Low-density low-pressure sheet molding compound and preparation method thereof

A technology of sheet molding compound and low density, which is applied in the field of sheet molding compound. It can solve the problem that the sheet molding compound cannot take into account the low pressure and low density characteristics, and achieve the effect of improving the viscosity in the mold, reducing the loss of strength and high economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

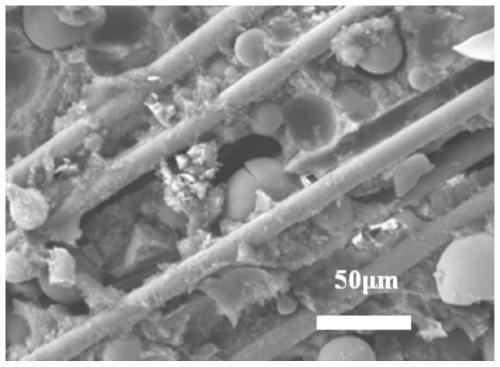

Image

Examples

Embodiment 1

[0030] A low-density, low-pressure sheet molding compound, comprising the following components by weight: unsaturated polyester resin: 55 parts, low-shrinkage additive: 33 parts, styrene: 6.5 parts, magnesium oxide paste: 2 parts, crystallization Resin: 2.5 parts, tert-butyl benzoyl peroxide: 1.4 parts, light zinc stearate: 4 parts, calcium carbonate: 80 parts, hollow glass microspheres: 30 parts, chopped glass fiber: 50 parts. Among them, the density of hollow glass microspheres is 0.38-0.42g / cm 3 The density of magnesium oxide paste is 1.65g / ml, and the viscosity is 17000mpa s; the melting point of crystalline resin is about 55°C, and the particle size is 200-400 mesh; chopped glass fiber is obtained by cutting glass fiber, and its length is 3- 5cm.

[0031] The above-mentioned low-density and low-pressure sheet molding compound is specifically prepared by the following method:

[0032] 1) According to the above component formula, weigh each raw material, disperse benzoyl ...

Embodiment 2

[0036] A low-density low-pressure sheet molding compound, comprising the following components in parts by weight: unsaturated polyester resin: 64 parts, low shrinkage additive: 38 parts, styrene: 7.5 parts, magnesium oxide paste: 1.5 parts, crystallization Resin: 2 parts, tert-butyl benzoyl peroxide: 1.7 parts, light zinc stearate: 6 parts, calcium carbonate: 70 parts, hollow glass microspheres: 30 parts, chopped glass fiber: 55 parts. Among them, the density of hollow glass microspheres is 0.38-0.42g / cm 3 The density of magnesium oxide paste is 1.65g / ml, and the viscosity is 17000mpa s; the melting point of crystalline resin is about 55°C, and the particle size is 200-400 mesh; chopped glass fiber is obtained by cutting glass fiber, and its length is 3- 5cm.

[0037] The above-mentioned low-density and low-pressure sheet molding compound is specifically prepared by the following method:

[0038] 1) According to the above component formula, weigh each raw material, disperse ...

Embodiment 3

[0042] A low-density, low-pressure sheet molding compound, comprising the following components in parts by weight: unsaturated polyester resin: 60 parts, low shrinkage additive: 35 parts, styrene: 7 parts, magnesium oxide paste: 1.5 parts, crystallization Resin: 2 parts, tert-butyl benzoyl peroxide: 1.5 parts, light zinc stearate: 5 parts, calcium carbonate: 75 parts, hollow glass microspheres: 25 parts, chopped glass fiber: 52 parts. Among them, the density of hollow glass microspheres is 0.38-0.42g / cm 3 The density of magnesium oxide paste is 1.65g / ml, and the viscosity is 17000mpa s; the melting point of crystalline resin is about 55°C, and the particle size is 200-400 mesh; chopped glass fiber is obtained by cutting glass fiber, and its length is 3- 5cm.

[0043] The above-mentioned low-density and low-pressure sheet molding compound is specifically prepared by the following method:

[0044] 1) According to the above component formula, weigh each raw material, disperse ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com