Method for manufacturing single clamping piece of anchorage, and dedicated mould

A processing method and clipping technology, which is applied to metal processing equipment, metal extrusion dies, forming tools, etc., can solve the problems of high clip production cost, low material utilization rate, and large machining volume, so as to save machining Less man-hours and processing steps and higher production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for processing a single piece of a two-piece anchor clip, which comprises the following steps:

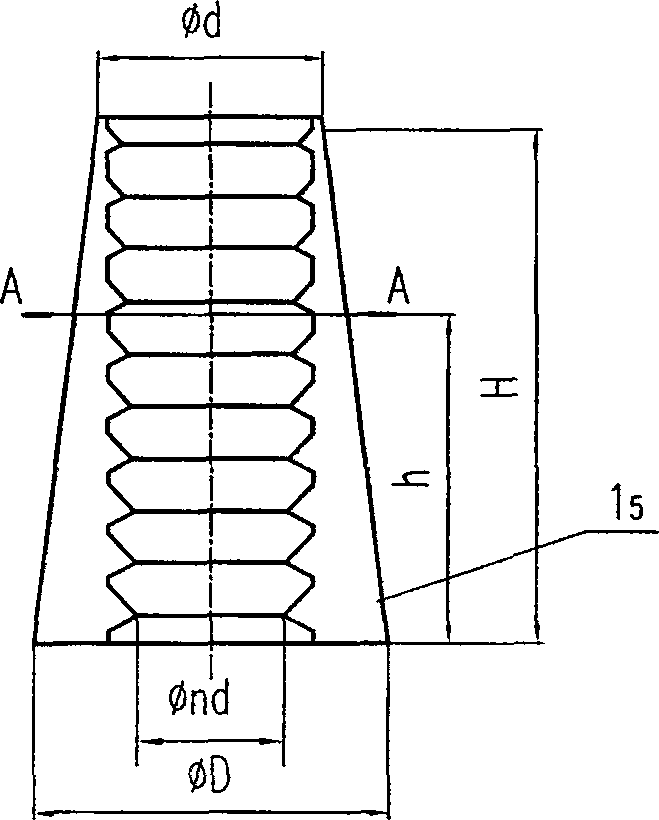

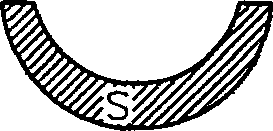

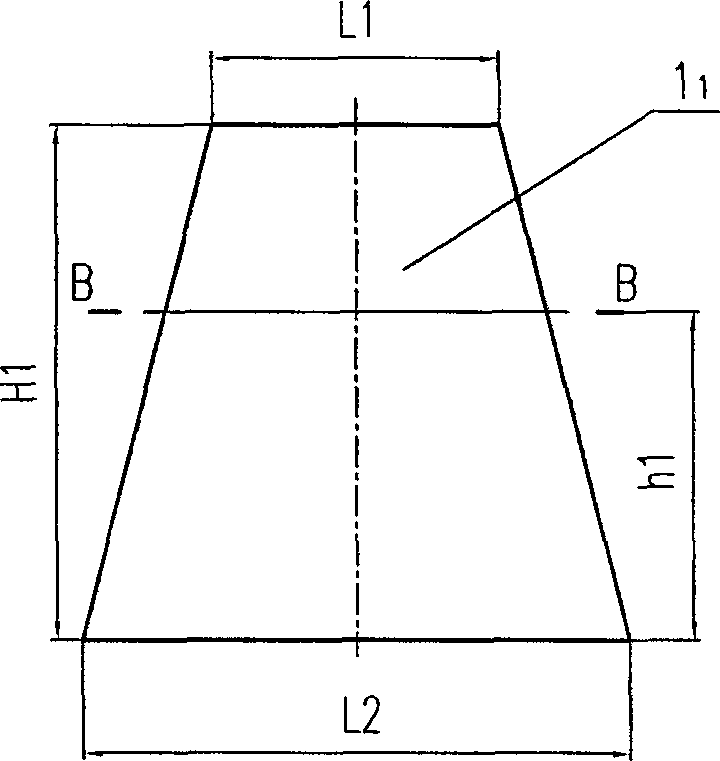

[0053] A. Blank blanking: Select a sheet with a thickness of δ according to the specifications of the clips to be processed, and cut it into a blank with an isosceles trapezoidal shape 1 1 , the isosceles trapezoidal slab 1 1 The upper bottom width is L 1 , the bottom width is L 2 , total height H 1 The final forming clip with the clip to be processed 1 5 The total height H is equal, and the cross-sectional area S of the isosceles trapezoidal slab corresponding to the two heights is equal 1 The final forming clip with the clip to be processed 1 5 The cross-sectional area S is approximately equal—that is: h 1 The cross-sectional area S of the isosceles trapezoidal slab equal to h 1 with final form clip 1 5 The cross-sectional area S is approximately equal, the above δ, L 1 , L 2 The value range is: δ = 3 ~ 8mm, the upper bottom width L 1 =5~10mm, bottom wi...

Embodiment 2

[0064] A processing method for a single piece of a three-piece anchor clip

[0065] The basic steps of its processing method are the same as embodiment one, and the difference is:

[0066] In A, the slab blanking step: isosceles trapezoidal slab 1 1 The size of the three-piece clip isosceles trapezoidal blank 1 1 The total height H 1 It is equal to the total height H of the final shaped clip to be processed, and the width of the upper bottom is L 1 =3~8mm, bottom width L 2 =20~40mm;

[0067] In B, the step of bending the base plate is to bend the isosceles trapezoidal base plate into a 120° arc-shaped base plate on an ordinary press with a bending die, and the outer diameter of the large end of the arc of the curved part of the arc-shaped base plate is D 2 0 ~ 1mm smaller than the outer diameter D of the large end of the final forming clip, the inner diameter nd of the arc of the curved part of the arc-shaped slab 2 1-4mm larger than the inner diameter nd of the final fo...

Embodiment 3

[0071] The special mold used in the processing method of anchor clip single piece of the present invention:

[0072] The special mold that the processing method of the anchorage clip single piece of the present invention adopts has bending die 2, forming die I3, forming die II4, forming die III5 totally 4 sets, and these 4 sets of dies are all made up of punch die, die 7 and guiding die. The guide sleeve 6 and the die 7 of the 4 sets of special molds have the same shape, and the top of the die 7 is a groove with a slope, which is consistent with the shape and size of the final forming clip , the longitudinal section of the groove is semicircular, the cross section is an isosceles trapezoid, the height of the isosceles trapezoid is the height H of the final forming clip, the width of the upper base is equal to the outer diameter d of the small end of the final forming clip, and the lower The bottom edge width is equal to the outer diameter D of the large end of the final formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com