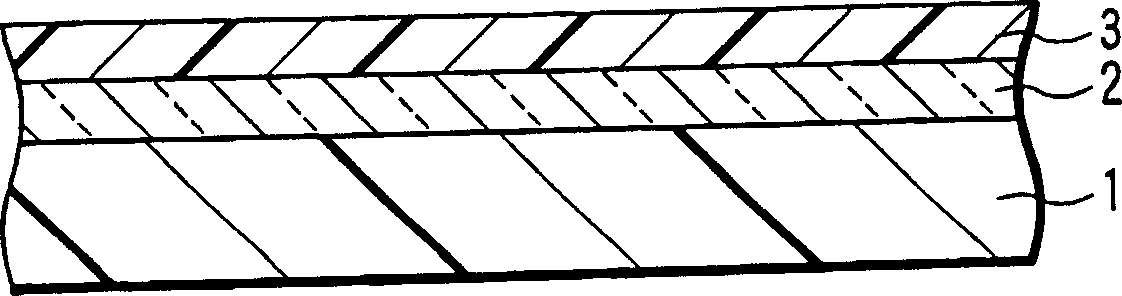

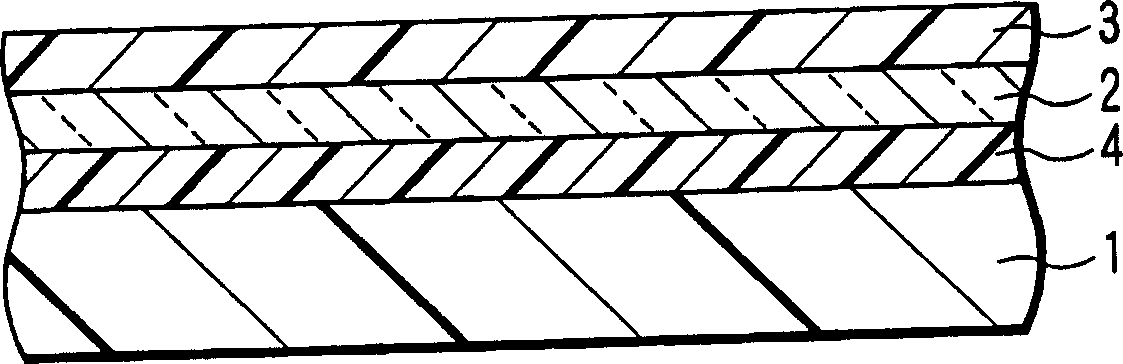

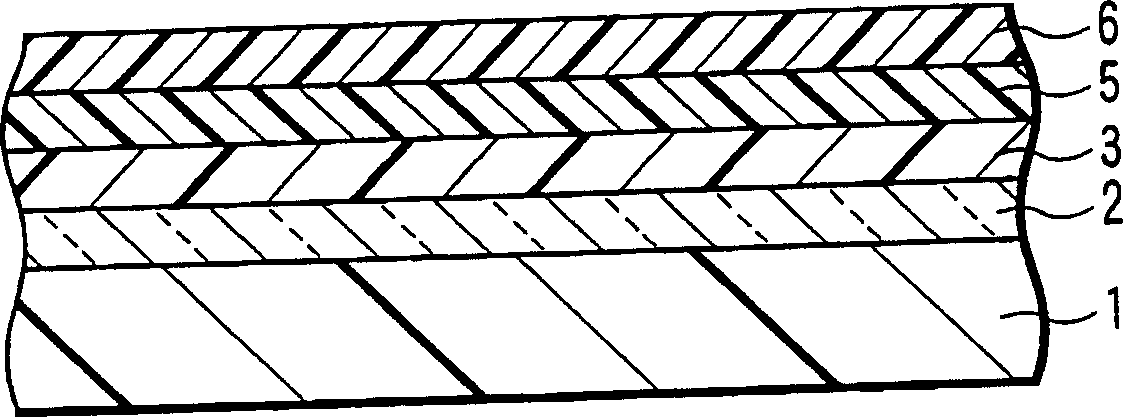

Gas barrier laminate film

A gas-barrier layer and film technology, applied in the direction of coating, layered products, etc., can solve the problems such as the inability to visually identify the contents of the package, the inability to use metal detectors, and the easy degradation of the gas barrier properties of the covering layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0067] Using biaxially oriented PET (P60; Toray Co., Ltd.) with a thickness of 12 μm and a corona-treated surface as a substrate, aluminum was thermally deposited on the corona-treated surface by an electron beam heating system using an aluminum evaporation source. In this case, the evaporation of aluminum was adjusted while adding oxygen to obtain a predetermined film composition, thereby forming a vapor-deposited layer of aluminum oxide with a thickness of 150 angstroms. The thin film composition of the aluminum oxide vapor-deposited layer including aluminum and oxygen was determined using an X-ray photoelectron spectroscopic analyzer (ESCA) (JPS-90SXV; Nippon Denshi Co., Ltd.) and by argon etching according to the Depth Profiling method, consisting of This was adjusted and the following film composition was obtained.

Embodiment 1-5、8

[0068] Examples 1-5, 8, comparative example; Al:O=1:1.8

Embodiment 6

[0069] Example 6; Al:O=1:1.0

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com