A MEMS piezoresistive pressure sensor and preparation method thereof

A pressure sensor, piezoresistive technology, applied in the measurement of the property force of the piezoelectric resistance material, fluid pressure measurement by changing the ohmic resistance, etc., can solve the problem of inability to obtain high linearity, high sensitivity, etc. problem, to achieve high reliability, improved stability, high sensitivity and linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

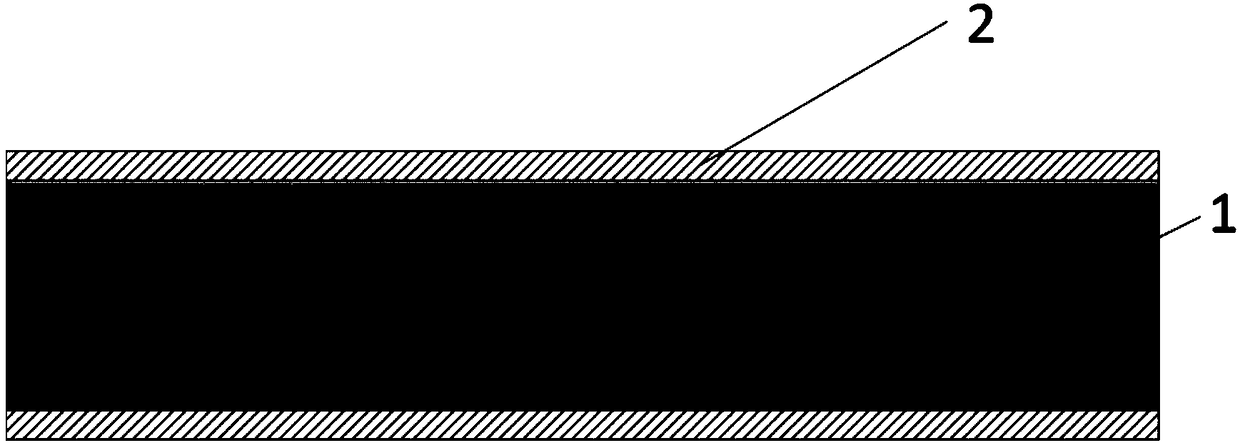

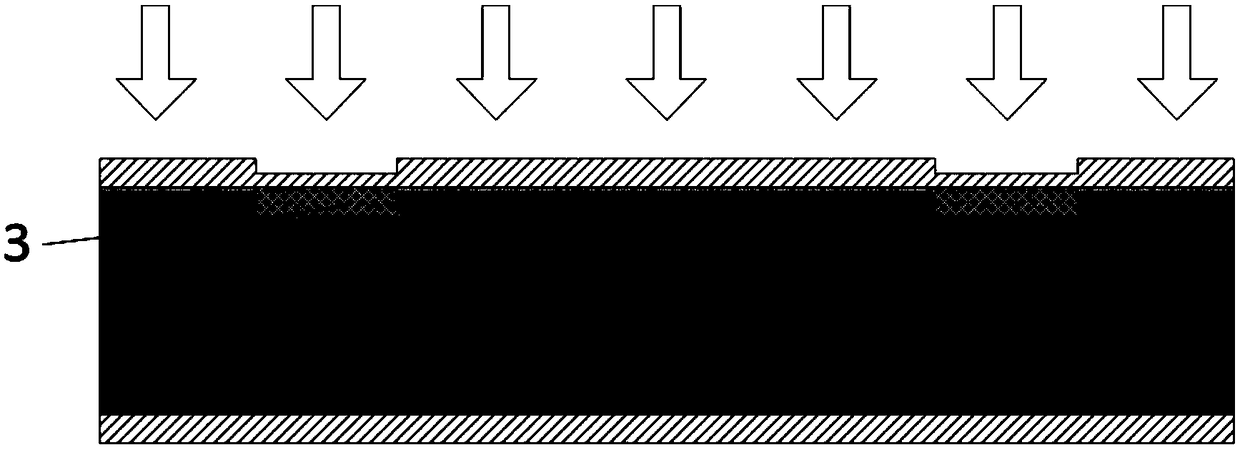

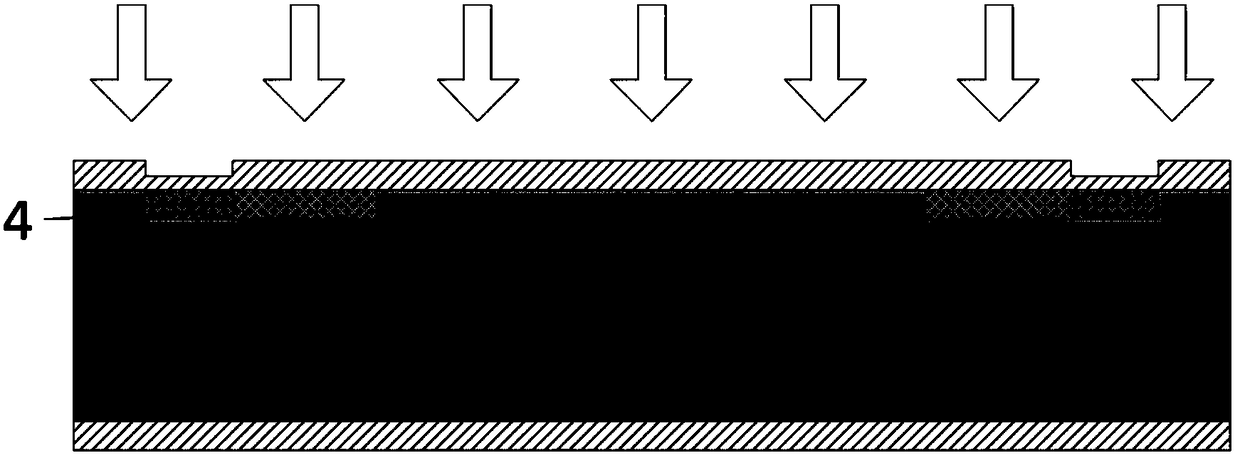

preparation example Construction

[0042] The preparation method of the MEMS piezoresistive pressure sensor of this embodiment: make 4 groups along the crystal direction at the midpoint position of the edge line of the square diaphragm (or circular diaphragm) produced by the back cavity etching process. The varistors of cloth, the number of each group of varistors can be arbitrary (generally 1-5), and the present embodiment is 4; The boomerang structure is etched out, the varistor is located at the edge of the boomerang structure, and the varistor is in the stress concentration area. Specifically, the steps of the method include:

[0043] 1) Manufacturing varistors and heavily doped contact areas by ion implantation on the front side of the silicon wafer;

[0044] 2) Double-sided fabrication of SiO 2 , and then make Si on both sides 3 N 4 , as a back cavity etching mask, the back cavity area of the silicon wafer is photoetched and a back cavity etching window is etched, and then the back cavity etching i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com