Form-fill-seal process

A technology for sealing bags and sheets, applied in the field of suitable devices, which can solve the problems of laborious initial packaging, production bottlenecks, damaged patches, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

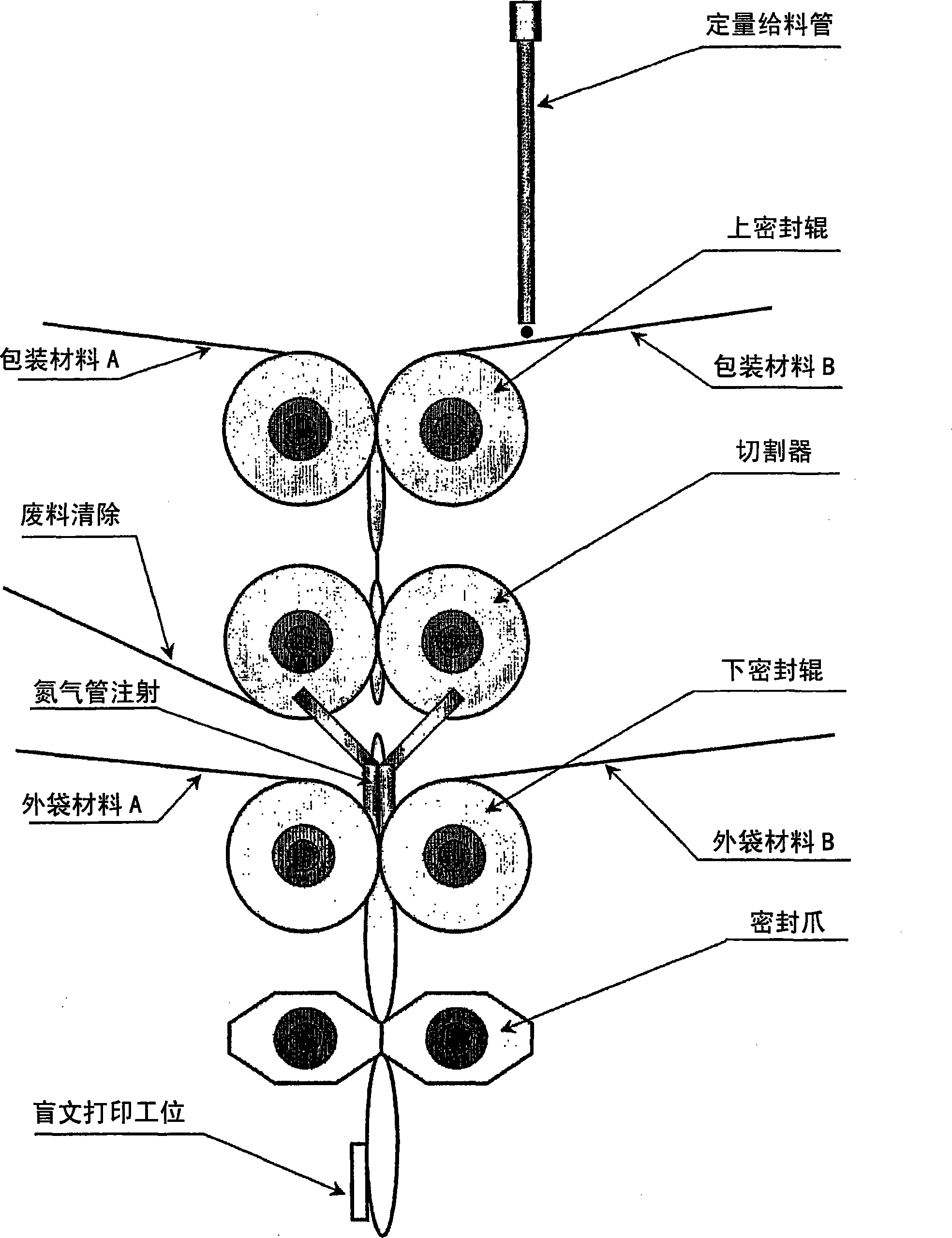

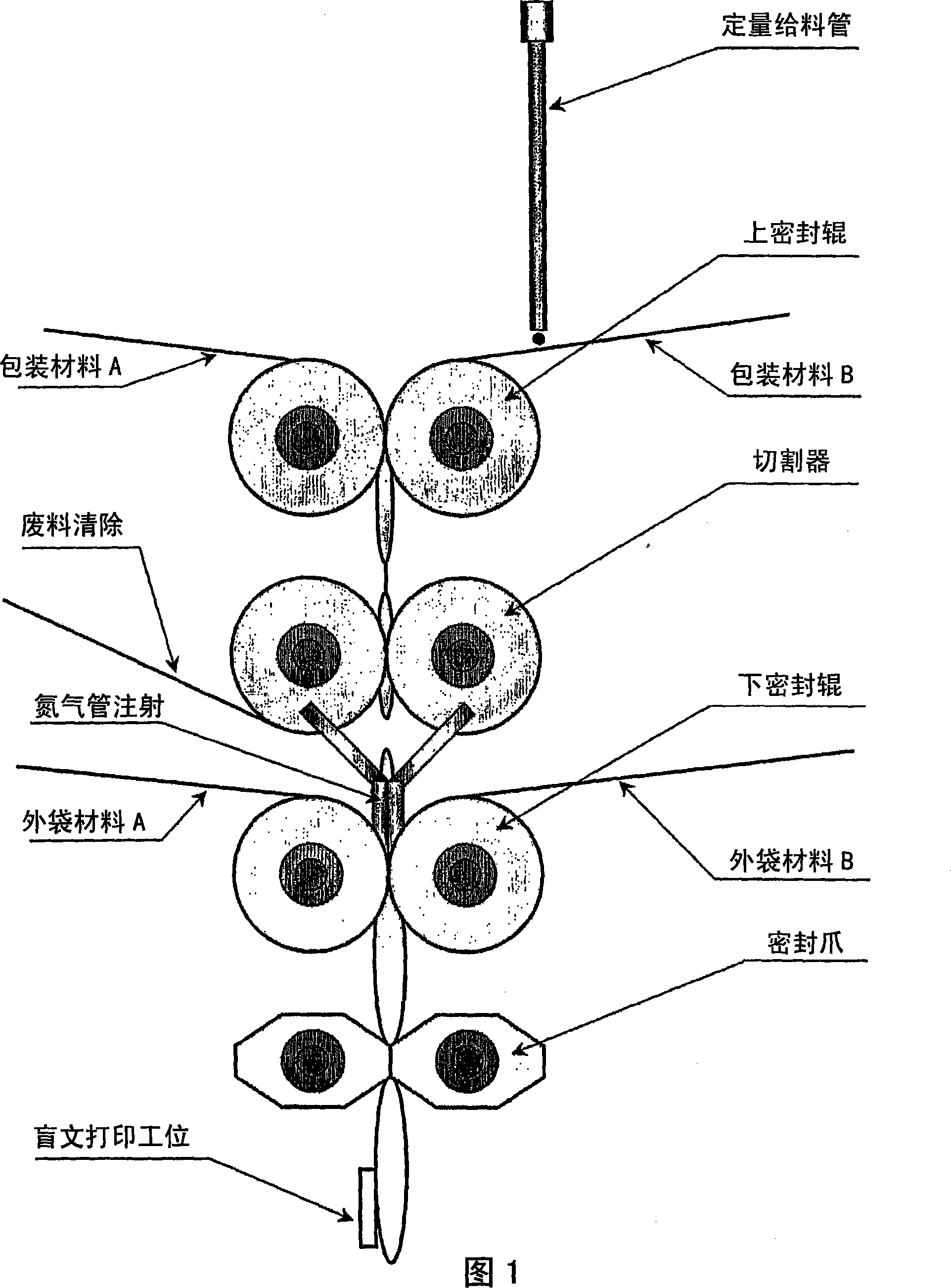

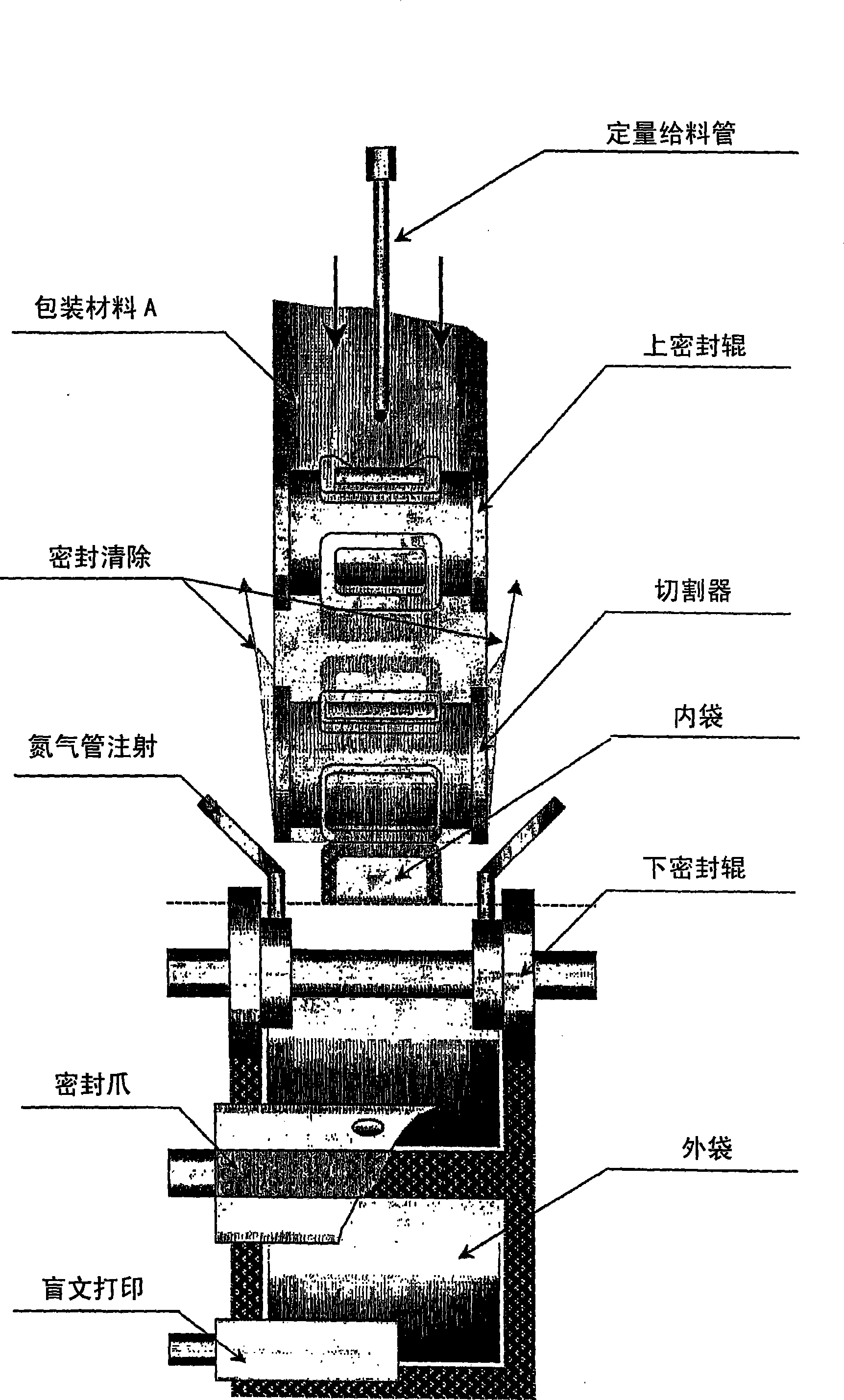

[0112] A particularly preferred embodiment of the invention is shown in Figures 1 and 2, and provides two series of pairs of opposing monolithic cylinder blocks for a continuous manufacturing process producing bags and patches. A first series of integral cylinder blocks seals together two parallel webs of material to create a storage space enclosing a selected formulation inserted between two sheets of material. The second series of integral cylinder blocks cut out sealed patch or bag templates. In the third station, the twin webs of outer bag material are drawn into twin sealing rolls, gathering one or more bags, and the sealing jaws are then used to seal the outer bag.

[0113] More specifically, pouch packaging materials A and B are fed to the upper sealing roll. In this example, a dosing tube is shown which dispenses a dose of the bag ingredient onto the packaging material B. This is for illustration purposes only and it will be appreciated that dosing may be applied to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com