Environment-friendly high-barrier packaging material and preparation method thereof

An environmentally friendly and packaging material technology, applied in the field of packaging materials, can solve the problems of difficult to use food packaging with long shelf life and short service life, and achieve excellent barrier effect, excellent barrier performance and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Correspondingly, the present invention also provides a preparation method of an environment-friendly high-barrier packaging material, the method is used for preparing the above-mentioned environment-friendly high-barrier packaging material, and the method comprises the following steps:

[0057] (1) Preparation of raw materials for the photodegradable layer: mixing the raw materials of the photodegradable layer evenly under light-shielding conditions to obtain a first raw material;

[0058] (2) Raw material preparation of the base layer: mix acrylic acid and toughening agent evenly, then add metal-modified polyvinyl alcohol and filler to fully mix to obtain the second raw material;

[0059] (3) Preparation of the raw materials of the first barrier layer: the starch-modified polyvinyl alcohol and the hydroxy fatty acid ester are mixed uniformly to obtain the third raw material;

[0060] (4) obtaining a composite film layer formed by the first raw material, the second raw ...

Embodiment

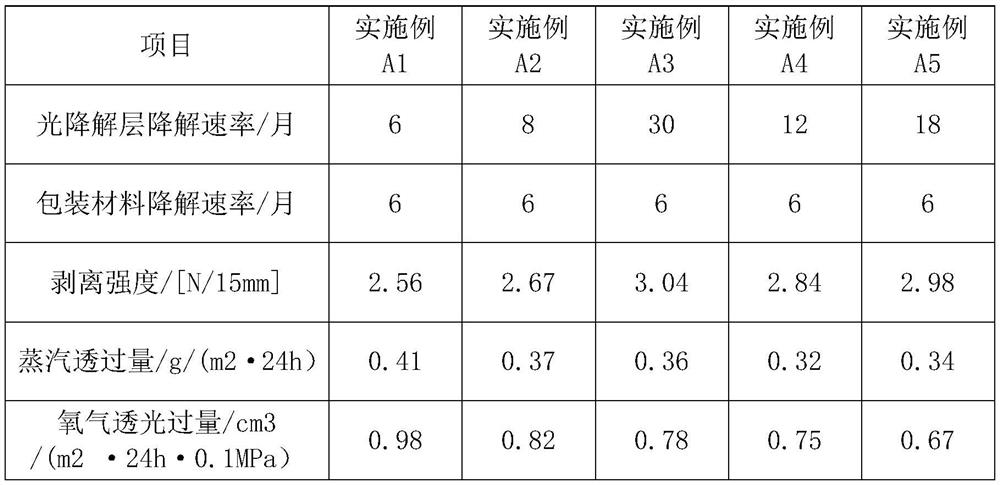

[0070] Example Group A Environmentally Friendly High Barrier Packaging Materials

[0071] The formulations of the environment-friendly high-barrier packaging materials of this example group are shown in the following table.

[0072]

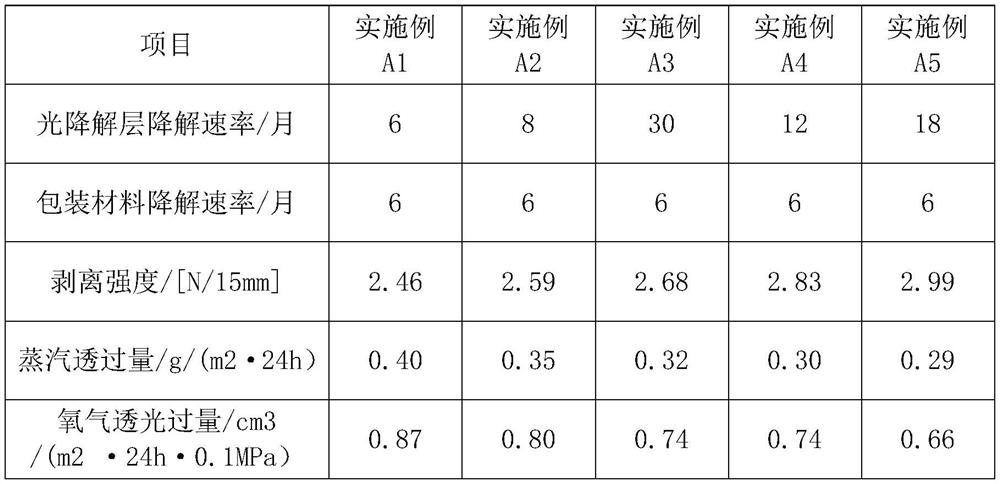

[0073] Preparation method of environment-friendly high-barrier packaging material of embodiment group B

Embodiment B1

[0075] The preparation method of the environment-friendly high-barrier packaging material of the present embodiment comprises the following steps:

[0076] (1) Preparation of raw materials for the photodegradable layer: mixing the raw materials of the photodegradable layer evenly under light-shielding conditions to obtain a first raw material;

[0077] (2) Preparation of the raw materials of the base layer: mix acrylic acid and toughening agent evenly, then add metal-modified polyvinyl alcohol and filler to fully mix to obtain the second raw material;

[0078] (3) Preparation of the raw materials of the first barrier layer: the starch-modified polyvinyl alcohol and the hydroxy fatty acid ester are mixed uniformly to obtain the third raw material;

[0079] (4) obtaining a composite film layer formed by the first raw material, the second raw material and the third raw material by a co-extrusion method or a film blowing method, and the composite film layer is a photodegradable la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com