barrier film

一种阻挡膜、阻挡层的技术,应用在应用、其他家里用具、合成树脂层状产品等方向,能够解决膜异常运转、阻挡特性劣化、膜损坏等问题,达到改善滑动特性、防止产品缺陷、优异阻挡特性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

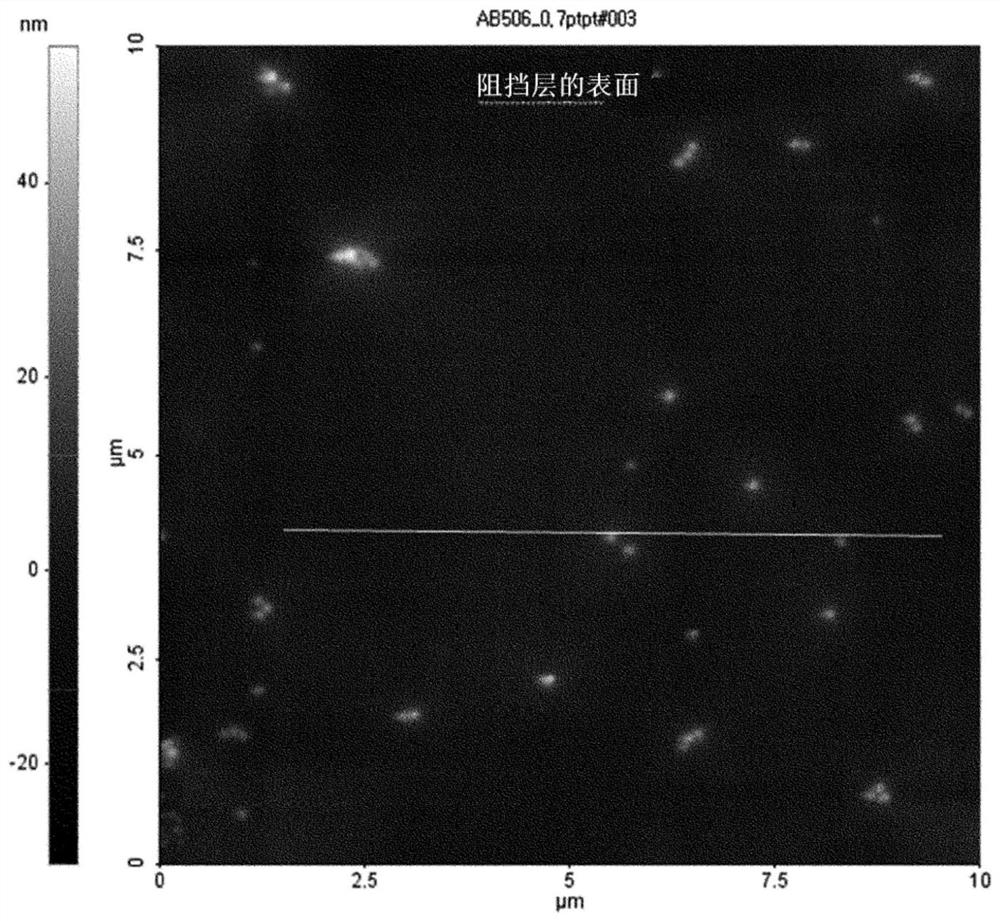

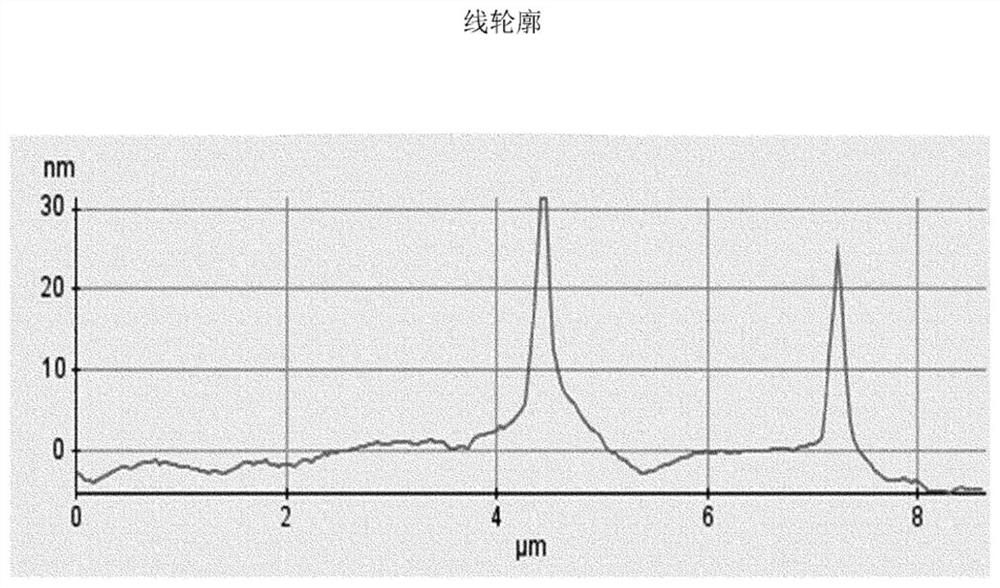

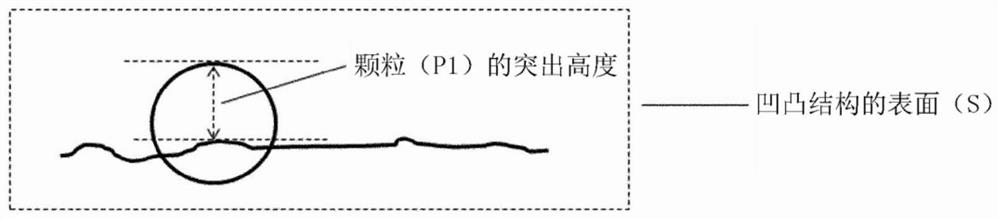

[0112] Experimental Example 1: Formation of Comparative Friction Coefficients Based on Surface Irregularities

Embodiment 1

[0114] An intermediate layer having a thickness of about 900 nm was formed on the surface of a PET (polyethylene terephthalate) base film having a thickness of about 50 μm using isocyanurate-based acrylate.

[0115] Subsequently, a composition comprising a polysilazane solution (by relative 100 parts by weight of Polysilazane was prepared by adding dimethylethanolamine (DMEA) as an organic catalyst to NN 120 solution from CLARIANT in an amount of about 2 parts by weight) and 0.7 parts by weight of hydrophobic Silica particles (particle diameter at the level of 80nm to 100nm). The coating of the dried film was passed through the guide rolls of a roll curing machine with a constant tension applied thereto, and in Ar:O 2 = Flow rate of about 1:1 (based on sccm), pressure of about 138 mTorr, about 0.27 W / cm 2 power and about 20J / cm 2 The plasma treatment of the polysilazane layer is carried out under the condition of energy.

Embodiment 2

[0117] A barrier film was produced in the same manner as in Example 1 except that in the polysilazane-containing composition, a trade name NL120 polysilazane (containing an inorganic catalyst other than DMEA) was used.

[0118] The evaluation results of the friction coefficients of the barrier films of Examples 1 and 2 are shown in Table 1.

[0119] *Static friction coefficient and dynamic friction coefficient: Usually, the friction coefficients of the polysilazane layer and the cured layer are measured against SUS (stainless steel) which is a main material of a roll for winding and unwinding a film in a roll-to-roll process. Specifically, according to the ASTM D1894 method, the SUS base material was placed on the surface S prepared in Examples and Comparative Examples, and the force of pulling the sample was measured in a state where a load of 200 g was applied thereto using a weight, and then the load and the pulling force were measured ratio between.

[0120] [Table 1]

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com