Patents

Literature

56results about How to "Good gas barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

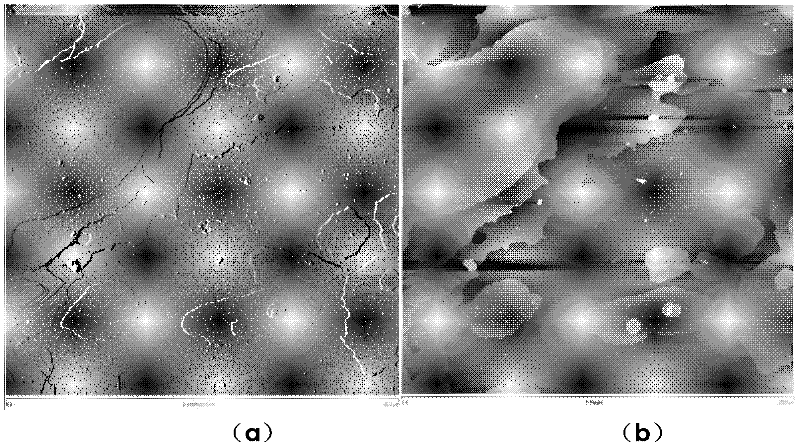

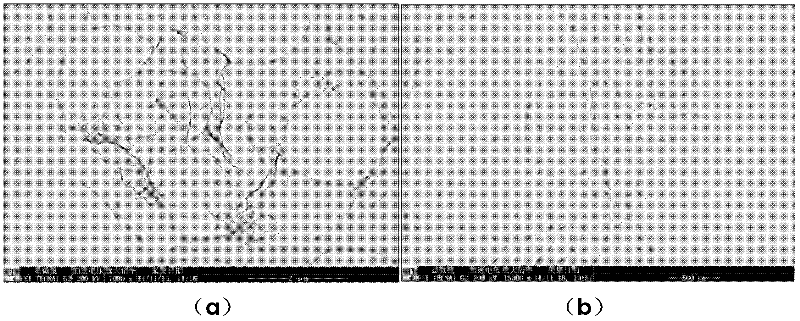

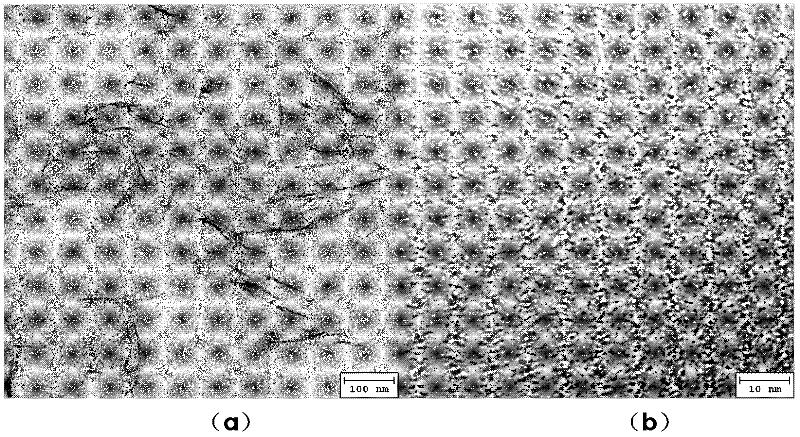

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

High-barrier polyester film and its preparation method

ActiveCN102225648AImprove barrier propertiesGood physical and mechanical propertiesSynthetic resin layered productsComposite constructionPolyester

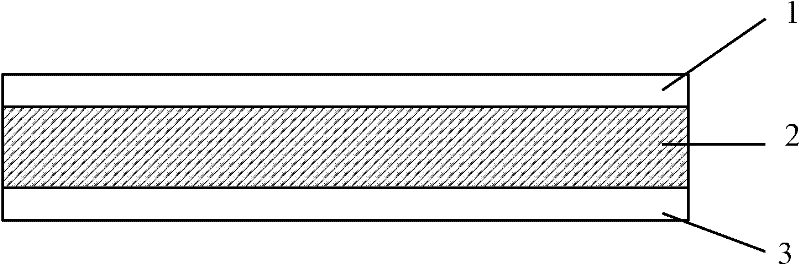

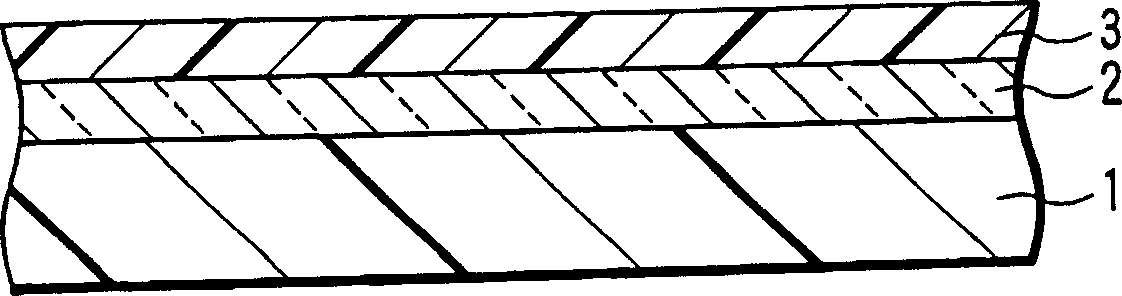

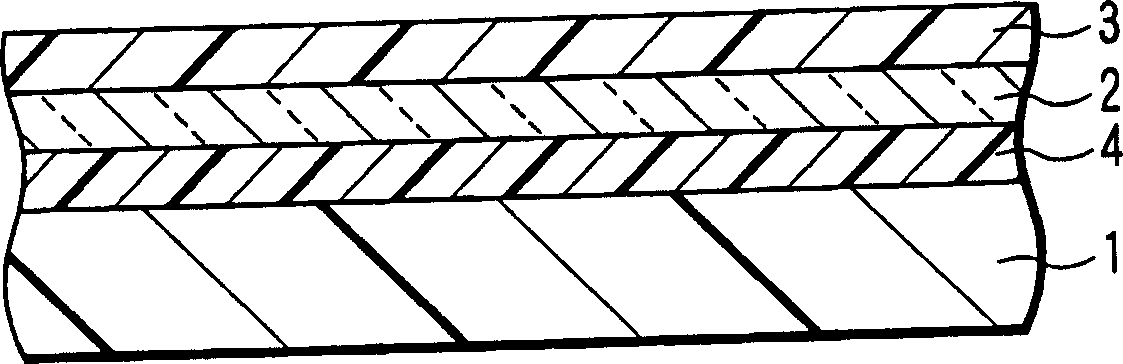

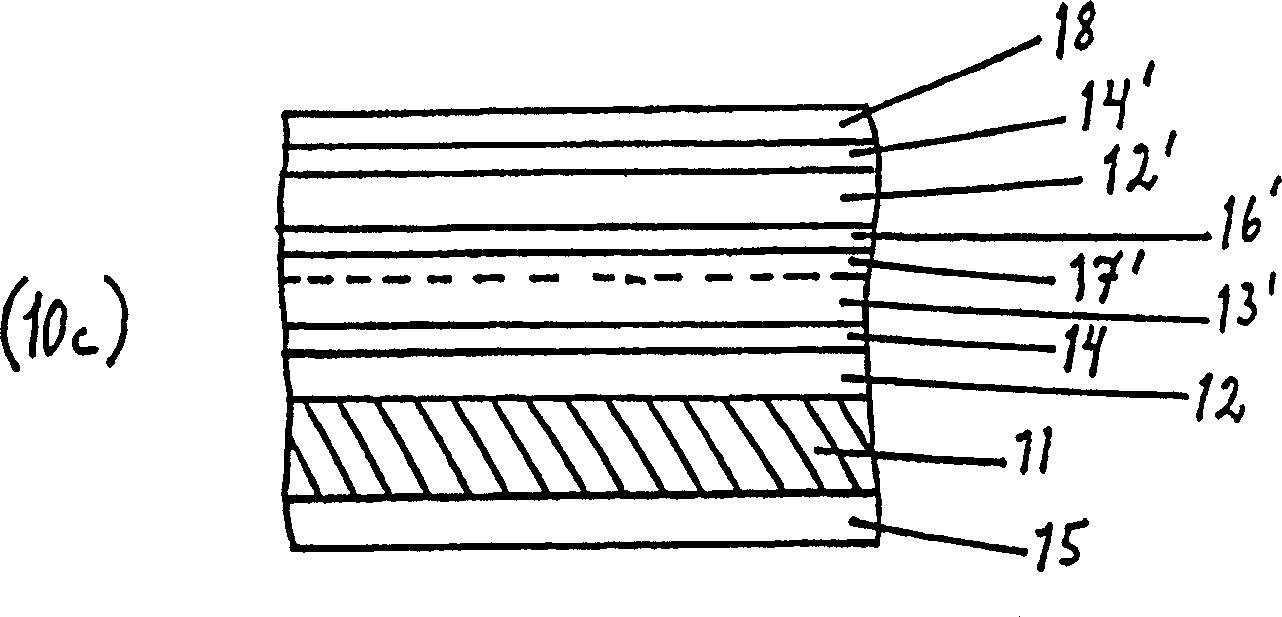

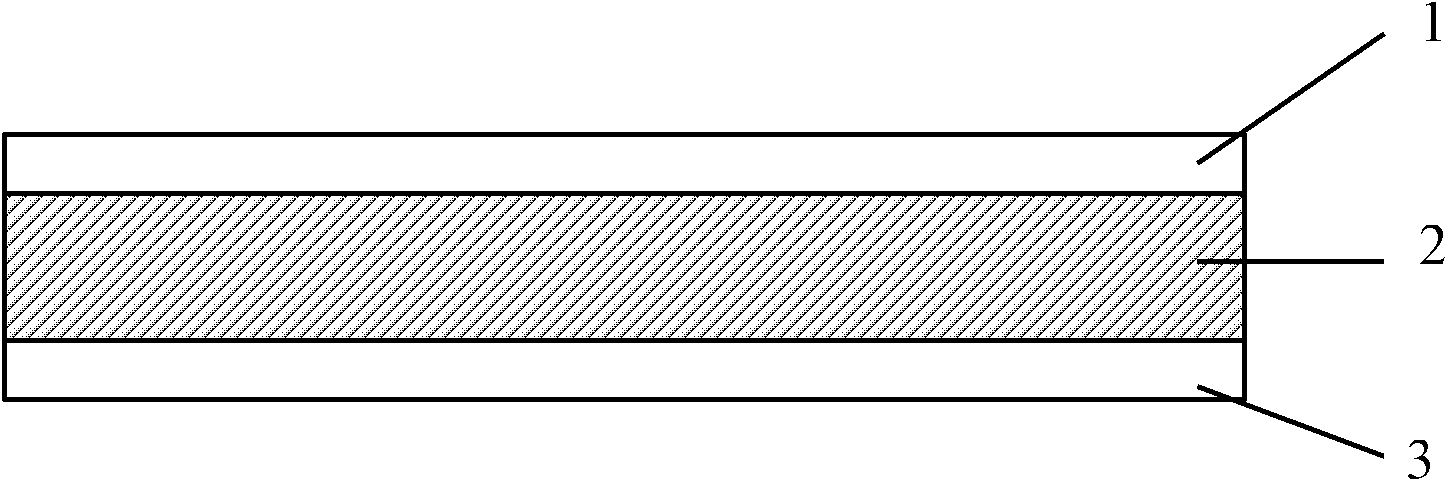

The invention discloses a high-barrier polyester film, which has a three-layer composite construction, comprising a core layer, an upper cortex and a lower cortex. The core layer comprises the following components of: 60-100 wt% of PET polyester slices, 0-40 wt% of PEN polyester slices; the cortexes comprise the following components of: 92-98 wt% of PEN polyester slices, 0.2-2 wt% of a nucleating agent and 1-6 wt% of a nucleating modifier. The invention also discloses a coextruding-drawing preparation method of the above high-barrier polyester film. The invention has a simple preparation technology; in addition to excellent physical properties, the produced polyester film has better gas barrier property, heat resistance and radiation resistance performance, and can be applied in the fields of solar energy cell back-piece and the like.

Owner:JIANGSU YUXING FILM TECH

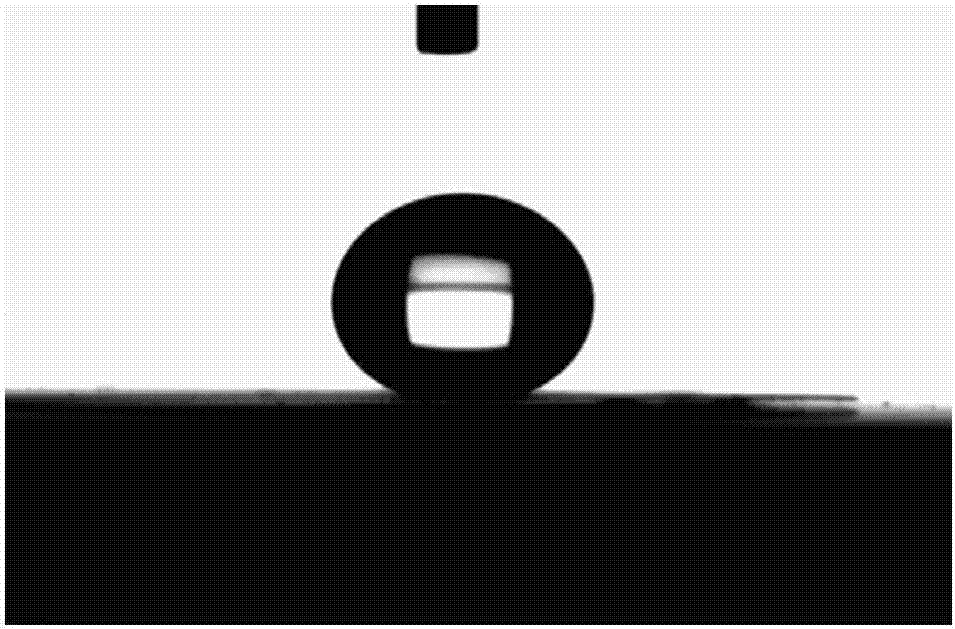

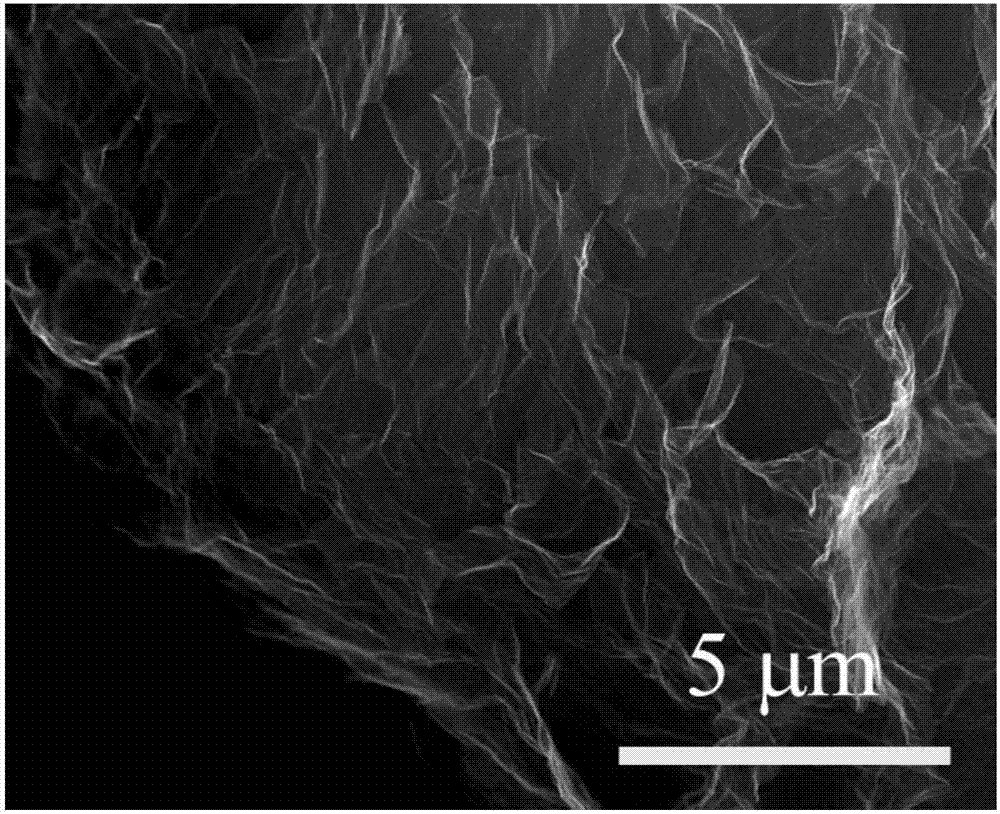

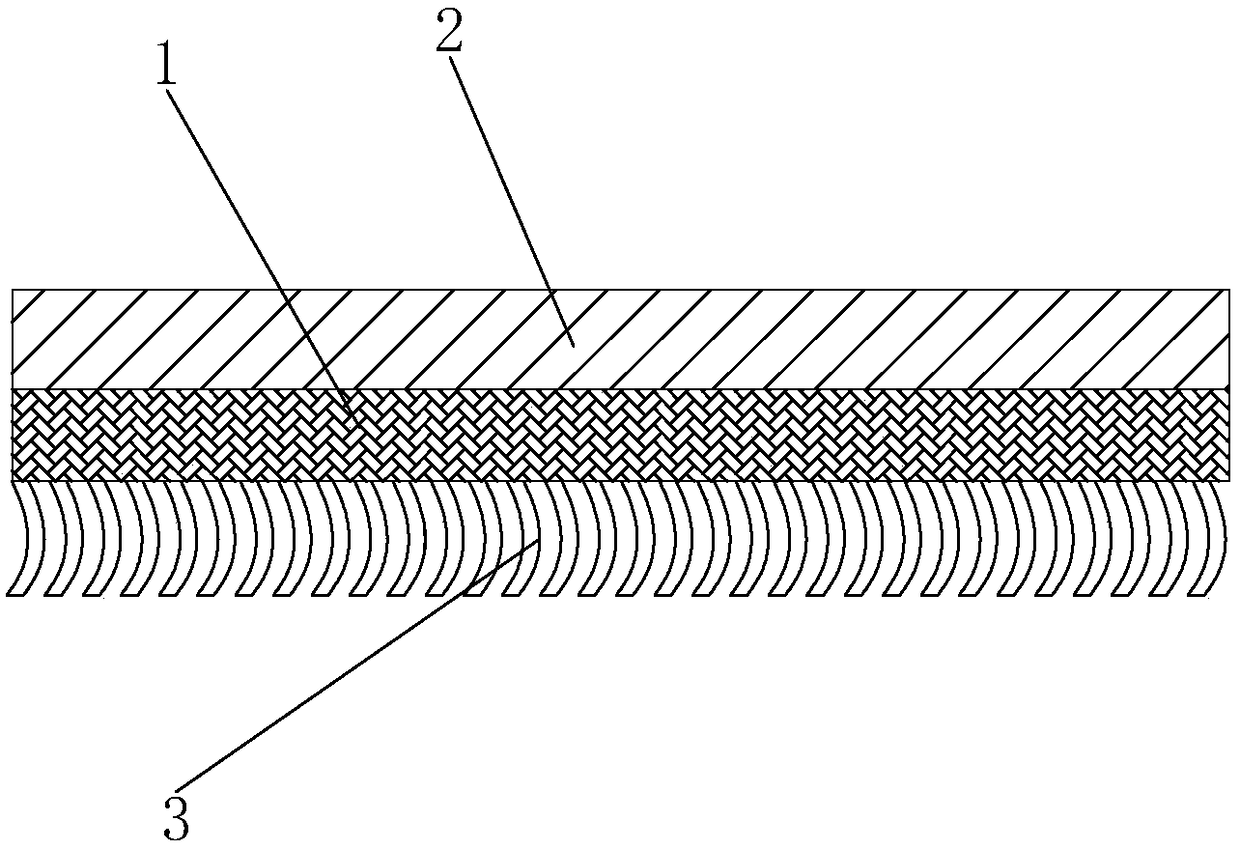

Polymer composite material with high gas-liquid barrier performance and preparation method thereof

ActiveCN107880305AImprove mechanical stabilityExcellent hydrophobic propertiesCoatingsPolymer scienceLiquid water

The invention discloses a polymer composite material. The polymer composite material comprises a polymer matrix layer, a modification layer and a barrier function layer, wherein the modification layeris a functional material layer which is chemically grafted with the surface of the polymer matrix layer through super-thermal hydrogen treatment; the barrier function layer is a silicon rubber polymer composite coating containing graphene oxide. According to the polymer composite material disclosed by the invention, the barrier function layer adopts the composite coating of the graphene oxide anda silicon rubber polymer; a sheet-shaped and laminar barrier structure is formed in silicon rubber through a sheet-shaped structure of the graphene oxide; the structure is cooperated with a silicon rubber material to have a natural hydrophobic property, and the surface energy is extremely low, so that the composite material has a super-hydrophobic liquid barrier and waterproof effect; meanwhile,the efficient gas and liquid water barrier performance of the composite material is realized.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

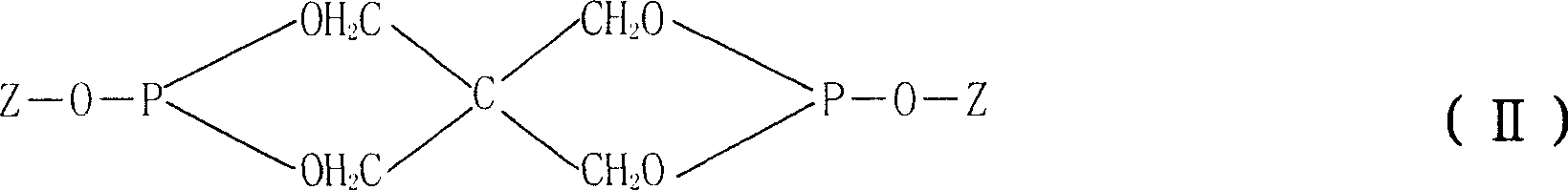

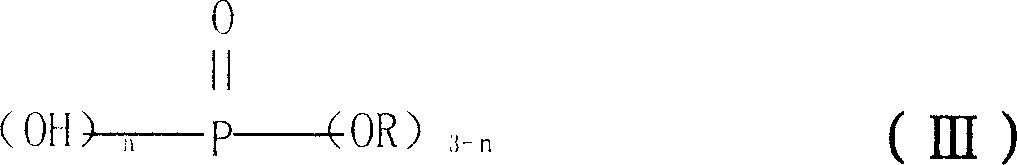

Gas barrier laminate film

ActiveCN1713983AHigh transparencyExcellent gas barrier performanceLayered productsCoatingsWater solubleHydroxy compound

A gas barrier laminate film comprising a resin substrate on which a gas barrier vapor deposition layer, and a gas barrier covering layer are laminated, wherein the gas barrier covering layer is formed through the coating, and drying of a coating liquid comprising Si(OR<1>)4 or the hydrolyzates thereof, (R<2>Si(OR<3>)3)n or the hydrolyzates thereof (wherein R<1> and R<3> are individually CH3, C2H5 or C2H4OCH3, and R<2> is an organic functional group) and a water-soluble polymer having a hydroxyl group. <IMAGE>

Owner:TOPPAN PRINTING CO LTD

Liner paper for environment protection cigarette

InactiveCN1888308ANo smellNo toxicityFlexible coversCoatings with pigmentsPulp and paper industryPrinting ink

The present invention relates to an internal lining paper for environment-protecting cigarette. It is made up by coating water printing ink on the surface of raw paper. The smoothness of raw paper is greater than on equal to 1000S, unit area paper weight is 60-80g / sq.m, water content is less than 35g / sq.m, thickness is 0.05-0.07 mm and the dose of water printing ink (by solid content) is 4-7g / sq.m. The procedures for coating printing ink are successively as follows: placing paper, leveling, tensioning, coating, drying, calendaring and rolling up.

Owner:CHANGDE FURONG INDAL DEV

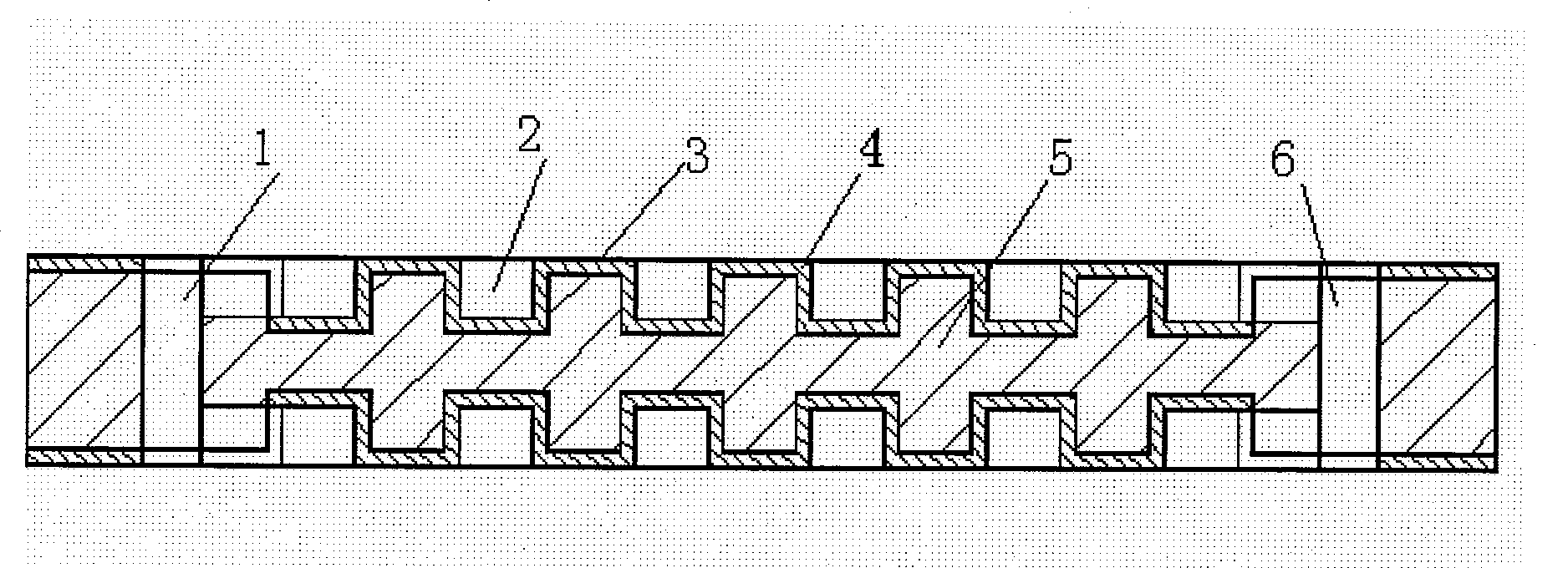

Fuel cell graphitc composite flow field plate and its manufacturing method

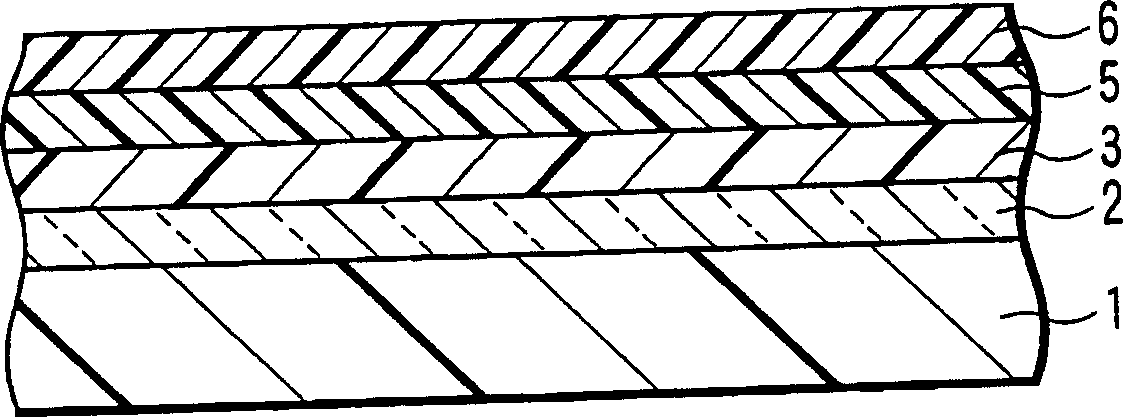

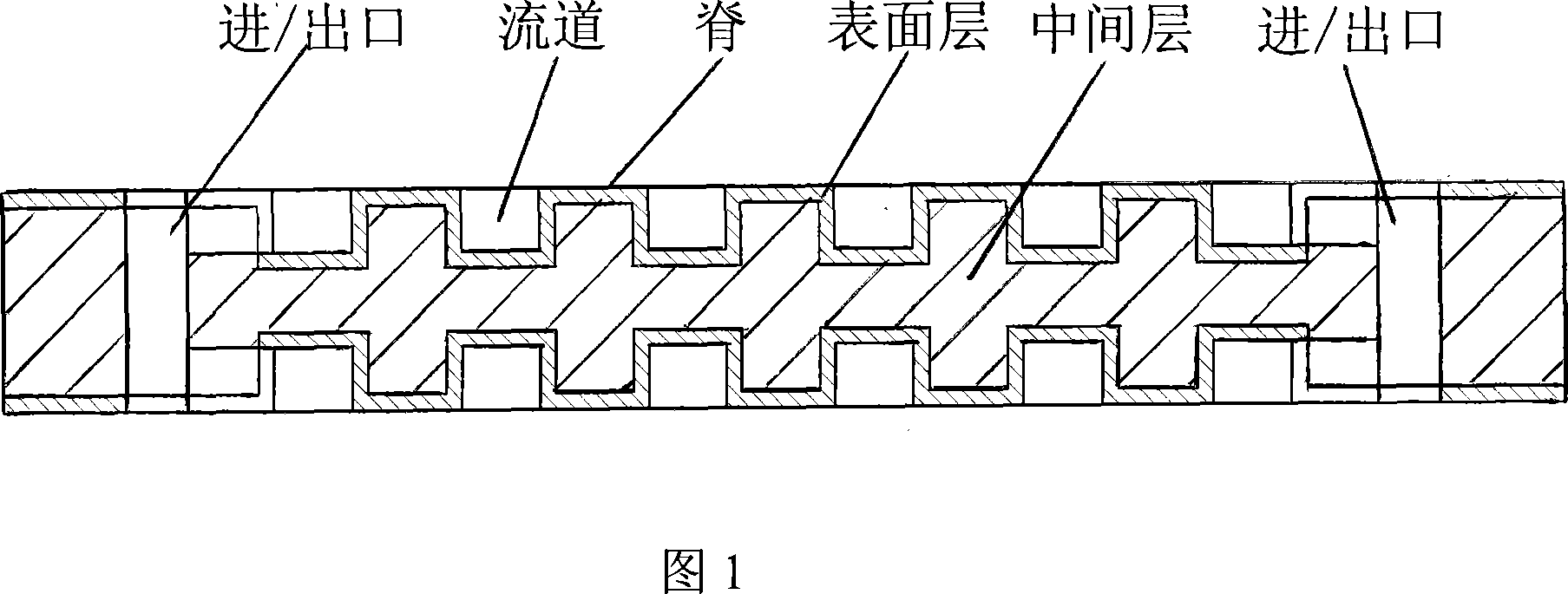

InactiveCN101071876ASimple preparation processReduce contact resistanceFinal product manufactureCell electrodesThermal conductivityGraphite composite

This invention discloses a graphite compound flow field board for fuel cell and manufacture method. On the wall of the flow field board there are fluid inlet, the fluid outlet and rib and channel forming flow field. The flow field is characterized in that it is formed by middle layer of graphite composite material and upper and lower surface layers of flexible graphite material that are compounded by sandwich layer. The preparation process includes: mix evenly electric conductive pellets and resin or polymer, put it in the mold to heat up, pressurize and maintain a certain time, the cool to draw mould to obtain sandwiched composite plate. Advantages: lower contact resistance, strong anti-corrosion ability, good electric conductivity and thermal conductivity, good gas barrier property, simple process and low cost.

Owner:TIANJIN UNIV

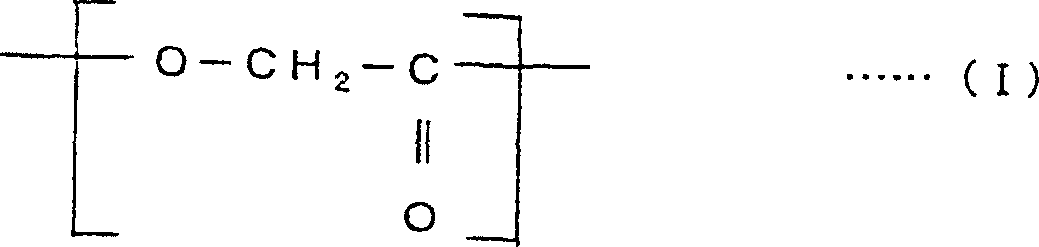

Polyglycolic acid-based resin composition and shaped product thereof

InactiveCN1768114AImprove shielding effectHigh transparencySynthetic resin layered productsPolymer sciencePolyester resin

A polyglycolic acid-based resin composition is formed by adding a relatively small amount of aromatic polyester resin to a polyglycolic acid resin. The thus-formed composition is provided with remarkably improved moisture resistance stability and hot-melt processability, and further improved stretchability, while retaining the excellent properties as represented by gas barrier property of the polyglycolic acid resin. As a result of stretching by utilizing the improved stretchability, a shaped product having an improved transparency can be obtained.

Owner:KUREHA KAGAKU KOGYO KK

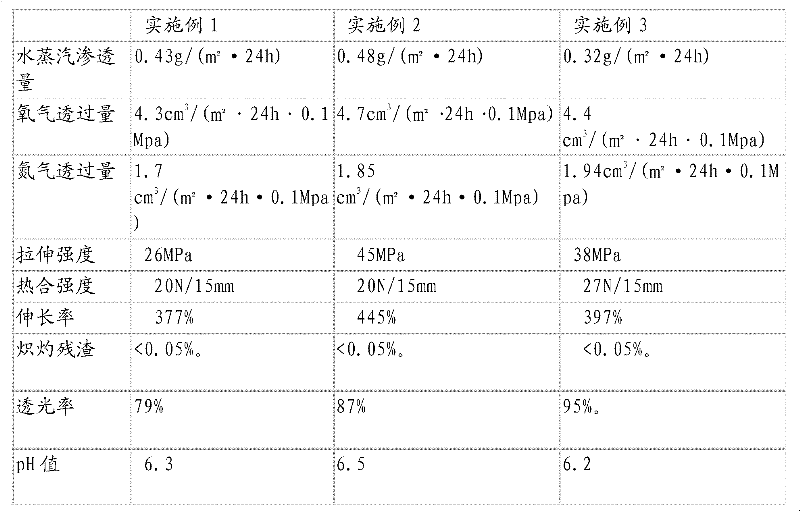

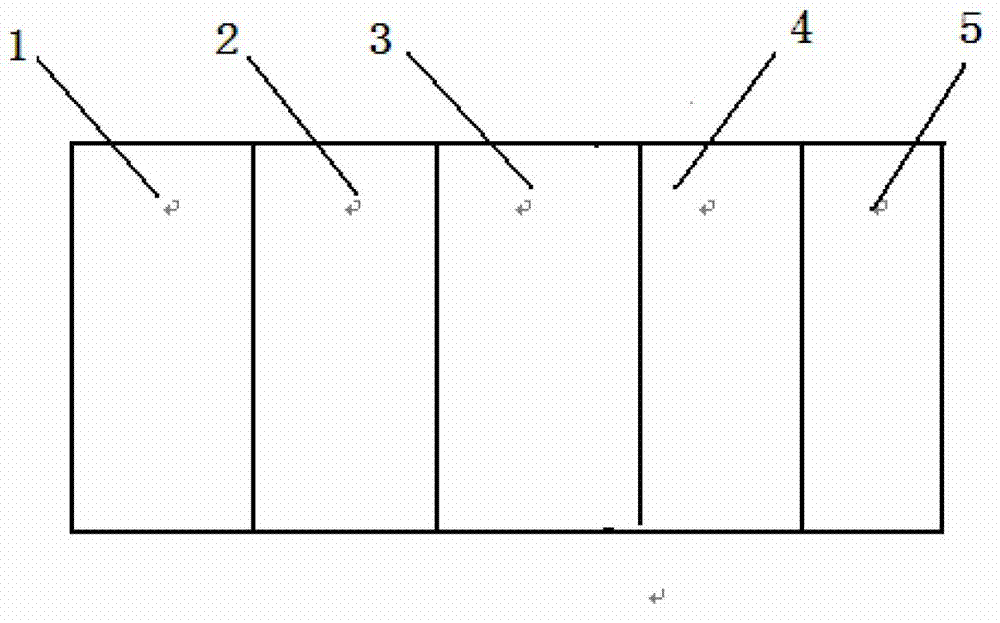

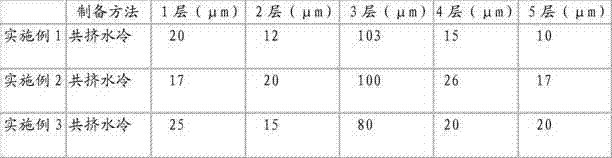

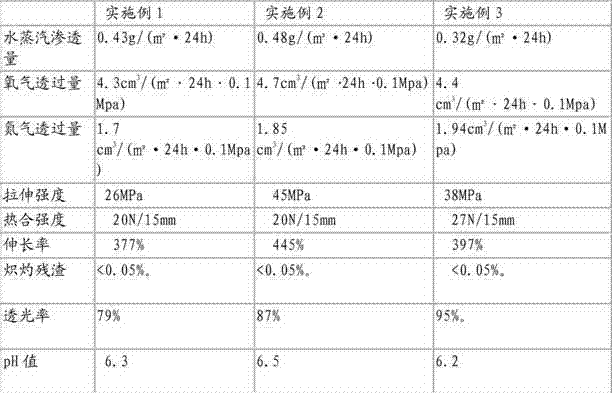

High-barrier multilayer co-extrusion infusion film

The invention relates to a high-barrier multilayer co-extrusion infusion film which is a five-layer composite film with the composition from the outer layer to the inner layer: polyethylene naphthalate modified polyester / ethylene acrylic acid polymer / polypropylene, ethylene- octylene copolymer blending resin / ethylene propylene polymer / modified polypropylene. The advantages of various functional polymer materials are combined by the high-barrier multilayer co-extrusion infusion film, so that not only are the light transmittance, the flexibility, the high barrier performance, the low-temperature thermal sealing property, the thermal bonding strength and the like of the high-barrier multilayer co-extrusion infusion film guaranteed, but also the high-temperature-resistant (121 DEG C and 30min) sterilization performance and the low-temperature-resistant (-30 DEG C) storage performance of the high-barrier multilayer co-extrusion infusion film can be improved; therefore, the matters (including nonvolatile matter, easily-oxidized matter, heavy metal and the like) dissolved out from the infusion film are fewer, a biological or chemical reaction is not caused between the infusion film and liquid medicine after filling sterilization, and toxin is not generated or environmental pollution is not caused when the infusion film is produced, used and recovered. Compared with other similar products, the high-barrier multilayer co-extrusion infusion film has excellent competitive advantages in the aspect of all technical indexes such as production formula, production technique and performances.

Owner:NINGBO HUAFENG PACKAGE

Rapid degradation type soybean protein simulation plastic film and preparation method thereof

ActiveCN105419193ANo pollution in the processPromote degradationEnvironmental resistancePolymer science

The invention discloses a rapid degradation type soybean protein simulation plastic film and a preparation method thereof and belongs to the processing field of biological materials and food packaging technologies. The preparation method of the soybean protein simulation plastic film which can be rapidly degraded and has a certain mechanical strength, elasticity, gas barrier property and water tightness is provided. The soybean protein simulation plastic film is prepared from 2-4% of soybean separation protein, 1.5-2.5% of polyvinyl alcohol, 2-3% of nano-crystalline cellulose and 2% of plasticizer. The nano-crystalline cellulose effectively increases the degradation speed of film materials and improves the mechanical performance of the film materials; the plasticizer is added so that the soybean protein, polyvinyl alcohol and the nano-crystalline cellulose can form a more compact and uniform three-dimensional net structure, and various properties of plastics can be highly simulated. The degradation time of the film ranges from 2 months to 7 months. The simulation plastic film is simple in preparation technology, is convenient to operate, free of pollution to the environment and good in biological compatibility and biodegradability, the requirement for environment friendliness is met, and the plastic film can be widely applied to the food packaging field.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

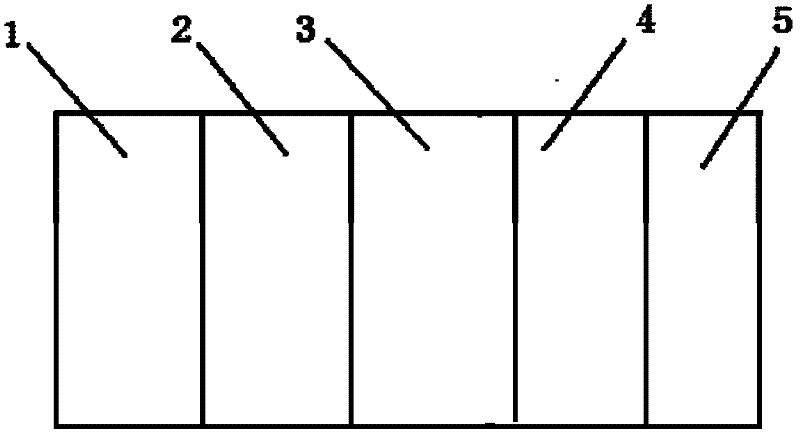

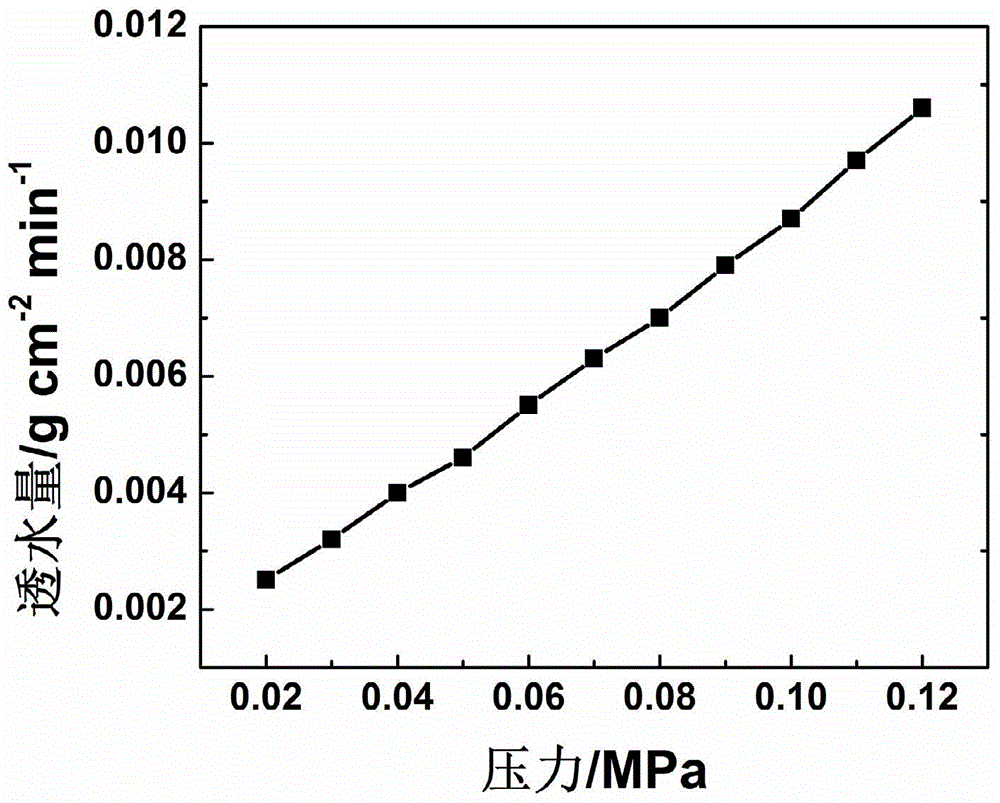

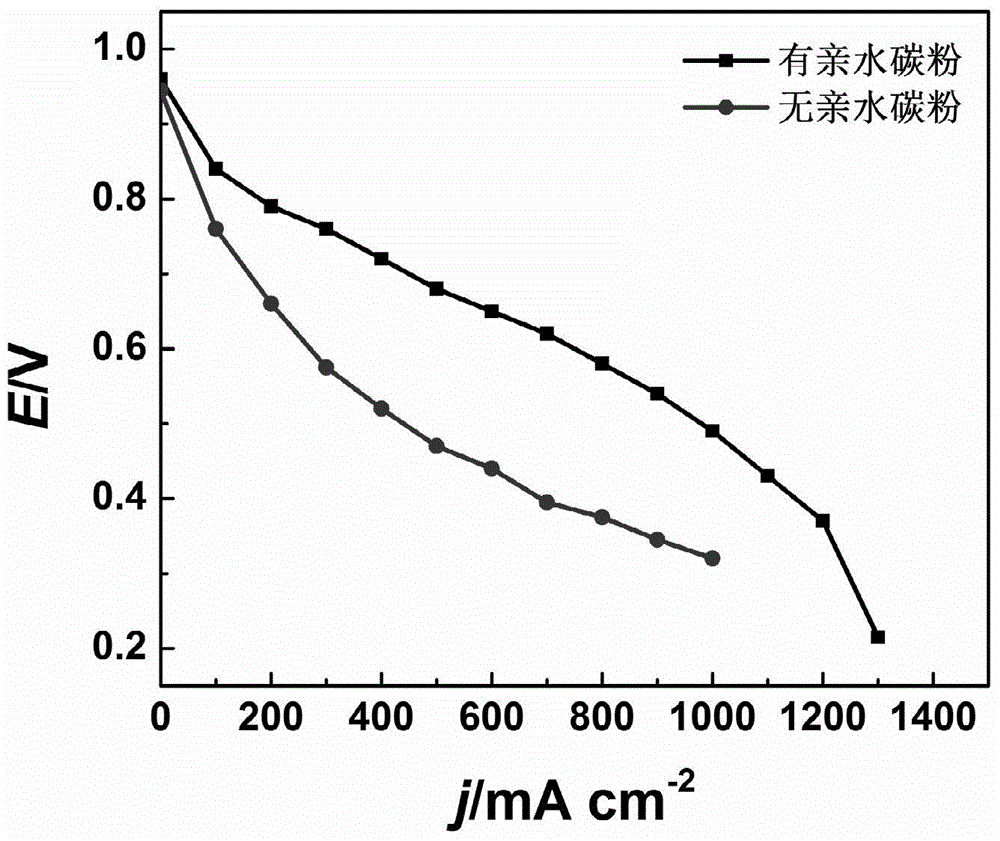

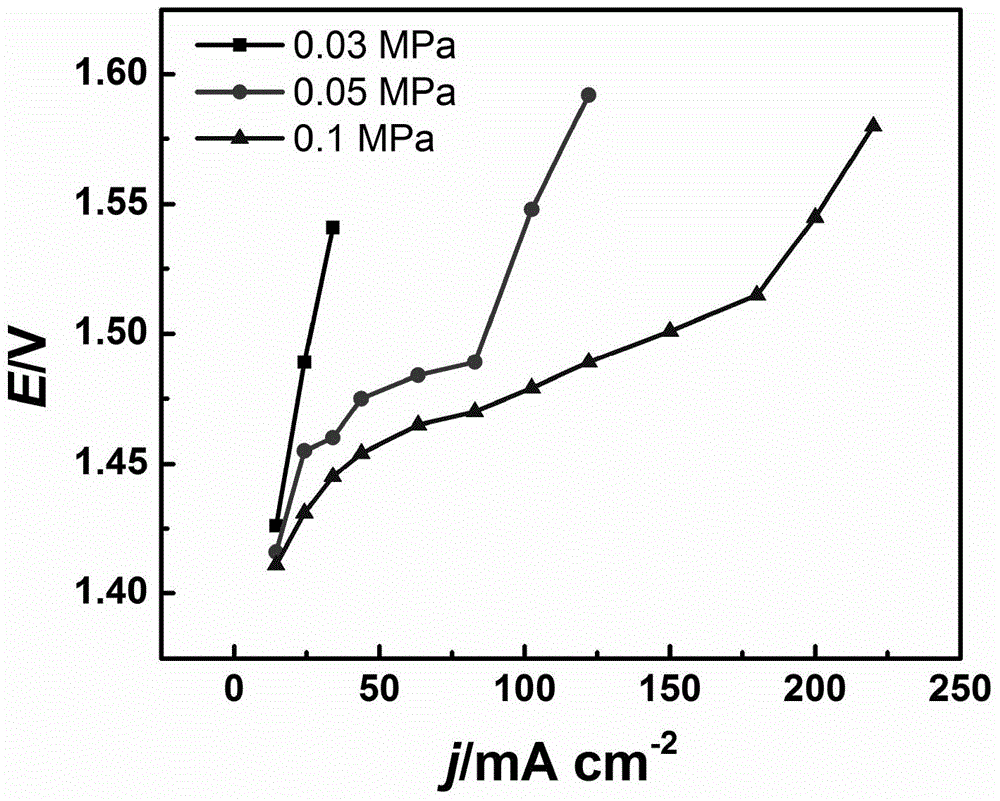

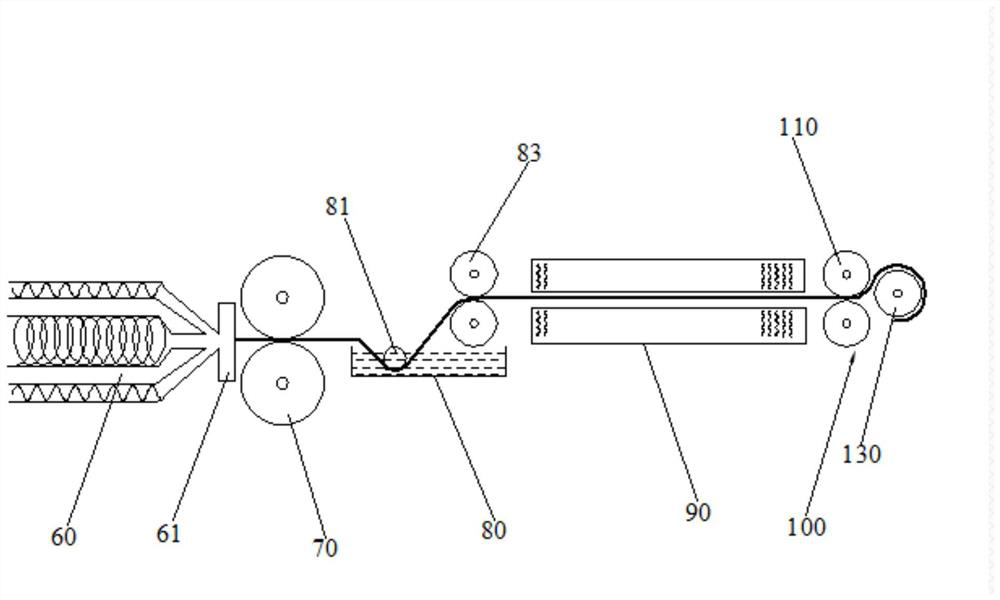

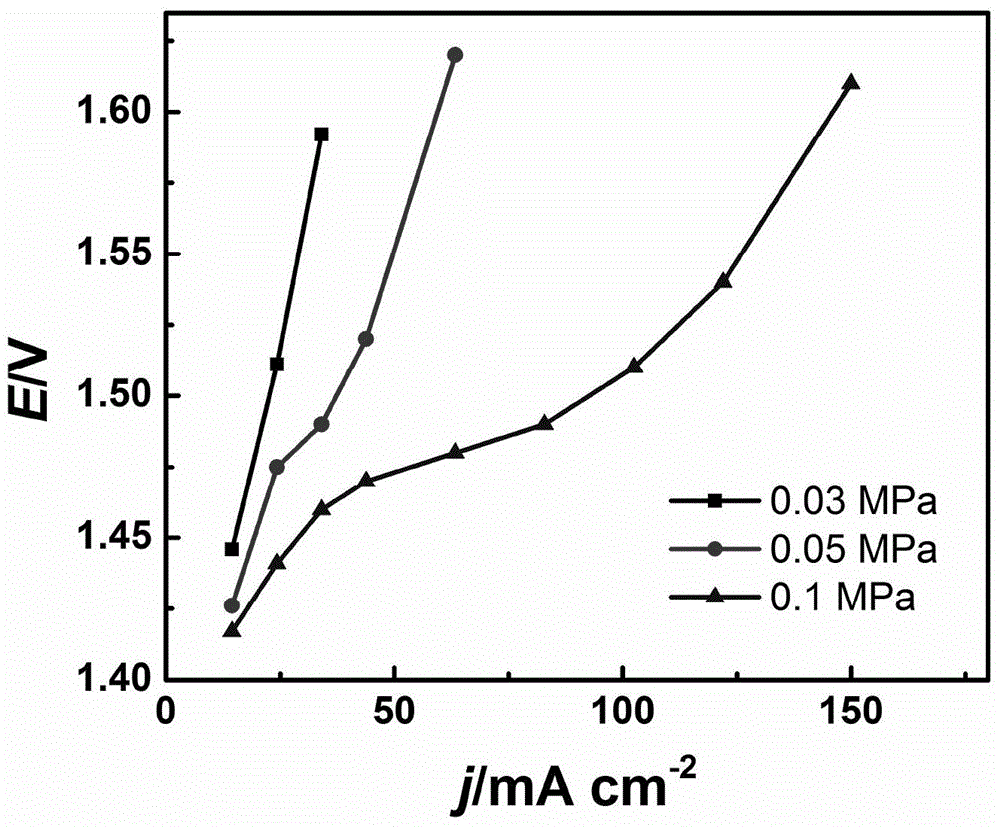

Application of water transport plate to integrated renewable proton exchange membrane fuel cell

ActiveCN105633427AAlleviate water shortageMitigationFuel cell auxillariesFuel cell detailsFiberCarbon fibers

The invention discloses a hydrophilic water transport plate for an integrated renewable proton exchange membrane fuel cell and a preparation method for the water transport plate. The method comprises the steps of firstly hydrophilically treating a carbon nanomaterial; secondly uniformly mixing the hydrophilically treated carbon nanomaterial, a conductive additive, a reinforced carbon fiber and a resin adhesive; and finally performing thermoforming in a mould to obtain the hydrophilic water transport plate, wherein the hydrophilic carbon nanomaterial achieves the effect of promoting water transport. The water transport plate serving as a bipolar plate for the integrated renewable proton exchange membrane fuel cell has good water-penetrating property; and the situations of water shortage and flooding in a working mode of the fuel cell can be effectively relieved, the performance of the fuel cell can be improved, the static water supply can be realized directly by utilizing cooling water in a working mode of an electrolytic tank, the anodic concentration polarization phenomena can be reduced, the electrolytic performance under high electric density can be improved, a system can be simplified, and the energy consumption can be reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Oxygen-uptake oxygen-resistance type plastic beer bottle cap lining and processing method thereof

ActiveCN1743241AThe process is easy to realizeImprove applicabilityFlexible coversWrappersChemistryMoisture

The inner mat material of absorbing and preventing oxygen type beer bottle cap is disclosed. The first layer is obstruct layer, which a film coated by ethyl acetate solution of polyvinylidene chloride. The second layer is oxygen-absorbing obstruct layer, whose substrate is ethylene vinyl alcohol polymer obstruct resin in which the ethhyene content is 29-46%, the oxygen absorbing mother grains distributes in the said substrate, the weight percentage of pyridines and the like oxygen absorbent in the said obstruct resin is 0.0001-0.1%, the moisture of obstruct resin is 0.1-0.3% and the resin density is 1.14-1.21gram / cm3. First resolve polyvinylidene chloride using ethyl acetate solution to a transparent solution, equally spray the solution to coat on the inner surface of cap, which comes into the first obstruct layer by natural drying; secondly on the first obstruct layer the said polymer obstruct resin oxygen-absorbing layer is extruded.

Owner:上海紫日包装有限公司

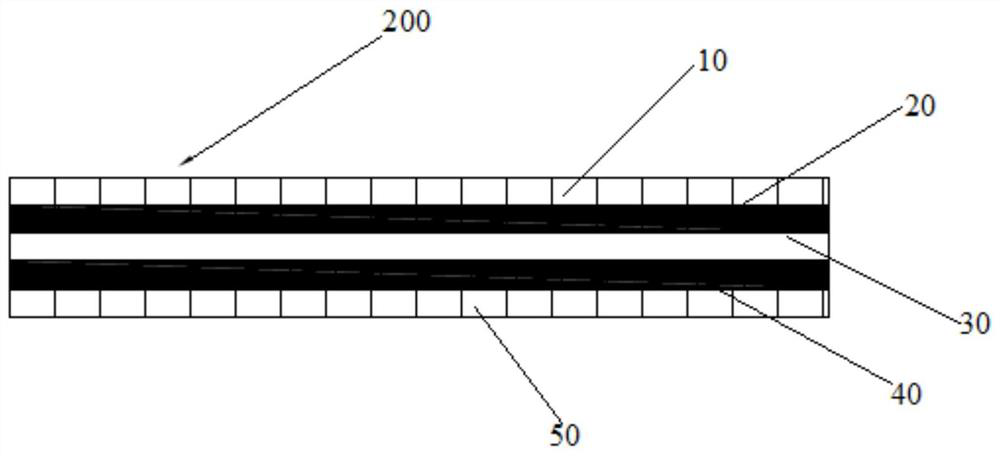

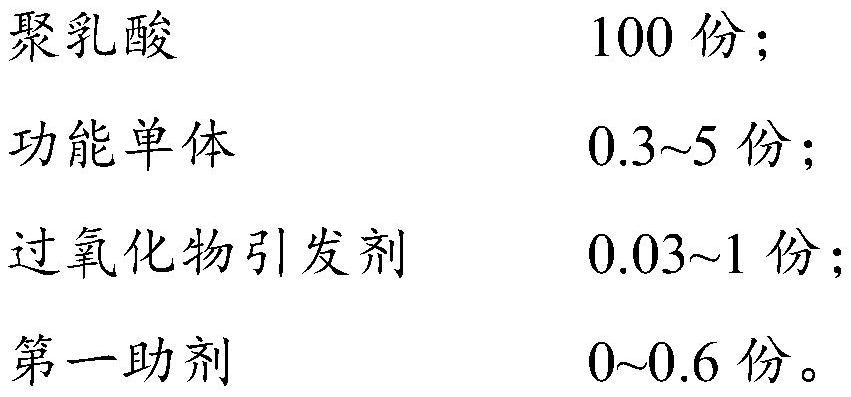

Biodegradable multilayer composite barrier film and preparation method thereof

PendingCN112874099AImprove adhesionImprove barrier propertiesSynthetic resin layered productsPolymer chemistryPolylactic acid

The invention provides a biodegradable multilayer composite barrier film and a preparation method thereof. The biodegradable multilayer composite barrier film comprises a matrix layer, bonding layers located on the two sides of the matrix layer and barrier layers located on the sides, away from the matrix layer, of the bonding layers, the matrix layer is made of biodegradable resin, the bonding layers are made of polylactic acid modified by active groups, and the barrier layers are formed by drying a polyvinyl alcohol solution on the bonding layers. The barrier layers are formed by drying a polyvinyl alcohol solution, and a continuous and compact PVA layer can be formed, so that the gas barrier property is better. Active groups in the modified polylactic acid can chemically react with hydroxyl groups on a PVA molecular chain, so that the adhesive force of the barrier layers on the matrix layer is improved, the interlayer binding force reaches an inseparable degree, and the barrier property is further improved. The number of hydroxyl groups on a PVA molecular chain is reduced due to chemical reaction, so that the original water intolerance of PVA is improved, and the corresponding water vapor barrier property is also improved.

Owner:东莞市普凯塑料科技有限公司

Aluminum-free anti-counterfeiting lining paper for cigarettes and production method thereof

InactiveCN102587206ALow priceNothing producedCoatings with pigmentsSpecial paperPolyvinyl alcoholAdhesive

The invention provides an aluminum-free anti-counterfeiting lining paper for cigarettes and a production method thereof. The lining paper is composed of an anti-counterfeiting paper layer, a coating layer and an aqueous printing oil layer. The technical indexes are as follows: the fixed quantify is 60+ / -3 g / m<2>; the thickness is 0.07+ / -0.005 mm; the flatness is more than or equal to 80 S; the tensile strength is more than or equal to 1.8 kN / m; the whiteness is more than or equal to 80%; the water content is 4-6%; and the air permeability is less than or equal to 0.01 micron / Pa.s. The production method comprises the following steps of: firstly preparing a coating; and then, coating the prepared coating on front and back sides of anti-counterfeiting paper on a coating machine, so as to prepare a product. According to the production method, the anti-counterfeiting paper is used as basic paper and an anti-counterfeiting function is organically combined with the lining paper for the cigarettes, thereby achieving the anti-counterfeiting effect and greatly reducing the cost. The formula of the coating used in the preparation method is unique and a main paint part is papermaking porcelain clay which is widely applied to the papermaking industry and is low in price and an adhesive is polyvinyl alcohol and has no extraneous odor or toxicity; in the production process, no organic solvent is used and no pollutant is generated, thereby protecting environment. Non-ferrous metal such as aluminum foils, aluminum powder and copper powder, is not used, so that the product cost is low, the energy consumption is low, and ideals of energy saving and environmental protection and low-carbon lifestyle are realized.

Owner:杜荣安 +2

High-barrier multi-layer coextrusion composite infusion film

The invention relates to a high-barrier multi-layer coextrusion composite infusion film. The high-barrier multi-layer coextrusion composite infusion film is a five-layer composite film and from the outer layer to the inner layer, the composite film consists of the following ingredients: polyethylene naphthalene modified polyester / ethylene acrylic acid polymer / polypropylene, ethylene-octene copolymer mixture resin / ethylene propene polymer / modified polypropylene. The advantages of various functional polymers are combined in the composite infusion film; the light transmittance, flexibility, high-barrier property, low-temperature heat sealing performance, heat sealing strength and the like of the film are ensured, the high-temperature resistant (121 DEG C, 30min) sterilization, and moreover the low-temperature resistant (minus 30 DEG C) storage performance of the film are improved, so that the dissolved matter (nonvolatile matter, readily oxidizable matter, heavy metal and the like) of the infusion film are very little; the infusion film neither generates biological and chemical reaction with liquid medicine after encapsulation sterilization, nor produces toxin or causes environmental pollution when in production, use and recovery. Compared with other similar products, the infusion film has huge competitive advantages on various technical indicators such as a production formula, a production technology and performance.

Owner:NINGBO HUAFENG PACKAGE

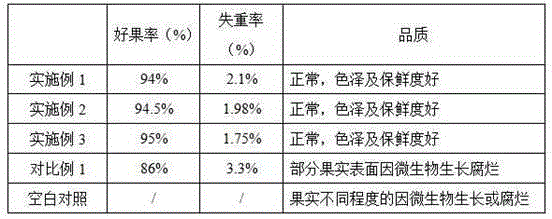

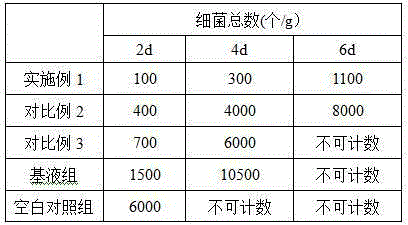

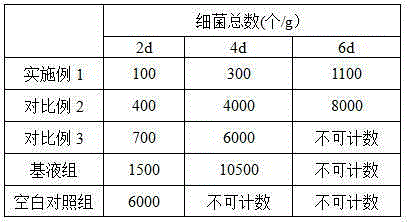

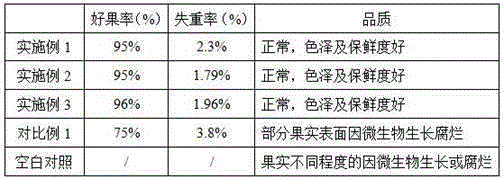

Composite coating fresh keeping agent containing hawthorn leaf flavone and preparation method and application thereof

The invention relates to an antioxidative and antibacterial composite coating fresh keeping agent containing hawthorn leaf flavone and a preparation method and application thereof, and belongs to the technical field of fresh agricultural product fresh keeping. The composite fresh keeping agent is prepared from, by weight, 0.5-1.5 parts of hawthorn leaf flavone, 10-30 parts of carboxymethyl chitosan, 30-40 parts of glycerinum, 5-10 parts of calcium chloride, 10-20 parts of polyethylene glycol, 0.3-0.5 part of tween-20 and 1000 parts of water. According to the composite fresh keeping agent, through synergistic action of all the components, the hygroscopicity and uniformity of a composite fresh keeping agent coating film are improved, the integrality of a finished film is enhanced, the film is not cracked after air drying is performed, the coating film not only has the good air-resisting and dampness-resisting properties, but also has the excellent antioxidative and antibacterial effects, and the fresh keeping effect is obvious; the composite fresh keeping agent is green and environmentally friendly in components, good in water solubility, easy to clean and free of toxic and side residues and has a wide market prospect.

Owner:QINGDAO AGRI UNIV

Concrete carbonization inhibitor

The invention relates to a concrete carbonization inhibitor which mainly comprises a water-soluble high-molecule polymer polyving akohol (PVA) solution which is formed into a film easily and acrylic ester emulsion and comprises the following materials in percentage by weight: 5 to 15 percent of polyving akohol, 0.02 to 0.05 percent of defoaming agent, 1 to 4 percent of acrylic ester, 0.5 to 3 percent of emulsifying agent and 80 to 93 percent of water, wherein a polyving akohol and acrylic ester compound film has high gas isolation performance, high tolerance and high anti-aging performance and can effectively prevent gas and water from entering concrete, so that the anti-carbonization capacity of the concrete is improved; and simultaneously other corrosive substances can be prevented from entering the concrete, thus the durability of the concrete is improved.

Owner:JIANGSU MINGHE GRP

Composite coating film fresh keeping agent containing persimmon leaf flavones as well as preparation method and application of composite coating film fresh keeping agent

InactiveCN105285077AHigh extraction rateHigh purityFruit and vegetables preservationClimate change adaptationPolymer sciencePolyethylene glycol

The invention relates to a composite coating film fresh keeping agent containing persimmon leaf flavones and having characteristics of oxidation resistance and bacteriostasis, as well as a preparation method and application of the composite coating film fresh keeping agent, and belongs to the technical field of fresh keeping of fresh agricultural products. The composite fresh keeping agent consists of the following raw materials in parts by weight: 0.5-1.5 parts of persimmon leaf flavones, 10-30 parts of carboxymethyl chitosan, 30-40 parts of glycerine, 5-10 parts of calcium chloride, 10-20 parts of polyethylene glycol, 0.3-0.5 part of tween 20 and 1000 parts of water. According to the composite fresh keeping agent provided by the invention, all the components have a synergistic reaction, so that the hygroscopicity and the homogeneity of composite coating film fresh keeping agent are improved, the filming integrity is strengthened, and after being air-dried, coating films are not cracked, so that the coating films not only have favorable properties of resisting air and resisting dampness but also have excellent antioxidative and antibacterial effects and obvious fresh keeping effects; all the components of the composite fresh keeping agent disclosed by the invention are environmental-friendly, good in water solubility, easy to clean and free from toxic and side residues, so that the composite fresh keeping agent has broad market prospects.

Owner:QINGDAO AGRI UNIV

Fuel cell graphitc composite flow field plate and its manufacturing method

InactiveCN100533831CReduce contact resistanceSimple preparation processCell electrodesFinal product manufactureFuel cellsSurface layer

This invention discloses a graphite compound flow field board for fuel cell and manufacture method. On the wall of the flow field board there are fluid inlet, the fluid outlet and rib and channel forming flow field. The flow field is characterized in that it is formed by middle layer of graphite composite material and upper and lower surface layers of flexible graphite material that are compounded by sandwich layer. The preparation process includes: mix evenly electric conductive pellets and resin or polymer, put it in the mold to heat up, pressurize and maintain a certain time, the cool to draw mould to obtain sandwiched composite plate. Advantages: lower contact resistance, strong anti-corrosion ability, good electric conductivity and thermal conductivity, good gas barrier property, simple process and low cost.

Owner:TIANJIN UNIV

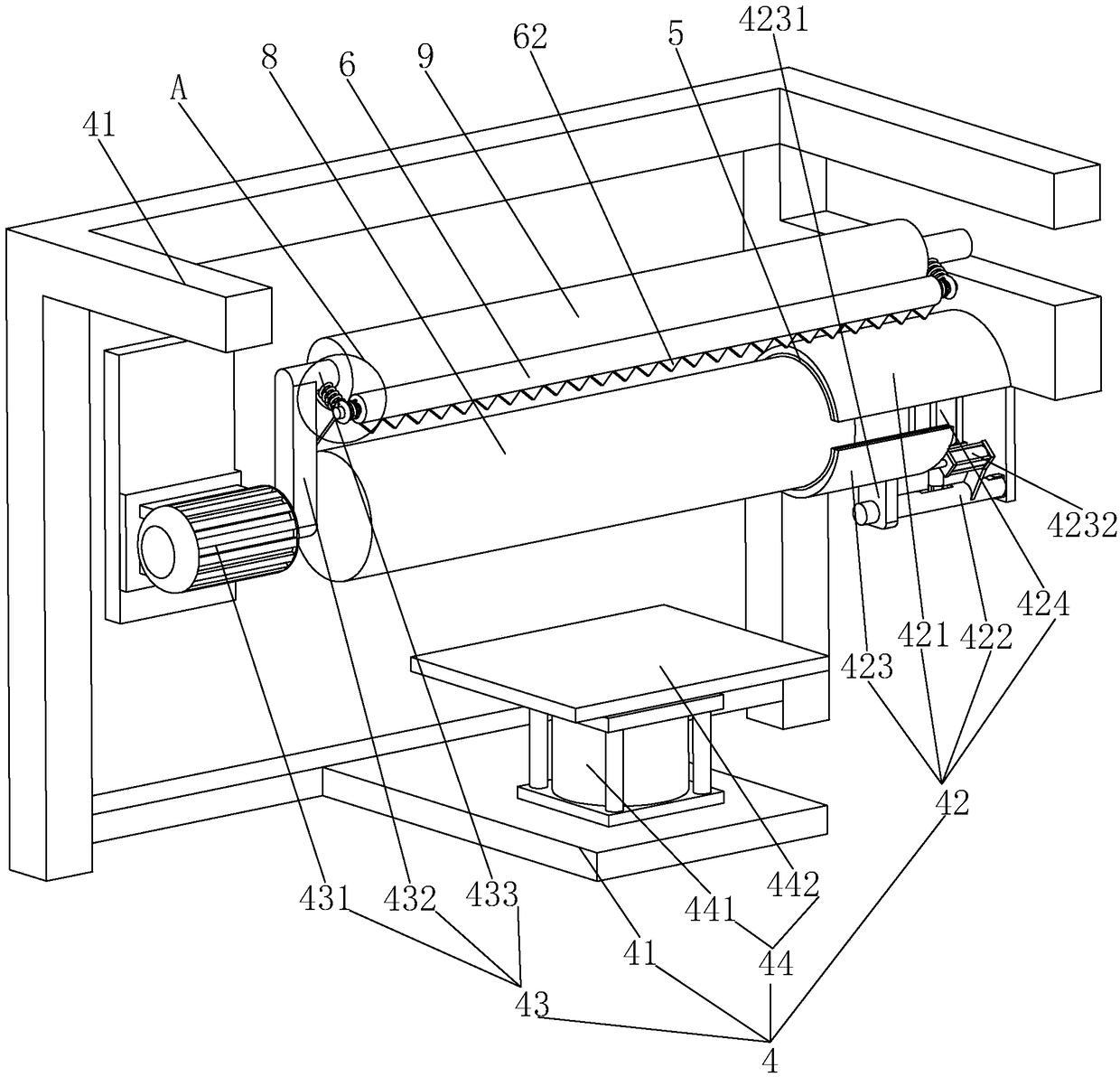

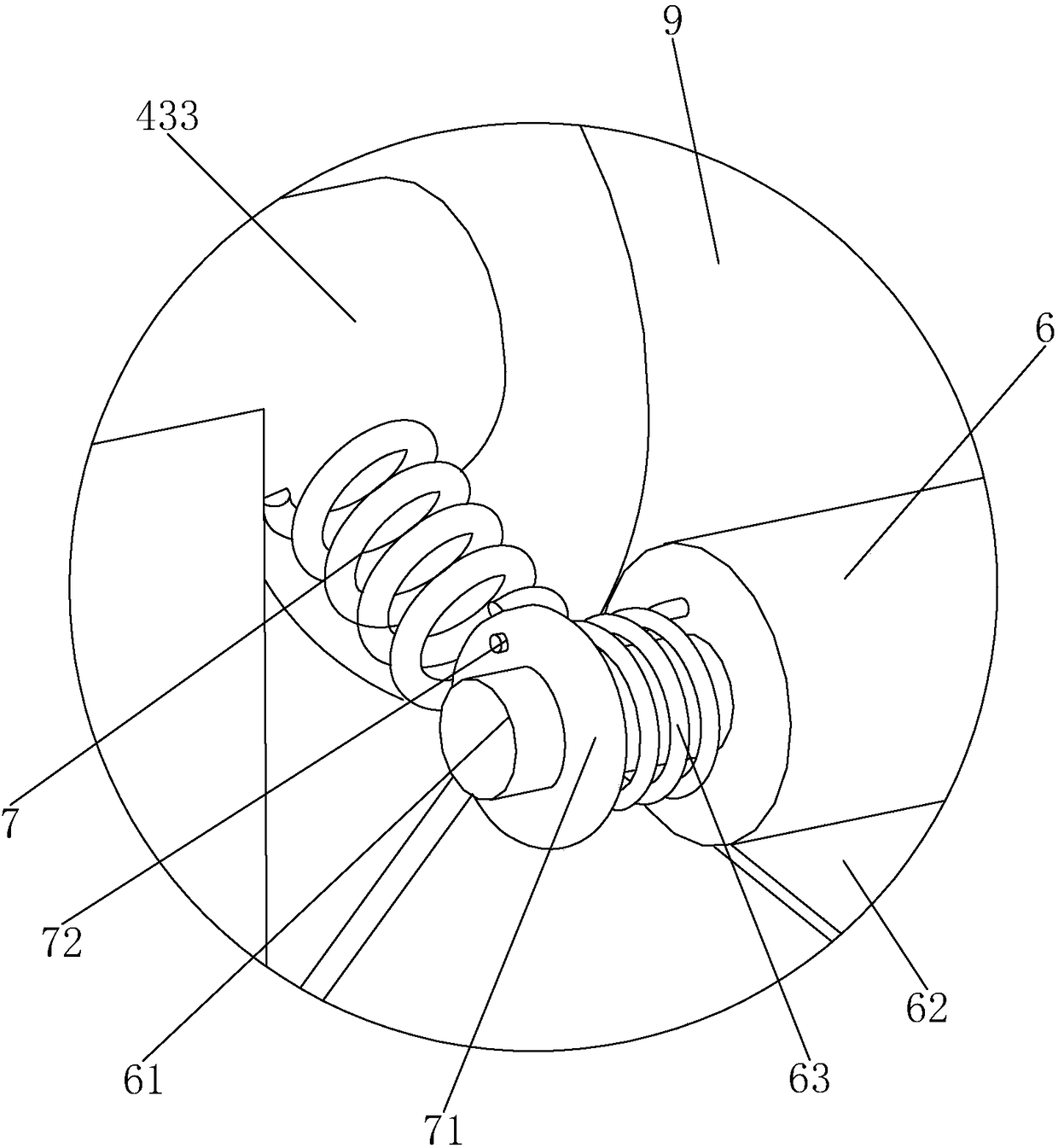

Fabric processing technique

ActiveCN108248916AReduces the possibility of mildewGood gas barrierLaminationLamination apparatusHigh resistanceSlurry

The invention relates to the technical field of fabric production and discloses a fabric processing technique. The fabric processing technique comprises the following steps that 1, spooling is conducted, specifically, warps and wefts are manufactured into twisted tubes through a spooling machine; 2, warping is conducted, specifically, the warps and the wefts on the twisted tubes are manufactured into warp shafts through a warping machine according to the warping technique; 3, slashing is conducted, specifically, the warps and the wefts on the multiple warp shafts are guided out at the same time through a slashing machine and immersed into slurry, waste slurry is pressed away, and drying is conducted; 4, reeding is conducted, specifically, reeding operation is conducted; 5, weaving is conducted, specifically, base-cloth fabrics are woven through a circular machine; 6, compounding is conducted, specifically, through a compounding machine, high-resistance thin films are compounded to onesides of the base-cloth fabrics, woolen fabrics are compounded to the sides, away from the high-resistance thin films, of the base-cloth fabrics, and thus the compound fabrics are formed; 7, cloth checking is conducted, specifically, a cloth checking machine checks cloths, as for the flawed cloths, the flawed positions are repaired manually, the cloth checking machine rolls up the compound fabrics, and thus the cylindrical fabrics are formed; and 8, fungus-resistant treatment is conducted, specifically, through a wrapping device, the cylindrical fabrics are wrapped with fungus-resistant paper.

Owner:浙江明强针织股份有限公司

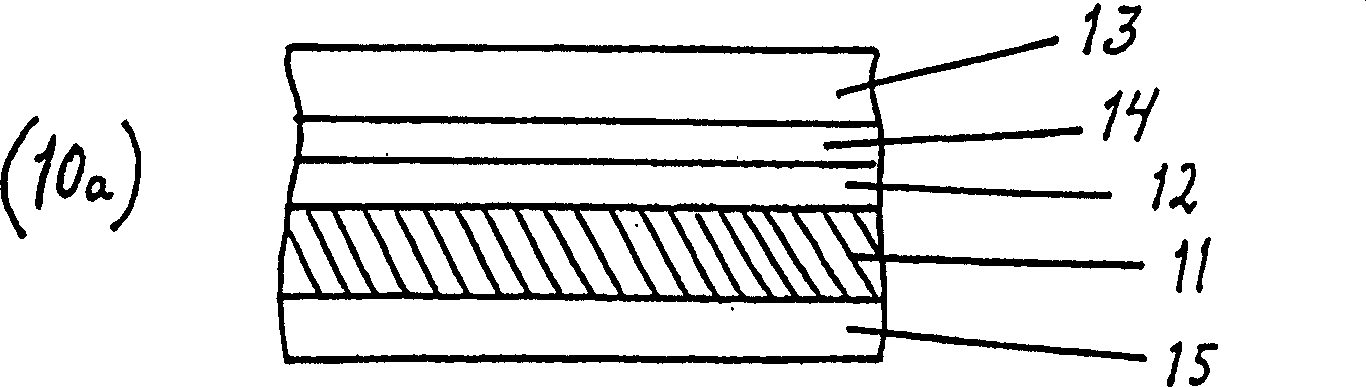

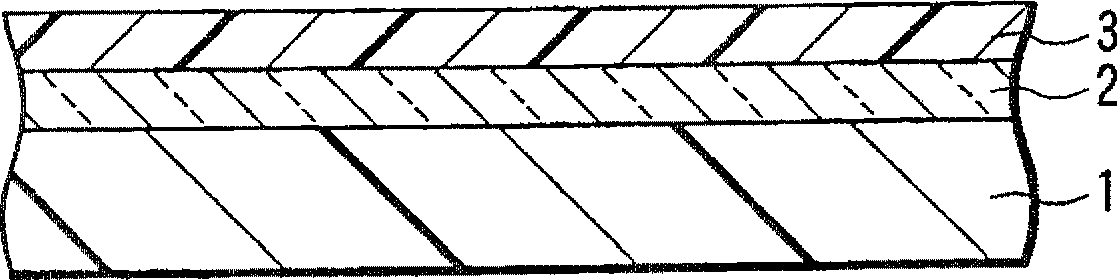

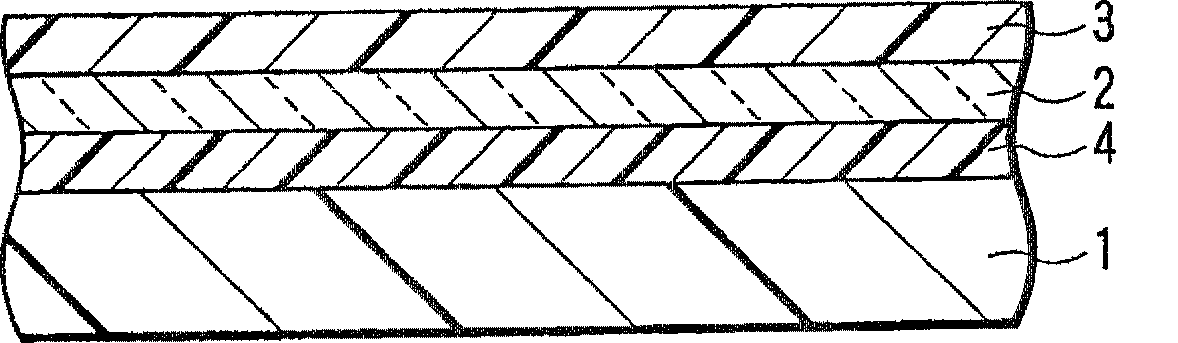

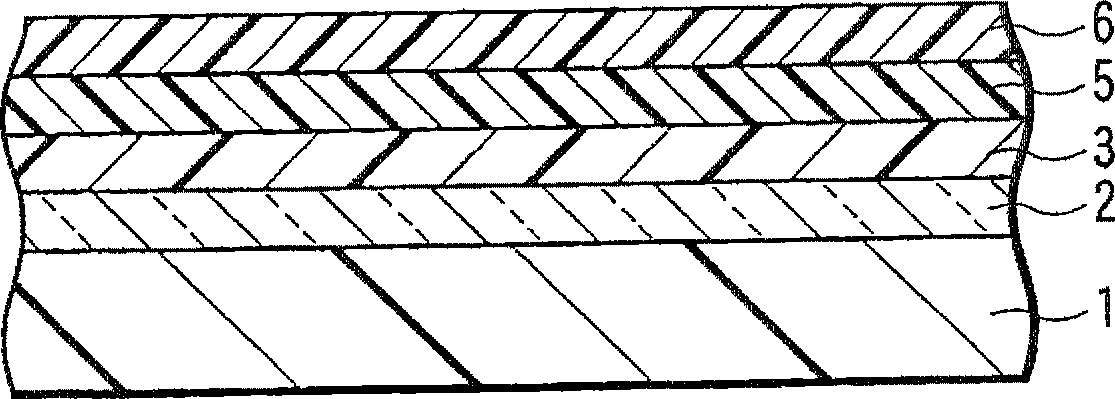

Laminated packaging material, method for making said laminated material and package container made of said laminated material

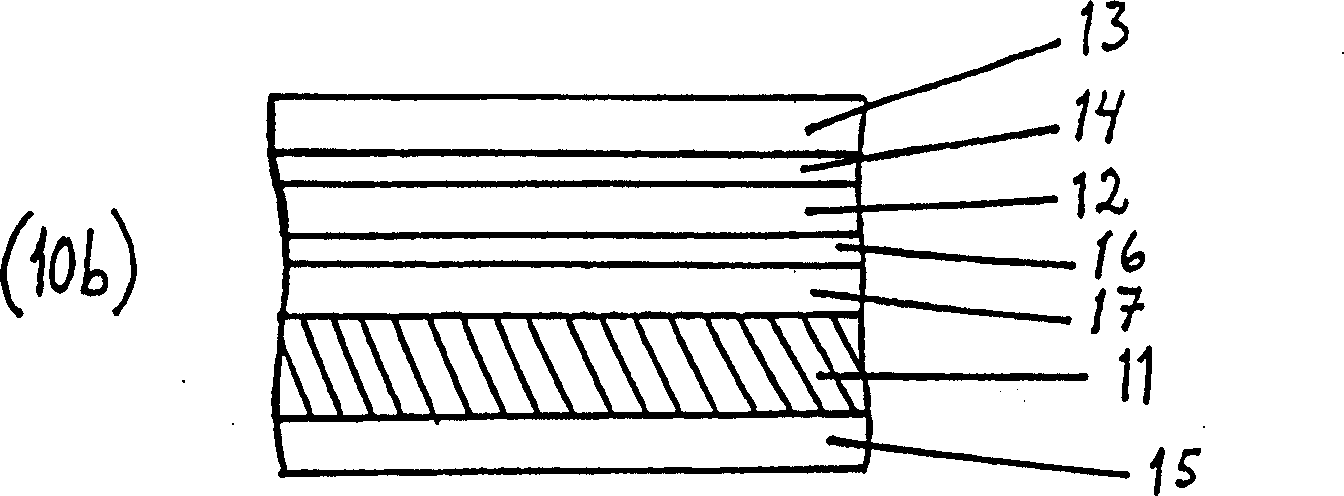

A laminated packaging material (10) comprising a core layer (11) of paper or paperboard and a gas barrier layer (12) of a polyamide mixture comprising m-xylenediamine and adipic acid A polycondensate of (Nylon-MXD6) and a second crystalline or semi-crystalline polyamide, which polycondensate is applied on one side of the core layer (11) by coextrusion coating. And a method of manufacturing a laminated packaging material and a packaging container (30) made from the laminated packaging material.

Owner:TETRA LAVAL HLDG & FINANCE SA

High-barrier polyester film and its preparation method

ActiveCN102225648BGood physical and mechanical propertiesHigh gas barrierSynthetic resin layered productsComposite constructionPolyester

The invention discloses a high-barrier polyester film, which has a three-layer composite construction, comprising a core layer, an upper cortex and a lower cortex. The core layer comprises the following components of: 60-100 wt% of PET polyester slices, 0-40 wt% of PEN polyester slices; the cortexes comprise the following components of: 92-98 wt% of PEN polyester slices, 0.2-2 wt% of a nucleating agent and 1-6 wt% of a nucleating modifier. The invention also discloses a coextruding-drawing preparation method of the above high-barrier polyester film. The invention has a simple preparation technology; in addition to excellent physical properties, the produced polyester film has better gas barrier property, heat resistance and radiation resistance performance, and can be applied in the fields of solar energy cell back-piece and the like.

Owner:JIANGSU YUXING FILM TECH

Processing method for color printing packaging compound film

The invention discloses a processing method for a color printing packaging compound film. The processing method for the color printing packaging compound film comprises the following steps of: selecting materials; purifying gel; preparing; spraying; and storing. The processing method disclosed by the invention has an obvious advantage in cost; the production technology is mature; the color printing packaging compound film has excellent properties, such as, air barrier property, toughness and water solubility; the application is more extensive; the color printing packaging compound film processed according to the invention has the advantages of bright color, difficulty in fading, excellent biological degradability, excellent mechanical property, and the like.

Owner:海宁市佳峰彩印包装有限公司

Gas barrier laminate film

InactiveCN100488765CHigh transparencyExcellent gas barrier performanceLayered productsCoatingsWater solubleHydroxy compound

A gas barrier laminate film comprising a resin substrate on which a gas barrier vapor deposition layer, and a gas barrier covering layer are laminated, wherein the gas barrier covering layer is formed through the coating, and drying of a coating liquid comprising Si(OR<1>)4 or the hydrolyzates thereof, (R<2>Si(OR<3>)3)n or the hydrolyzates thereof (wherein R<1> and R<3> are individually CH3, C2H5 or C2H4OCH3, and R<2> is an organic functional group) and a water-soluble polymer having a hydroxyl group.

Owner:TOPPAN PRINTING CO LTD

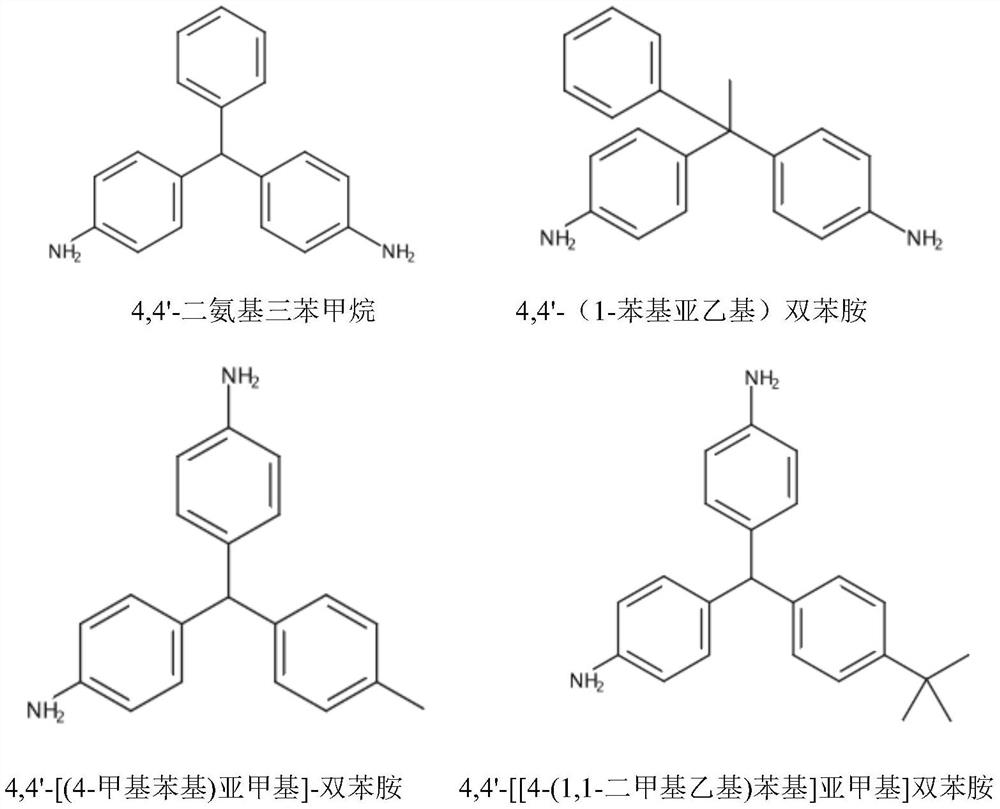

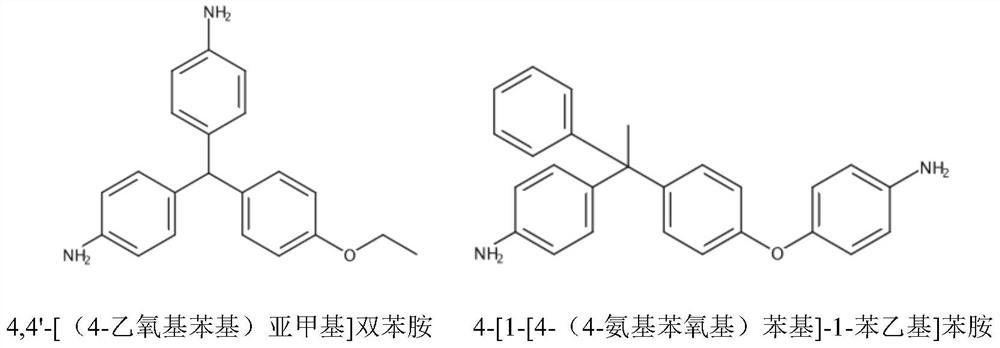

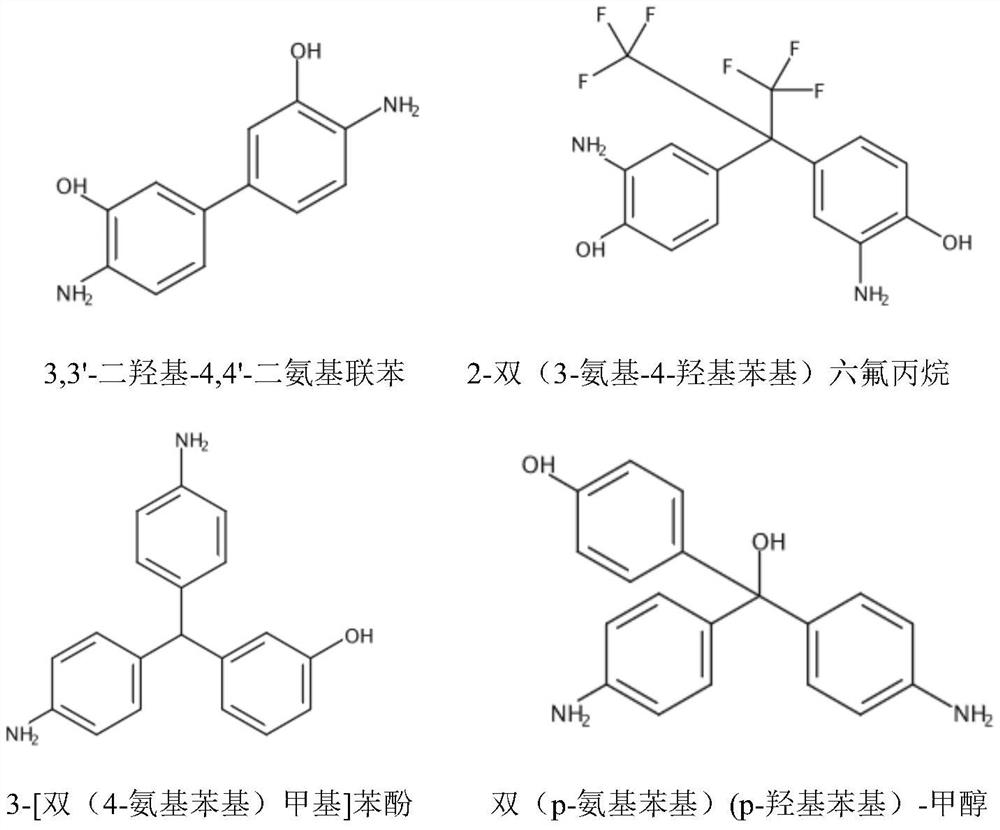

High-gas-barrier high-temperature-cooking-resistant transparent resin as well as preparation method and application thereof

The invention provides high-gas-barrier high-temperature-cooking-resistant transparent resin as well as a preparation method and application thereof. The high-gas-barrier high-temperature-cooking-resistant transparent resin disclosed by the invention is prepared from the following components in parts by weight: 62-78 parts of PETG (Polyethylene Terephthalate Glycol); 19 to 32 parts of polyimide; 3 to 6 parts of an end-capped polyurethane prepolymer; wherein the polyimide is obtained by reacting alicyclic carboxylic acid dianhydride with a diamine compound, and the diamine compound comprises triphenylmethane diamine and hydroxyl-containing diamine. According to the invention, under the synergistic effect of the polyimide with the specific molecular chain structure and the terminated polyurethane prepolymer, the prepared resin can still have better gas barrier performance (oxygen permeation amount lt; 80 cm < 3 > / m < 2 > * 24h * 0.1 MPa), is free of deformation and can be widely applied to the field of food packaging.

Owner:FOSHAN HUIHONG PLASTIC MOLD

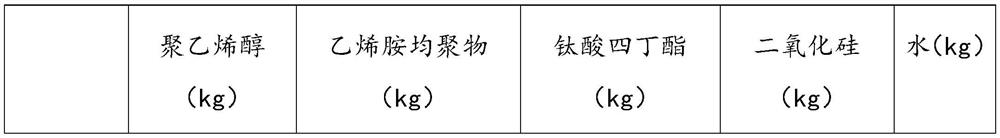

Barrier coating and high-barrier composite material applied in barrier coating

InactiveCN111690300AGood gas barrierStrong adhesionSynthetic resin layered productsPaper/cardboard layered productsPolyvinyl alcoholAluminum foil

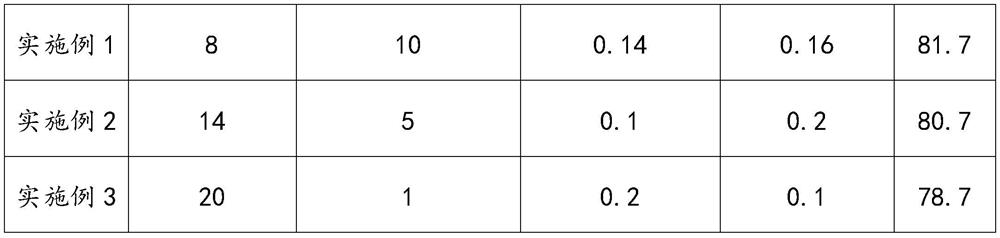

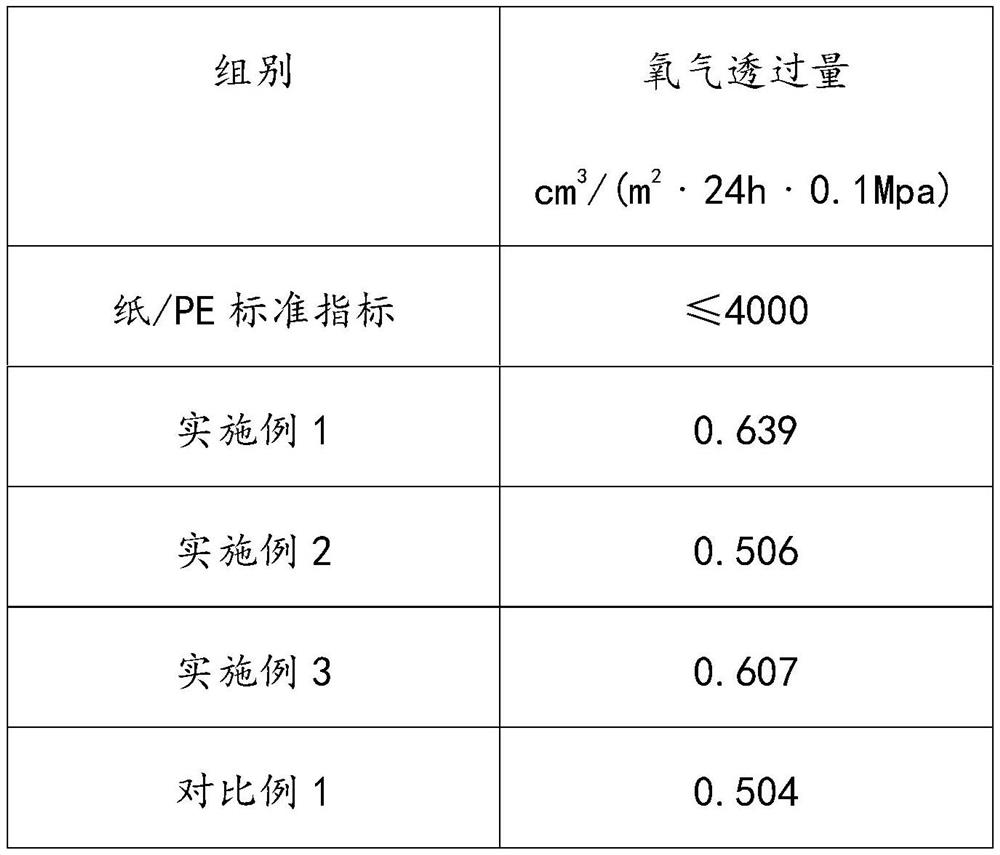

The invention relates to the field of packaging materials, in particular to a barrier coating and a high-barrier composite material applied in the barrier coating. The barrier coating is prepared fromthe following raw materials in percentage by mass: 8 to 20 percent of polyvinyl alcohol, 1 to 10 percent of vinylamine homopolymer, 0.1 to 0.2 percent of tetrabutyl titanate, 0.1 to 0.2 percent of silicon dioxide and the balance of water. The polyvinyl alcohol, the vinylamine homopolymer, the tetrabutyl titanate and the silicon dioxide in a specific mass ratio are added into the water for a mixing reaction, the effect of modifying the polyvinyl alcohol is achieved, the polyethylene barrier coating with high barrier performance is finally obtained, and compared with the aluminum foil, the polyethylene barrier coating has the advantage of being easy to recycle and meets the development requirement for environmental protection.

Owner:ZHEJIANG GOLDSTONE PACKING

Application of hydrophilic water transport plate in solid polymer electrolyte water electrolysis cell

ActiveCN105720279AReduce energy consumptionReduce anode concentration polarizationFuel cell auxillariesFuel cell detailsFiberCarbon fibers

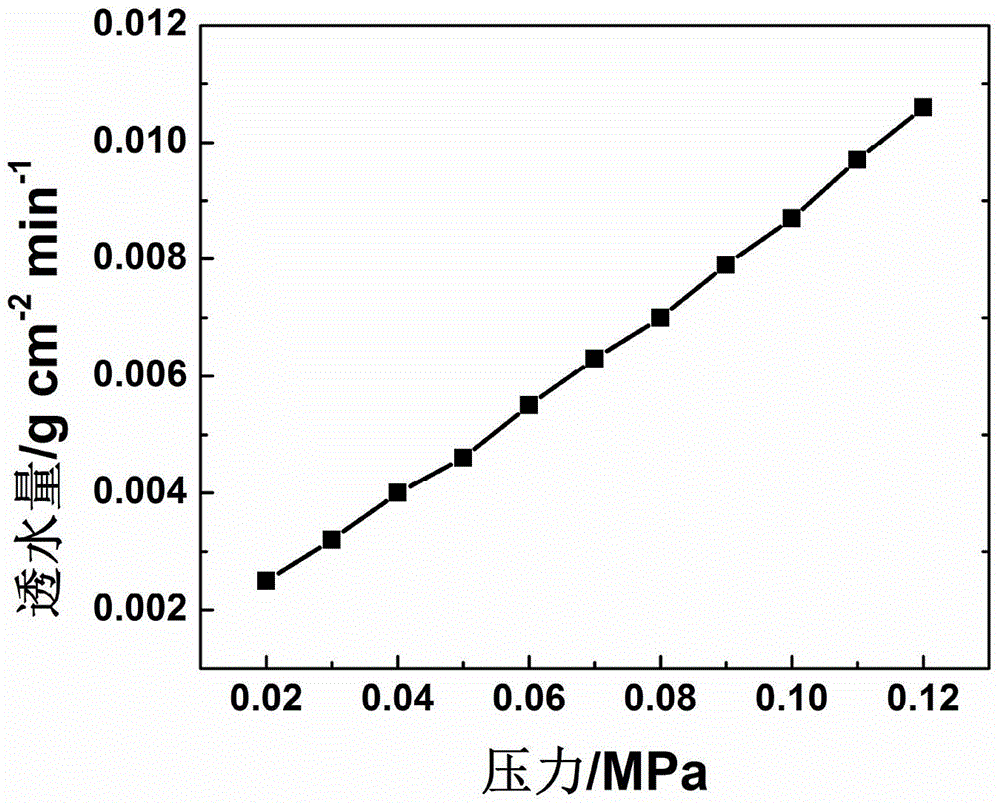

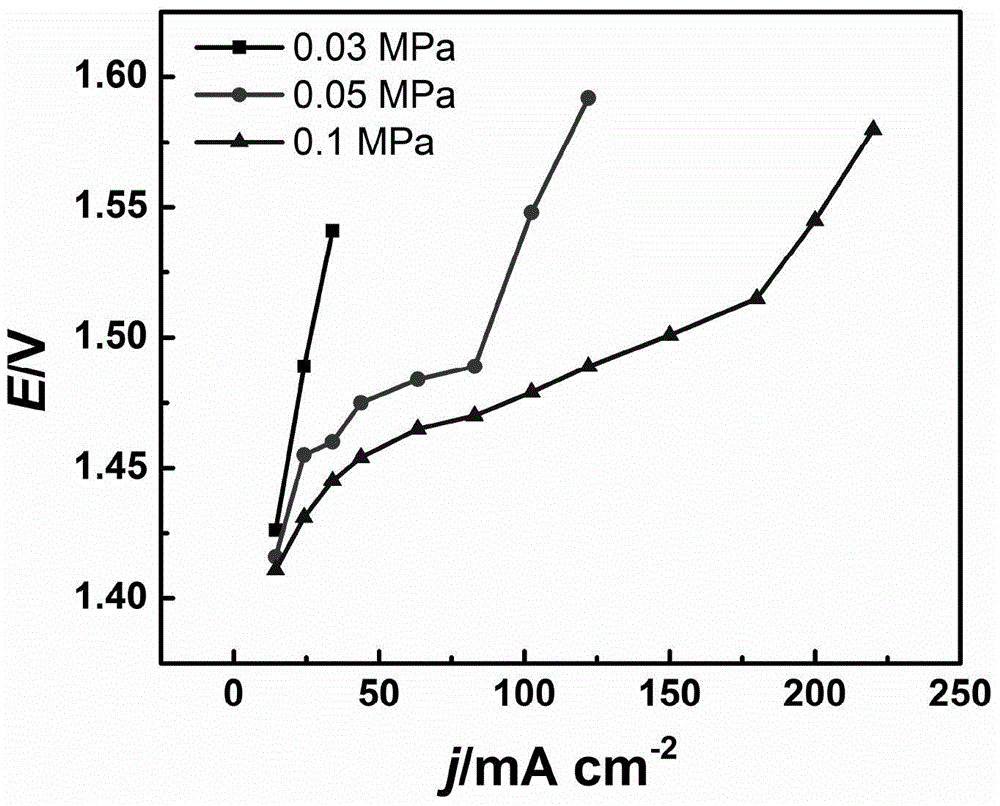

The present invention discloses a water transport plate used in a solid polymer electrolyte water electrolysis cell and a preparation method thereof, according to the method, first, hydrophilic treatment of a nano-carbon material is performed, the nano-carbon material after the hydrophilic treatment, a conductive additive, enhanced carbon fiber and a resin binder are uniformly mixed and then thermally pressed in a mold for forming to obtain the hydrophilic water transport plate, and the hydrophilic nano-carbon material plays the role of promotion of water transport. The water transport plate can be used as a bipolar plate of the solid polymer electrolyte water electrolysis cell, and has the good water permeability characteristic, static water supply can be achieved by direct use of electrolytic cell cooling water, anode concentration difference polarization can be reduced, high electric density electrolysis performance can be improved, and electrolysis cell system performance can be reduced.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Medical stone toughened polyvinyl alcohol film for preservation of fruits and vegetables and preparation method of polyvinyl alcohol film

InactiveCN106700361AInhibit growthLong antibacterial timeFlexible coversWrappersEndogenous metabolismCarvacryl acetate

A medical stone toughened polyvinyl alcohol film for preservation of fruits and vegetables is characterized by being prepared from raw materials as follows: camellia seeds, mint leaves, dried ginger, folium artemisiae argyi, clove flowers, acetone, anhydrous sodium sulfate, medical stone, whey protein, propylene glycol, agaric polysaccharide, corn starch, caustic soda, vinyl acetate, polyvinyl alcohol, an ammonium persulfate solution, hydroxyethyl acrylate, glyceryl monooleate, glycerin and a proper amount of deionized water. The medical stone toughened polyvinyl alcohol film for preservation of fruits and vegetables has good mechanical performance, is stable in structure and good in air permeability, also has a good antibacterial function, can reduce endogenous metabolism ageing of the fruits and vegetables and rotting caused by exogenous microorganisms, substantially prolongs the preservation time and effectively keeps the quality of the fruits and vegetables.

Owner:陈强

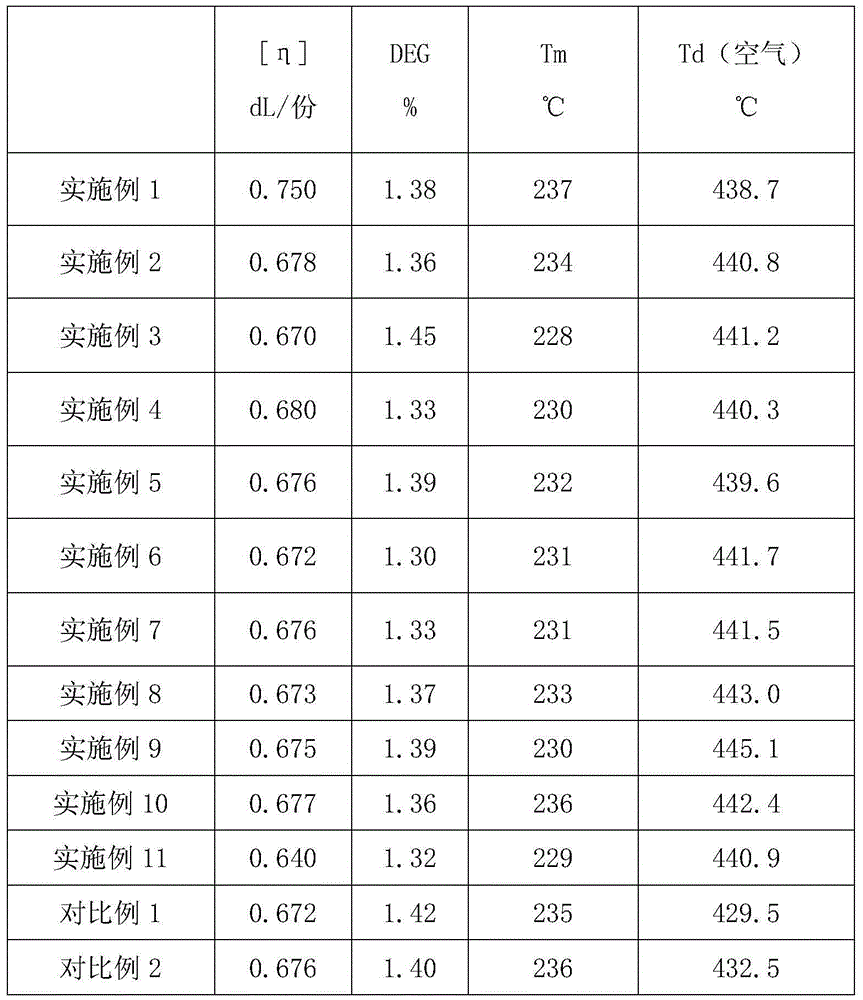

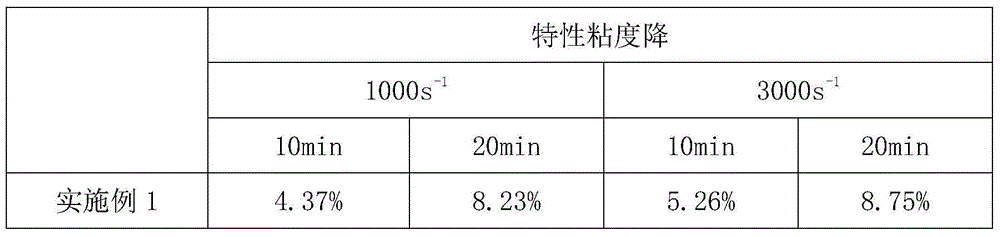

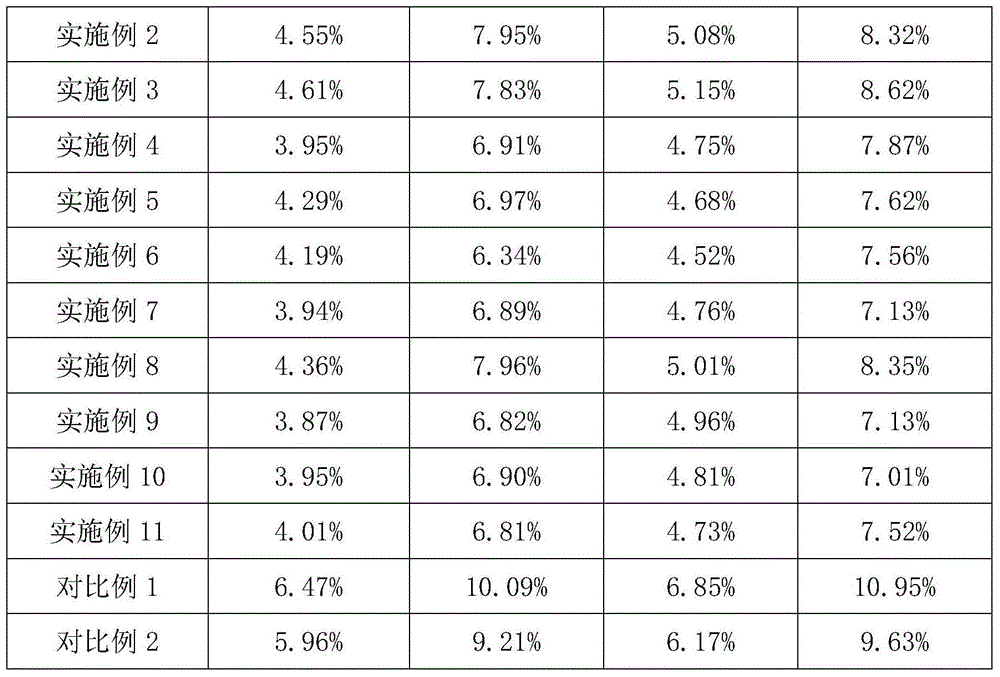

High-barrier bottle

The invention discloses a high-barrier bottle which is prepared by employing modified polyesteramide. The modified polyesteramide is prepared from the following raw materials: terephthalic acid, glycol, aliphatic polyamide, an additive A, an additive B and an additive C. The provided high-barrier bottle is prepared from modified polyesteramide, the cost is low, and through the combination of the additive A, the additive B and the additive C, the thermal stability of the high-barrier bottle is substantially improved, and thus the chain breaking speed of melt molecular chains during forming processing of the high-barrier bottle and the reducing degree of the product characteristic viscosity are reduced; and the provided modified polyesteramide is endowed with relatively good gas barrier property because an amide group is introduced into a polyester main chain, and oxygen-barrier membranes prepared from the modified polyesteramide are high in oxygen barrier property and carbon dioxide barrier property.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Polymer packaging material and preparation method thereof

The invention discloses a preparation method of a polymer packaging material. The preparation method is characterized by comprising the following steps: S1, preparation of an intermediate product; S2,preparation of fluorine-containing sulfuryl vinyl modified hydroxyl-terminated hyperbranched polycarbonate; S3, preparation of an acrylonitrile / caffeic acid / 2,2-dimethylvinyl boronic acid pinacol ester copolymer; S4, molding of the packaging material; and S5, radiation crosslinking. The invention further provides the polymer packaging material prepared according to the preparation method of the polymer packaging material. The polymer packaging material provided by the invention is better in comprehensive performance, better in antibacterial property, corrosion resistance, wear resistance andmechanical strength, more excellent in moisture resistance, gas resistance and oxidation resistance and safer and more environment-friendly to use.

Owner:程朝刚

Anticorrosive preservative film as well as preparation method and application thereof

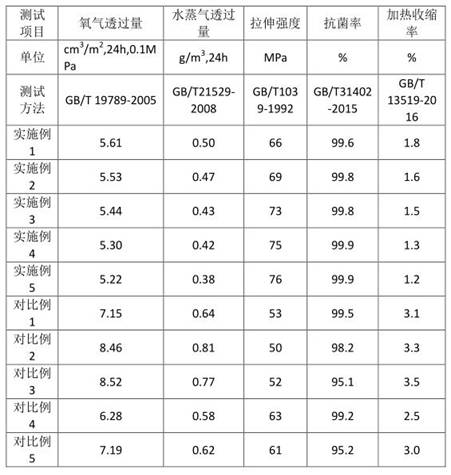

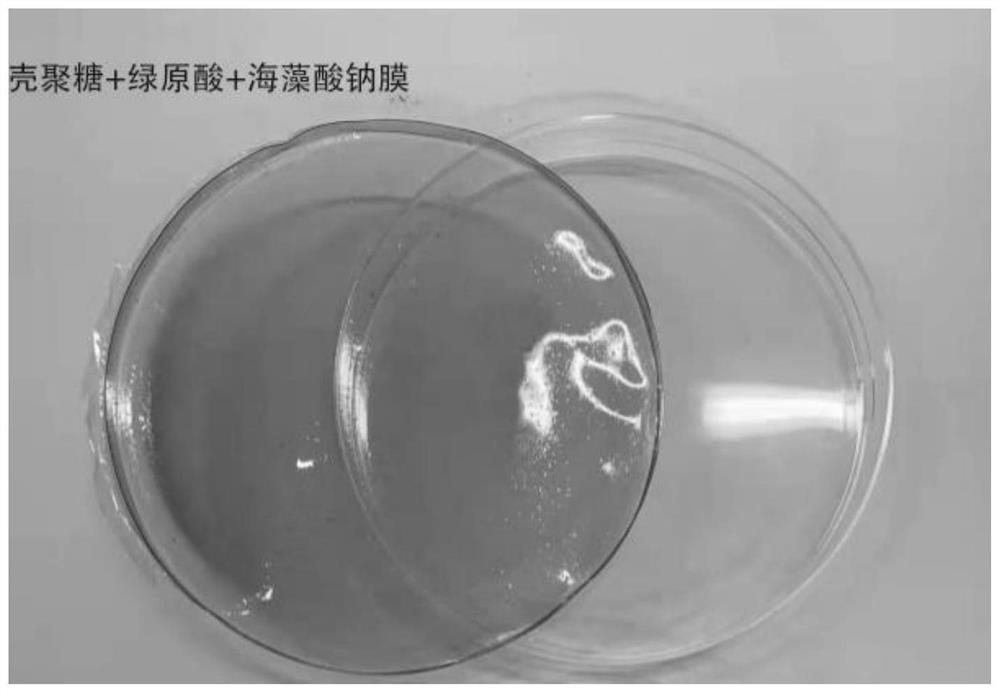

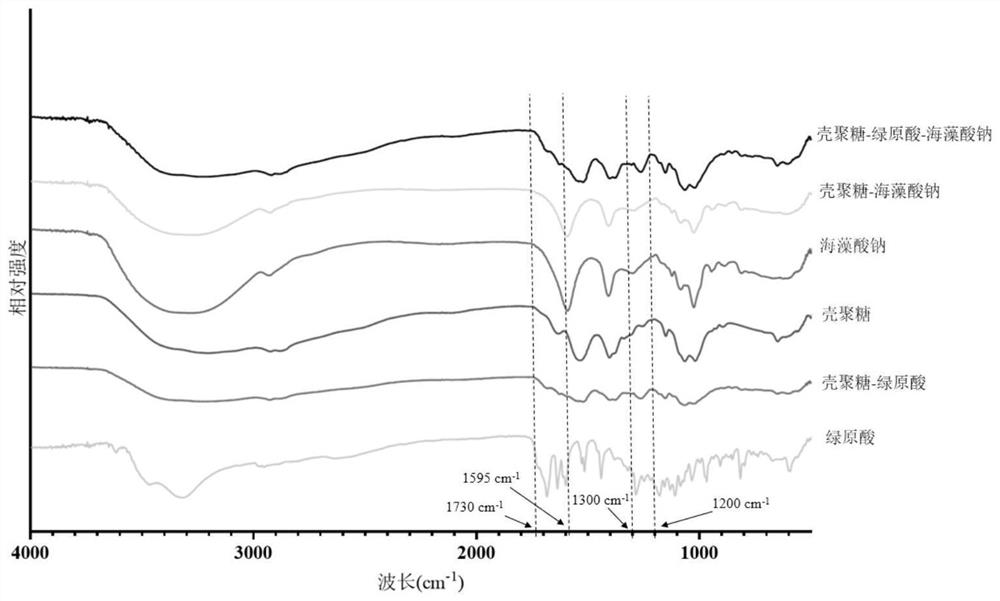

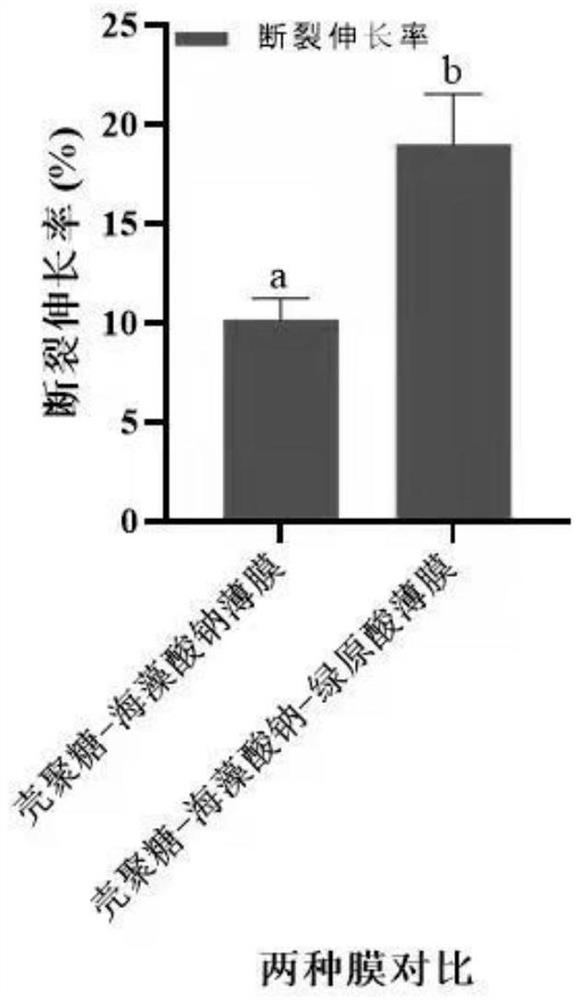

ActiveCN114591541AImprove antibacterial propertiesGood gas barrierBio-packagingClimate change adaptationFood industryChlorogenic acid

The invention discloses an anticorrosive preservative film as well as a preparation method and application thereof, and belongs to the technical field of food industry biology. The preservative film disclosed by the invention is prepared from the following components in parts by mass: 0.5 to 4 parts of sodium alginate, 0.5 to 4 parts of chitosan, 0.3 to 1 part of chlorogenic acid and 0.5 to 2 parts of glycerol. Compared with the traditional chitosan-sodium alginate film, the preservative film prepared by the invention has better antibacterial effect, mechanical property and gas barrier property, and can be used for preserving fruits and vegetables.

Owner:QINGDAO AGRI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com