Patents

Literature

287results about How to "Fully soaked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

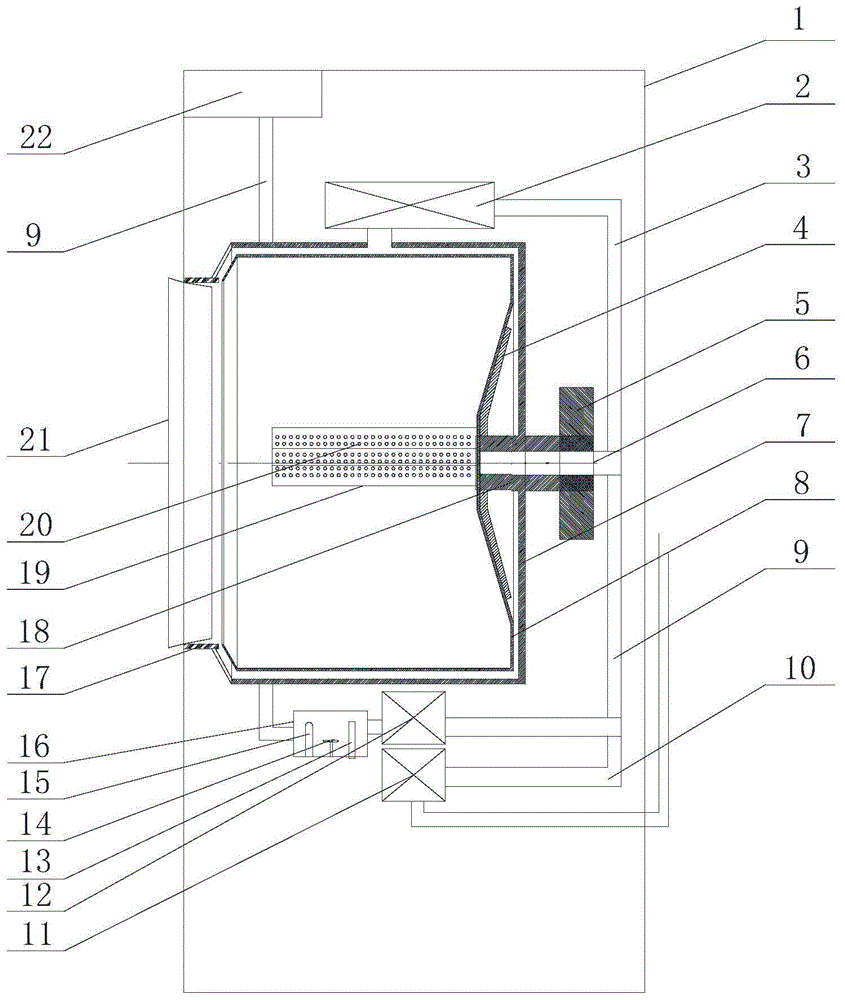

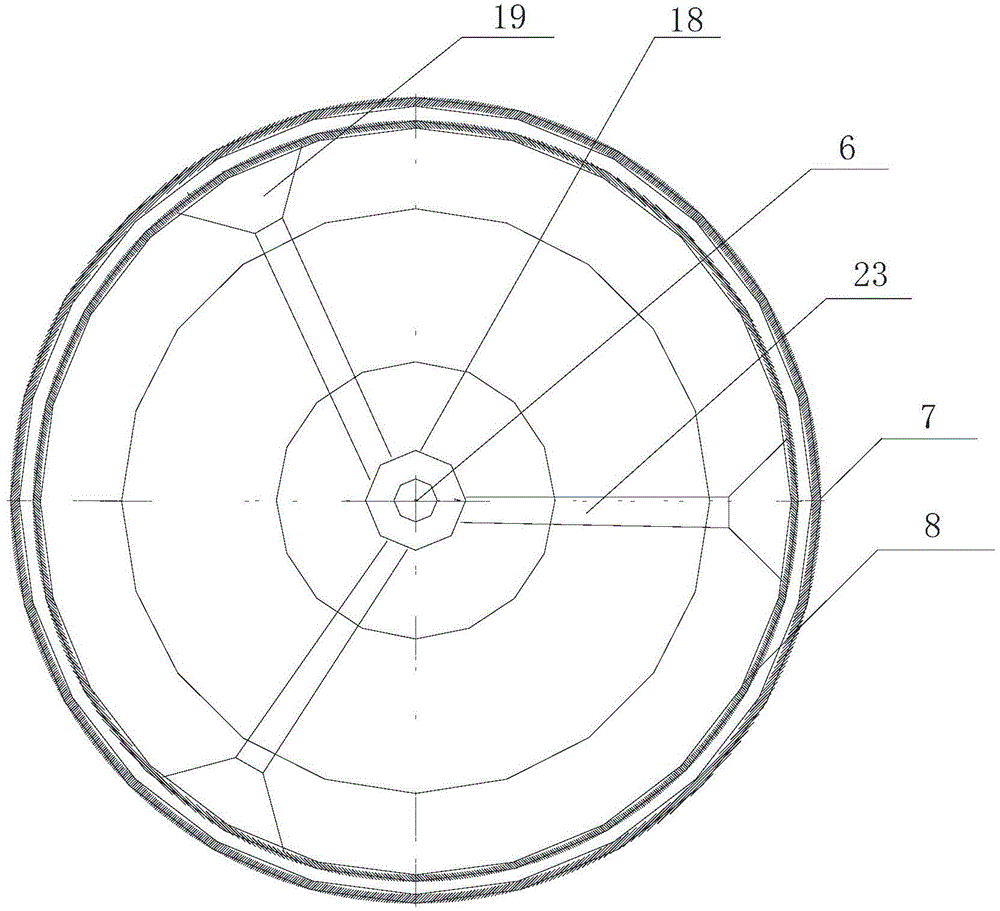

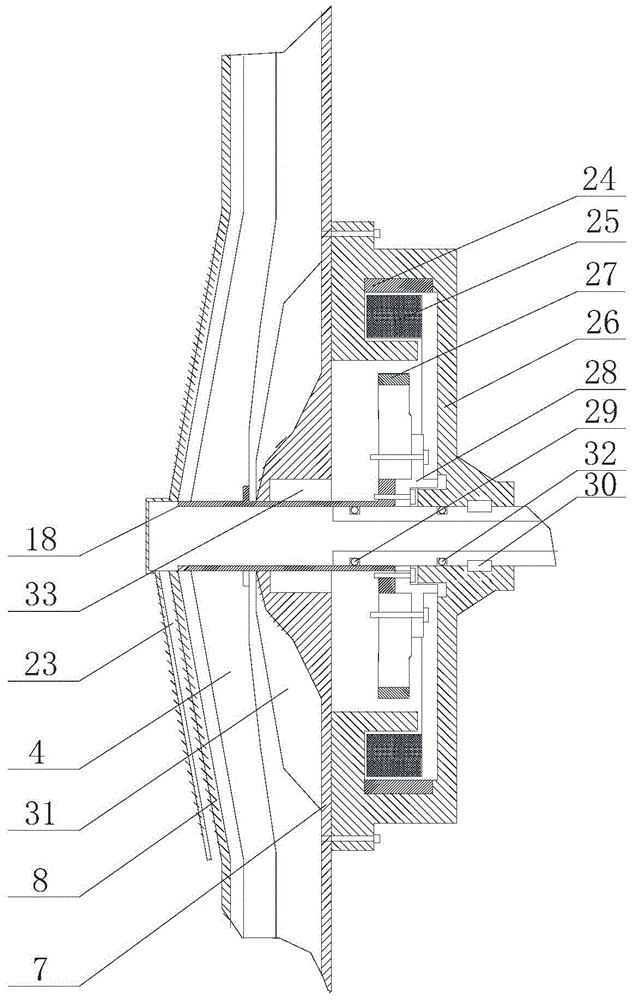

A water-saving drum washing machine

ActiveCN105696248AReduce the amount of waterRealize the purpose of saving waterOther washing machinesWashing machine with receptaclesWater savingMechanical engineering

The invention provides a water-saving drum washing machine comprising an outer drum, an inner drum disposed in the outer drum and a water inlet pipeline communicating with the inner drum. The inner drum and the outer drum are installed on a central shaft coaxially. The inner drum is a holeless inner drum. The inner wall of the inner drum is provided with a plurality of lifting devices; the central shaft is internally provided with a hollow structure; the water inlet pipeline and the lifting devices communicate with the hollow structure. The lifting devices are provided with a plurality of water outlets. The technical objective of saving water is mainly achieved by using the holeless inner drum and making the space between the inner drum and the outer drum free of water in a washing process. Since the holeless inner drum is used, the structure of the water-saving washing machine is redesigned for water feeding and water drainage of the washing machine; further a water feeding and drainage system, a washing and spinning system and an airing drying and drying system are improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

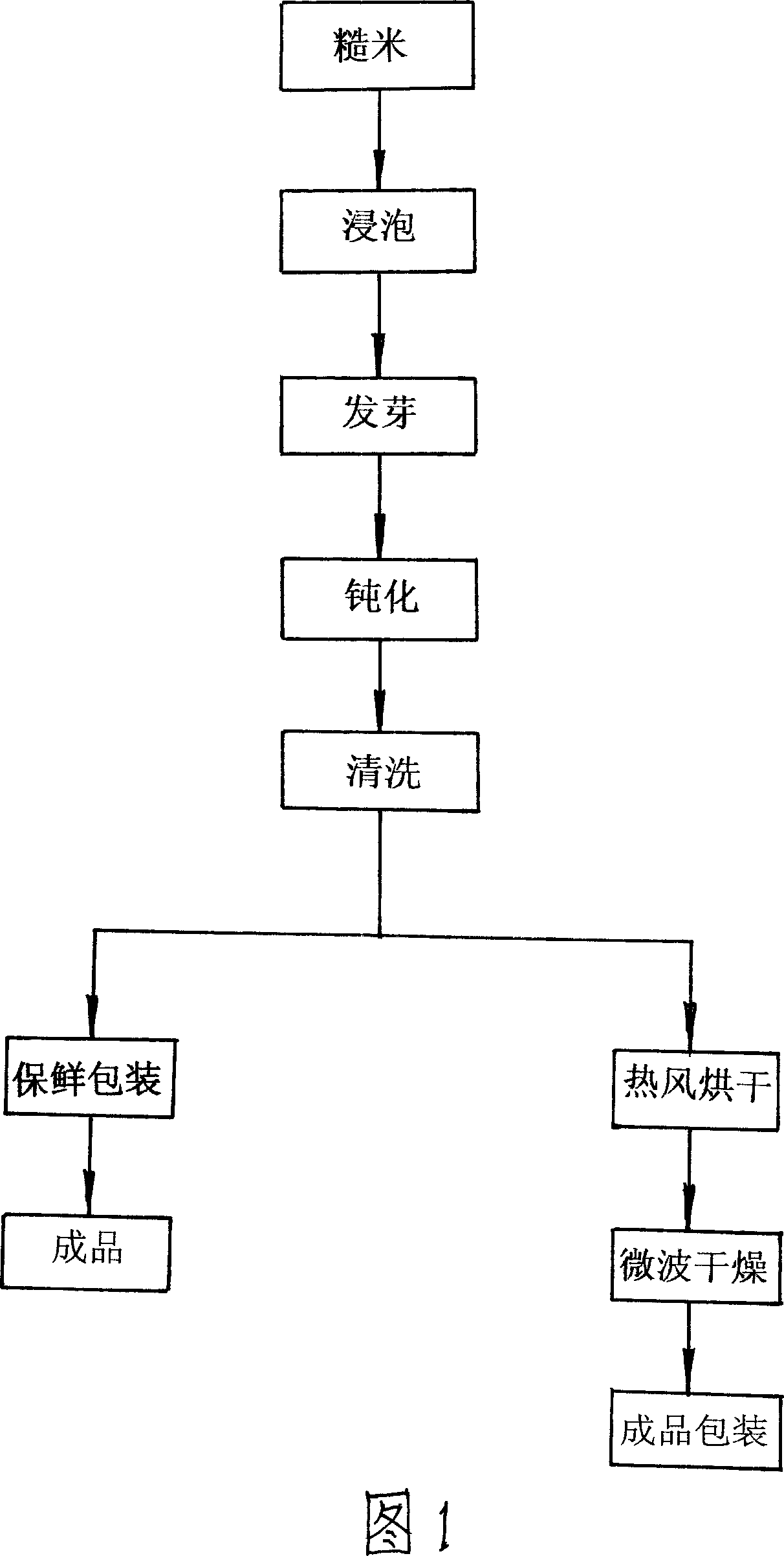

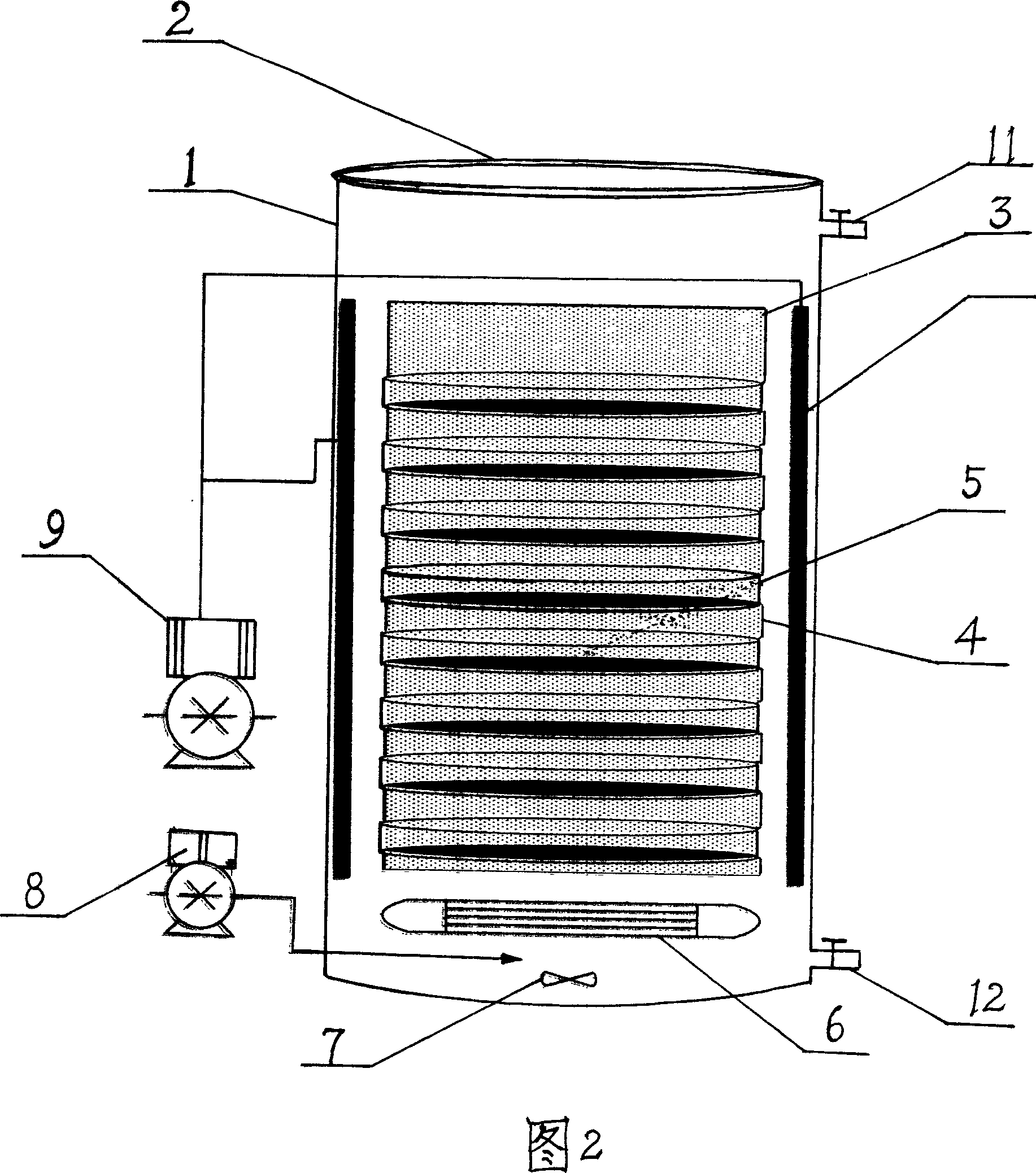

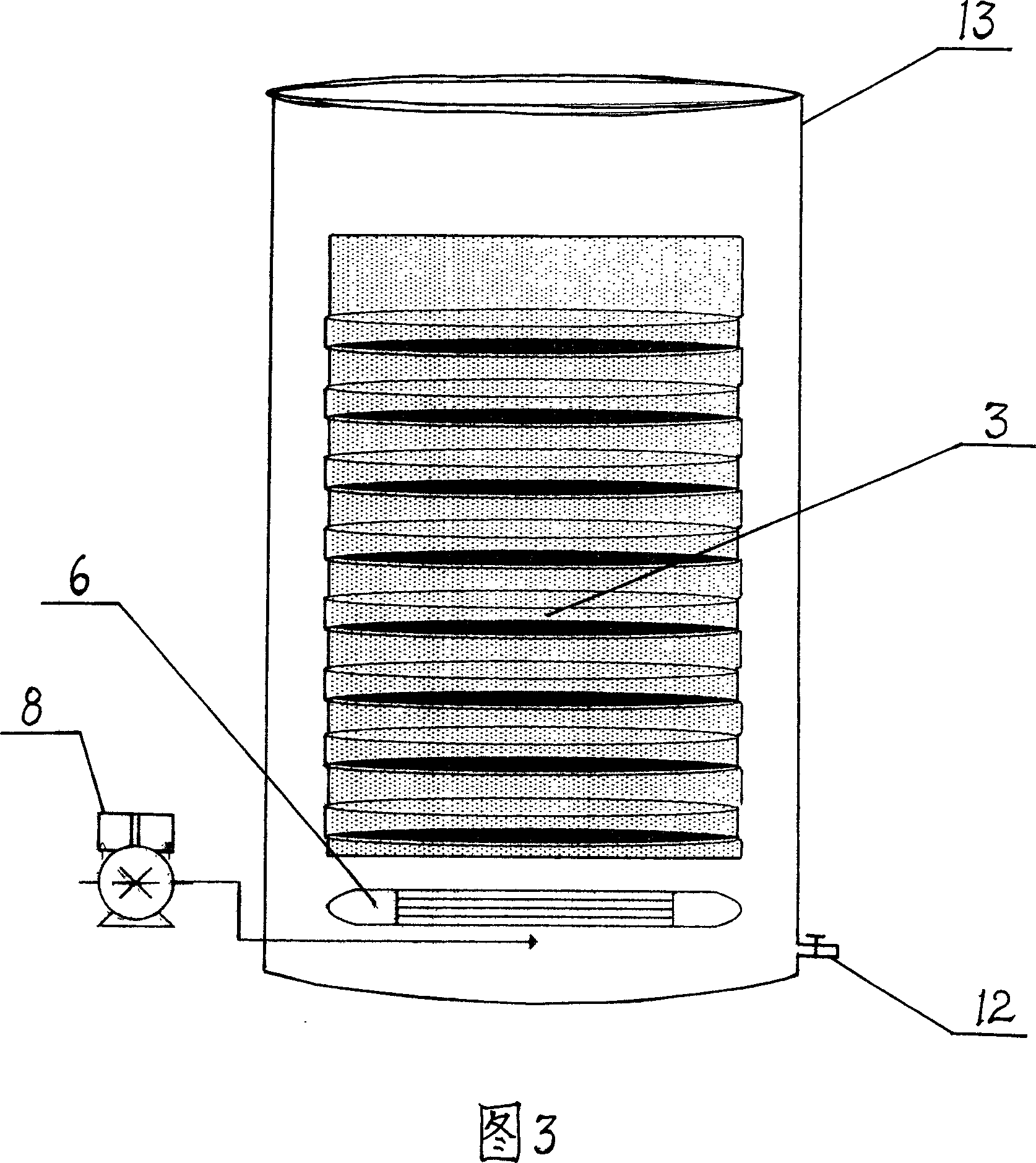

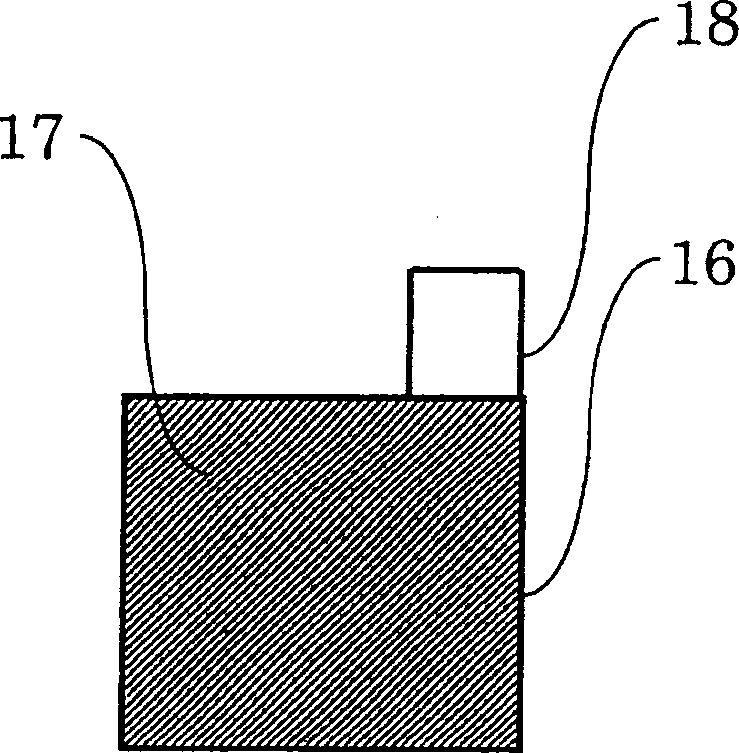

Method and equipment for producing sprouting half-polished rice

ActiveCN100998389AImprove whole bud rateHigh whole germination rateSeed preservation by heatingSeed preservation by dryingMicrowaveThin layer

A method for preparing the germinated embryo rice from non-glutinous rice includes such steps as spreading said rice to become thin layer, immersing in water, germinating, passivating in the water at 70-100 deg.C, washing, and antistaling packing or drying including hot air baking and microwave drying. Its apparatus is composed of container with openable cover or door, and rice spreading unit.

Owner:杨春华

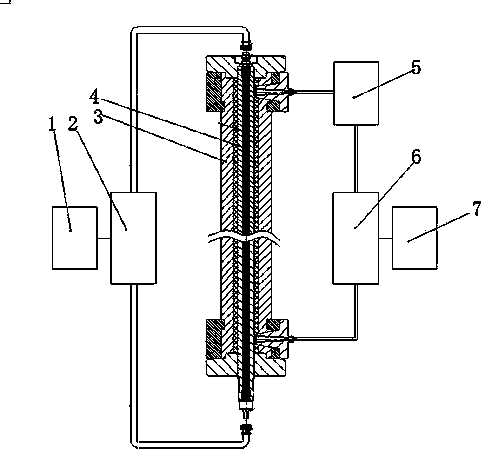

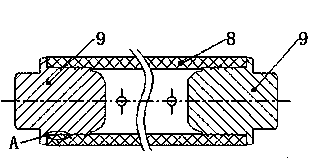

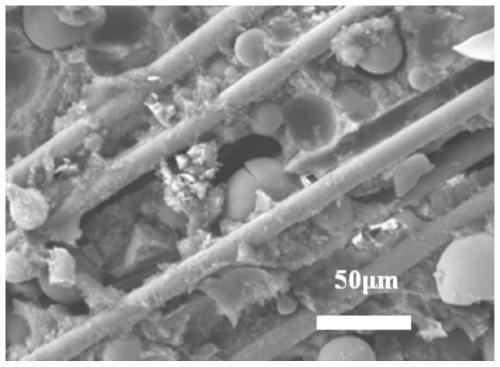

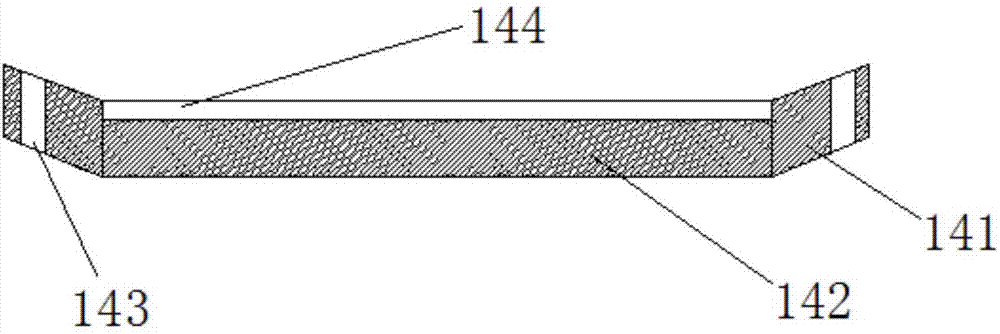

Production process of insulation pull rod

The invention discloses a production process of an insulation pull rod. The production process comprises an insulation pipe blank pipe curing and molding phase, an insulation pipe blank pipe machining phase and a connector bonding phase, wherein in the insulation pipe blank pipe curing and molding phase, fiber materials are dried in vacuum; resin is impregnated under a vacuum environment and the fiber materials are subjected to primary curing; after de-molding, the fiber materials are subjected to secondary curing to obtain an insulation pipe blank pipe; the insulation pipe blank pipe is machined; the insulation pipe blank pipe is bonded with a connector by adopting a heat-expansion and cold-contraction principle; and finally, the insulation pull rod is obtained. According to the production process of the insulation pull rod, the technical defects of a production process of the insulation pull rod that air gaps, micro-cracks, concentrated stress and layering are easy to generate, the connection of the connector is not reliable, the air gaps are easy to generate in a bonding layer of the connector and the insulation pipe and the like are overcome.

Owner:MOTIC XIAMEN ELECTRIC GRP

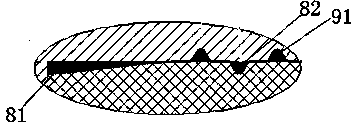

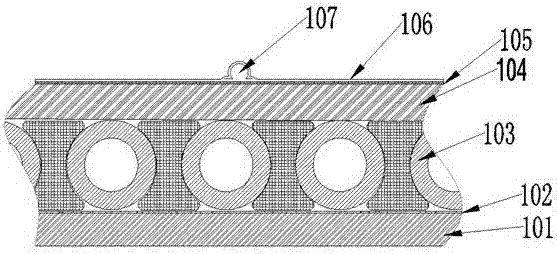

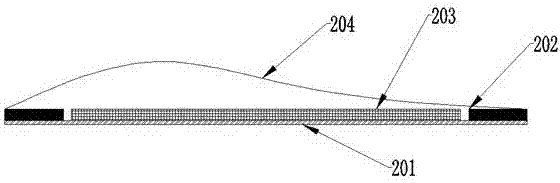

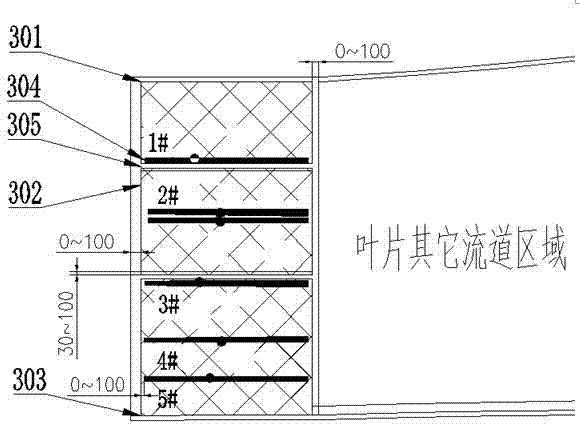

Blade root pouring method for bolt sleeve embedded blade

The invention discloses a blade root pouring method for a bolt sleeve embedded blade. The method comprises the die cavity preparing step; and lower glass fiber laying, continuous felt laying, embeddedpart laying, upper glass fiber laying, flow guide net laying, glue injecting pipe laying, air exhaust bag laying and glue pouring are carried out. A continuous felt is placed on the lower face of thebottom of an embedded part, a first flow guide net and a glue injecting pipe are laid on the embedded part and the upper glass fiber cloth, and the distance between the starting point of the first flow guide net and the starting point of the embedded part ranges from 0 mm to 300 mm; the first flow guide net is divided into three segments including a rear edge flow guide net, a middle segment flowguide net and a front edge flow guide net in the circumference direction, and a resin deceleration belt with the width ranging from 30 mm to 150 mm is arranged among the rear edge flow guide net, themiddle segment flow guide net and the front edge flow guide net, and the glue injecting pipe is arranged in the length direction of the embedded part; and air exhaust bags are arranged at the position, above the first flow guide net, of the front edge and the rear edge of a blade root. According to the method, the problem that due to uneven resin flow speed, resin in the blade root area of an embedded blade is hollow is solved, and the blade root connecting strength can be further improved.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

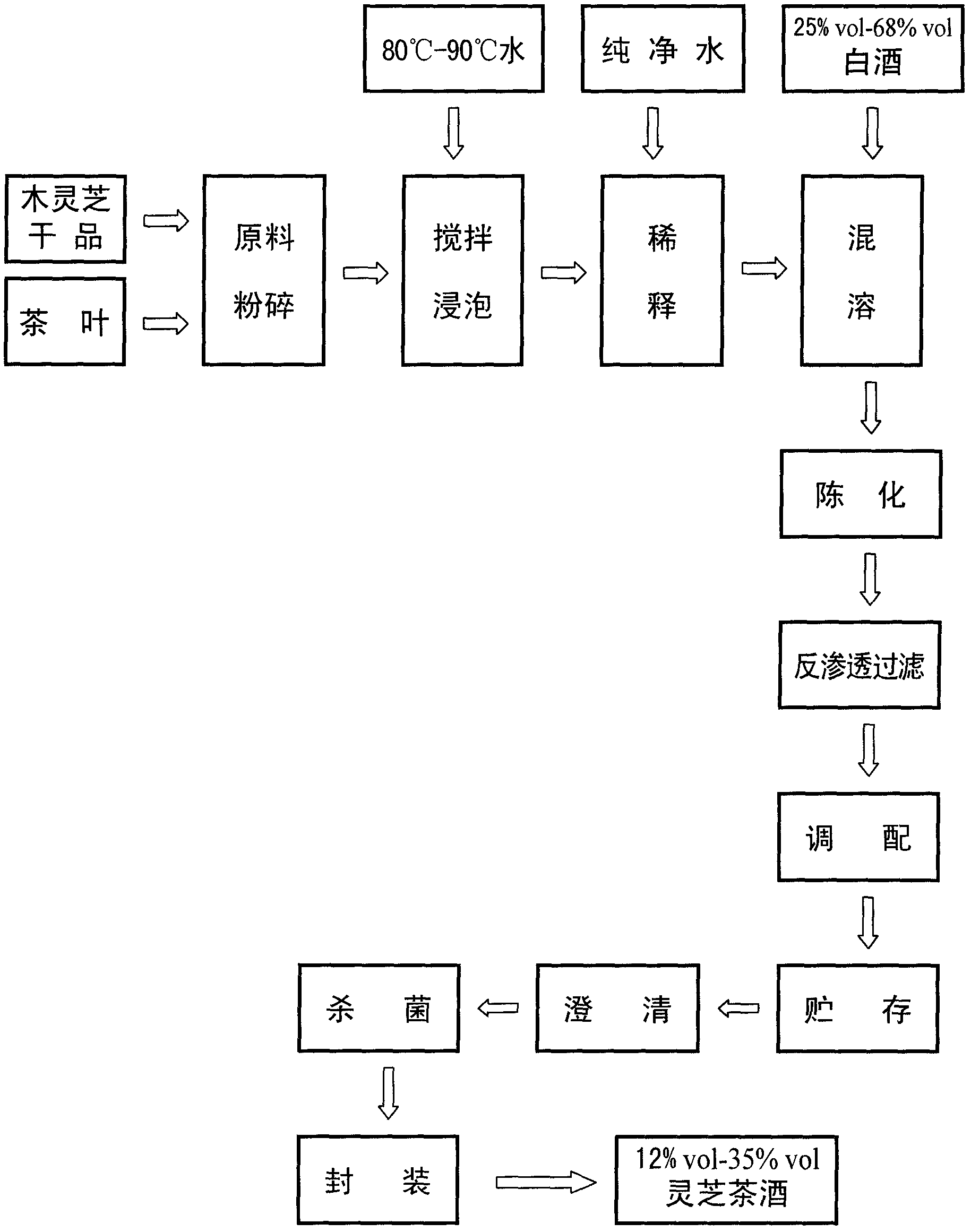

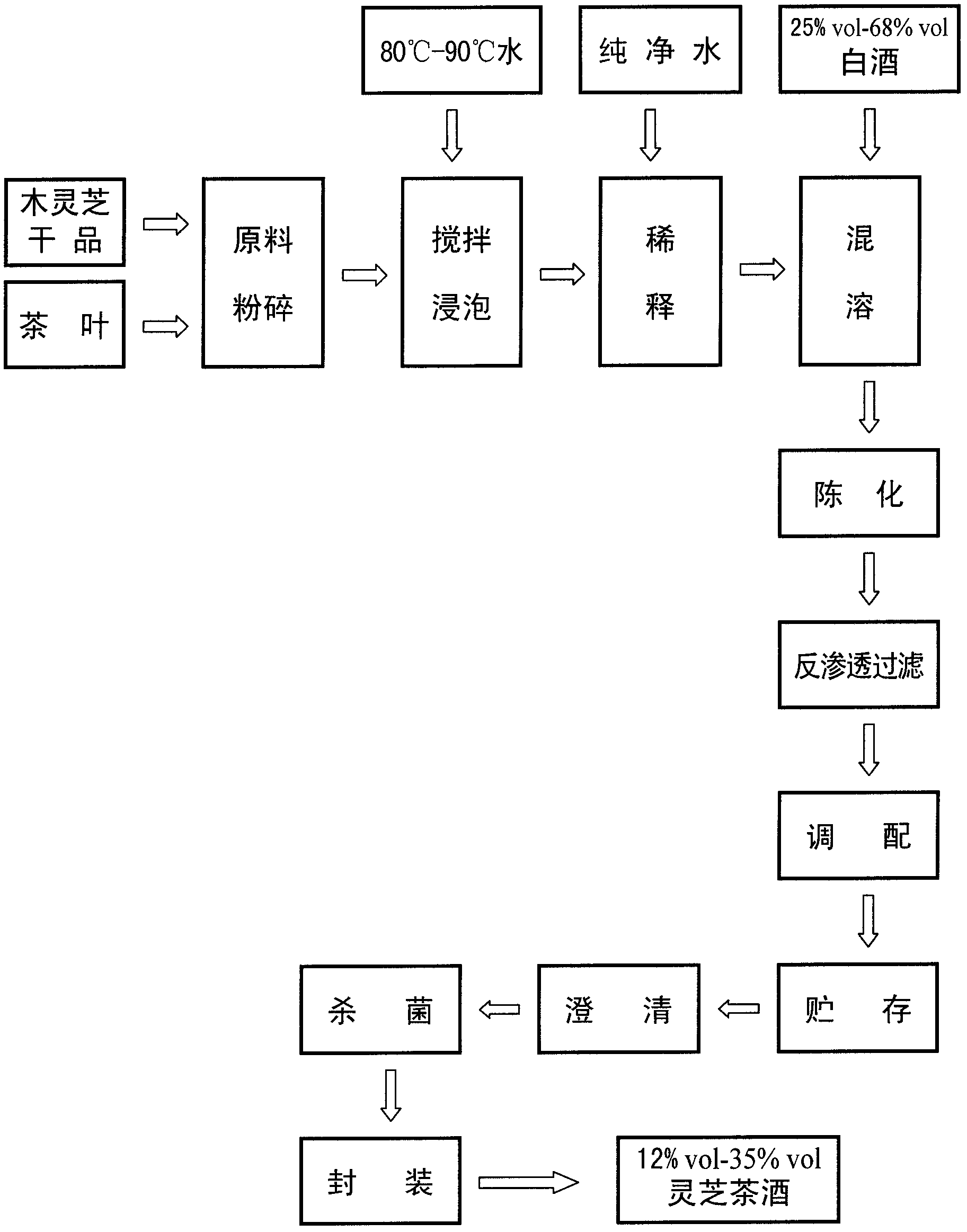

Preparation method of lucid ganoderma tea wine

InactiveCN102504990ARealize compound innovationIncrease added valueAlcoholic beverage preparationFiltrationReverse osmosis

The invention relates to a preparation method of lucid ganoderma tea wine, belonging to the production field of mixed wine. The method is characterized by comprising the following steps of: crushing the raw materials of dry wood lucid ganoderma and tea leaves to 250-177 mu m; brewing with water at 80-90 DEG C; stirring and soaking; diluting an extraction solution with purified water; adding 25-68vol% white spirit, and mixing to form a lucid ganoderma tea wine base; enabling the precipitate of the lucid ganoderma tea wine base to enter an aging storage tank, and performing water condensation, cooling and aging for 15-30 days; performing reverse osmosis filtration to obtain the supernatant, and mixing to obtain the lucid ganoderma tea wind liquid; and finally storing, clarifying, sterilizing and encapsulating the lucid ganoderma tea wine liquid to obtain the 12-35vol% lucid ganoderma tea wine. The preparation method of the lucid ganoderma tea wine can effectively permeate the functionalnutrient components in the lucid ganoderma and tea leaves into the white spirit, thereby not only improving the content of flavor matters in the white spirit, but also reducing the alcohol degree, and not only maintaining the alcohol flavor of the white spirit relatively well, but also containing the fungus fragrance of lucid ganoderma as well as the phenol fragrance of the tea leaves; and moreover, the preparation method is clean and environment-friendly.

Owner:陈进军

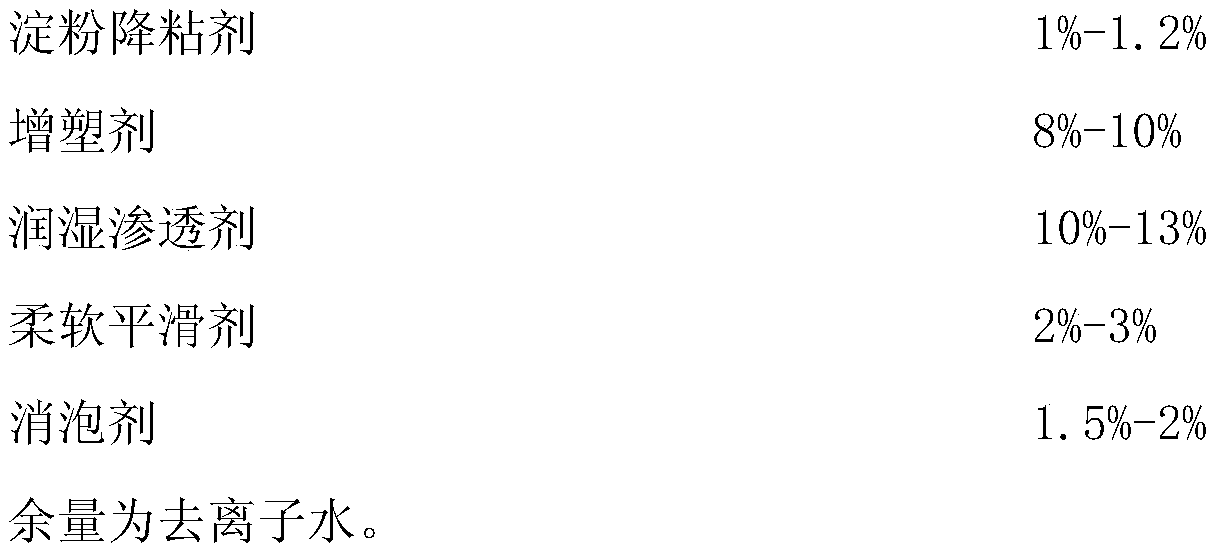

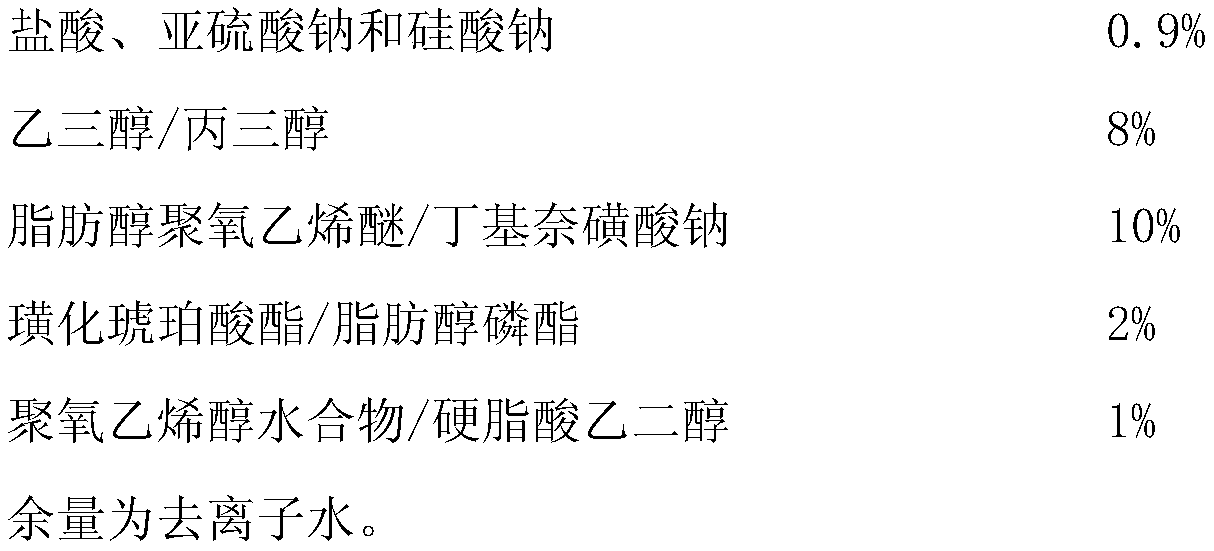

Environment-friendly sizing agent assistant, and preparation method and application of assistant

InactiveCN108004771ANo pollution in the processNot corrosiveDry-cleaning apparatus for textilesVegetal fibresPolyesterPolyvinyl alcohol

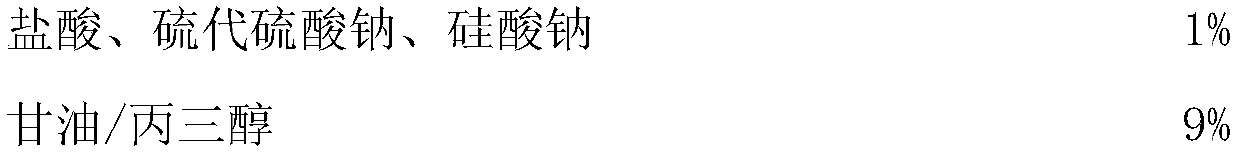

The invention discloses an environment-friendly sizing agent assistant, and a preparation method and an application of the assistant. The assistant is mainly applied to sizing of cellulose fibers or blend fibers and is characterized in that the sizing agent comprises 95-98% by mass of main material and 2-5% by mass of assistant, wherein the assistant is prepared from the following raw materials bymass percentage: 1-1.2% of starch viscosity reducer, 8-10% of plasticizer, 10-13% of wetting penetrant, 2-3% of soft smoothing agent, 1.5-2% of defoaming agent and the balance of deionized water. Theassistant is used for pure starch sizing and is applicable to the various cellulose fibers and the cotton-polyester blend fibers; no synthetic sizing agent is added; and PVA (polyvinyl alcohol)-freesizing is achieved in deed.

Owner:ZHEJIANG YUBO TEXTILE CO LTD

Waterborne aluminum paste for decorative waterborne metallic shining coating and soaking production process thereof

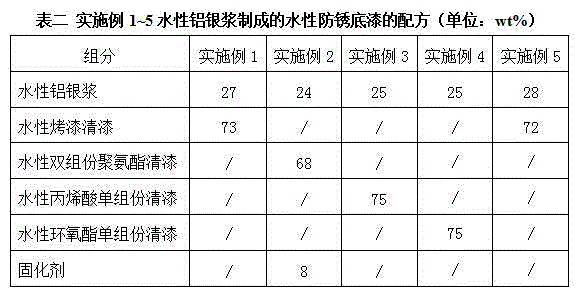

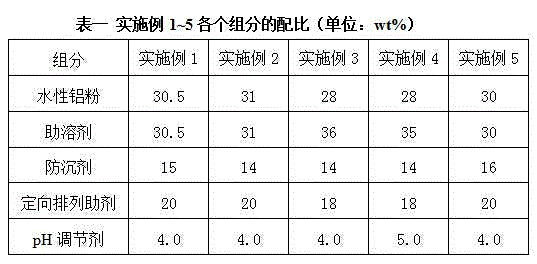

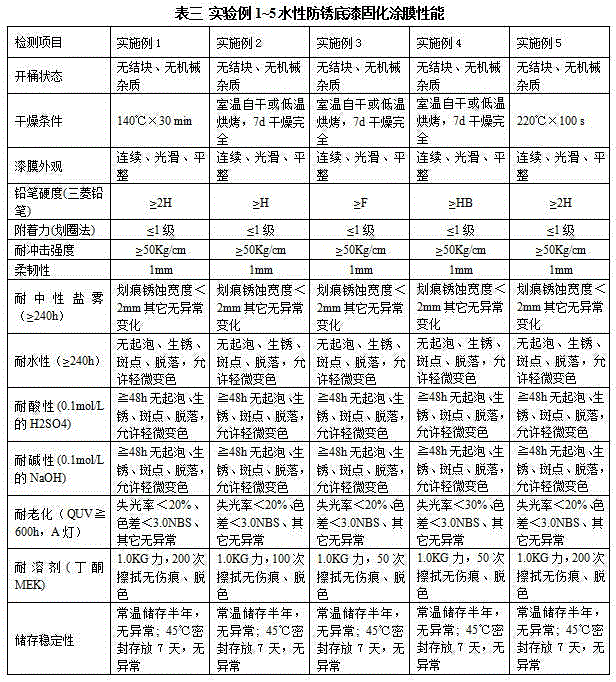

The invention discloses a waterborne aluminum paste for decorative waterborne metallic shining coating. The waterborne aluminum paste comprises the following components by mass: 25-35% of waterborne aluminum powder, 25-45% of a cosolvent, 8-18% of an anti-settling agent, 12-25% of a directional arrangement assistant, and 1-5% of a pH regulator. The invention also discloses a preparation method of the waterborne aluminum paste. The waterborne aluminum paste has stable performance during 1-2d short-term storage, can be directly added into a waterborne varnish system to reduce the product quality problem caused by poor dispersion of waterborne aluminum powder and improve the primary production qualified rate, and the operation is simple, thus being suitable for industrial mass production.

Owner:GUANGZHOU KINTE IND

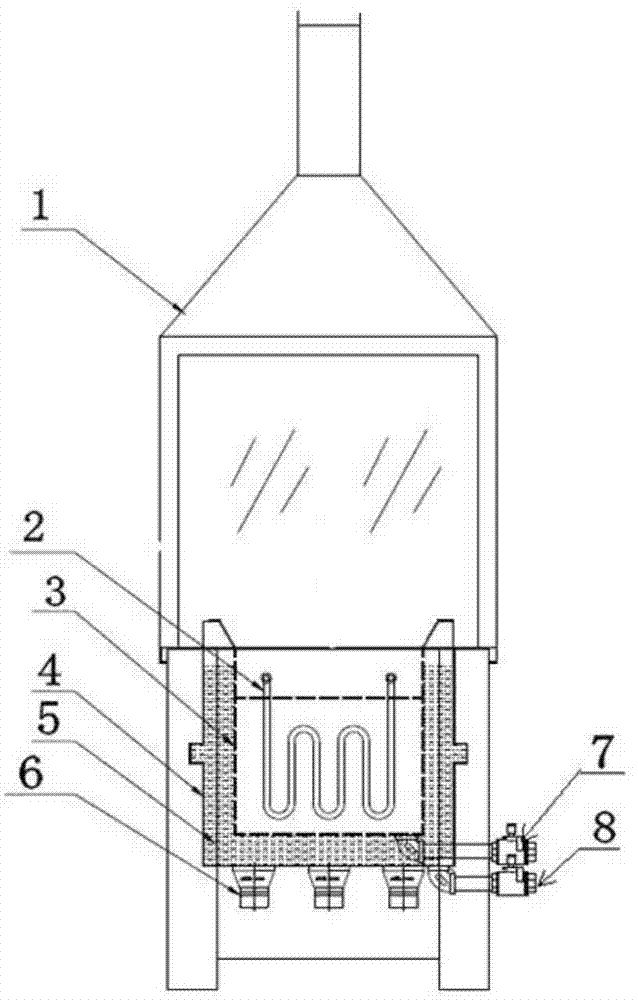

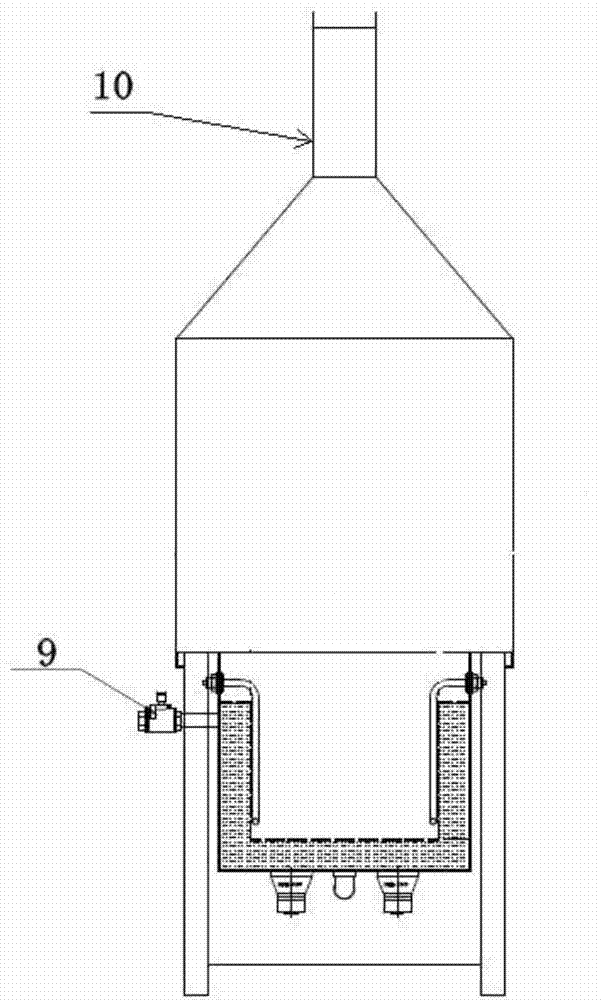

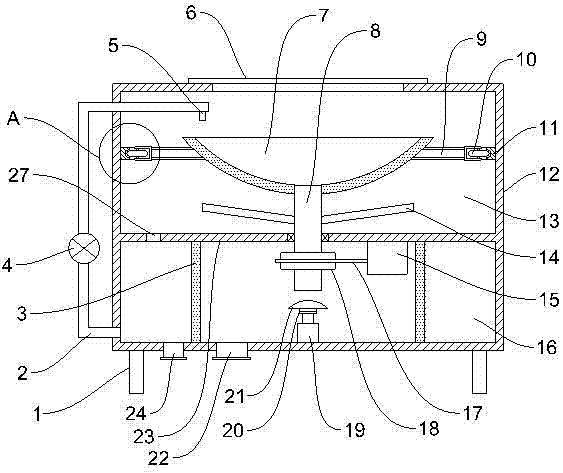

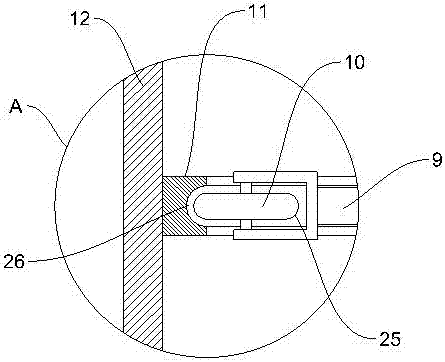

Ultrasound salt-bath composite cleaning machine

ActiveCN103042006AEfficient removalImprove cleaning qualityCleaning using liquidsUltrasonic sensorPulp and paper industry

The invention specifically discloses an ultrasound salt-bath composite cleaning machine. The ultrasound salt-bath composite cleaning machine comprises an upper part and a lower part, wherein the upper part comprises a sealing cover, and an exhaust duct communicated with the sealing cover is arranged at the top of the sealing cover; and the lower part comprises an inner groove and an outer groove, an enclosed cavity is formed between the inner groove and the outer groove, a salt exhausting hole communicated with the outside is formed in the bottom of the inner groove, a water inlet and a water outlet are formed in the bottom and the side surface of the outer groove, an electric heating pipe is arranged in the inner groove, a plurality of ultrasonic transducers are arranged at the bottom of the outer groove, and the bottom of the sealing cover is communicated with the top of the inner groove.

Owner:SHANDONG UNIV

Pulping process of high-cleanliness primary-color bamboo pulp

InactiveCN109706773AFully soakedIncrease concentrationCellulosic pulp after-treatmentPulp beating methodsFiberHigh concentration

The invention relates to the technical field of household paper, in particular to a pulping process of high-cleanliness primary-color bamboo pulp, the process comprises the following steps: fully soaking and moistening bamboo pulp, carrying out high-concentration pulping by using a high-concentration pulping machine, carrying out low-concentration grinding by using a low-concentration grinding machine, carrying out coarse screening, two-section pressure screen fine screening and grading screening treatment to obtain long-fiber pulp and short-fiber pulp, and finally, mixing 50-90% of the long-fiber pulp and 10-50% of the short-fiber pulp to prepare pulp, adding a certain amount of a softening agent and a wet strength agent, and uniformly mixing to obtain the high-cleanliness primary- colorbamboo pulp. According to the process, redundant fibrous impurities can be removed so as to ensure the paper surface cleanliness, the pulping uniformity is good, and the strength, the softness and thehand feeling of domestic paper are improved.

Owner:CHONGQING LIWEN SANITARY PAPER MFG CO LTD

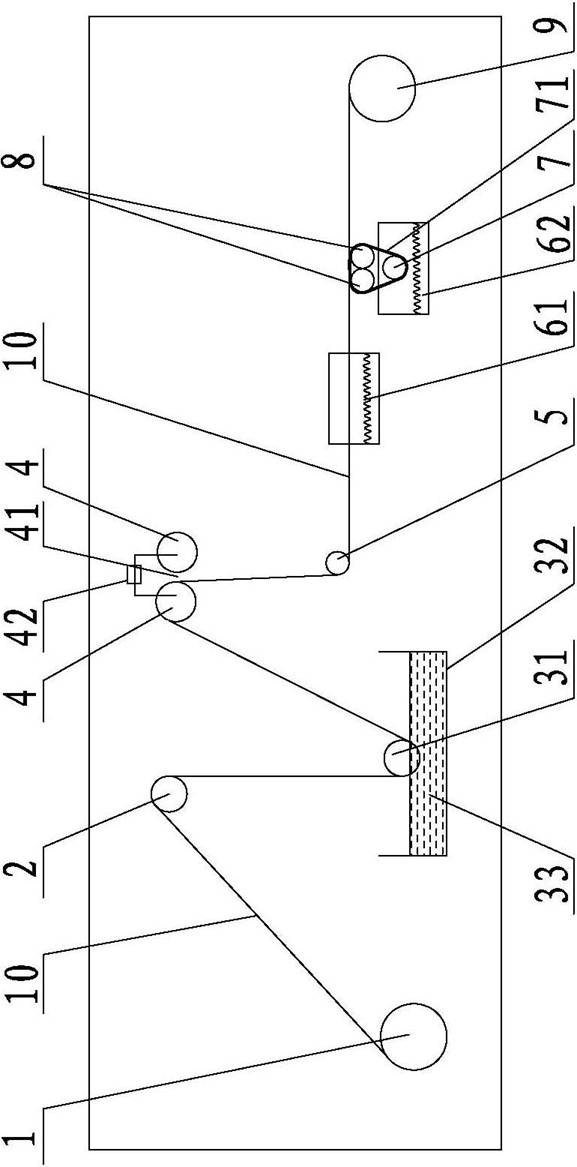

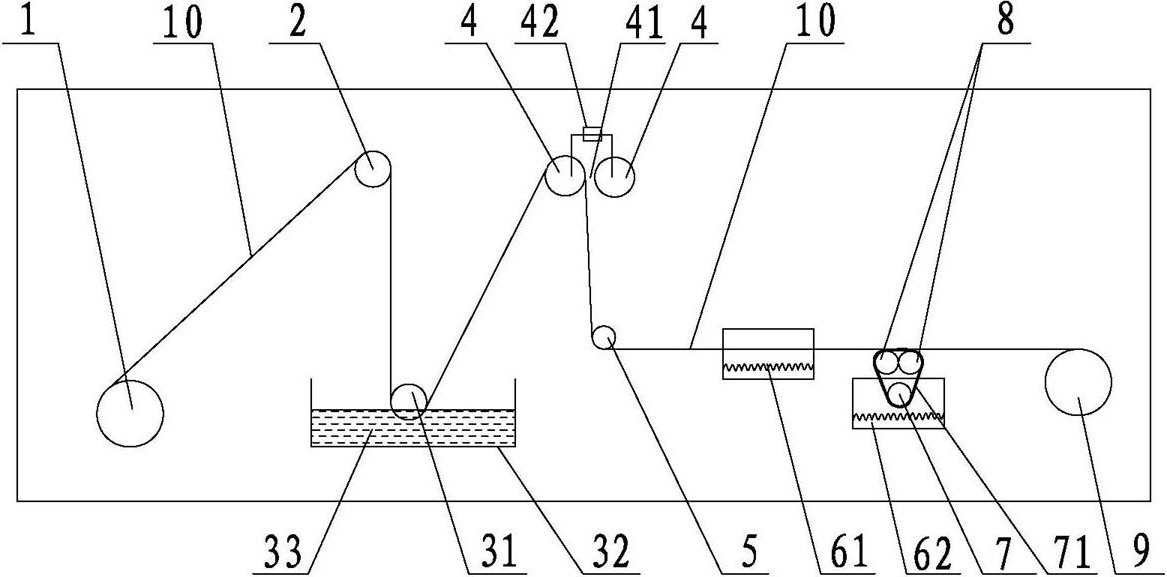

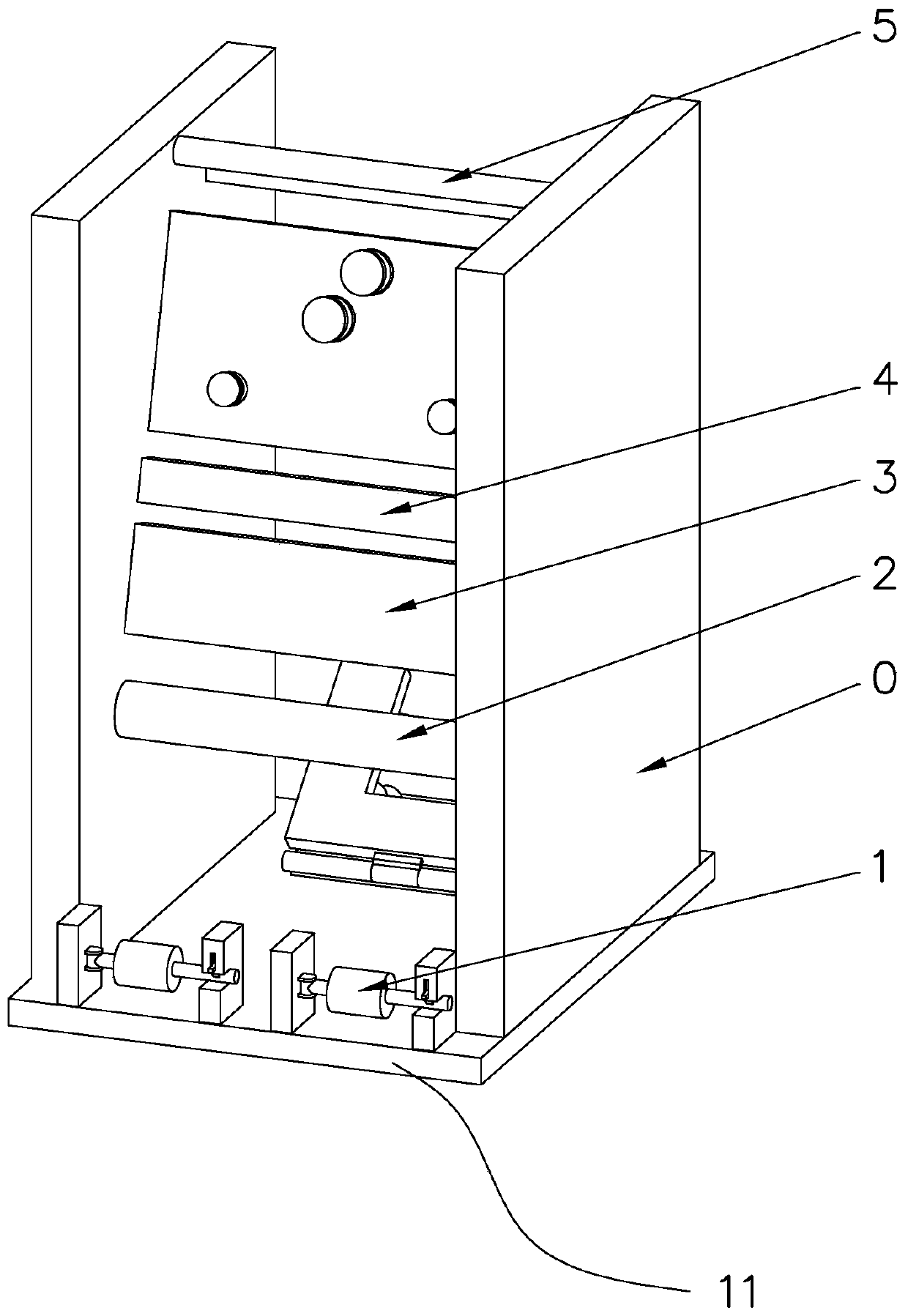

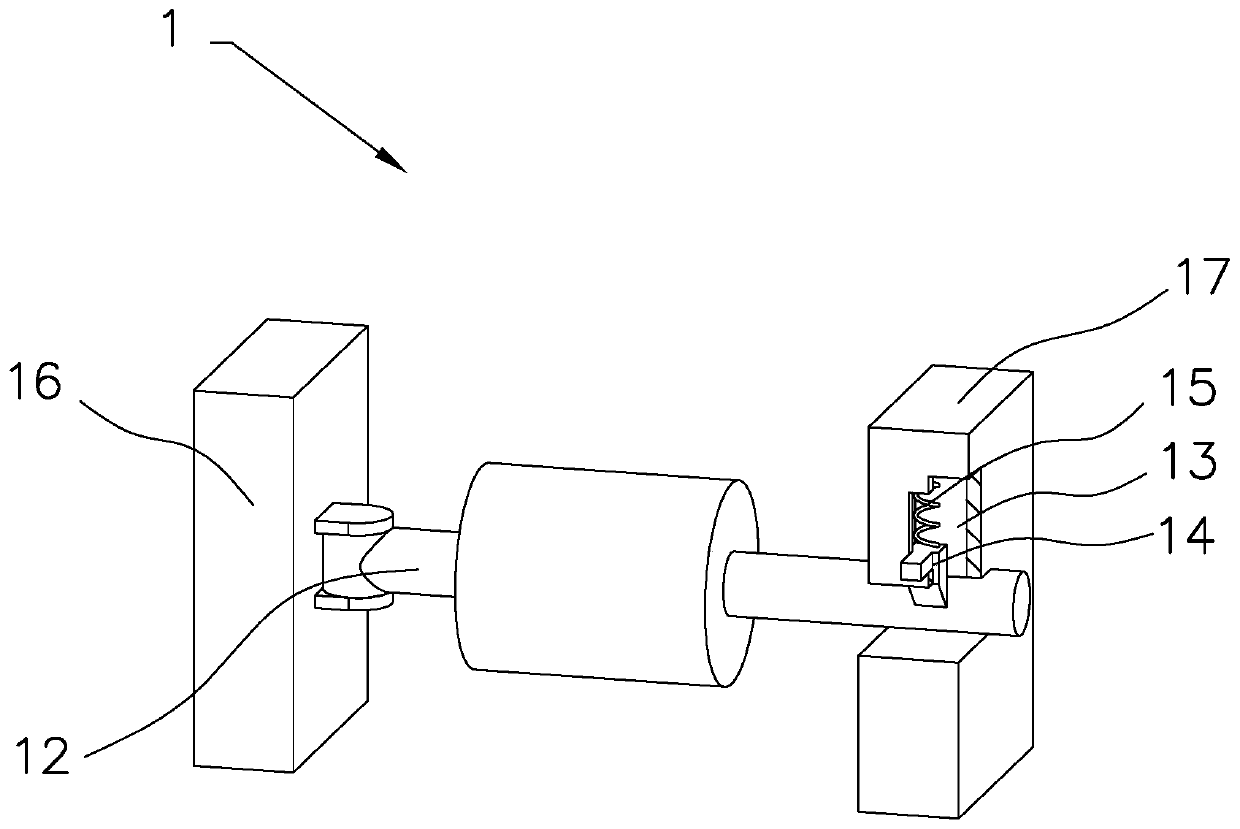

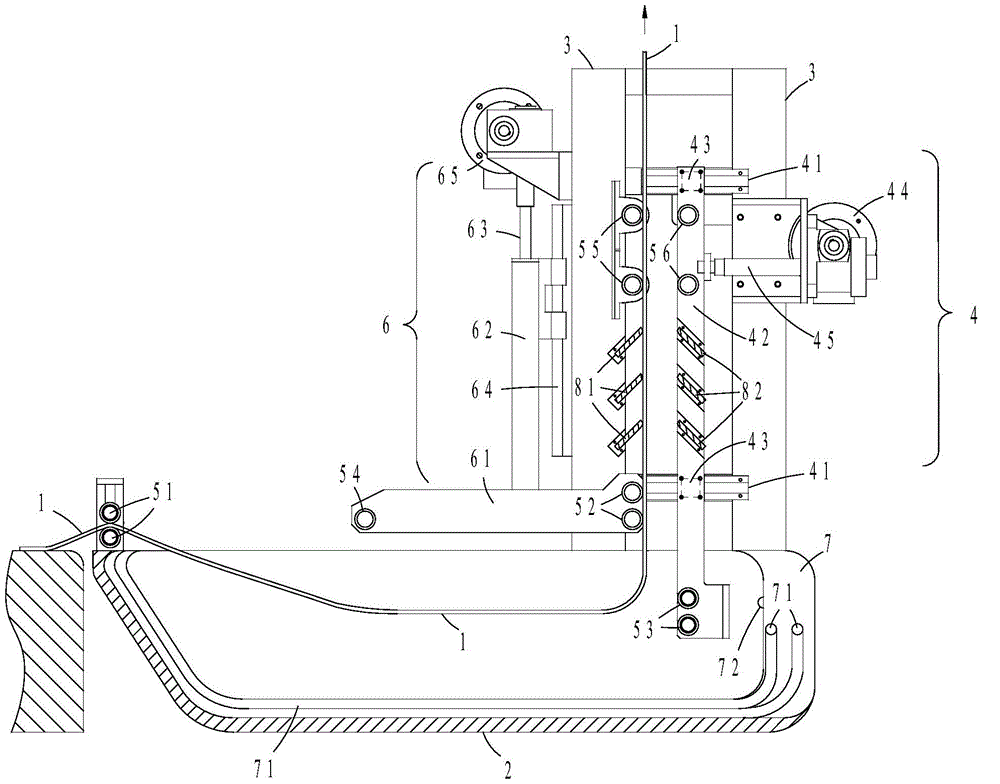

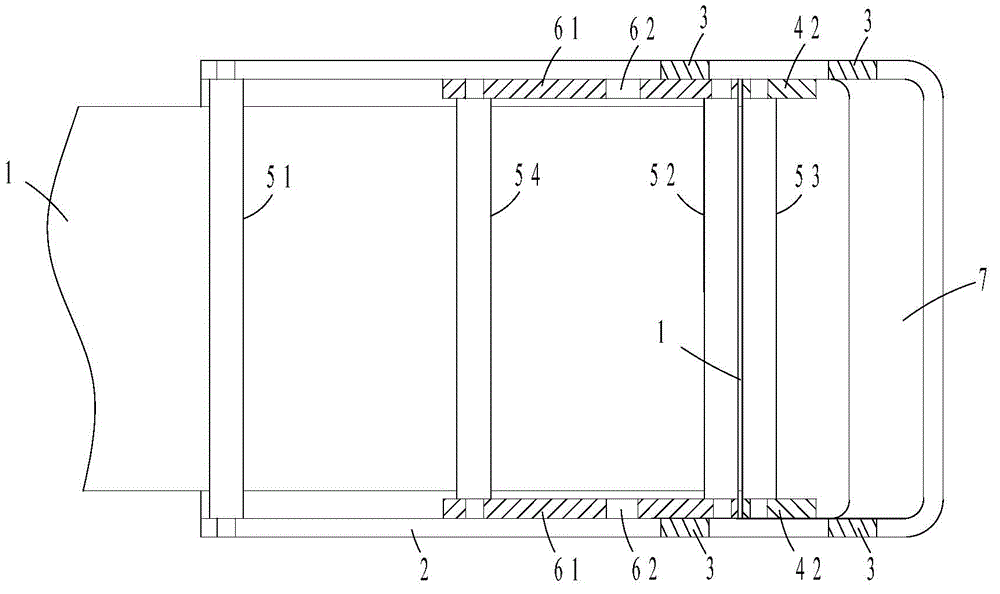

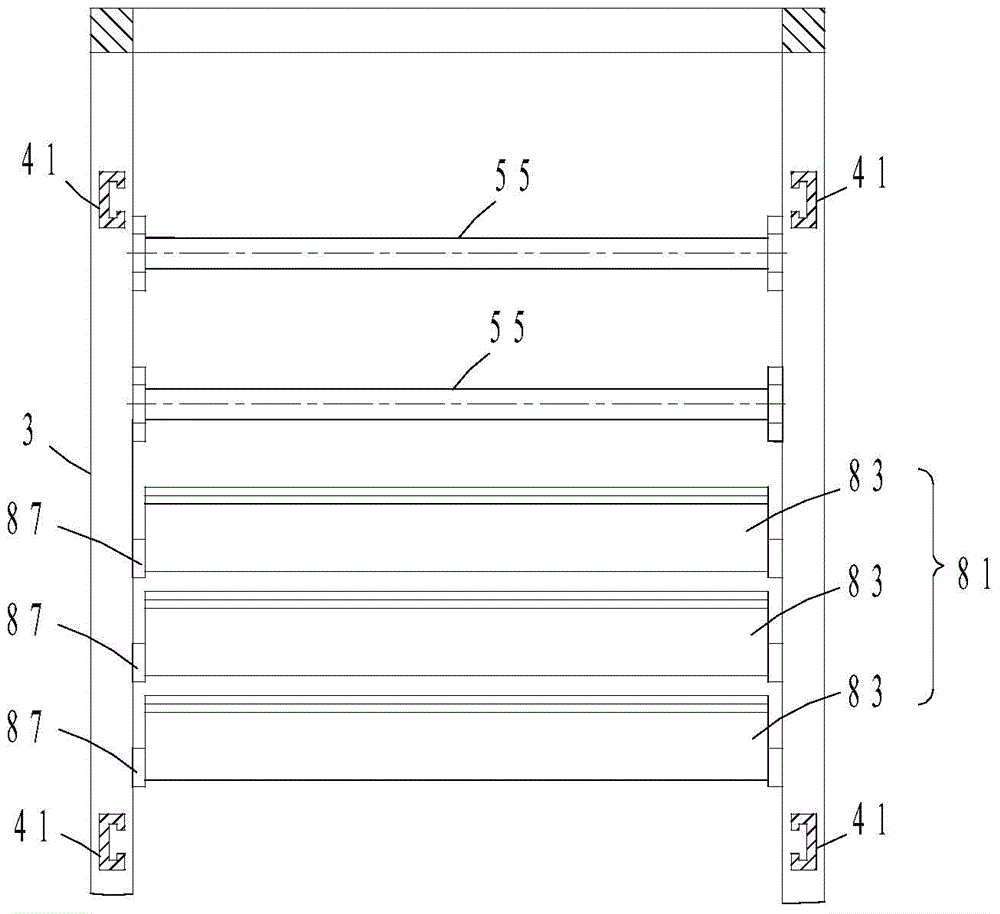

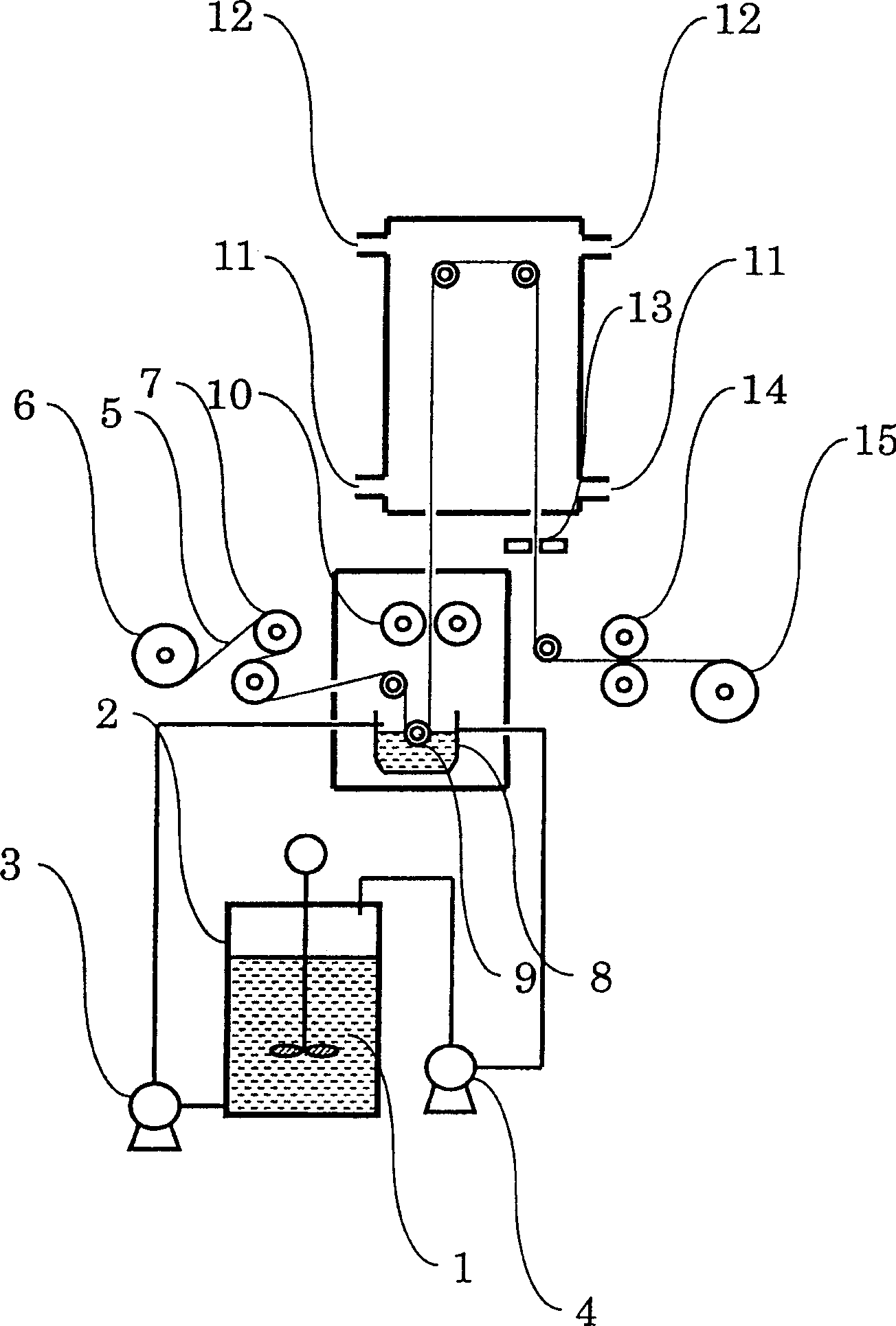

Fabric sizing machine

InactiveCN102321959AUniform sizing thicknessQuality improvementLiquid/gas/vapor removalLiquid/gas/vapor textile treatmentLaboratory ovenMechanical engineering

The invention relates to a fabric sizing machine, which is used for sizing and drying a fabric. The fabric sequentially passes through an unreeling roller, a driving roller and a sizing roller to enter into a sizing slot. The sizing roller is positioned in the sizing slot. A gap exists between a pair of squeeze rollers, and the fabric penetrates through the gap between the squeeze rollers. A tension adjusting device is further arranged on the pair of squeeze rollers and is used for adjusting the size of the gap between the squeeze rollers. A first baking oven and a second baking oven are arranged between a second driving roller and a reeling device, and a heating roller is arranged in the second baking oven and is connected with a support roller through a woolen blanket. The woolen blanket is butted with the bottom of the fabric, extends into the second baking oven and is heated in the second baking oven. The fabric sizing machine has the advantages that the sizing thickness is uniform and can be adjusted, pulp can be fully soaked into the fabric, and the like.

Owner:SHAOXING COUNTY YONGTONG SILK PRINTING

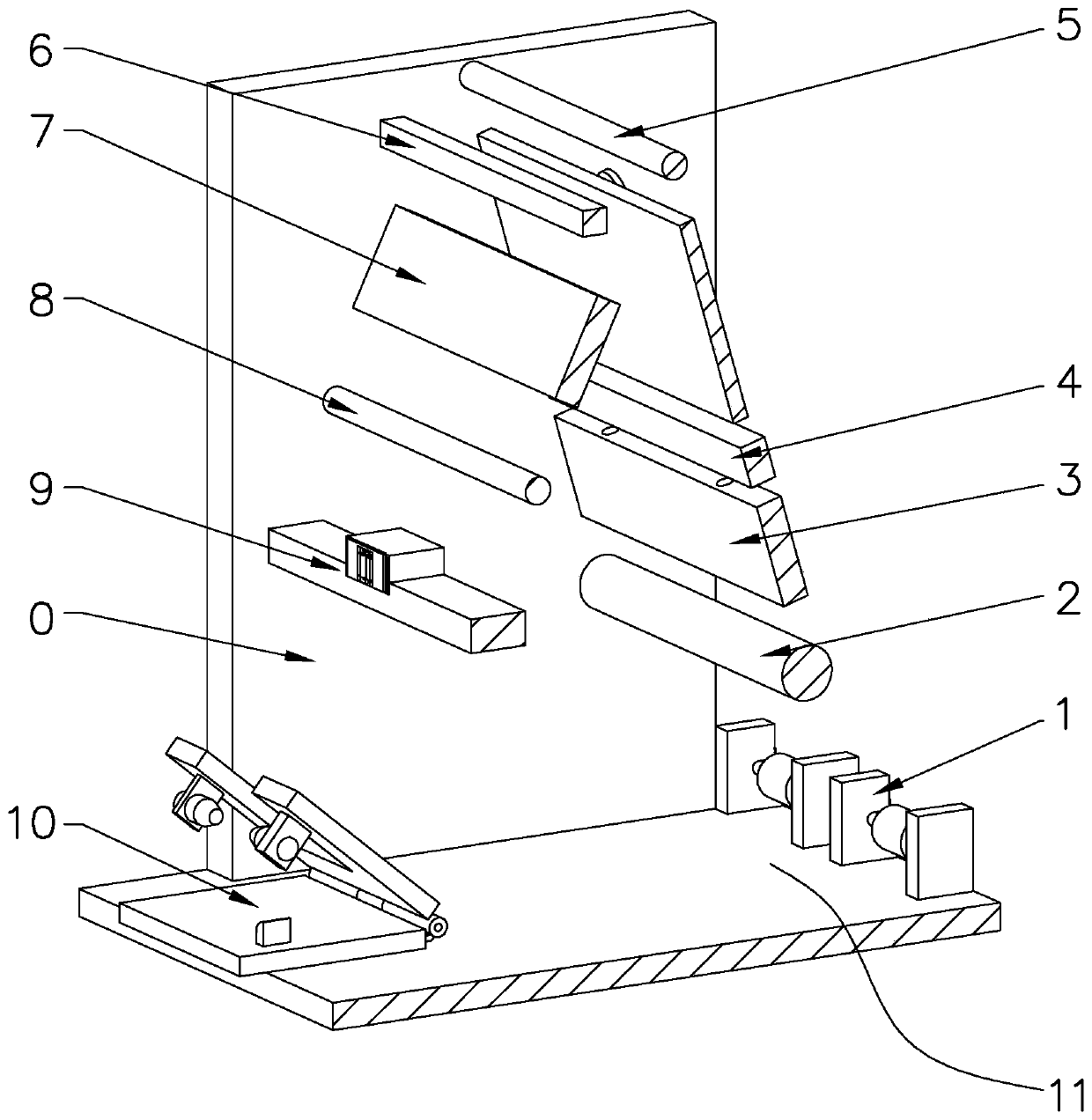

Draw texturing system of DTY high stretch yarn for knitted socks

The invention relates to a draw texturing system of a DTY high stretch yarn for knitted socks, and relates to the technical field of textile production. The draw texturing system comprises a base frame, and further comprises yarn inlet mechanisms, a first roller, a first hot box, a false twister, a second roller, a network nozzle, a second hot box, a third roller, an oiling mechanism and a windingmechanism, wherein the yarn inlet mechanisms, the first roller, the first hot box, the false twister, the second roller, the network nozzle, the second hot box, the third roller, the oiling mechanismand the winding mechanism are sequentially arranged on the base frame in the stretch yarn moving direction. The oiling mechanism comprises an oil box fixedly arranged on the base frame and an oil cover rotationally arranged on the base frame, the oil cover is located on the upper side of the oil box, the oil box is filled with an oiling agent, the oil cover is rotationally provided with an oilingwheel, and the lower end of the outer ring surface of the oiling wheel stretches into the oiling agent. The oil cover is provided with an oil control assembly used for squeezing the end face of the high stretch yarn to control the oiling quantity of the high stretch yarn, and the oil control assembly is located on the side, away from the third roller, of the oiling wheel. The draw texturing system has the advantages that the oil containing rate of the DTY high stretch yarn is controlled, so that the quality of the DTY high stretch yarn is improved.

Owner:浙江正堂实业股份有限公司

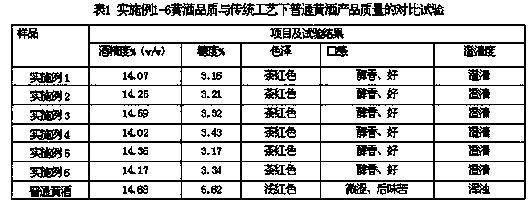

Preparation method for yellow rice wine

ActiveCN103695247AShorten the soaking timeSufficient soaking timeMicroorganism based processesAlcoholic beverage preparationFlavorFiltration

The invention discloses a preparation method for yellow rice wine and belongs to the technical field of yellow rice wine production processing. The preparation method comprises the following steps of (1) smashing, immersing, stewing and cooling coix lacryma-jobi and millets which serve as raw materials; (2) adding cooled rice into distilled yeast, uniformly mixing and stirring the materials for diastatic fermentation, adding yeast and purified water to implement constant-temperature fermentation, performing ultrasonic treatment after fermentation is executed, performing squeezed filtration, collecting filtrate, sterilizing the filtrate, and storing the filtrate in a sealed manner to obtain the yellow rice wine. The preparation method for the yellow rice wine is low in production cost and simple in technology; the yellow rice wine has good color, fragrance and flavor, tastes delicious and mellow and does not contain any additive and pigment; by virtue of long-time drinking, the yellow rice wine has good effects for resisting fatigue, enhancing the immunity of a human body, tonifying Yang and kidney and the like.

Owner:福建老福洲酒业股份有限公司

Low-density low-pressure sheet molding compound and preparation method thereof

The invention provides a low-density low-pressure sheet molding compound and a preparation method thereof. The invention discloses a low-density low-pressure sheet molding compound. The composite material is prepared from the following components in parts by weight: 55 to 65 parts of unsaturated polyester resin, 30 to 40 parts of low-shrinkage additive, 6 to 8 parts of styrene, 3.5 to 4.5 parts ofthickening agent, 1 to 2 parts of benzoyl peroxide tert-butyl ester, 4 to 6 parts of light zinc stearate, 70 to 80 parts of calcium carbonate, 20 to 30 parts of hollow glass beads and 45 to 55 partsof chopped glass fibers. According to the invention, a low-pressure sheet molding compound (LPMC) technology is adopted; mutual cooperation of components, therefore, the sheet molding compound prepared by the invention has lower density and the forming pressure can be greatly reduced; the magnesium oxide paste and the crystalline resin are used as a combined thickening system, so that the materialis formed under low pressure; the hollow glass beads are used as a filling material, so that the material density and the heat conductivity coefficient are reduced; the density of the sheet molding compound is 1.216-1.330 g / cm<3>, the heat conductivity coefficient of the sheet molding compound is 0.288-0.347 W / m.K, and the bending strength of the sheet molding compound is 59.15-82.39 Mpa.

Owner:WUHAN UNIV OF TECH

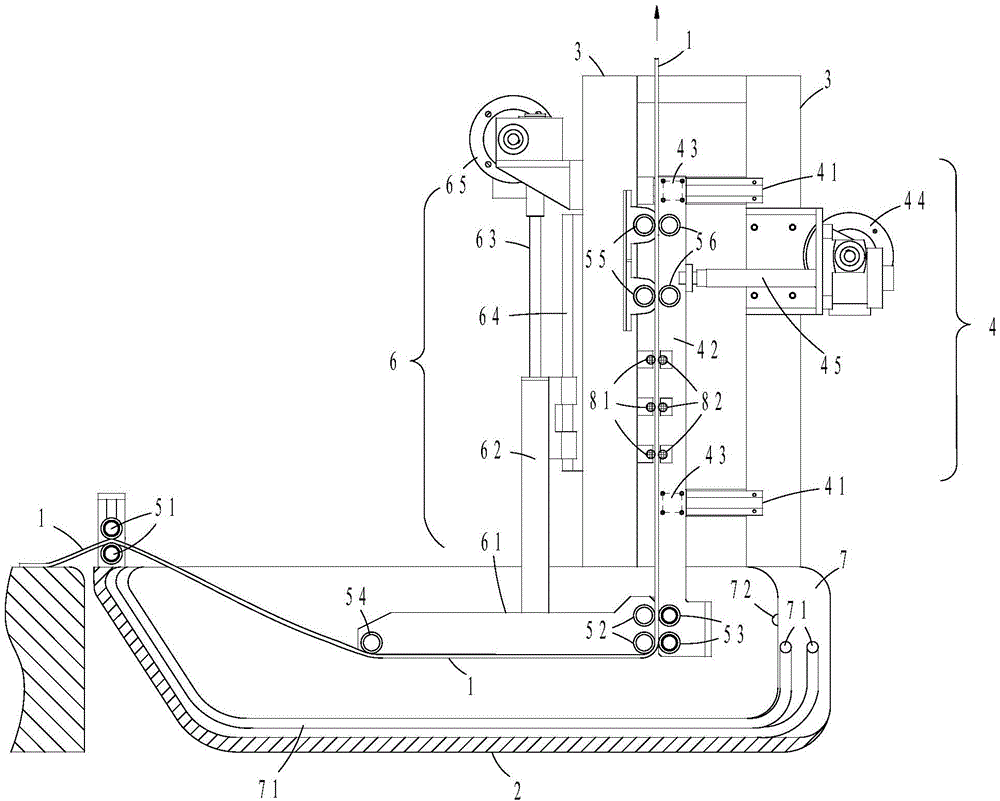

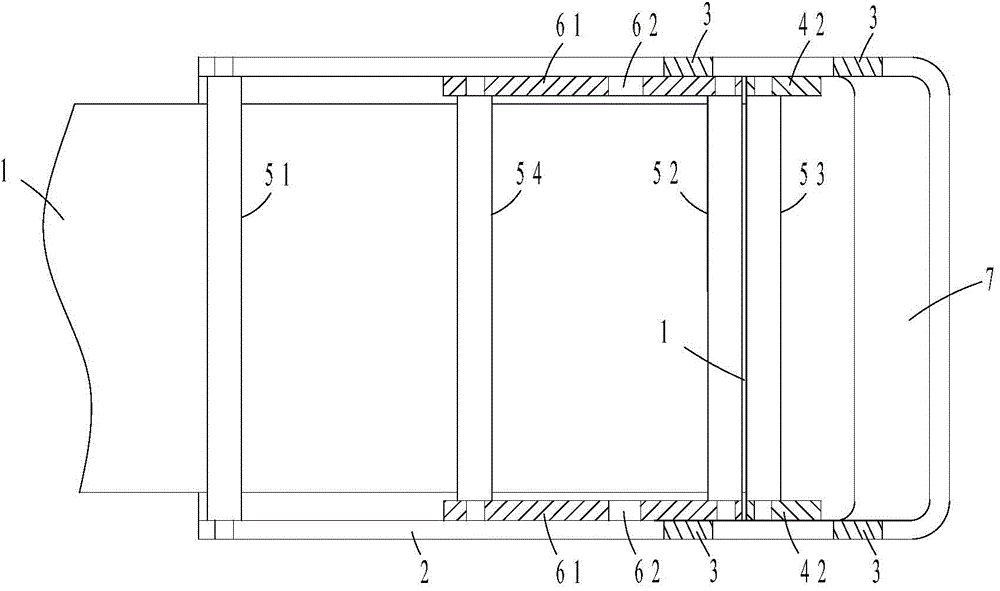

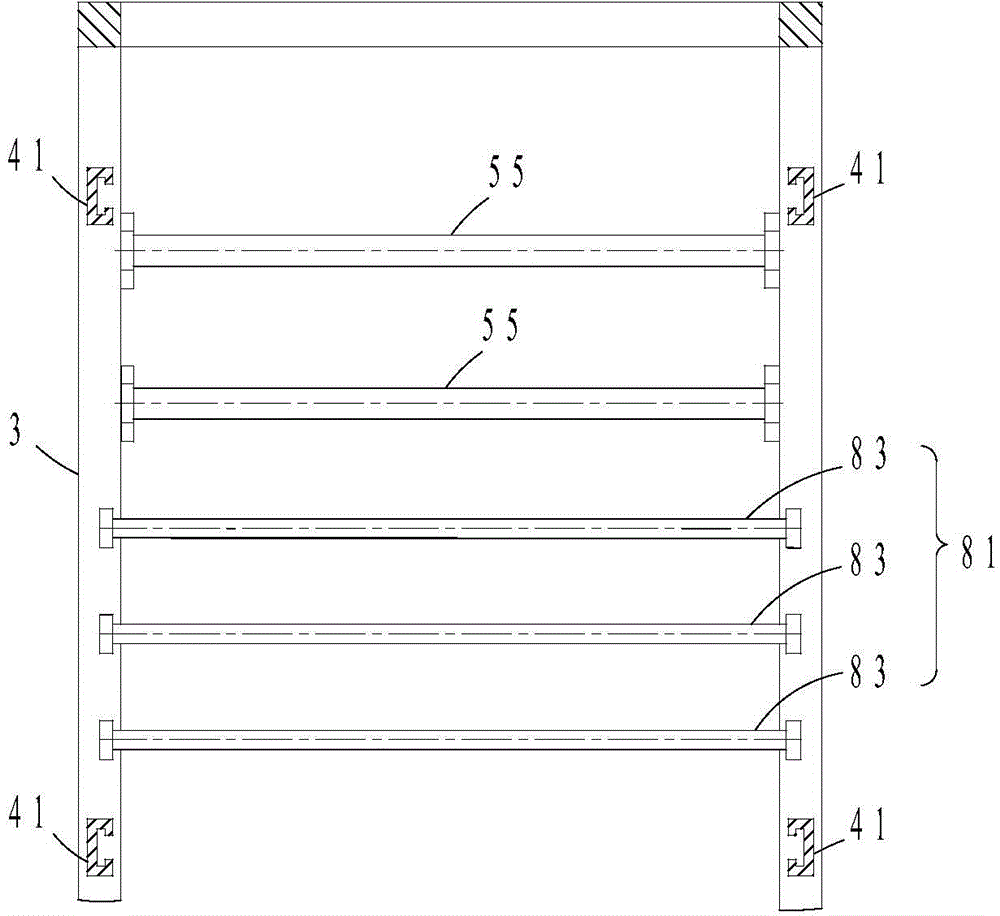

Feeding device for seamless ventilation ducting fabric production

ActiveCN104562718AEasy to pass throughEven scrapingTunnel/mines ventillationTextiles and paperBiochemical engineeringGroup ii

The invention relates to a feeding device for seamless ventilation ducting fabric production. The feeding device comprises a concave tank body, wherein a bracket is arranged on the tank body; a clamping roll group I and a scraper group I are arranged on the bracket; a slidable clamp device is further arranged on the bracket; a clamping roll group II and a scraper group II are arranged on the clamp device; base cloth can pass through a gap between the clamping roll group I and the clamping roll group II and a gap between the scraper group I and the scraper group II; each of the clamping roll group I and the clamping roll group II comprises at least one clamping roll; each of the scraper group I and the scraper group II comprises at least one scraper which adopts a steel wire; a soaking and lifting device capable of lifting relative to the tank body is arranged on the bracket; and a heat conduction box for heating size is arranged on the inner wall of the tank body. The feeding device can perform uniform feeding on seamless ventilation ducting fabric, the gap between the two clamping roll groups and the gap between the two scraper groups are adjustable, so that the requirement for different thicknesses of the size on the base cloth can be met, and the production efficiency is improved; and the scrapers adopt the steel wires, accordingly, the cost is lower, and the replacement is convenient.

Owner:成都众成新型复合材料有限公司

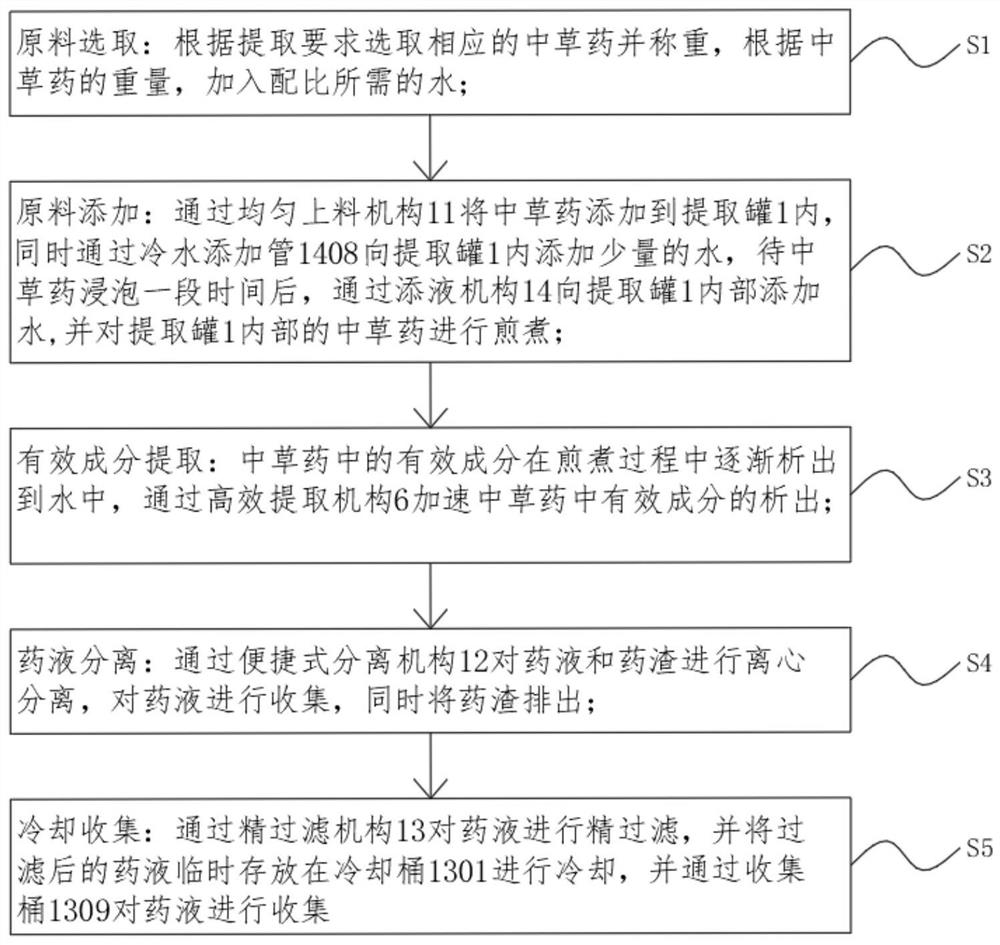

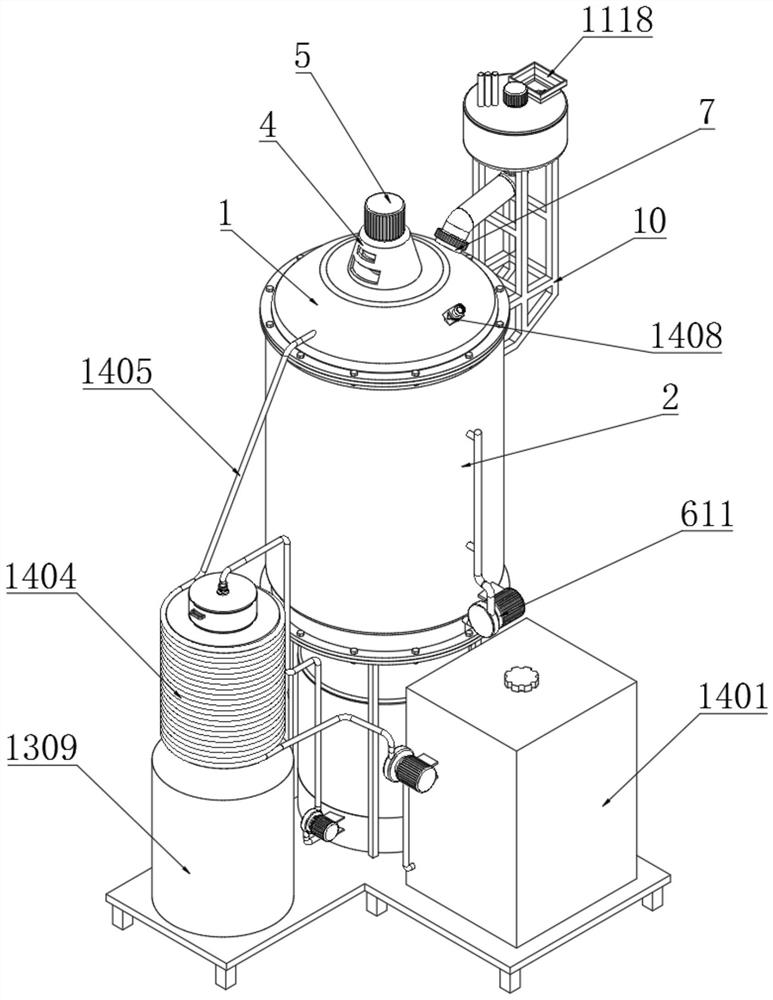

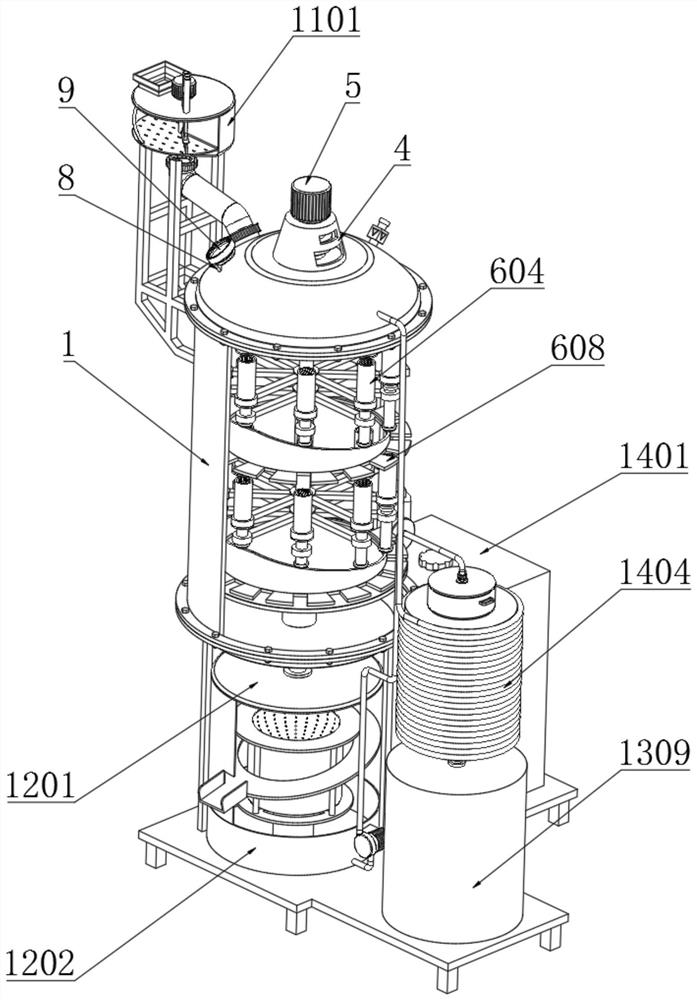

Chinese herbal medicine extraction method with high extraction rate

InactiveCN112245967APromote precipitationScientific and reasonable structurePharmaceutical product form changeSolid solvent extractionMedicinal herbsEngineering

The invention discloses a Chinese herbal medicine extraction method with high extraction rate, which comprises the following steps: raw material selection: selecting and weighing corresponding Chineseherbal medicines according to extraction requirements, adding water required by proportioning according to the weight of the Chinese herbal medicines, and adding raw materials by adding the Chinese herbal medicines into an extraction tank through a uniform feeding mechanism; meanwhile, adding a small amount of water into the extraction tank through a cold water adding pipe, and after the Chineseherbal medicine is soaked for a period of time, carrying out active component extraction, wherein the effective components in the Chinese herbal medicine are gradually separated out into the water inthe decocting process. According to the traditional Chinese medicine extraction device, the liquid exchange efficiency in the medicinal materials is improved by actively and repeatedly mechanically squeezing the decocted medicinal materials, so that effective components in the medicinal materials are diffused into liquid medicine in the liquid exchange process, the decocting time and the decoctingfrequency of traditional Chinese medicines are shortened, and the extraction efficiency of the traditional Chinese medicines is effectively improved.

Owner:温书

Dried-crisp flavor bean curd thin sheets

InactiveCN106561834AFully soakedGuaranteed yieldMilk preservationCheese manufactureCooking & bakingFood flavor

The invention relates to dried-crisp flavor bean curd thin sheets, which are produced by sequentially carrying out soaking, grinding, pulp filtering, pulp cooking, solidification, molding, pressing, cutting, stirring, baking, packaging and other technical steps. According to the present invention, the dried-crisp flavor bean curd thin sheets have advantages of green property, health, high protein content, thin skin, easy taste achieving, good taste, crispness, long shelf life, easy eating, easy water returning, good toughness after water returning, and significant economic value.

Owner:金仁元

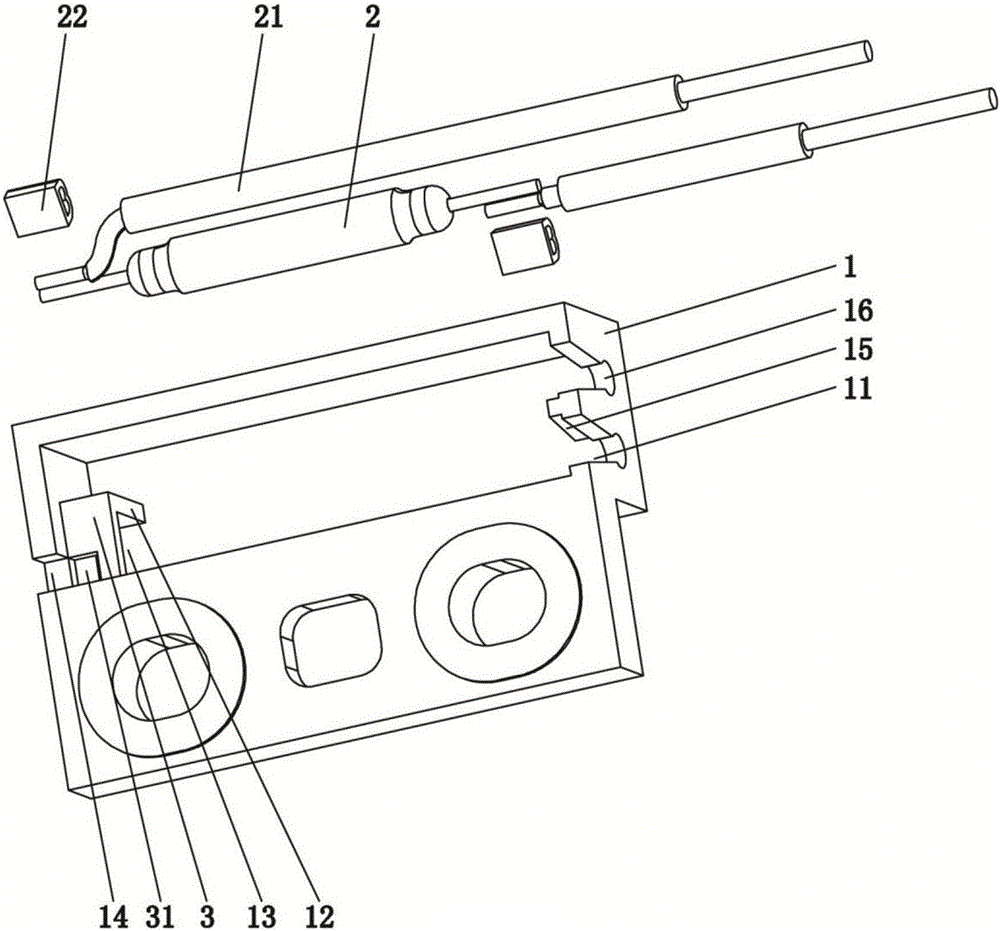

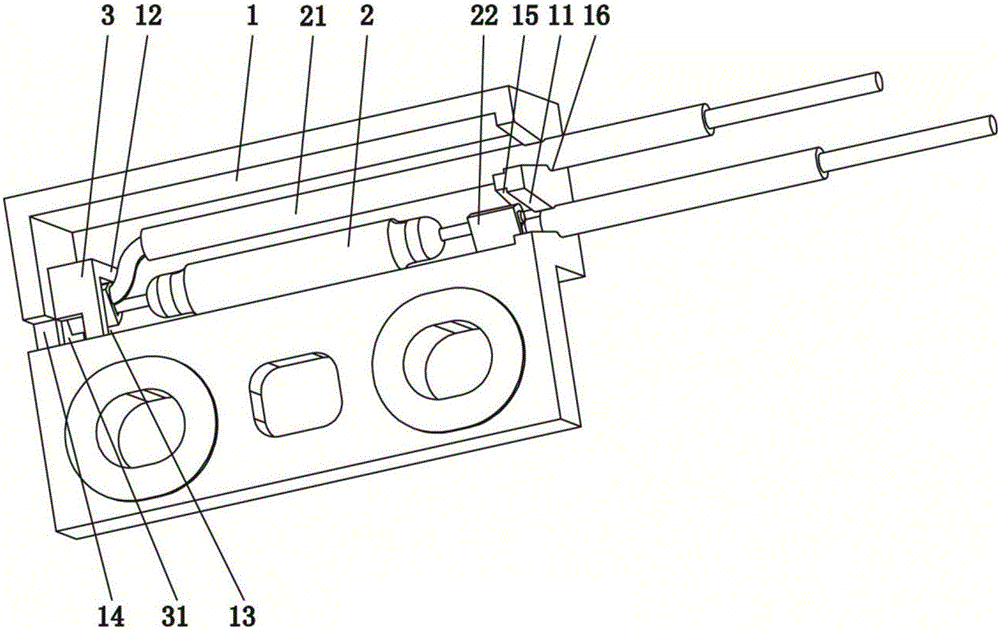

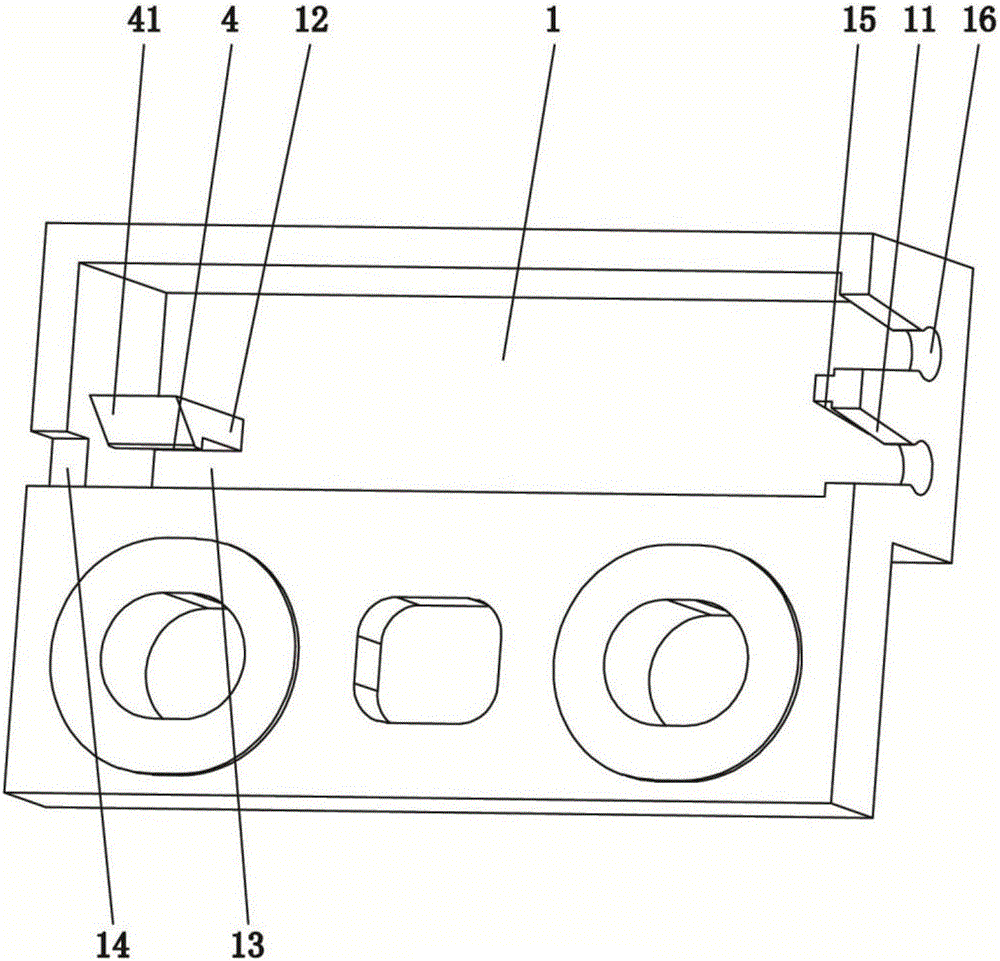

Low-pressure injection molding magnetic proximity switch

InactiveCN105845498AHigh impact strengthImprove stabilityMagnetic/electric field switchesContact electric connectionElectricityEngineering

The invention relates to the technical field of magnetic proximity switches, in particular to a low-pressure injection molding magnetic proximity switch, which comprises a plastic box, a reed switch and an inlet and outlet lead, wherein an opening is formed in the upper end of the plastic box; two threading slots are formed in the right end wall of the plastic box; a wire fixing pinch plate is arranged at the inner side of the left end wall of the plastic box; the wire fixing pinch plate is matched with the lateral wall of the plastic box to form a wire fixing opening; the inlet and outlet lead is electrically connected with two pins of the reed switch respectively; one pin of the reed switch is fixedly arranged in the wire fixing opening; and the inlet and outlet lead is transversely led out from the corresponding threading slot. The low-pressure injection molding magnetic proximity switch is reasonable in structure; one pin of the reed switch is integrally connected with the lead through a rivet; the electric connection strength is high; and the performance is stable. The rivet at one end of the reed switch is arranged in the wire fixing opening in a penetrating manner; the other end of the reed switch is limited through the positions of a wire clamping hole and a rib plate, so that the assembly position of the reed switch in an inner cavity of the plastic box is reasonable; a low-pressure injection molding process is achieved; and the impact strength and the electrical stability of the reed switch can be effectively improved.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY

Rust prevention soaking device for automotive part

InactiveCN107321561AImprove stabilityFully soakedLiquid surface applicatorsCoatingsEngineeringPiston rod

The invention discloses an anti-rust soaking device for auto parts, which comprises a box body, a transverse partition is arranged on the inner side of the box body, a fittings placement frame is arranged in the soaking chamber, and a supporting cylinder is connected in the middle of the bottom of the fittings placement frame , the upper side of the diaphragm is installed with stirring blades on the support tube, the lower side of the diaphragm is installed with a pulley on the support tube, the pulley is connected with the drive motor through the transmission belt, and the bottom of the separation chamber is equipped with a telescopic cylinder. The piston rod of the cylinder is connected with a plug through the rotation of the rotating body. There is also a filter plate on the outside of the separation chamber, and a return pipe connected to the bottom of the separation chamber is provided on the side of the box. The other end of the pipe extends to the top of the accessory placement frame, and a spray head is installed at the end of the pipe. The invention has a novel structure, is convenient to use, has better antirust oil immersion effect on auto parts, and is easy to remove impurities and is beneficial to popularization.

Owner:韩祥

Process for preparing kudzu root cymarose

Disclosed is a process for preparing kudzuvine root candy, wherein the constituents include (by weight portions) kudzuvine root slices 70-90 parts, miscible liquid for immersion, barley sugar 8-13 parts, white sesame seed 1-2 parts, the miscible liquid for immersion includes chrysanthemum flower 3-7 parts, honeysuckle flower 3-7 parts, edible saccharin 0. 1-0. 3 part, edible ethanol 0. 4-0. 8 part, lemon acid 0. 4-0. 8 parts, peppermint oil 0. 1-0. 3 part. The preparing process consists of immersing and drying.

Owner:武汉市石门山天然食品有限责任公司

Feeding system for production of seamless air duct cloth

ActiveCN104562496AEasy to pass throughMeet the needs of different thicknessTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentMechanical engineeringPhysics

The invention relates to a feeding system for production of seamless air duct cloth. The feeding system comprises a tank body, wherein a bracket is arranged on the tank body; a clamping roller group I and a scraping blade group I are arranged on the bracket; a slidable clamp device is further arranged on the bracket; a clamping roller group II and a scraping blade group II are arranged on the clamp device; each of the clamping roller group I and the clamping roller group II comprises at least one clamping roller; each of the scraping blade group I and the scraping blade group II comprises at least one scraping blade; the end, in contact with base cloth, of each scraping blade is inclined in the moving direction of the base cloth; the included angle between each scraping blade and the base cloth is smaller than 90 degrees; a liftable prepreg lifting device is arranged on the bracket; a heat conduction box for heating a sizing agent is arranged on the inner wall of the tank body. The feeding system can uniformly feed the seamless air duct cloth, can adjust the interval between two clamping roller groups as well as between the two scraping blade groups, is reliable in scraping, can meet the requirement for different thicknesses of the sizing agent fed on the base cloth and improves the production efficiency; the scraping blades are connected with compression springs, so that damage to the base cloth can be reduced.

Owner:成都众成新型复合材料有限公司

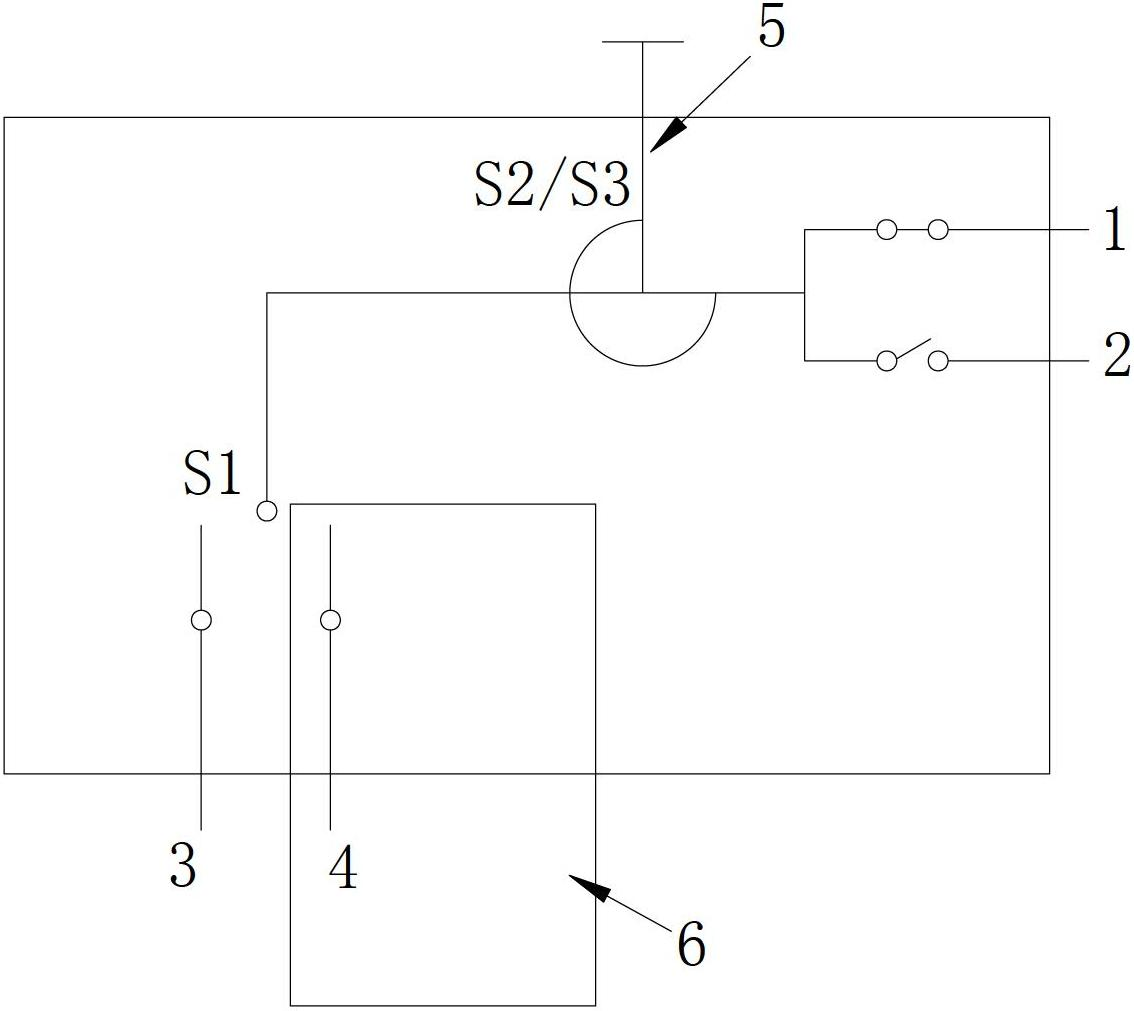

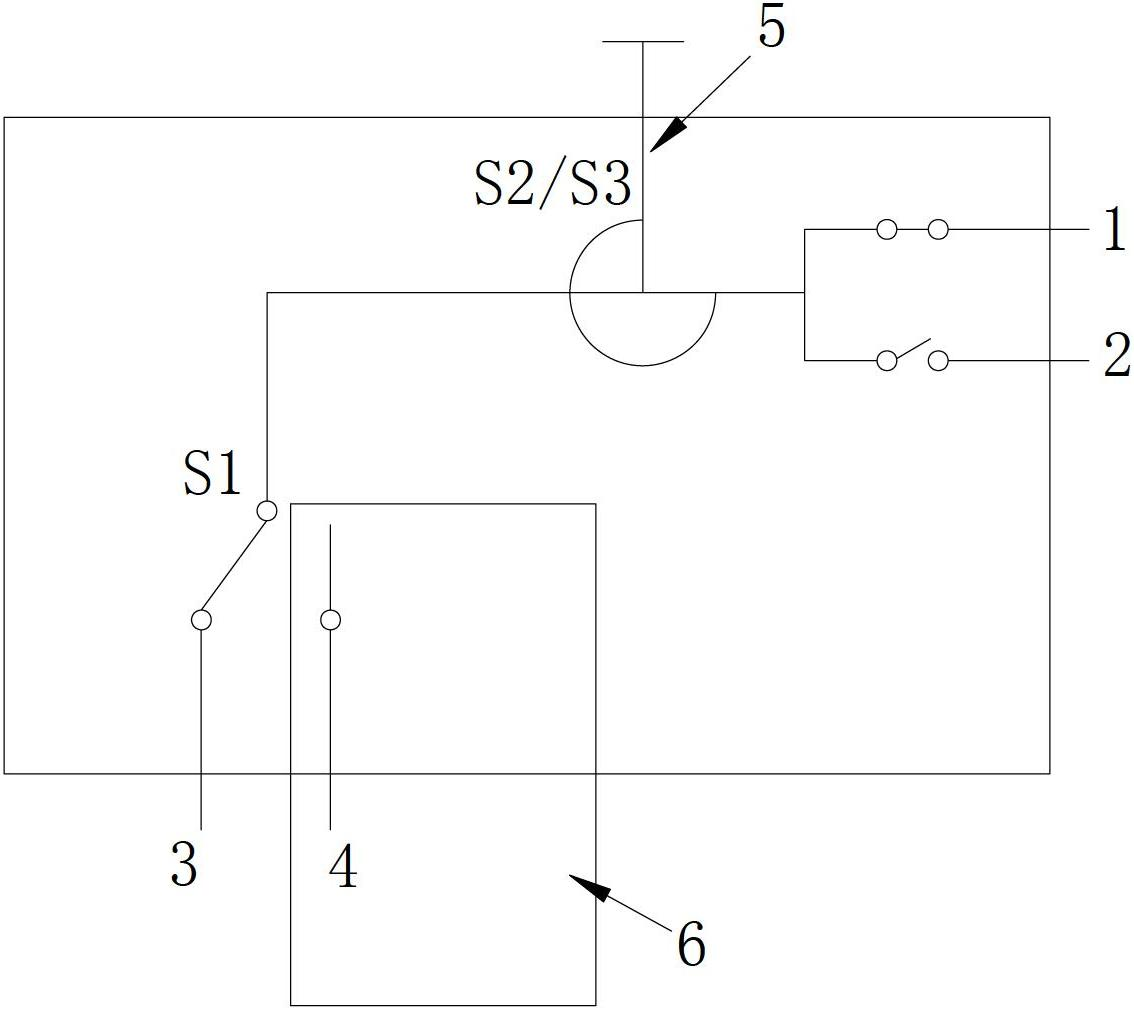

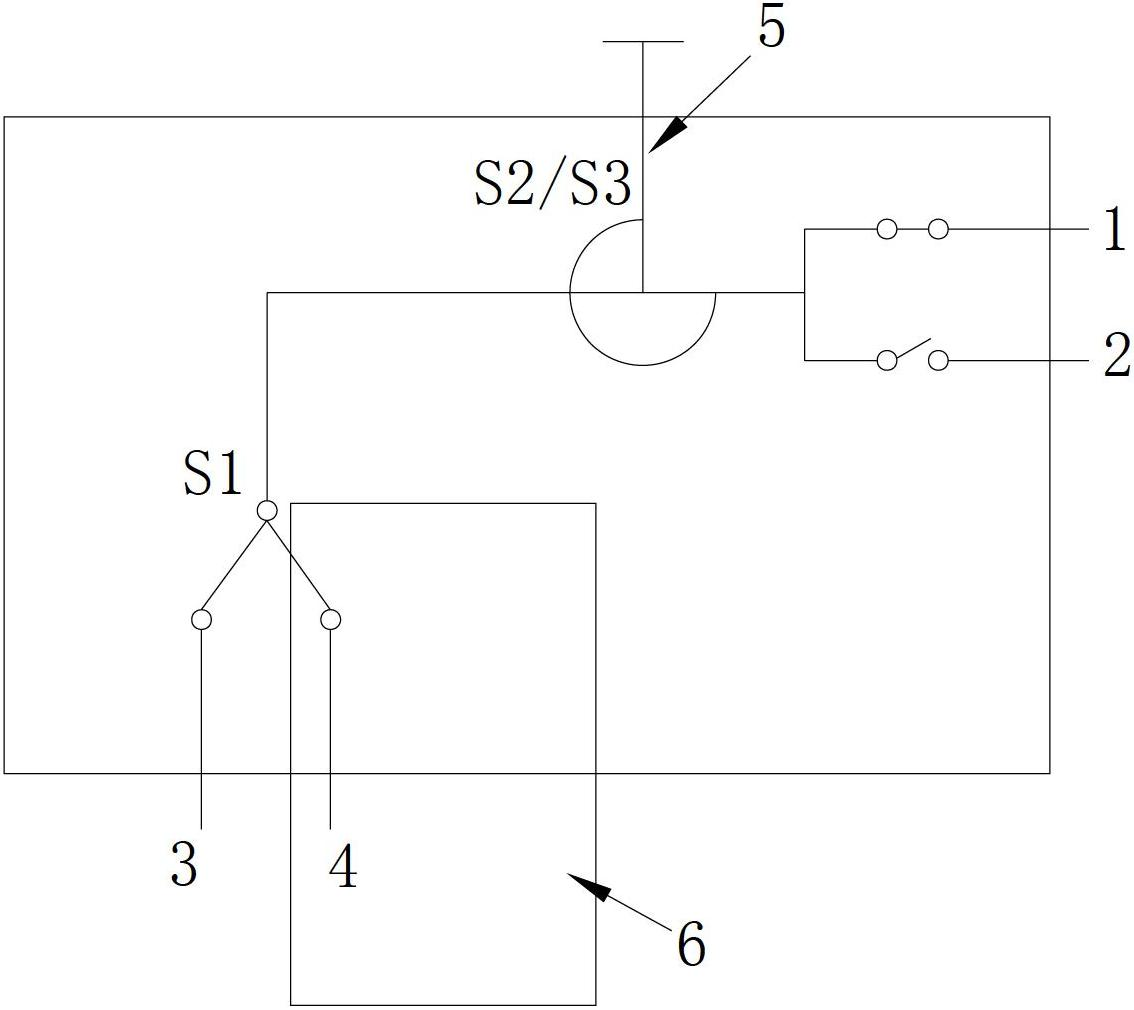

Washing machine timer capable of controlling circulating water flow and double-barrel washing machine

ActiveCN102677421APromote dissolutionFunction increaseTime-programme switchesOther washing machinesEngineeringCam

The invention discloses a washing machine timer capable of controlling circulating water flow and a double-barrel washing machine. The total working time of the timer contains soaking and washing time and continuous washing time; and at least the soaking and washing time is synchronized with an internal circulating water flow washing time for controlling periodical and intermittent circulation of a water discharging pump. The timer comprises an input end, an output end and a manual converter, wherein the output end is provided with two groups of washing contacts connected with a washing motor; one washing contact of the output end is selected for connection by switching of the manual converter; the input end is provided with two groups of contacts which respectively control a power supply and the water discharging pump; the timer is also provided with a cleaning cam for switching on and off the power supply in a timing manner to control the continuous washing time and the soaking and washing time and an internal circulating cam for switching on and off the water discharging pump in a timing manner to control the internal circulating water flow washing periodically, intermittently and circularly. According to the timer disclosed by the invention, the starting and stopping of the water discharging pump can be controlled for the internal circulation of the washing water flow, so that the dissolving performance and the washing performance of washing powder are improved. The double-barrel washing machine has the characteristic of saving water and power.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

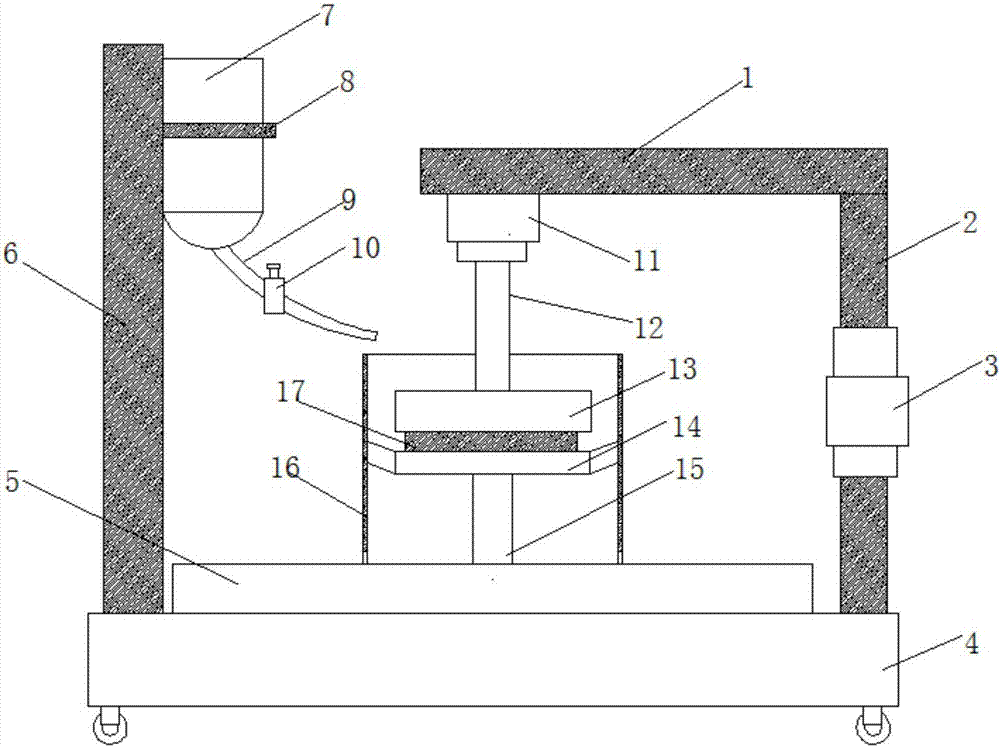

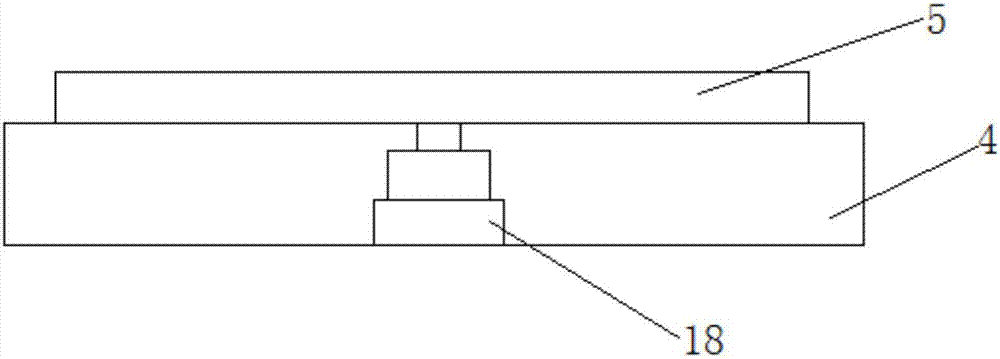

Chemo-mechanical grinding equipment

The invention belongs to the technical field of semiconductor mechanical grinding equipment, in particular to a chemical mechanical grinding equipment. The grinding fluid supply position of the existing grinding fluid supply pipe is relatively single, and the centrifugal force of the rotation of the turntable alone cannot ensure the polishing of the grinding pad under the grinding head. The grinding liquid can be evenly distributed, and the uneven distribution of the grinding liquid will directly affect the grinding effect of the grinding head, resulting in uneven grinding results of the substrate and other shortcomings. The following scheme is proposed, a chemical mechanical grinding equipment, including a support base, The support base has a hollow structure, and the inner cavity of the support base is fixed with a first drive device through a bracket. The output shaft of the first drive device passes through the upper side wall of the support base and is connected with the turntable through a flange. The cross section of the turntable It is circular and has a rectangular vertical section. The chemical mechanical grinding equipment can make the object to be ground fully soaked by the grinding liquid, thereby making it evenly ground, improving the uniformity and flatness.

Owner:HUANGHE S & T COLLEGE

Soya-bean milk production method with efficient pulverization and noise reduction

ActiveCN105941635AFully water-swellableImprove crushing efficiencyMilk substitutesSlurryNoise reduction

The invention relates to a soya-bean milk production method with efficient pulverization and noise reduction. The method at least comprises the following steps: (a) a step of pre-heating and soaking, in which, water and materials are added in a heating cup of a heating apparatus, a pre-set temperature no less than 70 DEG C is achieved by heating at a heating rate in a range of 3 DEG C per minute to 10 DEG C per minute, and the next step is carried out; (b) a step of pulverization, in which, water and materials in the cup are pulverized into a thick liquid through rotation of a pulverization blade driven by an electric motor, and the next step is carried out; and (c) a step of cooking, in which, the thick liquid in the cup of the heating apparatus is heated until the thick liquid is fully cooked. Through comparison with the prior art, according to the technical scheme, the method enables the water absorption and expansion rate between epidermis and cotyledon of soya-beans to be preferably uniform, so that the soya-beans can fully absorb water and swell. The method has improved pulverization efficiency and has the function of noise reduction.

Owner:JOYOUNG CO LTD

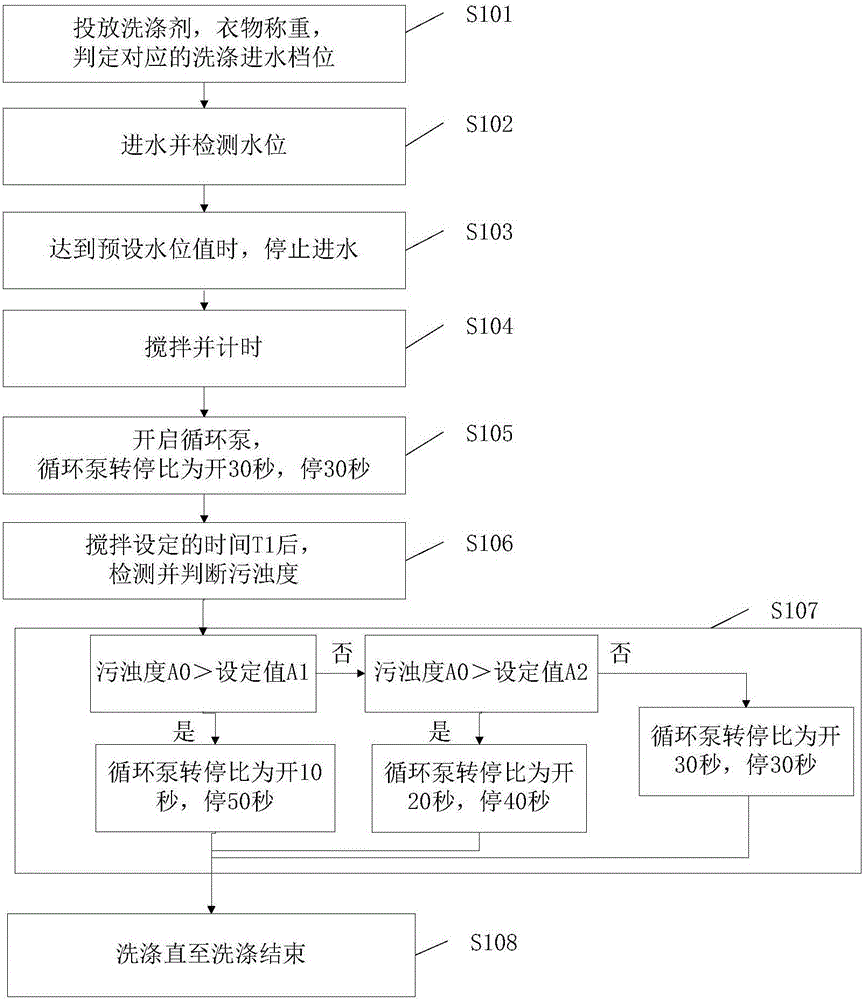

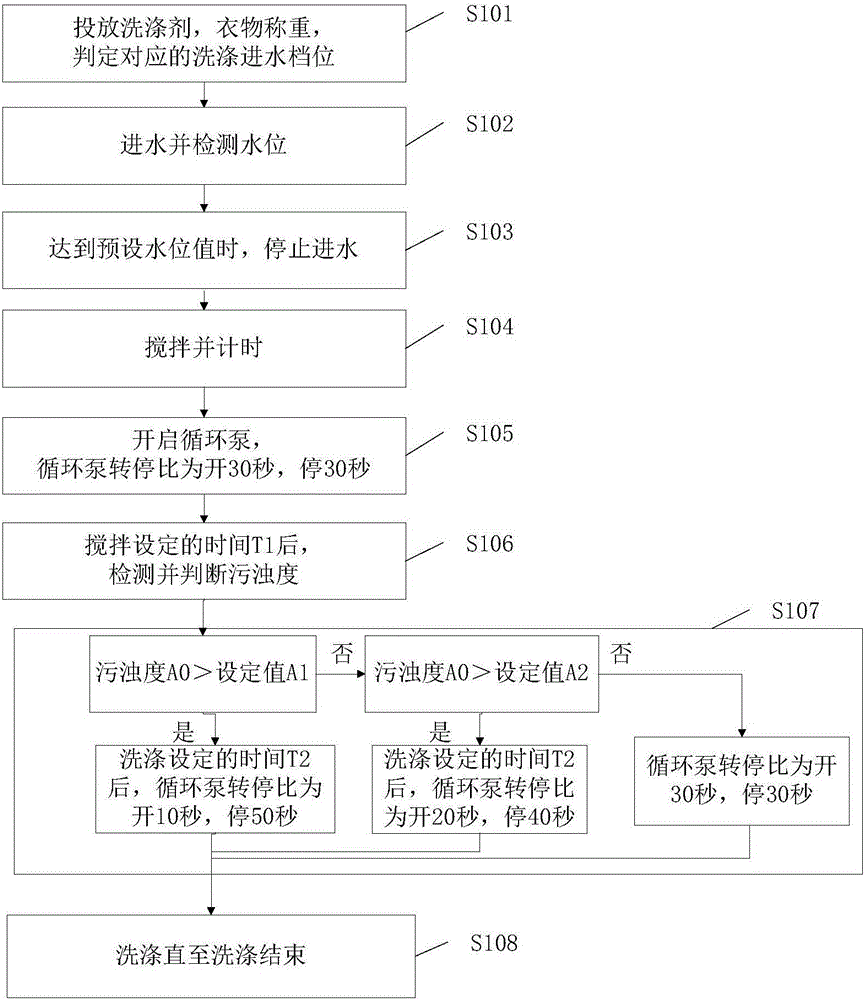

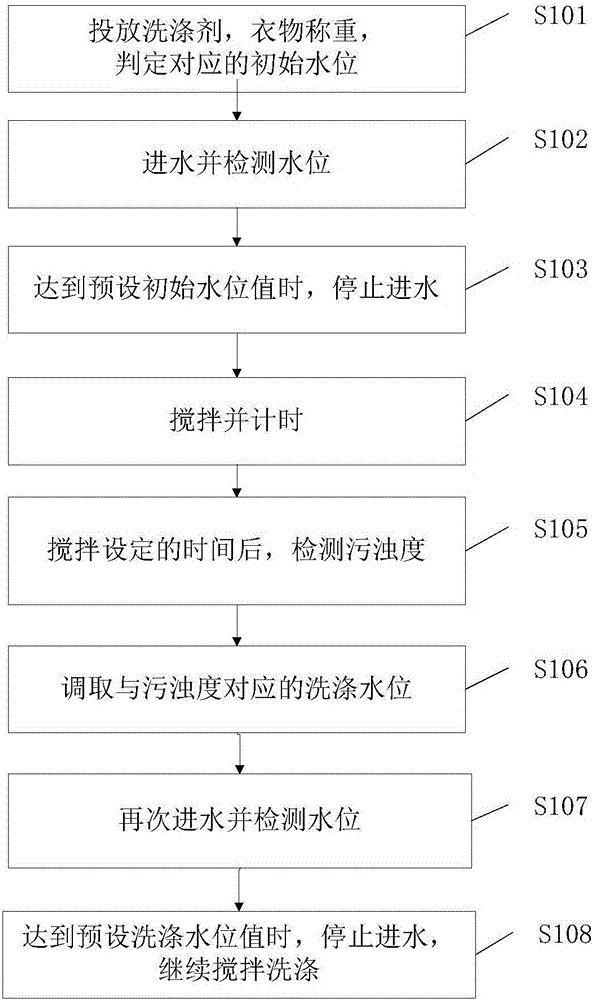

Washing control method and washing machine

ActiveCN107177954AEasy to soakReduce flow timeControl devices for washing apparatusTextiles and paperProcess engineering

The invention provides a washing control method and a washing machine. The external cyclic flowing time of washing water in an outer barrel is determined according to the dirty degree of the washing water, thereby solving the problem that when the dirty degree of clothing is high, in the process that a circulating device pumps the washing water from the barrel bottom and sprays the washing water onto the clothing, the dirty components stripped from the washed clothing adhere to the clothing again and result in poor cleaning effect and low washing efficiency.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Electrode sheet and electric double layer capacitor using the same

InactiveCN1776848AFully soakedImprove wetting propertiesCapacitor electrodesMetal foilInternal resistance

The present invention provides an electrode sheet and an electric double layer capacitor using the same, in which a polarized electrode is easily and firmly formed on the surface of a current collector such as a metal foil, even if it is generated due to repeated charging and discharging. The adhesive strength between the current collector and the polarized electrode is hardly lowered even if there is no gas or vibration, etc., and the performance such as internal resistance can be maintained for a long period of time in a state of good performance. The solution is to use the following electrode sheet and the electric double layer capacitor using it. The electrode sheet is formed by drying and heat-treating the coating liquid on the surface of the collector. The liquid is formed by dispersing at least activated carbon and / or carbon black, and a graft polymer obtained by graft polymerization of an organic monomer in a solvent.

Owner:MITSUBISHI GAS CHEM CO INC +1

Manufacturing process of high-elasticity fire-retardant fiber band for wind energy cable

InactiveCN102304849ASimple processEasy to manufactureFibre typesInsulated cablesEngineeringFire retardant

The invention relates to a manufacturing process of fire-retardant fiber bands, and in particular relates to a manufacturing process of a high-elasticity fire-retardant fiber band for a wind energy cable. The manufacturing process comprises the following steps: (1) soaking the nylon-based fiber cloth in water, warming and finishing, ironing and setting; (2) preparing a fire retardant; (3) completely soaking the finished and ironed nylon-based fiber cloth in the fire retardant, and removing redundant glue solution on the nylon-based fiber cloth soaked in the fire retardant by use of a roller; (4) putting the product obtained in the step (3) in an oven and drying until the dryness degree is 70-80%; (5) drying and curing; and (6) coiling to obtain the high-elasticity fire-retardant fiber band for the wind energy cable. The process provided by the invention is simple and easy; the manufactured product has a dense structure, resists cold, salt, oil and ultraviolet rays, has long service life, good fire retardancy and strong twist resistance, and is suitable for paving the wind energy cable.

Owner:扬州新奇特电缆材料有限公司

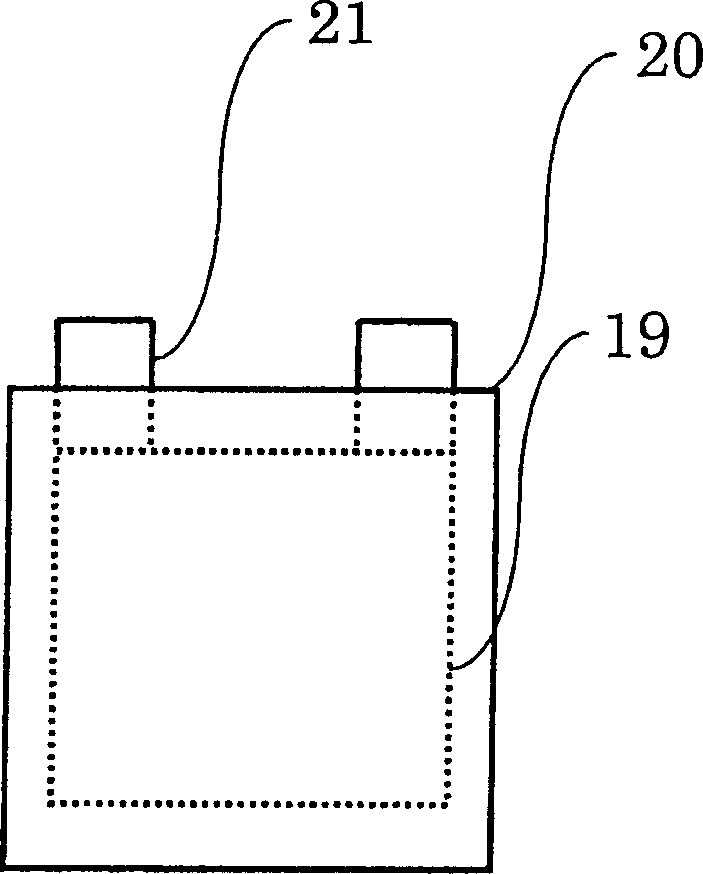

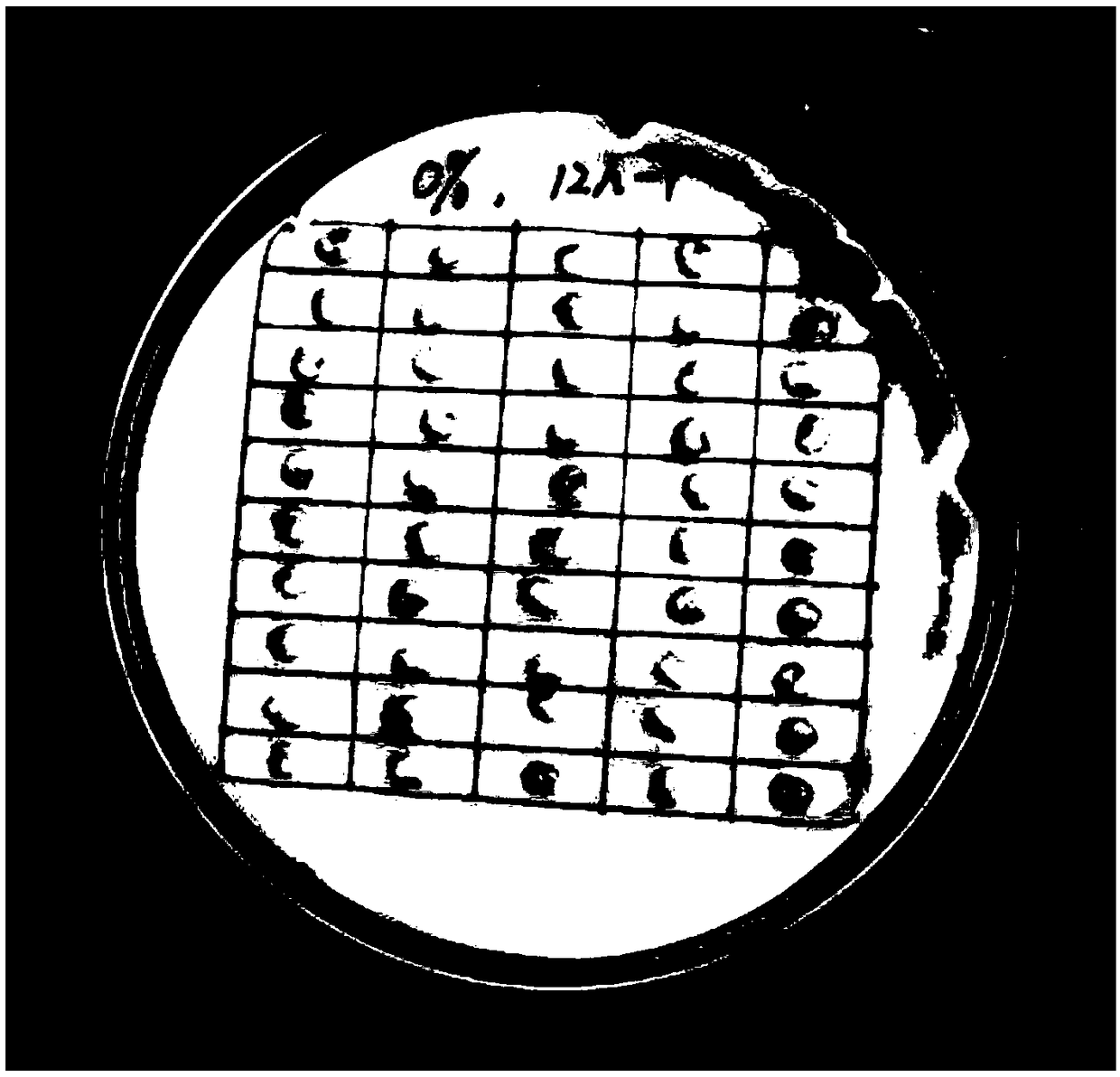

Method for constructing pepper mutant library from ethylmethane sulfonate

PendingCN108617502AImprove anti-aphid performanceHigh yieldPlant genotype modificationGenomicsEthylmethane Sulfonate

The invention discloses a method for constructing a pepper mutant library from ethylmethane sulfonate. The method is characterized in that a Zunla 1 is used as a mutagenesis object; on the premise ofpointing out the influence of treating fluid dose and excluding space of each seed on germination percentage, semi-lethal dose is determined by comparing the germination percentage of pepper seeds with EMS treating fluid with different concentrations at different mutagenesis time; the pepper seeds are treated by mutagenesis of the semi-lethal dose; mutation frequency and mutation types of M2 generation are investigated, a mutant capable of stably inheriting of M4 generation is identified and a mutant library is constructed; the mutation types of leaves, stems, fruits, growth period, flower organs, fertility and the like are obtained and create abundant materials for functional genomics reach of pepper; and meanwhile, partial beneficial mutation can be directly applied to breeding practice.

Owner:GUIZHOU SERICULTURE RES INST GUIZHOU PEPPER RES INST

Method for automatically processing almond slices

ActiveCN103535796AFully soakedEasy to peelMulti-step food processesFood shapingMicrowaveFluidized bed

The invention relates to a method for processing nuts and in particular relates to a method for automatically processing almond slices. The method comprises the following steps: A. cleaning almonds to be processed by a nut cleaning device; B. carrying out rolling stewing on the cleaned almonds by a precooker; C. peeling the stewed almonds by a peeling machine; D. carrying out color sorting on the peeled almond pulps by a color sorter; E. carrying out microwave baking on the almond pulps by a microwave baker; F. cutting the almond pulps into almond slices by a slicing machine; G. carrying out vibratory screening on the cut almond slices by a vibrating screen; and H. drying and dehydrating the almond slices by a fluidized bed through high-temperature vapor being 160-190 DEG C. According to the method for automatically processing the almond slices, the efficiency is high, the cost is low, the qualification rate of the produced almond slices is high, and raw materials are saved.

Owner:东莞市绰士食品有限公司

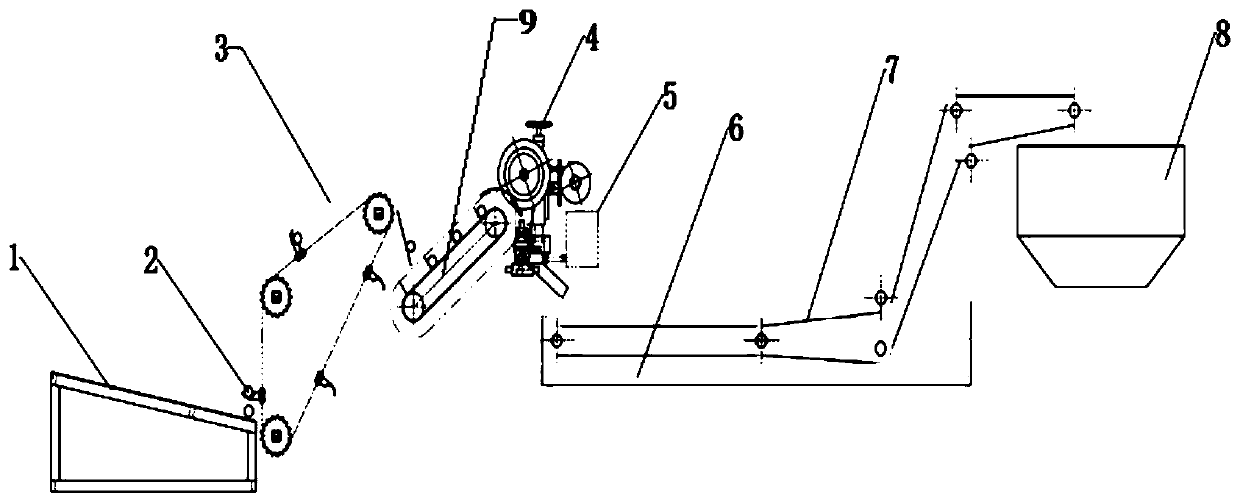

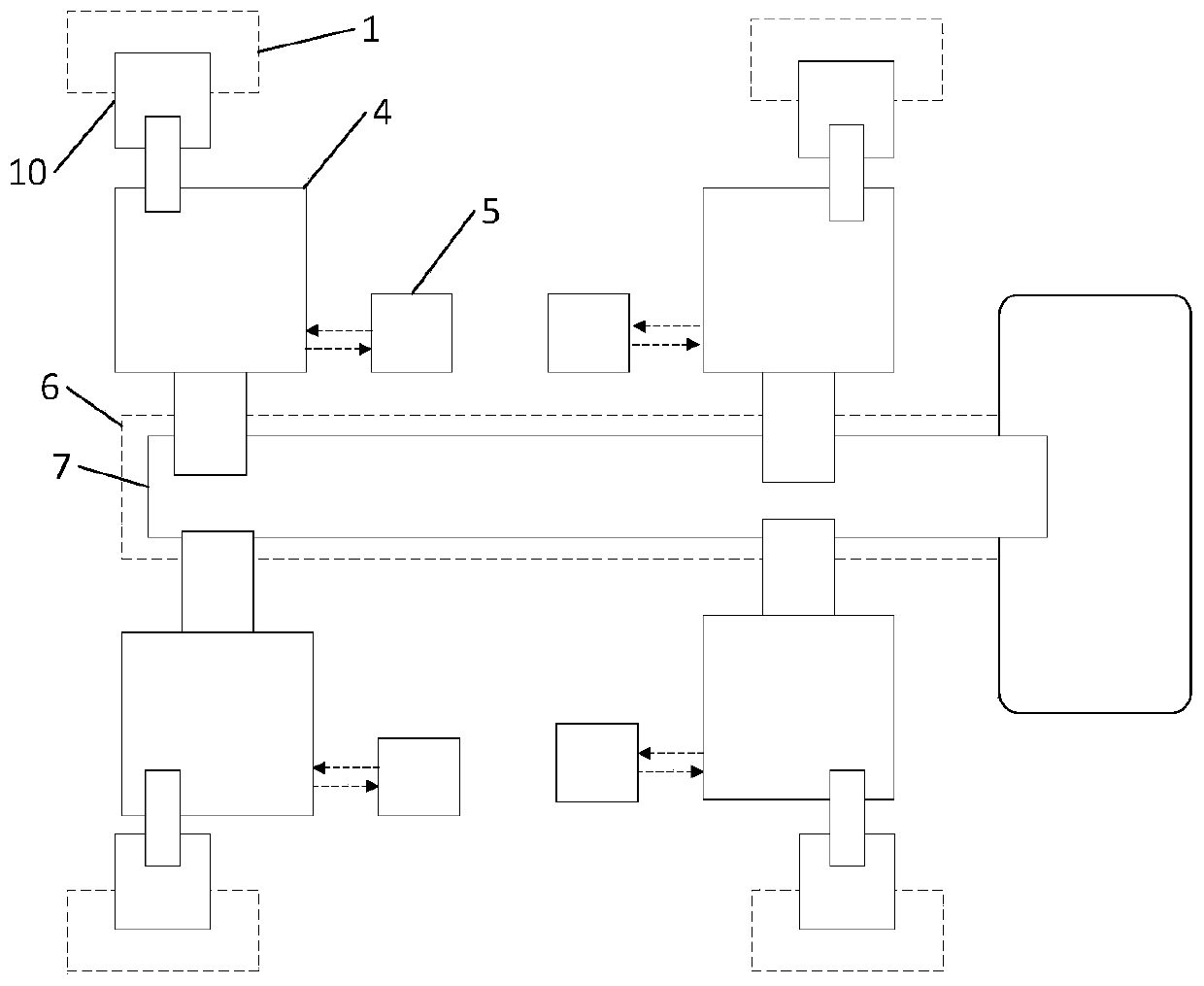

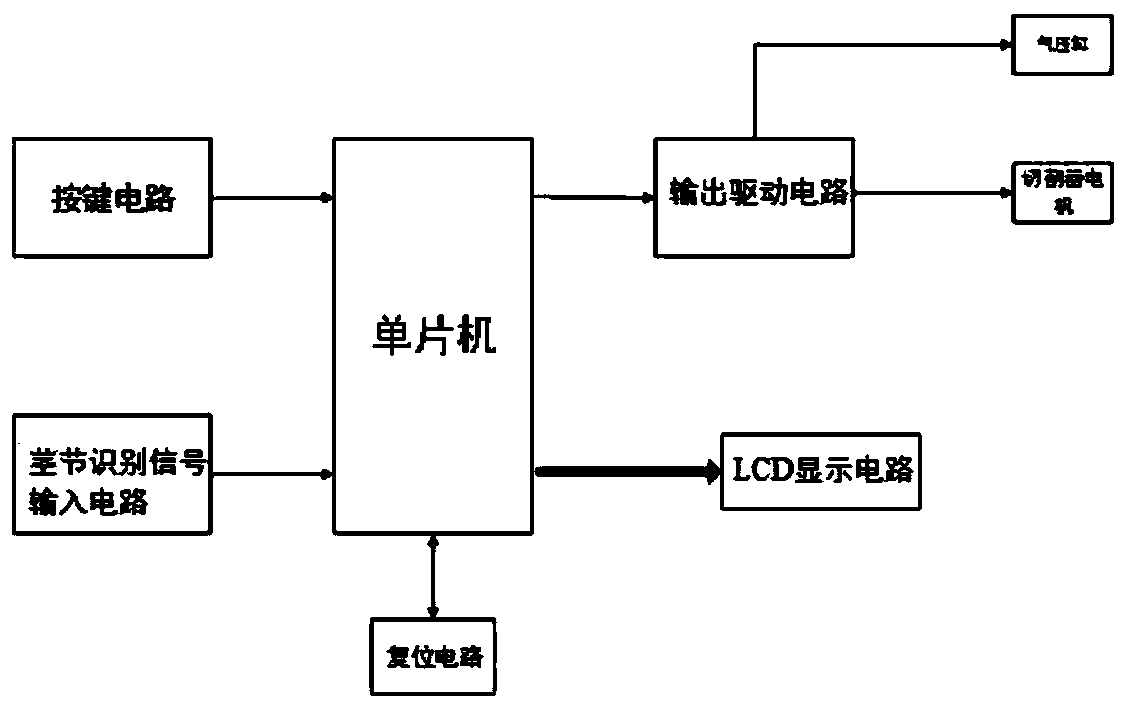

Sugarcane seed cutting production line and work method thereof

InactiveCN109699231AAvoid destructionGuaranteed germination rateSeed immunisationAgricultural engineeringSugar cane

The invention relates to a sugarcane seed cutting production line which is used for cutting sugarcane seeds in batches. The production line comprises a sugarcane fishing device, an intelligent single-bud-segment seed cutting machine and a sugarcane seed conveying device which are arranged in sequence in the sugarcane conveying direction. The production line also comprises a stem segment recognition system which is electrically connected with the intelligent single-bud-segment seed cutting machine; the stem segment recognition system is used for identifying sugarcane stem segments and feeding back data to the intelligent single-bud-segment seed cutting machine, and the intelligent single-bud-segment seed cutting machine is used for completing sugarcane seed cutting. The invention further relates to a work method of the production line. The stem segment recognition system is adopted to be matched with the intelligent single-bud-segment seed cutting machine to cut sugarcane seeds, the stem segment recognition system is used for recognizing stem segment signals through image recognition or sensor recognition and transmitting the stem segment signals to the intelligent single-bud-segment seed cutting machine, and the intelligent single-bud-segment seed cutting machine is used for fixing sugarcane and also using the stem segment signals to complete the seed cutting work. The stem segment recognition system is matched with the intelligent single-bud-segment seed cutting machine to identify the sugarcane segments, the sugarcane segments of the sugarcane seeds are prevented from being damaged, and the germination rate of the sugarcane seeds is guaranteed.

Owner:SOUTH CHINA AGRI UNIV

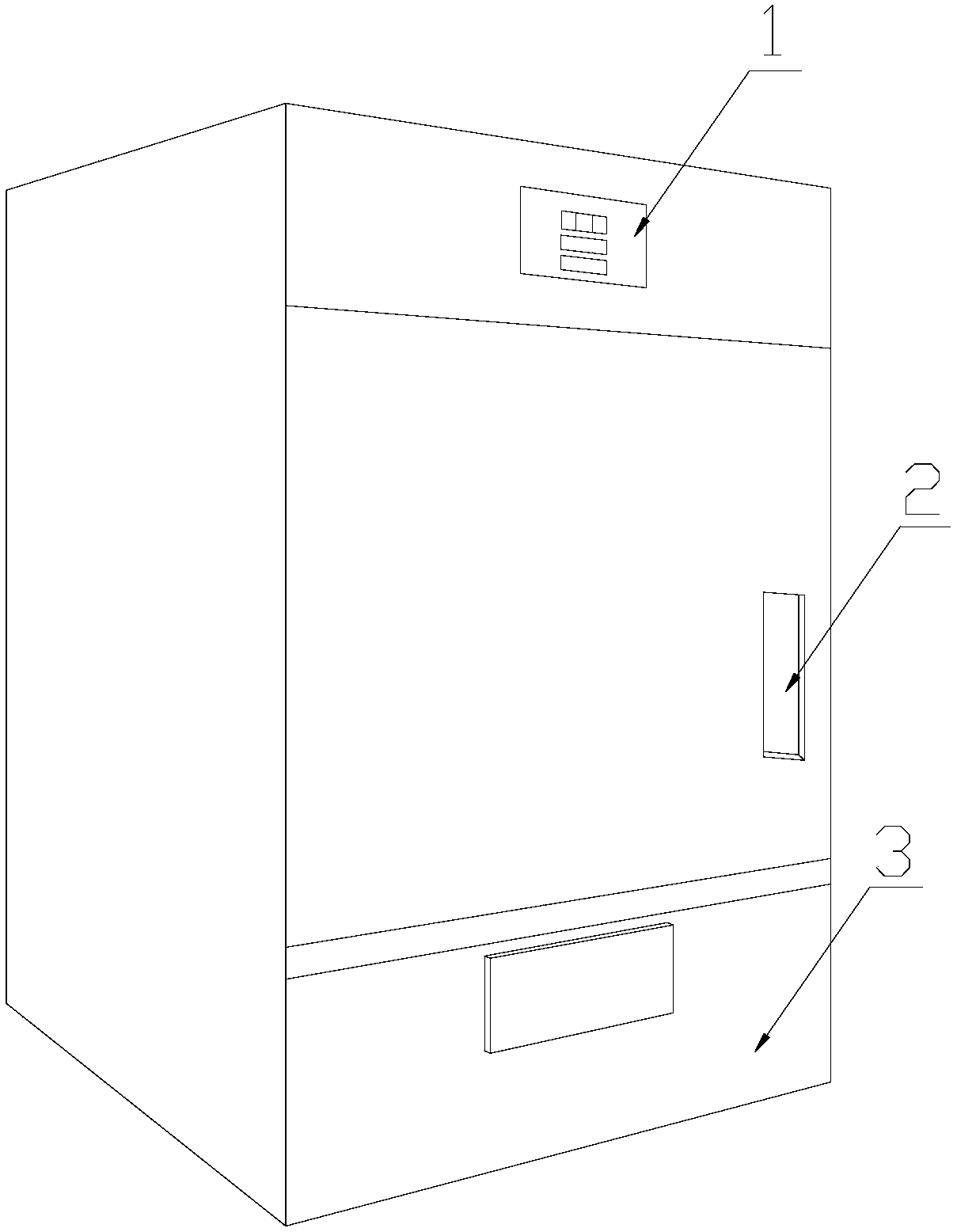

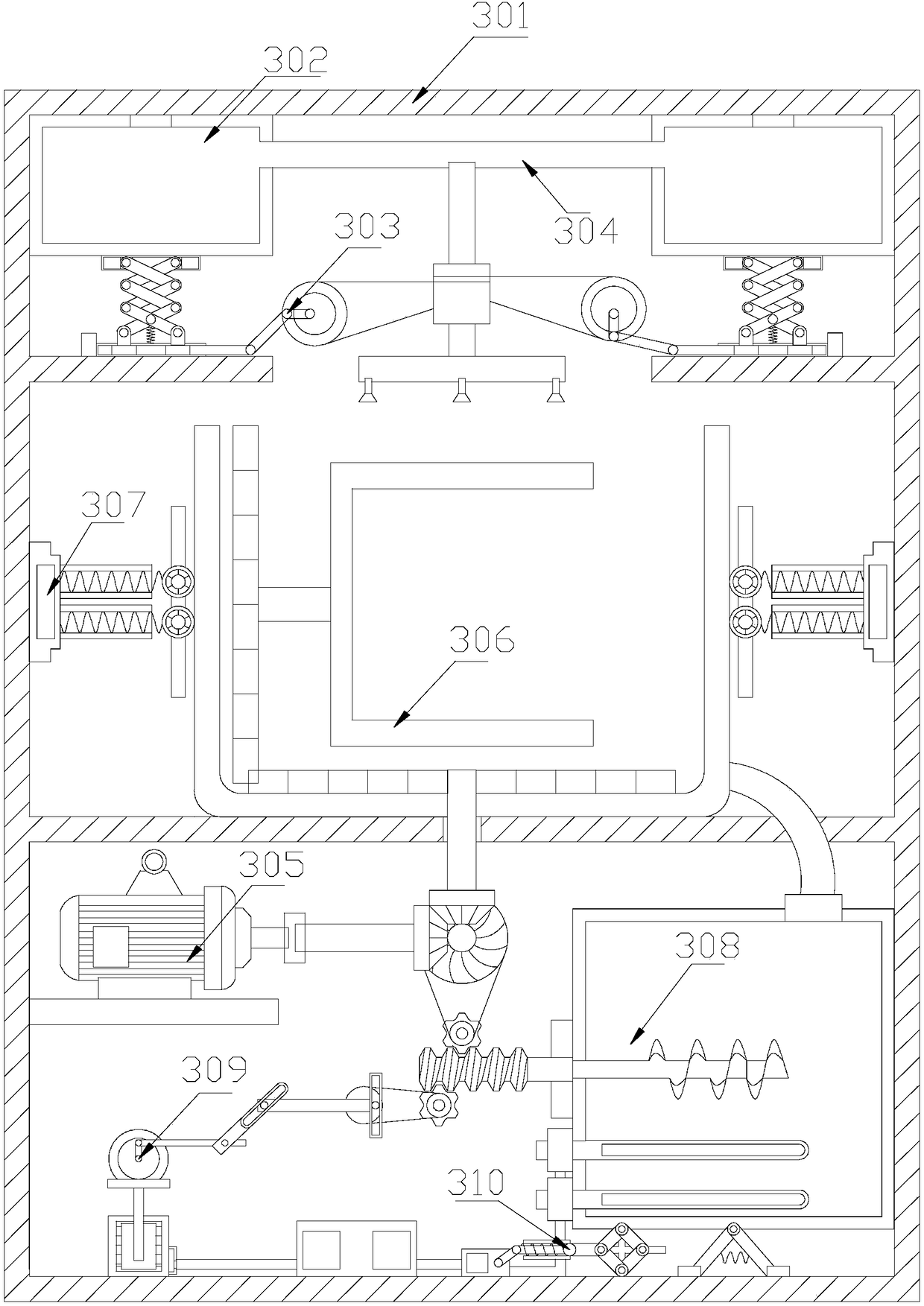

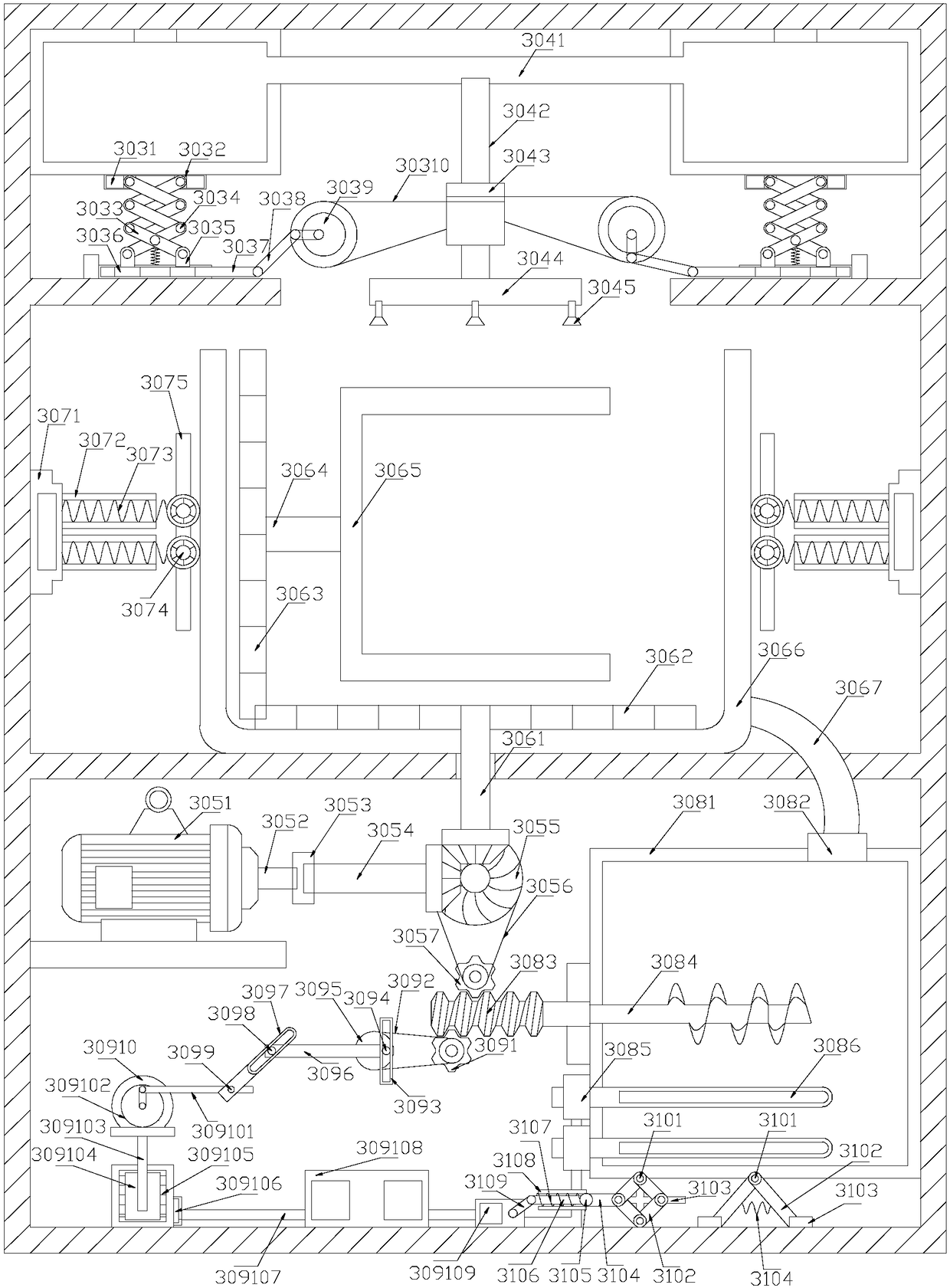

Work clothes washing device for petroleum refining workers

InactiveCN108252018AComprehensive cleaningFully soakedOther washing machinesWashing machine with receptaclesElectricityWater concentration

The invention discloses a work clothes washing device for petroleum refining workers. The structure of the device comprises an operation interface, a doorknob and a washing main engine. The operationinterface is in embedded arrangement on the upper end of the washing main engine and is electrically connected with the washing main engine through wires, and the doorknob is arranged at the outer surface of the washing main engine; a waste water concentration box is subject to the gravity effect to descend, so that a first connecting shaft and a second connecting shaft descend, the first connecting shaft descending drives a first connecting plate to support at two sides, thereby generating a buffered effect to avoid displacement in the descending process; the second connecting shaft descending drives a first pushing plate to move towards the left, thereby a steel ball inside a fixed tube pushes a second pushing plate towards the left, a second spring has a certain buffer effect, the second pushing plate pushes a switching gate towards the left, so that a switch box is started, the device is powered on, a heating rod begins to carry out the sewage heating treatment on powder particlesand bacteria in the sewage, after the treatment, the sewage is discharged, and the environmental safety is ensured.

Owner:莆田市荔城区浩旺贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com