Patents

Literature

46results about How to "Excellent barrier properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

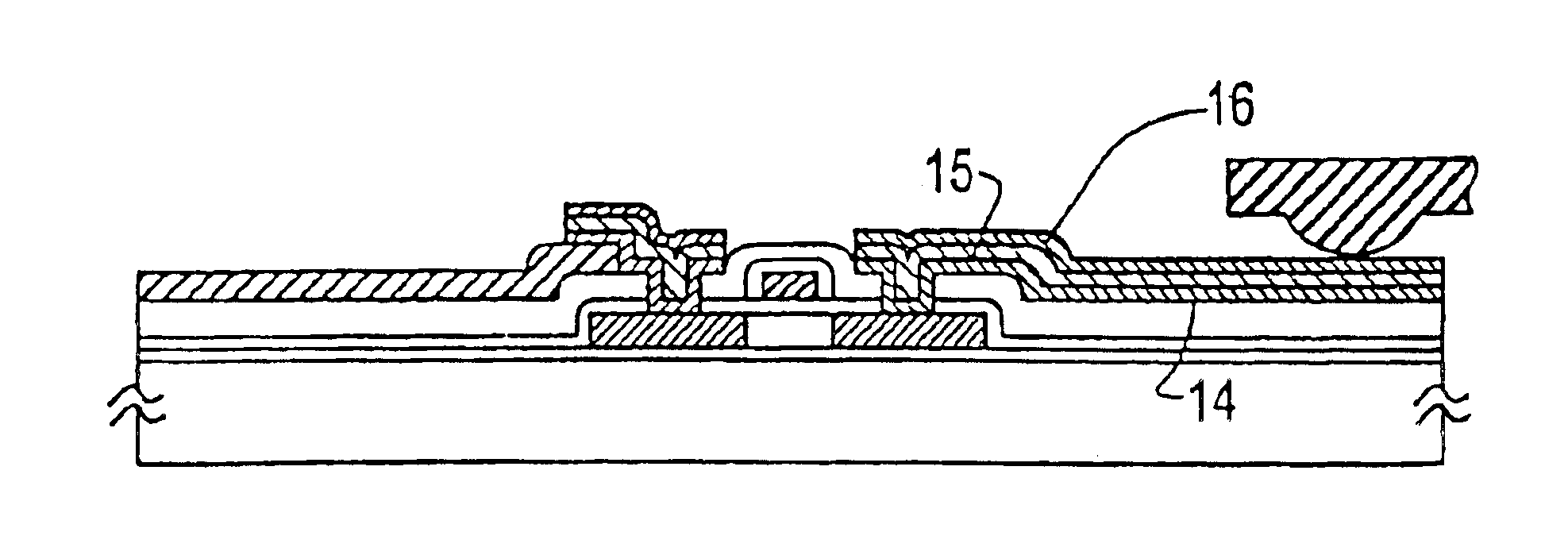

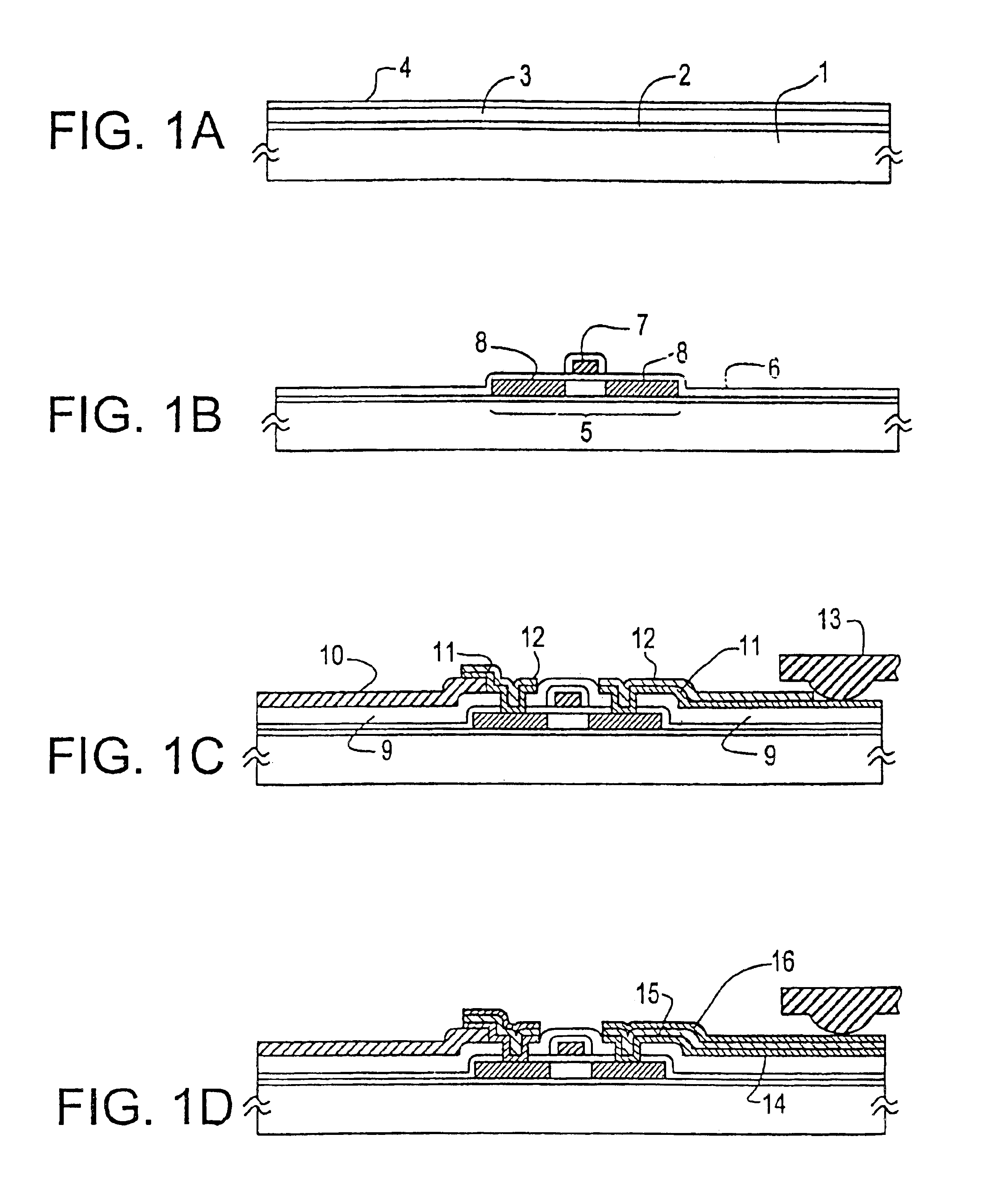

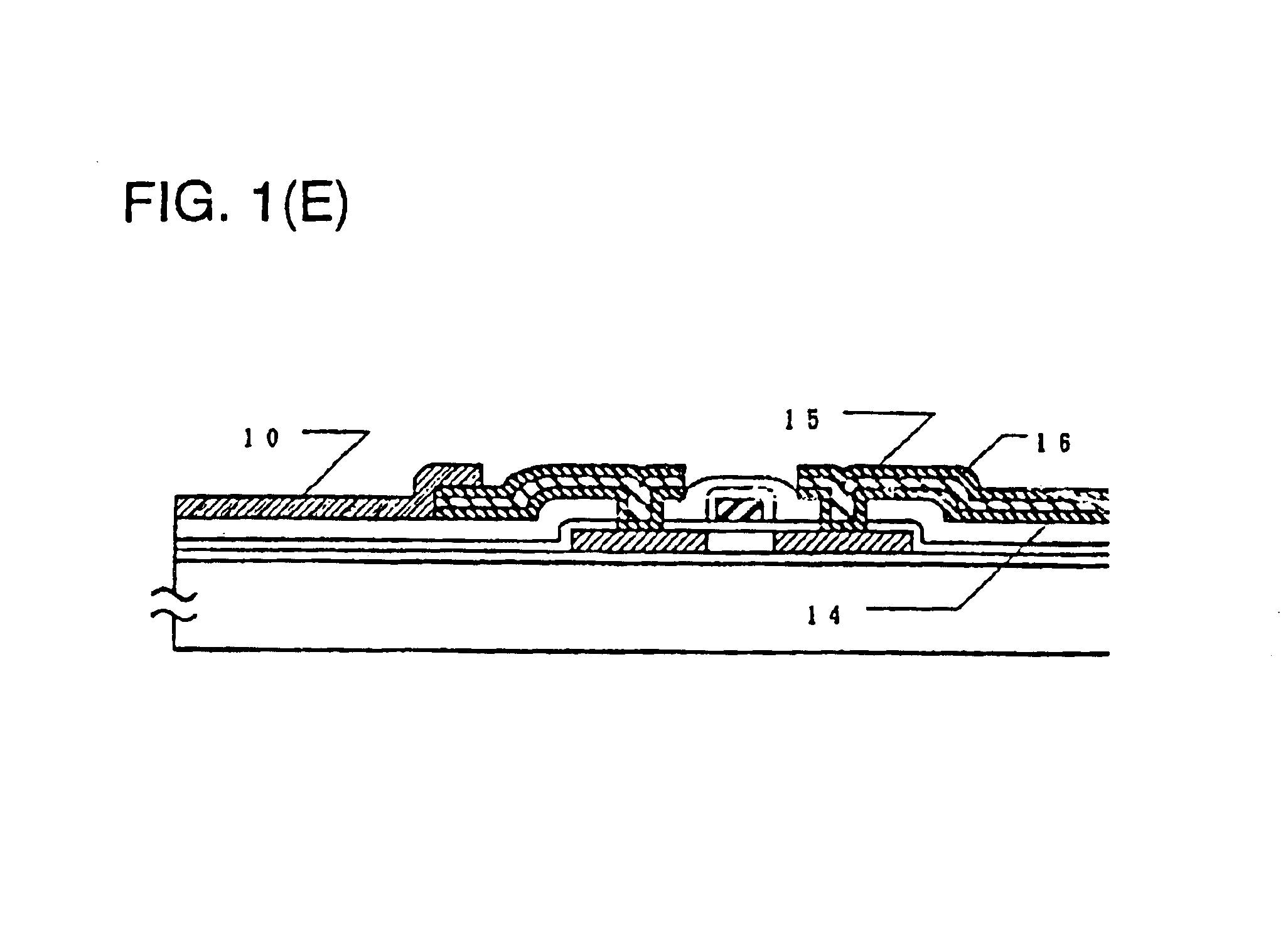

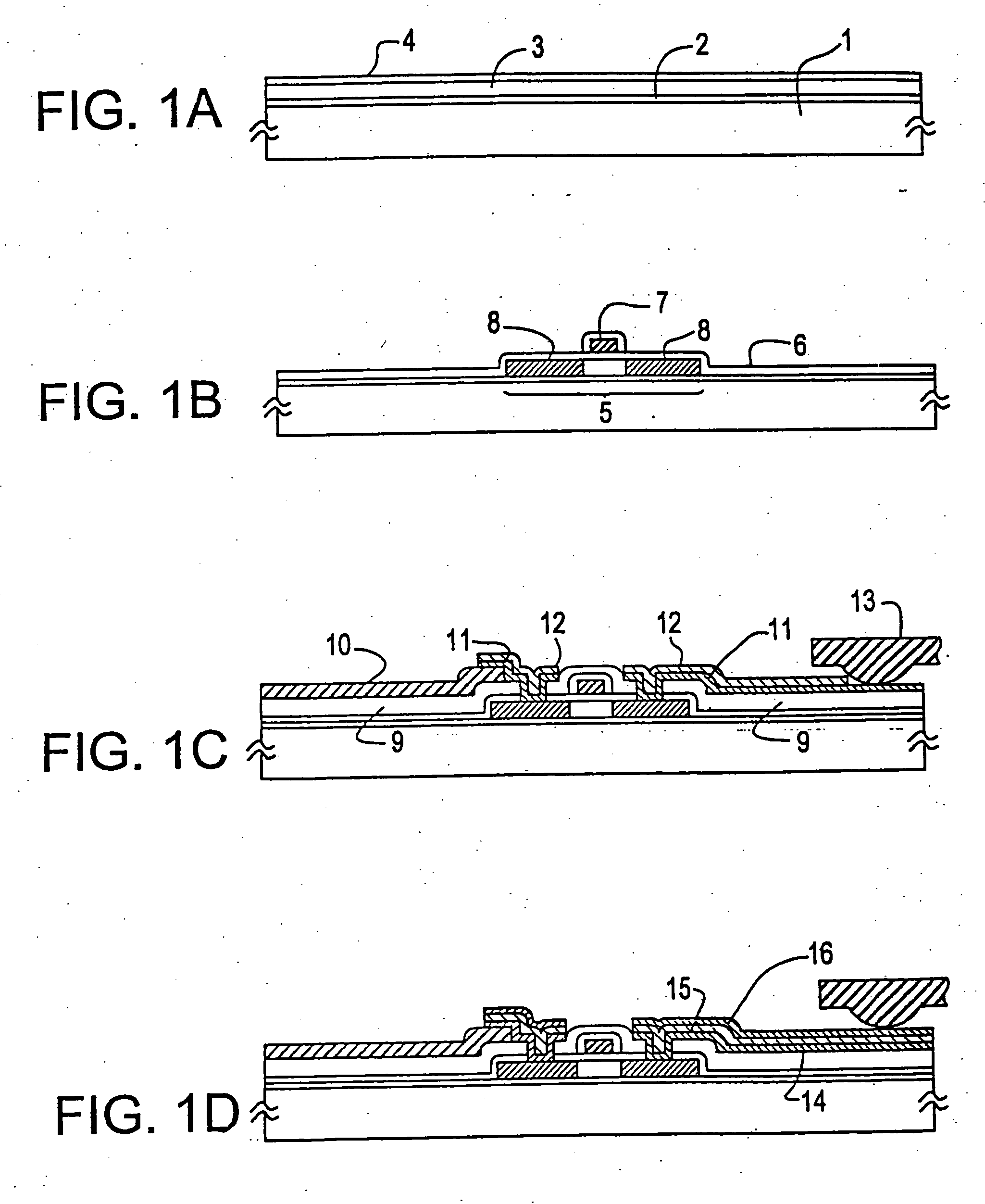

Electronic circuit

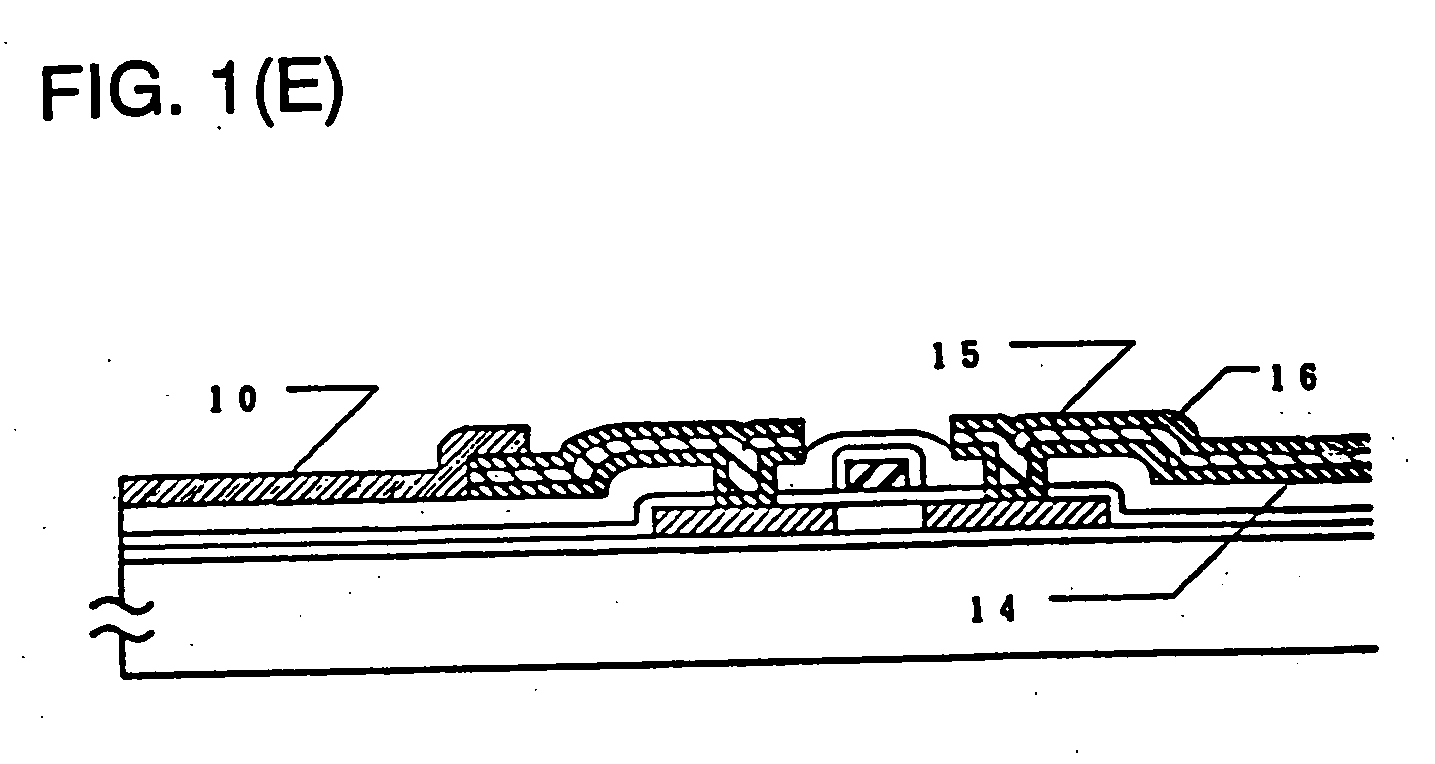

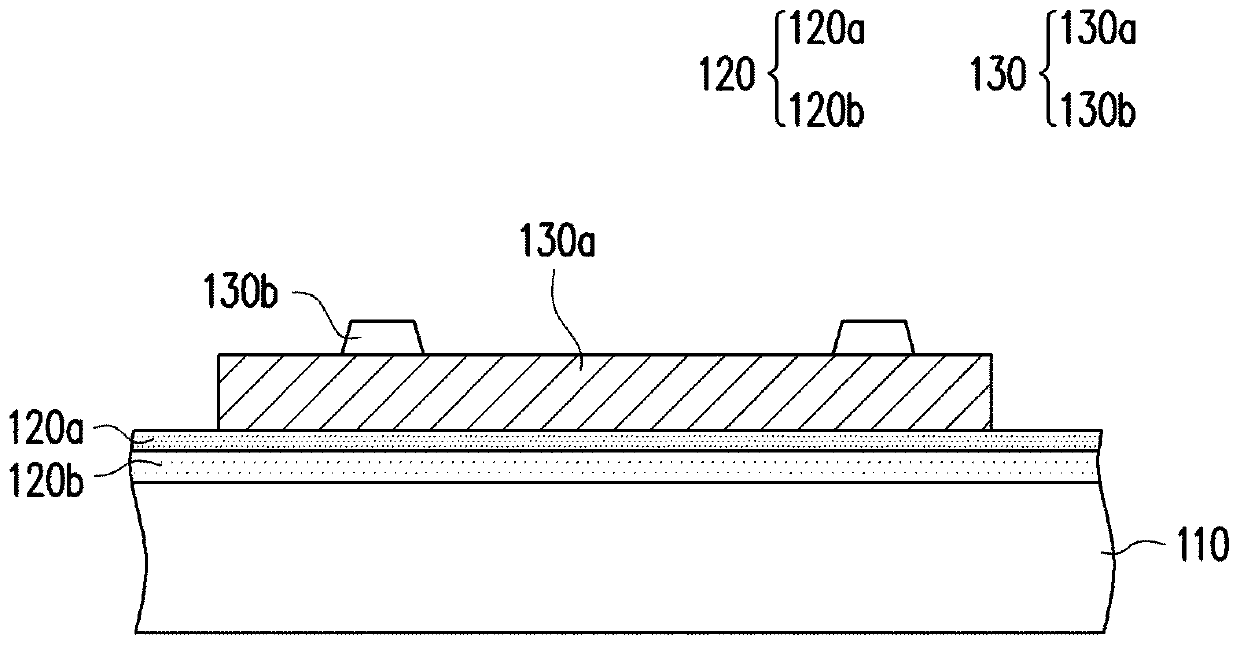

InactiveUS7045399B2Increase contactExcellent barrier propertiesTransistorStatic indicating devicesOptoelectronicsTitanium

An electronic circuit formed on an insulating substrate and having thin-film transistors (TFTs) comprising semiconductor layers. The thickness of the semiconductor layers is less than 1500 Å, e.g., between 100 and 750 Å. A first layer consisting mainly of titanium and nitrogen is formed on the semiconductor layer. A second layer consisting aluminum is formed on top of the first layer. The first and second layers are patterned into conductive interconnects. The bottom surface of the second layer is substantially totally in intimate contact with the first layer. The interconnects have good contacts with the semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

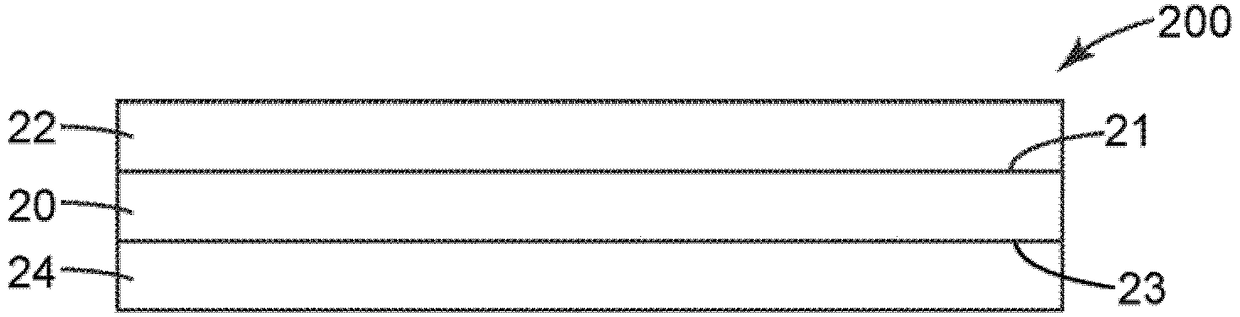

High barrier flexible packaging structure

ActiveUS7252878B2Excellent barrier propertiesImprove barrier propertiesFilm/foil adhesivesSynthetic resin layered productsMaleic anhydridePolyester

The invention relates to a high oxygen barrier, multilayer flexible packaging structure having a vacuum metallized, biaxially oriented polypropylene (met-BOPP) or metallized polyester (met-PET) film substrate; a high barrier EVOH layer coextruded or laminated directly on the metal-containing layer; and optionally an adjacent layer of anhydride modified polyolefin such as blend of LDPE, or MDPE, or PP and maleic anhydride modified adhesive resin on the EVOH layer.

Owner:TORAY PLASTICS AMERICA

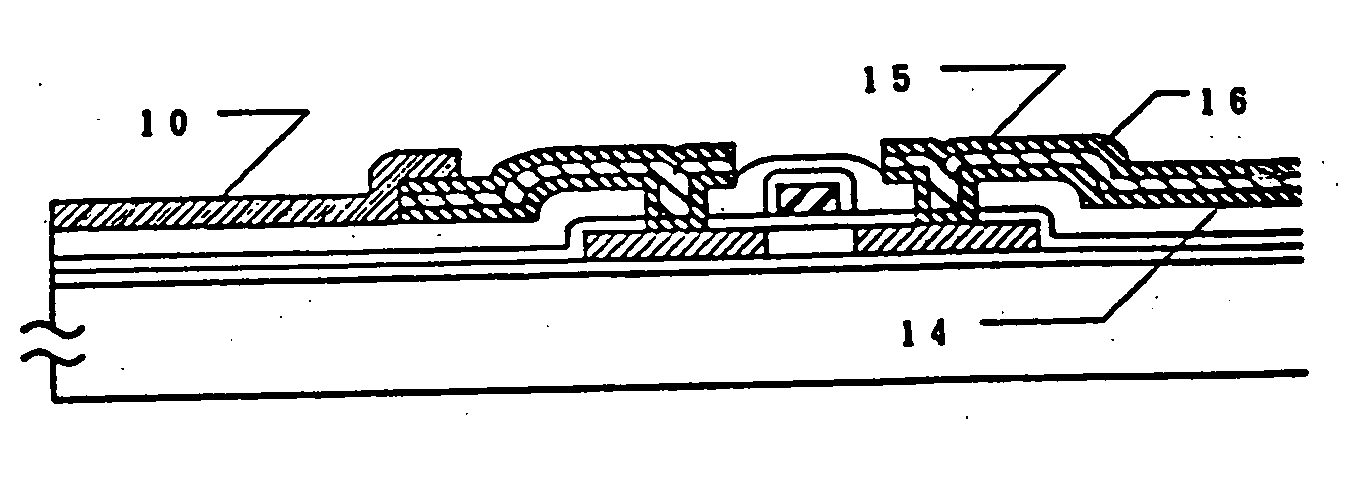

Electronic circuit

InactiveUS20050145847A1Increase contactExcellent barrier propertiesTransistorThyristorElectronic circuitTitanium

An electronic circuit formed on an insulating substrate and having thin-film transistors (TFTs) comprising semiconductor layers. The thickness of the semiconductor layer is less than 1500 Å, e.g., between 100 and 750 Å. A first layer consisting mainly of titanium and nitrogen is formed on the semiconductor layer. A second layer consisting of aluminum is formed on top of the first layer. The first and second layers are patterned into conductive interconnects. The bottom surface of the second layer is substantially totally in intimate contact with the first layer. The interconnects have good contacts with the semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

Single-layer and transparent high-impedant composite materials terephthalate product swith polyethylene glycol

InactiveCN1817963AExcellent barrier propertiesEase of processing and recyclingPolyethylene glycolOxide

A single-layer transparent product of polyethylene basic formate glycol ester composite material consists of polyethylene basic formate glycol ester, inorganic nanometer oxide 0.05~20wt% and polymer compound stabilizer 0.0001~3.5wt%, granular diameter is 1nm~1um and inorganic nanometer oxide of granular diameter >760nm accounts below total 5%. The products can be bottles, membranes, bags, cases or pots and has excellent block performance.

Owner:PETROCHINA CO LTD

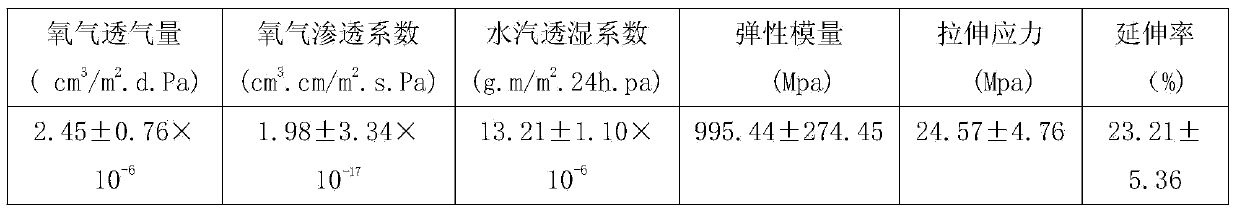

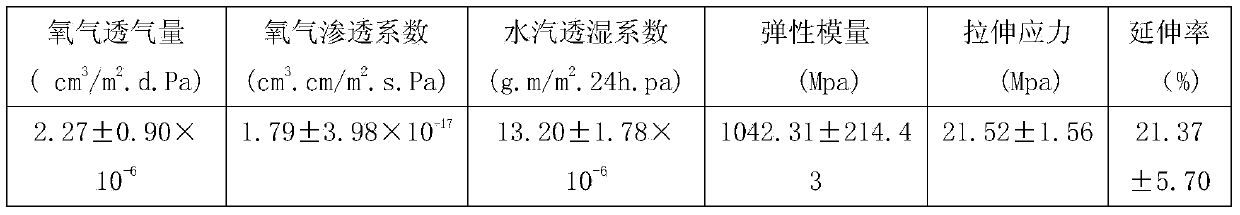

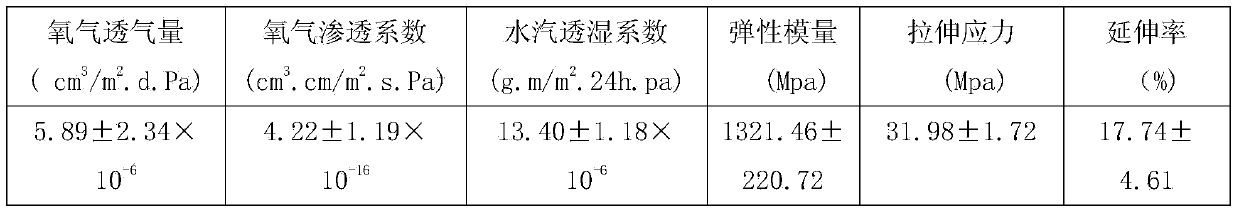

Preparation method of water-blocking oxygen-blocking edible film

ActiveCN104211975AExcellent barrier propertiesExtended shelf lifeFlexible coversWrappersChemistryFilm material

The invention discloses a preparation method of a water-blocking oxygen-blocking edible film. The method comprises the following steps: adding chitosan which accounts for 0.5-2.0% and 0.03-0.06% of the mass of an acetate solution into the acetate solution respectively, sufficiently hydrating the mixtures to obtain a first chitosan acetate solution and a second chitosan acetate solution; adding corn alcohol soluble protein into an ethanol solution to be sufficiently dissolved to obtain a corn alcohol soluble protein ethanol solution; adding the second chitosan acetate solution into the corn alcohol soluble protein ethanol solution, carrying out water-bath rotary evaporation on the obtained material until the mass of the material is 40%-80% of the original mass, centrifuging the solution and taking liquid supernatant; adding corn oil into the liquid supernatant, shearing and homogenizing the mixture to prepare Pickering emulsion; adding the Pickering emulsion into the first chitosan acetate solution, adding glycerol into the solution, ultrasonically treating and the drying the mixture to obtain the water-blocking oxygen-blocking edible film material. According to the invention, in comparison with a chitosan film, the water-blocking oxygen-blocking capacity of the water-blocking oxygen-blocking edible film is greatly improved, and the water vapor blocking cavity of the water-blocking oxygen-blocking edible film is also greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

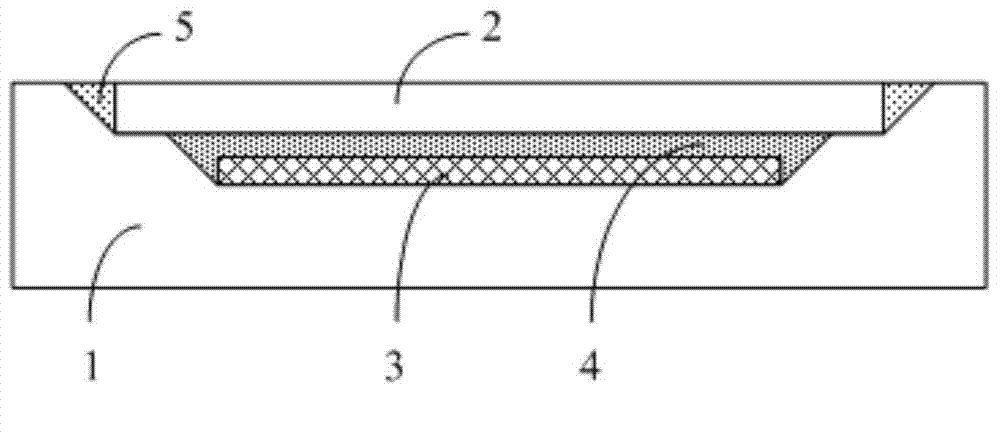

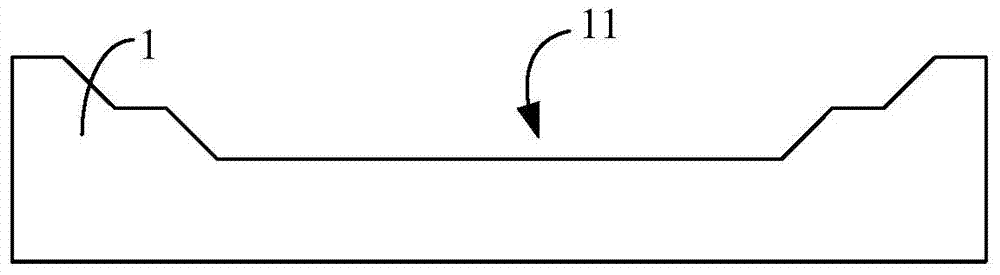

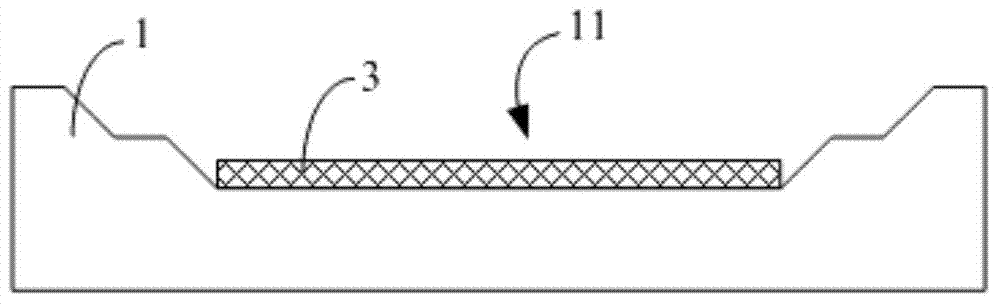

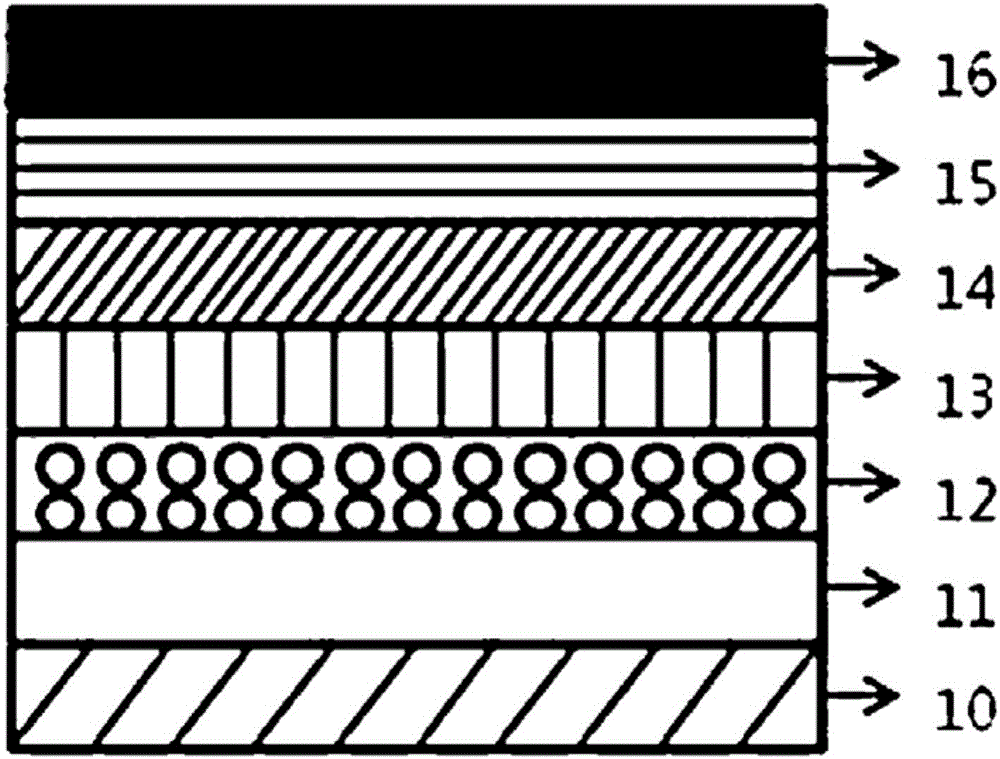

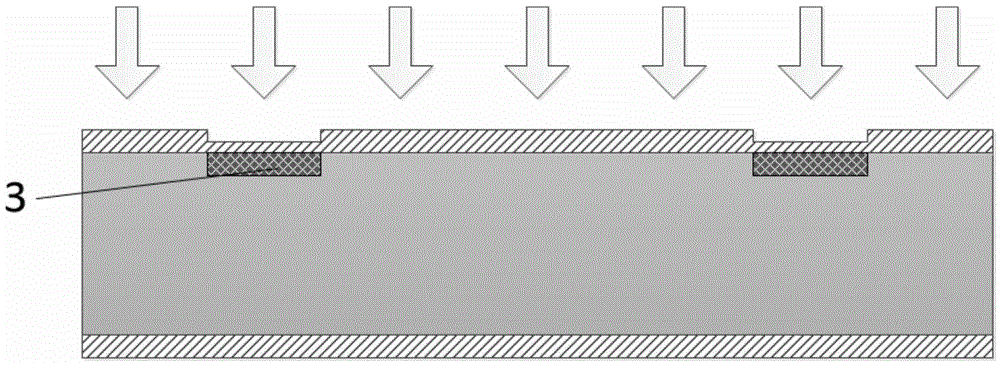

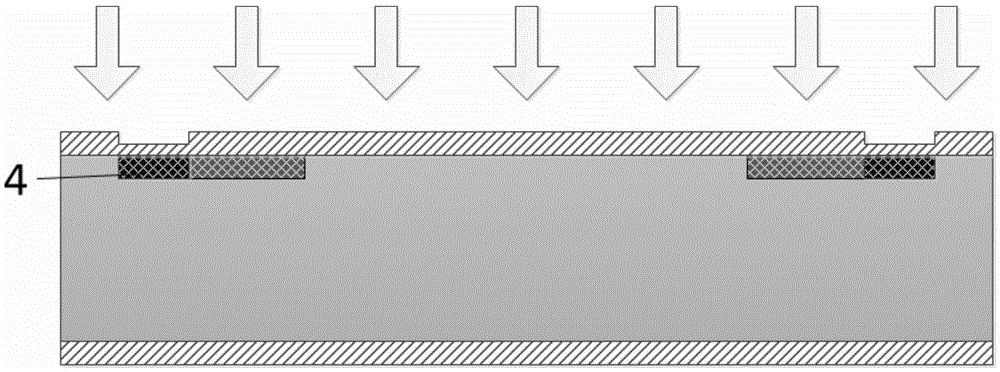

Packaging structure and method of OLED device

ActiveCN103500799AExcellent barrier propertiesExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringRetaining wall

Owner:BOE TECH GRP CO LTD

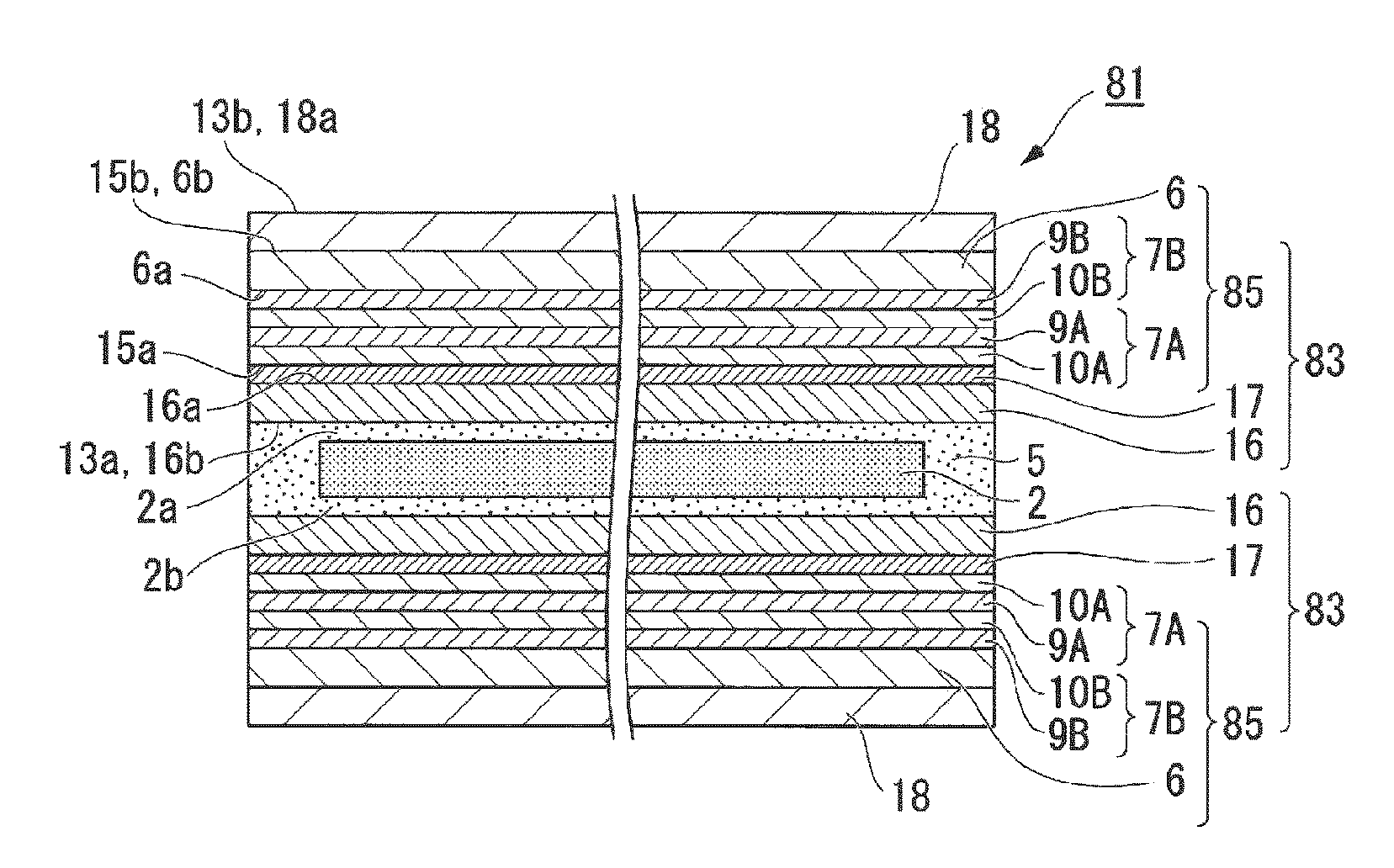

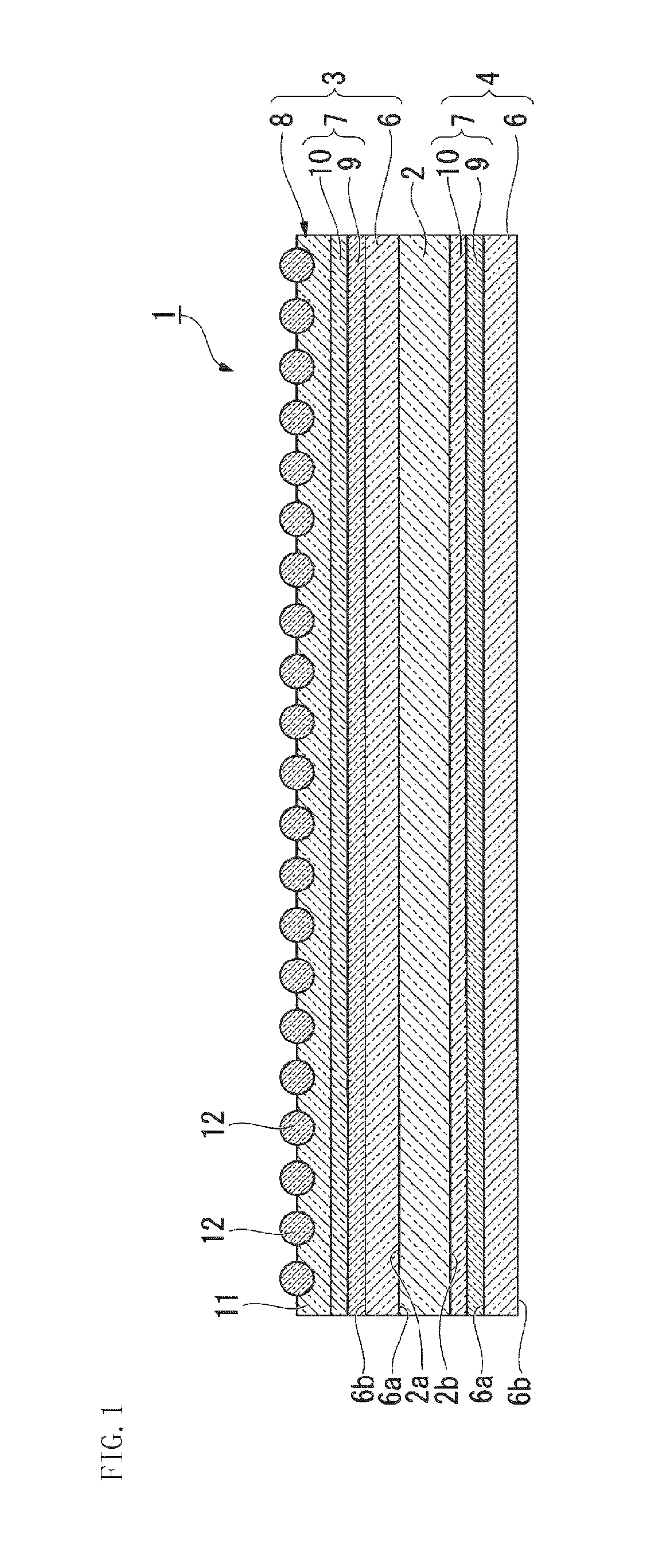

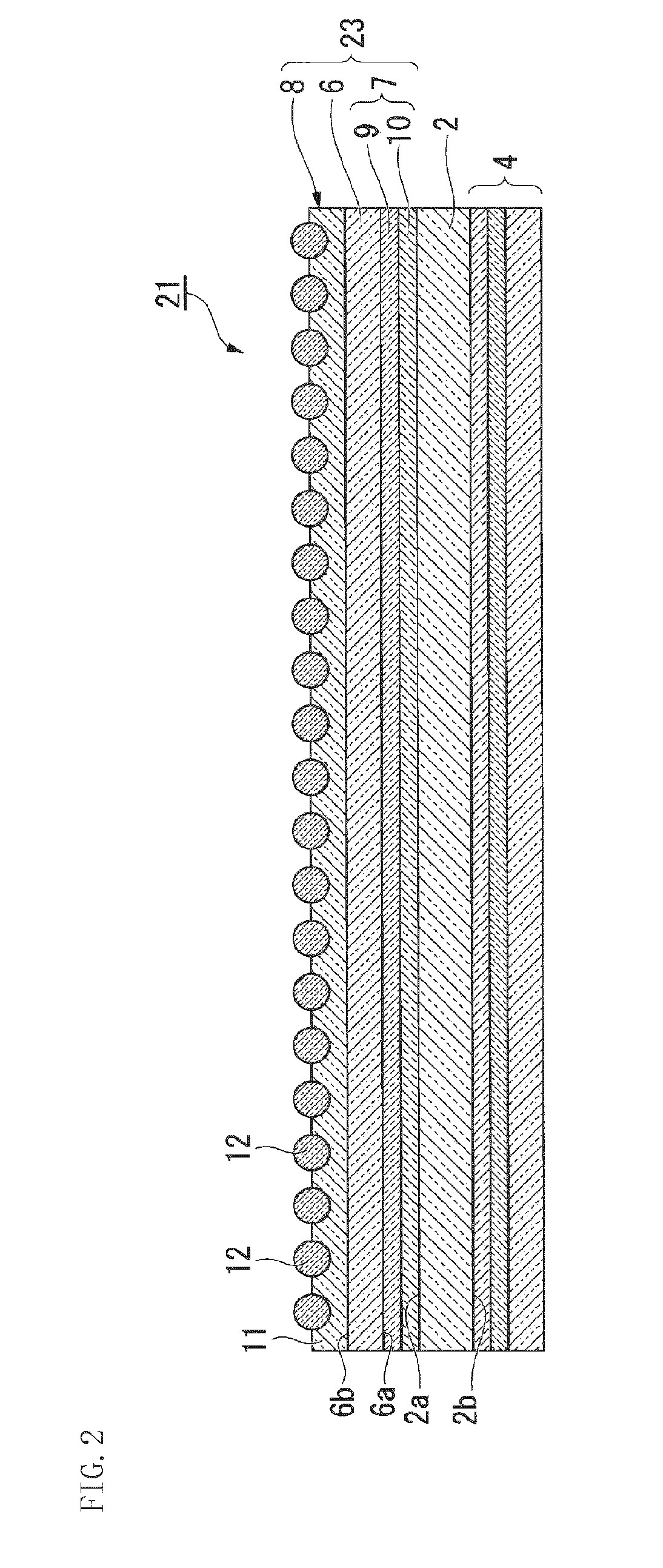

Wavelength conversion sheet, backlight unit, and phosphor protective film

ActiveUS20170017021A1Minimize adverse effectsExcellent barrier propertiesMechanical apparatusDiffusing elementsPhysicsWavelength conversion

A wavelength conversion sheet includes a phosphor, and one or more barrier films that seal the phosphor. At least one of the barrier films includes a coating layer having an optical function. The coating layer is provided to a surface of the barrier film.

Owner:TOPPAN PRINTING CO LTD

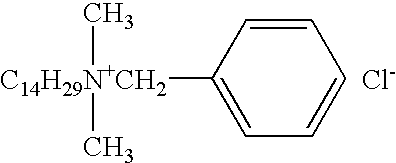

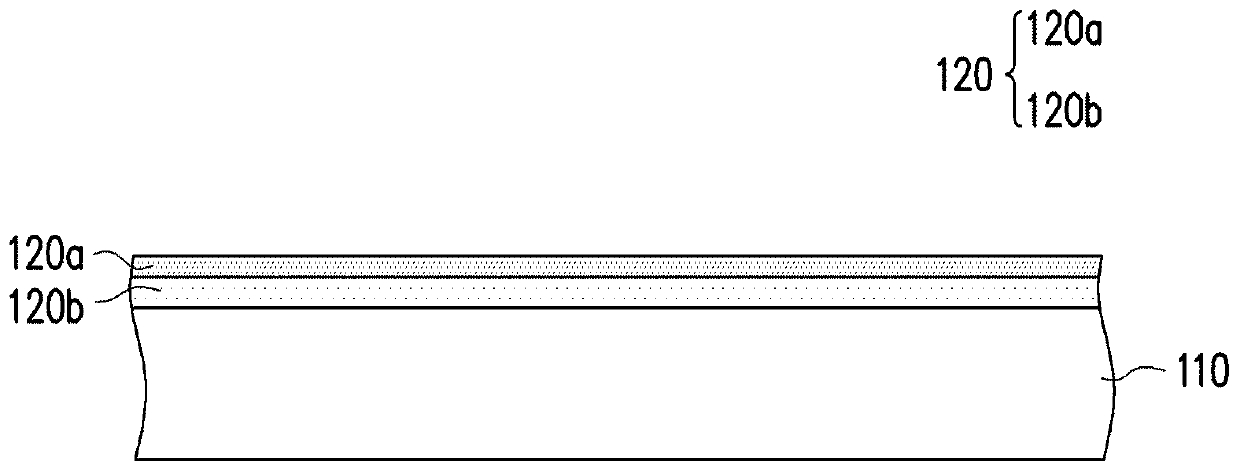

Inorganic composition, film, and method of producing film

InactiveUS6903035B2Superior barrier characteristicEfficiently formedOther chemical processesMixing methodsSol-gelMica

An inorganic composition comprises an inorganic matrix, wherein an inorganic layered compound is contained in the inorganic matrix. The inorganic matrix is preferably a metal oxide glass produced by a sol-gel method, and the inorganic layered compound is preferably swelling synthetic mica. A method of producing a film includes the steps of: hydrolyzing, dehydrating, and condensing an organic metal compound to obtain a reaction product; adding and dispersing the inorganic layered compound in the reaction product; coating the reaction product containing the inorganic layered compound on a substrate surface; and heating the substrate surface coated with the reaction product at a temperature of not more than 200° C. to vitrify the reaction product.

Owner:FUJIFILM CORP +1

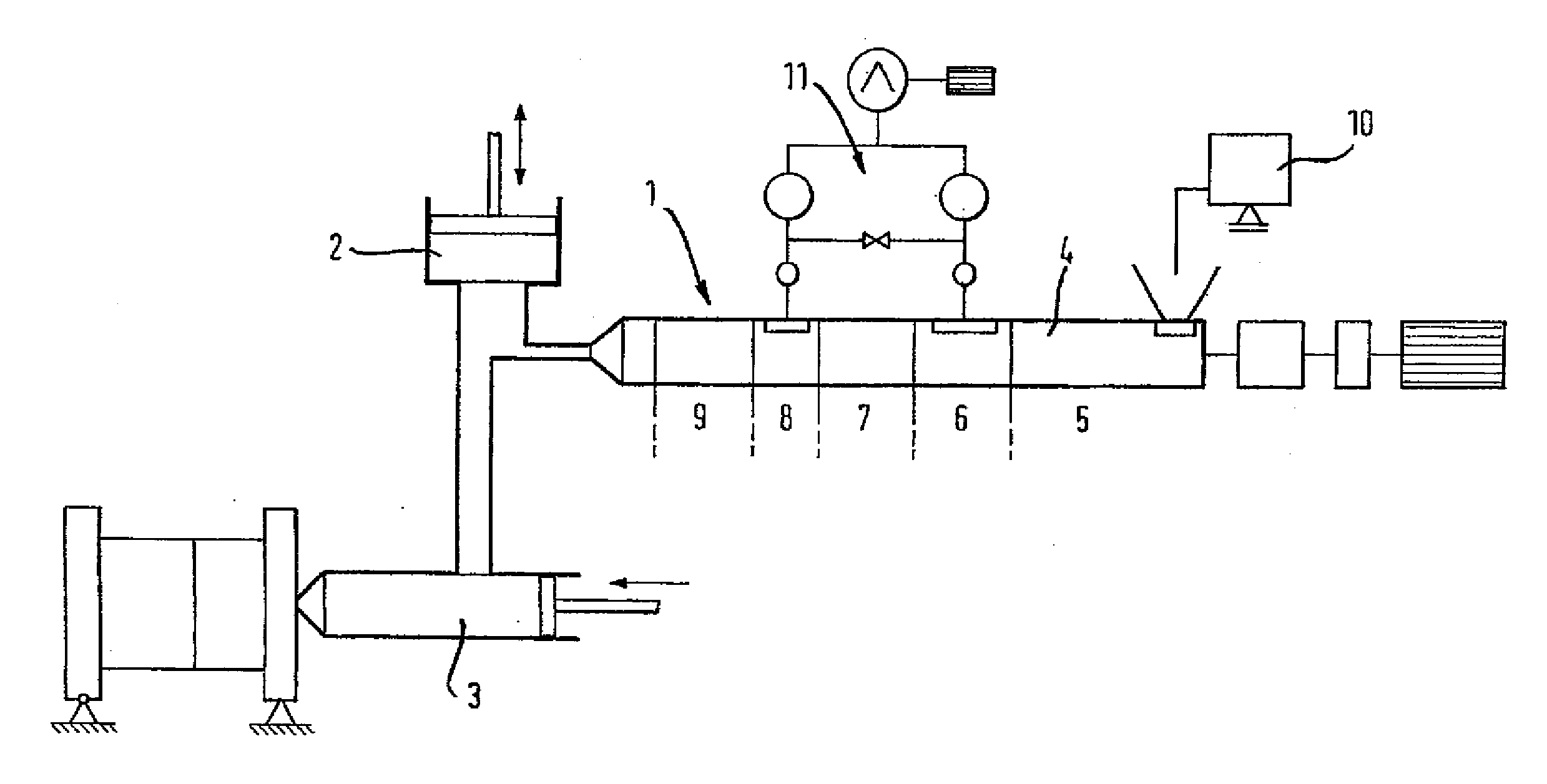

Apparatus for producing injection-molded parts

InactiveUS20070262489A1Excellent barrier propertiesSignificant energy savingEngineeringMechanical engineering

Apparatus for producing injection-molded parts, particularly PET preforms, includes a twin-screw extruder or multi-screw extruder for preparing and / or plasticizing material, preferably in granular form, which is transferred to a transfer reservoir. A piston unit further processes the material. The extruder has a plurality of processing zones, whereby at least two process zones are configured as degassing zones.

Owner:BERSTORFF GMBH +1

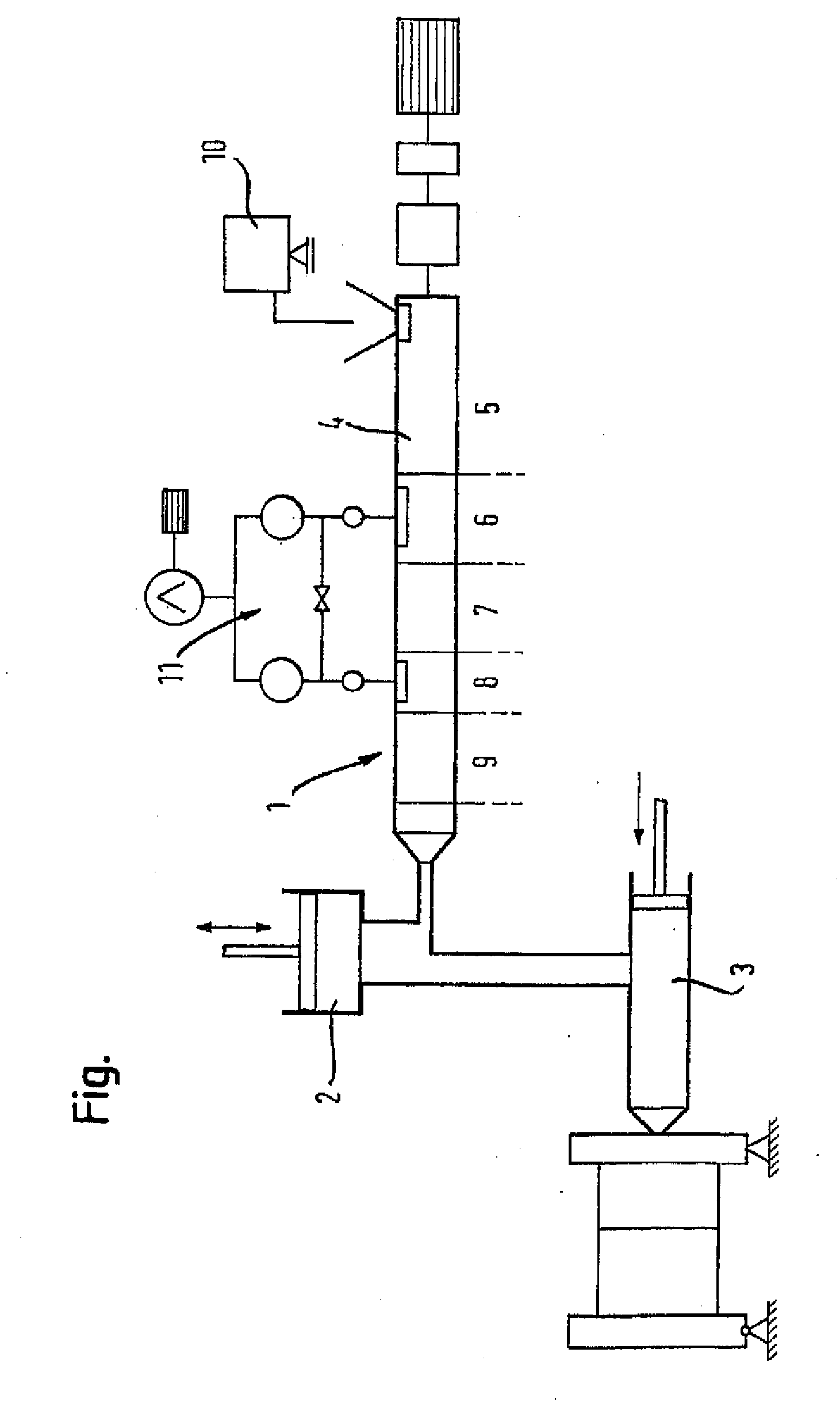

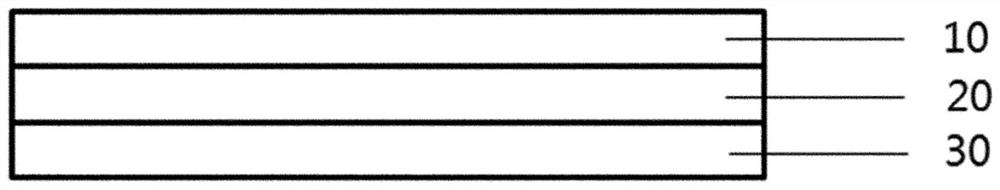

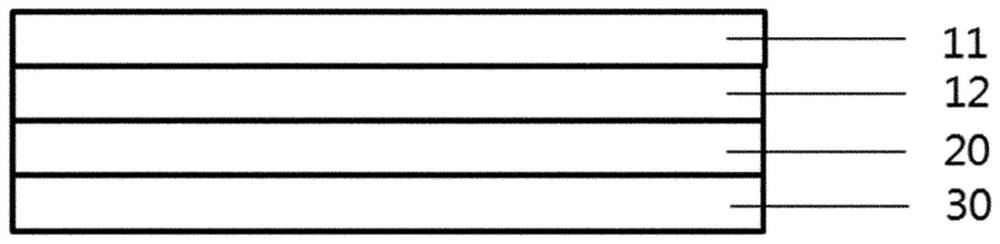

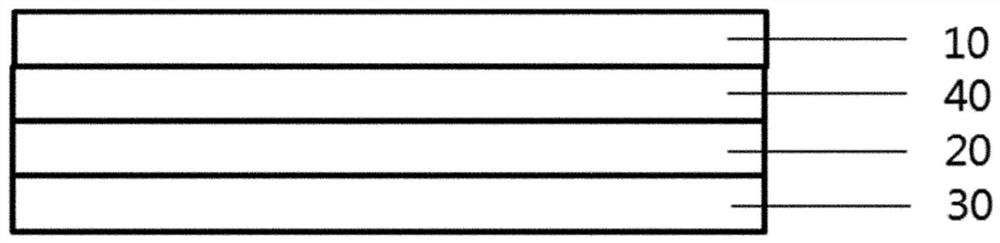

Barrier composite for plastic components

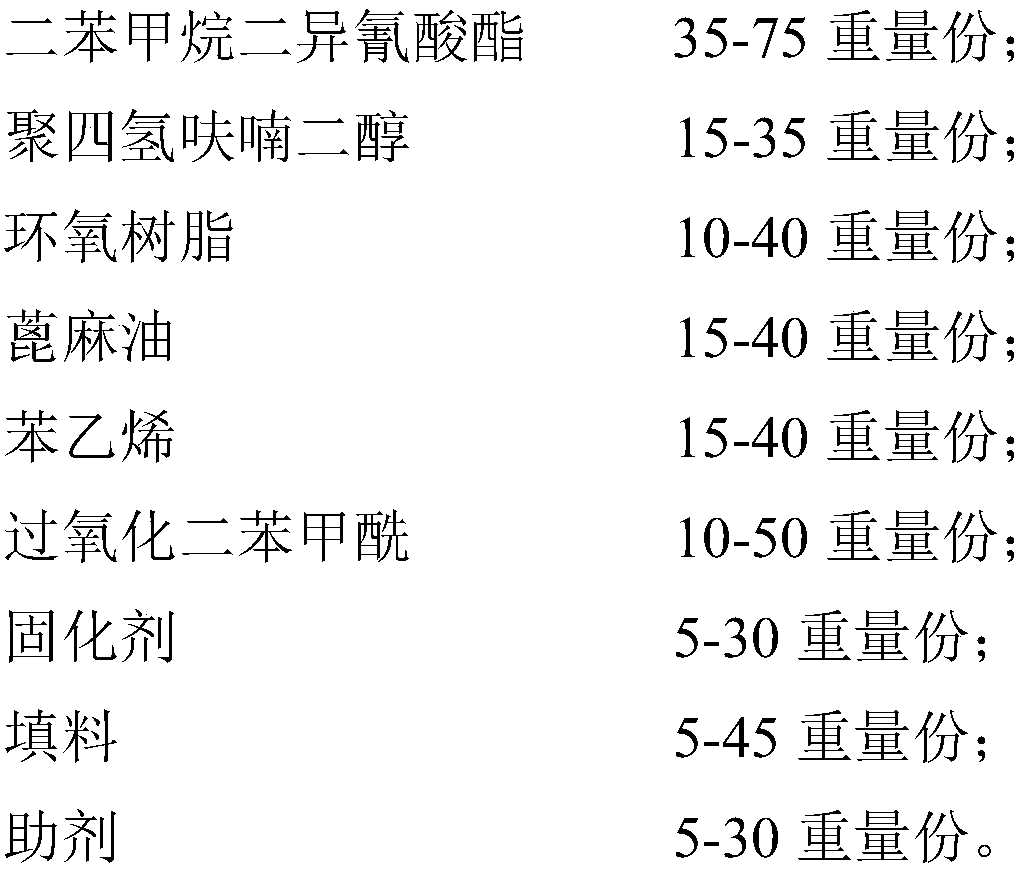

ActiveCN104936766AReduce penetrationExcellent mechanical propertiesSynthetic resin layered productsCell component detailsMetal foilThermoplastic matrix

The present invention relates to a barrier composite (10) for reducing the permeability of plastic components. The barrier composite comprises a metal foil (12), which has a coating on both sides made of a thermoplastic material (14), wherein a composite with a fibre composite layer (16) comprising a thermoplastic matrix is disposed on at least one side of the coated metal foil. The present invention further relates to a method for producing a component, in particular an encasement or a housing, made of such a barrier composite, and to the use thereof for encasing the plastic components.

Owner:ROBERT BOSCH GMBH

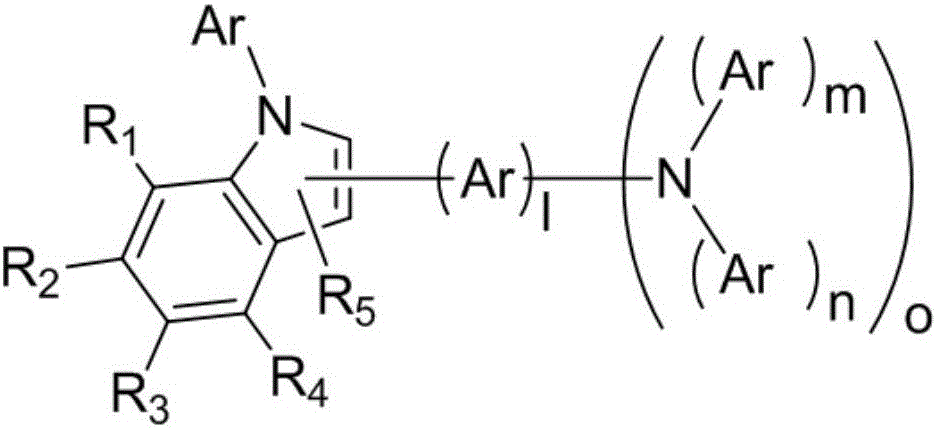

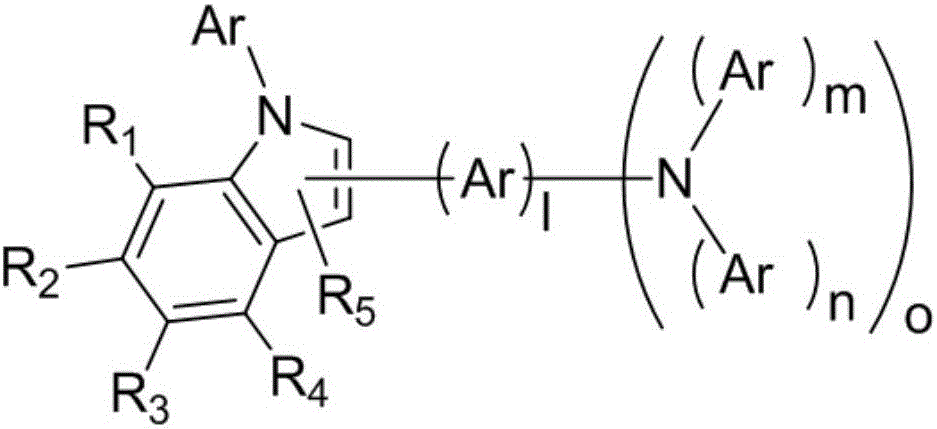

Novel compound and orgarnic light emitting device containing same

ActiveCN106573905AExcellent hole transport propertiesExcellent electron blocking propertiesOrganic chemistrySolid-state devicesVoltagePower consumption

The present invention relates to a novel compound and, especially, to a novel compound which, when applied to an organic light emitting device, has excellent hole injection and hole transport properties and simultaneously has an excellent electron blocking property, can implement high triplet energy and high Tg, and enables the organic light emitting device to have low driving voltage, low power consumption, high efficiency, and long lifetime.

Owner:DONGJIN SEMICHEM CO LTD

MEMS piezoresistive pressure sensor and production method thereof

ActiveCN105716750AHigh sensitivityImprove linearityFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsStress concentrationBiochemical engineering

The invention discloses a MEMS piezoresistive pressure sensor and a production method thereof. A silicon strain film provided with a boomerang structure is disclosed for the first time, and piezoresistors are arranged on the stress concentration part of the boomerang structure, and then the sensitivity and the linearity of the piezoresistive pressure sensor can be improved. The SiO2 / Si3N4 of the LPCVD are selected to be used as the mask of the KOH corrosion technology, and the barrier characteristic of the mask on the K+ can be improved according to the KOH back cavity corrosion technology, and therefore the high reliability of the sensor can be guaranteed. By adopting the silica glass anodic bonding technology, the glass is used for the stress buffering, and the stability of the sensor can be improved in the follow-up packaging and the follow-up tests. The MEMS piezoresistive pressure sensor is advantageous in that the higher sensitivity and the higher linearity can be provided at the same time, and the production method is compatible to the universal MEMS processing technology, and in addition, the product reliability and the product yield are high.

Owner:PEKING UNIV

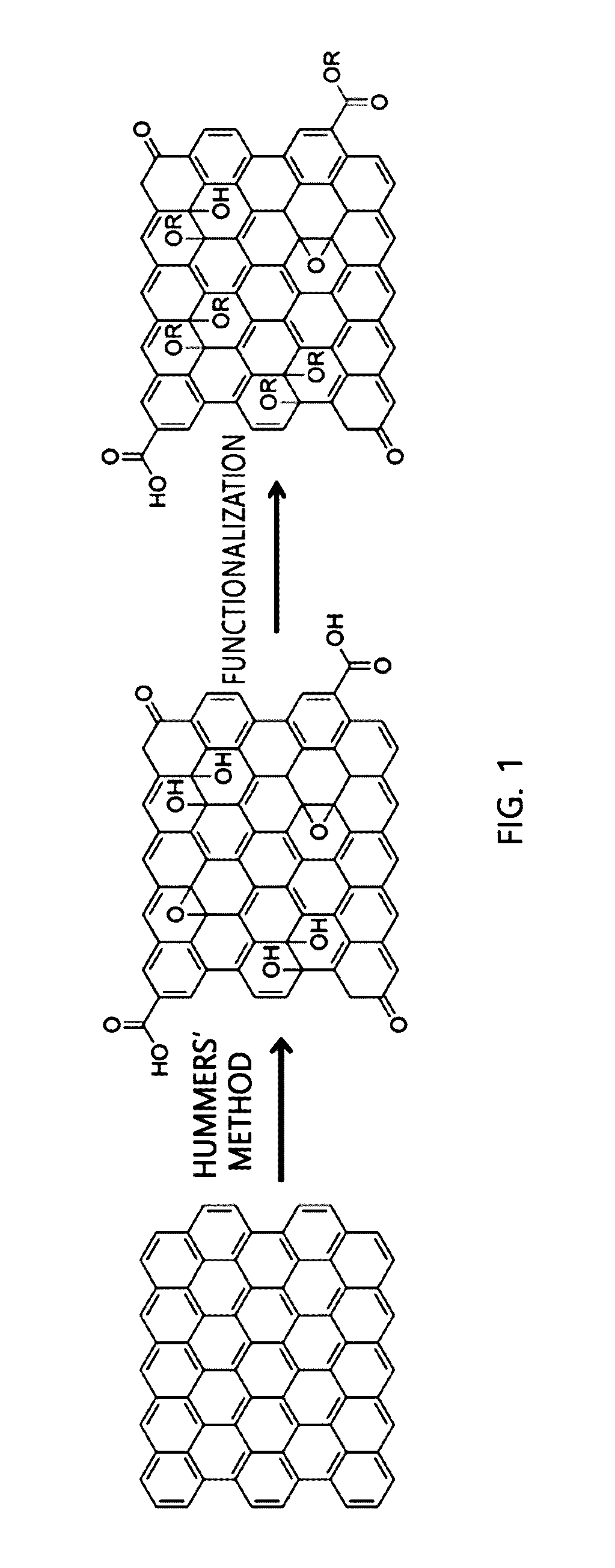

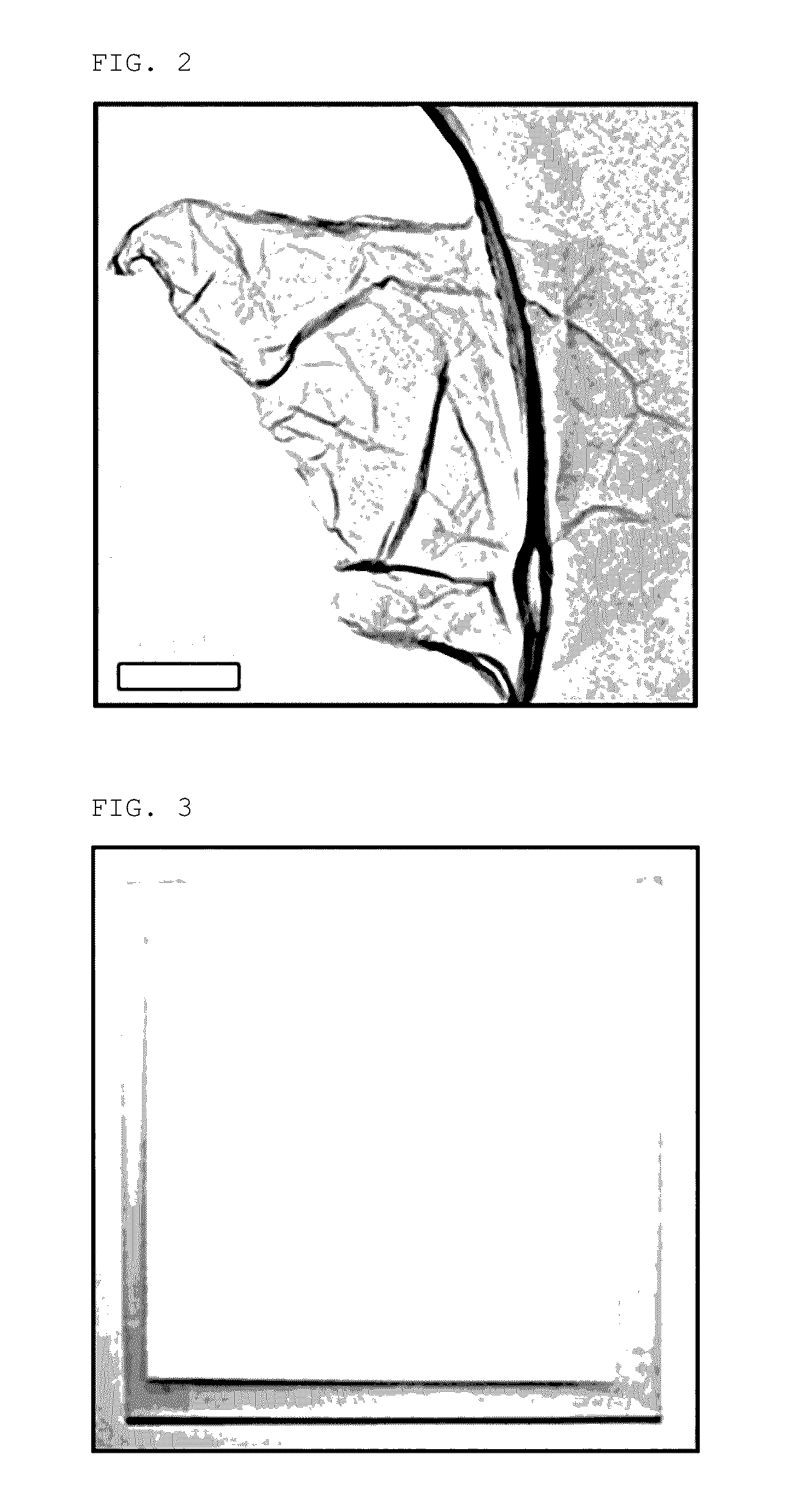

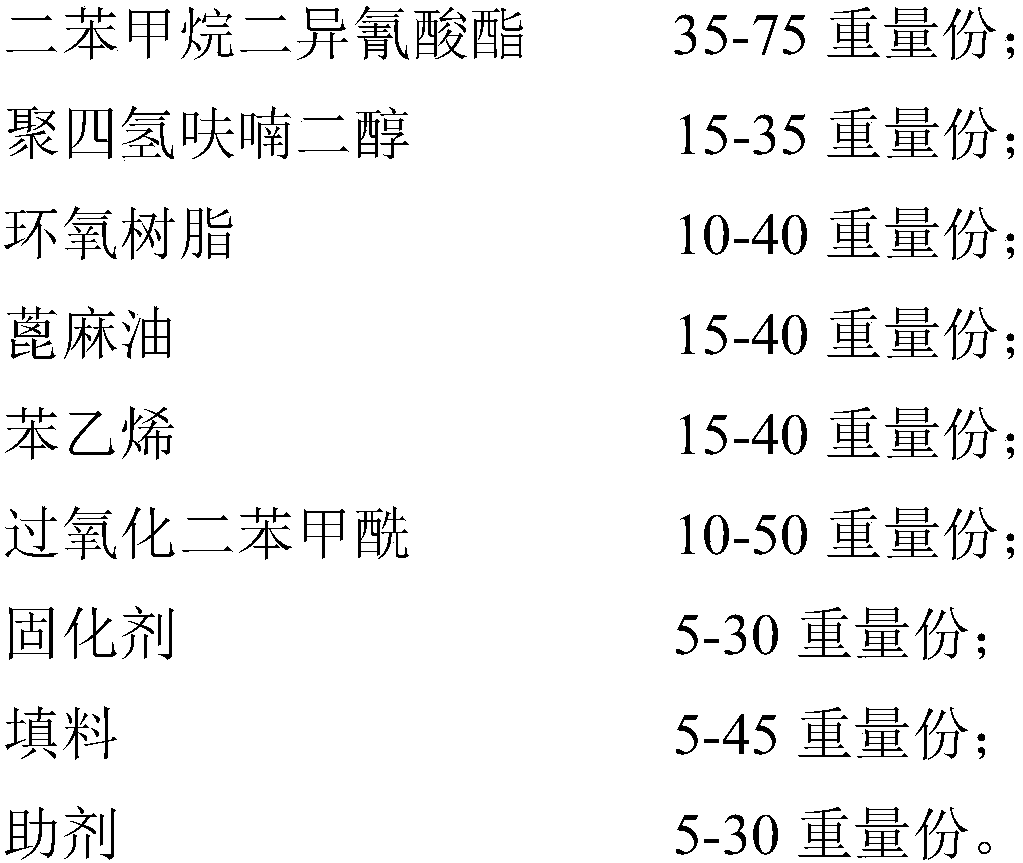

Graphene oxide nanocomposite membrane having improved gas barrier characteristics and method for manufacturing the same

InactiveUS20170015483A1Excellent barrier propertiesSimple structureMaterial nanotechnologySemi-permeable membranesDisplay deviceMedical product

The present invention relates to a technique of manufacturing a graphene oxide nanocomposite membrane in which 3 μm to 5 μm-sized graphene oxide is coated with a thickness of 10 nm or more on various supports, or a graphene oxide nanocomposite membrane having a structure in which graphene oxide is inserted into a polymer. The graphene oxide nanocomposite membrane manufactured according to the present invention has excellent barrier characteristics against various gases even when graphene oxide, of which the size is controlled to 3 μm to 5 μm, is coated as a nanometer-thick thin film on various supports or the graphene oxide nanocomposite membrane has a simple structure in which graphene oxide is inserted into a polymer, and thus the graphene oxide nanocomposite membrane can be applied to the packaging of display devices, food, and medical products.

Owner:IUCF HYU (IND UNIV COOP FOUNDATION HANYANG UNIV)

High-barrier polyolefin composite film

InactiveCN109435392AOvercoming technical deficienciesExcellent barrier propertiesFlexible coversWrappersFood packagingLiquid food

The invention discloses a high-barrier polyolefin composite film, which comprises a printing protection layer, a printing decoration layer, an adhesive layer, a sheet-shaped inorganic silica PVA coating layer and a heat sealing layer which are sequentially arranged. The high-barrier polyolefin composite film well overcomes the technical defects of the existing polyolefin composite film by adoptinga PVA coating technology of a sheet-shaped inorganic silica. The high-barrier polyolefin composite film still has excellent barrier performance under high humidity, can reach 0.5-1.0 CC / M2.24 H onlyby coating 0.6-0.8 micron, has excellent fragrance retention, is obviously superior to VMPET and PVDC coating layers, is environment-friendly, has no organic matter emission in the processing process,so that the film is beneficial to recycling; the high-barrier polyolefin composite film can be widely used for packaging liquid foods, such as refrigerated fresh milk, refrigerated yogurt, edible soybean oil, edible vinegar and the like, the packaging cost is reduced, and meanwhile, the quality guarantee performance is improved.

Owner:SHANGHAI HAISHUN NEW PHARMA PACKAGING

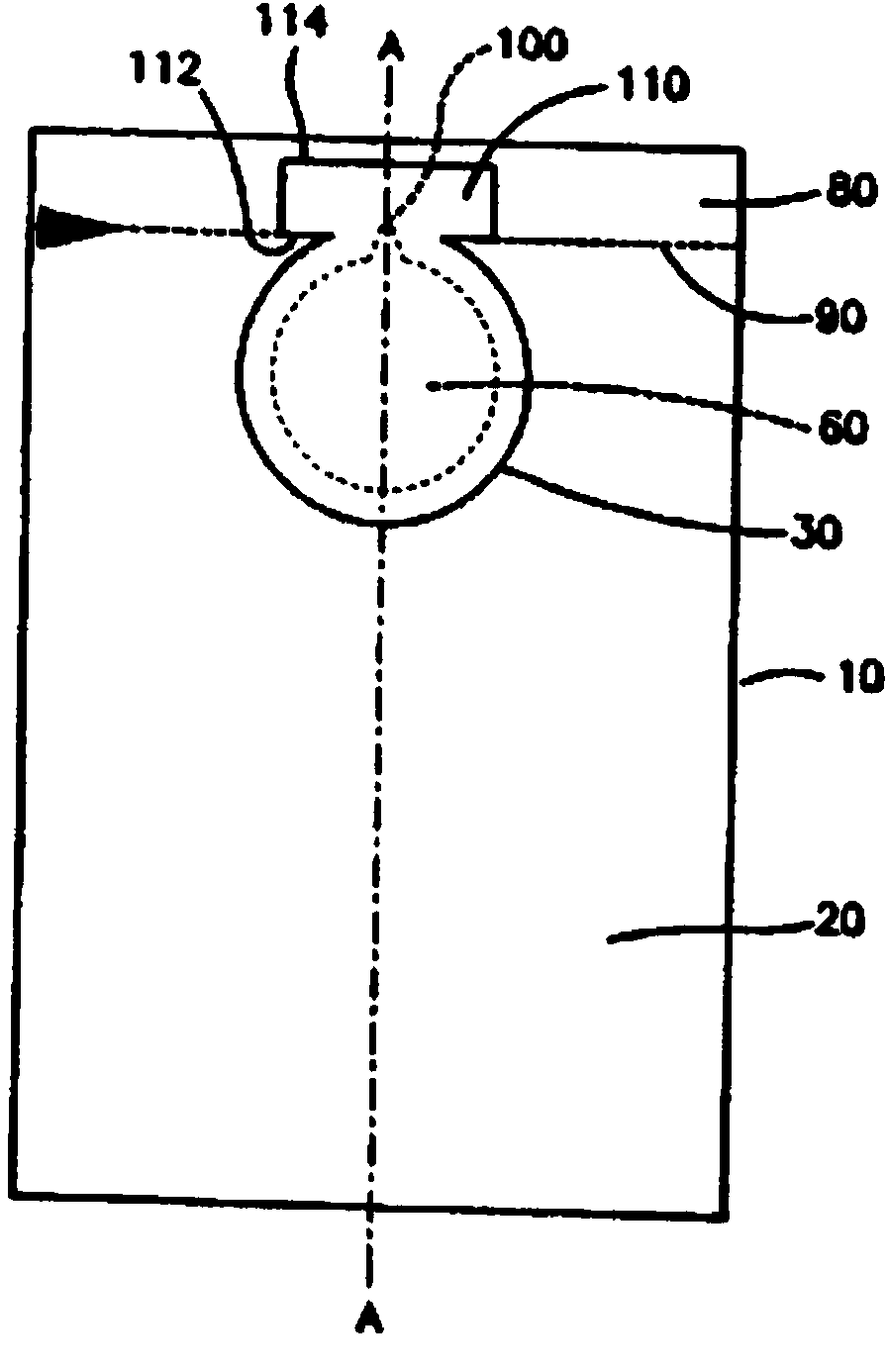

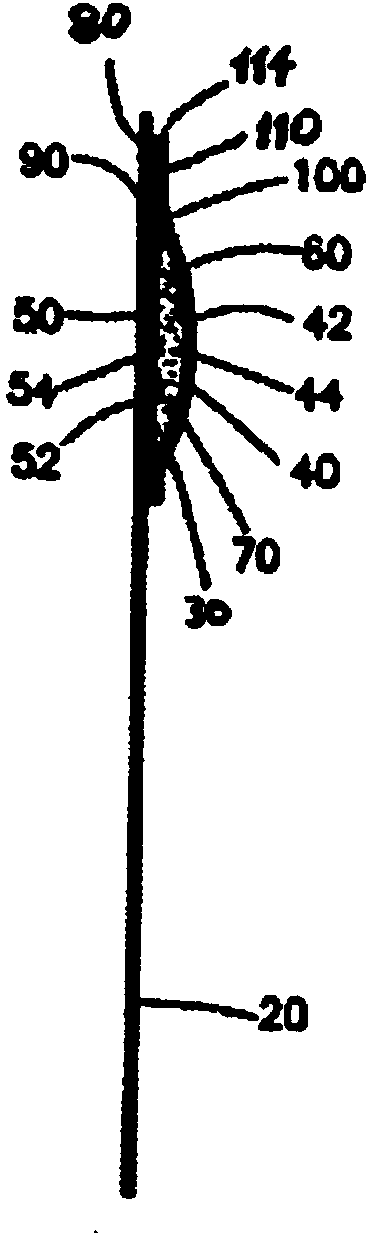

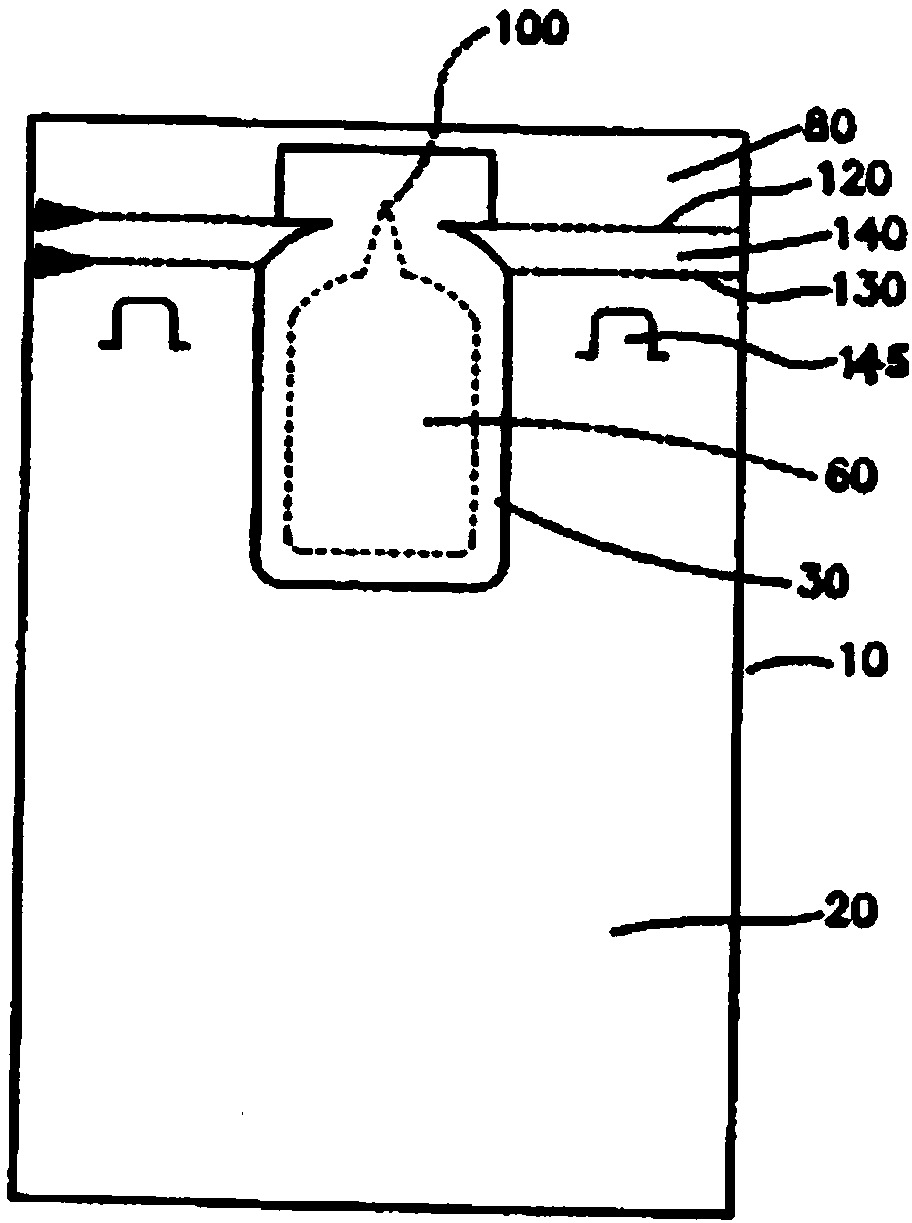

Planarising damascene structures

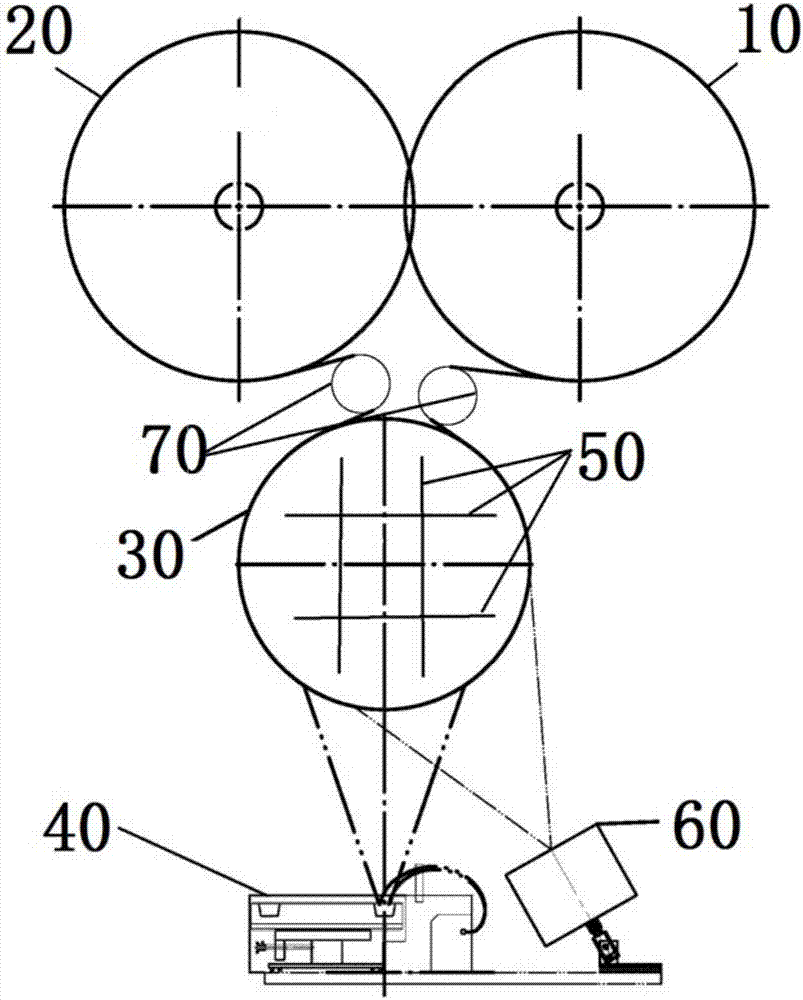

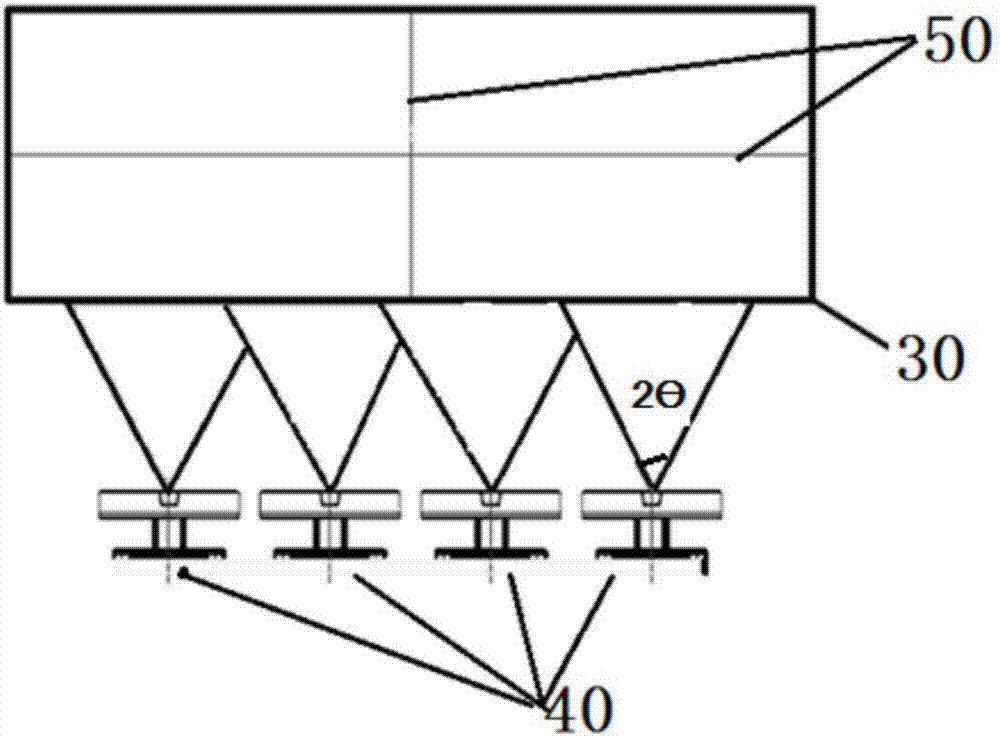

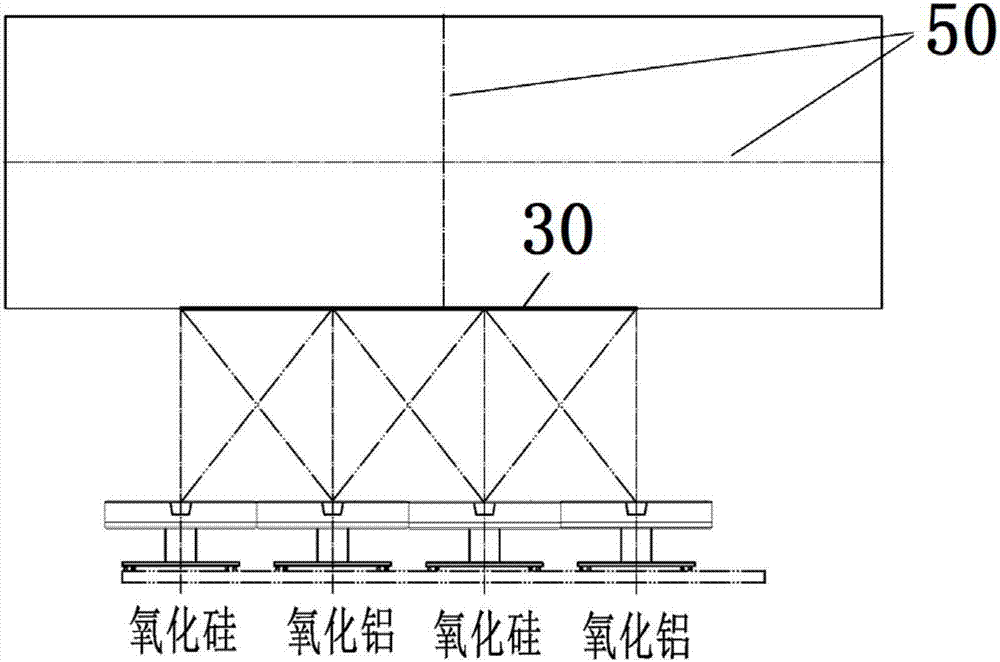

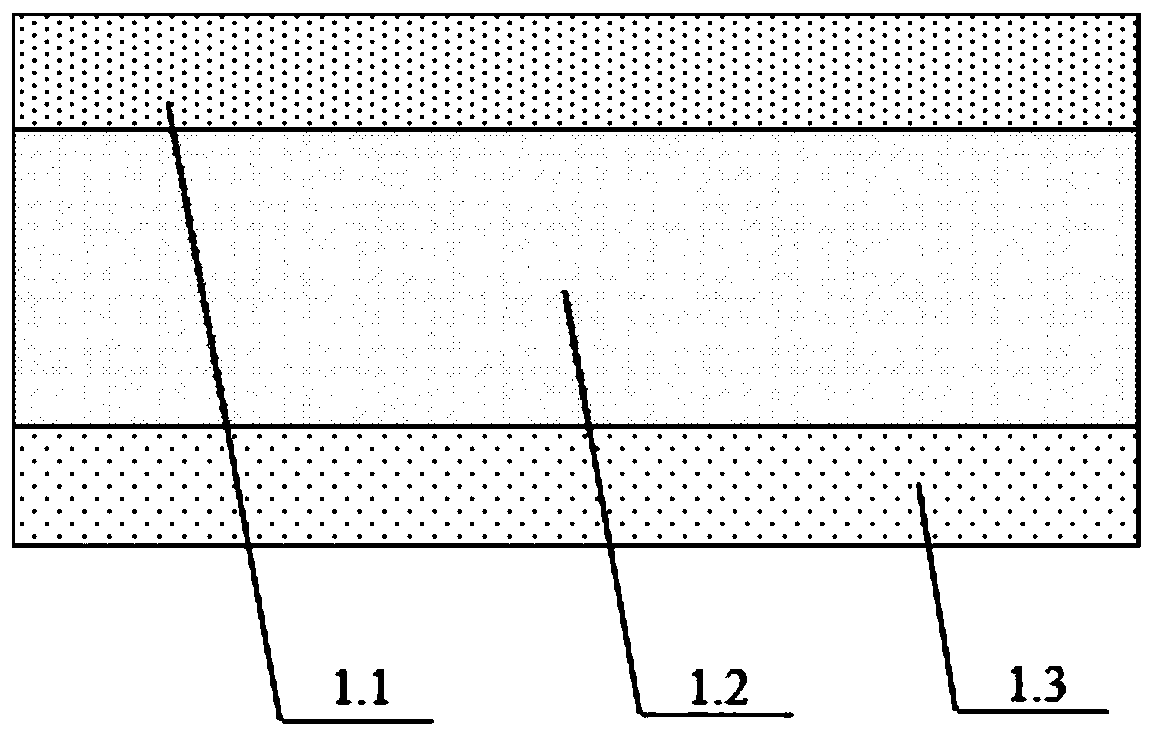

InactiveCN101053074AImprove performanceExcellent barrier propertiesSemiconductor/solid-state device manufacturingElectrochemical responseEngineering

Manufacturing a damascene structure involves: forming a sacrificial layer (20) on a substrate (10) to protect an area around a recess (30) for the damascene structure, forming a barrier layer (40) in the recess, and in electrical contact with the sacrificial layer, forming the damascene structure (50) in the recess, and planarising. During the planarising the sacrificial layer reacts electrochemically with the barrier layer or with the damascene structure. This can alter a relative rate of removal of the damascene structure and the sacrificial layer so as to reduce dishing or protrusion of the damascene structure, and reduce copper residues, and reduce barrier corrosion. The barrier layer can be formed by ALCVD. The barrier material being one or more of WCN and TaN. The sacrificial layer can be TaN, TiN or W.

Owner:NXP BV

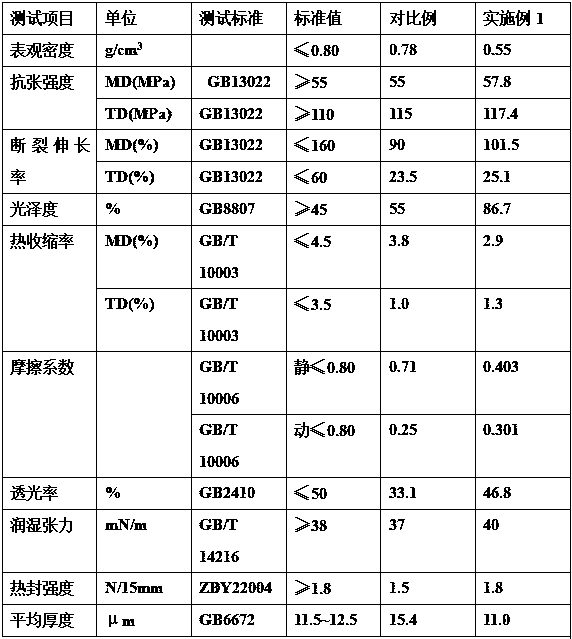

Ultrathin pearlescent film and production method thereof

InactiveCN108162533AExcellent barrier propertiesGood pearlescent effectFlexible coversWrappersMechanical properties of carbon nanotubesCo extrusion

The invention belongs to the field of production of BOPP films, and concretely relates to an ultrathin pearlescent film and a production method thereof. The pearlescent film comprises a surface layer1, a surface layer 2 and a core layer; the surface layer 1 comprises 97.0 wt% of HGX030 and 3.00 wt% of ABPP905, and the surface layer 2 comprises 97.5 wt% of T30S and 2.50 wt% of ABPP936; and the core layer comprises 62.6 wt% of a main material, 1.60 wt% of AS3030PP, 35.00 wt% of LG703T and 0.80 wt% of S2020PP. The pearlescent film obtained by biaxial stretching after co-extrusion of a three-layer structure has the advantages of excellent barrier property, good pearlescent effect, strong decorative property and excellent mechanical properties, can be used for high-end packaging of foods and the like, and has a broad market prospect.

Owner:FU RONG HUI IND FUJIAN

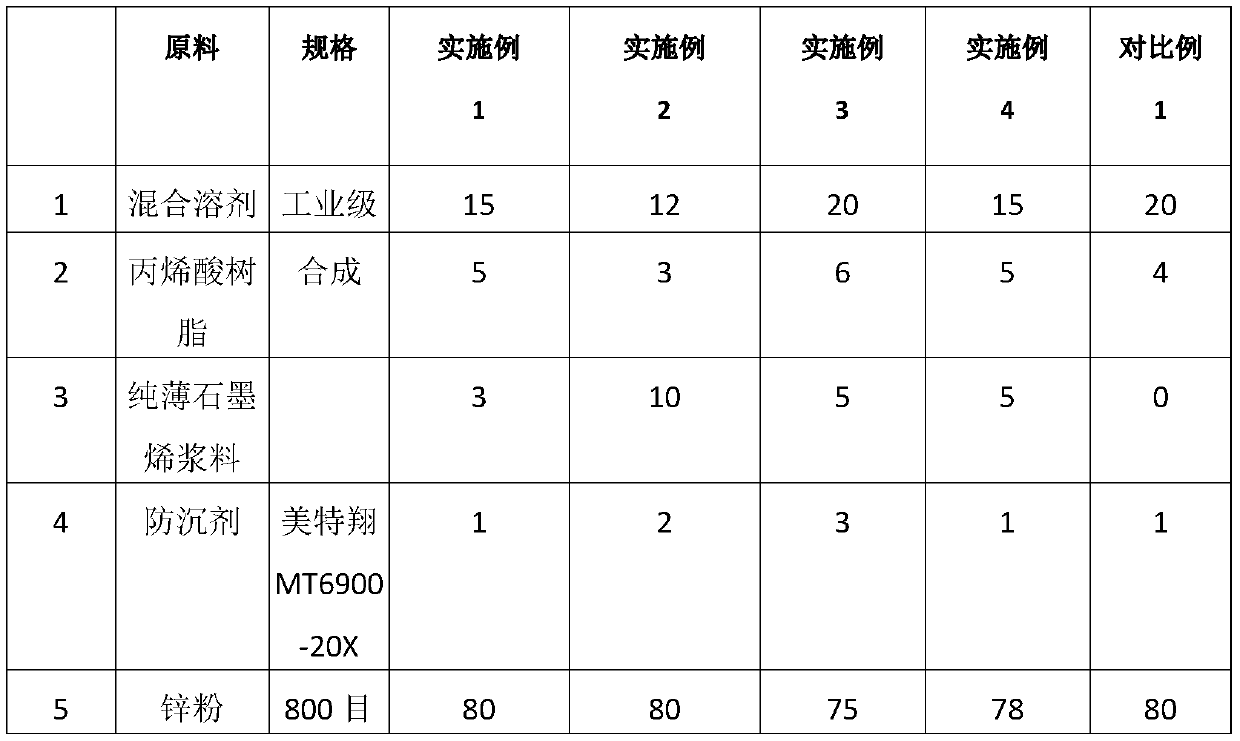

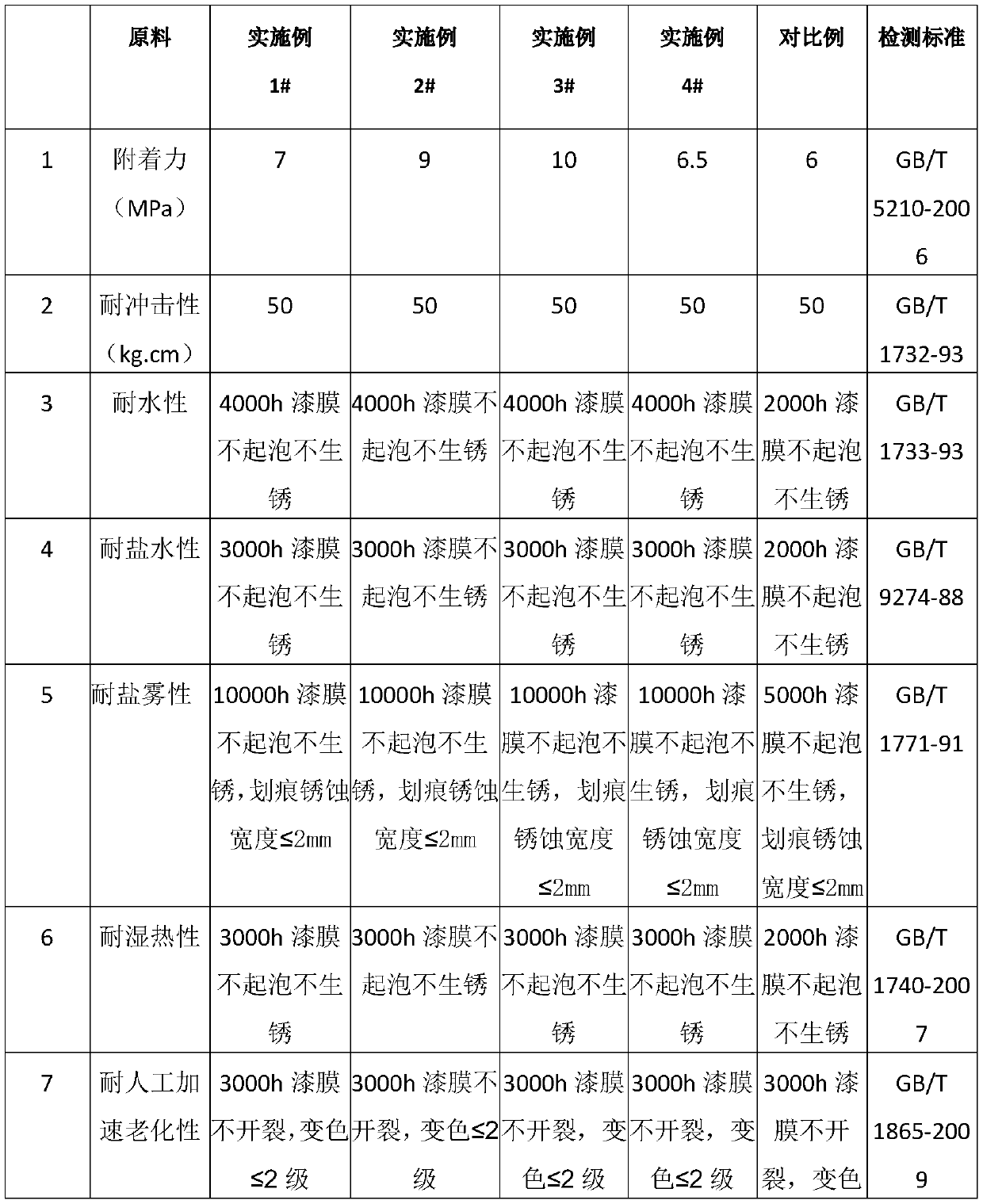

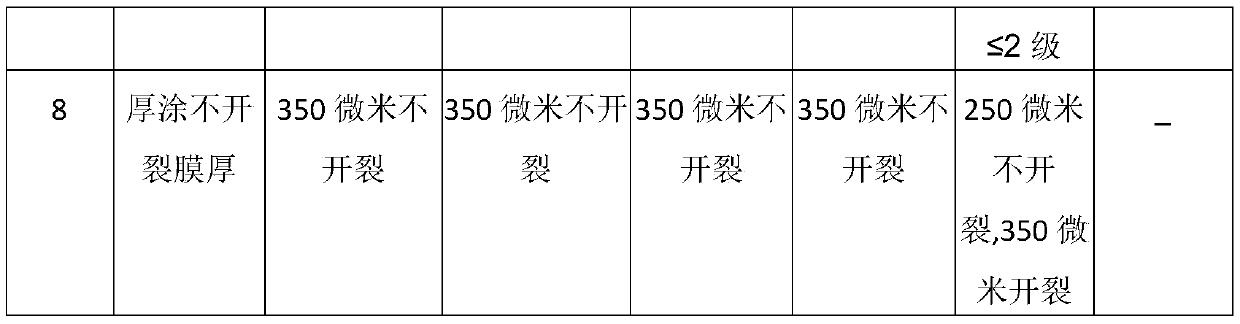

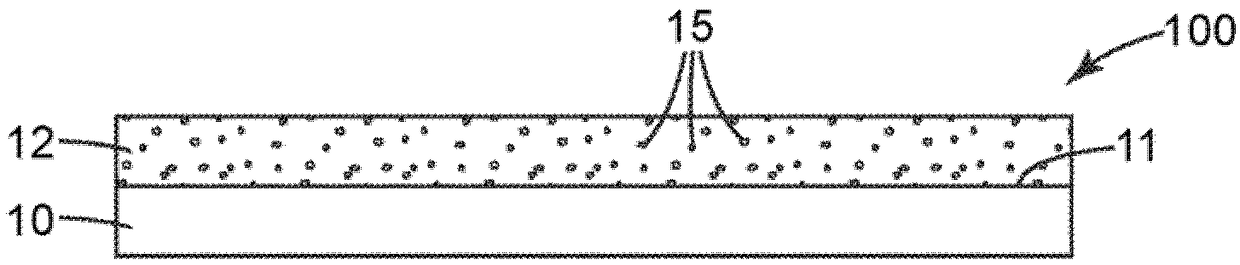

Cold-spraying graphene-zinc coating and preparation method thereof

InactiveCN111286238AImproved resistance to thick film crackingExcellent barrier propertiesAnti-corrosive paintsAcrylic resinAcrylic acid

The invention discloses a cold-spraying graphene-zinc coating. The cold-spraying graphene-zinc coating comprises 3 to 6 parts of acrylic resin, 3 to 10 parts of pure thin graphene slurry, 12 to 20 parts of a mixed solvent, 75 to 80 parts of zinc powder, and 1 to 3 parts of an anti-settling agent. The invention also discloses a preparation method of the cold-spraying graphene-zinc coating. According to the invention, the modified pure thin graphene is adopted, the compactness and thick film cracking resistance of the coating layer can be effectively improved, meanwhile, the sheet structure of the pure thin graphene endows the coating layer with excellent barrier property, and the synergistic effect of the pure thin graphene and the zinc powder can greatly improve the cathodic protection effect and the corrosion inhibition effect of the coating layer, so that the protection life of the cold-spraying graphene-zinc coating is prolonged.

Owner:WUXI HUADONG ZINDN TECH

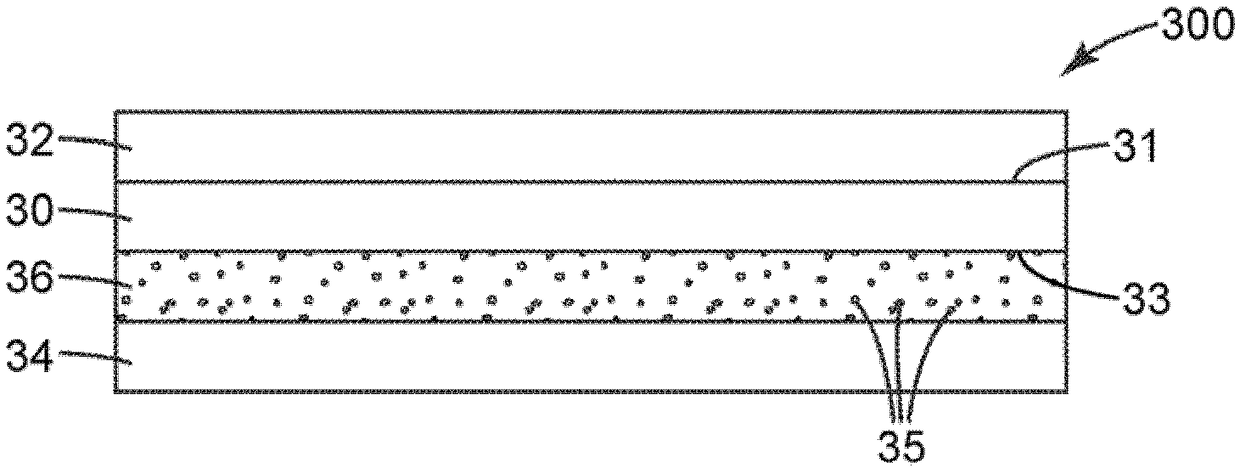

Multilayer construction including barrier layer and sealing layer

PendingCN108290391AExcellent barrier propertiesLiquid crystal compositionsOther chemical processesCrosslinked polymersSilsesquioxane

Multilayer constructions are provided, for instance including a barrier layer, a sealing layer, and a polymer layer. The barrier layer has a major surface on which the sealing layer is disposed, and the sealing layer includes crosslinked silsesquioxane. The polymer layer includes a crosslinked polymer, and is disposed adjacent to a major surface of the barrier layer opposite from the sealing layer. The multilayer construction may further include additional layers, such as a substrate. Devices are also provided including the multilayer constructions.

Owner:3M INNOVATIVE PROPERTIES CO

Macromolecule thin film material and method for preparing same

InactiveCN108530690AReduce processing costsExcellent barrier propertiesFunctional monomerFilm material

The invention provides a macromolecule thin film material and a method for preparing the same. The macromolecule thin film material is prepared from graphene, macromolecule base materials, natural starch, functional monomers, stearic acid, paraffin, polyvinyl alcohol, sodium dodecyl sulfate, sodium carboxymethyl celluloses, additives, initiators, lactic acid, curing adhesive and water. The macromolecule thin film material and the method have the advantages that the processing cost of thin films can be reduced, the macromolecule thin film material is harmless for environments, is flexible, andis high in transparency and degradation rate and excellent in water vapor and oxygen barrier property and mechanical property, and the macromolecule thin film material and the method are wide in applicable range.

Owner:合肥市晨雷思建筑材料科技有限公司

Heater package

ActiveCN111200879AGood barrier propertiesNot easy to warpOhmic-resistance electrodesOhmic-resistance waterproof/air-tight sealsPhysicsComposite material

The invention discloses a heater package, including a substrate, a first barrier layer, at least one heater, and a second barrier layer. The first barrier layer is disposed on a surface of the substrate and has a first treatment layer on a side away from the substrate. The heater is disposed on the substrate and includes a heating layer and at least one electrode. The at least one electrode and the heating layer contact with each other. The second barrier layer covers an upper surface and a sidewall of the heater and has a second treatment layer on an opposite side or the side away from the substrate. A ratio of a thickness of the first treatment layer to a thickness of the first barrier layer and a ratio of a thickness of the second treatment layer to a thickness of the second barrier layer range from 0.03 to 0.2.

Owner:IND TECH RES INST

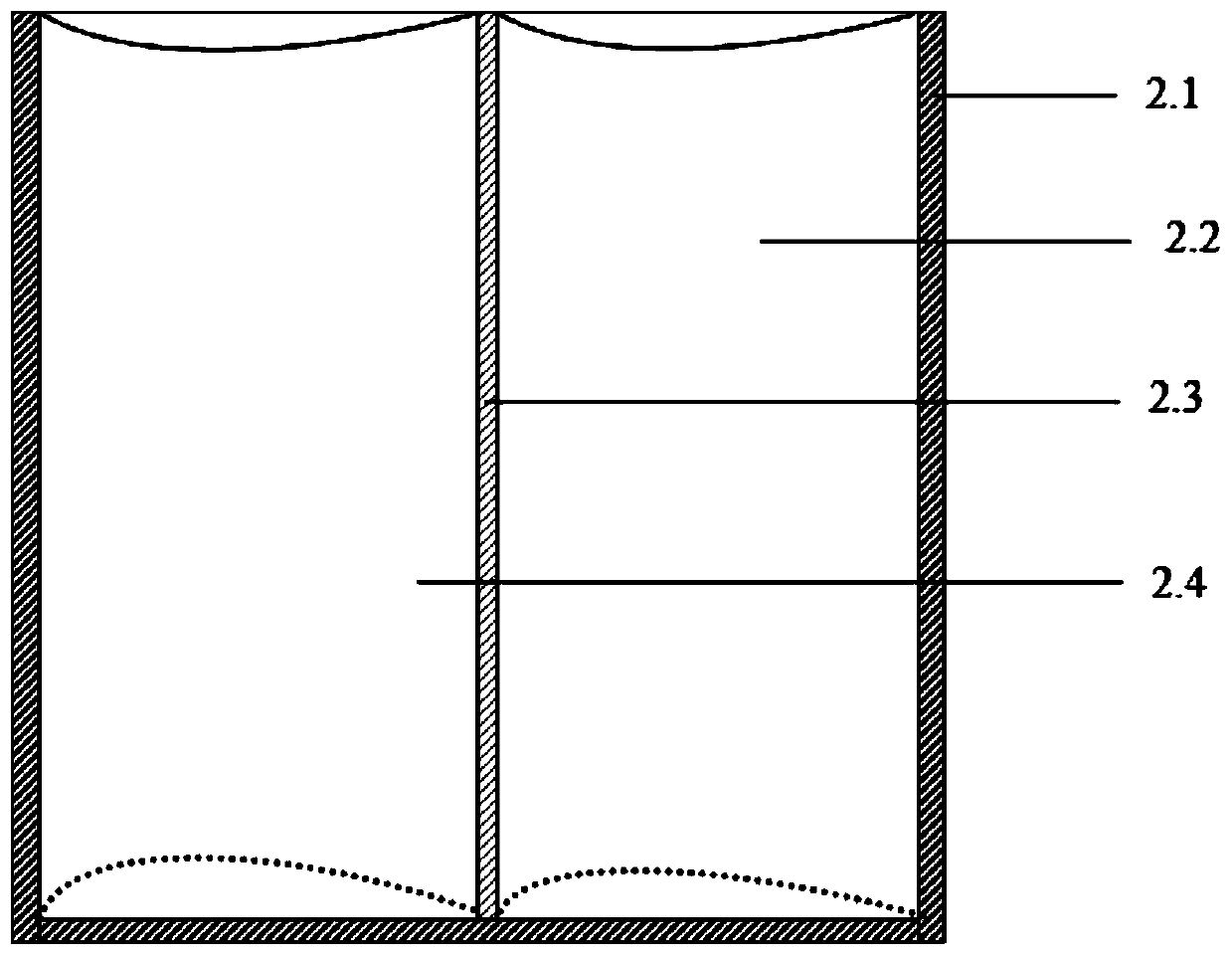

Unitized package and method of making same

InactiveCN104220344ARaise the degree of orientationIncreased resistance to deformationSuccessive articlesProduct gasEngineering

The invention generally relates to unitized packages for containing and dispensing a product material. In particular, the unitized packages comprise a printed base card and a fluid vessel permanently bonded to the printed base card. The fluid vessel comprises a first laminate barrier layer comprising at least one layer of a biaxially oriented thermoplastic polymer, a portion of which is formed into a modified dome shape, and a planar second laminate barrier layer. The first and second laminate barrier layers are sealed together to form a fluid-tight enclosure, wherein the product material substantially fills the enclosure and the modified dome shape is resiliently sustainable. A method of manufacturing the unitized packages as described above is also provided. In particular, the method includes forming a portion of the first laminate barrier layer comprising the biaxially oriented polymer into the modified dome shape using a force such as pressurized gas.

Owner:AKI INC

High-barrier nano inorganic nonmetal thin film, preparation method thereof and vacuum coiling coating equipment

ActiveCN106929806AExcellent barrier propertiesIncrease evaporation rateVacuum evaporation coatingSputtering coatingProduction rateTransmission system

The invention discloses a high-barrier nano inorganic nonmetal thin film, a preparation method thereof and vacuum coiling coating equipment. the preparation method comprises the steps that to-be-evaporated materials are placed in an electronic gun annular crucible of an e-shaped electronic gun set evaporation device; a flexible substrate is arranged on an uncoiling device of a coiling transmission system, and film penetrating is completed according to a coiling film moving path; the vacuum degree of a coating chamber is adjusted and controlled, a coiling transmission system and the e-shaped electronic gun set evaporation device are started, high-temperature evaporation is conducted on the to-be-evaporated materials, so that an evaporation thin film is formed on the surface of the flexible substrate, and an e-shaped electronic gun set is formed by combining at least two e-shaped electronic guns; and the power of the e-shaped electronic guns is 1-10 kW. In the evaporation process, the e-shaped electronic guns are adopted for emitting electron beams in a linear one-line or para-position staggered arrangement mode, the evaporation rate is increased, the production rate of coiling coating is increased, production cost is reduced, and what is more, the nano inorganic nonmetal oxide high-barrier thin film with excellent performance is obtained.

Owner:广东振华科技股份有限公司

Unstretched polyethylene film with strong and weak heat sealability

InactiveCN110328948AExcellent barrier propertiesExcellent dimensional stability in bag makingSynthetic resin layered productsDomestic containersScrapLow-density polyethylene

The invention discloses an unstretched polyethylene film with strong and weak heat sealing performance, which comprises at least three layers, namely a heat sealing layer, a core layer and a corona layer. The heat sealing layer is prepared from the following components in percentage by mass: 56-65% of metallocene polyethylene, 27-34% of polyolefin elastomer, 2.5-4.5% of slipping agent and 1.0-2.5%of anti-blocking agent mixed resin. The core layer is formed by blending 95.52-99.04 mass% of low density polyethylene and 0.96-4.48 mass% of slipping agent. The corona layer is mainly made of low-density polyethylene. The polyethylene film has excellent heat sealing performance and a wide heat sealing window, the requirement for high heat sealing strength of the edge of a multi-cavity bag can bemet, and the weak sealing performance and the proper heat sealing strength of a middle isolation seam can be provided. The polyethylene film is convenient for bare-handed stripping, the stripping surface is smooth, and the phenomena of damage and scrap falling are avoided.

Owner:安徽双津实业有限公司

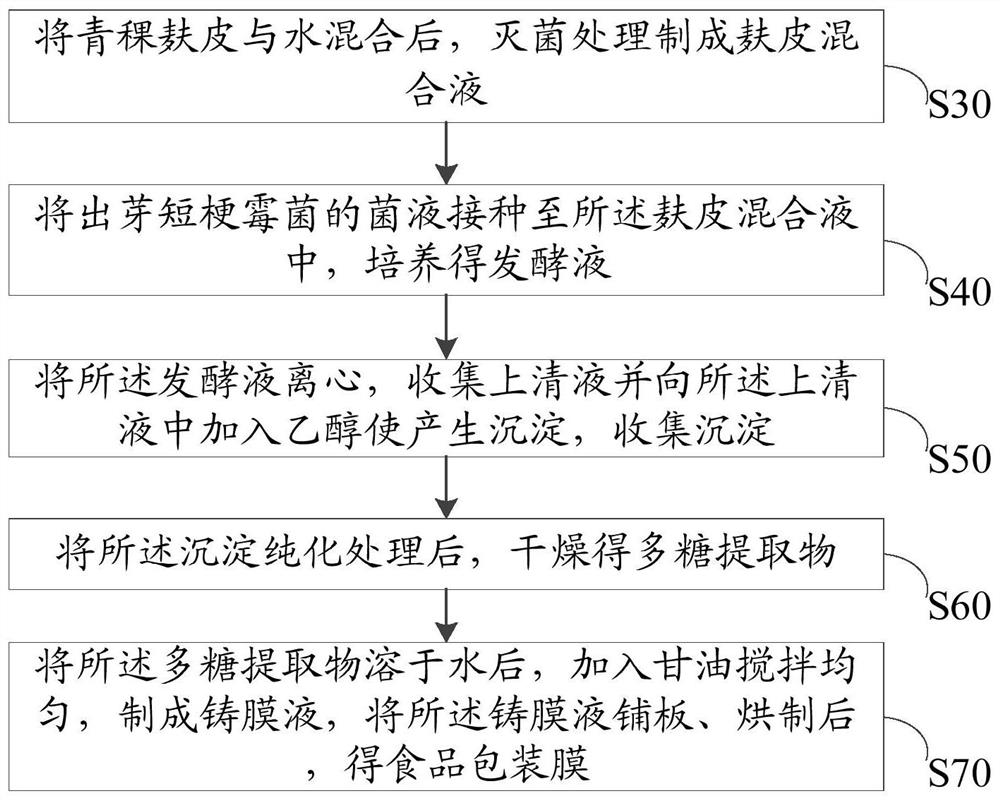

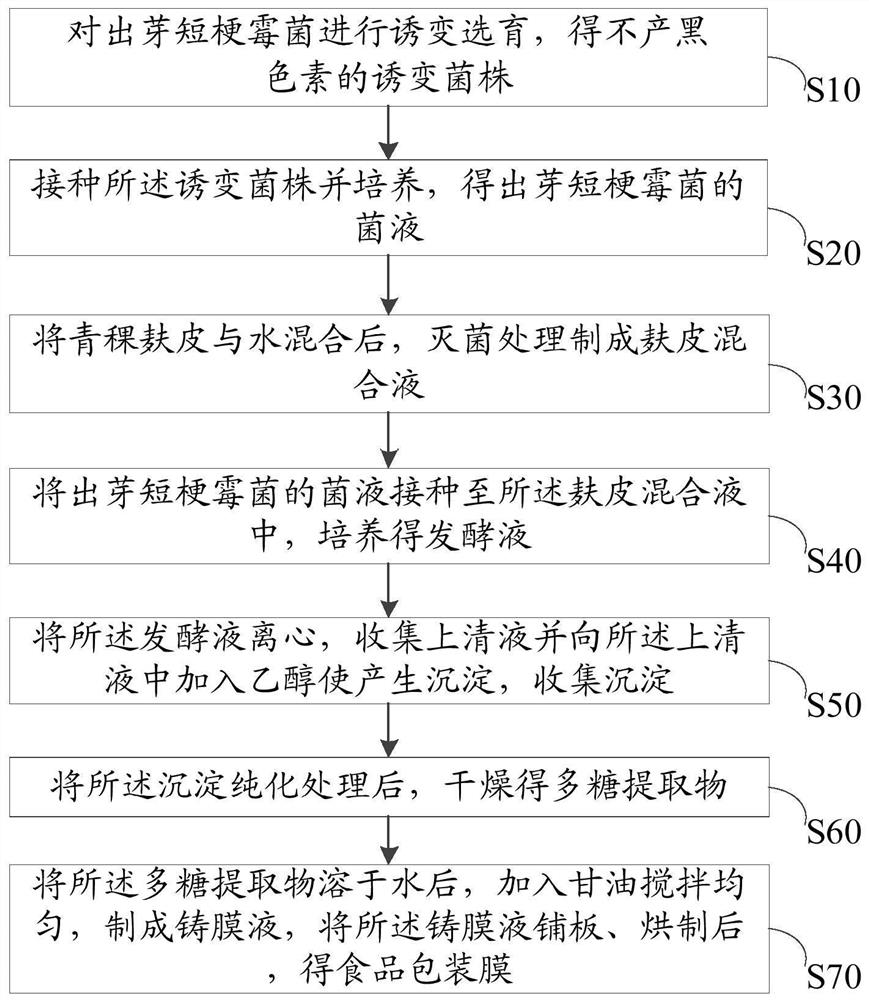

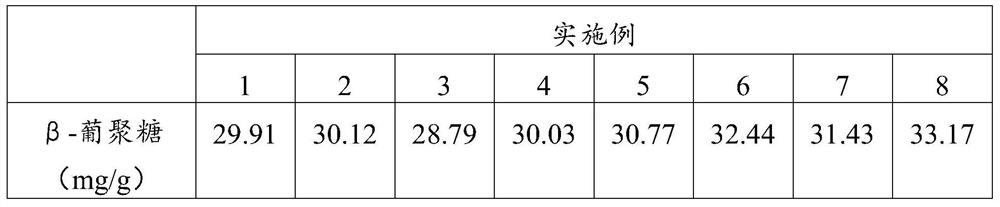

A kind of preparation method of food packaging film

ActiveCN110172169BImprove mechanical propertiesGood film-forming propertiesMicroorganism based processesFermentationBiotechnologyBARLEY BRAN

The invention discloses a preparation method of a food packaging film and relates to the technical field of food packaging. The preparation method of the food packaging film comprises the following steps: mixing highland barley bran with water, and then sterilizing the bran mixture; inoculating the bacterial solution of Aureobasidium pullulans into the bran mixture, culturing Obtain a fermentation broth; centrifuge the fermentation broth, collect the supernatant, add ethanol to the supernatant to produce a precipitate, and collect the precipitate; after purifying the precipitate, dry the polysaccharide extract; extract the polysaccharide After the extract is dissolved in water, glycerin is added and stirred evenly to prepare a casting liquid, which is laid on a board and baked to obtain a food packaging film. The present invention aims to prepare a food packaging film, which has the advantages of good mechanical properties and barrier properties.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Light-diffusing barrier film

ActiveCN111989598AAvoid damageEasy to produceOptical filtersSynthetic resin layered productsOrganic light emitting deviceMoisture barrier

The present application relates to a light-diffusing barrier film. The film is an integrated film comprising, in order, a barrier layer, a base layer and a light-diffusing layer. The film can preventmoisture ingress into a device such as an organic light emitting device, and also provides the device with a light-diffusing function. Particularly, the film can have excellent moisture barrier properties even after a roll-to-roll process.

Owner:LG CHEM LTD

A MEMS piezoresistive pressure sensor and preparation method thereof

ActiveCN105716750BHigh sensitivityImprove linearityFluid pressure measurement using ohmic-resistance variationForce measurement using piezo-resistive materialsStress concentrationElectrical resistance and conductance

The invention discloses a MEMS piezoresistive pressure sensor and a production method thereof. A silicon strain film provided with a boomerang structure is disclosed for the first time, and piezoresistors are arranged on the stress concentration part of the boomerang structure, and then the sensitivity and the linearity of the piezoresistive pressure sensor can be improved. The SiO2 / Si3N4 of the LPCVD are selected to be used as the mask of the KOH corrosion technology, and the barrier characteristic of the mask on the K+ can be improved according to the KOH back cavity corrosion technology, and therefore the high reliability of the sensor can be guaranteed. By adopting the silica glass anodic bonding technology, the glass is used for the stress buffering, and the stability of the sensor can be improved in the follow-up packaging and the follow-up tests. The MEMS piezoresistive pressure sensor is advantageous in that the higher sensitivity and the higher linearity can be provided at the same time, and the production method is compatible to the universal MEMS processing technology, and in addition, the product reliability and the product yield are high.

Owner:PEKING UNIV

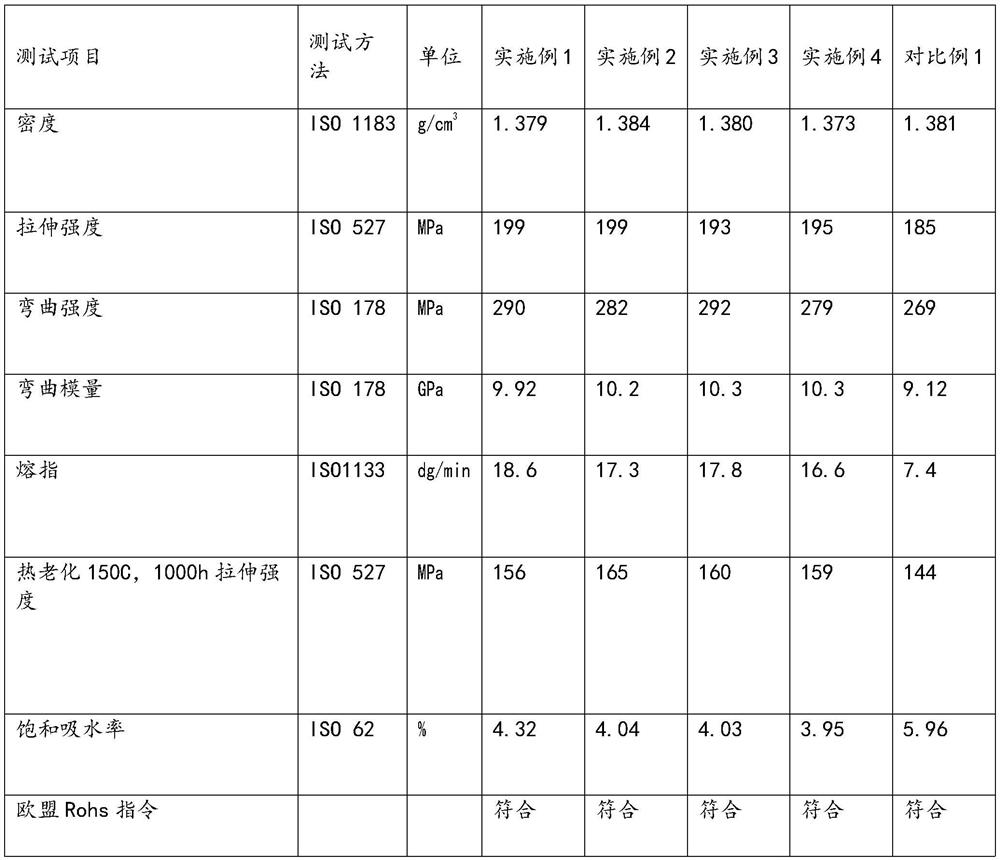

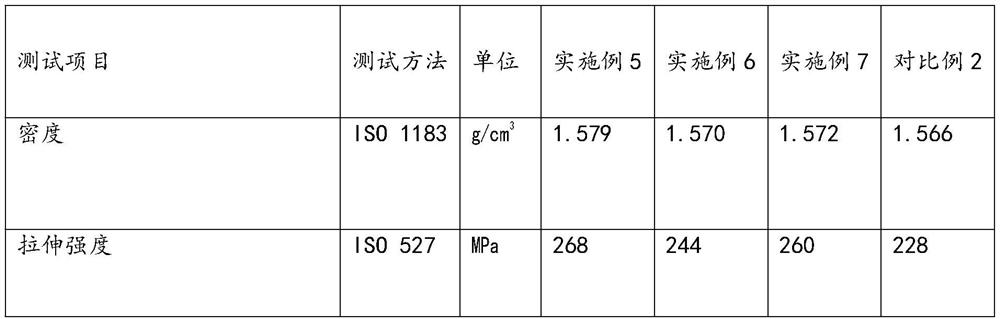

Nylon glass fiber reinforced composite material and preparation method thereof

PendingCN113881222AExcellent barrier propertiesReduce moisture absorption rate and saturated water contentPelletizingPolyamide

The invention discloses a nylon glass fiber reinforced composite material and a preparation method thereof. The composite material comprises, by weight, 40-70 parts of thermoplastic polyamide resin, 20-50 parts of glass fiber, 2-20 parts of phenolic resin and 1-2 parts of an auxiliary agent; and the glass fiber is alkali-free and arsenic-free chopped glass fiber, and the molecular weight of the phenolic resin is 500-1000000. The preparation method comprises the following steps: weighing raw materials; adding the thermoplastic polyamide resin, the phenolic resin and an auxiliary agent into a high-speed mixer, and uniformly mixing for 3-5 minutes; and adding the mixed raw materials into a double-screw extruder, adding the glass fiber under the conditions that the temperature is 230-280 DEG C and the screw rotation speed is 250-400 rpm, carrying out melt blending, and carrying out extrusion granulation. The composite material has the advantages of high fluidity, low moisture absorption, high mechanical strength and excellent aging resistance.

Owner:NANJING JULONG SCI&TECH CO LTD +1

Composite film for biological medicine packaging

InactiveCN110481126AImprove puncture strengthExcellent barrier propertiesSynthetic resin layered productsDomestic containersPolyurethane adhesiveTemperature resistance

The invention discloses a composite film for biological medicine packaging, which comprises a CPP layer, an aluminum foil layer, a PET layer, a polyurethane adhesive layer and an antibacterial layer,and is characterized in that the CPP layer, the aluminum foil layer, the PET layer, the polyurethane adhesive layer and the antibacterial layer are sequentially and adjacently connected together fromtop to bottom. The packaging material has the characteristics of being simple in structure, high in high temperature resistance, good in antibacterial property, high in strength and the like, and canwell meet the requirements of biological medicine packaging.

Owner:成都申子辰供应链管理有限公司

Environment-friendly high-barrier packaging material and preparation method thereof

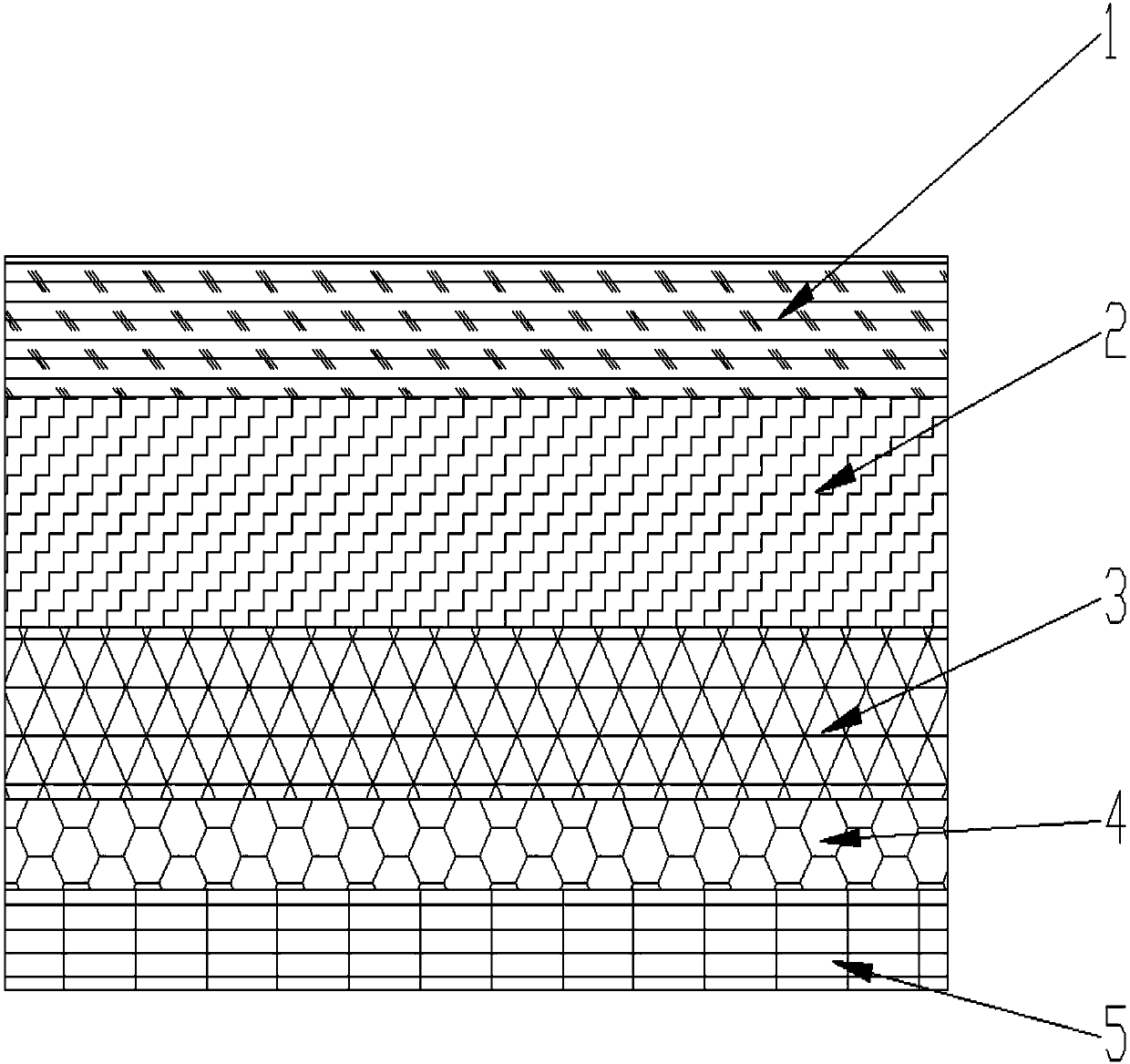

ActiveCN114751089AExcellent barrier propertiesExtended service lifeFlexible coversWrappersPolyvinyl alcoholAcrylic acid

The invention relates to the technical field of packaging materials. The environment-friendly high-barrier packaging material comprises a photodegradation layer, a base layer, a first barrier layer and a second barrier layer which are sequentially arranged, raw materials of the photodegradation layer comprise a photodegradation agent and polyethylene, an irreversible color-changing layer is arranged on the surface of the photodegradation layer, and the irreversible color-changing layer is changed into light color or transparent color from dark color under the color-changing condition; the base layer comprises the following raw materials: acrylic acid, metal modified polyvinyl alcohol, a filler and a flexibilizer; the raw materials of the first barrier layer comprise starch modified polyvinyl alcohol and hydroxy fatty acid ester; the raw materials of the second barrier layer are aluminum elementary substance, copper elementary substance and oxygen, and the second barrier layer is arranged on the first barrier layer in a vacuum coating mode. The packaging material achieves the effects of high barrier and long service life through the photodegradation layer, the base layer, the first barrier layer and the second barrier layer, and can be applied to packaging of food with long shelf life.

Owner:广东正一包装股份有限公司

barrier film

ActiveCN111356583BExcellent barrier propertiesGood sliding propertiesLamination ancillary operationsSynthetic resin layered productsOptical propertyChemistry

This application relates to barrier films. In the present application, a barrier film having excellent barrier properties to the external environment and optical properties can be provided. The barrier films produced by this application can be used in electronic products sensitive to moisture and the like.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com