Vehicle Pneumatic Tires

A technology for pneumatic tires and vehicles, applied to vehicle parts, tire parts, tire treads/tread patterns, etc., can solve the problems of high cleaning and maintenance, high clogging, high consumption, etc., and achieve simple methods, snow The effect of optimized ground grip characteristics and reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

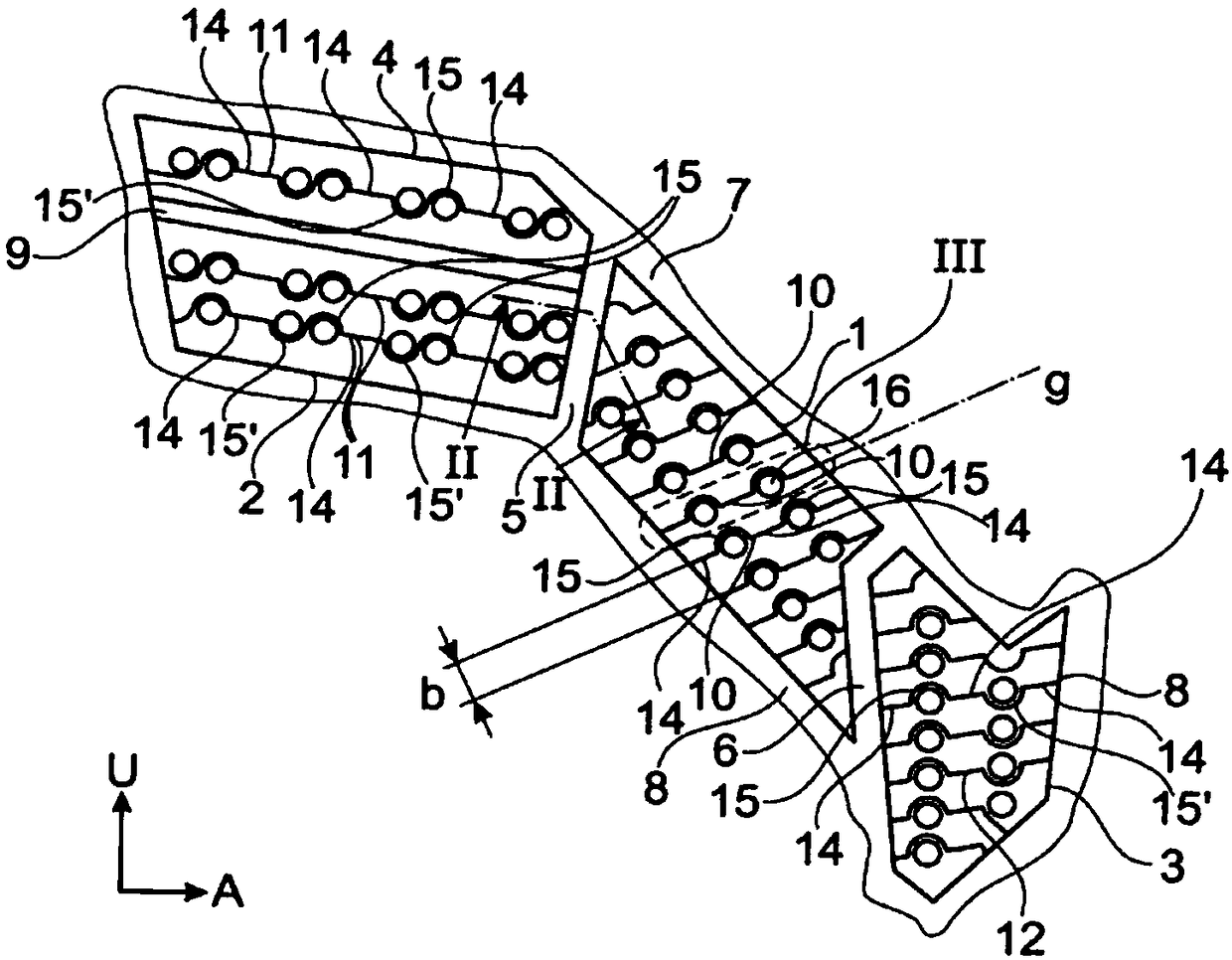

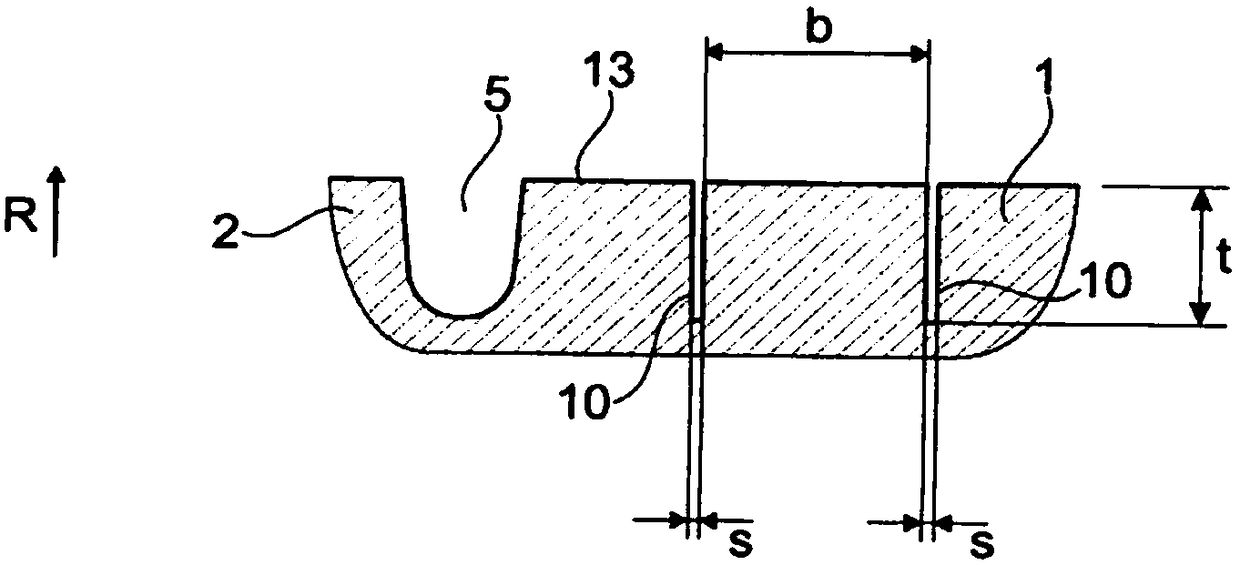

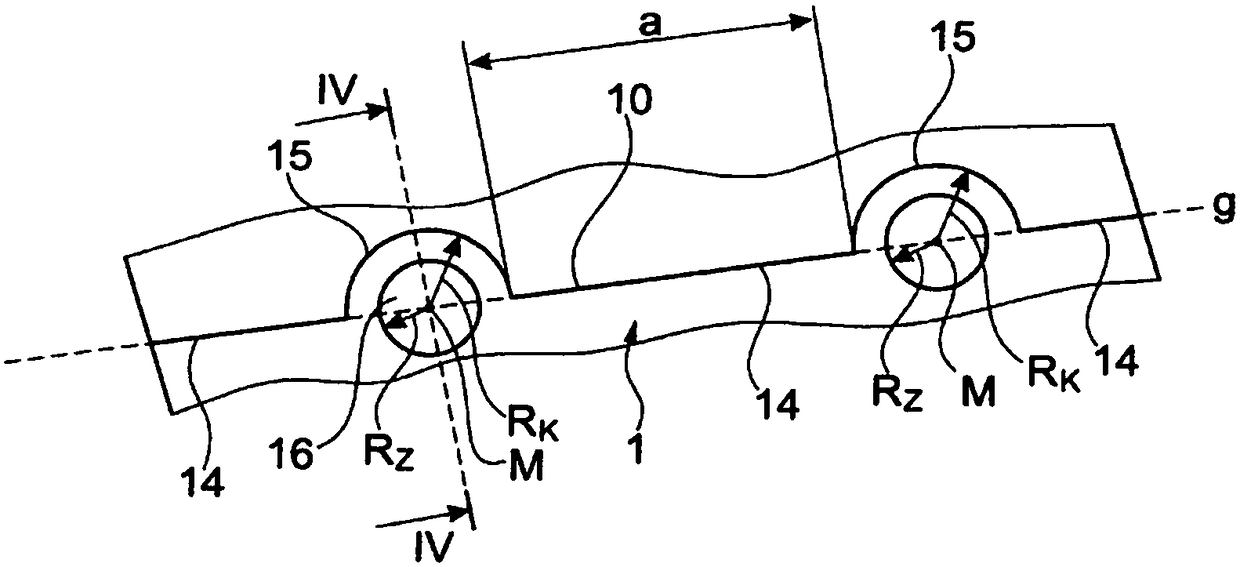

[0025] Figures 1 to 4 Shows the vehicle pneumatic tires for passenger cars (PKW), with the figure 1 A partial view of the tread pattern of the radially raised block units 1 , 2 , 3 and 4 shown in FIG. Spaced out. Here, these block units 1, 3 and 4 are in the circumferential direction U of the vehicle pneumatic tire at figure 1 The direction of rotation shown upwards in the middle is delimited by a transverse groove 7 . These tread block units 1, 2 and 3 are in the circumferential direction U at figure 1 The direction of rotation shown downwards in is correspondingly limited by a transverse groove 8 . The block units 2 and 4 are arranged one behind the other in the circumferential direction and are spaced apart from one another by a transverse groove 9 . The block unit 1 is spaced apart from the block units 2 and 4 in the axial direction A of the vehicle pneumatic tire by a sipe 5 oriented with its main direction of extension in the circumferential direction U. The bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com