Fabric processing technique

A processing technology and fabric technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of human skin damage, chemical gas barrier and other problems, achieve good softness, reduce the possibility of mildew, and good gas barrier properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

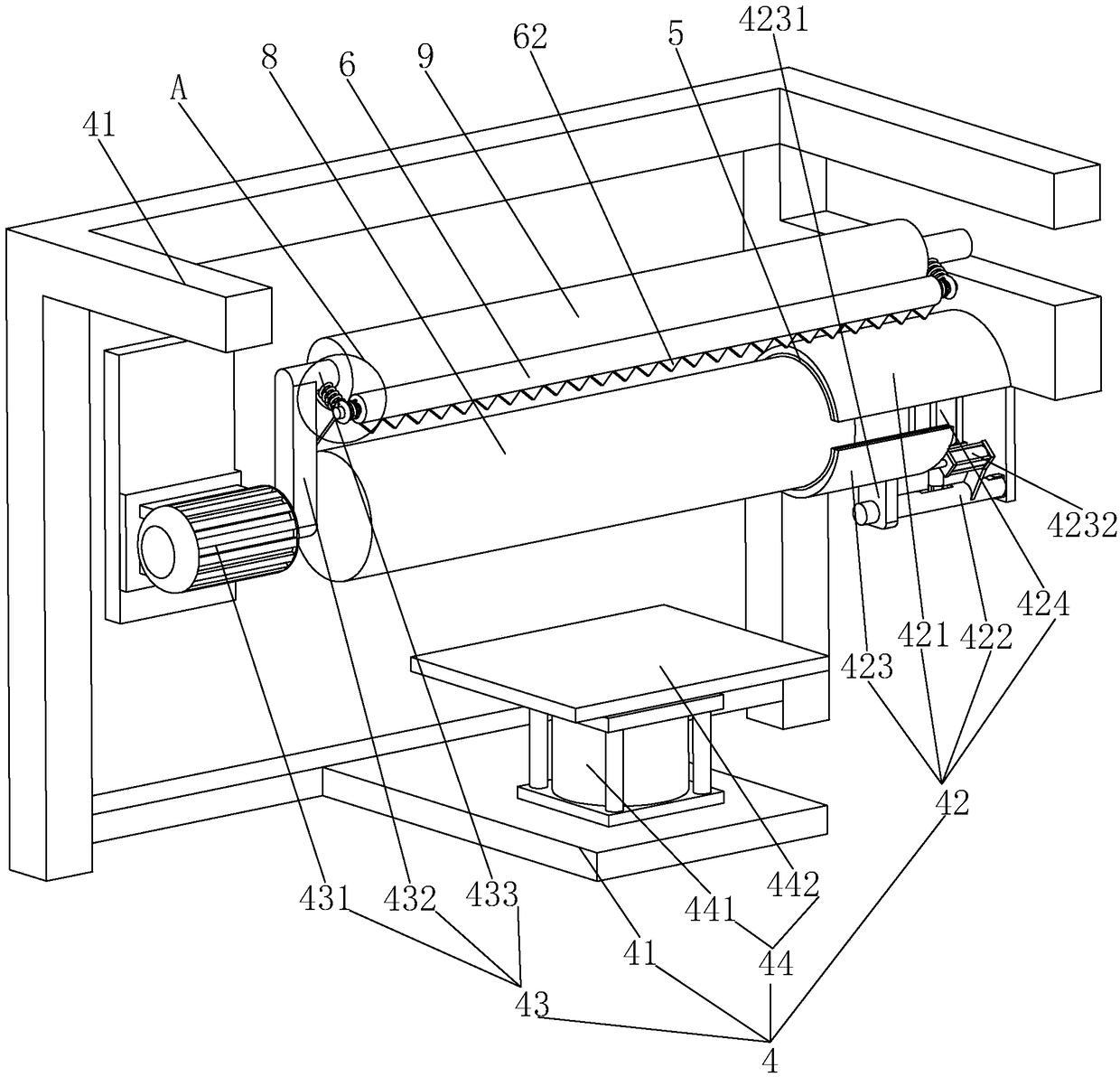

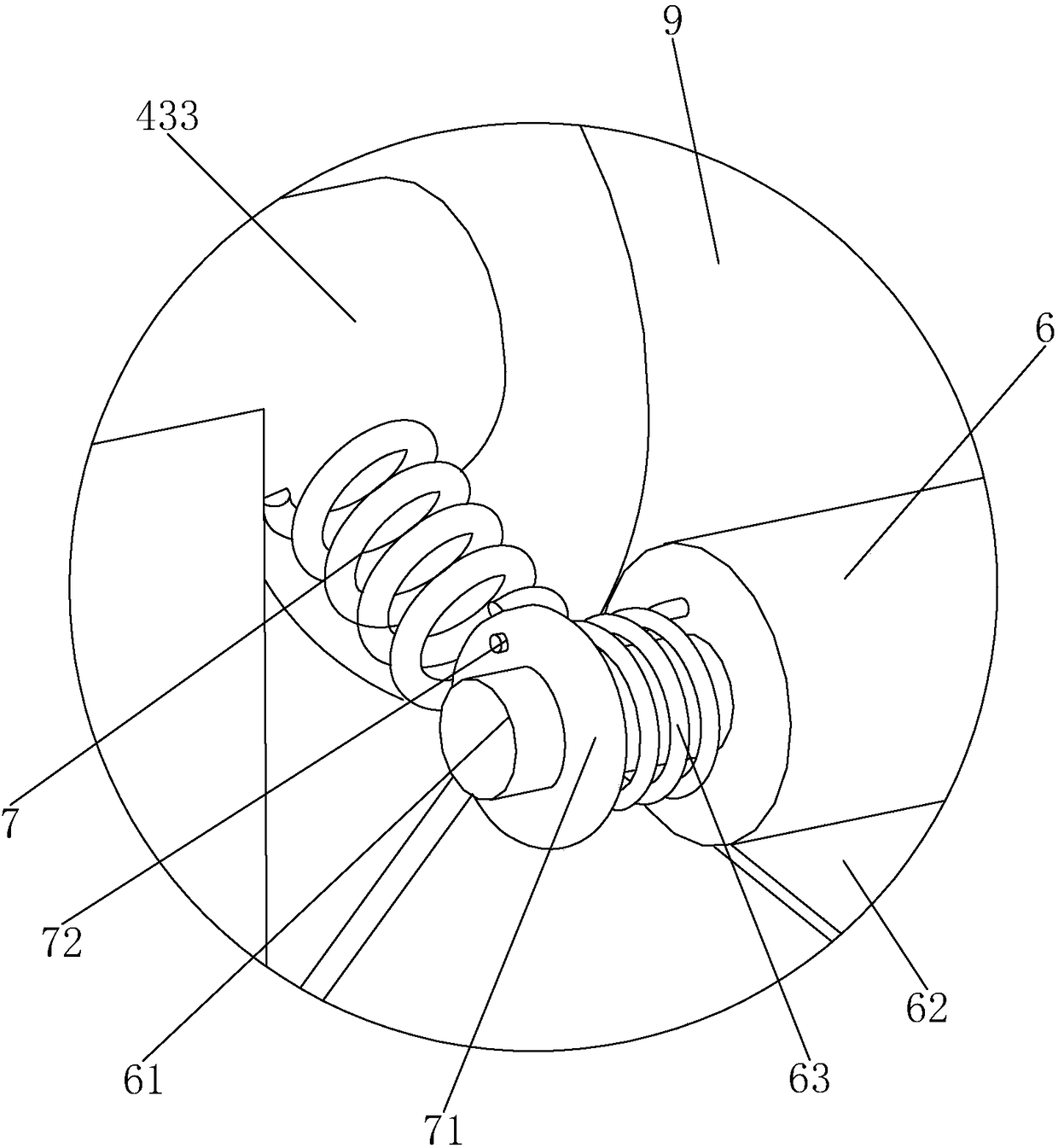

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0043] A kind of fabric processing technique, the processing technique of this kind fabric comprises the following steps:

[0044] Step 1: Winding, first use the winding machine to make the warp and weft into twisted bobbins;

[0045] Step 2: Warping, the warp and weft on the twisted package are made into warp beams through the warping machine according to the requirements of the warping process;

[0046] Step 3: sizing, the warp threads and weft threads on several warp beams are simultaneously drawn out through the sizing machine, immersed in the size liquid, pressed to remove the excess liquid, and dried;

[0047] Step 4: reeding, carry out reeding operation;

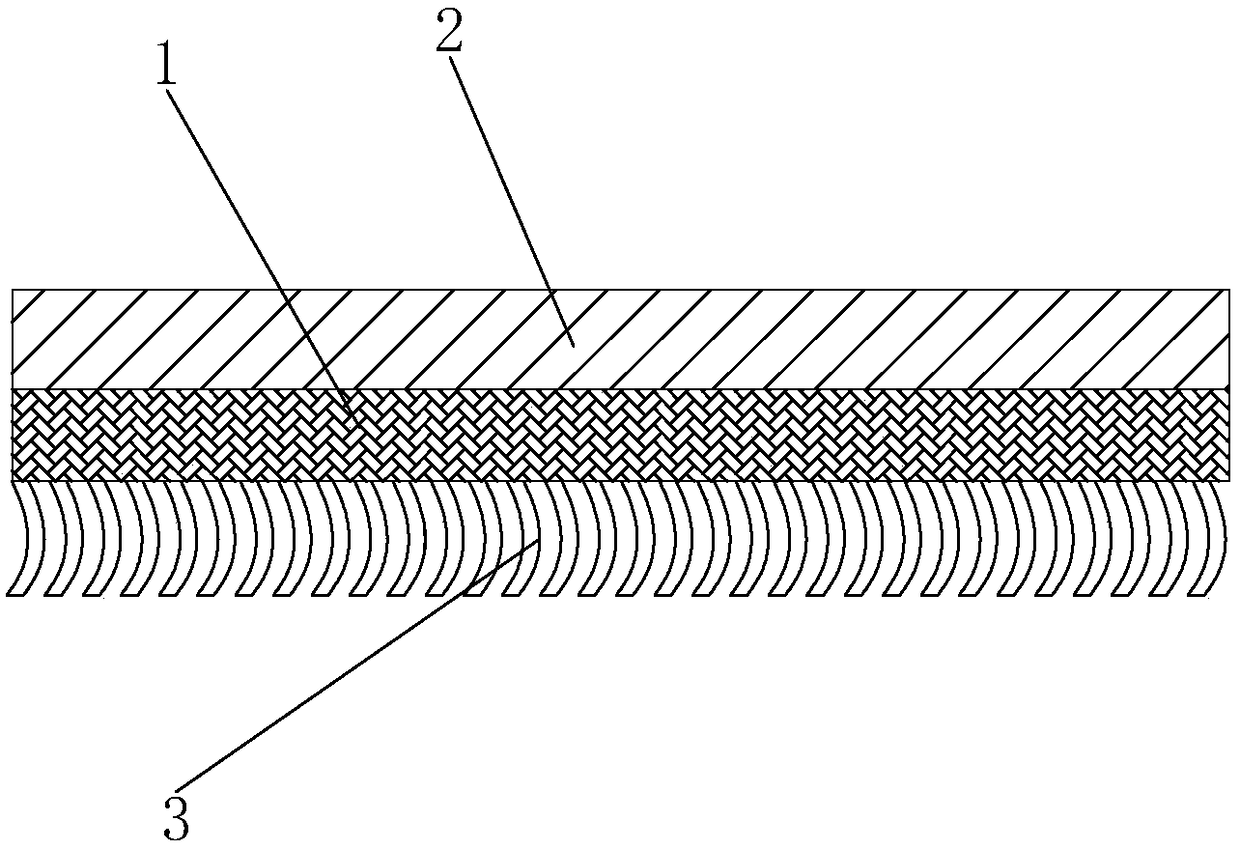

[0048] Step 5: Weaving, weaving the base fabric 1 through a large circular machine (refer to figure 1 );

[0049] Step 6: Composite, refer to figure 1 , the high-barrier film 2 is compounded on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com