Expandable polylactic acid composite micro-particle with core-shell structure, foamed bead and preparation method of molded piece of expandable polylactic acid composite micro-particle

A technology of composite particles and core-shell structure, which is applied in the field of biodegradable materials, can solve the problems of weak impact resistance protection performance, limiting the use range of foamed polylactic acid materials, and materials that cannot be molded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

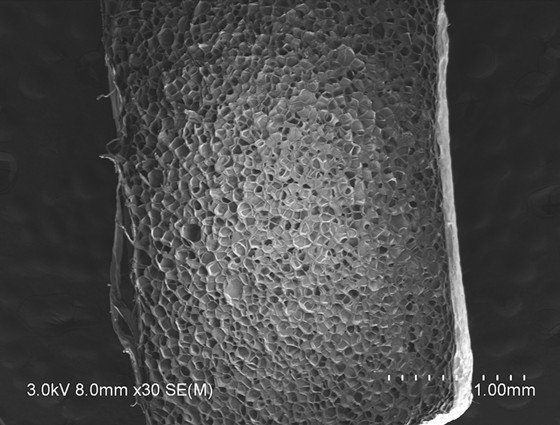

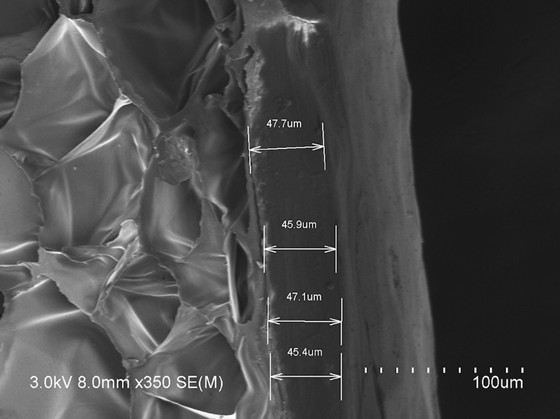

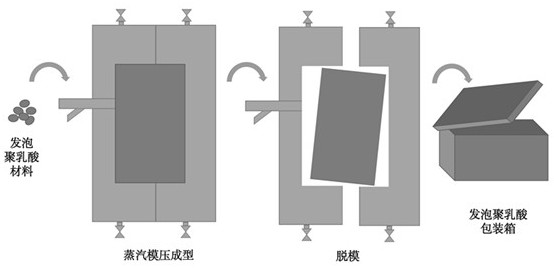

Image

Examples

Embodiment 1

[0036] Step 1: 100 parts by mass of polylactic acid resin, 2 parts by mass of carbodiamine, 1 part by mass of a copolymer of methacrylates and styrene, 0.5 parts by mass of talcum powder, 1 part by mass of 1,3,5- After trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene and 1 mass part of glyceryl stearate are mixed uniformly, they are added to the extruder host. 100 parts by mass of polybutylene adipate / butylene terephthalate copolymer, 3 parts by mass of maleic anhydride grafts, 2 parts by mass of carbodiamine, 1 part by mass of 1,3,5- Trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene and 1 mass part of glyceryl stearate are mixed evenly, and then added to the auxiliary machine of the extruder . The main and auxiliary extruders co-extrude the melt at an extrusion rate ratio of 85:15, and after cooling and pelletizing, expandable polylactic acid composite particles with a core-shell structure are obtained.

[0037] Step 2: Add 100 parts by mass of th...

Embodiment 2

[0040] In addition to adding 3 parts by mass of methacrylate and styrene copolymers as chain extenders in the expandable polylactic acid core layer, the same method as in Example 1 was used to prepare polylactic acid composite beads with a core-shell structure And its foam beads and foam products.

Embodiment 3

[0042] In addition to adding 0.3 parts by mass of methacrylate and styrene copolymers as chain extenders in the expandable polylactic acid core layer, polylactic acid composite beads with a core-shell structure were prepared in the same manner as in Example 1 And its foam beads and foam products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com