Light-diffusing barrier film

A blocking film and light diffusion technology, applied in optics, optical filters, optical components, etc., can solve the problems of expensive, blocking material damage, and not easy to increase the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

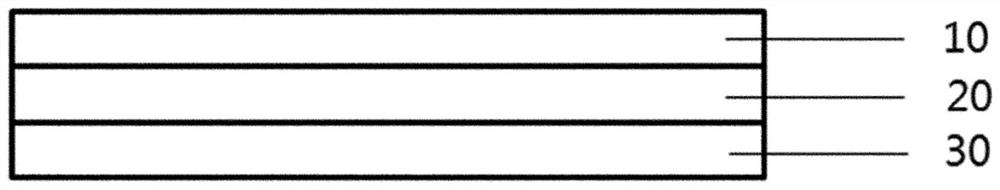

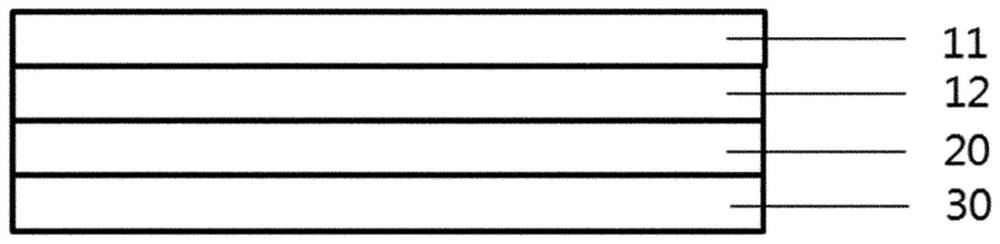

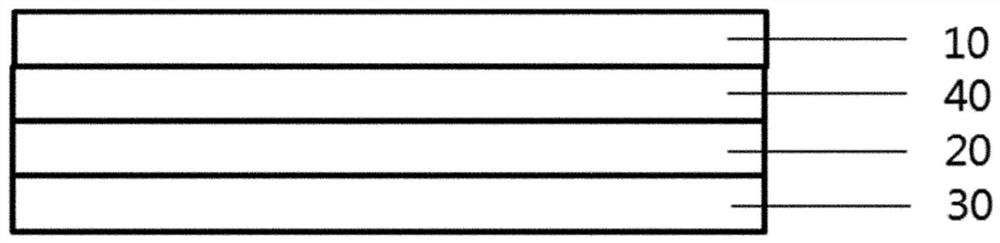

Method used

Image

Examples

Embodiment 1

[0195] 1) Form a light diffusion layer on the base layer

[0196] A light-diffusing layer coating composition containing 20 parts by weight of the photocurable resin relative to the solvent was prepared. Specifically, 80 parts by weight of pentaerythritol triacrylate (PETA) and 20 parts by weight of dipentaerythritol hexaacrylate (DPHA) were dissolved in a solvent (propylene glycol monomethyl ether). To this solution, 4 parts by weight of polymerization initiator (Irgacure 127, Ciba), 5 parts by weight of antistatic agent (ELEC ME-2, Kao) and 10 parts by weight of particles (MX80, Soken) with an average particle size of 0.8 μm were added to A light-diffusing layer composition is prepared.

[0197] It was applied on one side of a polyethylene terephthalate (PET) film (T600E50, Mitsubishi) having a thickness of 50 μm by bar coating (using a #5 rod) method. Thereafter, the obtained coating film was heated and dried at 100° C. for 2 minutes, and then subjected to vacuum UV light...

Embodiment 2

[0207] The light-diffusing barrier film of Example 2 was produced in the same manner as in Example 1, except that another coating bar was used (#4 bar was used) when coating the light-diffusing layer composition. The surface roughness (Rt) values of the light-diffusing layer are shown in the table below.

Embodiment 3

[0209] The light-diffusing barrier film of Example 3 was produced in the same manner as in Example 1, except that no antistatic agent was used, and another coating bar was used when coating the light-diffusing layer composition (using #3 bar ). The surface roughness (Rt) values of the light-diffusing layer are shown in the table below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com