Ultrathin pearlescent film and production method thereof

A pearlescent film, ultra-thin technology, applied in the direction of chemical instruments and methods, other household appliances, flexible coverings, etc., can solve the problems of black spots, easy to break the film, poor physical and mechanical properties, etc., to achieve strong decoration, barrier The effect of excellent performance and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

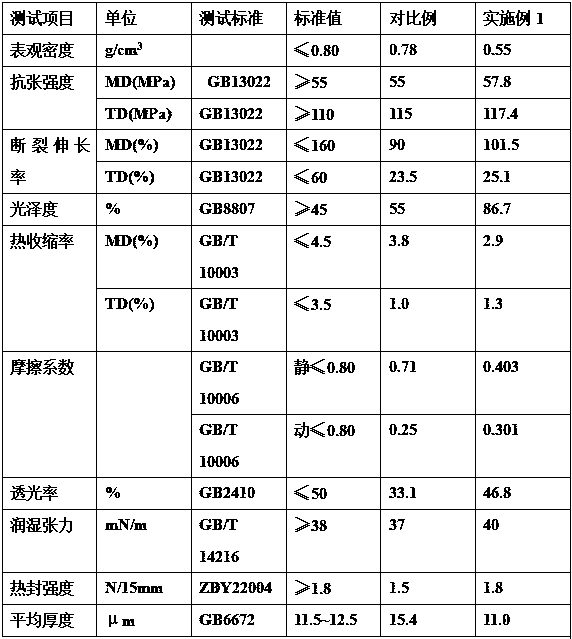

Examples

Embodiment 1

[0014] An ultra-thin pearlescent film consisting of a surface layer 1, a surface layer 2 and a core layer;

[0015] Table 1 layer is composed of the following components by weight fraction: HGX030 (Saudi polymer) 97%, ABPP905 (anti-bonding masterbatch) 3.00%,

[0016] The layer in Table 2 is composed of the following components by weight fraction: T30S (polypropylene PP material, Quanzhou Fulian Petrochemical) 97.5%, ABPP936 (anti-stick and slippery mixture, Shantou Best Technology Co., Ltd.) 2.50%; core The layer is composed of the following components by weight fraction: main material 62.6%, AS3030PP (antistatic masterbatch, Furongsheng (Fujian) Packaging Material Co., Ltd.) 1.60%, LG703T (pearlescent masterbatch, Foshan Yuntongchen Masterbatch Co., Ltd. Company) 35.00%, S2020PP (smooth masterbatch, Furongsheng (Fujian) Packaging Materials Co., Ltd.) 0.80%.

[0017] The main material is composed of the following components by weight fraction: T36F (polypropylene film) (poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com