Degassing method for electrode paste

A technology for electrode paste and degassing, applied in separation methods, liquid degassing, electrode manufacturing, etc., can solve problems such as stripe defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0020] A specific embodiment to which the present invention is applied will be described in detail below with reference to the drawings. However, the present invention is not limited to the following embodiments. For clarity of explanation, the following description and drawings are appropriately simplified.

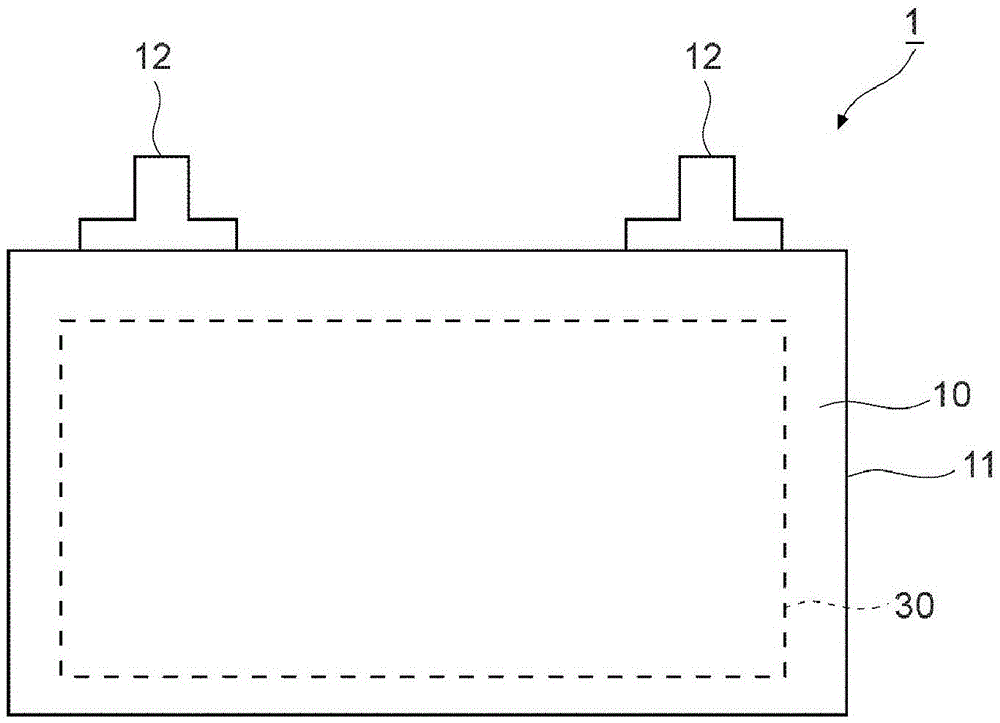

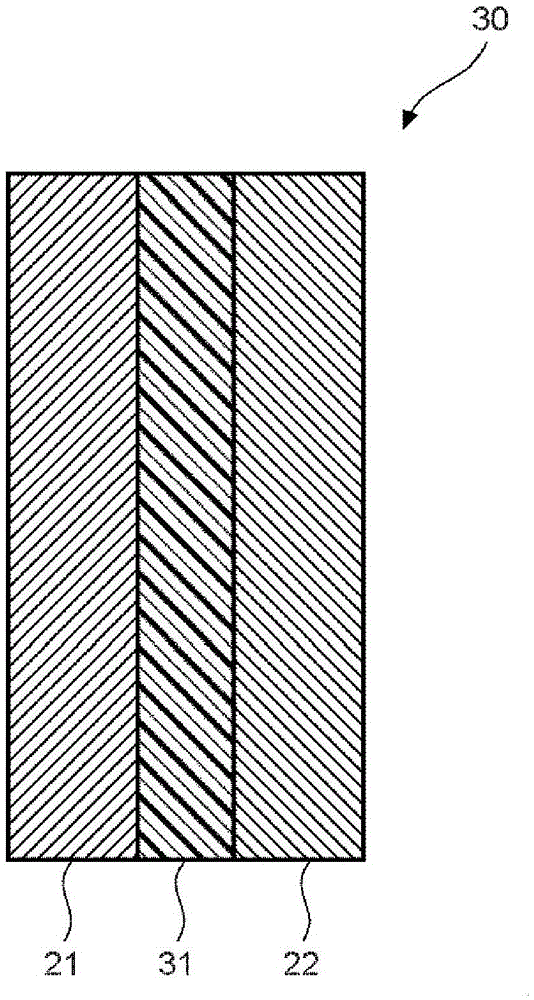

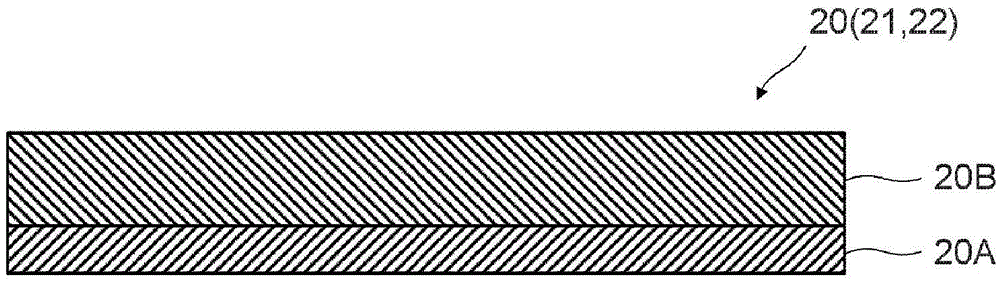

[0021] reference Figure 1 to Figure 3 , describes a nonaqueous electrolyte secondary battery made using an electrode paste that has been degassed by the electrode paste degassing method according to the first embodiment of the present invention. In this embodiment, a lithium ion secondary battery is explained as an example of a nonaqueous electrolyte secondary battery. figure 1 is a schematic overall view of a configuration example of a nonaqueous electrolyte secondary battery. figure 2 is a schematic cross-sectional view of an electrode layered body. image 3 is a schematic cross-sectional view of the electrode.

[0022] By housing the electrode layered body 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com