Novel compound and orgarnic light emitting device containing same

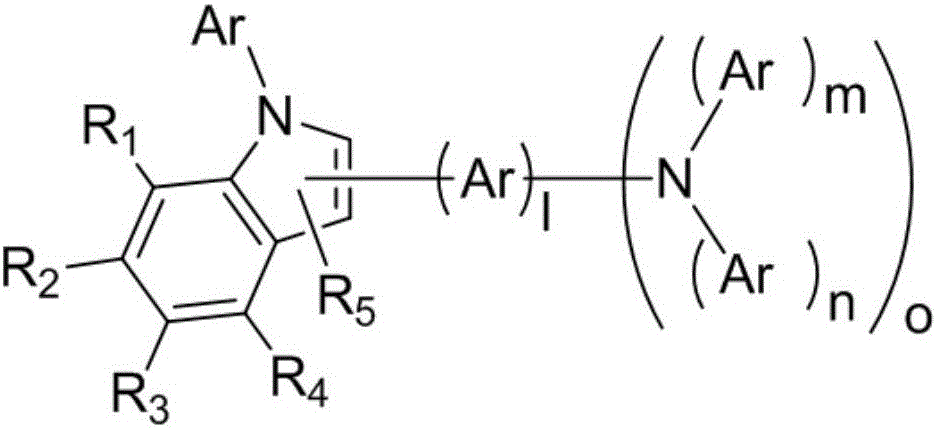

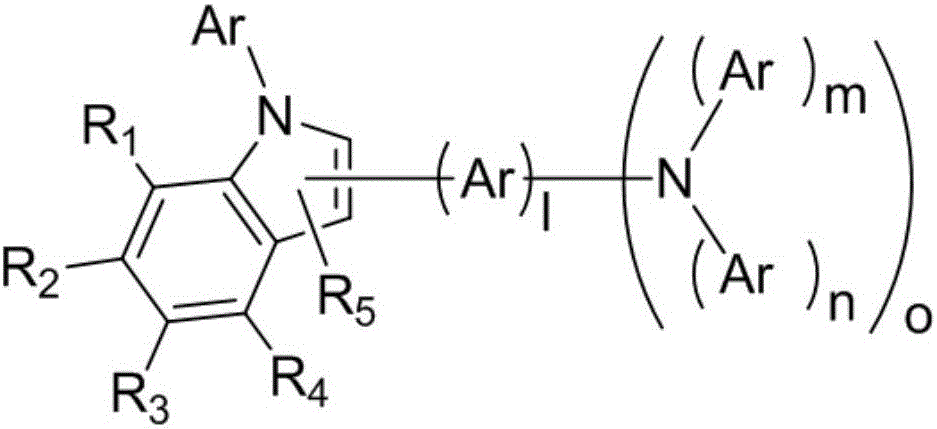

A compound and chemical formula technology, applied in the field of new compounds and organic light-emitting elements containing them, can solve the problems of high driving voltage, difficulty in practical application, and low efficiency, and achieve low driving voltage, high triplet energy, and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

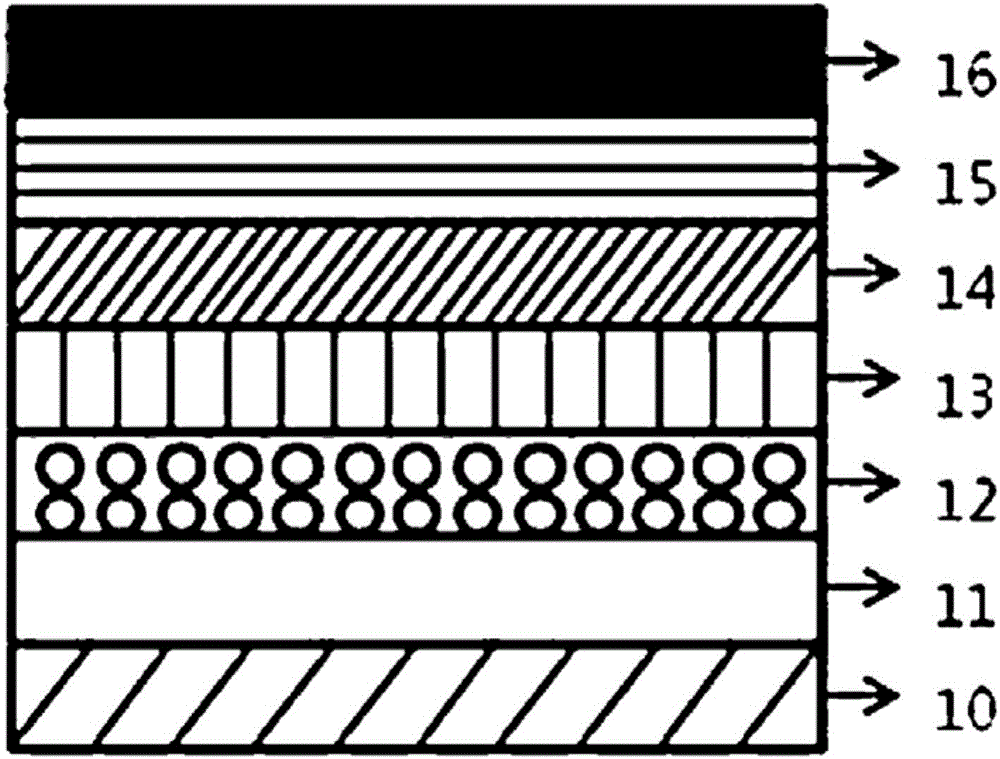

[0224] will be Thin film coated glass substrates with indium tin oxide (ITO) were cleaned ultrasonically with distilled water. After cleaning with distilled water, ultrasonically clean and dry with solvents such as isopropanol, acetone, methanol, etc., and then transfer to a plasma cleaner, use oxygen plasma to clean the above-mentioned substrate for 5 minutes, and then use a thermal vacuum coating machine (thermalevaporator) , on the top of the ITO substrate, the hole injection layer HT01 is fabricated film, compound as hole transport layer membrane. Then, as the above-mentioned light-emitting layer, BH01 was doped with 3% BD01 in host BH01 to fabricate membrane. Then, as an electron transport layer, fabricated with ET01:Liq (1:1) After the film is fabricated LiF film, Aluminum (Al) film, the device was sealed in a glove box (Encapsulation), thereby producing an organic light-emitting device.

Embodiment 2 to 20

[0226] By the same method as in Example 1, organic light-emitting devices were prepared using Compounds 2 to 20 to form a hole transport layer.

Embodiment 21

[0228] By the same method as in Example 1, an organic light-emitting device in which a hole transport layer was produced using a composition obtained by mixing Compound 4 and Compound 5 at a ratio of 50:50 (weight ratio) was fabricated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com