Gypsum mold for aluminum alloy casting

A technology of aluminum alloy castings and plaster molds, which is applied in the direction of casting molding equipment, casting molds, casting mold components, etc., can solve the problems of degassing and impurity removal conditions, etc., to increase peelability, improve efficiency, and increase adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

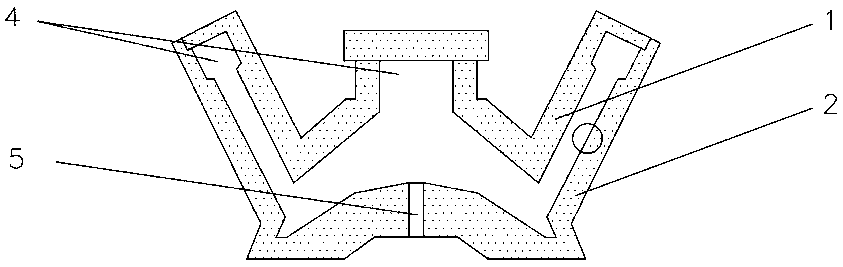

[0026] see figure 1 , figure 1 It is a schematic structural diagram of a plaster mold for aluminum alloy casting according to the present invention. The plaster mold includes a mold shell composed of an upper mold shell 1 and a lower mold shell 2, and a mold cavity enclosed by the mold shells for forming aluminum alloy castings.

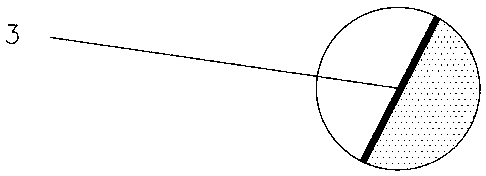

[0027] see figure 2 , figure 2 Yes figure 1 A partial enlarged view at the middle circle, it can be seen from the figure that the inner wall of the cavity is at least partially provided with the adhesion layer 3 .

[0028] The material of the adhesion layer is mainly composed of molten salt substances that can degas the aluminum alloy liquid and exclude metal inclusions, and its combination can also consider the adhesion to the inner wall of the plaster mold cavity and the peelability of the casting (this adhesion and Peelability needs to be controlled with coating thickness).

[0029] According to the above principles, the above-mentioned ad...

Embodiment 2

[0034] This embodiment is a description of the specific composition of the material of the adhesion layer in the plaster mold for aluminum alloy casting proposed in Example 1. Specifically, the adhesion layer is composed of the following materials in parts by weight:

[0035] NaCl+KCl: 15-25 parts by weight; NaF: 8-12 parts by weight; CaF2: 5-8 parts by weight; K3AlF6: 5-8 parts by weight; Na2SO4+K2SO4: 3-5 parts by weight; Graphite: 1-3 parts by weight parts; CaCO3: 4-6 parts by weight.

[0036] Wherein, in the 15-25 parts by weight of NaCl+KCl, the weight ratio of NaCl and KCl is 1:0.5-2.

[0037] Wherein, in the 3-5 parts by weight of Na2SO4+K2SO4, the weight ratio of Na2SO4 and K2SO4 is 1:0.5-2.

[0038] The above materials are mixed and hot-melted and then dip-coated on the inner wall of the mold cavity.

Embodiment 3

[0040] This embodiment is a further optimization of the material of the adhesion layer proposed in Example 2. Specifically, the adhesion layer is composed of the following materials in parts by weight:

[0041] NaCl: 12 parts by weight; KCl: 10 parts by weight; NaF: 9 parts by weight; CaF2: 6 parts by weight; K3AlF6: 6 parts by weight; Na2SO4: 1.5 parts by weight; K2SO4: 2 parts by weight; Graphite: 2 parts by weight; CaCO3: 4.5 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com