A kind of preparation method of food packaging film

A technology of food packaging film and film casting liquid is applied in the field of preparation of food packaging film to achieve the effects of improving film-forming properties, good mechanical properties and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

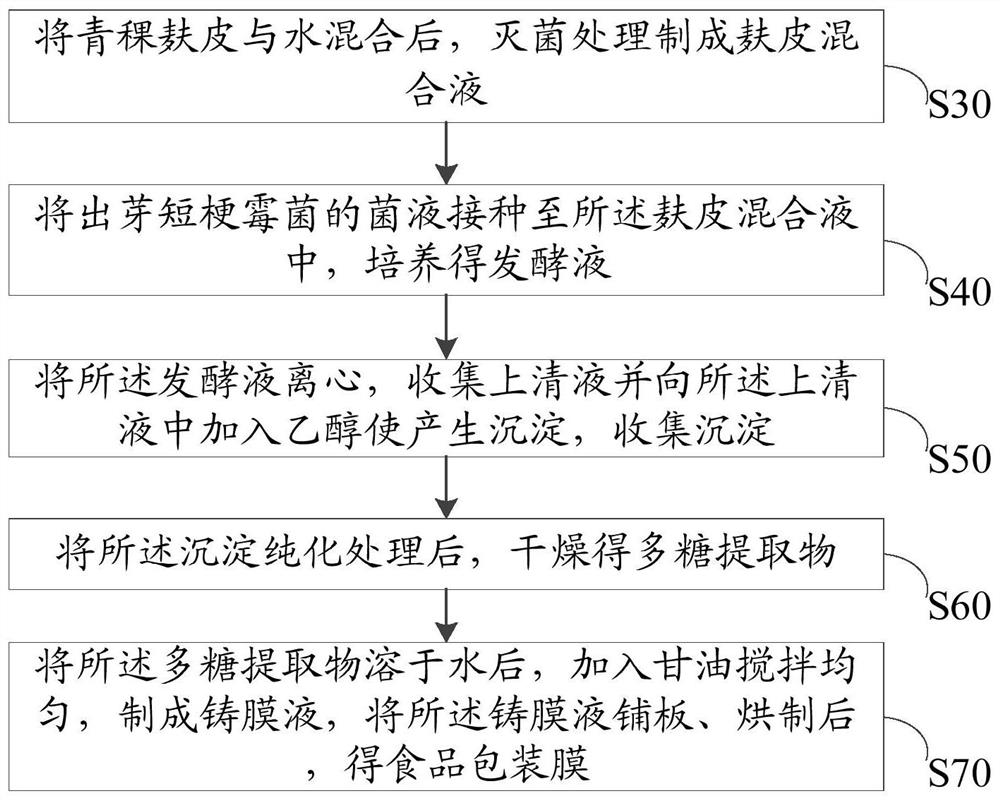

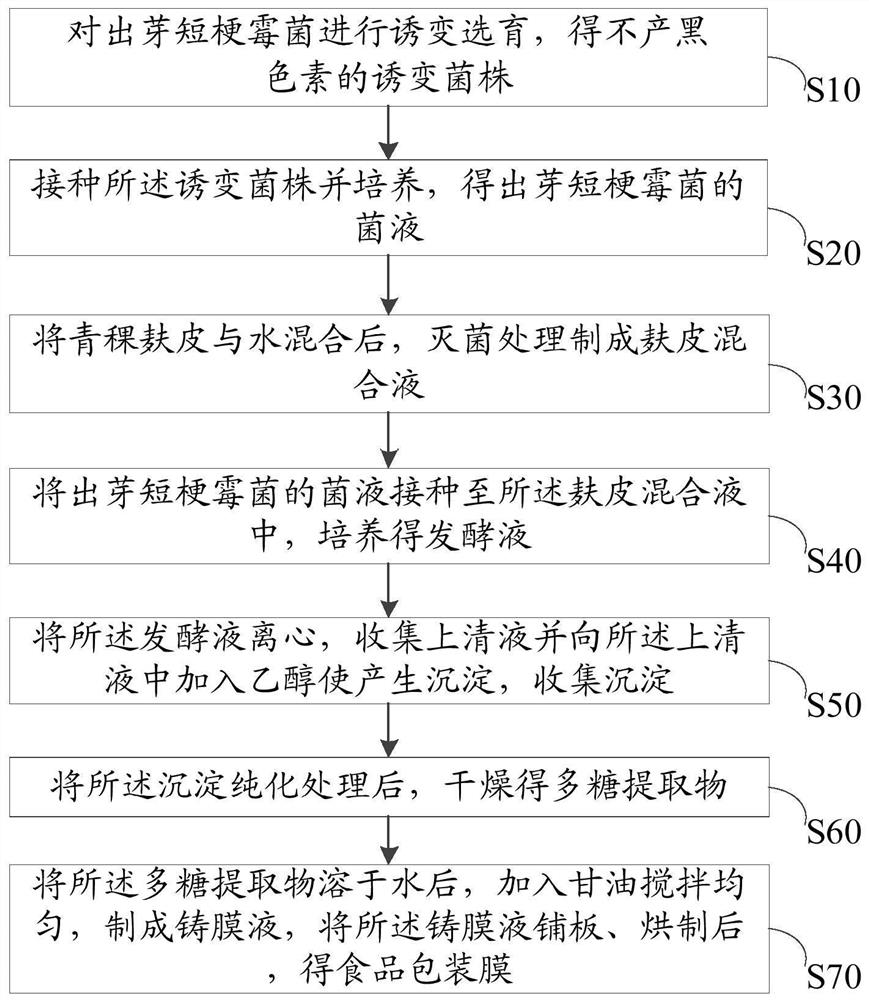

[0042] In view of this, the present invention proposes a method for preparing a food packaging film, through which a food packaging film can be prepared, which can be used as food packaging. The food packaging film has good mechanical properties and barrier properties, and is healthy Safety. combine figure 1 The schematic flow chart of an embodiment of the preparation method of the shown food packaging film, the preparation method of described food packaging film comprises the following steps:

[0043] Step S30, after mixing the highland barley bran with water, sterilize to prepare the bran mixture.

[0044] Among them, the highland barley bran is preferably white highland barley rice bran.

[0045] Highland barley is rich in β-glucan, which is the crop with the most β-glucan content among wheat crops in the world, with an average content of 5%. However, the study found that β-glucan in highland barley is mainly enriched in the bran, and mainly distributed in the cell wall ...

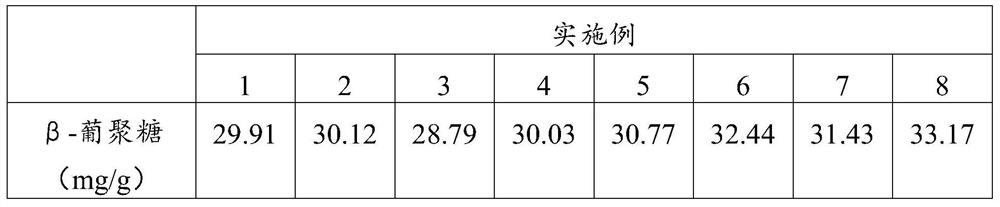

Embodiment 1

[0091] After pulverizing the highland barley bran, pass through a 100-mesh sieve to obtain highland barley bran powder; take 2g of highland barley bran powder, add 40g of deionized water to make a suspension, adjust the pH of the suspension to 5, and then sterilize at 120°C , to get the bran mixture, set aside.

[0092] Inoculate 2% of the volume of the bran mixture into the bran mixture with the bacterium liquid of Aureobasidium pullulans, and cultivate it in a constant temperature incubator at 37°C for 2 days to obtain a fermentation liquid; centrifuge the fermentation liquid, collect the supernatant, and remove the supernatant After adding ethanol at 0-4°C, place it at 0-4°C for 10 hours, and collect the precipitate.

[0093] Add a calcium nitrate solution with a mass fraction of 60 to 70% to the precipitate, place it in a boiling water bath for 10 minutes, centrifuge at a speed of 4000 r / min for 10 minutes, collect the supernatant, and obtain the concentrated solution for ...

Embodiment 2

[0096] After pulverizing the highland barley bran, pass through a 200-mesh sieve to obtain highland barley bran powder; take 3g of highland barley bran powder, add 80g of deionized water to make a suspension, adjust the pH of the suspension to 5.5, and then sterilize at 121°C , to get the bran mixture, set aside.

[0097] Inoculate 3% of the volume of the bran mixture into the bran mixture with the bacterium liquid of Aureobasidium pullulans, and cultivate it in a constant temperature incubator at 37°C for 3 days to obtain a fermentation liquid; centrifuge the fermentation liquid, collect the supernatant and pour the supernatant After adding ethanol at 0-4°C, place it at 0-4°C for 12 hours, and collect the precipitate.

[0098] Add a calcium nitrate solution with a mass fraction of 60-70% to the precipitate, place it in a boiling water bath for 15 minutes, centrifuge at a speed of 3500-4500 r / min for 15 minutes, collect the supernatant, and obtain the starch-removed concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com