Electrode sheet and electric double layer capacitor using the same

A technology of electrode sheets and current collectors, applied in the direction of electrolytic capacitors, capacitors, capacitor electrodes, etc., to achieve the effects of maintaining internal resistance, improving bonding strength, and excellent wet characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

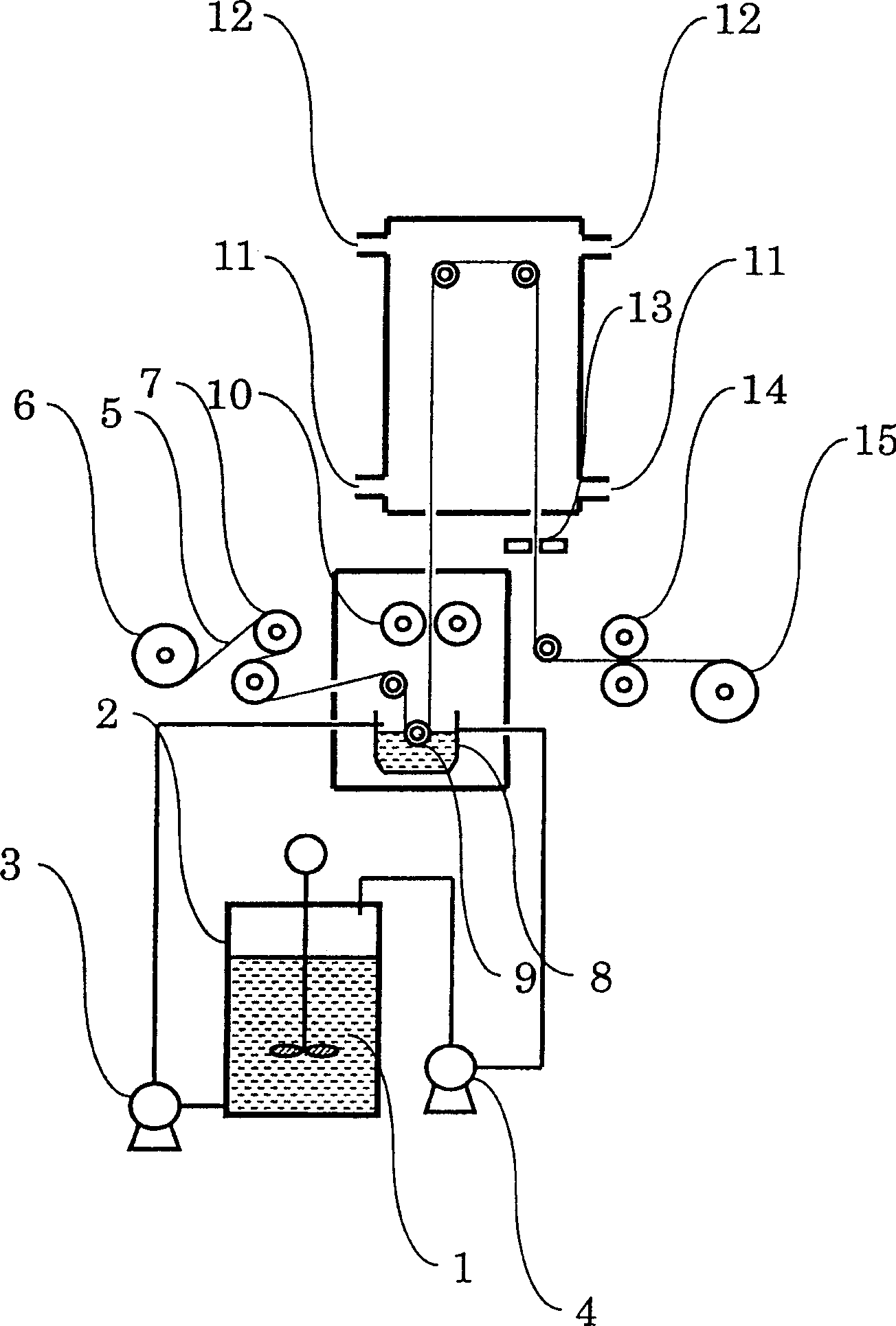

Method used

Image

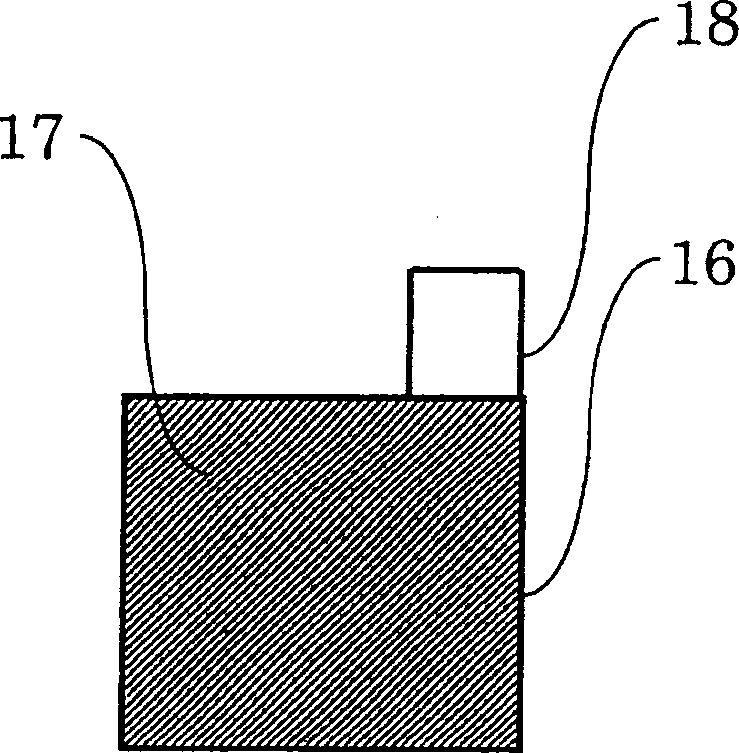

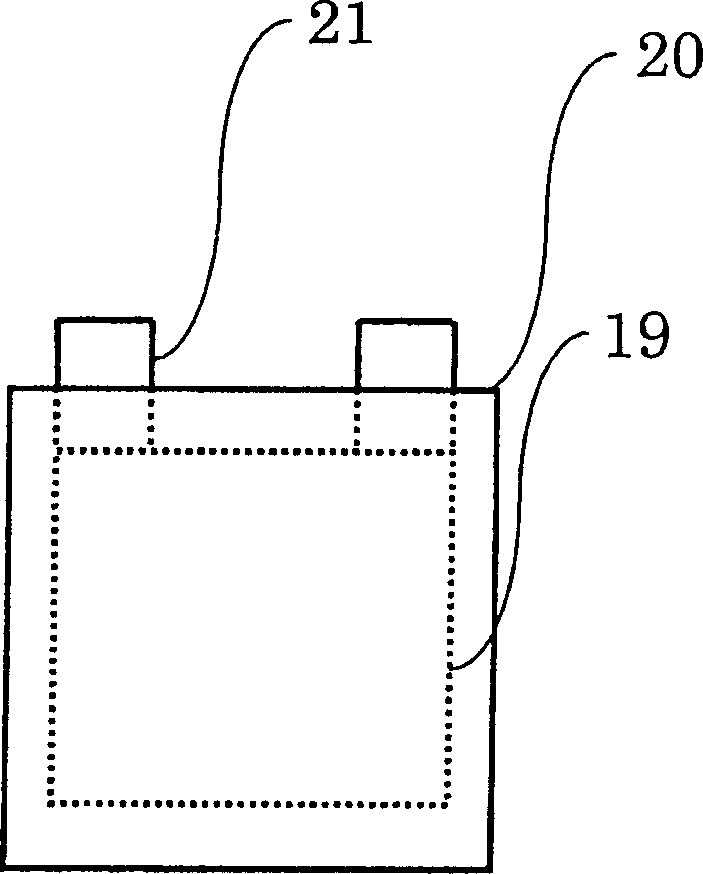

Examples

Embodiment 1

[0039] (Preparation of coating liquid)

[0040] In a reaction vessel with a stirrer, 100 parts by weight of activated carbon (activated carbon A-BAC-PW15 manufactured by Kureha Chemical Industry Co., Ltd.) and 10 parts by weight of carbon black (denka black manufactured by Denki Kagaku Kogyo Co., Ltd.) were charged to synthesize 5 parts by weight of pitch (synthetic pitch manufactured by Mitsubishi Gas Chemical Co., Ltd., synthetic pitch prepared by polymerizing condensed polycyclic hydrocarbons in the presence of hydrogen fluoride and boron trifluoride) as an organic monomer 75 parts by weight of butyl acrylate, and 150 parts by weight of ethylene glycol monomethyl ether as a solvent. After replacing the interior of the container with nitrogen, 5 parts by weight of azobisisobutyronitrile are added in multiple times. The isobutyronitrile is heated at a temperature above the temperature at which free radicals are generated, and the solution is stirred to complete the graft poly...

Embodiment 2

[0053] (Preparation of coating liquid)

[0054] In the same reaction vessel as in Example 1, 100 parts by weight of activated carbon (activated carbon A-BAC-PW15 manufactured by Kureha Chemical Industry Co., Ltd.), 10 parts by weight of carbon black (denka black manufactured by Denki Kagaku Kogyo Co., Ltd.), 75 parts by weight of butyl acrylate as an organic monomer, and 150 parts by weight of ethylene glycol monomethyl ether as a solvent. After replacing the inside of the container with nitrogen, add 5 parts by weight of azobisisobutyronitrile in multiple times, and heat to a temperature above the temperature at which azobisisobutyronitrile generates free radicals, and the solution is stirred to complete the graft polymerization reaction.

[0055] Similar to Example 1, at the initial stage of the above-mentioned graft polymerization, it was considered to have relatively hard muddy lumps, but in the middle of the reaction, it was in the form of a slurry that had fluidity and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com