Blade root pouring method for bolt sleeve embedded blade

A bolt sleeve and pre-embedded technology, applied to other household appliances, household appliances, household components, etc., can solve the problem of resin voids, and achieve the effect of enhancing the connection strength of the blade root, widely used, and ensuring infiltration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

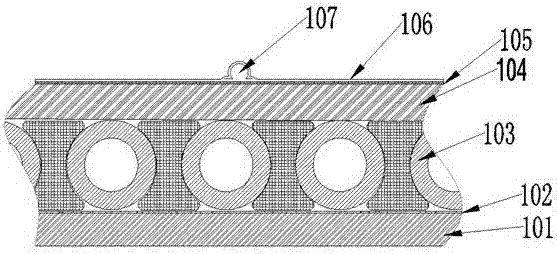

[0019] Please refer to figure 1 , perfusion system and perfusion method. The whole perfusion system is mainly composed of lower glass fiber cloth 101 , continuous mat 102 , embedded parts 103 , upper glass fiber cloth 104 , diversion net 1 105 , air pumping bag 106 , and glue injection tube 107 . The upper glass fiber cloth and the lower glass fiber cloth are located above and below the embedded part respectively. The continuous mat is placed between the embedded part and the lower glass fiber cloth, and the diversion net and the injection pipe are laid on the embedded part and the upper glass fiber cloth. The suction bag is placed on the first diversion net. During the pouring process, the upper glass fiber cloth above the embedded part is infiltrated with a diversion net, and the lower glass fiber cloth under the embedded part is guided with a continuous mat 102...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com