A compound, an organic light-emitting display device

A light-emitting display and compound technology, which is applied in the field of compound and organic light-emitting display devices, can solve the problems of low device life, low efficiency, instability, etc., and achieve the effects of prolonging device life, widening the light-emitting area, and improving life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

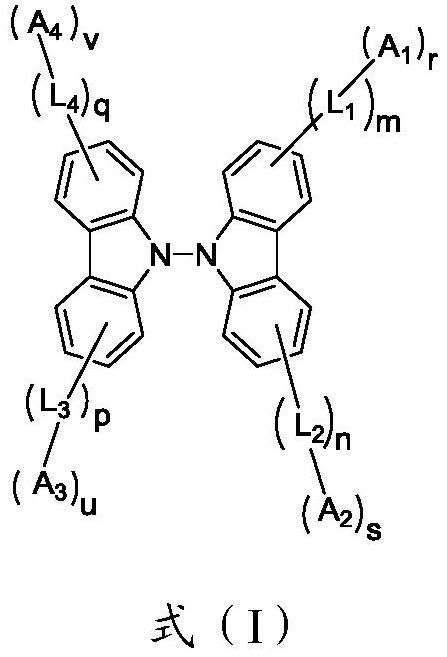

[0081] According to one embodiment of the present invention, the compound is selected from

[0082]

[0083]

[0084]

[0085]

[0086]

[0087]

[0088] any of the.

[0089] According to one embodiment of the present invention, the compound is selected from any one of H12, H33, H44, H46, H60 and H79.

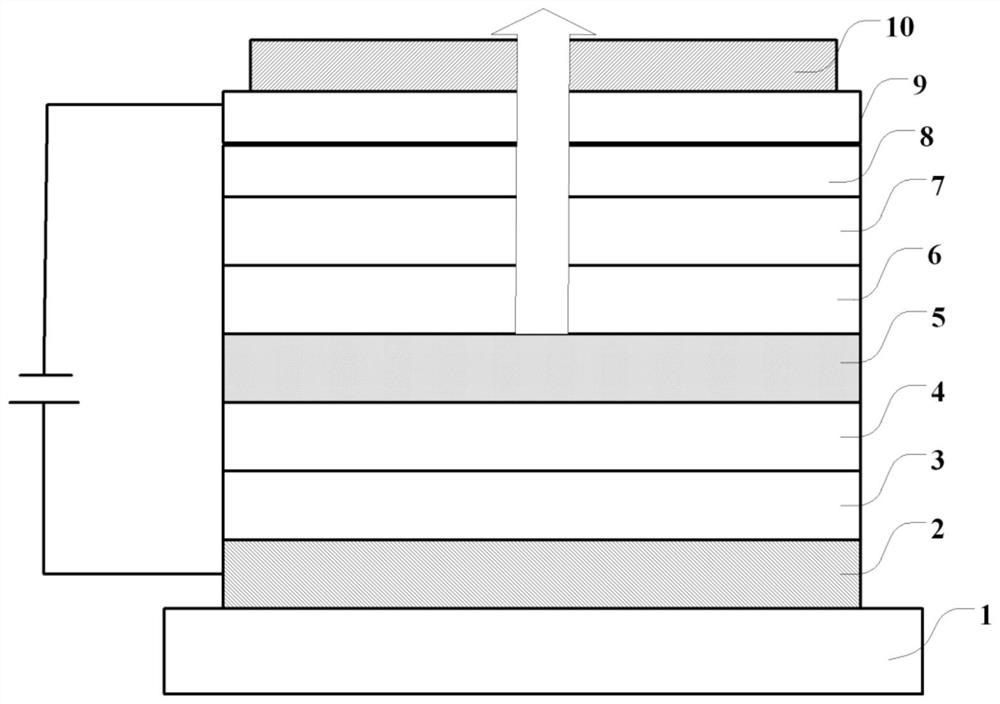

[0090] According to another aspect of the present invention, an organic light-emitting display device is provided, including an organic electroluminescent device, and the organic electroluminescent device includes:

[0091] An organic functional layer, the organic functional layer includes one or more organic film layers, and at least one of the organic film layers is a light-emitting layer;

[0092] The luminescent layer includes a luminescent material, and the luminescent material includes any one or more of the compounds described in the present invention.

[0093] According to one embodiment of the present invention, the compound is used as a host materi...

preparation Embodiment 1

[0124] Preparation Example 1 Synthesis of H12:

[0125]

[0126] Under nitrogen protection, weigh compound S2 (1.5mmol), S7 (3.2mmol), [Pd 2 (dba) 3 ]·CHCl 3(0.1mmol) and HP(tBu) 3 ·BF 4 (0.2mmol), was added to a 100mL two-necked flask. Inject 30 mL of toluene into the two-necked flask (pass N in advance 2 15min to remove oxygen), and then add 2.5mL concentration of 1M K 2 CO 3 Aqueous solution (pass N in advance 2 15min to remove oxygen), and stirred overnight at room temperature. After the reaction was completed, 20 mL of deionized water was added, followed by a few drops of 2M HCl. Extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel column chromatography, and the final purification afforded solid H12 (1.16 mmol, 71%).

[0127] MALDI-TOF MS: m / z calc...

preparation Embodiment 2

[0129] Preparation Example 2 Synthesis of H33:

[0130]

[0131] Under nitrogen protection, weigh compound S6 (1.95mmol), S8 (4.16mmol), [Pd 2 (dba) 3 ]·CHCl 3 (0.12mmol) and HP(tBu) 3 ·BF 4 (0.24mmol), was added to a 250mL two-necked flask. Inject 50mL of toluene into the two-necked flask (pass N in advance 2 15min to remove oxygen), and then add 3.5mL of 1M K2CO3 aqueous solution dropwise (pass N 2 15min to remove oxygen), and stirred overnight at room temperature. After the reaction was completed, 25 mL of deionized water was added, followed by a few drops of 2M HCl. Extract with dichloromethane, collect the organic phase, and wash with anhydrous Na 2 SO 4 Dry processing. The dried solution was filtered, and the solvent was removed by a rotary evaporator to obtain a crude product. The crude product was purified by silica gel column chromatography, and the final purification afforded solid H33 (1.32 mmol, 68%).

[0132] MALDI-TOF MS: m / z calculated: C40H20F6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com