Biodegradable multilayer composite barrier film and preparation method thereof

A multi-layer composite and biodegradable technology, applied in the field of plastics, can solve the problems of reducing the excellent barrier properties of PVA, making the molecular aggregation structure less compact, reducing the crystallinity of PVA, etc., achieving uniform and fine thickness, improving water resistance, and improving The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

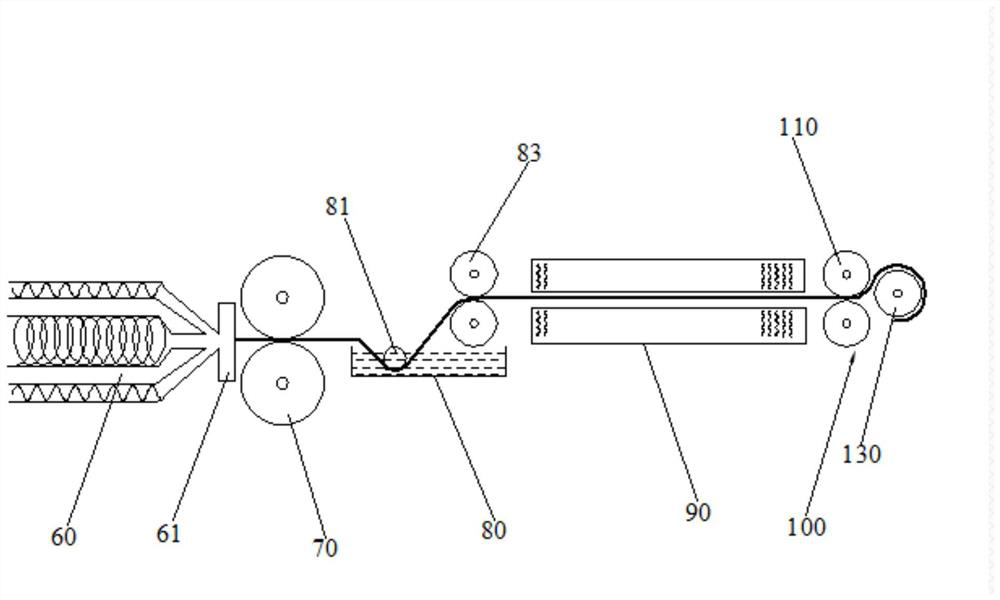

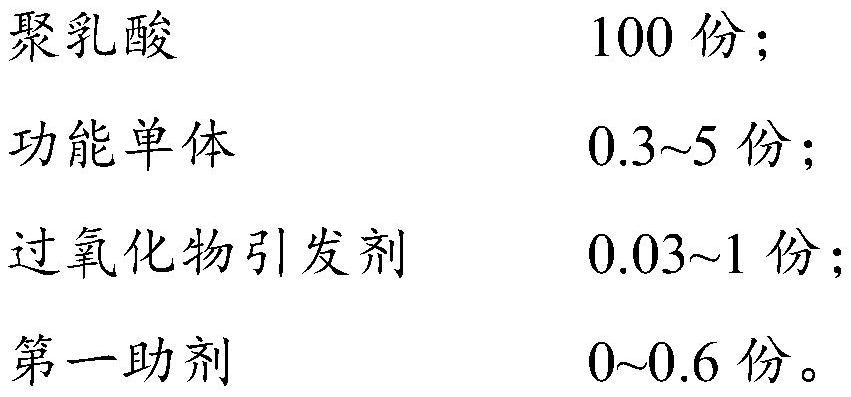

[0023] The preparation method of the polylactic acid modified by the active group comprises: mixing the polylactic acid, the functional monomer, the peroxide initiator and the auxiliary agent uniformly at high speed according to the formula amount, melt extruding and granulating in the extruder, After drying, functional monomer-grafted polylactic acid can be obtained.

[0024] The preparation raw material of polyvinyl alcohol solution comprises in weight parts:

[0025] 100 parts of deionized water;

[0026] 5-30 parts of PVA resin;

[0027] The second auxiliary agent 0-0.2 parts.

[0028] Wherein, the content of PVA resin can be but not limited to be 5 parts, 7 parts, 10 parts, 15 parts, 20 parts, 25 parts, 30 parts, and the alcoholysis degree of PVA resin is 80~99%, preferably 83~95% %, more preferably 88% to 93%.

[0029] The content of the second auxiliary agent can be but not limited to 0 part, 0.05 part, 0.1 part, 0.15 part, 0.2 part, and it can be a co-solvent and / o...

Embodiment 1

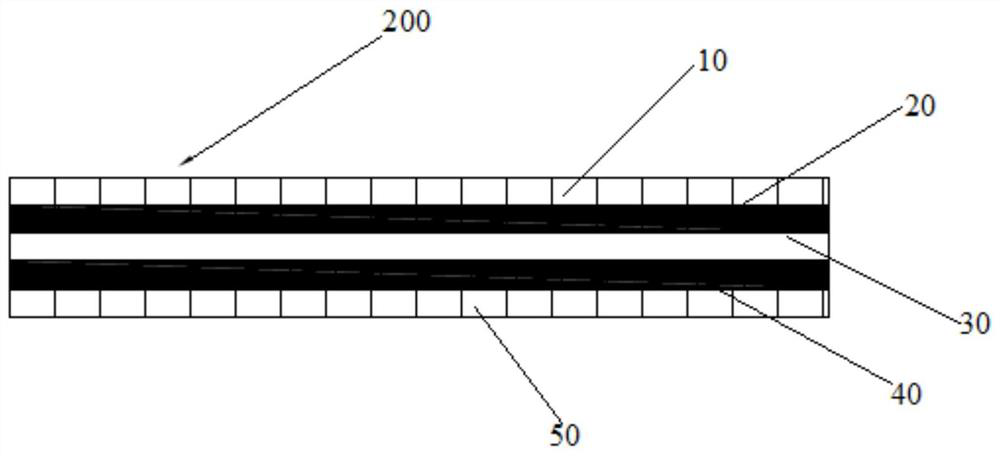

[0037] A biodegradable multilayer composite barrier film, comprising a base layer, an adhesive layer on both sides of the base layer, and a barrier layer located on the side of the adhesive layer away from the base layer, the base layer is made of polyadipate terephthalate Butylene formate, the material of the adhesive layer is polylactic acid grafted and modified by vinyltrimethoxysilane, and the barrier layer is formed by drying polyvinyl alcohol solution on the adhesive layer.

[0038] Among them, the preparation method of the polylactic acid grafted and modified by vinyltrimethoxysilane is as follows: 100g of polylactic acid is calculated, and 2g of vinyltrimethoxysilane and 0.1g of dicumyl peroxide are added to the polylactic acid. Mix evenly at high speed, melt and extrude in an extruder, granulate, and then dry to obtain polylactic acid grafted and modified by vinyltrimethoxysilane.

[0039] The preparation method of polyvinyl alcohol solution is: add deionized water 10...

Embodiment 2

[0044] The biodegradable multilayer composite barrier film comprises a base layer, an adhesive layer located on both sides of the base layer, and a barrier layer located on the side of the adhesive layer away from the base layer, the base layer is made of polylactic acid, and the adhesive layer The material is polylactic acid grafted and modified by vinyltrimethoxysilane, and the barrier layer is formed by drying polyvinyl alcohol solution on the adhesive layer.

[0045] Among them, the preparation method of the polylactic acid grafted and modified by vinyltrimethoxysilane is as follows: 100g of polylactic acid is calculated, and 2g of vinyltrimethoxysilane and 0.1g of dicumyl peroxide are added to the polylactic acid. Mix evenly at high speed, melt and extrude in an extruder, granulate, and then dry to obtain polylactic acid grafted and modified by vinyltrimethoxysilane.

[0046] The preparation method of polyvinyl alcohol solution is: add deionized water 100g in the dissolvi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com