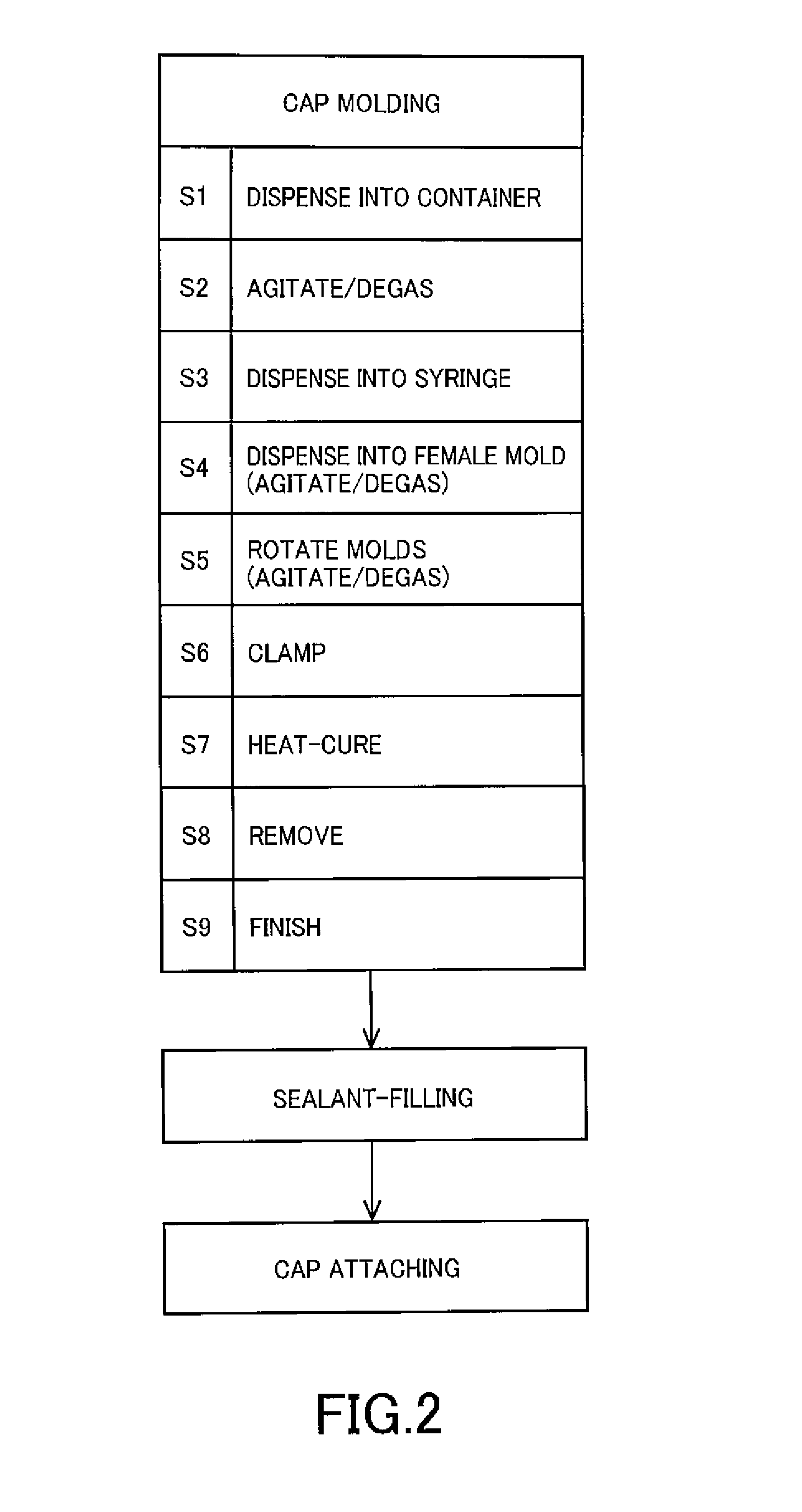

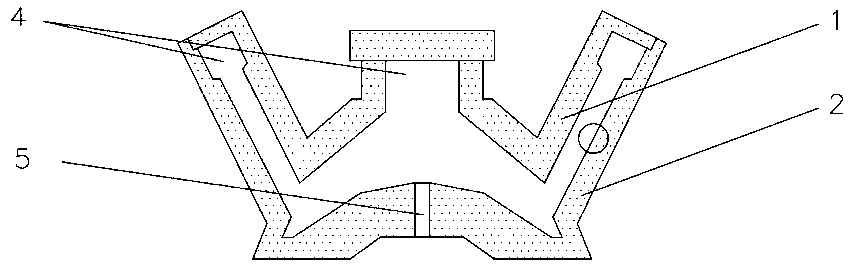

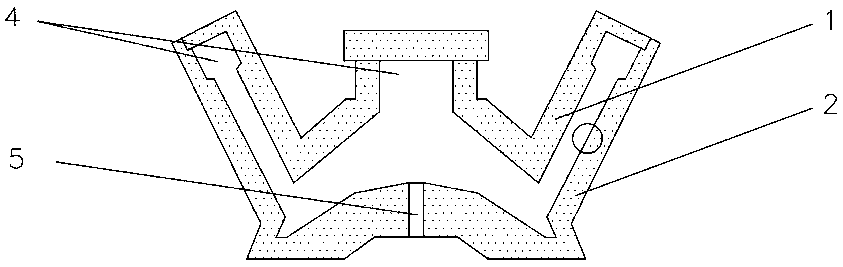

Molding method and mold therefor

Molding methods and molds for making a synthetic resin molded product include disposing a curable liquid resin mixture in a recess of a female mold. The curable liquid resin mixture is then simultaneously agitated and degassed by a mixer while under a partial vacuum. More specifically, at least the female mold is orbited around an orbital axis while being rotated about a rotational axis that is eccentric to the orbital axis. After being thoroughly mixed and degassed, the liquid mixture is then cured in the mold unit.

Owner:KAGA SANGYO

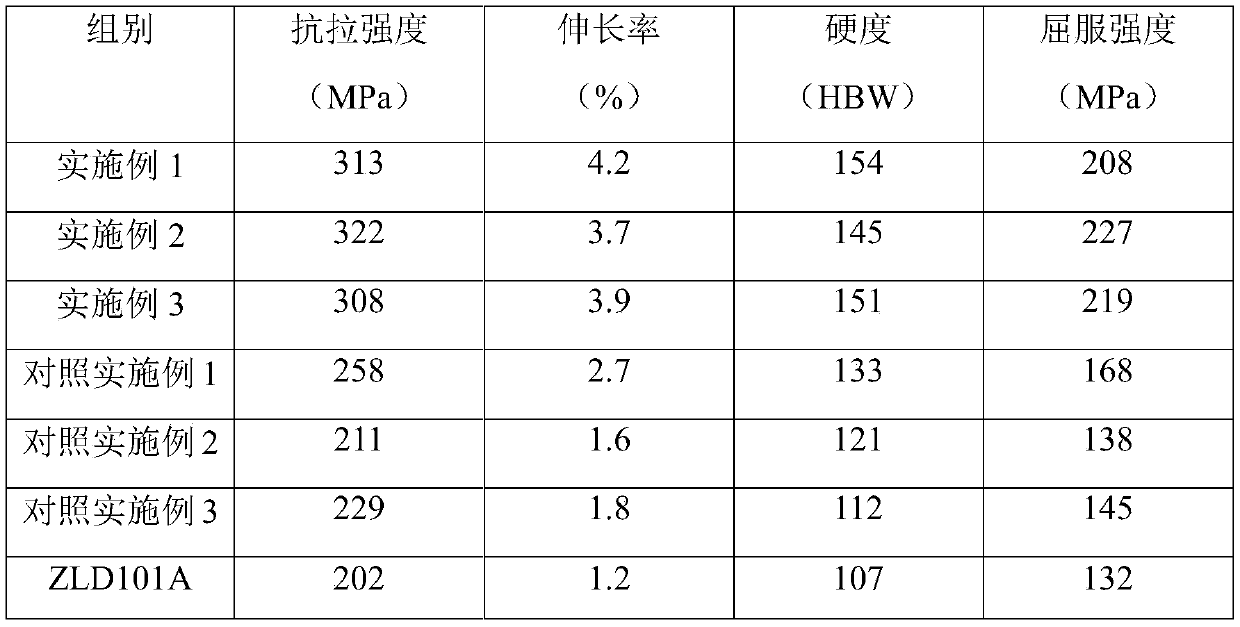

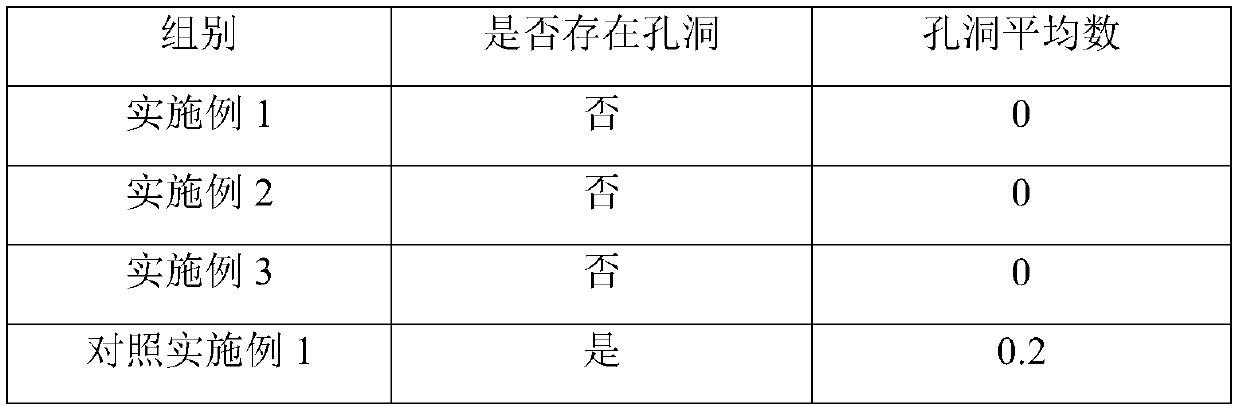

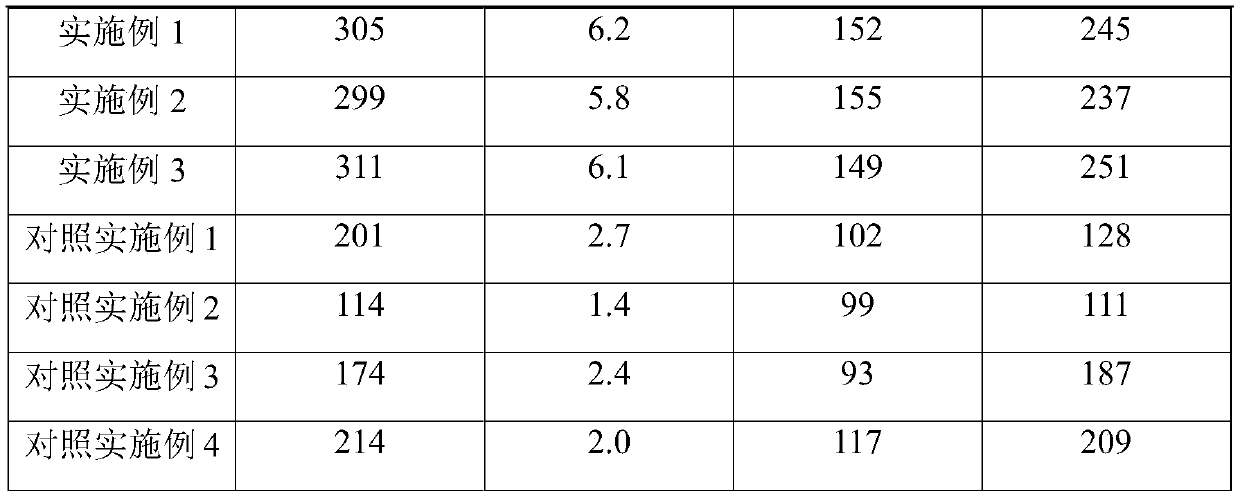

Cast aluminum alloy with pinholes removed and smelting method thereof

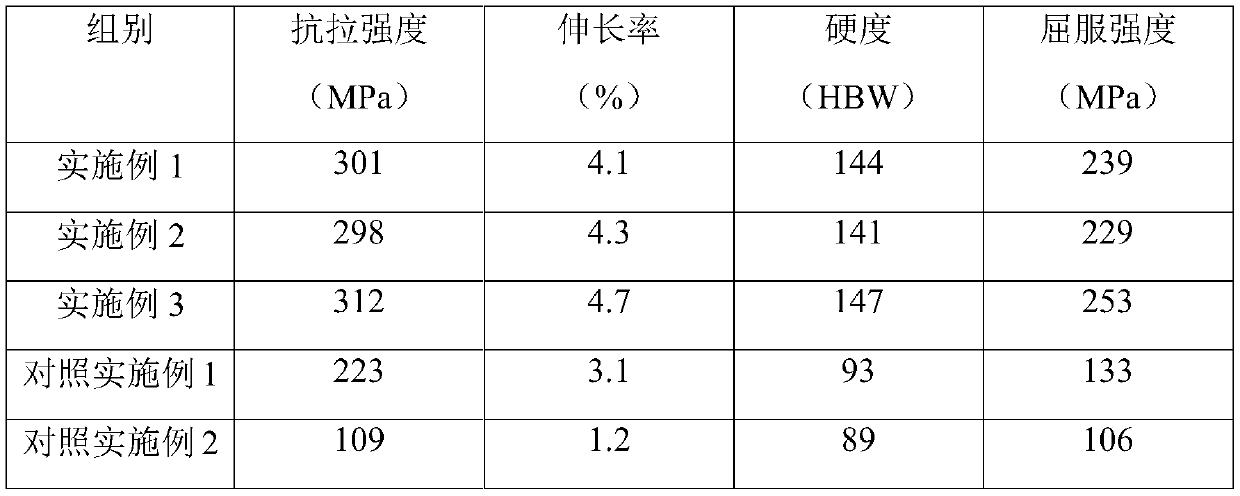

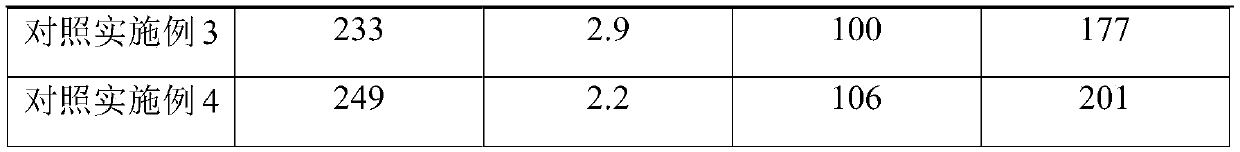

The invention discloses a cast aluminum alloy with pinholes removed and a smelting method thereof. The smelting method comprises the steps of: firstly, heating an aluminum ingot or molten aluminum for completely melting the aluminum ingot or molten aluminum; adding Si, Fe, Cu, Mn, Mg, Zn and Ti, and completely dissolving and melting the added components; refining, and maintaining the temperature at 700-1000 DEG C to obtain alloy melt; degassing and purifying the alloy melt by using nitrogen or inert gas or mixed gas of nitrogen and inert gas at any ratio, and persistently introducing the gas until reaction is finished; simultaneously adding MoB and LiAlH4 powder to the alloy melt in a fluidized manner along with the gas; stirring to make MoB and LiAlH4 be uniformly distributed in the alloy melt and sufficiently react with the alloy melt; and standing, adjusting the temperature to 680-730 DEG C, discharging the molten alloy out of a furnace and carrying out casting production. According to the cast aluminum alloy with pinholes removed and the smelting method thereof, the defects of the performance of the traditional aluminum alloy are overcome, the tenacity, forming performance andhardenability of the aluminum alloy are improved, and high-grade base materials are provided for high-efficiency deep processing.

Owner:GUIZHOU ALUMINUM MATERIALS ENG TECHRES CENT

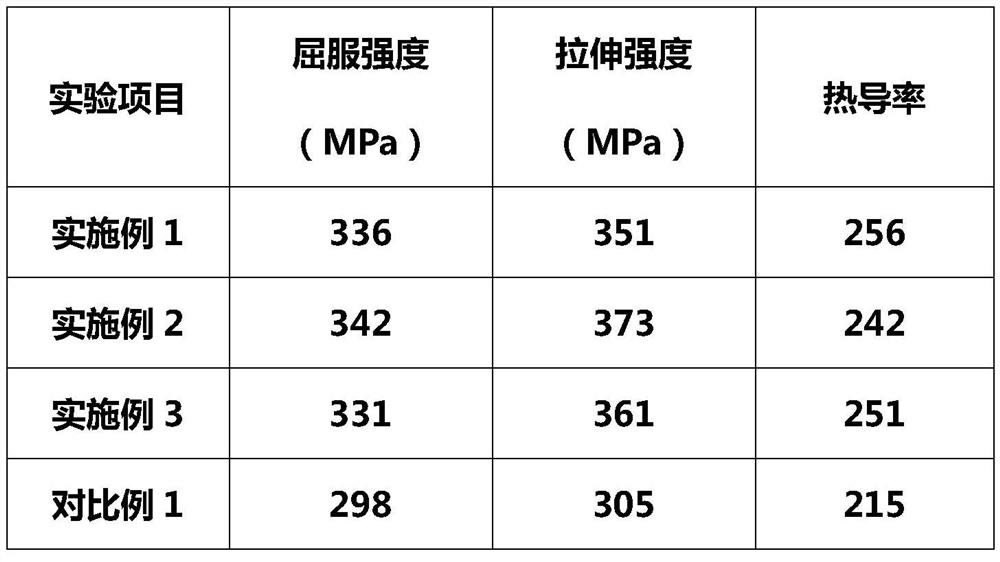

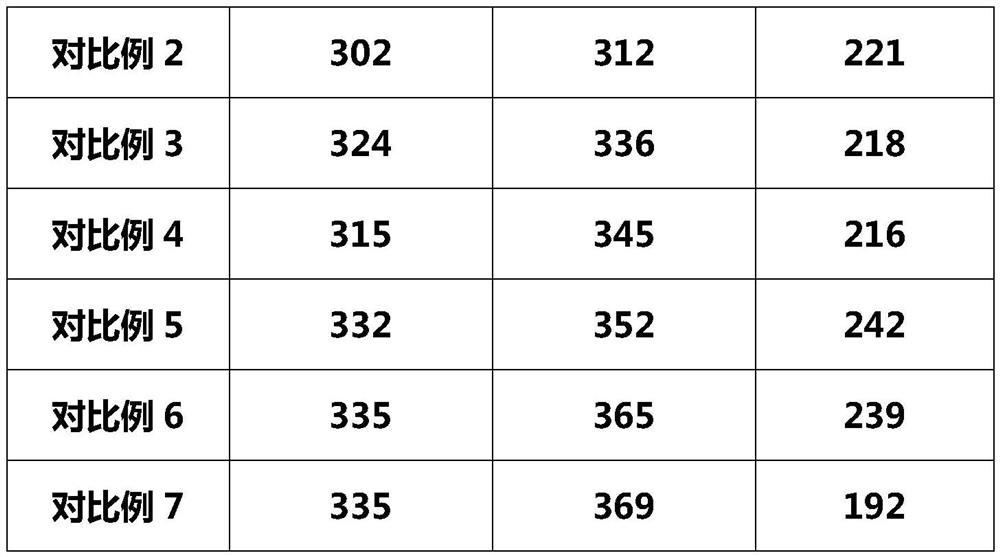

High-thermal-conductivity aluminum alloy and casting method thereof

The invention discloses a high-thermal-conductivity aluminum alloy. The high-thermal-conductivity aluminum alloy comprises the following components: 0.2%-0.85% of Mg, 0.1%-0.3% of Si, 0.05%-0.2% of Cu, 0.1%-0.2% of Zn, 0.1%-0.2% of Fe, 0.1%-0.15% of Ti, 0.1%-0.15% of other alloy elements and the balance of Al. the other alloy elements comprise the combination of Mn, B, Ni, V, Cr, Zr and rare earthelements, and the ratio of the Mn to the B to the Ni to the V to the Cr to the Zr to the rare earth elements is (0.1-0.2): (0.05-0.1): (0.2-0.4): (1.0-1.2): (0.2-0.4): 0.5; the rare earth elements comprise one of Gd, La and Eu. The high-thermal-conductivity aluminum alloy disclosed by the invention has good mechanical properties while having good thermal conductivity.

Owner:福建祥鑫股份有限公司

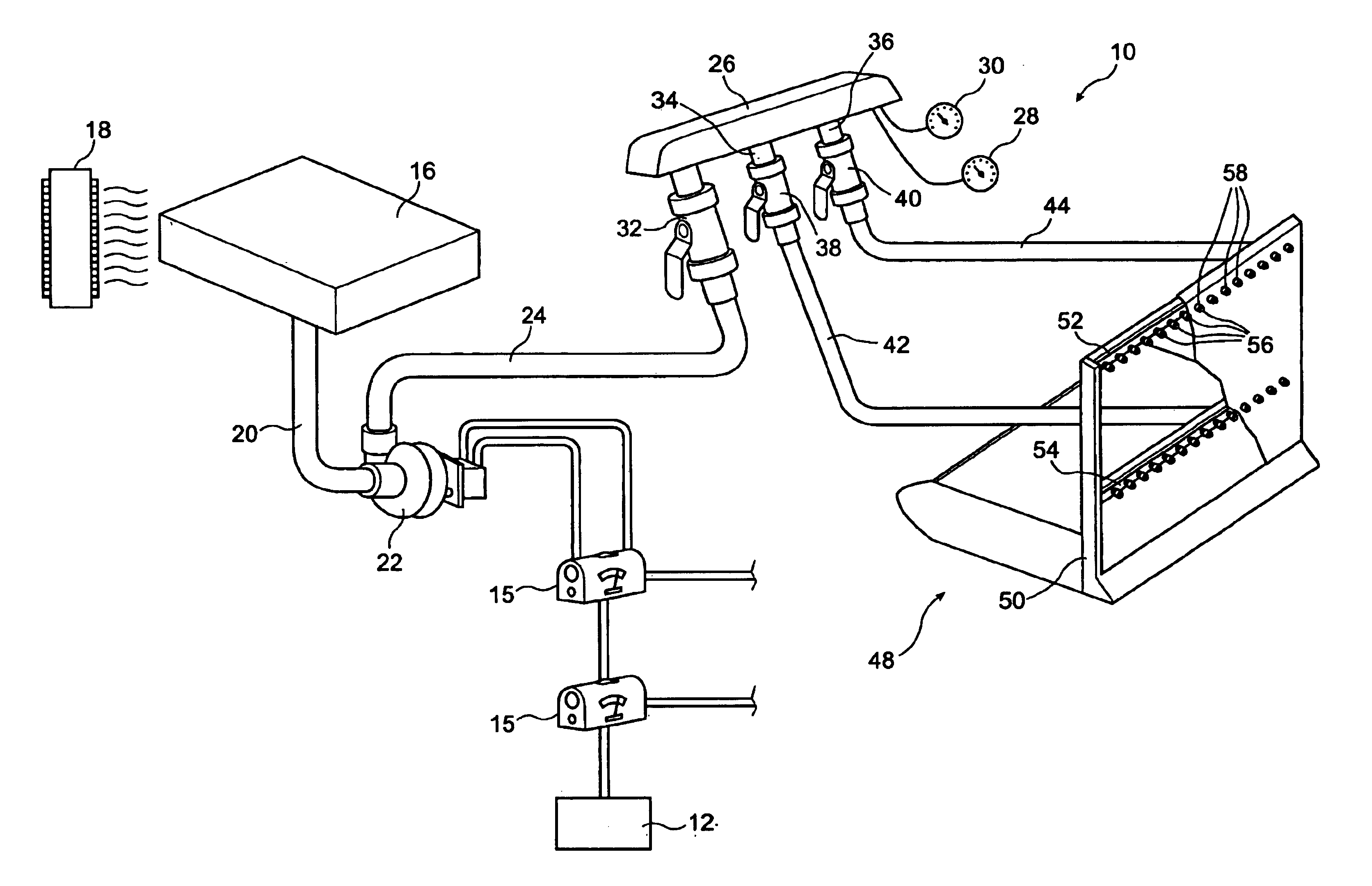

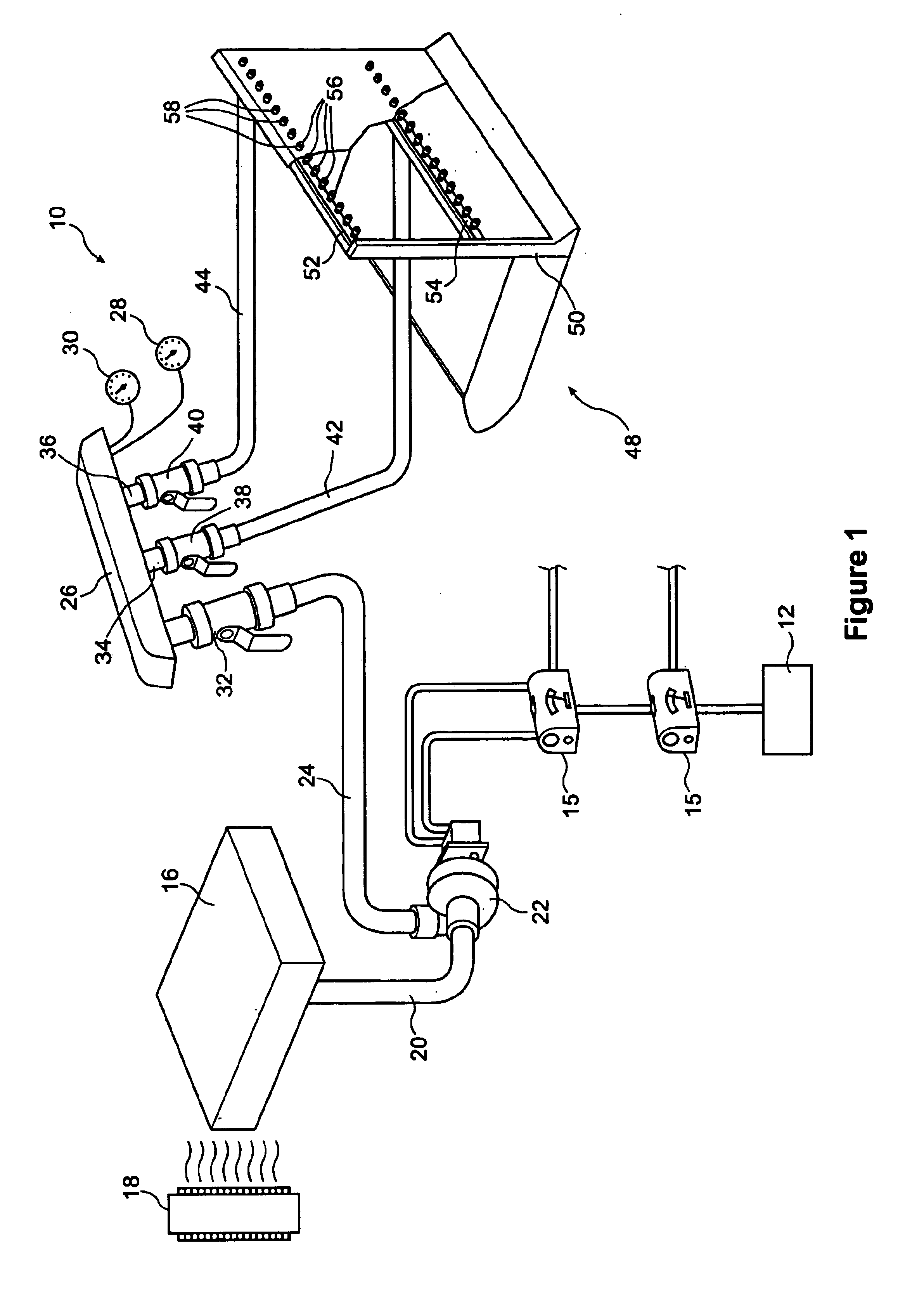

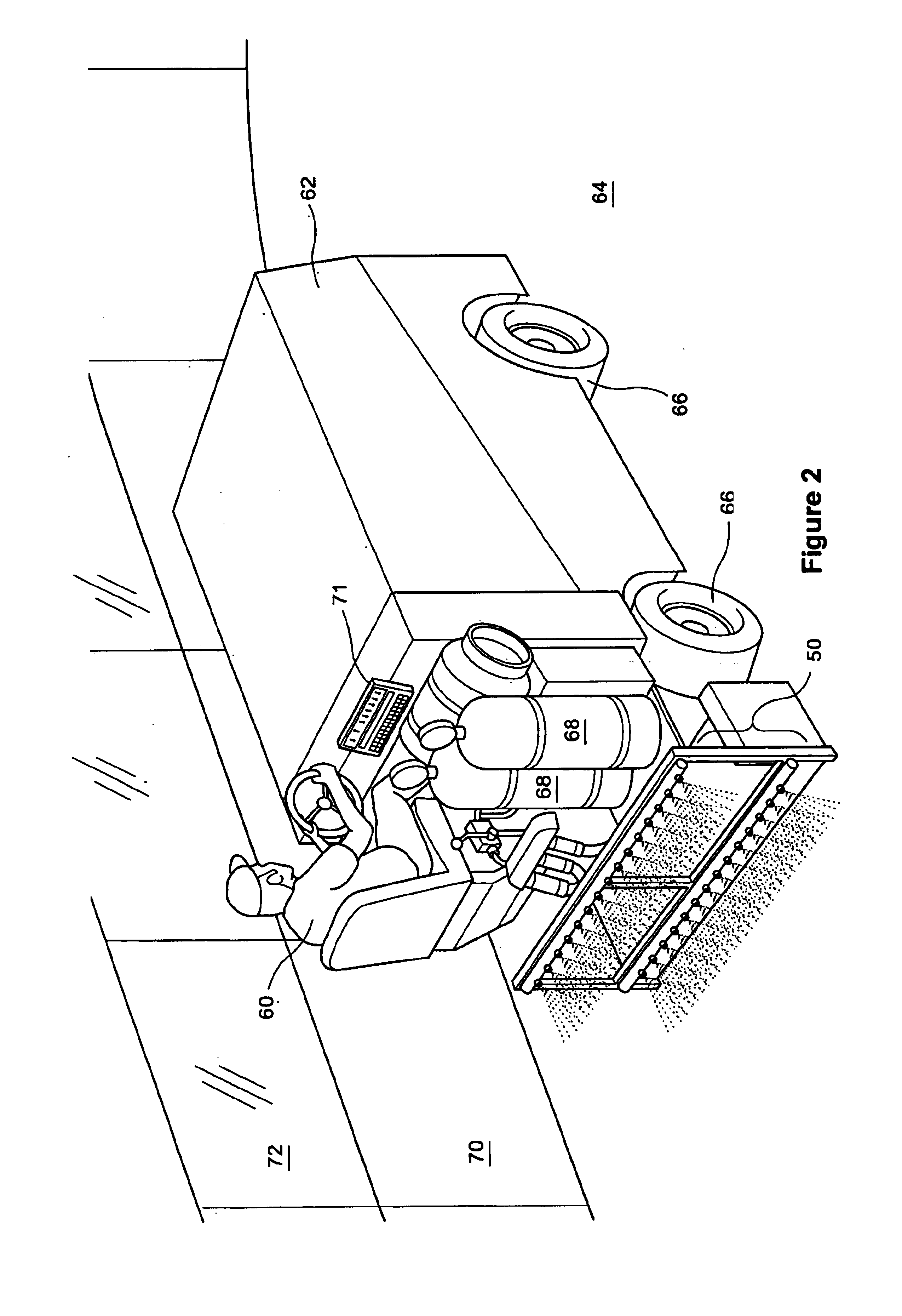

Ice maker and a method of making ice

An ice maker for creating a layer of ice on a cooled surface, is disclosed. The ice maker has a source of de-gassed water, which may be de-gassed by being heated. A pump to pressurize the de-gassed water is provided and the water is passed to a sprayer hydraulically connected to the pump. The sprayer has nozzles sized and shaped to convert the pressurized water into a fine de-gassing droplet spray directed at the cooled surface. The droplets are sized to substantially freeze on contact with the cooled surface. In one embodiment a microprocessor is provided to change the volume sprayed according to the speed of the ice maker to ensure an even coat of ice is layed down.

Owner:FRANK J ZAMBONI & CO LTD

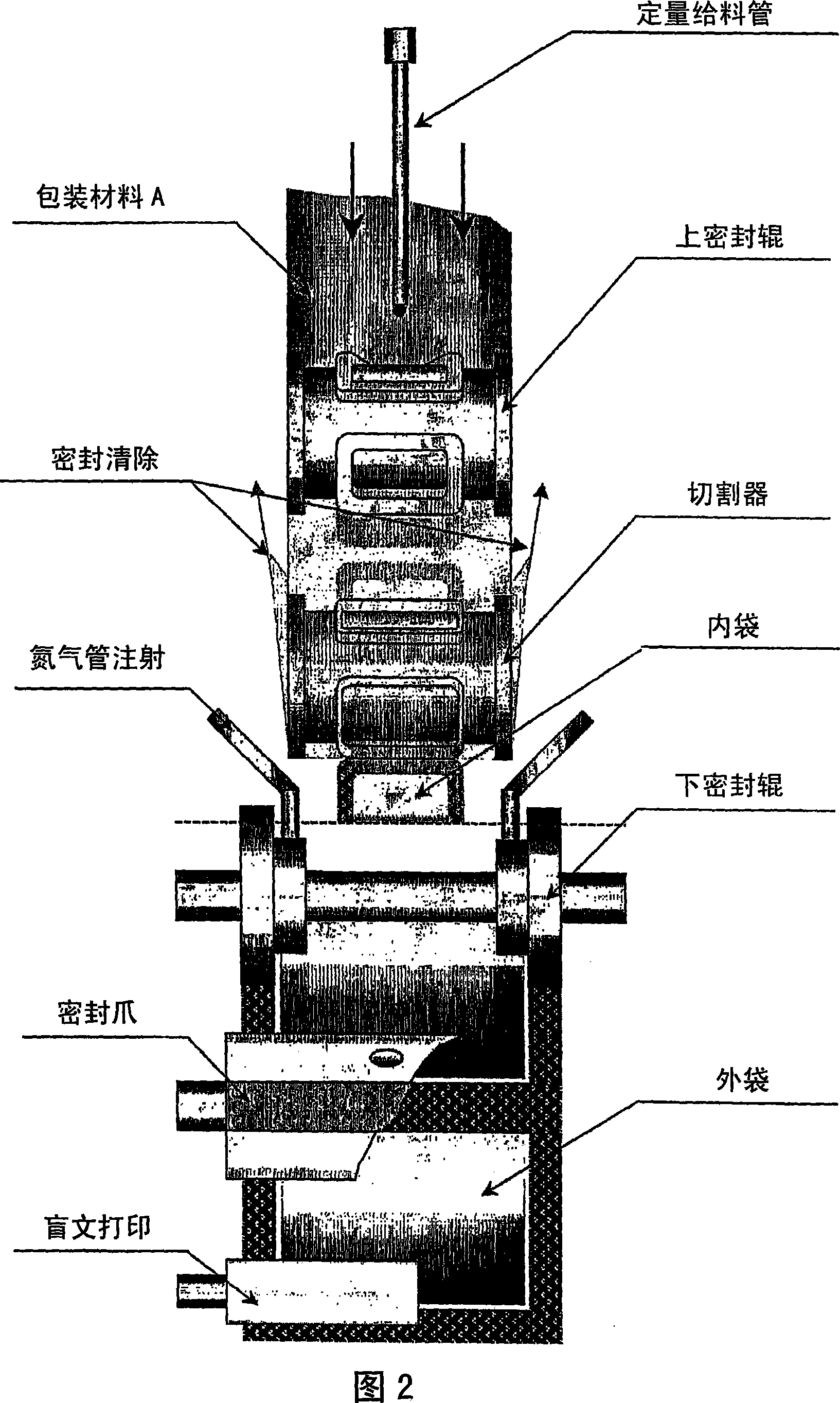

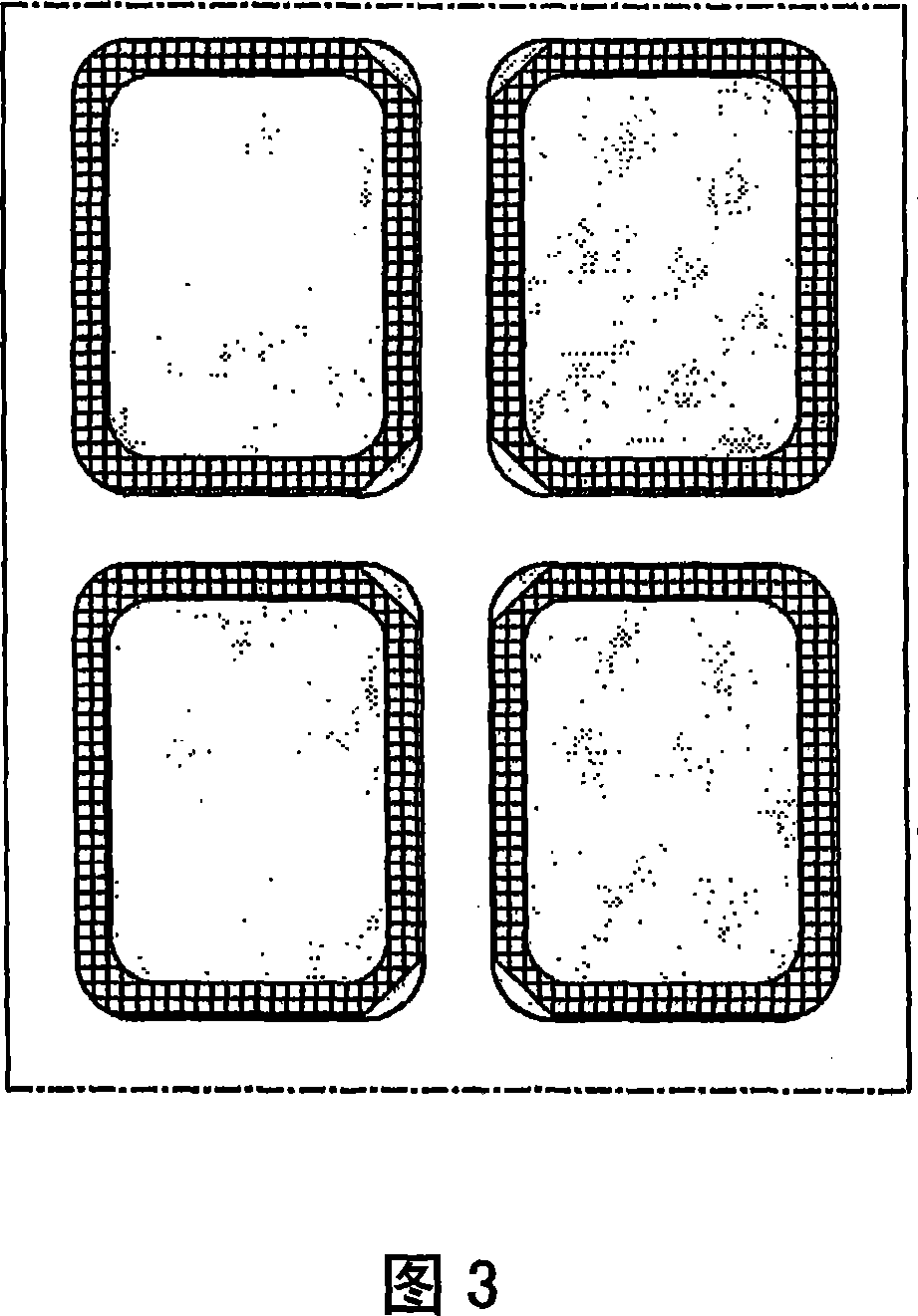

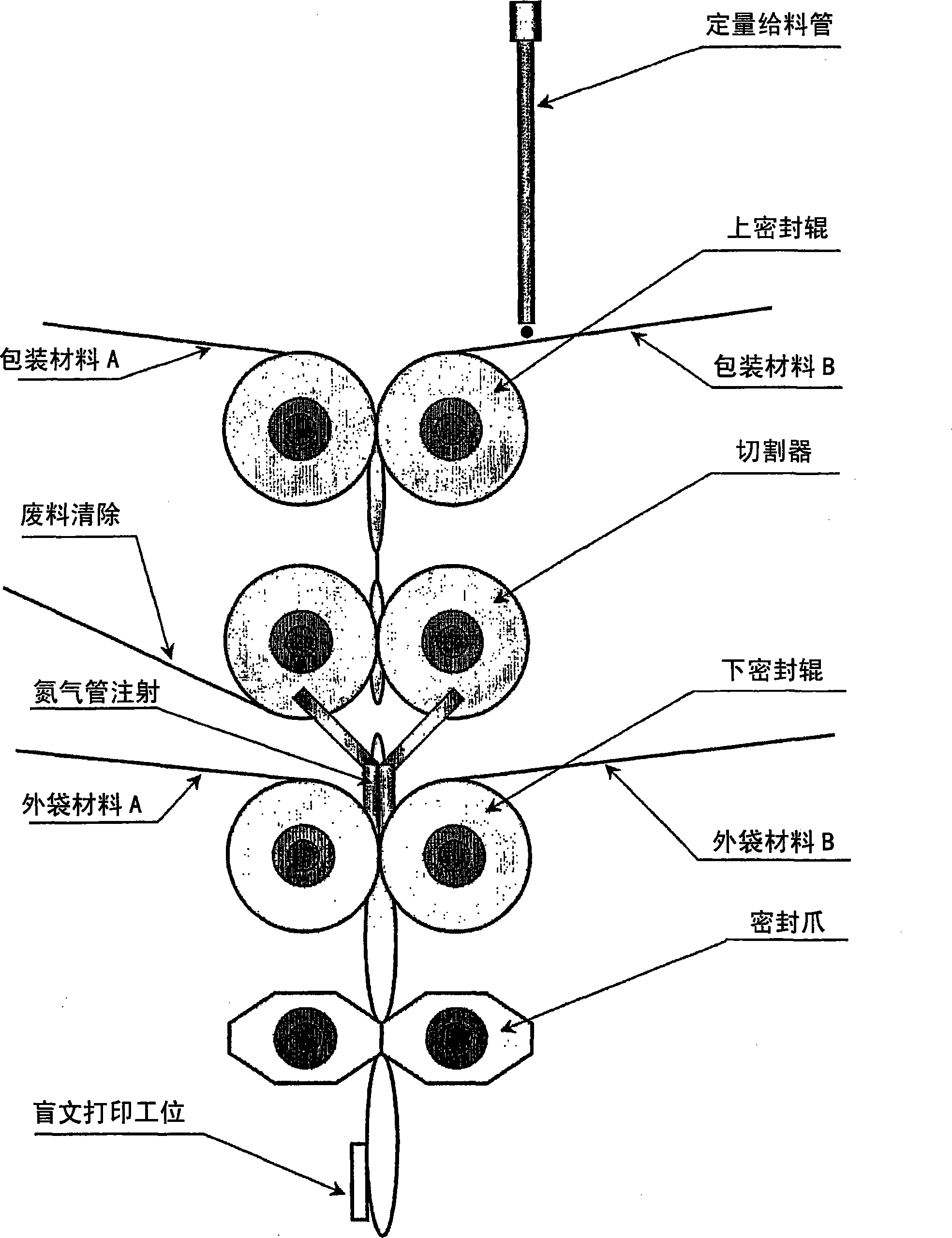

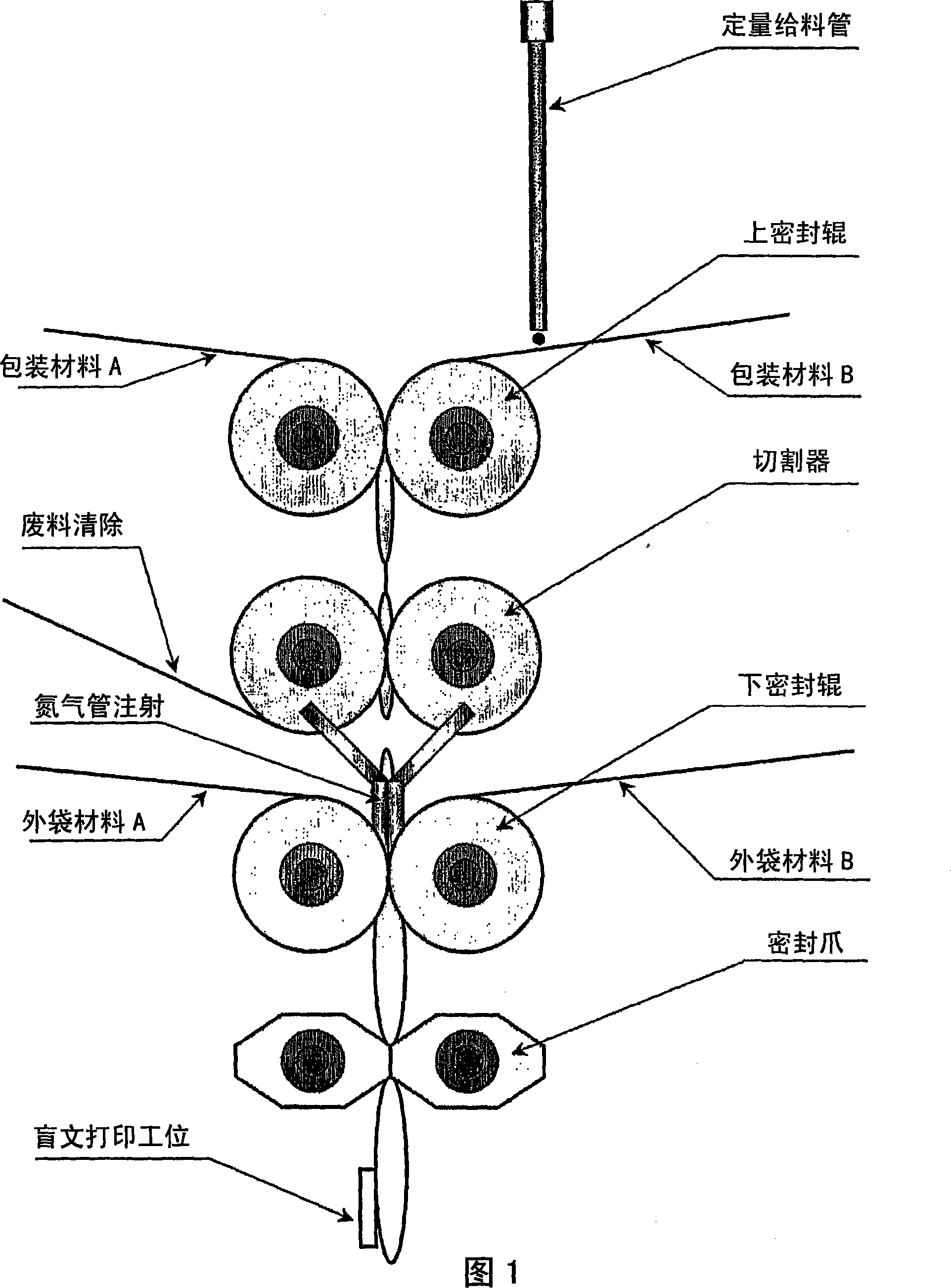

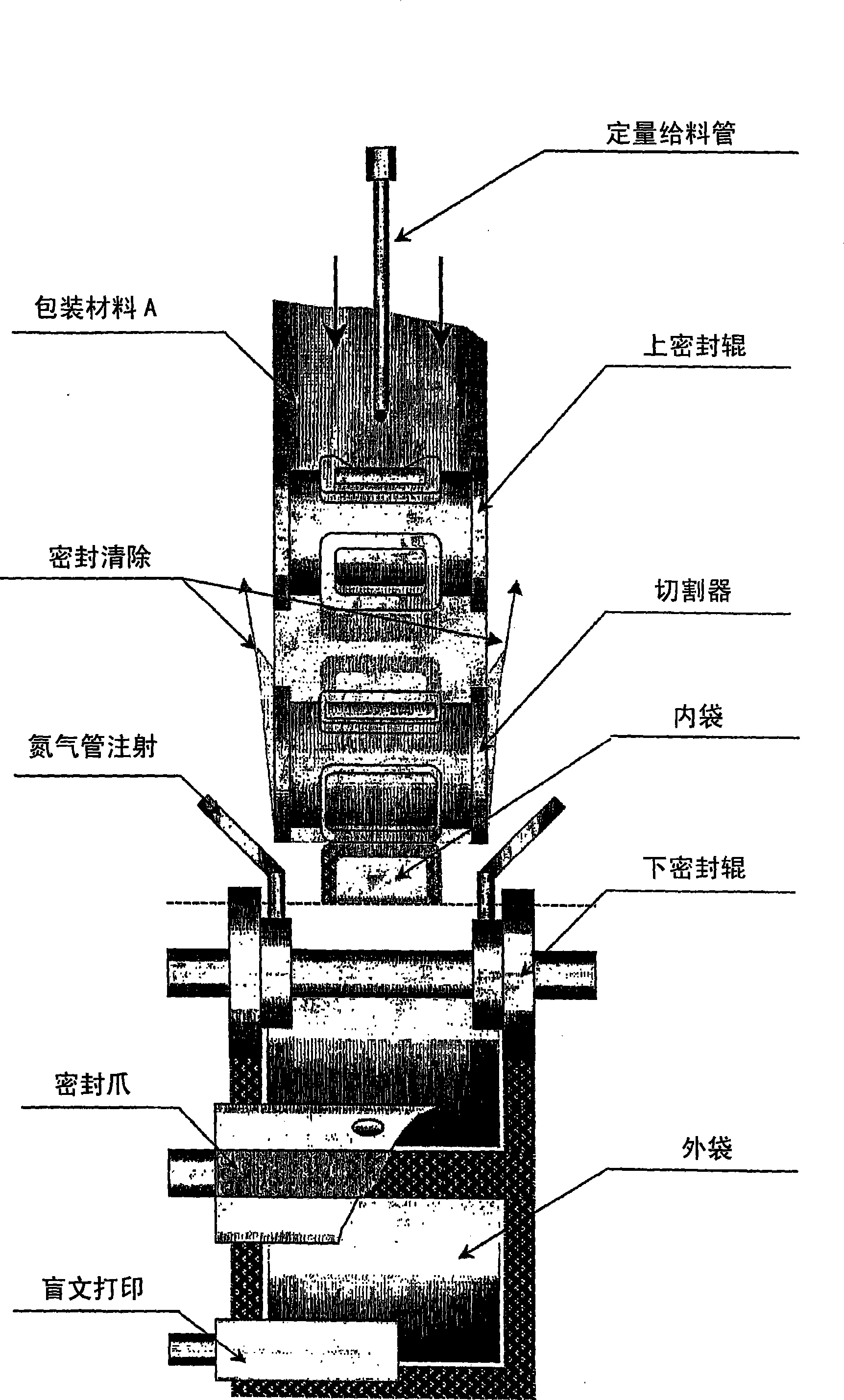

Form-fill-seal process

InactiveCN1984813ATamper evidentEffective degassingAdhesive dressingsWrapper twisting/gatheringMechanical engineeringOne stage

A one stage process for the preparation reservoir patches comprises feeding webs to a first pair of sealing rollers and, thence, directly to a second pair of die-cutting rollers, and preferably directly into a packaging step, thereby avoiding most operatorrelated error, and substantially increasing overall sterility and reproducibility.

Owner:TRANSDERMAL TECH & SYST TTS

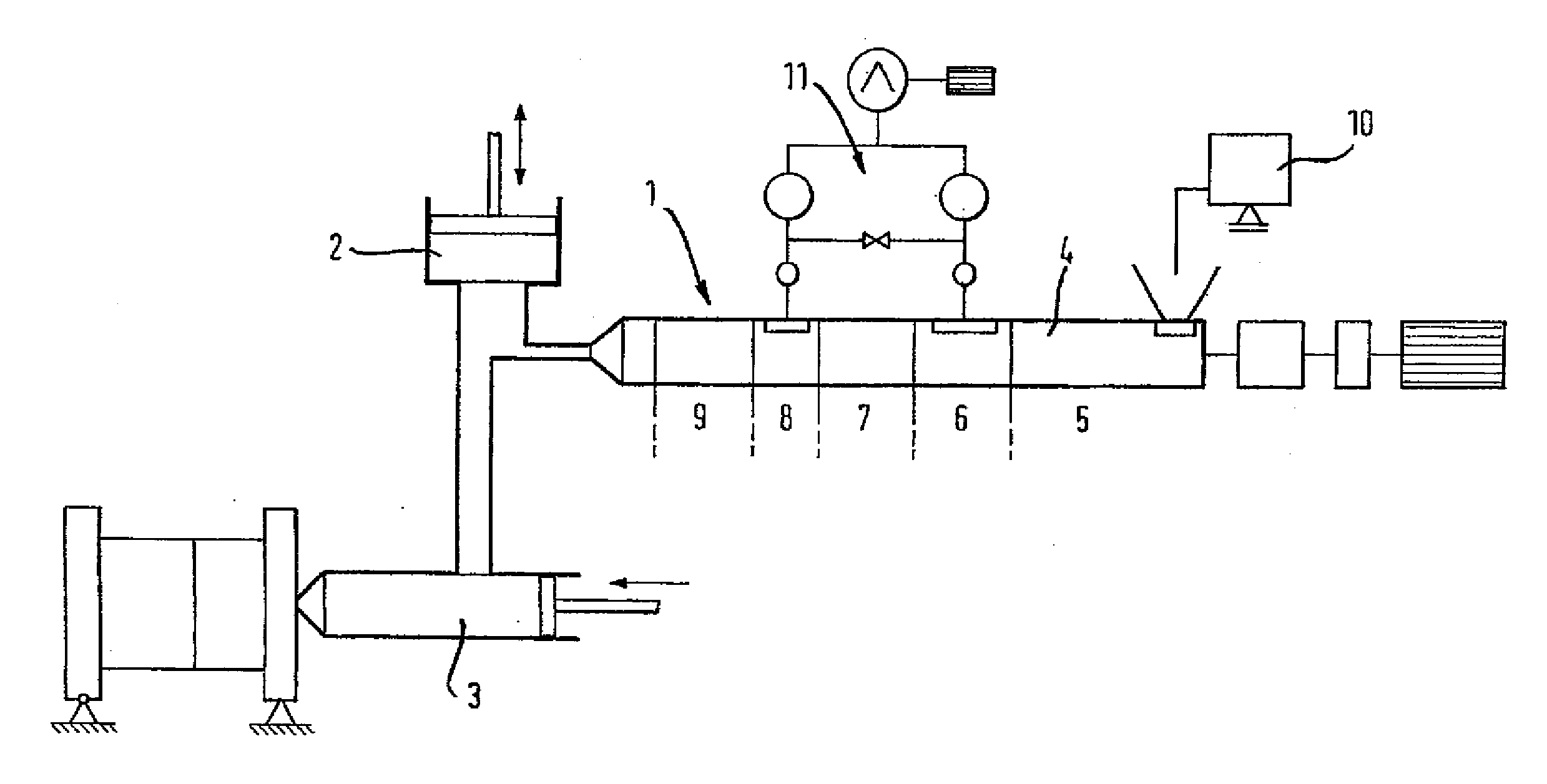

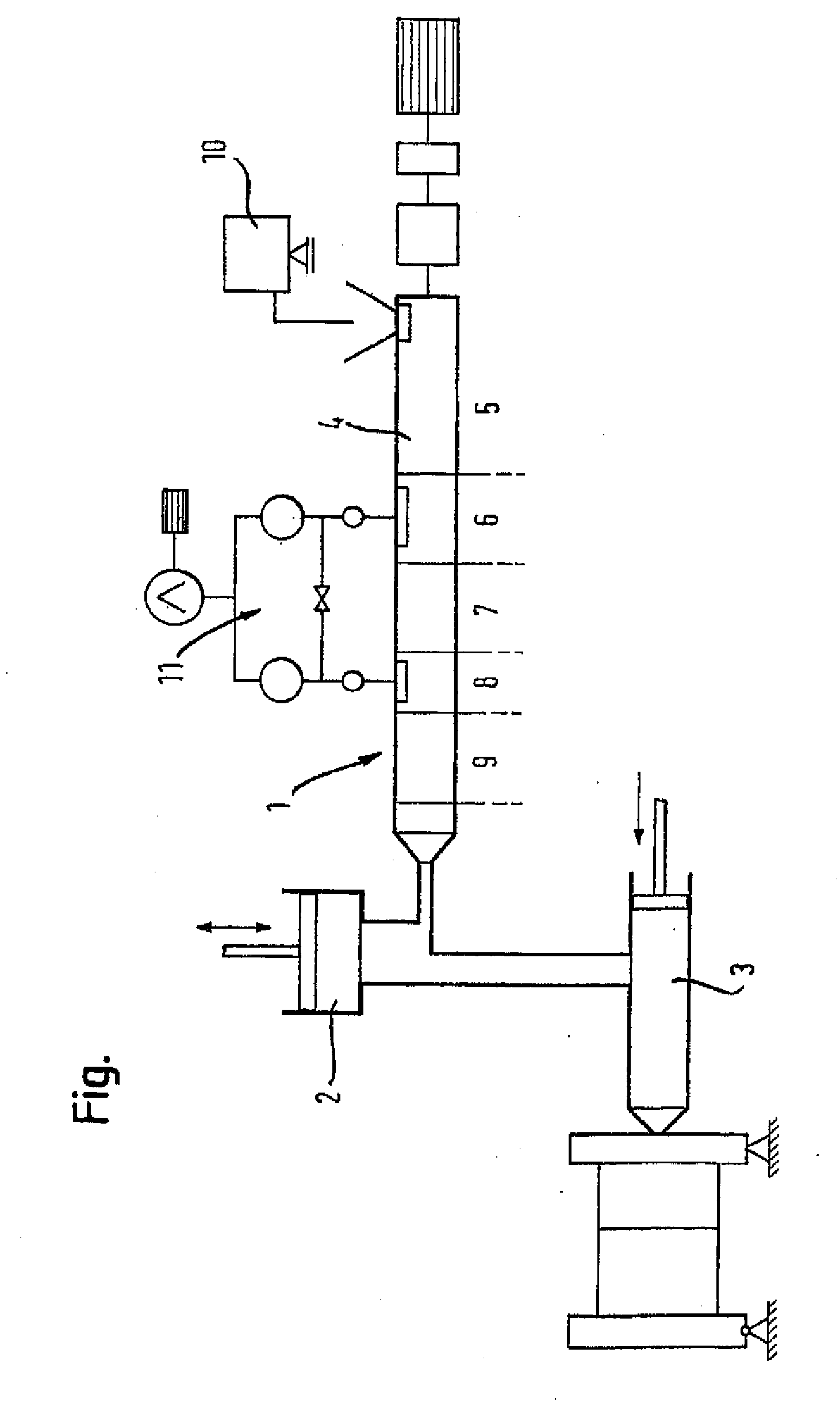

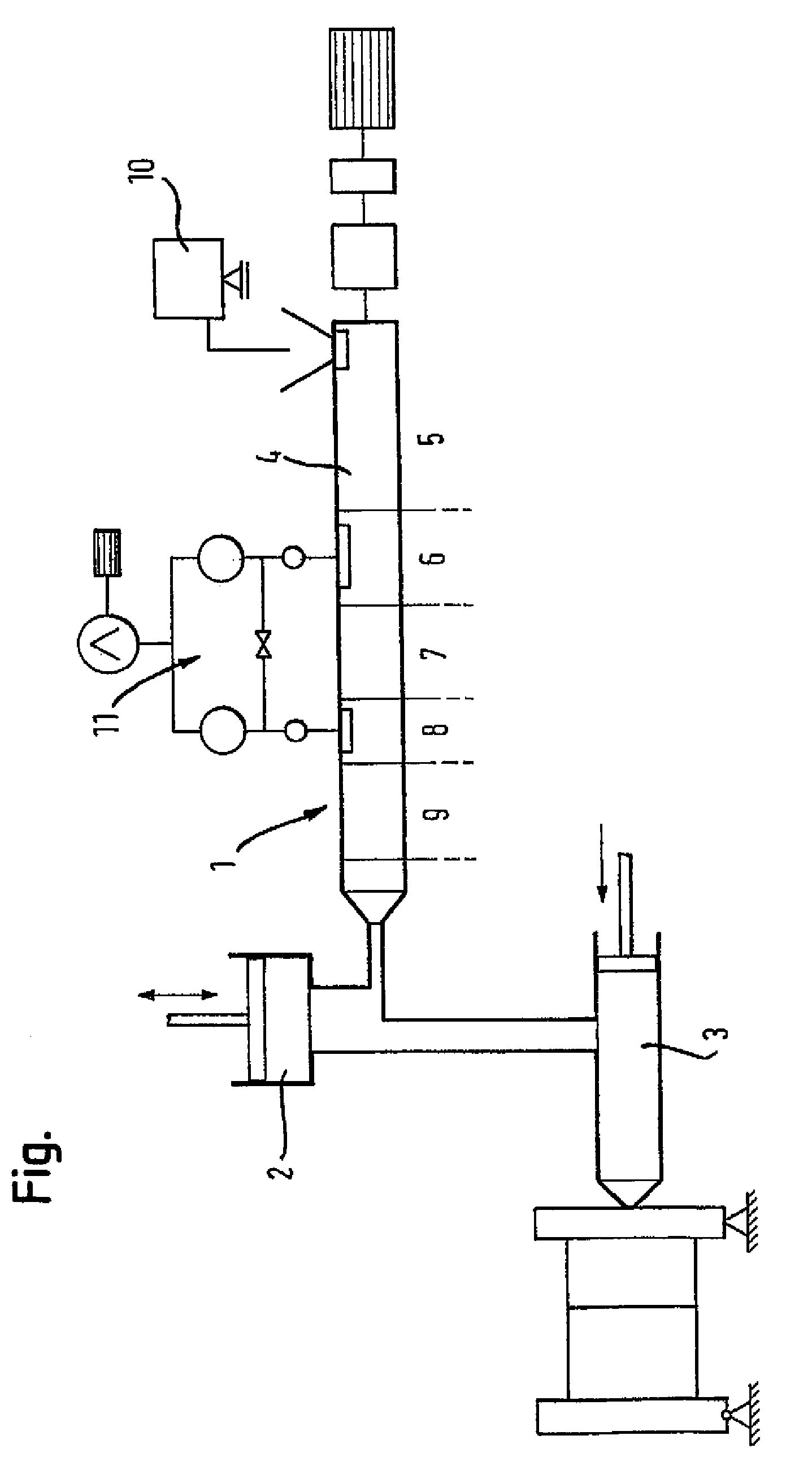

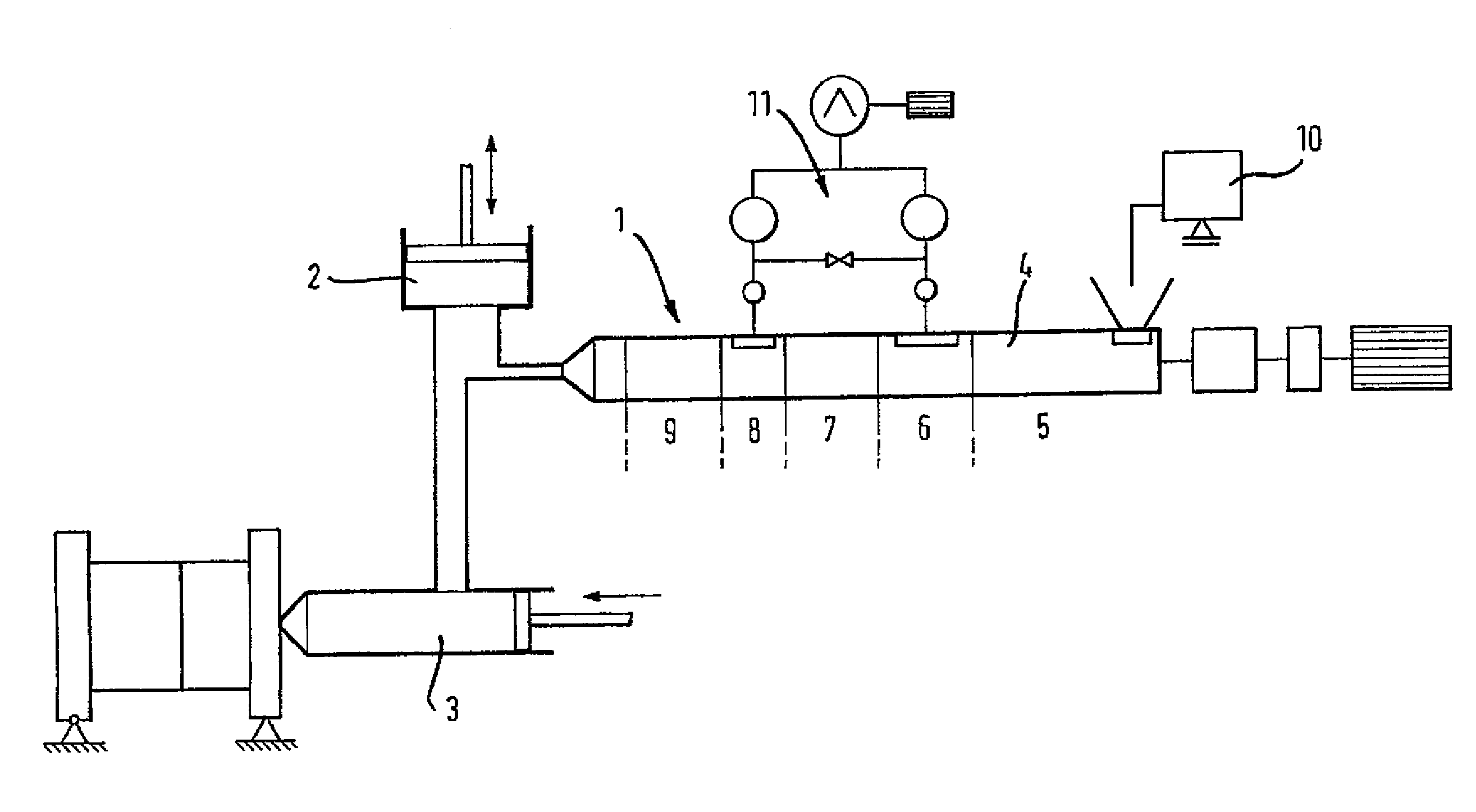

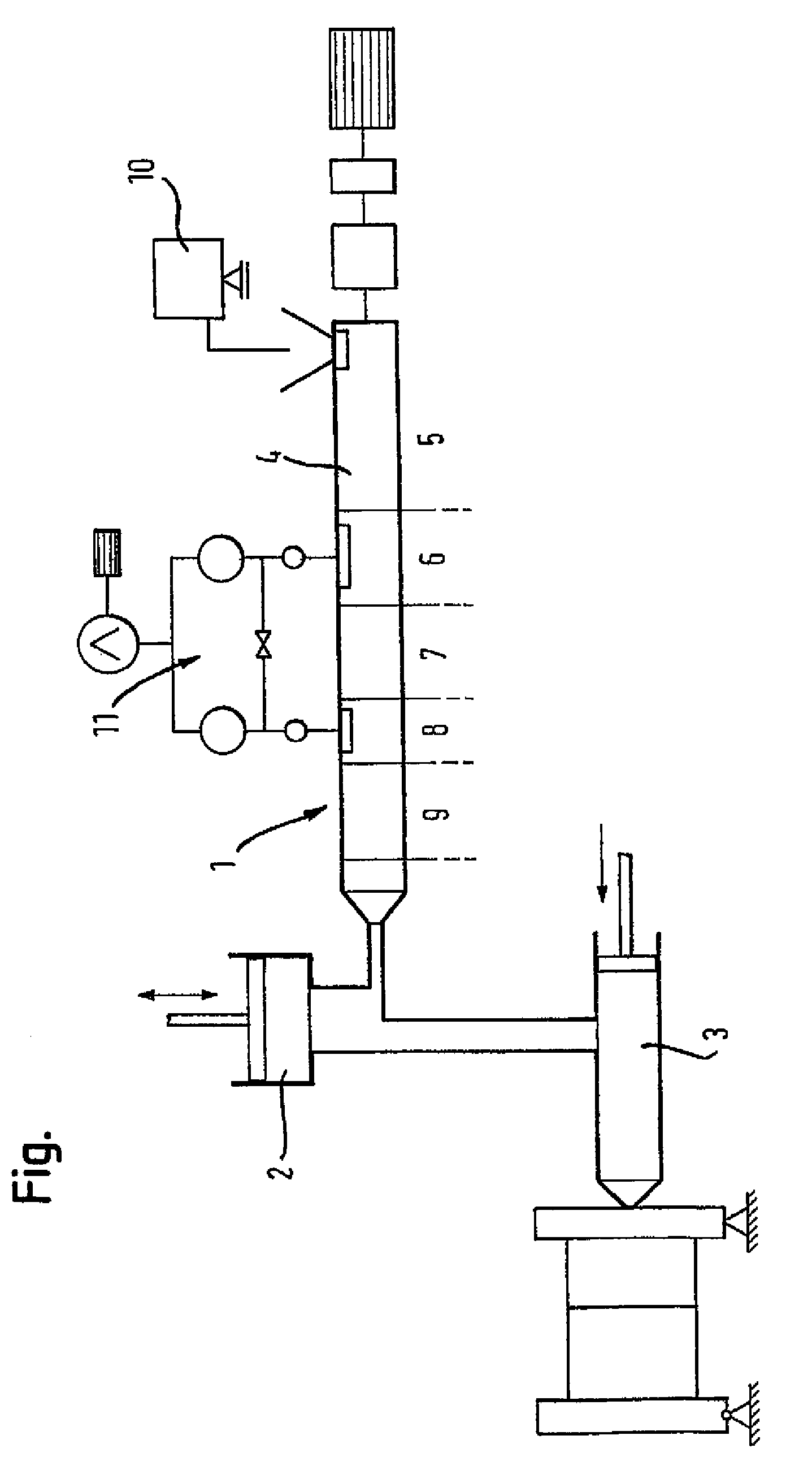

Apparatus for producing injection-molded parts

InactiveUS20070262489A1Excellent barrier propertiesSignificant energy savingEngineeringMechanical engineering

Apparatus for producing injection-molded parts, particularly PET preforms, includes a twin-screw extruder or multi-screw extruder for preparing and / or plasticizing material, preferably in granular form, which is transferred to a transfer reservoir. A piston unit further processes the material. The extruder has a plurality of processing zones, whereby at least two process zones are configured as degassing zones.

Owner:BERSTORFF GMBH +1

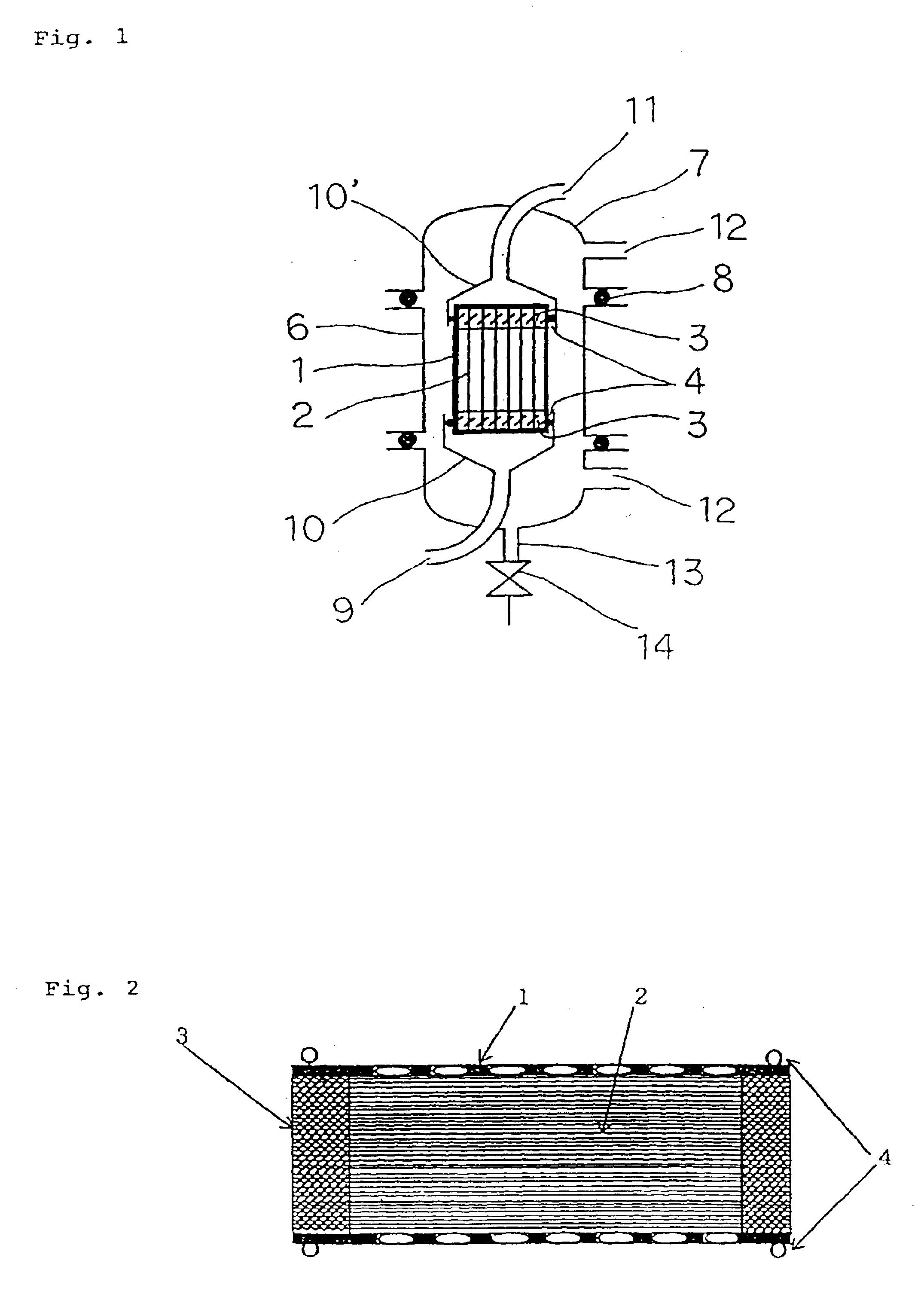

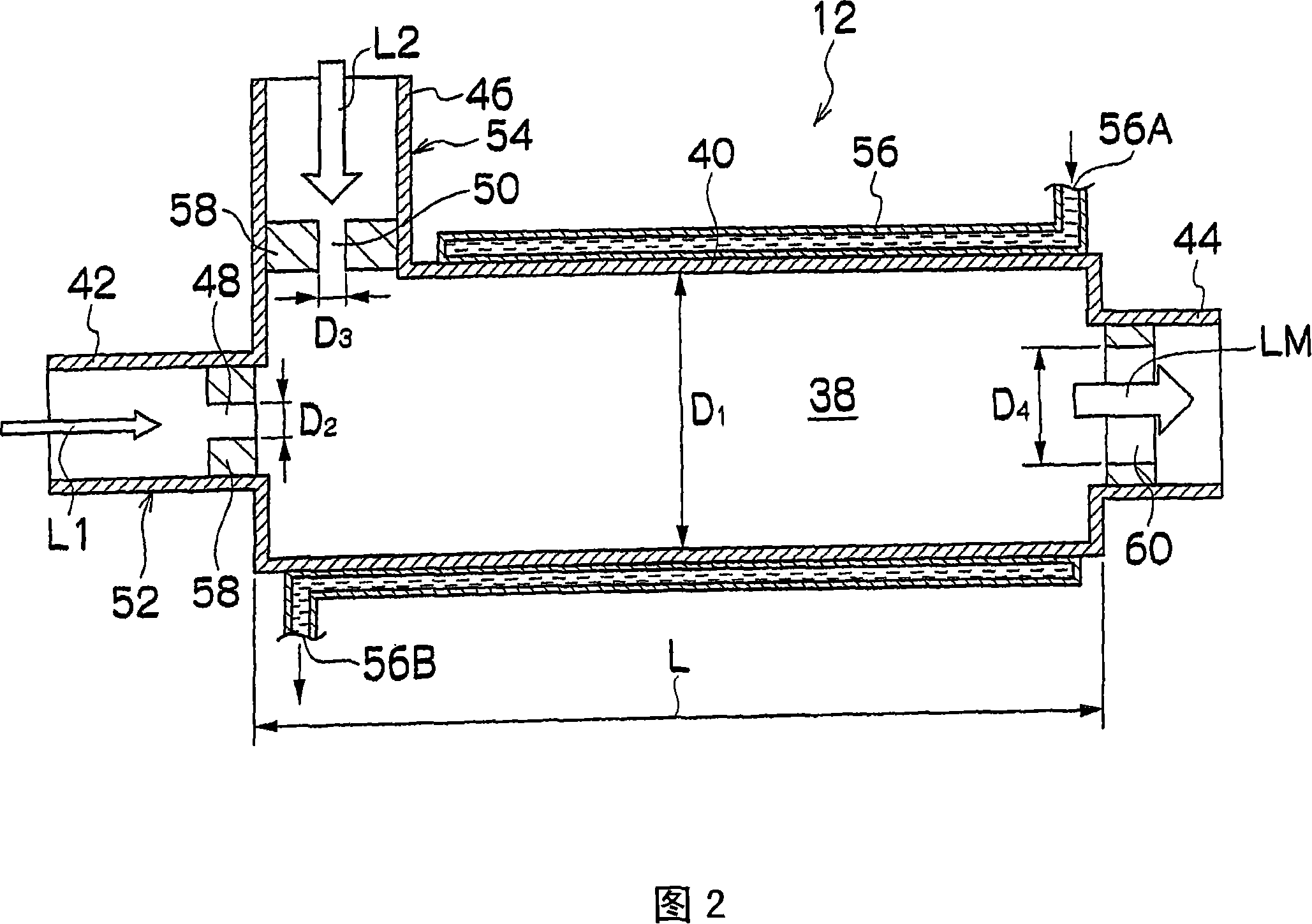

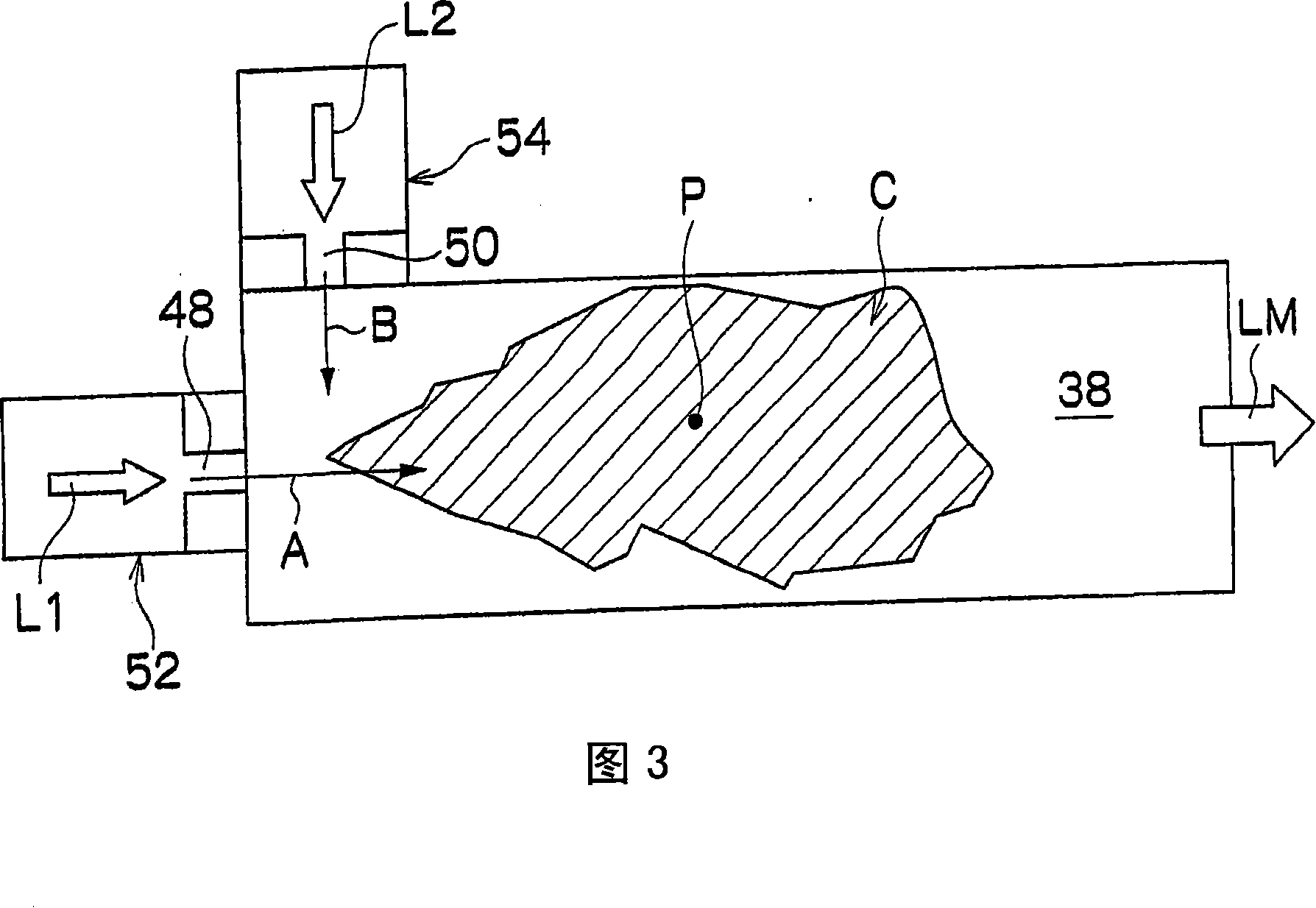

Hollow fiber membrane for the degassing of inks, ink degassing method, ink degassing apparatus, method for the fabrication of an ink cartridge, and ink

InactiveUS6858063B2Efficient degasEffective degassingSemi-permeable membranesMembranesHollow fibre membraneProduct gas

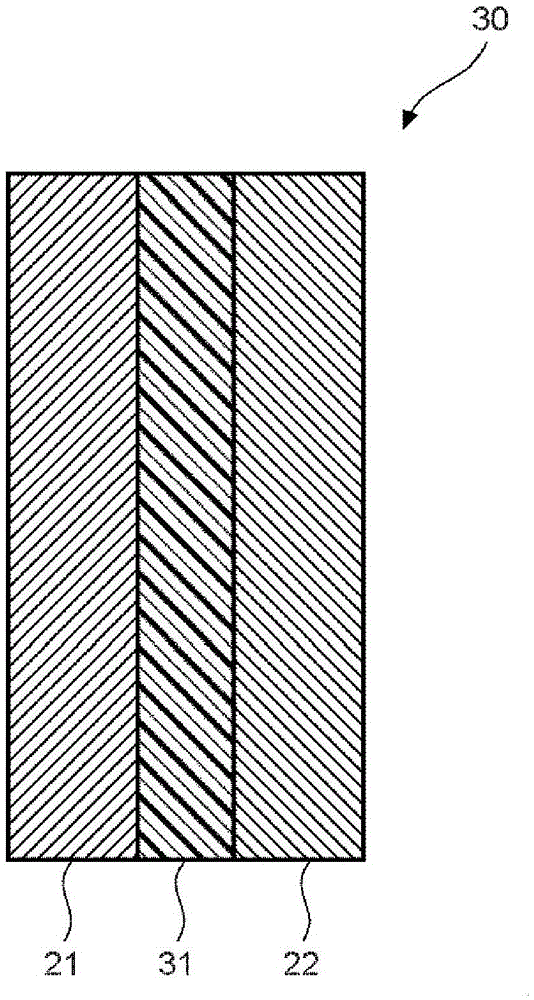

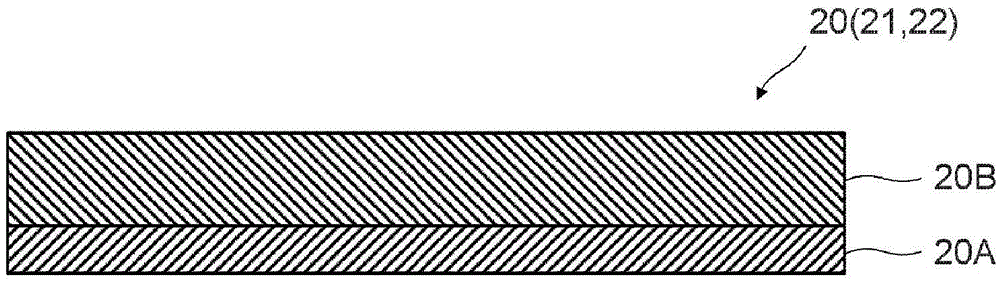

The present invention provides a gas-permeable hollow fiber membrane having an inner diameter of 50 to 500 μm and a membrane thickness of 10 to 150 μm, which is preferably a composite hollow fiber membrane having a three-layer structure consisting of a nonporous layer having porous layers disposed on both sides thereof. Dissolved gases present in an ink can be removed by passing the ink through the bores of hollow fibers comprising such a hollow fiber membrane, and evacuating the outer surface side of the hollow fibers. This method makes it possible not only to degas inks with a slight pressure loss, but also to degas inks stably even if pressure changes occur during degassing.

Owner:MITSUBISHI CHEM CORP

Degassing method for electrode paste

ActiveCN105914342AEffective degassingLiquid degasification by filtrationFlash degasificationDispersed mediaSolid content

Provided is a degassing method for an electrode paste that introduces the electrode paste formed by kneading a solid content containing an electrode active material and a dispersion medium into a decompressed container and degassing the electrode paste while a shear force is applied to the electrode paste. A ratio of the solid content in the electrode paste is set to be 55 mass% or more, and a pressure in the decompressed container is set to be -50 kPa or more. It is possible to suppress both remaining bubbles and dry of the electrode paste, thus enhancing a product yield.

Owner:TOYOTA JIDOSHA KK

Alloy improved material and preparation method thereof

InactiveCN109943742APrevent impurity phase segregationEliminates slag removal stepHardnessSilicon oxide

The invention relates to an alloy improved material and a preparation method thereof and relates to the field of aluminum alloy modifier. The alloy improved material is composed of spraying depositionpowder, sodium salt modifier and a binding agent. The weight ratio of the spraying deposition powder to the sodium salt modifier to the binding agent is (5-10):(1-3):1. Three modifiers strontium, sodium and rare earth neodymium are combined according to the characteristic, the modification activity is effectively retained, and the alloy improved material has the characteristics of being short inmodification incubation period, long in effective modification time and stable in modification effect. Kaolinite clay powder in raw materials can serve as a modifier carrier to remove gas and slag, the smelting efficiency is improved, and rich aluminum oxide and silicon oxide can improve hardness of an alloy. The luminescence property of a neodymium element enables the aluminum alloy to have the luminescence characteristics, and coating of luminescent materials is not needed. According to the preparation method, the spraying deposition method is adopted for further smelting and preparing tinyintermediate alloy powder, the intermediate alloy powder is bonded with the sodium modifier for extrusion forming, the modifier can be dissolved and dispersed rapidly, the incubation period is shortened, and rapid and effective modification is achieved.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Molding method and mold therefor

Molding methods and molds for making a synthetic resin molded product include disposing a curable liquid resin mixture in a recess of a female mold. The curable liquid resin mixture is then simultaneously agitated and degassed by a mixer while under a partial vacuum. More specifically, at least the female mold is orbited around an orbital axis while being rotated about a rotational axis that is eccentric to the orbital axis. After being thoroughly mixed and degassed, the liquid mixture is then cured in the mold unit.

Owner:KAGA SANGYO

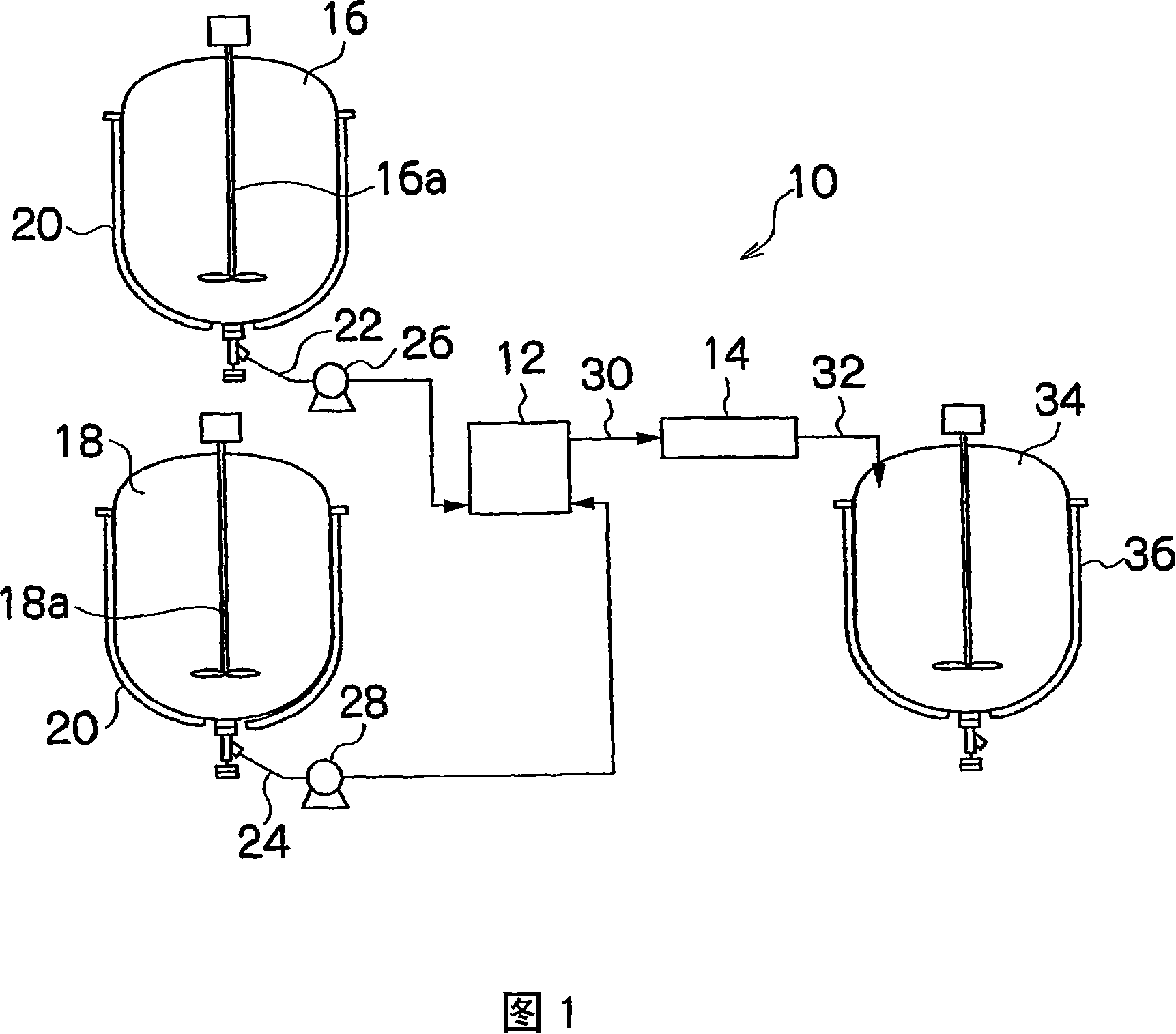

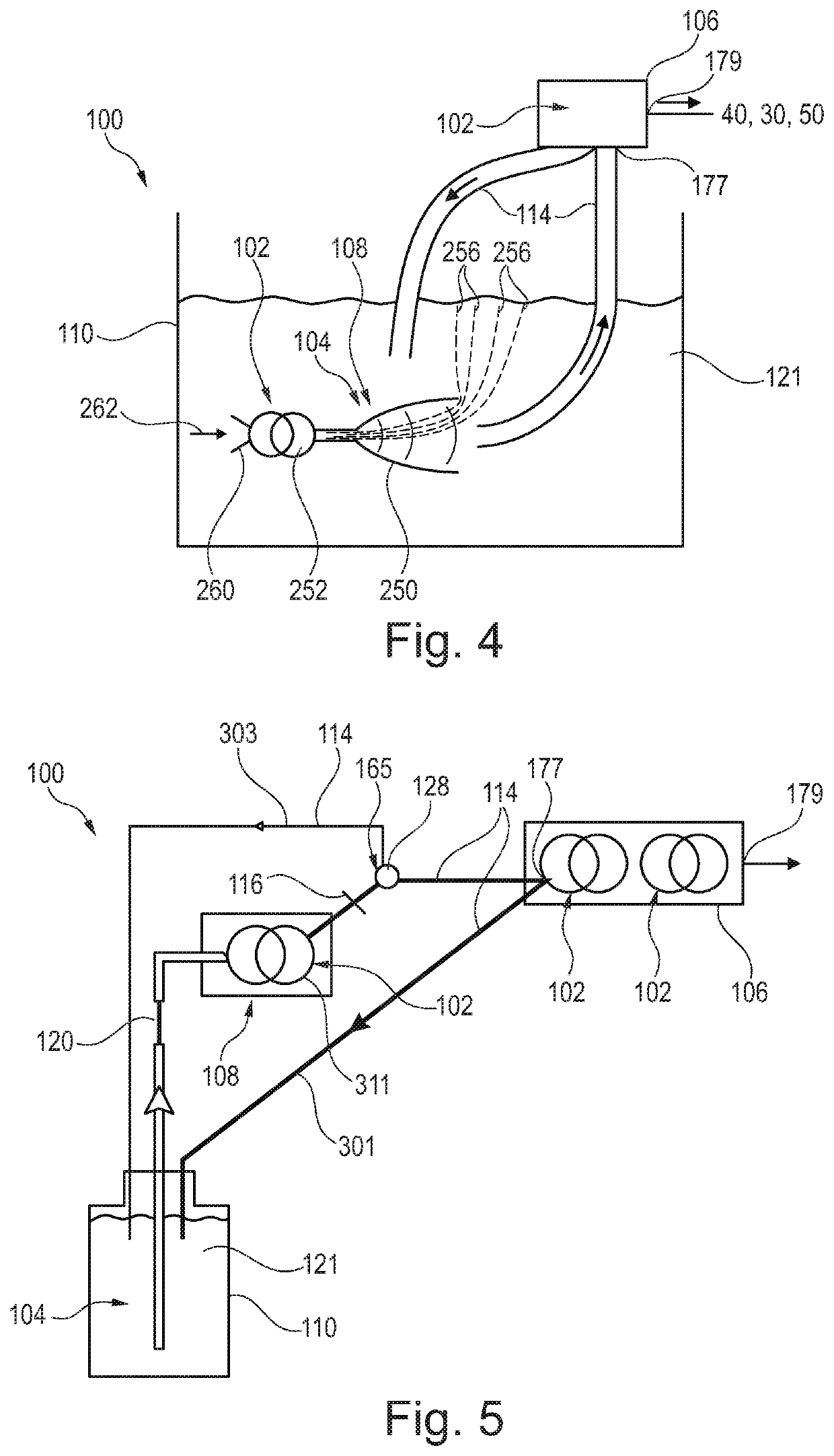

Reaction method and apparatus and method and apparatus for manufacturing chemical substance using the same

InactiveCN101151093AStable supplySpeed up the flowLiquid degasificationMixing methodsReaction systemGas bubble

The present invention provides a reaction method for a reaction system generating gas by a reaction, comprising the steps of: providing a sealed mixing section for mixing a plurality of liquids to start a reaction and a degassing section having a gas-liquid interface for removing, from a reaction liquid, gas bubbles generated from a mixed reaction liquid, separately; and feeding the reaction liquid mixed in the mixing section to the degassing section, without being interfered by gas bubbles even in a reaction system where gas is generated by a reaction, so that it is possible to stabilize a reaction at the start of the reaction and in the progress of the reaction and stably feed liquid to a subsequent process.

Owner:FUJIFILM CORP

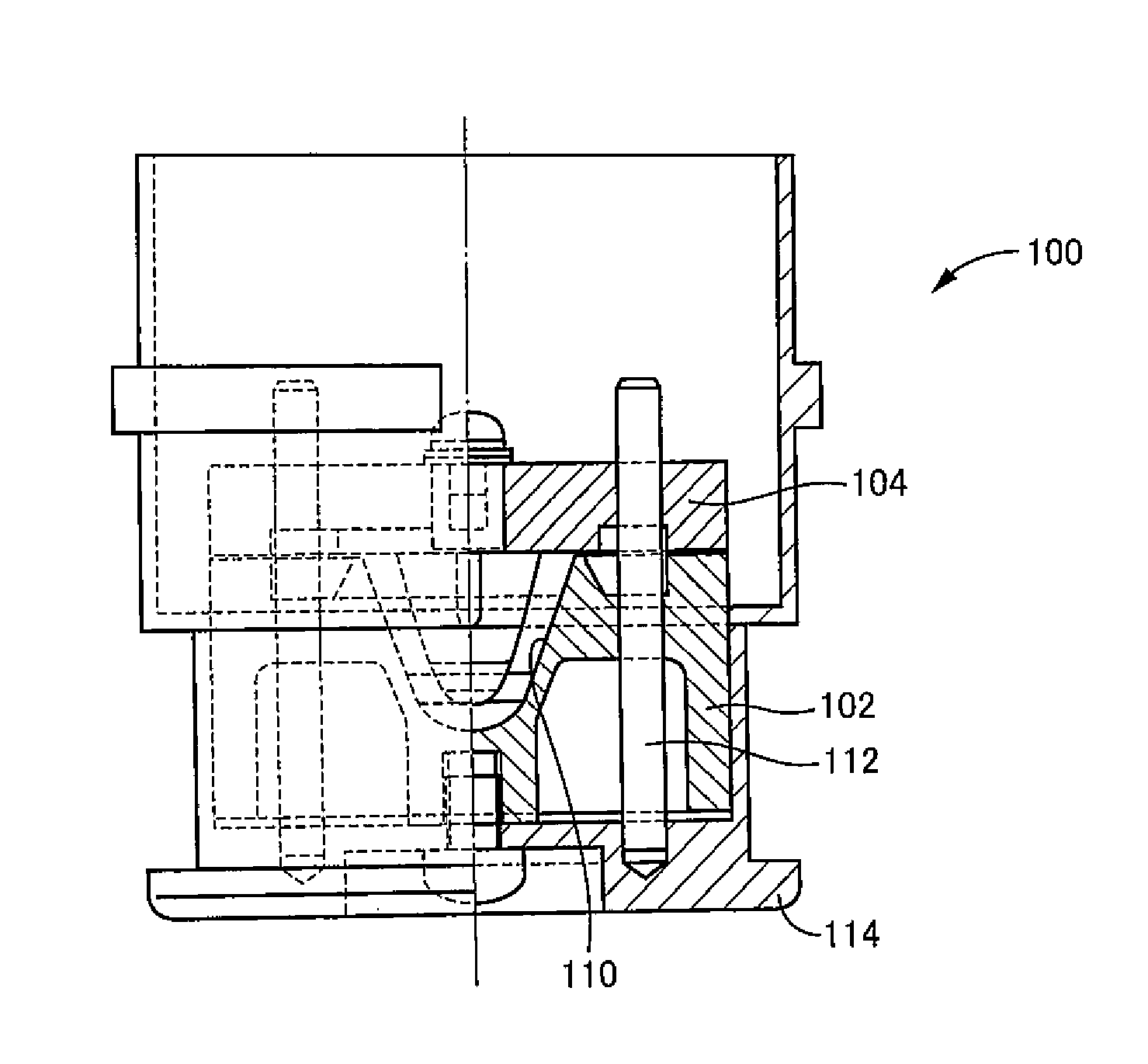

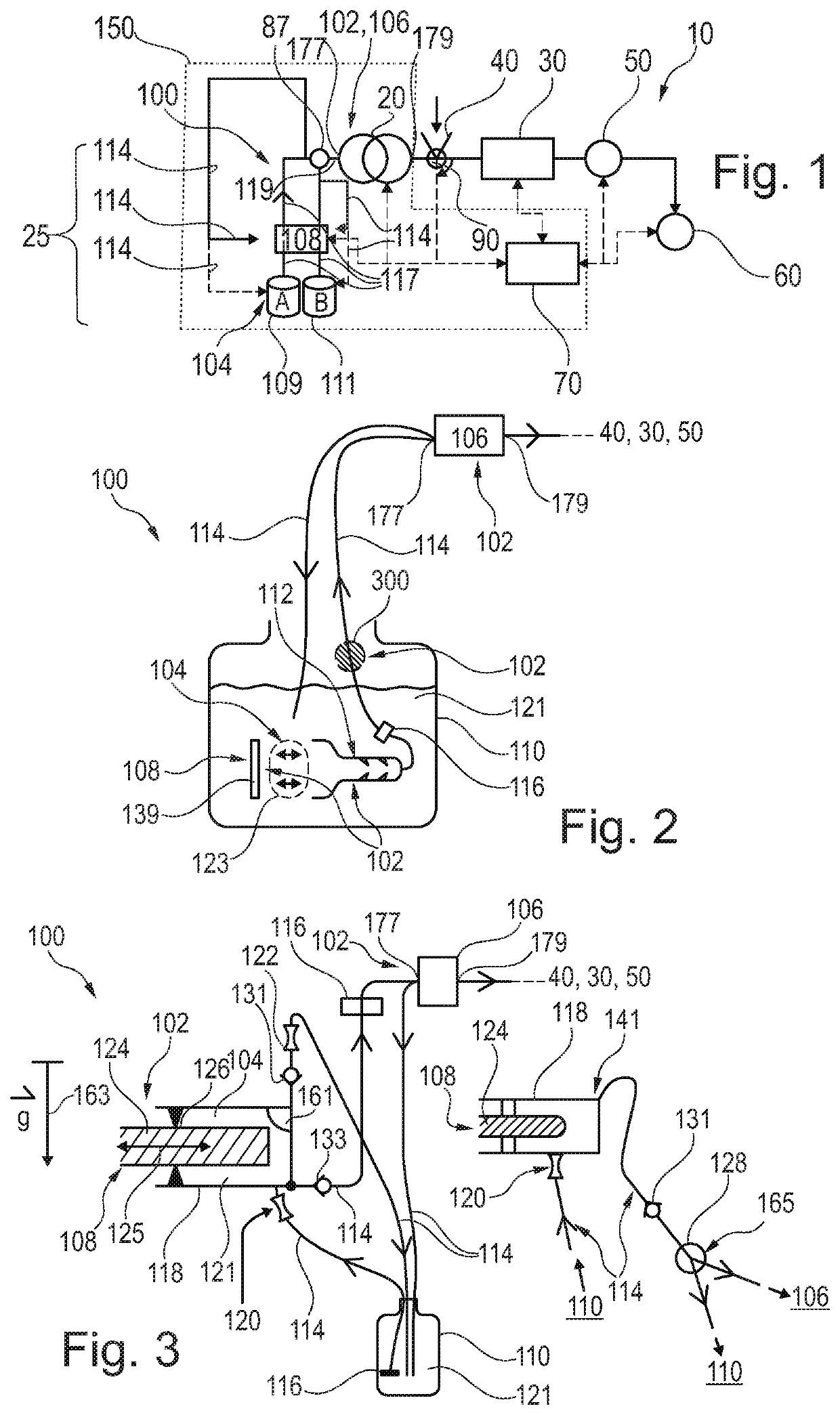

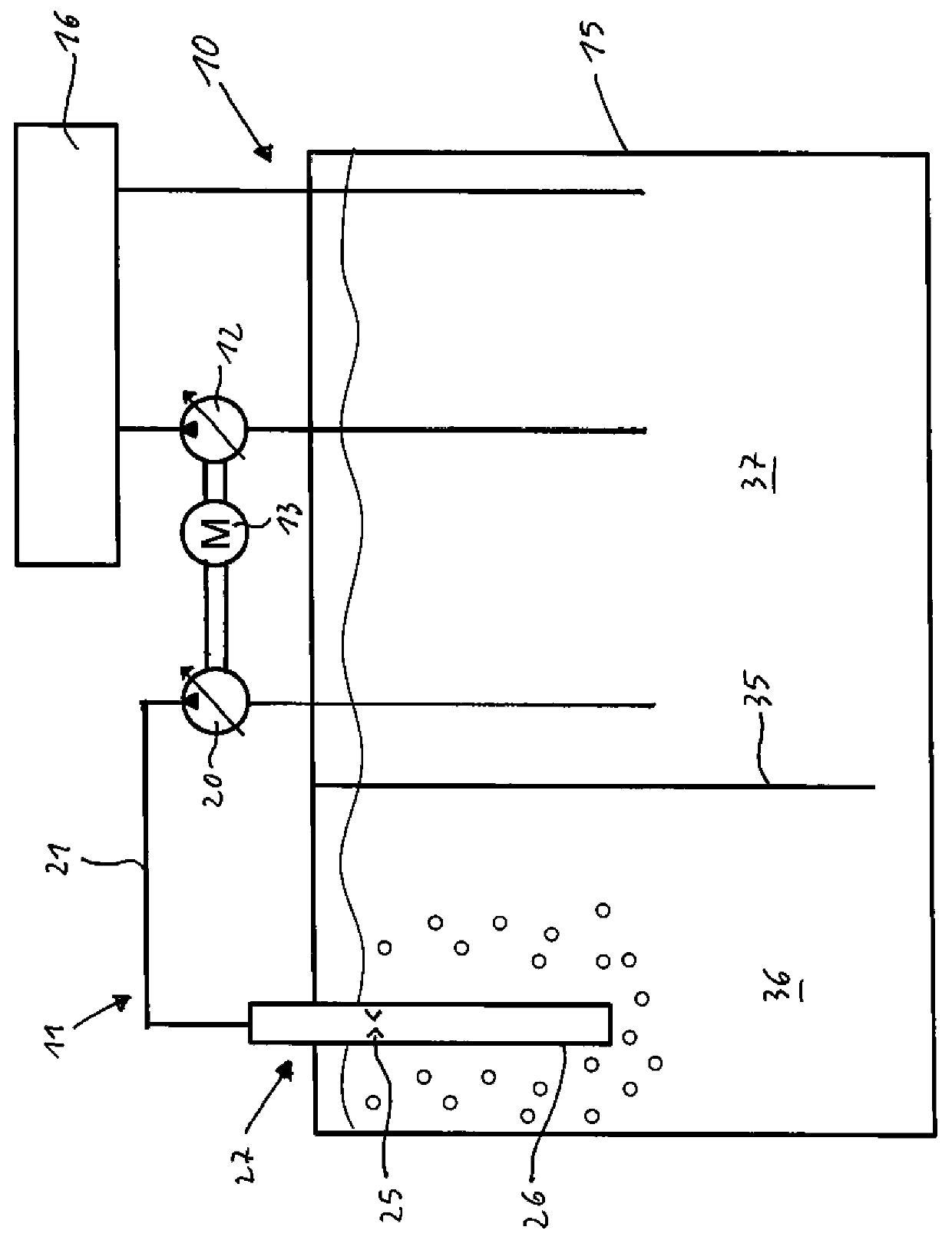

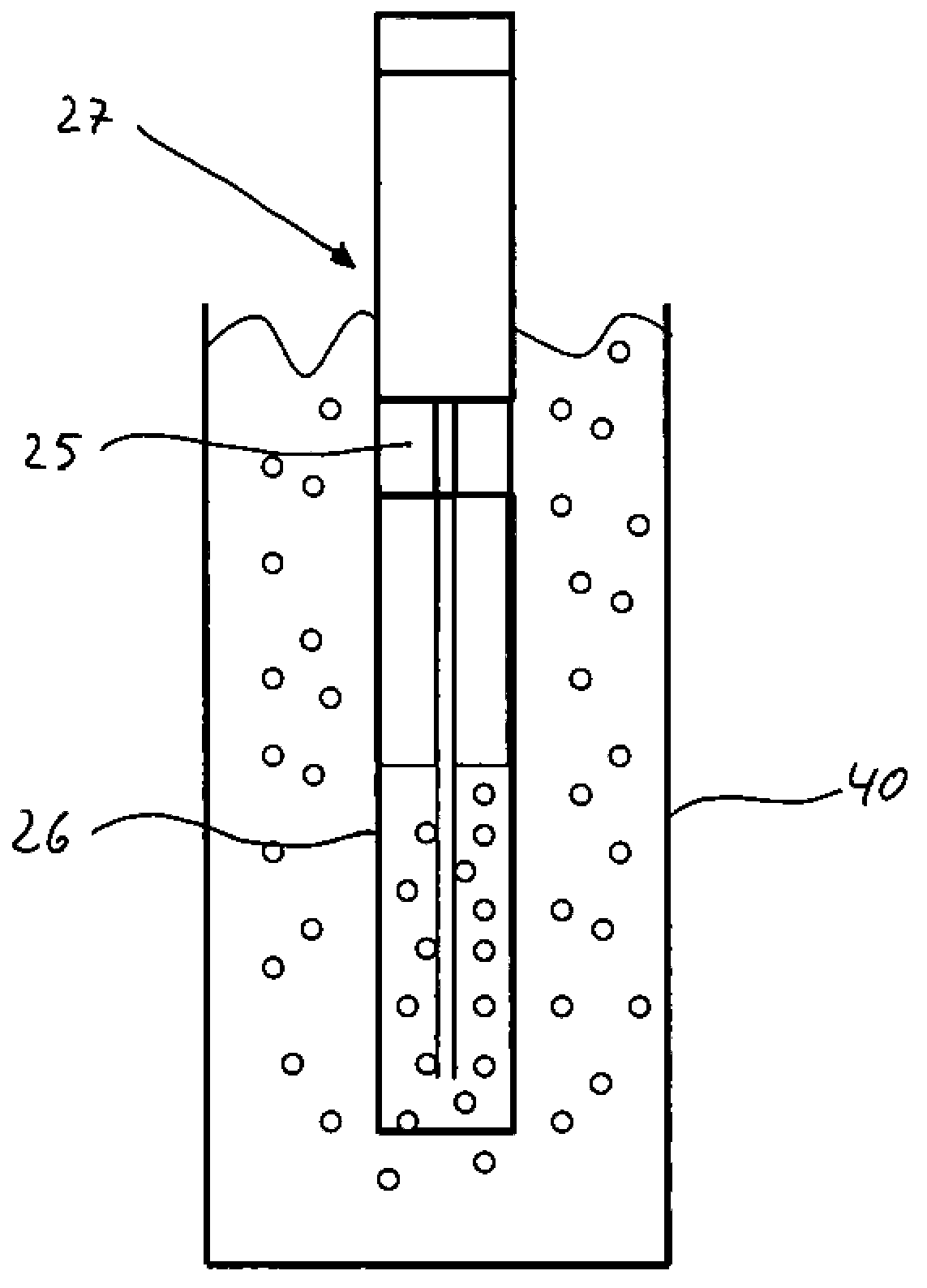

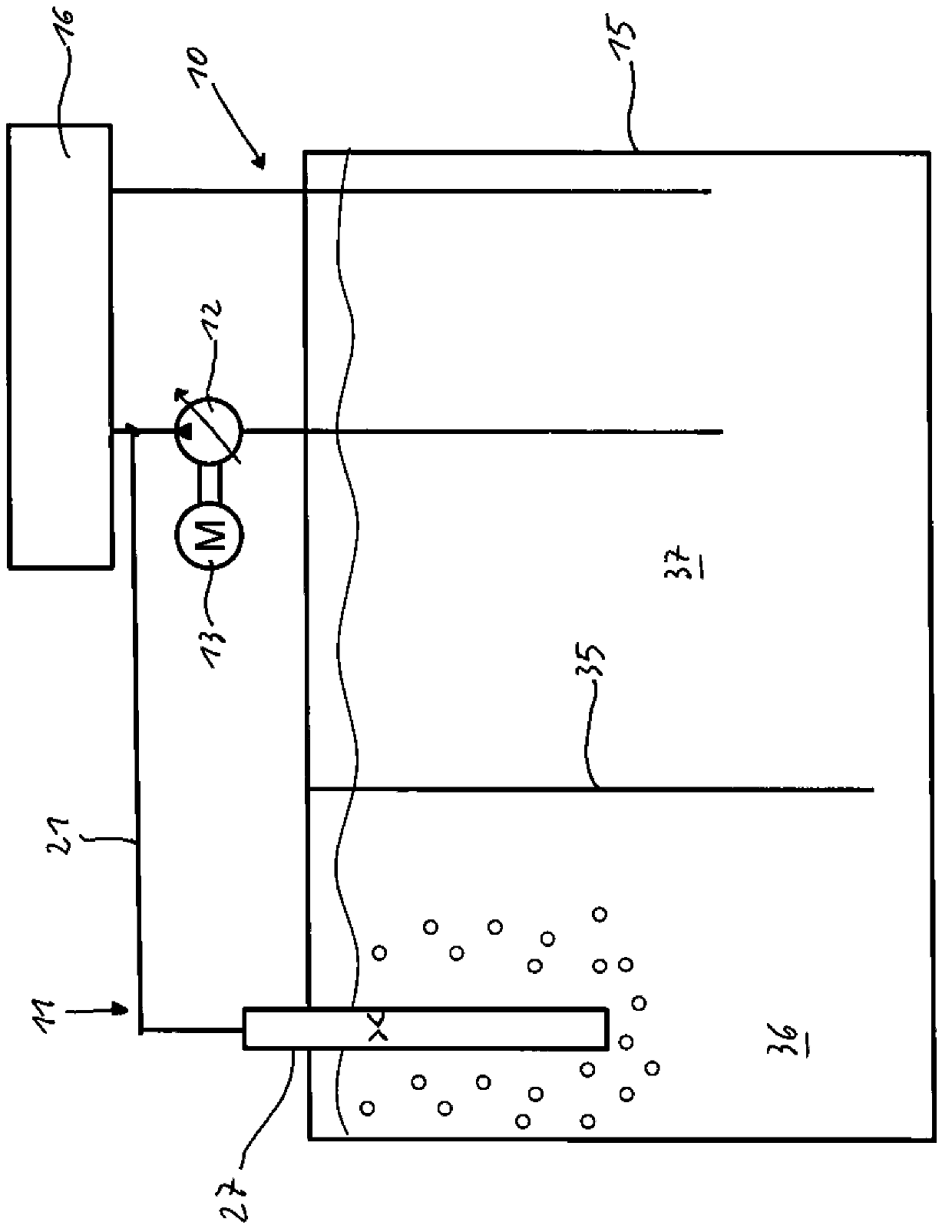

Combined Degassing and Circulation of Liquid

PendingUS20200246724A1Effective degassingEfficient separationComponent separationSolid sorbent liquid separationDegasserConsumer unit

A degasser for at least partially degassing a gas-containing liquid, in particular for a sample separation device, includes a circulation path along which the liquid can be circulated between a liquid accommodation volume and one of an inlet to a consumer unit consuming degassed liquid or a conduit leading to the inlet, a drive unit configured for circulating the liquid in the circulation path, and a filter in the circulation path for filtering particles or debris out of the liquid, wherein the liquid is forced through the filter by the drive unit. The drive unit includes a movable body, in particular a movable piston or a movable membrane, configured for at least partially degassing the liquid by generating a negative pressure in the liquid.

Owner:AGILENT TECH INC

Molding method and mold therefor

Molding methods and molds for making a synthetic resin molded product include disposing a curable liquid resin mixture in a recess of a female mold. The curable liquid resin mixture is then simultaneously agitated and degassed by a mixer while under a partial vacuum. More specifically, at least the female mold is orbited around an orbital axis while being rotated about a rotational axis that is eccentric to the orbital axis. After being thoroughly mixed and degassed, the liquid mixture is then cured in the mold unit.

Owner:KAGA SANGYO

Aluminum alloy refining material and preparation method and application thereof

The invention discloses an aluminum alloy refining material and a preparation method and an application thereof and relates to the field of aluminum alloy modifiers. The aluminum alloy refining material comprises the following raw materials in percentage by weight: 5-8% of potassium fluoroaluminate, 7-11% of sodium fluoroaluminate, 3-5% of disodium hydrogen phosphate hydrate, 5-7% of potassium chloride, 4-8% of sodium chloride, 0.4-0.8% of barium acetate, 3-6% of barium nitrate, 0.2-0.9% of samarium fluoride, 0.2-0.9% of aluminum acetate, 6-8% of aluminum chloride, 15-20% of lepidolite compound powder and the balance of pure aluminum. The aluminum alloy refining material has the beneficial effects that the four modifiers of barium, sodium, lithium and samarium are combined according to thecharacteristics and a sintered body with a loose structure is prepared by adopting spray deposition and extrusion calcination in one step, so that the metamorphic activity is effectively retained andthe material has the characteristics of short metamorphic incubation period, long effective metamorphic time and stable metamorphic effect; and the lepidolite powder can serve as a modifier carrier for degassing and slag removal and the alloy hardness can be significantly increased by utilizing high hardness matters contained in the lepidolite powder.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Thermal management device for vehicle

ActiveUS10837348B2Supercharging efficiency may deteriorateCooling and heating performance is deterioratedLiquid coolingAir-treating devicesThermodynamicsHeat management

Owner:DENSO CORP

Process of producing Zn-Cu-Ni alloy strip

Owner:ANHUI XINKE NEW MATERIALS

A kind of molten salt material and its preparation method and application

ActiveCN109868396BAvoid it happening againImprove refinement metamorphic effectMANGANESE ACETATEAluminium chloride

The invention discloses a molten salt material, a preparation method and application thereof, and relates to the field of aluminum alloy modifiers. The molten salt material is made of the following raw materials in parts by weight: sodium phosphate 13-18%, aluminum chloride 5-9%, manganese fluoride 0.6-1.2%, manganese acetate 5-8%, manganese nitrate 3-6%, fluorine Sodium chloride 11‑15%, sodium fluorosilicate 3‑7%, lithium fluoride 0.2‑0.6%, ceramic powder 2‑7%, the rest is potassium chloride; rare earth ytterbium, thulium, sodium, lithium, etc. The mutual cooperation of elements makes the metamorphic effect excellent. The chlorite powder in the raw material can be used as a modifier carrier to remove gas and slag, simplify the smelting steps, and improve the smelting efficiency. The rich alumina and silicon oxide can significantly increase the hardness of the alloy. Combining the molten salt electrolytic deposition process with the metamorphic smelting process can give full play to the excellent metamorphic effect of molten salt materials, which can significantly improve the strength, plasticity and hardness of aluminum alloy castings.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Method for producing injection-molded parts

InactiveUS20090051070A1Quality improvementSignificant comprehensive benefitsProcess regionProcess engineering

In a method for producing injection-molded parts, PET material is processed and / or plasticized by means of a twin-screw extruder having a plurality of processing zones. At least two processing zones are implemented as degassing zones. The processed and / or plasticized material is transferred to a transfer reservoir and then further processed by a piston unit.

Owner:KRAUSSMAFFEI TECH GMBH

Mold coating and method for preparing the same

The invention provides a mold coating. A mold is used for producing an aluminum alloy part. The mold coating is at least partially attached to the inner wall of a mold cavity. The materials of the coating comprise NaCl and / or KCl, NaF, CaF2, K3AlF6, Na2SO4 and / or K2SO4. When the mold is a metal mold, the materials of the coating further comprise graphite. When the mold is a plaster mold, the materials of the coating further comprise graphite and CaCO3, and the thickness of the coating can be selected to range from 0.5 mm to 5 mm. According to a preparation method of the mold coating, the materials of the coating are sprayed or dip-coated to the inner wall of the mold cavity after being subjected to hot melting.

Owner:芜湖中关村硬创空间科技有限公司

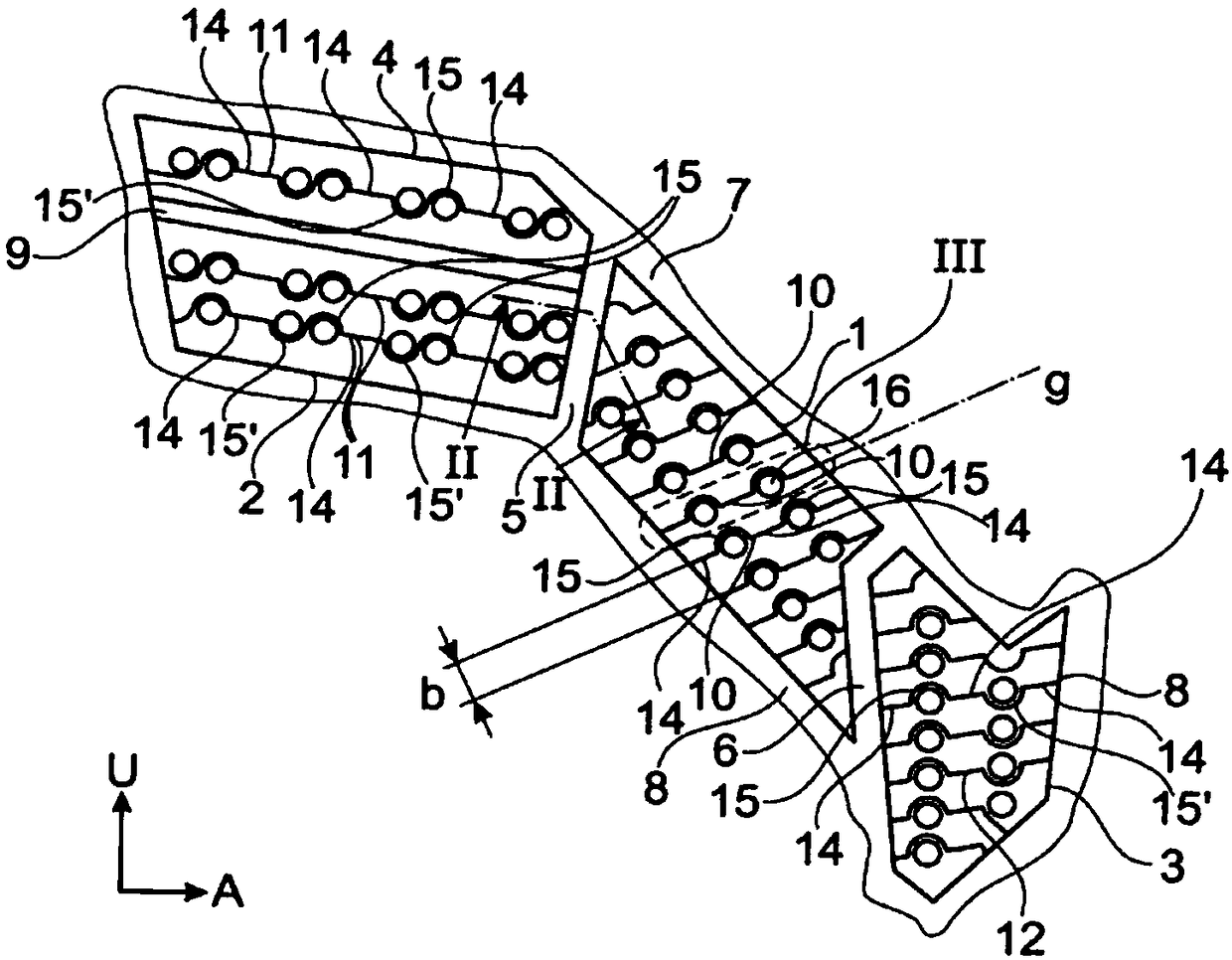

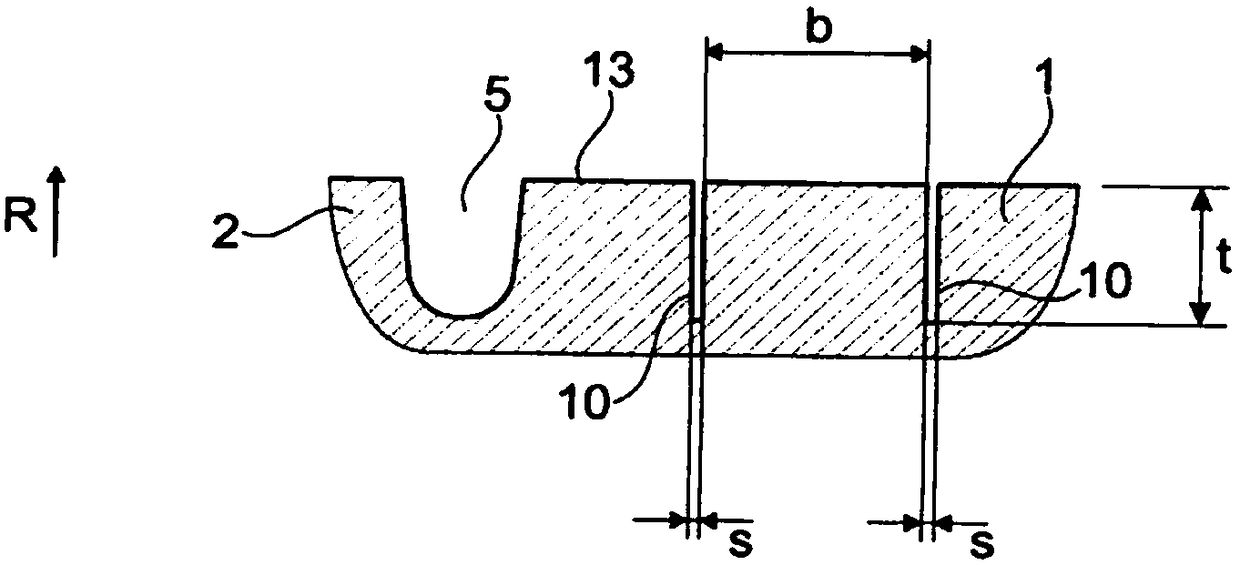

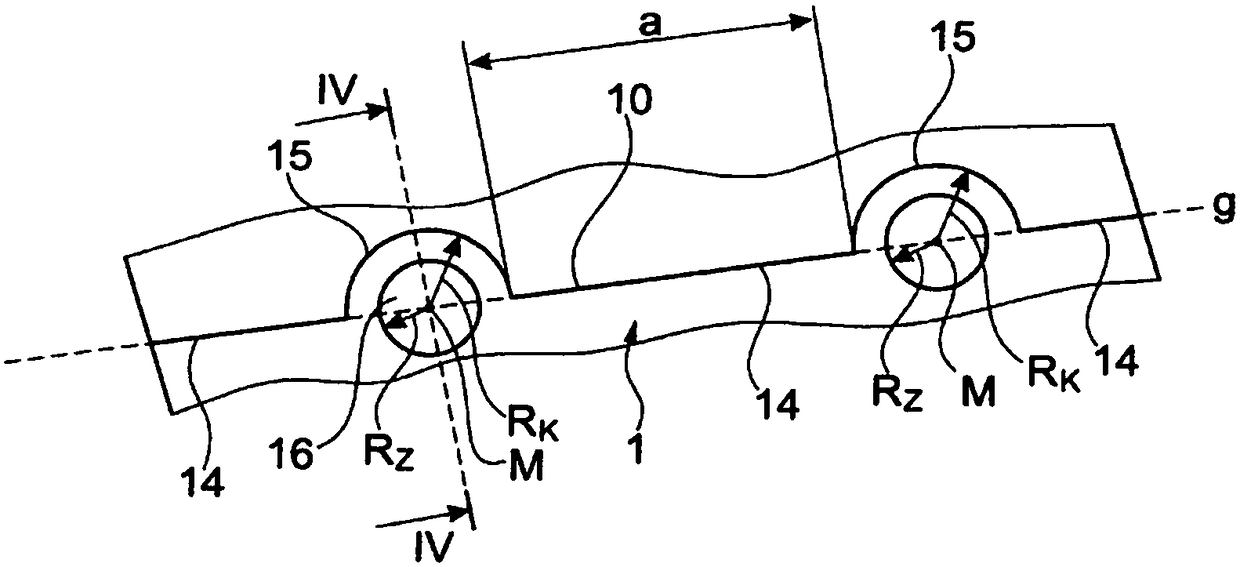

Vehicle Pneumatic Tires

The invention relates to a tread pattern for a vehicle tire with radially protruding positive profiles (1) delimited by grooves (5, 6, 7, 8) - such as profiled block elements or profiled ribs - delimited in the radial direction R of the tire by a radially outer surface (13), and with mutually spaced apart, fine incisions (10) formed in the positive profiles (1), the tread pattern being characterised in that fine incisions (10) extending along their main direction of extension in the radially outer surface (13) are formed in the positive profile (1) and have first straight sections (14) - oriented, in particular, in the main direction of extension - and second sections (15) in the shape of circle segment lines,

Owner:CONTINENTAL REIFEN DEUTSCHLAND GMBH

Plaster mold for aluminum alloy casting

InactiveCN108480563BEffective degassingEfficient removal of impuritiesFoundry mouldsFoundry coresGraphiteGypsum

The invention discloses a gypsum mold for aluminum alloy casting, and the gypsum mold is applicable to low-pressure casting. The gypsum mold comprises a mold shell and a mold cavity formed by the moldshell and used for the forming of an aluminum alloy casting, an adhesion layer is arranged on the inner wall of the mold cavity, and the adhesion layer material comprises NaCl, KCl, NaF, CaF2, K3AlF6, Na2SO4, K2SO4, graphite and CaCo3; the thickness of the adhesion layer can be 0.5-5 mm; and the mold cavity is preferably provided with a dead head structure positioned at the top or a process machining allowance corresponding to the product.

Owner:ZHEJIANG GAOAO SANITARY WARE CO LTD

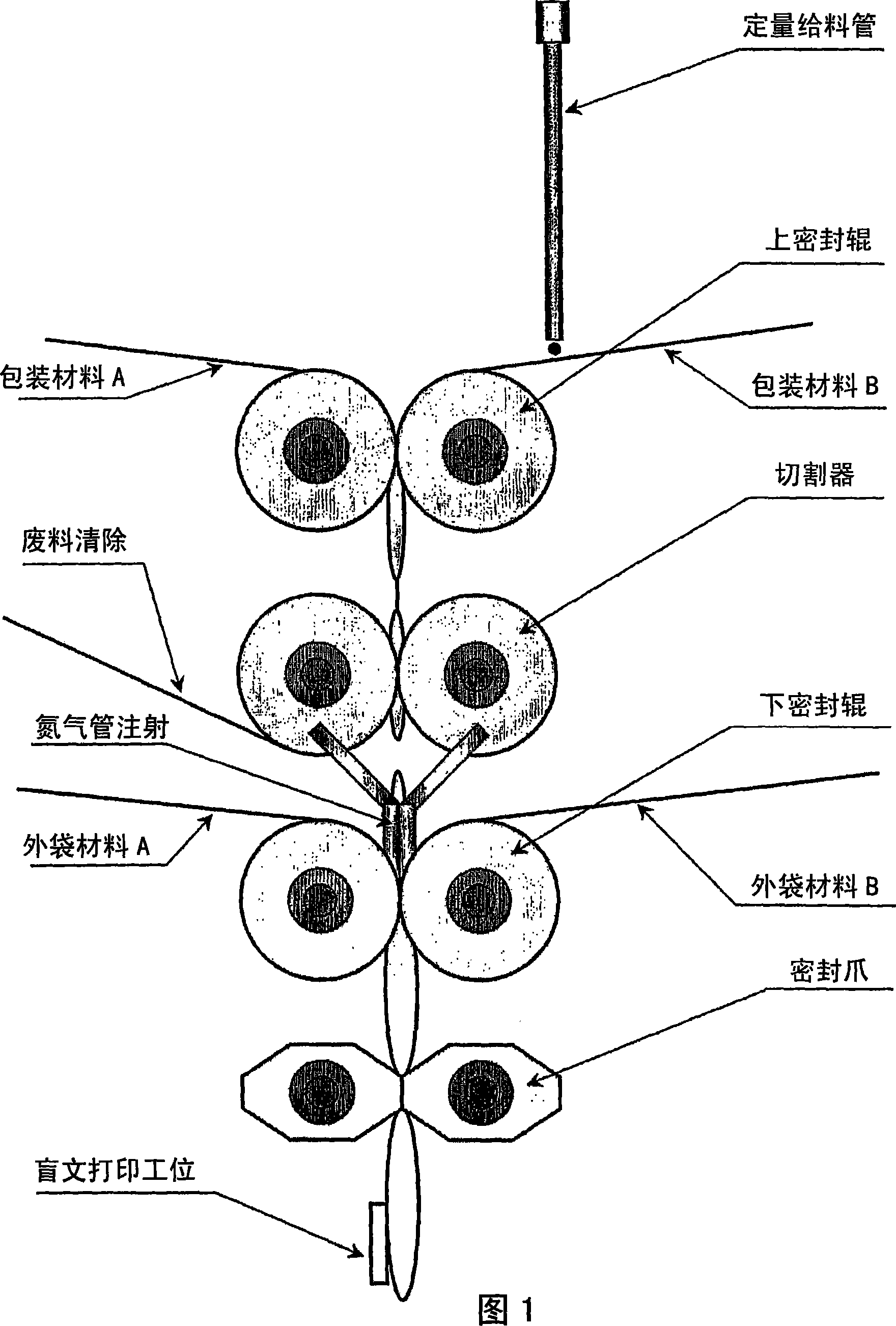

Form-fill-seal process

InactiveCN1984813BTamper evidentEffective degassingAdhesive dressingsWrapper twisting/gatheringStructural engineeringSterility

A one stage process for the preparation reservoir patches comprises feeding webs to a first pair of sealing rollers and, thence, directly to a second pair of die-cutting rollers, and preferably directly into a packaging step, thereby avoiding most operatorrelated error, and substantially increasing overall sterility and reproducibility.

Owner:TRANSDERMAL TECH & SYST TTS

Process for the preparation of edible fat-continuous spreads

PendingUS20140342066A1Reduce processing timeEffective degassingEdible oils/fats ingredientsButter manufactureChemistry

Process for the preparation of an edible fat-continuous spread comprising at most 45 wt. % of fat using liquid oil, a fat powder comprising structuring fat and a water-phase, comprising the steps of: a. providing amixture comprising the water-phase and the fat powder; b. subjecting said mixture to at least a partial vacuum; c. mixing the mixture prepared at step ‘b’ to provide a fat-continuous spread, wherein the liquid oil may be added to the mixture at any of steps ‘a’, ‘b’, or ‘c’ or when added in parts in any combination at steps ‘a’, ‘b’ and ‘c’.

Owner:UPFIELD EURO BV

Method for producing injection-molded parts

InactiveUS7815833B2Quality improvementSignificant comprehensive benefitsProcess regionProcess engineering

In a method for producing injection-molded parts, PET material is processed and / or plasticized by means of a twin-screw extruder having a plurality of processing zones. At least two processing zones are implemented as degassing zones. The processed and / or plasticized material is transferred to a transfer reservoir and then further processed by a piston unit.

Owner:KRAUSSMAFFEI TECH GMBH

Hydraulics for degassing liquids

ActiveCN105909599BPromote precipitationFast degassingPump assembliesLiquid degasification regulation/controlLiquid jetEngineering

Owner:ROBERT BOSCH GMBH

Gypsum mold for aluminum alloy casting

The invention discloses a gypsum mold for aluminum alloy casting, and the gypsum mold is applicable to low-pressure casting. The gypsum mold comprises a mold shell and a mold cavity formed by the moldshell and used for the forming of an aluminum alloy casting, an adhesion layer is arranged on the inner wall of the mold cavity, and the adhesion layer material comprises NaCl, KCl, NaF, CaF2, K3AlF6, Na2SO4, K2SO4, graphite and CaCo3; the thickness of the adhesion layer can be 0.5-5 mm; and the mold cavity is preferably provided with a dead head structure positioned at the top or a process machining allowance corresponding to the product.

Owner:ZHEJIANG GAOAO SANITARY WARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com