Production process of insulation pull rod

The invention relates to an insulating tie rod and a production process technology, which is applied in the field of production technology of fiber reinforced composite insulating tie rods, and can solve the problems of easy generation of air gaps in the joint layer of joints and insulating pipes, easy generation of air gaps in insulating tie rods, unreliable joint connection, etc. Achieve the effects of improved bonding strength, high temperature controllability, and elimination of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

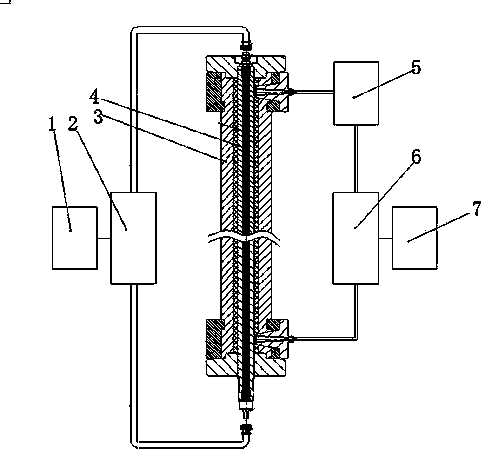

[0041] figure 1 The shown vacuum pressure impregnated insulating tube billet solidification molding mold includes a temperature sensing control device 1, a circulation pipeline device 2, a mold cavity 3, a mold core 4, a vacuum pump 5, a mixing device 6 and an air compressor 7, and a temperature sensing control device 1 Connect the circulation pipeline device 2, the circulation pipeline device 2 is filled with heat medium, and form a circulation loop with the mold core 4 through the oil outlet pipe and the oil return pipe, the upper end of the mold cavity 3 is connected to the vacuum pump 5, and the lower end is connected to the mixing device 6, and the mixing device 6 It is connected with the vacuum pump 5 and the air compressor 7 to form an insulating tube blank tube production mold.

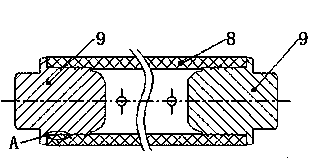

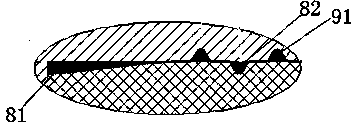

[0042] figure 2 , image 3 The bonding structure betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com