Anticorrosive preservative film as well as preparation method and application thereof

A technology of plastic wrap and sodium alginate, which is applied in sustainable manufacturing/processing, bio-packaging, sustainable packaging, etc., can solve the problems of poor water resistance, poor antibacterial and anti-corrosion effects, and insufficient mechanical strength to achieve good antibacterial effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

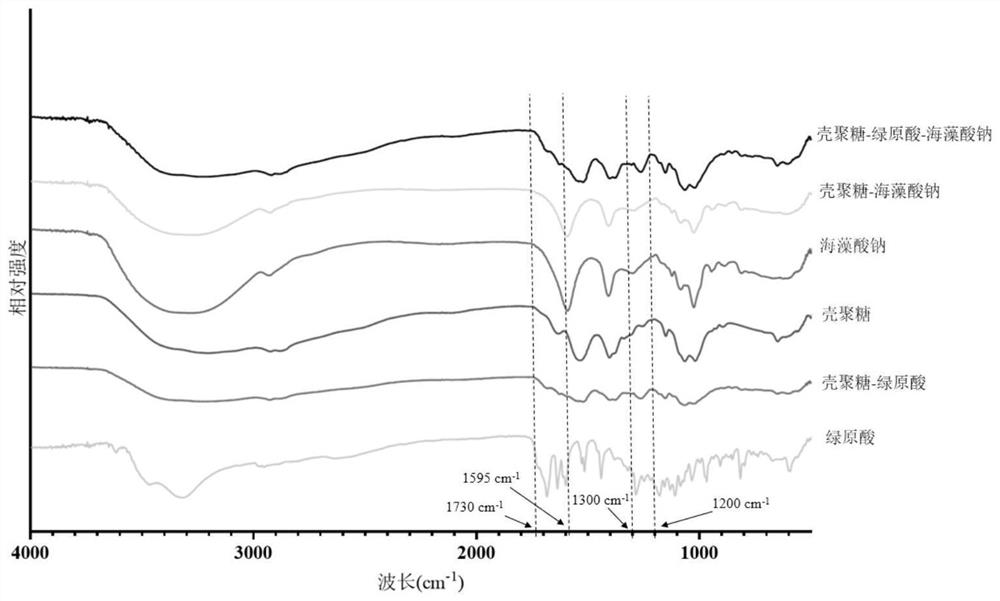

[0024] The preparation of anti-corrosion preservative film (chitosan-chlorogenic acid-sodium alginate film), the steps are as follows:

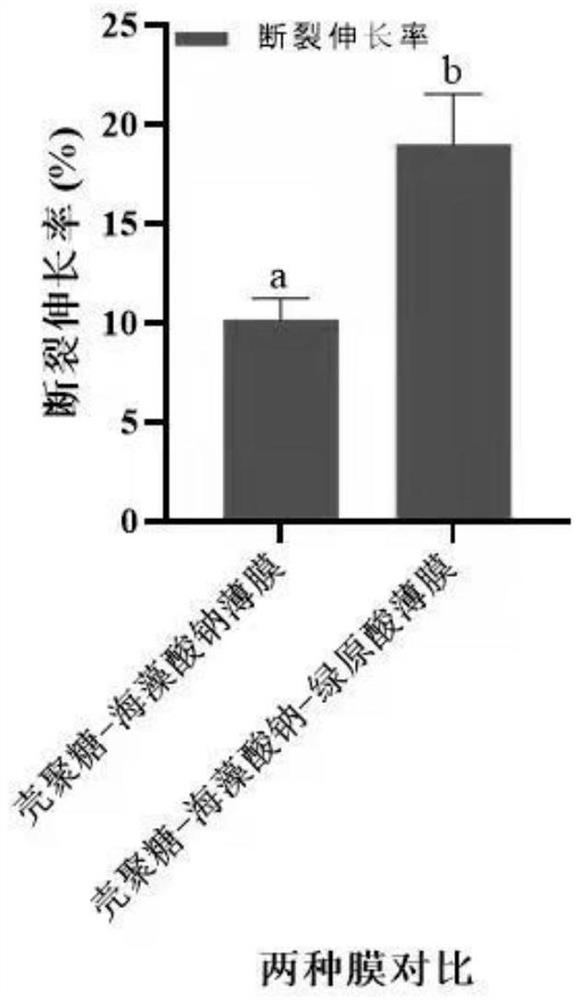

[0025] Weigh 2 g of chitosan powder, slowly add it into 100 mL of acetic acid solution (concentration of 2%, V / V) under the action of a magnetic stirrer, and continue stirring for 1 h to obtain a chitosan solution. Weigh 2 g of sodium alginate powder and dissolve it in 100 mL of ultrapure water under the action of a magnetic stirrer to obtain a sodium alginate solution. Under the action of a magnetic stirrer, 1 g of glycerol was added to the chitosan solution and the sodium alginate solution, respectively. 0.6 g of chlorogenic acid powder was weighed and added to the above chitosan solution under the action of a magnetic stirrer to obtain a chitosan-chlorogenic acid mixed solution. Pour 25 mL of chitosan-chlorogenic acid mixed solution into a 150 mm disposable plate, dry it with hot air at 50°C for 1 hour, and then pour 25 mL of sodium algin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com